Beruflich Dokumente

Kultur Dokumente

Technical Specification

Hochgeladen von

jimboy_123Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Technical Specification

Hochgeladen von

jimboy_123Copyright:

Verfügbare Formate

Technical Specification For Design and supply of Water Mist cum CAFS (Compressed Air Foam System) Backpack

Fire Fighting System

pg. 1

INTRODUCTION : HPCL is in the process of procurement of Water mist cum CAFS (Compressed Air Foam system) Fire fighting system for its major Installations in India. A Water mist based fire fighting system utilises very fine water spray to extinguish fire. Water is recognised as an outstanding physically acting fire fighting agent with exceptionally high heat absorbing capacity and latent heat of vaporisation. Water droplets with size of 1 to less than 1000 micron are referred to as mist. The water mist when used in fire fighting system creates a blanket thus making the atmosphere inert around the fire. This results in effective and rapid fire extinguishing. The compressed air foam (CAF) used along with water mist further enhances the fire extinguishing power. Water mist fire fighting system covered in this configuration. specification are with Backpack

A pressure vessel to hold the media with safety valve, a compressed air cylinder coupled with a reducer, hose pipe for discharge of water mist media and extinguishing gun are the main components covered in the main specification. The system uses a mixture of water and aqueous film forming foam (AFFF) as media. Compressed air is used as propellant for the media through nozzle where atomization takes place. SCOPE : 1. Scope of supply includes Design, manufacture , procurement, inspection and testing of Backpack mounted water mist cum-CAFS- fire fighting equipment in the range of minimum 10 Lit to maximum 15 Lit capacity, pneumatically operated through a compressed air cylinder provided with a reducer and high pressure hose at an operating pressure of not less than 9 Bar and not more than 35 Bar for fighting Class A, B and Electrical fire with a single nozzle. The equipment shall have rapid and efficient operating mechanism and maintenance free design.

2. The whole system has to meet the performance ratings as per Clause 6.4.2 & 6.4.3 of EN 3-7 and shall be able to fight fire as per Annexure I on Fire Tests of EN 3 7 for A 43 & B 233 Class fire. One random sample chosen by the purchaser shall be sent for testing at CBRI, Roorkee and for Di-electric test (as per clause 9 of EN 3-7 or IS 15683 of 2006) at ERDA, Vadodara.

3. Equipment shall be new, unused and recent manufacture. 4. Repair facility and list of users for the offered model to be indicated by the vendor/manufacturer. 5. All dimensions are in metric system. 6. The backpack water mist fire fighting equipment shall conform to EN 3-7:2007-10 Standard as applicable for portable type fire extinguishers and fire ratings shall be tested accordingly except for the deviations in weight (which is in excess of 20 Kg), the nominal charge/ capacity (which are specifically mentioned in this specification

pg. 2

and the safety feature as specified in para 10.3 (second sub para) of EN 3-7 regarding manual attempt to initiate discharge without releasing the safety device; as the backpack is a different type of configuration from the conventional portable fire extinguishers. 7. The equipment shall include a pressure gauge to monitor air cylinder pressure. The pressure vessels shall be painted red and provide markings as per clause 16.2 of the EN 3-7. The air hoses shall be suitable for minus 40 degree centigrade to 100 degree temperatures and conforming and marking to EN Standards. 8. The Canister (main vessel) hose and nozzle mechanism should have a safety relief system against mal-operation of air regulator which should operate within 1% of maximum allowable operating pressure. 9. The nozzle should be designed to have jet and spray options to be adjusted in-situ without much loss of time. 10. The air cylinder and pressure vessels shall comply with Gas Cylinder Rules 2004 and shall be supported by manufacturers test certificate. No objection certificate or approval as applicable from Petroleum and Explosives Safety Organisation (PESO), Nagpur shall also be furnished. The capacity of the air cylinder should be adequate for minimum two discharges . The air cylinder should be able to generate the design pressure of the Canister (main vessel) after two discharges and should maintain the operating pressure within the manufacturers permissible range during the course of the discharge. 11. The air regulator should have auto cut off mechanism once the downstream pressure reaches the maximum allowable operating pressure and hold for minimum 2 hrs. 12. All system shall be designed for maximum operating temperature TSmax and minimum operating temperature TSmin of 60 deg C or more and 5 deg C or less respectively and certified by the manufacturer accordingly. 13. The complete system shall be tested from internationally acclaimed laboratory for compliance to EN 3-7 as applicable. Specified fire ratings shall also be tested from such laboratory for back pack configuration. 14. The design of this system should be made as per applicable PED of Europe /IS /ASME pressure vessel code. The testing of the same should be witnessed and certified by a reputed third party inspection agency, like DNV / Llyods/Bureau Veritas and EIL or any other reputed agency approved by purchaser. 15. The manufacturer has to define the water Mist particle size, for which their product has been designed and provide a type test as per Mist particle size test as per EN or any other equivalent National / International codes. 16. For systems built from imported SKD kits the test report as above on OEM products with fire rating test report from a reputed Government Institution like CBRI, Roorkee and ERDA, Vadodara on the product assembled in India after value addition shall also be acceptable. In such cases, supplier shall clearly indicate the value additions made by them in India and shall furnish the specific consent of the OEM for the value

