Beruflich Dokumente

Kultur Dokumente

JSA For Soil Improvement

Hochgeladen von

Hilbrecht De PedroOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

JSA For Soil Improvement

Hochgeladen von

Hilbrecht De PedroCopyright:

Verfügbare Formate

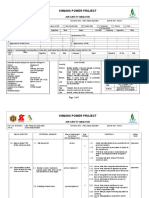

JOB SAFETY ANALYSIS FOR SOIL IMPROVEMENT BY DYNAMIC REPLACEMENT METHOD COMMON COOLING SEAWATER SYSTEM PHASE 2 SEQUENCE

OF BASIC ACTIVITY STEPS 1. Removal of temporary platform POTENTIAL HAZARDS HAZARDS CONTROL RESPONSIBLE Dodsal Site Supervisor Dodsal Site Supervisor Dodsal Site Supervisor Dodsal Site Supervisor Dodsal Site Supervisor Dodsal Site Supervisor

1.1 Collision between vehicles 1.1.1 Every moving equipments and vehicles must be manned with and equipments banks man. 1.1.2 All movable equipments shall bear reverse alarm and revolving hazard warning light. 1.2 Personnel hit with equipment and injury 1.2.1 Barricading all work place, equipment and plant at work site 1.2.2 No infringing activities shall be authorized and workers shall be warned adequately not to enter the working area.

2.0 Stockpile of natural crushed stone near the site

2.1 Equipment and vehicle hit 2.1.1 All material must be stored in designated area and if stored in with or trap with open area must be properly barricaded with warning tape and signage. 2.1.2 A safe access must be maintained all time, and the same must be demarked from the site area by putting barricading and warning light.

3.0 Excavation (4m to 5m) of 3.1 Fall of material, outer ring trench and equipments, personnel and backfilling with natural injury. crushed stone.

3.1.1 All excavation must be barricaded with signage. No materials shall store with in a proximity of 3 meter from the trench. 3.1.2 A clear access must be maintained all the time.

Dodsal Site Supervisor

Dodsal Site Supervisor

3.1.3 All equipments must be fitted with reverse alarm, revolving Dodsal Site Supervisor hazard warning light and must be manned with banks man. 1.2.2 Emergency vehicle must be kept available at site for attending any Dodsal Site Supervisor undue event.

1 of Pages 4

JOB SAFETY ANALYSIS FOR SOIL IMPROVEMENT BY DYNAMIC REPLACEMENT METHOD COMMON COOLING SEAWATER SYSTEM PHASE 2 SEQUENCE OF BASIC ACTIVITY STEPS POTENTIAL HAZARDS HAZARDS CONTROL RESPONSIBLE Dodsal Site Supervisor

4.0 Pre excavation for stone 4.1 Collapse of excavation, fall 4.1.1 Slopping, benching and shoring must be done as applicable columns and removal of soil. of equipment and personnel considering the nature of soil.

4.1.2 All equipment must keep a safety margin of 3 meters from the Dodsal Site Supervisor edge of excavation. 4.1.3 Excavated materials must not keep on the edge of excavation and Dodsal Site Supervisor the same must be kept away at least 3 meters from the edge of excavation. 5.0 Material handling 5.1 Manual handling and injury 5.1.1 Experienced workers shall be deployed for the handling of heavy Dodsal Site Supervisor equipments and their parts. 5.1.2 Manual handling procedure shall be explained to all workers. 5.2 Slip, Trip and fall 5.2.1 Material and tools must be handled as per the standard practices. Material and tools must be stored in its designated area only. 5.2.3 Area must be barricaded and unauthorized entry must be restricted. 6.0 Lifting and erection of dynamic compaction tools and equipments. 6.1 Fall of material, overturn 6.1.1 Crane and lifting tackles must be inspected and certified with of crane, collapse of crane and colour coded by QP approved third party. failure 6.1.2 Operator and Rigger assigned with crane must be certified with relevant certificate to prove competency. 6.1.3 Crane shall be erected only at a level and firm ground with safe boom length and angle. Dodsal Site Supervisor Dodsal Site Supervisor Dodsal Site Supervisor Dodsal Site Supervisor Dodsal Site Supervisor Dodsal Site Supervisor

2 of Pages 4

JOB SAFETY ANALYSIS FOR SOIL IMPROVEMENT BY DYNAMIC REPLACEMENT METHOD COMMON COOLING SEAWATER SYSTEM PHASE 2 SEQUENCE OF BASIC ACTIVITY STEPS POTENTIAL HAZARDS HAZARDS CONTROL 6.1.4 All lifting tackles and equipment associated must be checked daily prior to start of job. 6.2 Personnel injury and damage RESPONSIBLE Dodsal Site Supervisor

