Beruflich Dokumente

Kultur Dokumente

Specification For Construction of Manholes

Hochgeladen von

Wan MahiramOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Specification For Construction of Manholes

Hochgeladen von

Wan MahiramCopyright:

Verfügbare Formate

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________

SPECIFICATION FOR CONSTRUCTION OF MANHOLES, JOINT BOXES AND LAYING OF DUCTS

1.0

GENERAL This section of the Specification describes and specifies requirements for the supply, delivery, installation, testing, commissioning, handing over in approved working order and maintenance during the Defects Liability Period of the manholes, joint boxes and ducts all in accordance with the Specification, Supplementary Notes, Bill of Quantities, Conditions of Contract, Drawings etc.

2.0

STANDARDS AND APPROVAL The installation works shall comply with the latest relevant British Standard Specification and Syarikat Telekom Malaysia Berhad (STM) specification and requirements. All material used shall be of the types approved by STM and acceptance by the S.O.s Representative. Samples of materials shall be submitted to the S.O.s Representative for approval prior to installation. Sample of the materials which have been approved by the S.O.s Representative for use in the Works shall be displayed at the site office for reference.

3.0

WORK PROGRAMME The Contractor shall submit to the S.O.s Representative detail work programme for approval within two weeks after acceptance of tender of such shorter period as required by the S.O.s Representative. If the work programme submitted is not acceptance by the S.O.s Representative, the Contractor shall amend and resubmit the programme for final approval.

4.0

SITE DIARY The Contractor shall keep at the work site a site diary, to which the S.O.s Representative shall have access at all times during working hours. The Contractor shall keep the site diary posted up to date, entering therein all measurements on the day on which they are taken and details of any deviations or extra work. Records of works shall be submitted daily to the S.O.s Representative for verification. All entries in the said shall be considered to be, and shall remain, the property of the S.O.s Representative.

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________

5.0

SAFETY Adequate approved traffic warning signs and lamps shall be provided and displayed by the Contractor at all time. The form, placing and light of the warning signs must comply with all local and national regulations and safety codes for road works. The Contractor shall take all necessary precautions and follow the correct procedures to avoid accidents due to presence of explosive gases, asphyxiating gases and toxic gases in the underground network. The Contractor shall take all necessary measures to ensure the safety of the workmen, members of the public, plant or property, especially when carrying out any works in manholes or joint boxes. QUALITY OF MATERIALS CONCRETE Concrete shall be of quality A,B,C,F or G as provided by this Specification and the proportions of the ingredients shall be as follows :Concrete Mixture Cement Quality A Quality B 1 1 Parts by Measure Sand 2 2 Aggregate 4 7 All Jointing Chamber, Plinth. Placed between two sets of plant if separation clearance is 152mm or less. For supporting protecting or filling in purpose. Concrete Troughs. Filling in Manholes covers 3E & 7E. Encasement of Ducts. Dummy ducts in jointing chamber, repairing damaged or split ducts. Usage

6.0 6.1

Quality C

Quality F Quality G

1 1

2 1

3 3

Cement Mortar

1 1

4 3

3 -

The concrete used for encasing ducts shall be relatively dry and having the consistency of wet sand. In no circumstances shall the water content be increased appreciably as this will result in a weak concrete. The cement used for encasing ducts shall be rapid-hardening type.

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________

Concrete mixing shall be done manually or by machine. Ready mixed shall be the first preference if available. In the process of mixing the concrete, the ingredients shall be repeatedly turned over and mixed in a dry state on mixing boards, after which water from the nose of a watering can shall be added and the materials shall than again be turned over sufficiently to ensure thorough mixing. The mixing boards shall be sufficiently large to give ample room for turning over the ingredients entirely from one place to another and shall be so arranged or constructed that liquid cement shall not escape through the joints. When mixed by machine the water shall be poured in first and the ingredients shall be put into the machine dry without prior mixing. The standard of cleanliness of water for mixing is that it shall be fit for drinking. The quantity used shall be sufficient to effect the proper hydration of cement to obtain a plastic mixture. The S.O.s Representative may reject concrete which is, in his opinion, so over watered that it would be deficient in ultimate strength. The concrete shall be deposited carefully in its intended position as quickly as possible after being mixed and all concrete footings and foundations shall be tamped and carefully leveled. All concrete shall be compacted by the used of a poker type vibrator until a dense solid mass without voids is obtained. Under no circumstances must the vibrator be used longer than is necessary to obtain compaction nor left unattended in the concrete, otherwise segregation of the mixture will occur. Concrete which has become hard, dry, dirty or not placed within 30 minutes after being mixed shall not be used, and of any earth fall on top of any concrete after laying and before the work is completed, it shall be carefully removed.

6.2

CEMENT All cement used shall comply with the relevant British Standard Specification. The cement shall be fresh, fine, smooth, loose and warm and the S.O.s Representative reserves the right to reject the cement which is found unsatisfactory. The Contractor may employ generally rapid hardening Portland cement or high alumina cement in lieu of ordinary Portland cement for his convenience and acceleration of progress. Before high alumina cement is used, all tools and plants shall be cleaned. High alumina cement shall not be used with P.V.C. ducts. The Contractor shall ensure that all cement is protected adequately against moisture while being transported and stored. The used of cement aids where an additive is added to ordinary Portland cement to render it rapid hardening is not recommended and permission for its use shall first be obtained from the S.O.s Representative who shall also determine the amount of additive to be used.

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________

6.3

SAND All sand to be used shall be river sand. It shall be clean, sharp, gritty and free from loam or other impurities. If the sand is found to contain more than 5 percent by volume of silt, the sand shall not be used. The sand used shall be course and the grains graded in size to 5 mm.

6.4

AGGREGATE The aggregate for concrete shall be cleaned screened river ballast, gravel, stone or other materials as approved by the S.O.s Representative. The aggregate shall be of the nature of cubes, not of flakes and graded in size and free from dirt, floury stoned duct, loam, earth or any other impurities. Clinkers, brick sandstone or other porous stone shall not be used. The maximum size of aggregate for each of the qualities of mixture included in Section 6.1 shall be as follows :A ..20mm, B40mm, C..any size suitable for work, F&G 10mm, for encasement of ducts .6mm. Any portion which will pass a 5mm mesh shall be used as sand.

6.5

BRICKS The bricks used shall be best quality hard burned common bricks, either wire cut or plastic pressed, or selected hard hand-made, stock bricks or other hard or over-burned hand-made bricks of comparable quality. They shall be of good shape, free from visible particles or lime and from serious cracks, and shall not absorb more than 12 percent of their weight when immersed in water for 24 hours. Five bricks from each batch delivered at site shall be tested and all shall be required to pass the test. The dimensions of bricks described as type 2 and 3 in B.S. 657 shall be regarded as standard.

6.6

CEMENT MORTAR The cement mortar shall consist of one measure of cement and three measure of sand. The materials after being gauged shall be thoroughly mixed in a dry state and then thoroughly mixed with sufficient water to form a stiff mortar. Water, cement and sand shall not be added after mortar has one been mixed and set. If mortar has once begun to set and excess water has been used for mixing, further quantity of sand and cement not be added but the whole mortar shall be rejected.

