Beruflich Dokumente

Kultur Dokumente

20.312 D02 Rev 01 Design Brief

Hochgeladen von

Sarah PerezOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

20.312 D02 Rev 01 Design Brief

Hochgeladen von

Sarah PerezCopyright:

Verfügbare Formate

Contract Name/NumberSPCC ILO PERU /20.

312

Document No. 20.312/D02

Revision - 01 Page 1 of 17

SOUTHERN PERU COPPER CORPORATION RANDOM WAGON UNLOADING SYSTEM DESIGN BRIEF

REVISION RECORD Revision 00 Revision First issue for customer approval. (including kick off meeting discussions) Updated in line with SPCC comments in their email 28Jan2013 and telecom. 29Jan2013. See clauses 1, 1.1, 1.2, 4, 5.1, 5.4, 6.1 and 6.3. Drawn Date

JWH 20 Nov2012

Check Date

FAB 29/11/2012

Approve Date

MLJ 29/11/2012

01

JWH 30 Jan 2013

MLJ 30/01/2013

MLJ 30/01/2013

INTELLECTUAL PROPERTY

The information in this document was prepared using Intellectual Property owned by Schade Lagertechnik GmbH. This is confidential proprietary information and remains the exclusive property of Schade. The document is for use solely in connection with the performance of Schades Contracts.

Contract Name/NumberSPCC ILO PERU /20.312

Document No. 20.312/D02

Revision - 01 Page 2 of 17

CONTENTS

1. 2. 3. 4. 5. 6. 7. 8.

INTRODUCTION.......................................................................................................... 3 ENVIRONMENT ........................................................................................................... 6 WAGON UNLOADING SYSTEM DUTY .................................................................. 7 MATERIAL HANDLED............................................................................................... 7 BASIC DESIGN PARAMETERS ................................................................................ 8 DESIGN CODES............................................................................................................ 9 ELECTRICAL ............................................................................................................. 12 DESCRIPTION OF OPERATIONS .......................................................................... 14

Contract Name/NumberSPCC ILO PERU /20.312

Document No. 20.312/D02

Revision - 01 Page 3 of 17

1.

INTRODUCTION

The purpose of this document is to describe the design requirements for the supply of the Wagon Unloading System for discharging Copper Concentrate from 119 tonne (# max.) gross wagons at the Southern Peru Copper Corporation (SPCC) Patio Puerto ILO plant. # From the wagon data issued to Schade during the tender stage, the max. wagon gross mass is 119t. From SPCC email 29/01/2013, revised max. wagon (3045mm high) masses that are to be used for design purposes are: Normal wagons25t (empty) + 100t (payload) = 125t (gross) Occasional wagons- 23.8t (empty) + 104.4t (payload) = 128.2t (gross)

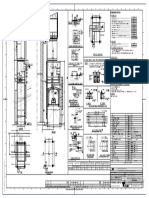

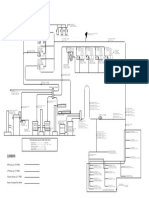

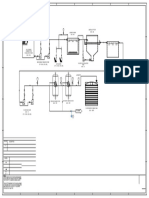

The Unloading System consists of a Wagon Tippler (Dumper), Exit Run-Back Stop and a Dust Control System. There is no Charger required for this system; the wagons are positioned by a locomotive. 1.1 Schade Drawings

This Design Brief is to be read in conjunction with the following Schade drawings: 6003_00_003 rev 02, General Arrangement of Wagon Unloading System. 6966_00_006 rev 01, Wagon Details. Note as part of the Schade internal QA system, Schade require the above drawings and this document to be approved by the customer. 1.2 6000_00_003 rev 01, Family Tree of Assemblies. WUS11_0030_16_rev. 00, Tender Drawing. Description of main system components One 14m x 3.11m x 128 tonne Pivot Frame design. One Wagon Run Back Stop (manual operation via trackside lever). One spray system mounted around the clients discharge chute. The type of system is to be finalised per SPCCs kick off meeting request for Schade to investigate using a dry fog system. Centralised automatic systems.

Tippler: Exit Rake Holding Device:

Dust Suppression:

Lubrication:

Contract Name/NumberSPCC ILO PERU /20.312

Document No. 20.312/D02

Revision - 01 Page 4 of 17

1.3

Contract Specifications and Drawings

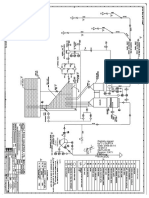

The following SPCC documents are to be worked to, except where noted in Schade tender document WUS11_0030 rev 03, Appendix D:Document Number 321196-RM01 321196-GA01 321196-SM02 321196-GM 321196-GE 321196-SI01 321196-DC01 321196-ZM02 Revision 1 B 1 1 1 0 0 1 Title Equipment Request Rotary Car Dumper General Site Conditions Patio Puerto ILO Technical Specification Rotary Car Dumper Technical Specification Mechanical Technical Specification - Electrical Instruments Supplied with Package Equipment Civil Structural Design Criteria #3 Data Sheet Hydraulic Rotary Car Dumper (as completed by Schade at the tender stage) Operation Room Rotary Railcar Dumper Plant and Elevations #1 Overall Settlement Phase 2 Conveying and Auxiliary Systems, Floor Level #4 Overall Settlement Phase 2 Tunnel Elevations/Filters and Auxiliary Systems #4 Overall Settlement Phase 2 Operation Room for Wagon Tippler #4 Railroad Cars (Cobrasma 44m, 34m, Iochpe-Maxion 44m) Views and Sections #2

3211-1-702

3211-1-723

3211-1-726

3211-1-730

3211-5-700

#1 As given to Schade at the kick off meeting, which has an identical number and revision number to the drawing included in the tender documentation. #2 The data given on SPCC drawing 3211-5-700-B has been included on Schade drawing 6966_00_006. The Schade drawing has been produced to show the following additional design information:o Approx. payload level/profile for Schade Clamp Beam dimensional design.

