Beruflich Dokumente

Kultur Dokumente

Unity Check Examples (ASD Vs LFRD) PDF

Hochgeladen von

Laurence Arcon BanalOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Unity Check Examples (ASD Vs LFRD) PDF

Hochgeladen von

Laurence Arcon BanalCopyright:

Verfügbare Formate

CE 331, Spring 2007

Example ASD & LRFD Failure Checks

1/3

Example problem 1. A simply-supported beam, laterally braced full length. Dead Load (D) = 2.0 klf Live Load (L) = 4.0 klf

15 ft wL = 4.0 klf wD = 2.0 klf

Beam is a steel wide flange, W12x53 Yield Stress (Fy) = 50 ksi S = 70.6 in3 Z = 77.9 in3

w D L2 2.0klf (15 ft ) 2 = = 56.3k ft MD = 8 8 L 2 klf 4.0 (15 ft ) 2 w L = = 112.5k ft ML = 8 8

Design Method ASD Allowable Stress Design

fb = fb =

Load Effect

M D+L y I (5.63k ft + 14.06k ft ) 4.94in 53.8in

4

Resistance

allowable bending stress

Failure Check

f b 21.7ksi = Fb 23.8ksi

= 0.91 < 1, OK

Fb = 0.66 Fy = 23.8 ksi

f b = 21.7ksi

unity check

LRFD Load and Resistance Factor Design

Mu = 1.2 MD + 1.6 ML Mu = 1.2 (5.63 ) + 1.6 (14.06 ) Mu = 29.3k-ft

factored moment

k-ft k-ft

Mn = () Fy Z Mn = (0.9) 36ksi 12.6in3 / 12 in/ft Mn = 34.0k-ft

nominal moment capacity strength reduction factor

Mu 29.3k ft = M n 34.0k ft

= 0.86 < 1, OK

CE 331, Spring 2007

Example ASD & LRFD Failure Checks

2/3

Example problem 2. A simply-supported beam, laterally braced full length. Dead Load (D) = 2.0 klf Live Load (L) = 4.0 klf

w D L2 2.0klf (15 ft ) 2 M = = = 56.3k ft 8 8 w L L2 4.0klf (15 ft ) 2 ML = = = 112.5k ft 8 8

D

wL wD

Beam is a steel wide flange, W12x53 Yield Stress (Fy) = 50 ksi

15 ft

S = 70.6 in3

section modulus = I / y

Z = 77.9 in3

Design Method ASD Allowable Stress Design

fb = M

D+ L

Load Effect

Resistance

Lc = 9.0ft, Lu = 15.9ft (p 132 FE Ref) Lc < (Lb = 15ft ) < Lu Fb = 0.60 Fy = 0.6 (50ksi) Fb = 30ksi

Failure Check

unbraced length of compression flange

S (56.3 k ft + 112.5 k ft ) 12 in / ft = 28.7 ksi fb = 3 70.6 in

f b 28.7 ksi = = 0.96 < 1 Fb 30 ksi

OK

LRFD Load and Resistance Factor Design Mu = 1.2 MD + 1.6 ML Mu = 1.2 (56.3k-ft) + 1.6 (112.5k-ft) Mu = 248k-ft

Lp = 8.8ft, Lr = 25.6ft (p 128 FE Ref) Lp < (Lb = 15ft) < Lr Mn = Cb [ Mp BF(Lb Lp)] < Mp Cb = 1.0 (always for this class) Mp = 292k-ft (p 128 FE Ref) BF = 4.78k (p 128 FE Ref) Mn = (1) [292kpft (4.78k(15ft 8.8ft)] Mn = 262k-ft (< 292k-ft = Mp)

Mu 248 k ft = = 0.95 < 1 M n 262 k ft

OK

CE 331, Spring 2007

Example ASD & LRFD Failure Checks

3/3

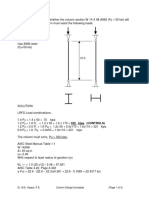

Example problem 3. A single column, laterally braced at mid-height for buckling in the weak direction, no lateral support for buckling in the strong direction. Dead Load (D) = 25k Live Load (L) = 75k