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________

6.7

STEEL, IRONWORK AND HARDCORE All structural steel shall be in accordance with British Standard Specification. All invoices for steel shall be inspected by the S.O.s Representative. If the Contractor cannot procure such reinforcing steel in the Imperial sizes as described in the Drawings but can obtain such steel in the Metric sizes and the dimensions approximating to those in the following table, then the Contractor shall forthwith obtain the approval of S.O.s Representative before such steel are ordered. Imperial size (ins) 5/16 3/8 5/7 7/8 Metric size (mm) 6 8 10 12 16 20 22 Imperial size (ins) 1 11/8 1.25 1.5 Metric size (mm) 25 28 32 40 Bolts, nuts, rivets and other accessories shall be in accordance with the relevant British Standard Specification. All invoices for iron shall be inspected by the S.O.s Representative. All hardcore shall consist of hard brick, concrete or stone graded down to a minimum of 80mm. Sufficient hardcore material under the sizes of 80mm shall be added up to fill voids and aid consolidation.

7.0

EXCAVATION The Contractor shall carefully segregate the surface and foundation material from the lower sub-soil. Sub-soil shall be protected whilst above ground from weathering action which could cause a damaging increase in the natural moisture content of soil leading to the formation of voids and/or settlement after back-filling. Sub-soil which is damages shall be removed and replaced by undamaged sub-soil. Except where otherwise provided, the excavation shall include all necessary/timbering and shoring. Mechanical excavator shall be used in a manner as to fulfill the requirements of excavation work. A timber base support or platform shall be placed under the fees of the excavation machine as a protection to prevent the carriageway surface being marked when the machine is in operation. Pneumatic drills or other power driver appliance shall be fitted with efficient silencing devices and the compressor machine shall be maintenance in an efficient condition so as to avoid undue noise. The Contractor shall obtain prior approval of the S.O.s Representative to dig pilot holes and excavation of trenches. Pilot holes shall be dug at positions selected by the S.O.s Representative, normally one per sectional length to ascertain the most suitable position for the work. Timber support for excavation shall be so designed and placed as to permit wherever possible withdrawal of such timber and consolidation of the space it occupied.

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________ The routes of the trench shall be marked out and approved by the S.O.s Representative before excavation. The width of trench excavated shall not be greater than is necessary for satisfactory execution of the work. The routes of the excavated trench shall be as straight as possible and any bends or curves shall be of the maximum radius possible. Where ducts are to be encased in concrete the width of trench shall be dependent upon the number of ducts to be laid in a horizontal direction. In unstable ground, timbering shall be used to support the trench and to act as a former for the concrete. The depth of trenches shall comply with the specification and as directed by the S.O.s Representative. The floor of the trench shall be leveled and shall not follow surface irregularities. The bottom of the trench shall be normally leveled with 50mm of sand and rammed. In passing from footway to carriageway and vice versa or where ducts enter jointing chambers below standard depth or in any other circumstances where it is necessary to change level, the bottom of the trench shall rise or fall gradually as directed by the S.O.s Representative. The Contractor shall dispose of the water in the trench so as to prevent any risk of the ducts, cables and other materials to be laid in it being detrimentally affected. He shall provide all pumps and appliances required and shall carry out the necessary pumping and bailing. 8.0 8.1 DUCTS LAYING GENERAL PROCEDURES The routes of ducts shall be kept as possible. In the case of 4-ways ducts or more, the lines shall break joint by approximately half the duct length in alternative lines, horizontally and vertically. Unless otherwise permitted by the S.O.s Representative, no ducts shall be laid and covered up in the absence of the S.O.s Representative. All ducts laid direct in the ground shall be kept well clear of water mains, service pipes, sewers, subways, manholes, joint boxes etc. belonging to others. In order to permit the use of tapping machine on water mains, a minimum clearance of 152mm shall be given wherever possible. This clearance shall also be given, if practicable, to the other service mentioned above. In no case shall the clearance be less than 25mm, where the two services cross each other, the minimum vertical clearance shall be 50mm. The following minimum separating distance between supply cables and lines of ducts shall be provided :(a) the electrical

High-voltage single-core cables (exceeding 650 volts) Standard minimum clearance .460mm No exception to this requirement will be permitted. High-voltage multi-core cables (exceeding 650 volts)

(b)

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________ Standard minimum clearance . 300mm If difficult cases a reduced clearance shall be permitted. Where it is impossible to provide a greater clearance than 150mm, a layer of quality B concrete, not less than 50mm thick and of a width to overlap the electrical services by 50mm on each side, shall be placed between the two services. Where the two service cross each other, the length of the layer of concrete shall not be less than the width of the telephone services. (c) Low and medium-voltage cables (not exceeding 650 volts) Standard minimum clearance .50mm Where the two services cross each other no exception to this requirement shall be permitted. At other points a clearance down to 25mm shall be allowed in difficult cases. Wherever the clearance is 50mm or less, the spare between the two services shall be filled with a layer of quality B concrete. In all cases the concrete shall overlap the electrical services by 50mm on each side, and at crossing, the length of the layer of concrete shall nor be less than the width of the telephone services. The Contractor shall cut and bend the ducts according in the requirements of the work. Inside edges of cut ducts shall be thoroughly rounded off to prevent damages to cables from the edges. The trench bottom shall be filled with a layer of sand 50mm thick and holes shall be taken out of the bottom of the trench at all points where sockets occur so that the barrels of the ducts rest on solid ground. In rocky soils, the trench shall be bedded with 80mm thick sand on which the ducts are laid. On completion of the ducts line between any two jointing chambers of sites, a cylindrical brush connected to the following end of a mandrel shall be passed twice through each way to clean the duct and to remove any foreign matter which may have entered. All test shall be carried out in the presence of the S.O.s Representative. If any obstruction or other defect be discovered, it shall be rectified to the satisfaction of the S.O.s Representative. A hardwood plug shall be inserted at the ends of each way in a line of ducts until the length has been tested and passed. When jointing chambers are provided on an existing duct routes or when any disturbance takes place which may affect the alignment of the ducts, a test mandrel of appropriate dimensions shall be drawn through each of the spare ways. The Contractor shall take all reasonable steps to prevent damage to the paving by his plants.

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________ 8.2 GALVANISED IRON PIPES All galvanized iron pipes shall comply with STM Specification Lines D 0010. Galvanized iron pipes shall be provided in nominal lengths of 6m and provided with screwed socket at one end. The procedures of laying galvanized iron pipes shall be as specified in Section 8.0. Where one line of ducts is laid over the lower line of ducts and carefully rammed to form a bedding of 50mm in thickness for the top ducts. Sand shall also be rammed between the ducts laid said by side in the same trench. The ducts shall break joint by approximately half the length in alternative lines, horizontally and vertically. Joints shall be made by positioning the threaded end of the pipes to the screwed socket of the other pipe end. One of the pipes shall be turned until it cannot be turned any more and the thread of the threaded end cannot be seen. Pipes shall be cut where necessary at right angle to the bore only. The inside edges shall be filed so that there can be no possibility of damages to cables from the edges. To ensure the alignment of the ducts, a working mandrel of 457mm in length and 83mm in diameter shall be drawn through as the ducts are laid. The test mandrel used for testing and cleaning shall be 457mm in length and 83mm in diameter, the cylindrical brush shall be 108mm in diameter.