pg. 3

additions made along with a confirmation that the fire ratings of the equipment would not be affected by these additions. 17. The whole system should be designed for operation between +5 deg. to +65 deg. centigrade with normal AFFF. However, with addition of anti-freezing additives, system should be able to operate upto 10 deg. centigrade. 18. Backpack configuration shall be mounted on a sturdy frame suitably cushioned for comfort, provided with shoulder pads for carrying as a backpack and a handle to be carried by hand. All materials used shall be of fire retardant type. The supply shall include along with the system , a spare compressed air cylinder of the same size, pressure and material, 10 nos. O-rings for the pressure vessel, one can of 5 L special AFFF compound, tool kit, manufacturers test certificates, operations manual and spare parts list. 19. Product should be guaranteed for minimum 24 months against any manufacturing defect and performance. 20. Field training should be given to at least 5-10 employees of each location (indenting location) including training for regular maintenance. 21. Support for After Sales Service should be provided by the vendor in India. Unit rates for individual components to be given for post warranty replacements, valid for at least 5 years. Unit rates of 5% of all individual components will be loaded for evaluation. Party has to submit unit rates for individual components in Un-priced bid envelope.

pg. 4

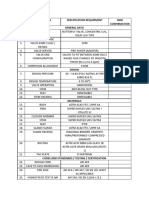

Technical Specifications of Water mist-cum-CAFS Backpack Fire fighting system Sr.no. 1 Description Working principle Requirement The water mist-cum-CAFS (compressed air foam system) fire fighting system shall work on 9 to 35 bar pressure with negligible recoil. The system shall be capable of carrying 10 L- 15 L of water in the main vessel. Air cylinder, duly approved by PESO, Nagpur, shall have minimum rating of 2 litre 200 bars to be used for the discharge of fine water mist and CAFS through discharge gun. The same nozzle of the gun shall be suitable to fight Class A , Class B and also live electrical fire without any modification. Gross wt of the charged system along with air cylinder should not exceed 25 KG with plus 10% variation (25 Kg+10%). The system should meet EN 3 standard requirements. Main vessel shall be made of minimum 5 mm thick high grade stainless steel or corrosion free aluminium alloy with water storage capacity of 10 lit to 15 litre and shall be provided with a pressure gauge on top of the vessel as per EN standard. The main vessel (reservoir) shall be handheld and backpacked. Main vessel shall be tested 1.43 times the operating pressure for safety. System shall have the feature of quick recharge without cleaning. The vessel should have No Objection certificate from PESO (Petroleum and Safety Organisation) India. The Compressed air cylinder shall be PESO approved and shall have minimum rating of 2 Lit/200 Bars to be used for discharge of 10L-15L solution with full power. The MOC (Material of construction) of compressed air cylinder shall be Carbon composite material or Stainless steel. The air cylinder ports should be of standard dimensions to enable local refills. The design of the gun shall be such that there is minimum recoil pressure during operation and shall have the locking facility to avoid misuse. The weight of the gun shall be less than 1500 gms. Minimum weight of the gun will be preferred. Nozzle shall be completely stainless steel with SS 304 grade. Weight of the system in fully charged condition shall not be more than 25 KG +10% allowance for comfortable operation. The system shall be provided with a pressure safety valve. The Canister (main vessel) should have manual pressure release facility with pressure gauge. Mechanical inter lock is preferred for canister lid opening and the pressure release mechanism. The hose length shall be minimum 1 meter. Material of hose shall be EPDM or oil resistant synthetic rubber with high tensile steel braid reinforcement having high abrasion , ozone and weather resistant synthetic rubber cover.