Contract Name/NumberSPCC ILO PERU /20.312

Document No. 20.312/D02

Revision - 01 Page 5 of 17

o Tippler Clamp Beam positions and loadings on the wagons for the wagon designers to check the wagon design. Drawing 3211-5-700-B also shows an outstand around the wagon top and dimension F (width overall) is not shown on any view. Per discussions whilst viewing several wagons at the kick off meeting, it was concluded that the drawing is pictorially incorrect. Dimension F (width overall) is to be taken as 3168mm (for all wagons per drawing table) over the wagon top sill and side vertical members. #3 Not applicable to Schade scope of work. #4 Received with email 21 Nov 2012.

Contract Name/NumberSPCC ILO PERU /20.312

Document No. 20.312/D02

Revision - 01 Page 6 of 17

2.

ENVIRONMENT +5C to +30C (design) 55% to 75% average (design) Not applicable to Tippler design as it operates inside a building. 5mm yearly maximum 1.01 bar 10m above sea level 85dB (A) max. at 1m 0.40g (per SPCC specification 321196-GA01-B) In line with standard industry practice for Tipplers (low height, no onboard personnel, no risk to services etc.) Schade will carry out a static seismic analysis only for the Tippler pivots & foundation loads (for civil design by client). Schade have not included for a dynamic FEA of the seismic effects on structures. Yes. Arid, dusty, wet (from Dust Suppression), marine and adjacent to the ILO refinery from which corrosive gases may be emitted. The Tippler is located inside a building. A Dust Suppression System is included in Schade supply, mounted around the clients discharge chute. Dust extraction will be installed by the client. Without a Dust Suppression System, during the Tippler cycle, the atmosphere will become dust laden with the material handled (which is highly abrasive/corrosive). All equipment shall be designed to operate in these conditions. Not applicable as the Tippler operates within a building.

Ambient temperatures: Relative humidity: Max. wind speed/pressure:

Rainfall: Barometric pressure: Altitude: Noise level: Seismic:

Saline/coastal:

Location: Dust suppression:

Dust Extraction: Atmosphere:

Solar Radiation:

Contract Name/NumberSPCC ILO PERU /20.312

Document No. 20.312/D02

Revision - 01 Page 7 of 17

3.

WAGON UNLOADING SYSTEM DUTY

All components shall be designed for heavy duty continuous operation. Working hours per day: 24 hours continuous with frequent full load operation. 12 days 30 years >90% >90% 60,000 hours minimum

Working days per month: Design Life: Utilisation: Availability: Bearing Life L10:

4.

MATERIAL HANDLED

All components shall be designed for the following payload characteristics. Material: Size: Moisture: Angle of repose: Aerated bulk density: Copper Concentrate 1mm maximum 9% average (sticky) 32 nominal 1.92 t/m (material unloaded from wagons onto +3.321m level) 2.24 t/m (material compacted in the wagons)

Packed bulk density:

Notes Using the revised wagon payloads given by SPCC email 28/01/2013, 100t payload 44m wagon volume = 2.27 t/m (i.e. approx. 2.24 t/m given above). When the 100t payload discharges onto the +3.321m level, its density will revert to its aerated value of 1.92 t/m, thus increasing to a volume of 52m. The available volume at this level is 132m, thus for wagons loaded with 100t of material, the Front End Loaders will have to operate every 2 wagons. Material abrasiveness: Material corrosiveness: Highly abrasive Highly corrosive

Contract Name/NumberSPCC ILO PERU /20.312

Document No. 20.312/D02

Revision - 01 Page 8 of 17

5. 5.1

BASIC DESIGN PARAMETERS Wagons handled

The Wagon Unloading System will be designed to handle wagons as shown Schade drawing 6966_00_006, Wagon Details. For normal working (strength and fatigue design), the maximum gross mass of a wagon is 125 tonnes (25t tare + 100t payload). For out of service working (strength only design), the maximum gross mass of a wagon is 128.2 tonnes (23.8t tare + 104.4t payload). Also per the kick off meeting, SPCC stated that the maximum retained sticky payload is 10%. For design purposes, use 104t x 0.10 = 10.4 tonnes.

5.2

Locomotive

There is no locomotive passage onto or through the Tippler.

5.3

Track data 1435mm (1505mm rail centres) 115lb AREMA rail 168mm high x 69mm head width Not applicable to the design of the Tippler. Downhill gradient sufficient to ensure the empty wagons roll away from the Tippler as a result of being impacted by the next wagon as the locomotive positions it onto the Tippler platform.

Rail gauge (K): Rail type:

Entry track profile: Exit track profile:

5.4

System throughput 3 max. working, 10 Tippler design. 70 seconds tip, 10 second pause #, 70 seconds return = 150seconds total.

Wagons unloaded per hour: Tippler cycle time:

# - During commissioning, the Tippler pause duration at maximum tip angle can be increased to allow more time for any sticky material to be dislodged from the wagon by the vibrators. The existing SPCC Tippler at the Smelter Plant has a total cycle time of 150 seconds, including a 10 second pause at the fully tipped angle.