PL PD

= 75k = 25k

9 ft

Beam is a steel wide flange, W6x20 Yield Stress (Fy) = 50 ksi Ixx = 41.4 in4 Iyy = 13.3 in4 A = 5.87 in2 Lu_x = 18 ft (unbraced length for buckling in the strong direction)

9 ft

Lu_y = 9 ft (unbraced length for buckling in the weak direction)

Design Method ASD

fa =

Load Effect

Resistance

Failure Check

P D + L 25k + 75k = A 5.87 in 2

rx = ry =

Ix = A Iy A =

41.1in 4 = 2.65in 5.87 in 2 13.3in 4 = 1.50in 5.87 in 2

f a 17.0ksi = Fa 18.7ksi

= 0.91 < 1, OK

f a = 17.0ksi

k x Lu _ x

(1.0)(18 ft =

slenderness ratio

rx k y Lu _ y ry

12in ) 1 ft = 81.5 2.65in controls

ft

unity check

12in (1.0)( 9 ) 1 ft = 72.0 = 1.50in

allowable axial stress

Fa = 18.7ksi [ from Table on pg 134 FE Ref. for Fy = 50ksi and kL/r = 81.5 ]

kL = 81.5 (from above) r max

LRFD

Pu = 1.2 PD + 1.6 PL Pu = 1.2 (25k) + 1.6 (75k) Pu = 150k factored axial force

Pu 150 k = Pn 153.8 k

= 0.98 < 1, OK

c Fcr = 26.16ksi (Table p 131 FE Ref.)

cFcr = 26.16 [from Table on pg 131 FE Ref. for Fy = 50ksi and kL/r = 81.5 ]

ksi

Pn = c Fcr A = 26.2ksi 5.87in2 Pn =153.8kt

nominal axial capacity

Das könnte Ihnen auch gefallen

- Tedds Foundation DesignDokument7 SeitenTedds Foundation DesignMasaba SolomonNoch keine Bewertungen

- Torsion 9Dokument13 SeitenTorsion 9Vasanth KumarNoch keine Bewertungen

- Class A Loads Govt. of West Pakistan - Code of Practice Highway BridgesDokument1 SeiteClass A Loads Govt. of West Pakistan - Code of Practice Highway BridgesBunkun150% (1)

- φ - Vc b f ' c Vu b Tu - P: Design for Torsion and Shear According to ACI-318-99Dokument2 Seitenφ - Vc b f ' c Vu b Tu - P: Design for Torsion and Shear According to ACI-318-99mahmoud IbrahemNoch keine Bewertungen

- General Input:-: Flexural Crack Width Calculation For Rectangular RC According ACI350-06 &ACI224R-01Dokument6 SeitenGeneral Input:-: Flexural Crack Width Calculation For Rectangular RC According ACI350-06 &ACI224R-01Anil kumar RNoch keine Bewertungen

- Mathcad - Pile Cap Design2 PDFDokument17 SeitenMathcad - Pile Cap Design2 PDFVictorAndresCamposCamposNoch keine Bewertungen

- Foundation Design For Dynamic Equipment Based On ACI 351.3 & ACI 318-19Dokument12 SeitenFoundation Design For Dynamic Equipment Based On ACI 351.3 & ACI 318-19ZuzarNoch keine Bewertungen

- ACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev1.1 - 09-Nov-2014Dokument21 SeitenACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev1.1 - 09-Nov-2014coreteamNoch keine Bewertungen

- Plain Concrete FootingDokument4 SeitenPlain Concrete Footingjoshua humirangNoch keine Bewertungen

- Aisc Lrfd-99 Example 001Dokument7 SeitenAisc Lrfd-99 Example 001Ilham Hussein Rasyid100% (1)

- Members With Combined Bending and Axial ForceDokument32 SeitenMembers With Combined Bending and Axial ForceJohn RomanusNoch keine Bewertungen

- MonorailDokument14 SeitenMonorailZain AndabloNoch keine Bewertungen

- Composite Filled Composite Circular Column DesignDokument1 SeiteComposite Filled Composite Circular Column DesignAli SamaniNoch keine Bewertungen

- Anchor bolt design calculation for piperack foundationDokument10 SeitenAnchor bolt design calculation for piperack foundationArivoli JayaramanNoch keine Bewertungen