8.3

P.V.C. DUCTS P.V.C ducts shall be supplied in 6m lengths. The ducts shall be stored away from the direct rays of the sun. A solvent cement shall be used for the process of jointing. The ducts shall comply with STM Specification Lines D 0011. The trench shall be scooped out at all points where the spigot rest, so that the duct lies upon rammed sand. The condition for duct laying as detailed in Section 8.1 shall be applied. Where one line of ducts is laid over another in the same trench, sand shall be filled in and over the lower lone of ducts and carefully rammed to form a bedding of 50mm in thickness for the top ducts. Sand shall also be rammed between the ducts laid side by side in the same trench. The ducts shall break joint by approximately half the duct length in alternative lines, horizontally and vertically. If it is necessary to deflect from a straight line or to vary the depth, sets shall be given to the joints but deflections shall not be greater than 12mm per 610mm run of the single ducts. Short ducts not less than 610mm in length, shall be built into the track in order to ensure the required deviation. Ducts shall be cut when necessary, at right angles to the bore only, preferably with a saw in a simple cutting guide. The inside edges of

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________ the ducts shall be trimmed so that there shall be no possibility of damages to cables from the edges. The spigot of the ducts shall be wiped clean. The solvent cement shall be applied to the spigot as well as the end of another duct. The end of the ducts where the solvent cement ware applied shall be positioned and pressure applied for the two ducts to be jointed. In no circumstances shall dirt or grit be allowed to enter the joint. To ensure the alignment of the ducts, a working mandrel of 457mm in length and 83mm in diameter shall be drawn through as the ducts are laid. When the construction of the jointing chamber is deferred, the last joint of each duct shall be tested on completion of the jointing chamber by means of the working mandrel mentioned above. The test mandrel used for testing shall be 457mm in length and 83mm in diameter, the cylindrical brush shall be 108mm in diameter.

8.4

ENCASING IN CONCRETE The method of encasing ducts in concrete in the layer by layer method where each duct is completely surrounded by concrete. To install P.V.C ducts around curves, the rigid ducts shall be bent to avoid obstacles or to negotiate curves. The ducts shall be cold bent around stakes for radii above 10.6m. To provide favourable cable hauling conditions, the radii should be as large as possible. Cold bending in situ to the curve required is achieved by provision of stakes to form the ducts to the required shape. The stakes must be spaced at intervals not greater in length than 1/20th of the radius of curvature or alternatively as indicated in the Table below.

Bend Radius Support Spacing

11.6m 11.2m 53.3 cm

12.2m15.2m 61.0 cm

15.2m18.2m 76.2 cm

18.2m21.3m 91.5 cm

21.3m24.3m 106.7 cm

24.3m 27.4m 122.0 cm

27.4m 304m 137.2 cm

Concrete cover above the top duct of a complete tier is to be a minimum of 51mm. After the initial set of concrete has occurred and before it sets hard, all stakes shall be withdrawn by applying a lifting and turning action to the stakes. Where additional ducts are to be installed above the first nest, the stakes shall be withdrawn until approximately 305mm remain embedded.

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________

8.5

FIXING DUCTS TO BRIDGES The following two methods shall be used for fixing ducts to bridges :(i) fixing to steel R.S.Js or fabricated beams.

(ii) Fixing to reinforced concrete bridge beams and masonry walls. It should be noted that extra care shall be taken when it is necessary to make holes for fixing bolts in existing bridge beams. All bridge fittings shall be thoroughly cleaned and painted with one coat of bituminous paint. Where it is necessary for duct to pass through abutment walls, the masonry or brickwork shall be arched over the pipe, the diameter of the hole thus formed shall be at least 13mm more than the external diameter of the duct. The space between with masonry or brickwork and the pipe shall then be filled with bitumen to provide a cushion of bitumen to the perimeter of the pipe at least 13mm thick.

8.6

DUMMY DUCTS One length of P.V.C ducts shall be positioned, in a wall of the chamber or above the row of ducts terminated at a jointing chamber. When it is necessary to increase the number of ways, the new ducts shall be jointed to the dummy ducts and the ducts shall be made available by breaking the mortar seal that was set previously in position when the ducts and chamber were constructed.

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________

9.0 9.1

JOINTING CHAMBERS TYPE OF MANHOLES The standard types and sizes of manholes with code reference are shown in the following tables :-

Reinforced Concrete Construction Throughout Code STM Figures Standard Drg. No. RO 13359/1 Rectangular SHTI&4 RIA RIB R2B mod fr RI3 RI3 mod. R2A R2B R2AE R2A Mod. R4 R6 R7 SM. No.1 SM. No.2 SM. No.3 TABLE 1 (Contd.) }13359/1 }SHT&4 }19488/0 } } 19658/0 } }13359/1 }SHT3&4 19636/0 19632/0 19634/0 19614/1 19615/1 } } }10750/2 } } } } } } }

Internal Dimensions Length (cm) 152 Breadth (cm) 106 Height (cm) 152

152 152 152 305

122 122 122 122 122

168 198 198 182 182

132

305

122

192

305 305 366 410 140

122 152 182 305 213

182-244 182 182 182 305

144

122

182

305

244

213

305

244

213

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________

R3 R5 R9 R9 MOD. R10

19633/0 19609/1 19578/2 19649/0

A S S O R T E D

19579/2 R10 MOD. 19652/0 R11 R12 R13 R14 R15 R16 19580/0 19588/0 & 19594/0 19638/0 19637/0 19635/0 S I Z E S H A P E S

See STM Drawing 19650/0 for size and shape

Table 1 (Contd.)

Code

Reinforced Concrete STM Standard Drg No. 19485/0 D 19482/0 SHT.1&2 19484/1 B 19486/0

Figure

Internal Dimensions Length Breadth Height

RT88

A A D 117cm

B 107cm F 274cm

C 244cm

182cm

B F

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________

9.2

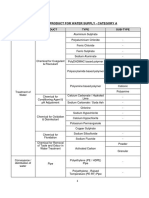

TYPE OF JOINT BOXES The standard types and sizes of joint boxes are shown in the following table :-

TABLE 2 Item Code STM Standard Drawing Number 19647/1 Length Breadth Internal Depth

Carriag eway Joint Box Carriag eway Joint Box Carriag eway Joint Box to accommo date L.P. 200 pr

JC9 Mod.

157cm

66cm

107cm

JC9C Mod.