Contract Name/NumberSPCC ILO PERU /20.312

Document No. 20.312/D02

Revision - 01 Page 9 of 17

Wagon rotation:

3 (nominal) platform tilt plus 157 Tippler rotation = 160 total.

6. 6.1

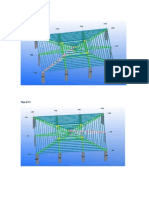

DESIGN CODES Primary design codes BS2573 part 1 Rules for the Design of Cranes (Classification, stress calculations & design criteria structures) Operating cycles (fatigue design) 2 x 10^6 (U7) $ Load spectrum Group classification Impact factor Duty factor (strength design) 0.85~

Structural design:

Item

Tippler

1.0 (Q4)

A8

1.1#

#$~-

Impact factor 1.3 to be used for wagons rolling onto the platform 10 wagons/hour x 24 hours/day x 12 days/month x 12 months/year x 30 years required life = 1,036,800 wagons/cycles, which is less than the above design life. Duty factor of 0.85 is for normal working. For all other load cases use 0.85 x 1.13 = 0.96.

Mechanical design:

BS2573 part 2 Rules for the Design of Cranes (Classification, stress calculations & design criteria mechanisms) Load spectrum 1.0 (L4) Group classification M8 Duty factor 0.63#

Item Tippler

Service life (hours) >50,000 (T9)

For fatigue calculations, number of cycles N > 1 x 10^6 #Use for all load cases. Note The above codes are used by Schade as there is no suitable standard or code directly applicable to the design of wagon unloading equipment. As the above codes are applicable to cranes with hoisting applications, they adopt a conservative approach to design (i.e. duty factors etc.). They are also complete in their content, covering strength, buckling and fatigue for steelwork & shafts etc., welds and bolts.

Contract Name/NumberSPCC ILO PERU /20.312

Document No. 20.312/D02

Revision - 01 Page 10 of 17

6.2

Other design codes

In support of the codes given above, and those listed in the SPCC Technical Specification, use may be made of codes from the following organisations:BS ISO DIN EN British Standards International Standards German Standards European Standards

6.3 6.3.1

Design load cases Tippler Platform (at rail level, 0 tip angle)

a) Passage of 1x loaded wagon (125t gross max.) onto (impact factor 1.3) & across the Platform. Platform supported on land supports. Strength & fatigue cases (i.e. normal working). b) Passage of 1x loaded wagon (125t gross max.) onto (impact factor 1.3) & across the Platform plus ejecting 1x empty wagon (25t tare max.). Platform supported on land supports. Strength & fatigue cases (i.e. normal working). c) Passage of 1x loaded wagon (128.2t gross max.) onto (impact factor 1.3) & across the Platform. Platform supported on land supports. Strength only case (i.e. not normal working). d) Passage of 1x loaded wagon (128.2t gross max.) onto (impact factor 1.3) & across the Platform plus ejecting 1x empty wagon (23.8t tare + 10.4t sticky payload ). Platform supported on land supports. Strength only case (i.e. not normal working).

6.3.2

Tippler Cage and Platform (during tip rotation)

a) Tipping of 1x loaded wagon (125t gross max.) with free flowing material (100t payload) 100% discharge to 160 rotation, plus return of 1x empty wagon (25t tare max.) to 0 rotation. Strength & fatigue cases (i.e. normal working). b) Tipping of 1x loaded wagon (128.2t gross max.) with 10.4 tonnes retained sticky payload to 160 rotation, plus return of wagon (23.8t tare + 10.4t payload) to 0 rotation. Strength only case (i.e. not normal working). 6.3.3 Tippler Clamps

a) Supporting 1 x empty wagon (25t tare max.) plus retained sticky payload (10.4t max.) plus a dynamic factor (1.2) at the Tippler fully tipped angle. Strength & fatigue cases (i.e. normal working, say to design on the safe side). The resultant load being distributed onto all 3 clamps. There is no failed clamp design case where only 2 clamps are required to support the wagon.

Contract Name/NumberSPCC ILO PERU /20.312

Document No. 20.312/D02

Revision - 01 Page 11 of 17

6.3.4

Exit Wagon Run back Stop The Exit Run Back Stop nominal capacity is 15kN, based on a 4 axle wagon of 23.8t tare (empty) mass. The stop is a Schade standard design for this load.

6.4

Materials of construction EN 10025 S275J0 The Tippler main pivot shafts will be manufactured from BS970 grade 817M40 condition T Materials for other load bearing shafts and pins will be as above or BS970 grade 605M36 condition R

Structural steelwork: Shafts and pins:

Racks: Pinions: Wear and Spill Plates:

Cast steel to BS3100 grade A3 BS970 grade 817M40 condition T UHMW PE 25mm thick minimum. (per client specification 321196-SM02) EN 14399-3 (ISO 7412, DIN 6914) grade 8.8S All bolts, nuts and washers etc. will be self finish/lubricated, not plated (i.e. zinc). Phosphor bronze DYN GZ14 AISI 316 or higher, not AISI 304 (review during design) All components will be dimensioned and manufactured using the metric SI system of units. All critical components will be manufactured in accordance with unique Inspection Plans. All welding will be carried out in accordance with a Schade Manufacturing Specification, using Euronorm standards.