- What Is Sustained Load?: 1 AnswerDokument1 SeiteWhat Is Sustained Load?: 1 AnswerDonald HamiltonNoch keine Bewertungen

- How To Apply Horizontal Moving LoadsDokument2 SeitenHow To Apply Horizontal Moving LoadsRojan MathewNoch keine Bewertungen

- Design of Corbel Shear Reinforcement (ACI 318-08Dokument2 SeitenDesign of Corbel Shear Reinforcement (ACI 318-08Shamim Ahsan ZuberyNoch keine Bewertungen

- Ibc 16Dokument114 SeitenIbc 16Luis Fernando BaqueNoch keine Bewertungen

- BEAMDokument3 SeitenBEAMTano BahabobaNoch keine Bewertungen

- WeldDokument7 SeitenWeldMuhammad Akbar Faereza NugrahaNoch keine Bewertungen

- Composite Floor Deck Design PDFDokument4 SeitenComposite Floor Deck Design PDFsaipodinNoch keine Bewertungen

- P-M interaction check wall capacity comparisonDokument5 SeitenP-M interaction check wall capacity comparisonVILCA100% (2)

- Staad Pro Stainless Steel ReportDokument29 SeitenStaad Pro Stainless Steel ReportRaviteja Girijala100% (1)

- The Design Procedures For Prestressed Reinforced ConcreteDokument87 SeitenThe Design Procedures For Prestressed Reinforced Concretepiolenc100% (1)

- Defining Automatic Seismic Static Load Cases in Etabs and Sap2000 (Based On Iran-2800)Dokument1 SeiteDefining Automatic Seismic Static Load Cases in Etabs and Sap2000 (Based On Iran-2800)cesarNoch keine Bewertungen

- Sample Interaction Diagram of ColumnDokument8 SeitenSample Interaction Diagram of ColumnArvin Edsel Sioson100% (1)

- Huong Dan MegafloorDokument11 SeitenHuong Dan Megafloortrung1983Noch keine Bewertungen

- Interaction Diagram For Concrete ColumnsDokument14 SeitenInteraction Diagram For Concrete Columnsgeogohigh100% (1)

- 498 Plate Girder CombinedDokument1 Seite498 Plate Girder CombinedapooladiNoch keine Bewertungen

- Reinforced Concrete Torsion DesignDokument47 SeitenReinforced Concrete Torsion DesignalaaNoch keine Bewertungen

- Tank Foundation DesignDokument2 SeitenTank Foundation DesignRamadanNoch keine Bewertungen

- Applying Non-Uniform Loads To Shell Elements - ETABS - Computers and Structures, Inc. - Technical Knowledge Base PDFDokument2 SeitenApplying Non-Uniform Loads To Shell Elements - ETABS - Computers and Structures, Inc. - Technical Knowledge Base PDFMd Niamul IslamNoch keine Bewertungen

- Rectangular Concrete Beam Analysis in ExcelDokument16 SeitenRectangular Concrete Beam Analysis in ExcelAli Syaputra100% (1)

- 2 Wind Load Procedures ASCE 7 05 PDFDokument13 Seiten2 Wind Load Procedures ASCE 7 05 PDFLeah AnnNoch keine Bewertungen

- EC2 Design CalculationsDokument81 SeitenEC2 Design Calculationscollins unankaNoch keine Bewertungen

- Two-span continuous box girder designDokument20 SeitenTwo-span continuous box girder designMuhammad ImranNoch keine Bewertungen

- Profis Anchor 2.5.0 HILTIDokument6 SeitenProfis Anchor 2.5.0 HILTIALONSO GOMEZNoch keine Bewertungen

- Advanced Structure AnalysisDokument37 SeitenAdvanced Structure AnalysisM_zizo7Noch keine Bewertungen

- Checklist For Concrete Shear Wall (ACI 318-14)Dokument5 SeitenChecklist For Concrete Shear Wall (ACI 318-14)renzo1221Noch keine Bewertungen

- Check Punching Shear of PILE and COLUMN REactionsDokument4 SeitenCheck Punching Shear of PILE and COLUMN REactionsMa'rruf AmarNoch keine Bewertungen

- Design of Concrete Structures: Amit Das Department of Civil Engineering I.I.T BombayDokument57 SeitenDesign of Concrete Structures: Amit Das Department of Civil Engineering I.I.T BombayKC Paguinto100% (1)