19646/1

182cm

97cm

144cm

19540/0

244cm

97cm

108cm + 61cms.H

Note: Normal depths are indicated and shall be measured from the carriageway of footway surface to the top of the floor in each case. They may however be varied to suit the depths of the ducts. All jointing chambers whether built of brick or reinforced concrete shall be of waterproof construction. Ducts shall enter manholes at such a depth to ensure a clearance of at least 460mm between the top of the barrel of the uppermost ducts and the underside of the roof of the manhole. Except where a duct seal is provided, when a clearance of 203mm is required clearance of 152mm depending on type of manhole, shall be given between the outside of the barrel of the ducts and the adjacent wall, and a minimum clearance of 460mm between the underside of the lowest duct duct and the floor. Where the duct capacity of any proposed manhole is not fully utilized, the space shall be fitted with dummy ducts for future duct growth by laying initially at standard depth. The dummy ducts shall be sealed with cement mortar inside the chamber wall. To ensure that cables can easily be housed in manholes with a minimum bending, the ducts shall be splayed over the last length to enter the manhole equally on either side.

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________

9.3

MANHOLE CONSTRUCTION The ground shall be excavated to the required dimension, the sides of the excavation shall be supported by poling boards or by other means if there is any likelihood of the earth falling in. The foundation shall taken leveled and rammed. Soft ground shall be dug out, filled in with hardcore and consolidated. Two light wooden template, slotted (not drilled) to receive the reinforced bare shall be set up. The lower template shall be fitted about 305mm above the foundation and shall be supported on four small pegs at its corners. The upper template shall be fixed to correspond with the lower template, but about 305mm below the position of the roof of the manhole. In the process of erecting the floor of manhole, shuttering for the sump hole shall be set up and concrete laid over the foundation to a thickness of 38mm. The ends of side-wall-to-floor corner reinforcement shall be placed so that horizontal portions are just covered by the concrete. The vertical portions shall pass through the slots in this template and be set so as to obtained 19mm cover from the outside face of the walls when these are erected. Additional concrete shall next be laid until the level is 19mm less than the concrete level for the floor. This shall be done as soon as possible after placing the first layer of concrete, so that the two layers units thoroughly. Anchor irons shall be set in the floor in accordance with the relevant STM Standard Drawings. The interior wall reinforcement shall be placed with the horizontal portions flush with the surface of the concrete in the floor and the vertical portions passing through the slots of both template as to obtain 19mm cover from the interior face of the walls when these are erected. To remaining 19mm layer of concrete shall than be laid to reach the specified floor level. The erection of the walls shall be commenced when the floor has been left for at least 12 hours. The portion of the floor on which the walls will be erected shall be cleaned and rendered with a 7mm thickness of neat cement., well trowelled and placed in position, just before wall concreting is commend. The wall shall as far as possible be erected continuously to their full height, but if during erection a break of 2 hours or more is unavoidable, the existing work shall be cleaned and rendered as previously described. The horizontal bars and side-to-end-wall corner reinforcement shall be placed as walls are built up. Steps, manholes, bolts and cable bearers shall than be set in the walls. The template shall be removed when work reaches such a stages that they impede the placing of the concrete.

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________

When the walls have been built to the requisite height, shuttering for the roof shall be set up and the boards being arranged to form a recess at the position of the roof beams. A 26mm thickness of concrete shall then be laid throughout the roof area, including the recess of the beams. The beam reinforcement which have been previously assembled by threading and wiring of stirrups to the bars may now be laid and the main reinforcing bars shall be set to obtain 26mm cover. The remainder of the roof reinforcement shall be laid and to give the correct cover of 19mm and the rods shall be just visible above the surface of the concrete. The alternate bent bars shall be conveniently supported by a single wire fixing at the point where they enter the beam reinforcement. The concrete in the roof shall than be made up to the necessary thickness and finally the roof-to-wall corner reinforcement shall be embedded. The correct cover of 19mm to the roof shall be checked by a wood spike. Correction at each end of the horizontal part of the rod shall ensure that the vertical portion has the correct cover throughout its length. The upper face of the beams shall be spade-finished and the roof given a slight slope to the sides to avoid accumulation of water on the roof. The shuttering shall be struck and the floor shall be rendered with a 19mm cement mortar, with a fall to the sump hole on all sides and the manhole frame shall then be fitted. The arrangement of reinforcement for each type of manhole are as shown pictorially in the relevant STM Standard Drawings as listed in Table 1. The minimum concrete curing time for jointing chamber after completion of concreting shall be as shown in the following table :TABLE 3 : Manholes Built In The Carriageway/Foot Way Type of Cement Used Minimum Period from Completion of Concreting (a) to removal of shuttering (b) before commencing commencing reinstatement Carriage -way 7days FootWay 5days c)before allowing passenger of traffic Carriage- Footway way 7days 7days

Carriageway Portland Cement or its equivalent RapidHardening Cement High Alumina 5days

Footway 5days

2days

2days

3days

2days

3days

3days

10hrs

10hrs

24hrs

24hrs

24hrs

24hrs

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________ Cement The striking of the shuttering shall be commenced before the expiration of 12 hours and the concrete shall be prevented from becoming dry at any time by watering it within 24 hours of mixing. 9.4 JOINTING CHAMBER FITTINGS The following fittings in the jointing chamber shall be hot-dip galvanized and the following requirements shall be followed :(a) Grating for sump holes shall be fitted to the sump holes of all manholes. Anchor iron shall be fitted in accordance with the relevant drawing. Steps shall be installed in the position shown in the relevant drawings for the manholes. The steps shall also be used in entrance shafts for all manholes. Steel ladders shall be used in all type of manholes. The ladders shall be fixed in accordance with the relevant drawings to suit the different heights of the manholes. Bolts shall be fitted for the attachment of cable bearers. In all types of manholes, the bolts required for the walls shall be fixed temporarily in the shuttering during the construction of the manhole to ensure that they shall remain in their correct position while the concrete is setting. The positions for holes in the shuttering shall be obtained by using the cable bearer as a template. The cable bearers shall be fixed to the walls as described in (e). The brackets for cable bearers shall be in accordance with relevant drawing and the initial provision shall be 2 per Cable bearer, e.g. in a R2A type manholes, where the cable bearers are fitted 3 to a wall making a total of 6 cable bearers, the number of brackets provided shall be 12. The pins locking and cable bearer facilitate the removal of brackets. shall be designed to

(b)

(c)

(d)

(e)

(f)

(g)

(h)

9.5

FITTING OF MANHOLE COVERS Manholes Cover No.3E shall be fitted in all classes of manholes in accordance with the relevant drawings. Manholes Covers No. 7E shall be fitted in all classes of joint boxes in accordance with the relevant drawing. (a) Where the manhole is to be set at the minimum depth (as shown on the standard manhole drawings), one course of brickwork shall be laid between the manhole roof and frame.

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________ (b) Where, due to anticipated alternations in level, the manhole is to be set at an increased depth, one or more additional course of brickwork shall be laid. This is particularly important in the case of manholes built in the footway where there is possibility of the frames and covers being installed to carriageway level at a later date. Cement mortar shall be used both for setting the brickwork and for bedding the manholes frame. 24 hours must elapse after the building of a jointing chamber before the frame and cover are installed. The water used in the concrete shall not exceed 643 litres per cubic metres.