Structural bolts:

Plain bushes: Stainless steel: Units:

Inspection Plans:

Welding:

Contract Name/NumberSPCC ILO PERU /20.312

Document No. 20.312/D02

Revision - 01 Page 12 of 17

7. 7.1

ELECTRICAL Supply Voltages AC 480 volts 60Hz, 3 phase + neutral, 4 wire AC 120 volts 60Hz, 1 phase + neutral, 2 wire

LV Distribution:

Transformer neutral point solidly grounded. Control Circuits MCC Starter Modules: PLC Digital I/O: PLC Analogue I/O: Solenoids: Motors LV Motors: Instrumentation Instrument Circuits: AC 120 volts 60Hz DC 24 volts AC 480 volts 60Hz AC 120 volts 60Hz DC 24 volts 4-20mA AC 120 volts 60Hz

Maintenance Power Circuits Single Socket: Welding Socket: AC 120 volts 60Hz AC 480 volts 60Hz

7.2

Permissible Voltage Variation & Loss at Equipment Terminals

The permissible voltage fluctuation and voltage loss are based on the rated voltage of the electrical equipment. 1. 2. Voltage variation for motors shall be no greater than 5%. Losses due to voltage drop between the supply terminals and equipment shall be no greater than 5%. The terminal voltage should not be less than 90% of the rated voltage when the motors are started.

3.

Contract Name/NumberSPCC ILO PERU /20.312

Document No. 20.312/D02

Revision - 01 Page 13 of 17

7.3

Electrical Distribution

Refer to the latest issue of Schades Single Line Diagram, drawing number TBA. 7.4 Tippler Control

Tippler operations will be carried out by the plant operator and be controlled by a Programmable Logic Controller (PLC) with the level of interlocking being dependent on the control mode selected. The Operator interface will be as follows: Human Machine Interface (HMI) for control of automatic operations, plant status and alarms Degrees of Protection

7.5

All electrical equipment shall be suitably sealed for use in the environment. The minimum protection levels shall be as follows:Outdoor Enclosures: *Indoor Enclosures: * 7.6 NEMA 4X NEMA 12

Indoor enclosures are deemed as enclosures within the Electrics House only. Main Products Moulded Case Circuit Breaker (MCCB) Miniature Circuit Breaker (MCB) Relays Panel Lamp Anti Condensation Heater Door mounted Filter Units Emergency Stop Relay PLC ControlLogix PLC Communication - DeviceNet PLC Communication - EtherNet HMI PanelView+ Motor Protection Circuit Breakers (MPCB) Contactors Pushbuttons / Lamps / Switches Sets of Power & Control terminations Allen Bradley Allen Bradley Allen Bradley RITTAL RITTAL RITTAL GuardMaster Allen Bradley Allen Bradley Allen Bradley Allen Bradley Allen Bradley Allen Bradley Allen Bradley Weidmuller

Contract Name/NumberSPCC ILO PERU /20.312

Document No. 20.312/D02

Revision - 01 Page 14 of 17

8.

DESCRIPTION OF OPERATIONS

The following is a basic description of how the plant will be operated. Once agreed with the customer, this description will be developed by Schade for the final control system design. 8.1 Composition of rakes

All rakes will consist of: A locomotive (at the rear of the rake), pushing An empty/dummy wagon (never tipped, used to ensure that the locomotive does not need to travel onto the Tippler to position the last wagon), pushing A number of full wagons 8.2 Operators

The wagon unloading system will be controlled by: 1 or 2 railway operator(s) located on the non-tip side of the track at rail level. 1 plant operator located in the elevated control room at the main control desk. The control room is on the tip side of the Tippler. 8.3 State of plant for train arrival

State of plant prior to train arrival must be as follows:The Tippler is ready Tippler at rail level, 0 tip (monitored by Tippler PLC) Tippler clamps raised (monitored by Tippler PLC) Entry and exit photocells are clear (monitored by Tippler PLC) The railway operator(s) are ready Manual selection of switch on local control station A railway signalling system (by client) on the entry end of the Tippler will be installed. The system will consist of two red (stop)/green (go) traffic lights, one located near the entry end of the Tippler and the other part way along the rake away from the Tippler. The traffic lights are controlled by both the railway operator(s) and Tippler PLC. If all of the above Tippler conditions are satisfied, the Tippler (plant operator) will signal the lights green. However, if the railway operator(s) are not ready for the wagons, they can signal the lights red from their local control station. The lights will remain red until both the Tippler (plant operator) and railway operator(s) are ready to start unloading wagons.

Contract Name/NumberSPCC ILO PERU /20.312

Document No. 20.312/D02

Revision - 01 Page 15 of 17

8.4

Modes of control

The wagon positioning by the railway operator(s) is a manual process using radio control with the locomotive driver. The Tippler is operated by the plant operator in one of the following modes of control: Automatic (full automatic control initiated from the main control desk) This will include Tippler rotation (tip, pause & return), clamp movement (lowering & raising) and complete system monitoring via the Tippler PLC Manual (fully interlocked) Maintenance (with minimum interlocking to ensure personnel and plant safety) Control modes are selected via the main control desk.

8.5

Unloading the first wagon

The railway operator(s) set the traffic lights to green and instructs the locomotive driver (via radio) to push the rake forward and stop with the first wagon in the designated position (central within 100mm) on the Tippler. The railway operator(s) then release the front coupler of the second wagon (this is the nearside lever) and instructs the locomotive driver to reverse back until the second wagon is clear of the entry photocell. The railway operator(s) then signal (via an audible horn) to the plant operator that the Tippler can tip. From the control room the plant operator starts the Tippler. With no further input from the plant operator, the Tippler tips the wagon to unload the copper concentrate, pauses at the fully tipped position and then returns the wagon to rail level. Note prior to all wagon tips, the PLC checks the tipped stockpile level sensors to ensure that there is enough space for another wagon payload. A further check is also made to ensure that the FELs are not operating in the tipped stockpile (+3.321m TOC level) area. The plant operator signals (via an audible horn) to the railway operator(s) that the Tippler cycle for the first wagon is complete, and the second wagon can be positioned.