Main Vessel

Air cylinder

Gun

Weight of fully charged system Pressure Safety valve

Hose

pg. 5

Fire Rating

9 10 11

Operating time Lancing distance Test Reports/Certificates

12

Automatic cleaning

13 14

Backpack TPI (Third Party Inspection)

The rating shall be minimum Class A43, Class B233 & Electrical Fire 1000V (Tested at 35KV) shall be as per EN 3 Standard with water and AFFF as extinguishing agent. System shall be capable of achieving A55 rating using special additives/foam. The operating time shall be more than 20 seconds The minimum lancing distance under test conditions should be 10 meters under jet mode and 5 meter under spray mode. Test Reports for complete system as per EN 3-7 standard should be submitted. The quoted Model No. should be clearly mentioned in test reports submitted. Additionally, Test reports/certificates shall be submitted from CBRI Fire Engineering Laboratory, Roorkee and ERDA, Vadodara. Model no. shall be clearly mentioned in test reports/ certificates for Class A, Class B and live electrical fire. The system shall clean automatically as the remaining air is blown out of the container and system shall be ready for quick second recharge. Material of backpack shall be heat resistant Polyethylene/ Polyamide/ Nylon 6 material. Material needs to be inspected by TPI agencies before despatch. Moreover, the testing of the system should be witnessed and certified by a reputed third party inspection agency, like DNV, Llyods, Bureau Veritas, EIL, PDIL and RITES or any other reputed agency approved by HPCL.

pg. 6

Das könnte Ihnen auch gefallen

- Testing and Commissioning of Plumbing PumpsDokument53 SeitenTesting and Commissioning of Plumbing PumpshadiNoch keine Bewertungen

- MSRODokument1 SeiteMSROAjay ChodankarNoch keine Bewertungen

- Steam Trap Calculation Sheet - 01Dokument7 SeitenSteam Trap Calculation Sheet - 01Erwin Firmansyah Saputro0% (1)

- A10-A-DOC-VE-068274 - 00 离心泵 设计要求Dokument14 SeitenA10-A-DOC-VE-068274 - 00 离心泵 设计要求zhangNoch keine Bewertungen

- Direct Contact Desuperheaters TI-P475-01Dokument9 SeitenDirect Contact Desuperheaters TI-P475-01LucasZanaNoch keine Bewertungen

- Design Considerations Orifice Plate 1590507843 PDFDokument5 SeitenDesign Considerations Orifice Plate 1590507843 PDFmanansudiNoch keine Bewertungen

- Angus MonitorsDokument16 SeitenAngus Monitorsmuhammadtayyab_87Noch keine Bewertungen

- West Qurna I Section 1 WQI Produced Water Treatment Project Pump Inspection ProcedureDokument8 SeitenWest Qurna I Section 1 WQI Produced Water Treatment Project Pump Inspection Procedurejacksonbello34Noch keine Bewertungen

- Catalogo PNRDokument115 SeitenCatalogo PNRKaren Isabel Ambiado RivasNoch keine Bewertungen

- Wind Turbine Fire ProtectionDokument26 SeitenWind Turbine Fire ProtectionAsif MohammedNoch keine Bewertungen

- vs1 DatasheetDokument22 Seitenvs1 DatasheetMojtabaNoch keine Bewertungen

- Document: Technical Specification: PBSIM & BFS Consulting EngineeringDokument15 SeitenDocument: Technical Specification: PBSIM & BFS Consulting EngineeringAmar RajawatNoch keine Bewertungen

- Knowsley SK Limited - Designer and Manufacturer of Fire Fighting EquipmentDokument4 SeitenKnowsley SK Limited - Designer and Manufacturer of Fire Fighting Equipmentgireeshkumarb3874100% (1)

- Portable Foam Applicator Set Technical Data and InstructionsDokument4 SeitenPortable Foam Applicator Set Technical Data and InstructionsMaksym KovalNoch keine Bewertungen

- Onshore Terminal For KG DWN 98/2 Development Project: B.Sunil PrasadDokument7 SeitenOnshore Terminal For KG DWN 98/2 Development Project: B.Sunil Prasadsumit kumar100% (1)