(c)

The frame shall be positioned accurately in relation to the cover before being filled so that the cover is flush and level with the surrounding carriageway. Two methods of filling and setting may be employed :(i) In-situ filling The frame shall be embedded on a layer of stiff cement mortar, care being taken to ensure that the frame is fully supported along all the four side. The level of the frame shall be adjusted to the level of the surrounding road surface by pieces of mild steel packing approximately 152mm x 51mm and of appropriate thickness. The cover shall than be placed in the frame. When the cover is correct suited, the edges of the frame and the cover shall be at the same level. If any irregularly can be felt by running the finger along the joint, or if the cover rocks, the frame shall be packed up until the edges are at the same level and the cover is free from rocking. The cover and the frame shall then be filled with concrete of Quality G, or an asphalt and granite mixture. Great care shall be taken when filling the frame to ensure that no voids are left, the concrete in each pocket shall be thoroughly tamped with to reinforcing rod. Finishing shall be done with a trower the concrete in the cover compartments being left slightly proud but not more than 3.2mm at the edge to 6.4mm crown in the center of the cover to allow for shrinkage, wear and to protect the metal webs. The lettering on the plate bearing the STM marking shall be left clear. (ii) Where in-situ filling is not possible, the frame shall be placed on a level surface with a piece of building paper beneath it to prevent concrete adhering to the floor. The leveling of the frame and cover, and the concrete filling shall then be done as described in method (i). The frames and covers must be left undisturbed for a minimum of 3 days. When the frame is installed, it shall be bedded on stiff 1:3 cement mortar.

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________ The minimum concrete during times for manhole covers shall be shown in the following table :A Type of concrete Before disturbing the frame or cover when in-situ filling is not used. B Before removing from the frame and after the complete installation including cement mortar bedding C Before allowing passage of traffic after the complete installation including cement mortar bedding

Ordinary Cement Rapid Hardening Cement High Alumina Cement

5 days 3 days

3 days 2 days

7 days 3 days

10 hours

10 hours

24 hours

9.6

CONSTRUCTION OF JOINT BOXES The ground shall first be excavated to the required dimensions and the sides of the excavation shall be timbered if necessary. The foundation shall then be leveled and rammed. The floor shall be laid and leveled to the required thickness with concrete of Quality A. Iron and anchor reinforcement bars shall be inserted where specified in the drawings. The fall of 25mm shown in the drawings for the floor, shall be achieved by rendering with a smooth finish cement mortar. Brickwork for the walls shall be laid in cement mortar and flush pointed. The bricks shall be dipped in water before they are laid. Brackets for joint box shall be fitted as the walls are erected. Roof shuttering shall be set up and concrete of Quality A for the roof shall be laid to a depth of 25mm and reinforcement set to give the correct cover. Additioned concrete shall then be placed to the specified thickness for the roof.

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________ Shuttering shall be struck as follows :(i) For carriageway joint boxes, after the lapse of time given in Table 3 of section 9.3 of this specification. For footway joint boxes, after 24 hours, irrespective of the type of cement used. A 20mm cement mortar rendering shall be applied to level the floors or they shall be built up to give 25mm drainage fall where required.

(ii)

Manhole cover No.7E shall be fitted to all joint boxes and the method as described in Section 9.5 of this specification shall apply.

9.7

PROTECTION OF CABLES AND ASSOCIATED EQUIPMENT The Contractor shall take such measures, to protect cables and associated equipment during the cutting of duct entries into existing structures or the demolition and rebuilding of jointing chambers. Such measures may include any or all of the following :(a) A ladder must be provided by the Contractor for the access of manhole excavation. Under no circumstances shall cable, joints and associated equipment be used for climbing, standing or sitting on. Sufficient pumping capacity shall be made available to ensure that when cables are removed from their bearers they shall not be immersed in water at any time. All cables shall be protected at duct entries by packing with foam rubber to act as cushion when any movement occurs. During demolition of the roof of a manhole the Contractor shall erect a deck of timber between the cables and the roof of the manhole to protect the cables etc. from falling debris in the following manner :(i) A minimum of three 229mm x 76mm timber upright shall be evenly spaced against each long wall of the manhole with the 229mm side against the wall. The length of the upright shall be such that the terminate approximately midway between the uppermost cables and the roof. Further length of horizontally on top of the uprights and between the uprights at the bottom, all positions shall be wedged and blocked to the satisfaction of the S.O.s Representative. Lengths of poling boards or other similar timber shall then be placed on top of the horizontal supports. When the manhole roof and walls have been demolished down to the level of the timber decking and all debris and decking removed, the cables and other associated equipment shall be suspended from beams on the surface of the ground to the satisfaction of the S.O.s Representative.

(b)

(c)

(d)

(ii)

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________ (iii) Cables and joints and other equipment shall be protected by wrapping (not tying) with several layers of sacking while timber decking is being erected or dismantled. (e) During rebuilding operations, cables shall be supported on wooden benches with cushions of sacking or similar material once the floor has been laid and the concrete allowed to set.

9.8

BONDING AT JOINTING CHAMBERS FOR EARTHING FACILITIES Where metal pipes are laid and terminated at jointing chambers, the break in continuity shall be made good by embedding 51mm x 3.2mm G.I. strips of required lengths in the walls of the jointing chambers during construction. The ends of the G.I. strips shall be welded to the pipes.

10.0

INTERIM RESTORATION, BACKFILLING AND PERMANENT REINSTATEMENT OF ROADS AND OTHERS INTERIM RESTORATION The Contractor shall execute interim restoration of all trenches and ducts in accordance with the provisions and specification laid down by JKR and other relevant authorities. A layer of sand shall first be laid on the bed of the trench and hand punned to a thickness of not less than 50mm before ducts are laid. All ducts shall be covered by a layer of sand and hand punned to a thickness of not less than 50mm.

10.1

10.2

BACKFILLING The spaces outside the walls of jointing chambers and surrounding area shall be completely filled with sand free from stones in 230mm layers and rammed. Care shall be taken such that the ramming shall not disturb any recently completed work. All materials shall be replaced in 150mm layers in the reverse order to which they were excavated. The remaining 300mm top of the trench shall be backfilled with good quality red earth and the materials previously excavated shall be placed on top and the gaps filled with quarry dust. All backfilling shall be thoroughly compacted at each layer using a mechanical rammer. If mechanical rammer is impracticable and hand ramming is employed, there shall be at least three persons ramming to one filling. Where S.O.s Representative required backfilling of trenches completely with sand or quarry duct, all excavated materials shall be removed from site, and backfilling shall be carried out as described in the following paragraph.