8.6

Unloading subsequent wagons

The railway operator(s) check that both the rear coupler of the first (tipped) wagon and the front coupler of the second (next) wagon are both closed. This is to ensure that the wagons do not automatically re couple when they contact.

Contract Name/NumberSPCC ILO PERU /20.312

Document No. 20.312/D02

Revision - 01 Page 16 of 17

The railway operator(s) set the traffic lights to green and instructs the locomotive driver (via radio) to push the rake forward and stop with the second wagon in the designated position on the Tippler. Part way through this travel, the closed front coupler of the second wagon hits the closed rear coupler of the first wagon and the first wagon is pushed off the Tippler and rolls away down the exit track gradient. The railway operator(s) then release the front coupler of the third wagon (this is the nearside lever) and instructs the locomotive driver to reverse back until the third wagon is clear of the entry photocell. The railway operator(s) then signal (via an audible horn) to the plant operator that the Tippler can tip. From the control room the plant operator starts the Tippler. With no further input from the plant operator, the Tippler tips the wagon to unload the copper concentrate, pauses at the fully tipped position and then returns the wagon to rail level. The plant operator signals (via an audible horn) to the railway operator(s) that the Tippler cycle for the second wagon is complete, and the third wagon can be positioned. The railway operator(s) open the front coupler of the tipped wagon. This ensures that when it rolls down the exit track gradient it will automatically recouple to the previous wagon, or the railway operator(s) open the rear coupler of the previous wagon (positioned some way down the exit track gradient). This procedure is repeated until the last full wagon is positioned on the Tippler. 8.7 Unloading the last wagon

With the last full wagon stopped at the designated position on the Tippler (the empty/dummy wagon in front of the locomotive is part on the Tippler), the railway operator(s) then release the front coupler of the empty/dummy wagon (this is the nearside lever) and instructs the locomotive driver to reverse back until the empty/dummy wagon is clear of the entry photocell. The railway operator(s) then signal (via an audible horn) to the plant operator that the Tippler can tip. From the control room the plant operator starts the Tippler. With no further input from the plant operator, the Tippler tips the last wagon to unload the copper concentrate, pauses at the fully tipped position and then returns the wagon to rail level. The plant operator signals (via an audible horn) to the railway operator(s) that the Tippler cycle for the last wagon is complete, and it can be pushed off the Tippler. The railway operator(s) check that both the rear coupler of the last (tipped) wagon and the front coupler of the empty/dummy wagon are both closed. This is to ensure that the wagons do not automatically re couple when they contact.

Contract Name/NumberSPCC ILO PERU /20.312

Document No. 20.312/D02

Revision - 01 Page 17 of 17

The railway operator(s) set the traffic lights to green and instructs the locomotive driver (via radio) to push the empty/dummy wagon forward and stop after hitting the last wagon and pushing it off the Tippler. The locomotive must not travel onto the Tippler. The locomotive then reverses back with the empty/dummy wagon to join the bypass track that runs parallel to the Tippler. The locomotive is then able to travel forward (provided other railway signalling allows this) and collect the rake of empty wagons on the Tippler exit track.

Das könnte Ihnen auch gefallen

- Training Manual Green Anode Plant Vedanta - Jharsuguda: File: 138-02-043 - 08 - 0.doc, Codeword: VedantaDokument47 SeitenTraining Manual Green Anode Plant Vedanta - Jharsuguda: File: 138-02-043 - 08 - 0.doc, Codeword: VedantaSubhransu MohapatraNoch keine Bewertungen

- Apron Feeder Data SheetDokument1 SeiteApron Feeder Data SheetPat AuffretNoch keine Bewertungen

- K TRON Loss in Weight Single Screw Feeder K ML S500 10DDokument2 SeitenK TRON Loss in Weight Single Screw Feeder K ML S500 10Ddeus_7Noch keine Bewertungen

- Sales Catalogue: Turbo-Dryer®Dokument31 SeitenSales Catalogue: Turbo-Dryer®thomas_v501925Noch keine Bewertungen

- MSN Labs 14 TPH Boiler Bag Filter Technical OfferDokument18 SeitenMSN Labs 14 TPH Boiler Bag Filter Technical OfferpavaniNoch keine Bewertungen

- Envicare - Product - Water Softner ADokument2 SeitenEnvicare - Product - Water Softner AshaileshvcNoch keine Bewertungen

- Data Sheet For Rotary Calciner - TEPLDokument2 SeitenData Sheet For Rotary Calciner - TEPLpuneet gehlotNoch keine Bewertungen

- BHEL ASh Handling Equp QA RequiremntDokument27 SeitenBHEL ASh Handling Equp QA Requiremntamol1321100% (2)

- Boiler SchematicDokument1 SeiteBoiler SchematicChristine GriffithNoch keine Bewertungen

- De MisterDokument2 SeitenDe MisterLaxman G GalipelliNoch keine Bewertungen

- "Type of Filter and Its Applications in Detail": G H Patel College of Engineering &technologyDokument11 Seiten"Type of Filter and Its Applications in Detail": G H Patel College of Engineering &technologyManav PatelNoch keine Bewertungen

- 20100PE-DW02-0005 Rev0 11-SD-2121-4Dokument1 Seite20100PE-DW02-0005 Rev0 11-SD-2121-4Jovit BeaNoch keine Bewertungen

- 20100PE-DW02-0002 Rev0 11-SD-2121-1Dokument1 Seite20100PE-DW02-0002 Rev0 11-SD-2121-1Jovit BeaNoch keine Bewertungen