- PB09FGe WS 10n-CAFS 07.2014 PDFDokument2 SeitenPB09FGe WS 10n-CAFS 07.2014 PDFNarendra Reddy BhumaNoch keine Bewertungen

- Advanced Reading Guide To The Selection BP Rp44-11Dokument54 SeitenAdvanced Reading Guide To The Selection BP Rp44-11vicopip100% (1)

- Cross FluteDokument6 SeitenCross FluteAvicena AlbiruniNoch keine Bewertungen

- Eil Spec For Architechture-6-75-0051 - Rev 0Dokument14 SeitenEil Spec For Architechture-6-75-0051 - Rev 0innovativekarthiNoch keine Bewertungen

- Technical Offer Rev.05 Tank 24x11.5 PDFDokument4 SeitenTechnical Offer Rev.05 Tank 24x11.5 PDFMohamedGhanemNoch keine Bewertungen

- Chapter 3: Simulating Flow in A Static Mixer Using WorkbenchDokument30 SeitenChapter 3: Simulating Flow in A Static Mixer Using WorkbenchHenry Yañez AliNoch keine Bewertungen

- LPG loading pump mechanical data sheetDokument8 SeitenLPG loading pump mechanical data sheetRudin Fahrudin RahmanNoch keine Bewertungen

- B5-Sprinkler Pumps With VDS Approval - 2009Dokument64 SeitenB5-Sprinkler Pumps With VDS Approval - 2009eimrehNoch keine Bewertungen

- Abha Najran Sulayyil Pipeline Preliminary EIA (Final 140115)Dokument80 SeitenAbha Najran Sulayyil Pipeline Preliminary EIA (Final 140115)M Alim Ur RahmanNoch keine Bewertungen

- ASABE Spray Droplet Sizing BasicsDokument35 SeitenASABE Spray Droplet Sizing BasicssaeedkheiratiNoch keine Bewertungen

- Steam Trap Data Sheet For: Warm Up Load Running LoadDokument1 SeiteSteam Trap Data Sheet For: Warm Up Load Running LoadShahzaibUsmanNoch keine Bewertungen

- Booster Pump-TechPart - 2of2 BDokument71 SeitenBooster Pump-TechPart - 2of2 BKatie RamirezNoch keine Bewertungen

- Standard Procedure For Vacuum Decay Test (Advisory Procedure)Dokument7 SeitenStandard Procedure For Vacuum Decay Test (Advisory Procedure)Jonathan MoralesNoch keine Bewertungen

- Guide to Industrial Leakage TestingDokument109 SeitenGuide to Industrial Leakage TestingMarzuki AlkindiNoch keine Bewertungen

- Skum Silv-Ex G F201132 - FDS14121 0214 LR PDFDokument2 SeitenSkum Silv-Ex G F201132 - FDS14121 0214 LR PDFAhmed El Sayed SalamaNoch keine Bewertungen

- GS134 9Dokument31 SeitenGS134 9vmohan01100% (1)

- 6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferDokument35 Seiten6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferAthar IqbalNoch keine Bewertungen

- Technical - Query - JIND - 2april2020 (Ed. LAPI)Dokument1 SeiteTechnical - Query - JIND - 2april2020 (Ed. LAPI)Nyayu SitimayaNoch keine Bewertungen

- Shell Type Fired Steam Generating PlantDokument29 SeitenShell Type Fired Steam Generating Plantahmed sobhy0% (1)

- Cooling Water PumpsDokument143 SeitenCooling Water PumpszalabiNoch keine Bewertungen

- Vertical PumpsDokument16 SeitenVertical PumpsAdel ShatlaNoch keine Bewertungen

- A-1-10-Specification For FRP Vessels and TanksDokument17 SeitenA-1-10-Specification For FRP Vessels and TanksbecemNoch keine Bewertungen

- Tanky 53 KL Rev.1Dokument187 SeitenTanky 53 KL Rev.1Priyo Jati WahyonoNoch keine Bewertungen

- Lift Arrangement Drawing for Portable Water FilterDokument2 SeitenLift Arrangement Drawing for Portable Water FiltervamcodongNoch keine Bewertungen