- Composite Columns Design GuideDokument66 SeitenComposite Columns Design Guideabdelrahman emadNoch keine Bewertungen

- Magnified Moment Calculation For Circular Slender ColumnsDokument12 SeitenMagnified Moment Calculation For Circular Slender ColumnsAli AkbarNoch keine Bewertungen

- Moment of Inertia of Compound Section Lip ChannelDokument7 SeitenMoment of Inertia of Compound Section Lip Channelabhi aroteNoch keine Bewertungen

- Mathcad - Tank Foundation Design Actions - 2611-501 & 502 - Rougher WMS Feed Tank 1 & 2Dokument15 SeitenMathcad - Tank Foundation Design Actions - 2611-501 & 502 - Rougher WMS Feed Tank 1 & 2shashank sharmaNoch keine Bewertungen

- Angle Seat Detail AllowableDokument4 SeitenAngle Seat Detail AllowablepiziyuNoch keine Bewertungen

- Thiet Ke Cot Composite - EC4. V1.0 (MS03)Dokument5 SeitenThiet Ke Cot Composite - EC4. V1.0 (MS03)luuvandong48xf396Noch keine Bewertungen

- ACI TSecDokument3 SeitenACI TSecمصطفى عبدالرحيمNoch keine Bewertungen

- KDS 41 17 00 건축물 내진설계기준Dokument131 SeitenKDS 41 17 00 건축물 내진설계기준colt0Noch keine Bewertungen

- Spreadsheets To BS 8110Dokument11 SeitenSpreadsheets To BS 8110NitinShepurNoch keine Bewertungen

- Structural Dynamics & Earthquake EngineeringDokument34 SeitenStructural Dynamics & Earthquake EngineeringHema Chandra Reddy Karimireddy100% (1)

- Moment Connection Using Mathcad PDFDokument11 SeitenMoment Connection Using Mathcad PDFbong2rmNoch keine Bewertungen

- MAthcad Wall Calcs PDFDokument4 SeitenMAthcad Wall Calcs PDFManoj JaiswalNoch keine Bewertungen

- Circular Section Crack Width Under Tension Plus MomentDokument2 SeitenCircular Section Crack Width Under Tension Plus MomentAbinash ModakNoch keine Bewertungen

- 07-Unity Check Examples PDFDokument3 Seiten07-Unity Check Examples PDFati100% (1)

- Determine lightest W section for 20 ft columnDokument5 SeitenDetermine lightest W section for 20 ft columnArshi ParveenNoch keine Bewertungen

- ColumnDesignExamples PDFDokument5 SeitenColumnDesignExamples PDFsimon petrasNoch keine Bewertungen

- ColumnDesignExamples PDFDokument5 SeitenColumnDesignExamples PDFsimon petrasNoch keine Bewertungen

- Monorail-DesignDokument8 SeitenMonorail-Designdicktracy11Noch keine Bewertungen

- =F sinθ : R= F F R= F F R= FDokument46 Seiten=F sinθ : R= F F R= F F R= FYhelly27Noch keine Bewertungen

- Configure Netis Broadband Router Wireless SettingsDokument1 SeiteConfigure Netis Broadband Router Wireless SettingsLaurence Arcon BanalNoch keine Bewertungen

- Evoluzn FX PR2 Stock FirmwareDokument5 SeitenEvoluzn FX PR2 Stock FirmwareLaurence Arcon BanalNoch keine Bewertungen

- Evoluzn FX PR2 Stock FirmwareDokument5 SeitenEvoluzn FX PR2 Stock FirmwareLaurence Arcon BanalNoch keine Bewertungen

- Diagnosis and Management of HyperhidrosisDokument8 SeitenDiagnosis and Management of HyperhidrosisLaurence Arcon BanalNoch keine Bewertungen

- Average Nails Per PoundDokument1 SeiteAverage Nails Per PoundAJothamChristianNoch keine Bewertungen

- Evoluzn FX PR2 Improve LTE SignalDokument5 SeitenEvoluzn FX PR2 Improve LTE SignalLaurence Arcon BanalNoch keine Bewertungen

- i1040-CM (2018)Dokument4 Seiteni1040-CM (2018)Laurence Arcon BanalNoch keine Bewertungen