- Evaporator: Causticizing Lime KilnDokument3 SeitenEvaporator: Causticizing Lime KilnSrinivasa Rao VenkumahanthiNoch keine Bewertungen

- THOR Installation Manual - Bridge Conveyor 1925C R01 10-01-08 PDFDokument45 SeitenTHOR Installation Manual - Bridge Conveyor 1925C R01 10-01-08 PDFIngeniero proyectosNoch keine Bewertungen

- P1064-00-M05-123-R1-Check ValveDokument10 SeitenP1064-00-M05-123-R1-Check ValveNarayana MugalurNoch keine Bewertungen

- Electrical Documentation For Radar Level TransmitterDokument6 SeitenElectrical Documentation For Radar Level TransmittersatfasNoch keine Bewertungen

- Document Deliverable List - CBFSF 2x450 TPD - R1 (Submitted 22102019)Dokument6 SeitenDocument Deliverable List - CBFSF 2x450 TPD - R1 (Submitted 22102019)Berkat HarefaNoch keine Bewertungen

- 3 - VP-SP2021-ON-MA-0700-0029-0200 - 1 - Startup CommDokument10 Seiten3 - VP-SP2021-ON-MA-0700-0029-0200 - 1 - Startup CommNishit KhuntNoch keine Bewertungen

- 2.heat-Exchangers From Ch6 - Mihir's HandbookDokument12 Seiten2.heat-Exchangers From Ch6 - Mihir's HandbookThế Quang LêNoch keine Bewertungen

- Raw Water SystemDokument11 SeitenRaw Water SystemChandraNoch keine Bewertungen

- Perhitungan Water Balance Pg. Pesantren Baru Kapasitas 6000 TCDDokument3 SeitenPerhitungan Water Balance Pg. Pesantren Baru Kapasitas 6000 TCDRahman SuyadiNoch keine Bewertungen

- Statiic Calculation For Mill Slurry TankDokument4 SeitenStatiic Calculation For Mill Slurry TankBimal DeyNoch keine Bewertungen

- Screw Screw Screw Screw Pump Pump Pump PumpDokument2 SeitenScrew Screw Screw Screw Pump Pump Pump PumpvictorvikramNoch keine Bewertungen

- Silo and Bin Discharger y PDFDokument2 SeitenSilo and Bin Discharger y PDFYousef AlipourNoch keine Bewertungen

- ABB Drive and Motor Selector ACS880-04 Module PDFDokument3 SeitenABB Drive and Motor Selector ACS880-04 Module PDFBataa BatsuuriNoch keine Bewertungen

- Belt Sway Switch-Nasik R1-Final Sent On 04.01.11Dokument4 SeitenBelt Sway Switch-Nasik R1-Final Sent On 04.01.11atulbhogare7Noch keine Bewertungen

- Efaa011741 1 0Dokument1 SeiteEfaa011741 1 0Hemant PatilNoch keine Bewertungen

- SFFDokument7 SeitenSFFAbhishek DuttaNoch keine Bewertungen

- Particle TechnologyDokument40 SeitenParticle Technologyasharab70Noch keine Bewertungen

- Gaga 2006 MKZM Drum SieveDokument6 SeitenGaga 2006 MKZM Drum SievelrbolNoch keine Bewertungen

- P&IDDokument1 SeiteP&IDeuitimecNoch keine Bewertungen

- Dust Extract SystemDokument17 SeitenDust Extract Systemmathan_aeNoch keine Bewertungen

- Wagon Loader SystemDokument12 SeitenWagon Loader Systemayaskant751001100% (1)

- DTS - Belt Conveyor Data SheetDokument3 SeitenDTS - Belt Conveyor Data SheetBRUNA NASCIMENTONoch keine Bewertungen

- Bunker Calculation - R0Dokument3 SeitenBunker Calculation - R0Sara LopezNoch keine Bewertungen

- PG ASE-10-MEC-DWG-192 As Built Electrostatic PrecipitatorDokument69 SeitenPG ASE-10-MEC-DWG-192 As Built Electrostatic PrecipitatorAgung Saputro100% (1)

- BOF Plant Write UpDokument20 SeitenBOF Plant Write UpKalyan HalderNoch keine Bewertungen

- FAM Apron Feeders: WWW - Fam.de Förderanlagen MagdeburgDokument4 SeitenFAM Apron Feeders: WWW - Fam.de Förderanlagen MagdeburgriteshsamantrayNoch keine Bewertungen

- Rotary Airlock FeedersDokument28 SeitenRotary Airlock Feederslhphong021191Noch keine Bewertungen

- Outotec Q1-Q3 2011 Roadshow Presentation 22112011Dokument69 SeitenOutotec Q1-Q3 2011 Roadshow Presentation 22112011Ivanoff Vladimir Rojas TelloNoch keine Bewertungen

- Operation & Maintenance Manual: Vishwasri-Oak Park CoimbatoreDokument17 SeitenOperation & Maintenance Manual: Vishwasri-Oak Park CoimbatoreSathishkumar DhamodaranNoch keine Bewertungen

- Steam Balance Layout (TPH) ModelDokument1 SeiteSteam Balance Layout (TPH) ModelRemington SalayaNoch keine Bewertungen

- FGD Project at 2X 525 MW MPL: Document Title: Gypsum Storage Shed Sizing CalculationDokument1 SeiteFGD Project at 2X 525 MW MPL: Document Title: Gypsum Storage Shed Sizing CalculationPiyush MalviyaNoch keine Bewertungen