- TGT M WPP DS 0012 - C - Datasheet For Caisson Sump PumpDokument7 SeitenTGT M WPP DS 0012 - C - Datasheet For Caisson Sump Pumpvovancuong8Noch keine Bewertungen

- 3 OEE 3 144 Mechanical Design Check ListsDokument13 Seiten3 OEE 3 144 Mechanical Design Check ListsAnonymous HDlK5cXc8Noch keine Bewertungen

- DR - Reciprocating Compressor Table of Contents (Process)Dokument5 SeitenDR - Reciprocating Compressor Table of Contents (Process)rutujaNoch keine Bewertungen

- 2WallTank NFPA ULDokument1 Seite2WallTank NFPA ULPolo VarsanNoch keine Bewertungen

- Special Support in PipingDokument6 SeitenSpecial Support in PipingAKHIL JOSEPHNoch keine Bewertungen

- CAFS Data Sheet2Dokument4 SeitenCAFS Data Sheet2Forum PompieriiNoch keine Bewertungen

- Hotspot Repair Report SummaryDokument14 SeitenHotspot Repair Report SummaryRajabuddin AhmedNoch keine Bewertungen

- Datasheet For Butterfly ValveDokument3 SeitenDatasheet For Butterfly ValvevishnuvarthanNoch keine Bewertungen

- TRU Waste Processing Center PBVS Design DescriptionDokument37 SeitenTRU Waste Processing Center PBVS Design DescriptionShaimaa SaadNoch keine Bewertungen

- Techincal Document VRVDokument84 SeitenTechincal Document VRVGiftson ImmanuelNoch keine Bewertungen

- 32 Samss 008Dokument27 Seiten32 Samss 008Eagle SpiritNoch keine Bewertungen

- Pump SPI PDFDokument4 SeitenPump SPI PDFRaghNoch keine Bewertungen

- Air Filter For TurbineDokument8 SeitenAir Filter For TurbineAnonymous Q9i062VNoch keine Bewertungen

- Timeline - 21-06-2012 by Lalji MaheshwariDokument106 SeitenTimeline - 21-06-2012 by Lalji Maheshwariલાલજી મહેશ્વરી100% (5)

- Is-951 Crash Fire Tender For Air FieldsDokument15 SeitenIs-951 Crash Fire Tender For Air FieldsCharls JamesNoch keine Bewertungen

- Instrument AirDokument11 SeitenInstrument AirShariq Ali100% (1)

- Instrument Air System EssentialsDokument22 SeitenInstrument Air System Essentialsabhi_mohit2005100% (1)

- Landfill Gas Candlestick Flare SystemDokument8 SeitenLandfill Gas Candlestick Flare SystemcandratrikusumaNoch keine Bewertungen

- Compressor SpecificationDokument9 SeitenCompressor Specificationcarzante100% (1)

- Compliance Statement ElmDokument5 SeitenCompliance Statement ElmdeepakjoyinNoch keine Bewertungen

- Specifications and TenderinvitationDokument27 SeitenSpecifications and TenderinvitationAbhiram ReddyNoch keine Bewertungen

- Sample Pipe Support PDFDokument1 SeiteSample Pipe Support PDFjimboy_123Noch keine Bewertungen

- Equipment&Craftlist&CostingDokument16 SeitenEquipment&Craftlist&Costingjimboy_123Noch keine Bewertungen

- One Piece by Oda SenseiDokument1 SeiteOne Piece by Oda Senseigeorgebuhay_666Noch keine Bewertungen