- Toyo Gate Valve PricelistDokument1 SeiteToyo Gate Valve PricelistLaurence Arcon BanalNoch keine Bewertungen

- STAAD-pro FinalDokument516 SeitenSTAAD-pro FinalMUUTHUKRISHNANNoch keine Bewertungen

- Assured Automation Flow Meter Price ListDokument3 SeitenAssured Automation Flow Meter Price ListLaurence Arcon BanalNoch keine Bewertungen

- IC72 Roof and Wall Panel SpecsDokument2 SeitenIC72 Roof and Wall Panel SpecsLaurence Arcon BanalNoch keine Bewertungen

- How To Find The Document Root of Your WebsiteDokument25 SeitenHow To Find The Document Root of Your WebsiteLaurence Arcon BanalNoch keine Bewertungen

- Basic Plumbing 3D 01Dokument1 SeiteBasic Plumbing 3D 01Laurence Arcon BanalNoch keine Bewertungen

- Assured Automation Flow Meter Price List PDFDokument3 SeitenAssured Automation Flow Meter Price List PDFLaurence Arcon BanalNoch keine Bewertungen

- Should I Be Setting Static IP Addresses On My RouterDokument4 SeitenShould I Be Setting Static IP Addresses On My RouterLaurence Arcon BanalNoch keine Bewertungen

- ORN - 09 - A Design Manual For Small BridgesDokument238 SeitenORN - 09 - A Design Manual For Small BridgesLaurence Arcon Banal100% (1)

- Motioneye (OPI) - Free - Armbian ForumDokument4 SeitenMotioneye (OPI) - Free - Armbian ForumLaurence Arcon BanalNoch keine Bewertungen

- Technical Reference 2007 CompleteDokument782 SeitenTechnical Reference 2007 CompleteIvan GradNoch keine Bewertungen

- Primavera TutorialDokument82 SeitenPrimavera Tutorialgalante gorky95% (20)

- Dlink CamCloud ComparisonDokument4 SeitenDlink CamCloud ComparisonLaurence Arcon BanalNoch keine Bewertungen

- RC DESIGN NOTES by GuimoDokument80 SeitenRC DESIGN NOTES by GuimoLaurence Arcon BanalNoch keine Bewertungen

- Steel Design BeamsDokument4 SeitenSteel Design BeamsLaurence Arcon BanalNoch keine Bewertungen

- British Examples 2005Dokument368 SeitenBritish Examples 2005Andrei Ulmeanu100% (1)

- Concrete BasicsDokument56 SeitenConcrete Basicsengcecbepc100% (6)

- Eliminating The Guesswork in Connection Design-The Role of The Design EngineerDokument14 SeitenEliminating The Guesswork in Connection Design-The Role of The Design EngineerLaurence Arcon BanalNoch keine Bewertungen

- Installing PROKONDokument622 SeitenInstalling PROKONLaurence Arcon BanalNoch keine Bewertungen

- Primavera TutorialDokument82 SeitenPrimavera Tutorialgalante gorky95% (20)

- Standard Pipe Rack Design AidsDokument18 SeitenStandard Pipe Rack Design AidsLaurence Arcon BanalNoch keine Bewertungen

- Primavera TutorialDokument82 SeitenPrimavera Tutorialgalante gorky95% (20)

- Box Culvert DeignDokument5 SeitenBox Culvert DeignLaurence Arcon BanalNoch keine Bewertungen

- PAI Industries, Inc. - Catalog Polea de MotorDokument2 SeitenPAI Industries, Inc. - Catalog Polea de MotorAlexis ValleNoch keine Bewertungen

- NMNR5104 Research MethodologyDokument2 SeitenNMNR5104 Research MethodologynadiaNoch keine Bewertungen

- Grade 6 MathDokument12 SeitenGrade 6 Mathapi-264682510Noch keine Bewertungen

- Powerfactory 2020: Technical ReferenceDokument13 SeitenPowerfactory 2020: Technical ReferenceDaniel ManjarresNoch keine Bewertungen