- Standard Specification For Hot Insulation Piping EquipmentDokument62 SeitenStandard Specification For Hot Insulation Piping EquipmentAri SupramonoNoch keine Bewertungen

- P&id For STP PlantDokument1 SeiteP&id For STP PlantHardik KhetaniNoch keine Bewertungen

- Monnet - Recommended Scheme and Write Up of Auto ControlsDokument34 SeitenMonnet - Recommended Scheme and Write Up of Auto ControlsDipti BhanjaNoch keine Bewertungen

- Belt Weigh Scale PDFDokument33 SeitenBelt Weigh Scale PDFMohammad AsifNoch keine Bewertungen

- 1108 Jaw Crusher MobileDokument2 Seiten1108 Jaw Crusher Mobilechand_yelNoch keine Bewertungen

- VOL IV - Mechanical PDFDokument144 SeitenVOL IV - Mechanical PDFVaijayanti JoshiNoch keine Bewertungen

- Extraction Flow Calculation by IterationDokument6 SeitenExtraction Flow Calculation by Iterationarunrajmech09Noch keine Bewertungen

- STP Technical SpecificationDokument26 SeitenSTP Technical Specificationgnbuildtech Pvt ltdNoch keine Bewertungen

- Dust Supression SystemDokument5 SeitenDust Supression SystemSUBHONoch keine Bewertungen

- Rhino Process Equipment: Product DescriptionDokument2 SeitenRhino Process Equipment: Product DescriptionMurli ramchandranNoch keine Bewertungen

- AgitatorDokument3 SeitenAgitatorMarcelo PerettiNoch keine Bewertungen

- DSL Car InspectionDokument78 SeitenDSL Car InspectionJanardan RamekarNoch keine Bewertungen

- 013-MS For Mass Concrete Works PDFDokument26 Seiten013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- 07 Ocs 0000 Itp 00002Dokument123 Seiten07 Ocs 0000 Itp 00002SamwailNoch keine Bewertungen

- 010-MS For Grouting PDFDokument33 Seiten010-MS For Grouting PDFKöksal PatanNoch keine Bewertungen

- Spec Detc 241011emuDokument91 SeitenSpec Detc 241011emuVishal ChaudharyNoch keine Bewertungen

- Manual: For The Installation of The LineDokument23 SeitenManual: For The Installation of The LineSarah PerezNoch keine Bewertungen

- Galigher 100-2100 SeriesDokument10 SeitenGaligher 100-2100 SeriesSarah Perez100% (1)

- What Is Rack Chock SystemDokument7 SeitenWhat Is Rack Chock SystemSarah Perez100% (1)

- Nº 02 - TAG 135 PU 007-008-009 - Modelo 3409 S 6x10-22 - MOTORDokument11 SeitenNº 02 - TAG 135 PU 007-008-009 - Modelo 3409 S 6x10-22 - MOTORSarah PerezNoch keine Bewertungen

- Pipe Span ChartDokument1 SeitePipe Span ChartcoyuncoNoch keine Bewertungen

- NDP-80 Data SheetDokument9 SeitenNDP-80 Data SheetSarah PerezNoch keine Bewertungen

- Plan, Foundation 39894472 5: ExhaustDokument1 SeitePlan, Foundation 39894472 5: ExhaustSarah PerezNoch keine Bewertungen

- PortaPump Service ManualDokument5 SeitenPortaPump Service ManualSarah PerezNoch keine Bewertungen

- Design of Anchor Reinforcement For Seismic Shear Loads-SubmissionDokument38 SeitenDesign of Anchor Reinforcement For Seismic Shear Loads-SubmissionSarah Perez100% (1)

- Pipeline Profile Import From AutocadDokument15 SeitenPipeline Profile Import From AutocadSarah PerezNoch keine Bewertungen

- Heyl & Patterson Equipment Streamlines Railcar Operations in The StockyardDokument1 SeiteHeyl & Patterson Equipment Streamlines Railcar Operations in The StockyardSarah PerezNoch keine Bewertungen

- SMB Determination Help PDFDokument100 SeitenSMB Determination Help PDFSarah Perez100% (1)

- Galigher 100-2100 SeriesDokument10 SeitenGaligher 100-2100 SeriesSarah Perez100% (1)

- VGS Linear Power Drier: Series 29126 "3D" Double Deck DrierDokument2 SeitenVGS Linear Power Drier: Series 29126 "3D" Double Deck DrierSarah PerezNoch keine Bewertungen

- Datasheet Sisto-Kbs Valve - KSBDokument4 SeitenDatasheet Sisto-Kbs Valve - KSBSarah PerezNoch keine Bewertungen

- KSB Valvula Diafragma SISTO10Dokument4 SeitenKSB Valvula Diafragma SISTO10Sarah PerezNoch keine Bewertungen

- Modelo de Prueba Con M20 ISAMILLDokument13 SeitenModelo de Prueba Con M20 ISAMILLSarah PerezNoch keine Bewertungen

- SteelDokument5 SeitenSteelSarah PerezNoch keine Bewertungen

- Yale KELC YL1006 0107Dokument2 SeitenYale KELC YL1006 0107Sarah PerezNoch keine Bewertungen

- Some Standards Executions For Piston Pumps: Execut. Pumphead Piston VALVE (Ball) Valve Seats Piston GasketsDokument1 SeiteSome Standards Executions For Piston Pumps: Execut. Pumphead Piston VALVE (Ball) Valve Seats Piston GasketsSarah PerezNoch keine Bewertungen