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________ For all road crossing in carriageway, after the bedding of a layer of sand in the trench has been satisfactorily carried out, the backfilling shall be done with nothing else except sand or quarry duct in layers. Each layer shall not be more than 230mm in thickness and well rammed with mechanical rammer or watered down before the next layer is laid. The top 300mm shall be backfilled with quarry dust only. This shall be done in tow layers, one layer to be rammed with mechanical rammers before the next layer is laid. The top layer shall be rammed with mechanical rammer until it is flushed with the road surface. Backfilled excavation shall be tested by applying a power frog rammer repeatedly over on half a square meter area for a period 3 minutes and shall performed by the Contractor as instructed by the S.O.s Representative at intervals he considers necessary. The compactness shall be considered satisfactory of the test shows no measurable change in level, a measurable change in level being a depression which cannot be rectified by reshaping the tested area and consequently requires additional imported material to restore the surface of the test to the original level. Should any measurable change in level occurred, then the area of faulty compaction, defined by the results of this and further tests, shall be rectified by the Contractor. The reinstatement portions of unpaved footways or other excavations shall be maintained by the Contractor and he shall ensure that they shall be leveled and turfing shall be replaced to the satisfaction of the S.O.s Representative. Any subsidence of other defects arising during the Defects Liability Period shall be made good by the Contractor.

10.3

PERMANENT REINSTATEMENT OF ROADS Permanent reinstatement shall commence only after the back filling and interim restoration has been allowed to settle well and that there is no measurable change in level. The reinstatement shall be carried out by removing the back filled material from the trench to a depth of 300mm which shall then be filled with a 250mm crusher-run stone (limestone or granite) not exceeding 62mm in size and the voids between the metal filled with quarry dust to serve as a bind. Where possible, consolidation by rolling shall be carried out with an 8 tonne roller utilizing a special hydraulic rolling wheel attachment. Elsewhere consolidation shall be effected by means of power driven rammer. The 300mm crusherrun stone base for trenches within carriageway shall be consolidated in 2 layers of 150mm each. The foundation of the footway shall be consist of a layer of not less than 125mm of quarry dust. The layer of quarry dust shall be rolled with a 2 tonne roller or by means of a power driven rammer.

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________ A tack coat cationic bituminous emulsion (40%) must be applied to the rolled crusher-run stone base/quarry dust base at the rate of 4.5 square metre per litre before the premixed asphalt macadam surface is laid. When the consolidation of the stone foundation is completed, premixed asphalt shall be spread evenly over the treated stone surface/quarry dust surface and rolled until complete consolidation has been obtained and the resultant surface left slightly proud of the existing adjacent surface. For carriageway consolidation, an 8 tonne roller shall be used and for footpath consolidation, a roller not exceeding 2 tonne shall be used. All surplus material shall be removed from site by the Contractor on the same day the trench has been backfilled. The Contractor shall be responsible for maintaining the backfilled trench until the surface reinstatement is complete.

11.0

WORKING DRAWINGS Within three weeks after award of the tender or such shorter period as may be required by the S.O.s Representative, the Contractor shall submit to the S.O.s Representative for his approval, four sets of detailed drawings the positions of manholes/joint boxes and cable ducts routes. The drawings submitted shall be modified if necessary as required by the S.O.s Representative and submitted for final approval. It is to be understood, however, that approval of the drawings will not exonerate the Contractor from any responsibility in connection with the works.

12.0

SERVICE AND MAINTENANCE During the Defects Liability Period, the Contractor shall perform service and maintenance work for the complete installation by skilled persons. All works, materials, tools and parts necessary to rectify the defects due to manufacturing/installation/construction faults shall be supplied/executed by the Contractor at no extra cost to the Government. The works to be performed shall include but not be limited to the following :(a) (b) Replacing and making good all manholes, joint boxes, ducts etc. Making good any damage to roads, buildings, drains, cables, pipes, concrete areas, paved areas etc. which had not been properly made good. All other works Representative. as deemed necessary by the S.O.s

(c)

The maintenance work shall be carried out as soon as the Contractor has been informed by the S.O.s Representative. If the work has not been carried out and completed within a reasonable period, the S.O.s Representative reserve the right to engage another party to carry out the work in which case, the Contractor shall be responsible for all the expenses incurred.

T-2 Specification for Construction of manholes, Joint Box and Laying of Ducts ____________________________________________________________________________________________ 13.0 AS INSTALLED DRAWINGS Within three calendar months after the practical completion of the project, one set of true to scale negative (110/115gm sq.m) and four sets of prints of the layout of cable duct routes, manholes and joint boxes with reference to easily recognizable buildings and structures shall be submitted. These drawings shall be provided whether or not they are separately itemzed in the Bills of Quantities of the Tender Document. The cost of all these drawings is deemed to be included in the Tender Price. These drawings shall be properly stenciled and shall have at the lower right hand corner the Contractors name and address date of commissioning, scale, drawings number. If the drawings submitted are not acceptable by the S.O.s Representative, the Contractor shall amend and resubmit the drawing within two weeks from the date of return of the drawings.

Das könnte Ihnen auch gefallen

- PDFDokument14 SeitenPDFAlexander RichardsonNoch keine Bewertungen

- QCS-2010 Section 20 Part 6 Surface Water DrainageDokument8 SeitenQCS-2010 Section 20 Part 6 Surface Water Drainagebryanpastor106Noch keine Bewertungen

- DBKL ChecklistDokument4 SeitenDBKL ChecklistJia Fei KuangNoch keine Bewertungen

- En 10138-4 2000 Prestressing Steels Part 4 BarDokument6 SeitenEn 10138-4 2000 Prestressing Steels Part 4 BarDigantNoch keine Bewertungen

- List of Bs CodesDokument2 SeitenList of Bs Codesravi1214Noch keine Bewertungen

- Method Statement For Providing Pipe Sleeve Opening On R.C. BeamDokument1 SeiteMethod Statement For Providing Pipe Sleeve Opening On R.C. Beamhiyumiwks100% (1)

- BS 3921.specification For Clay BricksDokument30 SeitenBS 3921.specification For Clay BricksChris OltonNoch keine Bewertungen

- Qatar Highway Design Manual PDFDokument254 SeitenQatar Highway Design Manual PDFsudhakarmn100% (13)

- MATERIALS ENGINEER REVIEWER - IV (Miscellaneous Items)Dokument13 SeitenMATERIALS ENGINEER REVIEWER - IV (Miscellaneous Items)Louie PascuaNoch keine Bewertungen

- J-Pillar Hydrant PDFDokument27 SeitenJ-Pillar Hydrant PDFdaveleyconsNoch keine Bewertungen

- Runway Design and Structural Design of An Airfield PavementDokument18 SeitenRunway Design and Structural Design of An Airfield PavementspruhatechNoch keine Bewertungen

- Method Statement PVD (Wick Drain)Dokument9 SeitenMethod Statement PVD (Wick Drain)Arq Mario Josue Lopez BasañezNoch keine Bewertungen

- BS 4660 2000 Drainage Ancillary Fittings For Nominal Sizes 110 - 160 Below GradeDokument16 SeitenBS 4660 2000 Drainage Ancillary Fittings For Nominal Sizes 110 - 160 Below GradeFenner ElectromechanicalNoch keine Bewertungen

- Uganda Standards Series 2000 - DrainageDokument37 SeitenUganda Standards Series 2000 - DrainageKintu Munabangogo100% (2)

- Specification For Suppliers PDFDokument7 SeitenSpecification For Suppliers PDFalep azizNoch keine Bewertungen