- The Density of a Fluid Changes With Temperature and Pressure Density and change in Temperature When temperature is changed the density of a fluid can be expressed as ρ1 = ρ0 / (1 + β (t1 - t0)) (1) where ρ1 = final density (kg/m3) ρ0 = initial density (kg/m3) β = volumetric temperature expansion coefficient (m3/m3 oC) t1 = final temperature (oC) t0 = initial temperature (oC) Volumetric Temperature Coefficients - β • water : 0.0002 (m3/m3 oC) at 20oC • ethyl alcohol : 0.0011 (m3/m3 oC) Note! - volumetric temperature coefficients varies strongly with temperature. Density and change in Pressure When pressure is changed the density of a fluid can be expressed as ρ1 = ρ0 / (1 - (p1 - p0) / E) (2) where E = bulk modulus fluid elasticity (N/m2) ρ1 = final density (kg/m3) ρ0 = initial density (kg/m3) p1 = final pressure (N/m2) p0 = initial pressure (N/m2) Bulk Modulus Fluid Elasticity some common Fluids - E • water : 2.15 109 (N/m2) • ethyl alcohol : 1.06 109 (N/Dokument3 SeitenThe Density of a Fluid Changes With Temperature and Pressure Density and change in Temperature When temperature is changed the density of a fluid can be expressed as ρ1 = ρ0 / (1 + β (t1 - t0)) (1) where ρ1 = final density (kg/m3) ρ0 = initial density (kg/m3) β = volumetric temperature expansion coefficient (m3/m3 oC) t1 = final temperature (oC) t0 = initial temperature (oC) Volumetric Temperature Coefficients - β • water : 0.0002 (m3/m3 oC) at 20oC • ethyl alcohol : 0.0011 (m3/m3 oC) Note! - volumetric temperature coefficients varies strongly with temperature. Density and change in Pressure When pressure is changed the density of a fluid can be expressed as ρ1 = ρ0 / (1 - (p1 - p0) / E) (2) where E = bulk modulus fluid elasticity (N/m2) ρ1 = final density (kg/m3) ρ0 = initial density (kg/m3) p1 = final pressure (N/m2) p0 = initial pressure (N/m2) Bulk Modulus Fluid Elasticity some common Fluids - E • water : 2.15 109 (N/m2) • ethyl alcohol : 1.06 109 (N/georgebuhay_666100% (1)

- The Density of a Fluid Changes With Temperature and Pressure Density and change in Temperature When temperature is changed the density of a fluid can be expressed as ρ1 = ρ0 / (1 + β (t1 - t0)) (1) where ρ1 = final density (kg/m3) ρ0 = initial density (kg/m3) β = volumetric temperature expansion coefficient (m3/m3 oC) t1 = final temperature (oC) t0 = initial temperature (oC) Volumetric Temperature Coefficients - β • water : 0.0002 (m3/m3 oC) at 20oC • ethyl alcohol : 0.0011 (m3/m3 oC) Note! - volumetric temperature coefficients varies strongly with temperature. Density and change in Pressure When pressure is changed the density of a fluid can be expressed as ρ1 = ρ0 / (1 - (p1 - p0) / E) (2) where E = bulk modulus fluid elasticity (N/m2) ρ1 = final density (kg/m3) ρ0 = initial density (kg/m3) p1 = final pressure (N/m2) p0 = initial pressure (N/m2) Bulk Modulus Fluid Elasticity some common Fluids - E • water : 2.15 109 (N/m2) • ethyl alcohol : 1.06 109 (N/Dokument3 SeitenThe Density of a Fluid Changes With Temperature and Pressure Density and change in Temperature When temperature is changed the density of a fluid can be expressed as ρ1 = ρ0 / (1 + β (t1 - t0)) (1) where ρ1 = final density (kg/m3) ρ0 = initial density (kg/m3) β = volumetric temperature expansion coefficient (m3/m3 oC) t1 = final temperature (oC) t0 = initial temperature (oC) Volumetric Temperature Coefficients - β • water : 0.0002 (m3/m3 oC) at 20oC • ethyl alcohol : 0.0011 (m3/m3 oC) Note! - volumetric temperature coefficients varies strongly with temperature. Density and change in Pressure When pressure is changed the density of a fluid can be expressed as ρ1 = ρ0 / (1 - (p1 - p0) / E) (2) where E = bulk modulus fluid elasticity (N/m2) ρ1 = final density (kg/m3) ρ0 = initial density (kg/m3) p1 = final pressure (N/m2) p0 = initial pressure (N/m2) Bulk Modulus Fluid Elasticity some common Fluids - E • water : 2.15 109 (N/m2) • ethyl alcohol : 1.06 109 (N/georgebuhay_666100% (1)

- Analytical PS A01 A10 Solutions 2Dokument14 SeitenAnalytical PS A01 A10 Solutions 2MarieNoch keine Bewertungen

- WISDM-dataset-description 2Dokument5 SeitenWISDM-dataset-description 2yuliasihkripsianditaNoch keine Bewertungen

- Design Considerations of High Voltage AnDokument114 SeitenDesign Considerations of High Voltage AnEL BRIGHLINoch keine Bewertungen