- If This Paper Were in Chinese, Would Chinese People Understand the Title? An Exploration of Whorfian Claims About the Chinese Language If This Paper Were in Chinese, Would Chinese People Understand the Title? An Exploration of Whorfian Claims About the Chinese Language If This PaperDokument69 SeitenIf This Paper Were in Chinese, Would Chinese People Understand the Title? An Exploration of Whorfian Claims About the Chinese Language If This Paper Were in Chinese, Would Chinese People Understand the Title? An Exploration of Whorfian Claims About the Chinese Language If This PaperDavid MoserNoch keine Bewertungen

- Fundamentals of Programming C++Dokument647 SeitenFundamentals of Programming C++Agustin Alvarez100% (1)

- Chapter 1. Griffiths-Vector Analysis - 1.1 1.2Dokument24 SeitenChapter 1. Griffiths-Vector Analysis - 1.1 1.2Hazem TawfikNoch keine Bewertungen

- DIN-Rail AC Current Transducer 0.25% AccuracyDokument3 SeitenDIN-Rail AC Current Transducer 0.25% AccuracyjoseluisbeitoNoch keine Bewertungen

- Border Security Using Wireless Integrated Network Sensors (WINS)Dokument18 SeitenBorder Security Using Wireless Integrated Network Sensors (WINS)Pradeep CheekatlaNoch keine Bewertungen

- Basic Engineering Correlation Calculus v3 001Dokument3 SeitenBasic Engineering Correlation Calculus v3 001Ska doosh100% (1)

- Active FilterDokument16 SeitenActive FilterRam SankarNoch keine Bewertungen

- Install and Configure Computer SystemsDokument18 SeitenInstall and Configure Computer SystemsAlbino LarozaNoch keine Bewertungen

- CM-4G-GPS Quick Guide: Short Guide How To Start Using CM-GPRS ModuleDokument4 SeitenCM-4G-GPS Quick Guide: Short Guide How To Start Using CM-GPRS Modulezakki ahmadNoch keine Bewertungen

- FirmcusbDokument123 SeitenFirmcusbAndry1975Noch keine Bewertungen

- Pipesim Model Management Program: For Reservoir, Production, and Process ModelingDokument2 SeitenPipesim Model Management Program: For Reservoir, Production, and Process ModelingMauricio AlvaradoNoch keine Bewertungen

- Simple Backup/Restore Utility With SQL-: Introduction To SQL-DMODokument8 SeitenSimple Backup/Restore Utility With SQL-: Introduction To SQL-DMOZaeni Marjiyanto, A.mdNoch keine Bewertungen

- AminesDokument12 SeitenAminesEmelda BanumathyNoch keine Bewertungen

- KUKA Sim 30 Installation enDokument49 SeitenKUKA Sim 30 Installation enRégis Naydo0% (1)

- Micro Shelter Product Description V5aDokument11 SeitenMicro Shelter Product Description V5aIan JaredNoch keine Bewertungen

- Airy stress function enables determination of stress components in pure beam bendingDokument19 SeitenAiry stress function enables determination of stress components in pure beam bendingmaran.suguNoch keine Bewertungen

- MotorDokument33 SeitenMotorLyka LasilasNoch keine Bewertungen

- Physics Investigatory Project Class 12 CbseDokument20 SeitenPhysics Investigatory Project Class 12 Cbsesyed50% (6)

- UntitledDokument135 SeitenUntitledtaraji dawlaNoch keine Bewertungen

- DefinitionsHypothesesPosterior Analytics (Landor)Dokument12 SeitenDefinitionsHypothesesPosterior Analytics (Landor)Daniel Rojas UNoch keine Bewertungen

- Preventing Generator Damage from Hydrogen MoistureDokument27 SeitenPreventing Generator Damage from Hydrogen MoistureIskerNoch keine Bewertungen

- Research Methods in PsychologyDokument2 SeitenResearch Methods in PsychologyHillaryNoch keine Bewertungen

- FGS80HAS 100 V 50-60 HZ 1Dokument3 SeitenFGS80HAS 100 V 50-60 HZ 1Tomas GuaiquireNoch keine Bewertungen

- 19Ma2Icmat Module 5 - Elementary Numerical MethodsDokument4 Seiten19Ma2Icmat Module 5 - Elementary Numerical Methods1DS19CH011 Jashwanth C RNoch keine Bewertungen

- Module 4Dokument24 SeitenModule 4MARIE ANN DIAMANoch keine Bewertungen