- QCDFSS 4.1 - External Access - 4.1 Rev 0307 PDFDokument16 SeitenQCDFSS 4.1 - External Access - 4.1 Rev 0307 PDFRotsapNayrbNoch keine Bewertungen

- ManholesDokument3 SeitenManholesmandeep2Noch keine Bewertungen

- Vol 1 of 2 (18TD07) PDFDokument519 SeitenVol 1 of 2 (18TD07) PDFDavid Hong100% (1)

- Reinforced Concrete Designers Handbook 10th Edition Reynolds Steedman 2 Part PrintDokument7 SeitenReinforced Concrete Designers Handbook 10th Edition Reynolds Steedman 2 Part Printikanyu79Noch keine Bewertungen

- MS 1058 - Part 3 - 2006 PDFDokument31 SeitenMS 1058 - Part 3 - 2006 PDFNurul AkmaNoch keine Bewertungen

- Drains and Sewers GuidanceDokument11 SeitenDrains and Sewers GuidanceSanjay Kumar100% (1)

- 4.WMS-04-reinforcement Steel Fixing WorkDokument11 Seiten4.WMS-04-reinforcement Steel Fixing WorkamolNoch keine Bewertungen

- Uganda Standard Specifications :series 5000 - Ancillary RoadworksDokument31 SeitenUganda Standard Specifications :series 5000 - Ancillary RoadworksKintu MunabangogoNoch keine Bewertungen

- BS 2499-1 1993Dokument12 SeitenBS 2499-1 1993yahNoch keine Bewertungen

- Concrete Formwork SpecsDokument6 SeitenConcrete Formwork Specsclive_2201Noch keine Bewertungen

- DD20 CircularPrecastConcreteManholesDokument5 SeitenDD20 CircularPrecastConcreteManholesericpardo59Noch keine Bewertungen

- Ductile Iron Pipes General Information PDFDokument15 SeitenDuctile Iron Pipes General Information PDFfernandoNoch keine Bewertungen

- Appendix H - TOR For Bridge and Viaducts StructureDokument11 SeitenAppendix H - TOR For Bridge and Viaducts StructureSara Ikhwan Nor SalimNoch keine Bewertungen

- Concrete Formwork and FinishesDokument15 SeitenConcrete Formwork and FinishesIm Chinith100% (1)

- Body Corporate Guidelines PDFDokument17 SeitenBody Corporate Guidelines PDFmaNoch keine Bewertungen

- Estimation and Costing TextbookDokument4 SeitenEstimation and Costing TextbookRajivKumar0% (2)

- Method Statement For Screed Concreting Aerator TWTDokument4 SeitenMethod Statement For Screed Concreting Aerator TWTChamara Nilantha KarunarathnaNoch keine Bewertungen

- Di Pipe DrawingsDokument6 SeitenDi Pipe DrawingsZatul Akmal ZamilNoch keine Bewertungen

- Sikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarDokument3 SeitenSikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarSulaim Al KautsarNoch keine Bewertungen

- Method Statement Honey CombDokument1 SeiteMethod Statement Honey CombMohd Hussairi100% (4)

- MS 628-3 2014 - PrepdfDokument7 SeitenMS 628-3 2014 - PrepdfMay OngNoch keine Bewertungen

- OKA G45 RC - Square PilesDokument4 SeitenOKA G45 RC - Square PilesTee Bun PinNoch keine Bewertungen

- TOR For Structural ProjectDokument3 SeitenTOR For Structural Projectephrem0% (1)

- MS For MLT On 300 Spun Pile Br583Dokument21 SeitenMS For MLT On 300 Spun Pile Br583giyat_prcNoch keine Bewertungen

- c3813 - Manhole Grounding DetailsDokument9 Seitenc3813 - Manhole Grounding DetailsgemotorresNoch keine Bewertungen

- BS 5114Dokument15 SeitenBS 5114Mustafa Falih100% (1)

- BoQ - IOM Benin CBR Fish Farm ProjectDokument3 SeitenBoQ - IOM Benin CBR Fish Farm ProjectHarrison Daka LukwesaNoch keine Bewertungen

- Method Statement For Fabrication of Concrete StairsDokument10 SeitenMethod Statement For Fabrication of Concrete StairsDenver Vera MendozaNoch keine Bewertungen

- Sample CHB InstallationDokument11 SeitenSample CHB InstallationCatherine CatacutanNoch keine Bewertungen

- IWK Guide On FeeDokument1 SeiteIWK Guide On FeeJohnyReubenNoch keine Bewertungen

- New Beam To Old Column Connection PDFDokument6 SeitenNew Beam To Old Column Connection PDFVan BGNoch keine Bewertungen

- Section V-2 Concrete Classes and Mixes: 502.01 DescriptionDokument5 SeitenSection V-2 Concrete Classes and Mixes: 502.01 DescriptionAbdullah Aboodi50% (2)

- ME REVIEWER ECI Part 5-9Dokument17 SeitenME REVIEWER ECI Part 5-9Marlatif SakandalNoch keine Bewertungen

- BeamDokument6 SeitenBeamFouad Hassan100% (1)

- Concrete Lab ReportDokument8 SeitenConcrete Lab ReportJun Kang100% (2)

- Specification For Construction - Designing Buildings Wiki PDFDokument2 SeitenSpecification For Construction - Designing Buildings Wiki PDFAngelo Lirio InsigneNoch keine Bewertungen

- IBS Score FormDokument8 SeitenIBS Score FormAriffin Ngah100% (2)

- 10 STD Specifications - Building - 2018 (A1)Dokument902 Seiten10 STD Specifications - Building - 2018 (A1)Logan LiNoch keine Bewertungen

- COP Vehicles Parking ProvisionDokument80 SeitenCOP Vehicles Parking ProvisionAden Foo100% (1)

- General Specifications For MaterialsDokument78 SeitenGeneral Specifications For MaterialsRajesh SinghNoch keine Bewertungen

- Concrete Works SpecificationDokument16 SeitenConcrete Works SpecificationLem1985100% (2)

- 6SecIX IX.2.03 Masonry&Allied WorksDokument12 Seiten6SecIX IX.2.03 Masonry&Allied WorksAnonymous 7ZYHilDNoch keine Bewertungen

- Mislang, Yvette BSDDokument12 SeitenMislang, Yvette BSDSilendrina MishaNoch keine Bewertungen

- Method Statement - Structural ConcreteDokument7 SeitenMethod Statement - Structural Concretearif_rubinNoch keine Bewertungen

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringVon EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringBewertung: 4 von 5 Sternen4/5 (5)

- Excel:earthwork Manual SpreadsheetDokument14 SeitenExcel:earthwork Manual SpreadsheetWan MahiramNoch keine Bewertungen

- EarthworkDokument26 SeitenEarthworkWan MahiramNoch keine Bewertungen

- GPT OgiDokument2 SeitenGPT OgiWan MahiramNoch keine Bewertungen

- Osd 1Dokument4 SeitenOsd 1Wan Mahiram100% (1)

- BS ListDokument7 SeitenBS ListWan Mahiram100% (1)