- Winitzki - Heidelberg Lectures On Advanced General Relativity 2007Dokument156 SeitenWinitzki - Heidelberg Lectures On Advanced General Relativity 2007winitzkiNoch keine Bewertungen

- Alpha 900 and HD LineDokument32 SeitenAlpha 900 and HD Linebertan dağıstanlıNoch keine Bewertungen

- EVER11 Final ProgramDokument20 SeitenEVER11 Final ProgramAdrian PopNoch keine Bewertungen

- Generator ProductsDokument16 SeitenGenerator Productspatro242Noch keine Bewertungen

- Fluid Mechanics II: Key Concepts of Fluid KinematicsDokument18 SeitenFluid Mechanics II: Key Concepts of Fluid KinematicsYousef FarajNoch keine Bewertungen

- Steam Engineering Principles and Heat TransferDokument99 SeitenSteam Engineering Principles and Heat Transferalex mobileNoch keine Bewertungen

- Flux 10 4 New Features Presentation ValideDokument22 SeitenFlux 10 4 New Features Presentation ValideleelNoch keine Bewertungen

- Fluidized Bed CombustionDokument600 SeitenFluidized Bed Combustionvikasnar100% (7)

- 2015-04-21 - 3 - LPE Firemans SyllabusDokument9 Seiten2015-04-21 - 3 - LPE Firemans SyllabusSumanNoch keine Bewertungen

- Analysis of Truss Using Abaqus SoftwareDokument7 SeitenAnalysis of Truss Using Abaqus SoftwareKarthick NNoch keine Bewertungen

- Modelling Urban Areas in Dam-Break Flood-Wave Numerical SimulationsDokument14 SeitenModelling Urban Areas in Dam-Break Flood-Wave Numerical SimulationsDaru Nurisma PramuktiNoch keine Bewertungen

- Electronics Engg.: Detailed Solutions ofDokument52 SeitenElectronics Engg.: Detailed Solutions ofAshish ChoudharyNoch keine Bewertungen

- TM - 11-5855-214-23&p - (N04596) PDFDokument65 SeitenTM - 11-5855-214-23&p - (N04596) PDFtyra24Noch keine Bewertungen

- Vector CalculusDokument62 SeitenVector CalculuswaleedNoch keine Bewertungen

- Numerical Analysis 1Dokument21 SeitenNumerical Analysis 1Maged Mohammad Hassan100% (1)

- Physics SL Paper 3 TZ2Dokument20 SeitenPhysics SL Paper 3 TZ2Dongjean SeoNoch keine Bewertungen

- Astm F1717-21Dokument11 SeitenAstm F1717-21wenhsiaochuanNoch keine Bewertungen

- Chemistry Project: To Study The Quantity of Casein Present in Different Samples of MilkDokument14 SeitenChemistry Project: To Study The Quantity of Casein Present in Different Samples of Milkveenu68Noch keine Bewertungen

- AE342 Lab1 Report Format 20182Dokument7 SeitenAE342 Lab1 Report Format 20182Mert YılmazNoch keine Bewertungen

- Text - Anuario Cader 2018 INGLÉS PDFDokument57 SeitenText - Anuario Cader 2018 INGLÉS PDFmicaelaNoch keine Bewertungen

- Single Disc Clutch DesignDokument32 SeitenSingle Disc Clutch DesignWeins GemerlapNoch keine Bewertungen

- Atomic absorption spectroscopy analysis of metalsDokument3 SeitenAtomic absorption spectroscopy analysis of metalsVishnu VichuZNoch keine Bewertungen

- Lab 6 SpectrophotometerDokument11 SeitenLab 6 SpectrophotometerChing Wai YongNoch keine Bewertungen

- Chapter 14 Modern SpectrosDokument24 SeitenChapter 14 Modern SpectrosChicken ChickenNoch keine Bewertungen

- SMS LteaDokument11 SeitenSMS LteaArdi CikaNoch keine Bewertungen

- Dosing Pump Innovata Drive ConceptDokument5 SeitenDosing Pump Innovata Drive ConceptgarpNoch keine Bewertungen

- Applications of Nano Biotechnology in Wastewater Treatment PDFDokument9 SeitenApplications of Nano Biotechnology in Wastewater Treatment PDFswaroop_exlncNoch keine Bewertungen