- Data Sheet Tag 180-Pu-011eDokument8 SeitenData Sheet Tag 180-Pu-011eSarah PerezNoch keine Bewertungen

- ImagenesDokument3 SeitenImagenesSarah PerezNoch keine Bewertungen

- CPE ManualDokument32 SeitenCPE ManualSarah PerezNoch keine Bewertungen

- Plegable MecanoDokument8 SeitenPlegable MecanoSarah PerezNoch keine Bewertungen

- Hygienic DesignDokument18 SeitenHygienic DesignSarah Perez100% (1)

- Tabaq With Tang Band 4Dokument4 SeitenTabaq With Tang Band 4Lmute MedioliNoch keine Bewertungen

- 839-4816 (Office) or (770) 301-8648 (Cell) : Corporate Finance: A Focused Approach, by Michael C. Ehrhardt / Eugene FDokument1 Seite839-4816 (Office) or (770) 301-8648 (Cell) : Corporate Finance: A Focused Approach, by Michael C. Ehrhardt / Eugene FlilbouyinNoch keine Bewertungen

- Exam2SampleProblems SP17 - 1507832832437Dokument5 SeitenExam2SampleProblems SP17 - 1507832832437rohitrgt4uNoch keine Bewertungen

- Wmwbqi J Cix Vi Cökœ de "Qvwi 2015-Avm÷ 2022Dokument17 SeitenWmwbqi J Cix Vi Cökœ de "Qvwi 2015-Avm÷ 2022JuwelNoch keine Bewertungen

- Curl (Mathematics) - Wikipedia, The Free EncyclopediaDokument13 SeitenCurl (Mathematics) - Wikipedia, The Free EncyclopediasoumyanitcNoch keine Bewertungen

- KTU BTech EEE 2016scheme S3S4KTUSyllabusDokument41 SeitenKTU BTech EEE 2016scheme S3S4KTUSyllabusleksremeshNoch keine Bewertungen

- Candy System Functionalities ListDokument4 SeitenCandy System Functionalities ListPauloKupesaNoch keine Bewertungen

- Njagi Substructures Boq 2020Dokument76 SeitenNjagi Substructures Boq 2020michaelNoch keine Bewertungen

- Parts Catalog: Imagerunner Advance 6075/6065/6055 SeriesDokument201 SeitenParts Catalog: Imagerunner Advance 6075/6065/6055 SeriesTally LeonNoch keine Bewertungen

- Constructing A Project PlanDokument2 SeitenConstructing A Project Planmariz angel d dagodogNoch keine Bewertungen

- Astm A875m-Zinc 5 % Alum-13Dokument8 SeitenAstm A875m-Zinc 5 % Alum-13Ahmed SalehNoch keine Bewertungen

- Tanuj CVDokument2 SeitenTanuj CVVikram Pratap SinghNoch keine Bewertungen

- The Self From Various PerspectivesDokument32 SeitenThe Self From Various PerspectivesAbegail ArellanoNoch keine Bewertungen

- Finite Element and Theoretical Investigations On PVC-CFRP Confined Concrete Columns Under Axial CompressionDokument42 SeitenFinite Element and Theoretical Investigations On PVC-CFRP Confined Concrete Columns Under Axial CompressionShaker QaidiNoch keine Bewertungen

- PERDEV Week3Dokument26 SeitenPERDEV Week3Coulline DamoNoch keine Bewertungen

- Assignment Strategic ManagementDokument18 SeitenAssignment Strategic ManagementDarmmini MiniNoch keine Bewertungen

- Health Economics AssignmentDokument5 SeitenHealth Economics AssignmentEzra AnyalaNoch keine Bewertungen

- Sixth Sense TechnologyDokument36 SeitenSixth Sense TechnologyMahtab ANoch keine Bewertungen

- The Road To Reinvention Linkner en 22668.simpleDokument10 SeitenThe Road To Reinvention Linkner en 22668.simplePrateek AroraNoch keine Bewertungen

- Workshop 3Dokument4 SeitenWorkshop 3Ajiri IvoviNoch keine Bewertungen

- 34630.Seneca-Resume Writing Guide PDFDokument8 Seiten34630.Seneca-Resume Writing Guide PDFfiq_hugo319Noch keine Bewertungen

- Asus X550JF x550jxDokument7 SeitenAsus X550JF x550jxCiprian BalalauNoch keine Bewertungen

- ROLAN BART Zadovoljstvo U TekstuDokument56 SeitenROLAN BART Zadovoljstvo U Tekstujokokokl100% (18)

- Practices Venn DiagramDokument2 SeitenPractices Venn DiagramNathanNoch keine Bewertungen

- Ambience LightingDokument340 SeitenAmbience Lightingdambe22Noch keine Bewertungen

- Bending Moment PresentationDokument21 SeitenBending Moment PresentationRiethanelia UsunNoch keine Bewertungen

- Form No. NTC 1 22 Application For Tvro Renewal SignedDokument1 SeiteForm No. NTC 1 22 Application For Tvro Renewal SignedAmor LicudoNoch keine Bewertungen

- Gkournelos Triantafillou 2023 Out of Plane Behavior of in Plane Damaged Masonry Infills Retrofitted With TRM andDokument14 SeitenGkournelos Triantafillou 2023 Out of Plane Behavior of in Plane Damaged Masonry Infills Retrofitted With TRM andN.prem kumarNoch keine Bewertungen

- Be11 enDokument12 SeitenBe11 enSaqlain Mir100% (1)

- MBA MCA Fee 2012Dokument53 SeitenMBA MCA Fee 2012Sudhir KumarNoch keine Bewertungen