- Authority Submission List in MalaysiaDokument3 SeitenAuthority Submission List in MalaysiaWan Mahiram100% (4)

- Authorities Approval Status (25!09!16)Dokument12 SeitenAuthorities Approval Status (25!09!16)Wan MahiramNoch keine Bewertungen

- REPORT Earthworks PDFDokument7 SeitenREPORT Earthworks PDFWan MahiramNoch keine Bewertungen

- 05 Drainage Works Inspection ChecklistDokument1 Seite05 Drainage Works Inspection ChecklistWan Mahiram100% (3)

- Sewer Hydraulic CalculationDokument3 SeitenSewer Hydraulic CalculationWan Mahiram100% (3)

- Product Grouping Under Category A For Water Supply ProductDokument6 SeitenProduct Grouping Under Category A For Water Supply ProductWan MahiramNoch keine Bewertungen

- L-Shape Wall Mar13Dokument2 SeitenL-Shape Wall Mar13Wan MahiramNoch keine Bewertungen

- How To Calculate Cut and Fill AccuratelyDokument8 SeitenHow To Calculate Cut and Fill AccuratelyWan MahiramNoch keine Bewertungen

- How To Calculate Cut and Fill AccuratelyDokument8 SeitenHow To Calculate Cut and Fill AccuratelyWan MahiramNoch keine Bewertungen

- U Shape Drain Mar13Dokument4 SeitenU Shape Drain Mar13Wan MahiramNoch keine Bewertungen

- DR Quek Time Area KL - MSMA2Dokument5 SeitenDR Quek Time Area KL - MSMA2Wan MahiramNoch keine Bewertungen

- Drainage CalculationDokument7 SeitenDrainage CalculationWan MahiramNoch keine Bewertungen

- PUAS RequirementDokument20 SeitenPUAS RequirementWan MahiramNoch keine Bewertungen

- Wash ThroughDokument0 SeitenWash ThroughWan MahiramNoch keine Bewertungen

- Humes ConcretePipeManualDokument65 SeitenHumes ConcretePipeManualGyorgy AdrienneNoch keine Bewertungen

- Conquas: The Bca Construction Quality Assessment SystemDokument67 SeitenConquas: The Bca Construction Quality Assessment SystemalfieNoch keine Bewertungen

- 2171 - Small P13609 - Ketchikan Repairs To The Airport Ferry Landing - FINALDokument23 Seiten2171 - Small P13609 - Ketchikan Repairs To The Airport Ferry Landing - FINALRomoex R RockNoch keine Bewertungen

- KITS RamtekDokument162 SeitenKITS RamtekdmadekaNoch keine Bewertungen

- Dynamics Architect (Mechanical Development) - Jobs - ASMLDokument2 SeitenDynamics Architect (Mechanical Development) - Jobs - ASMLRubina Mahtab KhanNoch keine Bewertungen

- Extrusion Is A Process Used To Create Objects of A Fixed Cross-SectionalDokument8 SeitenExtrusion Is A Process Used To Create Objects of A Fixed Cross-SectionalHaRi See RamNoch keine Bewertungen

- Lesson 4.4 The NanoworldDokument38 SeitenLesson 4.4 The NanoworldcadoarvinNoch keine Bewertungen

- Design and Construction of The UK's First Polystyrene EmbankmDokument10 SeitenDesign and Construction of The UK's First Polystyrene Embankmjitz1234Noch keine Bewertungen

- ABS - Part 4 - e PDFDokument700 SeitenABS - Part 4 - e PDFMuhammad Fauzan Mauliawan100% (1)

- M183Dokument2 SeitenM183Franz Richard Sardinas Mallco100% (1)

- ANSI/ASAE S572.1 MAR2009 (R2017) Spray Nozzle Classification by Droplet SpectraDokument6 SeitenANSI/ASAE S572.1 MAR2009 (R2017) Spray Nozzle Classification by Droplet SpectraБорис АстраханNoch keine Bewertungen

- B.tech - III Sem. Exam. 2013 14 ScheduleDokument19 SeitenB.tech - III Sem. Exam. 2013 14 ScheduleAnurag AryaNoch keine Bewertungen

- BhelDokument20 SeitenBheljiveshiamkingNoch keine Bewertungen

- European CV Format-1Dokument2 SeitenEuropean CV Format-1BayisaGebre100% (1)

- Engineering SurveyDokument10 SeitenEngineering SurveyBakhtiyar Q.KhawajaNoch keine Bewertungen

- Computerised Conceret Design by Engr. Ben David PDFDokument309 SeitenComputerised Conceret Design by Engr. Ben David PDFZENY FORTINNoch keine Bewertungen

- EPC Scope REV 6Dokument29 SeitenEPC Scope REV 6Anonymous uLAATWpfNoch keine Bewertungen

- IITs, NITs, IIMs Total No. of Seats For B.Tech./B.Arch (IIT-JEE/AIEEE) and M.Tech. (GATE)Dokument6 SeitenIITs, NITs, IIMs Total No. of Seats For B.Tech./B.Arch (IIT-JEE/AIEEE) and M.Tech. (GATE)Santosh Kumar100% (2)

- Bridge BearingDokument162 SeitenBridge BearingKabbilawsh Peruvazhuthi100% (6)

- ViewPublicDocument 3Dokument637 SeitenViewPublicDocument 3Prathamesh PatikNoch keine Bewertungen

- Manual CAEPipeDokument47 SeitenManual CAEPipeClaudio GimenezNoch keine Bewertungen

- Fracture Toughness - Measures The Ability of A Material Containing A FlawDokument2 SeitenFracture Toughness - Measures The Ability of A Material Containing A FlawAnonymous 1VhXp1Noch keine Bewertungen

- Educational Textbook CollectionDokument39 SeitenEducational Textbook CollectionSisi IbrahimNoch keine Bewertungen

- Cavitation PaperDokument6 SeitenCavitation PaperTony KadatzNoch keine Bewertungen

- D3261 16Dokument8 SeitenD3261 16masoudNoch keine Bewertungen

- UT Dallas Syllabus For Mech2310.001.11s Taught by P L Thamban (Stephan)Dokument7 SeitenUT Dallas Syllabus For Mech2310.001.11s Taught by P L Thamban (Stephan)UT Dallas Provost's Technology GroupNoch keine Bewertungen

- Building Energy SimulationDokument25 SeitenBuilding Energy SimulationNidas SameeraNoch keine Bewertungen

- Construction of Prefabricated CulvertsDokument2 SeitenConstruction of Prefabricated CulvertsJonah ScottNoch keine Bewertungen

- Is 4925Dokument14 SeitenIs 4925Naveen MatNoch keine Bewertungen

- Chance Reichel Templ TaskID WBS 05 12 00Dokument12 SeitenChance Reichel Templ TaskID WBS 05 12 00smshaidrNoch keine Bewertungen

- Curriculum ViateDokument3 SeitenCurriculum ViatesonyNoch keine Bewertungen

- Cyient - Oil and Gas IndustryDokument8 SeitenCyient - Oil and Gas Industrycyient_analyticsNoch keine Bewertungen