6.2.1 Area lifting is in progress must be barricaded with warning board Dodsal Site Supervisor " lifting is in progress" to prevent any unauthorized entry. 6.2.2 No infringing activity shall be allowed in the immediate visinity. 6.2.3 No personnel are allowed to stand below the pounder. 6.2.4 Safe access must be maintained all time. Dodsal Site Supervisor Dodsal Site Supervisor Dodsal Site Supervisor Dodsal Site Supervisor Dodsal Site Supervisor Dodsal Site Supervisor

7.0 Drilling works

7.1 Failure of equipments, damage and injury

7.1.1 Experienced and skilled workers shall be deployed for the job. 7.1.2 Equipments and tools must be inspected and certified prior to their intended use. 7.1.3 Materials and fittings must be approved prior to their use.

7.1.4 All high pressure flushing system must be maintained properly, if Dodsal Site Supervisor any defect noticed must be discarded from the service. 7.1.5 All area must be barricaded with warning boards to prevent any unauthorized entry. 7.2 Under ground services 7.3 Enviornmental 7.2.1 Prior to start of drilling works, it must be ensured no under ground services exists in the immediate visinity. Dodsal Site Supervisor Dodsal Site Supervisor

7.3.1 Contaminated water along with flushing medium and soil must be Dodsal Site Supervisor disposed properly to avoid nuisance to public. 7.3.2 Concrete waste and other waste generated from the activity must be disposed to designated area. Dodsal Site Supervisor

3 of Pages 4

JOB SAFETY ANALYSIS FOR SOIL IMPROVEMENT BY DYNAMIC REPLACEMENT METHOD COMMON COOLING SEAWATER SYSTEM PHASE 2 SEQUENCE OF BASIC ACTIVITY STEPS POTENTIAL HAZARDS 7.4 Deep fall and injury HAZARDS CONTROL 7.4.1 Completed bore hole must be adequately closed to prevent any accidental fall. RESPONSIBLE Dodsal Site Supervisor

7.4.2 The bore hole must be barricaded with warning board to alert the Dodsal Site Supervisor personnel in the area. 8.0 Weather 8.1 Sun Burn 8.1.1 Adequate shelter to be provided for workers to take rest Dodsal Site Supervisor Dodsal Site Supervisor Dodsal Site Supervisor Dodsal Site Supervisor Dodsal Site Supervisor

8.2 Heat stress and dehydration 8.2.1 Sufficient quantity of cool drinking water will be made 8.2.2 Rotation of workers will be made suitably 8.3 Dust 8.3.1 Water will be sprayed to suppress the dust and dust mask to be provided to workers Remarks: 1- Prior to start any work it will be made sure that personnel are safety inducted. 2- Prior to start any work Tool Box Talk will be carried out. 3- Personnel will wear all applicable PPE. 4- Adequate first aid facility will be provided. 5- Adequate fire extinguishers shall be provided with every equipments. Prepared By: M P Gupta ( Civil Engineer ) Reviewed By: Solayappan ( HSE Officer )

4 of Pages 4

Das könnte Ihnen auch gefallen

- JSA Earthwork Receiving BasinDokument4 SeitenJSA Earthwork Receiving BasinHilbrecht De Pedro100% (1)

- JOB SAFETY ANALYSIS FOR EARTHWORKS (37Dokument32 SeitenJOB SAFETY ANALYSIS FOR EARTHWORKS (37Hilbrecht De Pedro100% (1)

- Exavation Works PipercksDokument4 SeitenExavation Works PipercksHRTYR100% (1)

- Job Safety Analysis - Cone ErectionDokument7 SeitenJob Safety Analysis - Cone ErectionMohammed MinhajNoch keine Bewertungen

- Maintaining Structural Beams SafelyDokument1 SeiteMaintaining Structural Beams SafelySajith C PauloseNoch keine Bewertungen

- HSE-ICG/PCJ-3075-CA/JSA.010 Job Safety AnalysisDokument8 SeitenHSE-ICG/PCJ-3075-CA/JSA.010 Job Safety AnalysisYosua SitumorangNoch keine Bewertungen

- JSA For Washing and Air BlowingDokument3 SeitenJSA For Washing and Air BlowingMohammed MinhajNoch keine Bewertungen

- Sarawak JSA for Concrete CuttingDokument4 SeitenSarawak JSA for Concrete CuttingMohammad Irfan Kiki IsmailNoch keine Bewertungen

- Tower Crane Dismantling JSA HSE ProfessionalsDokument2 SeitenTower Crane Dismantling JSA HSE ProfessionalsnabeelNoch keine Bewertungen

- JSA FOR Concerate PlacementDokument1 SeiteJSA FOR Concerate Placementwahyu nugrohoNoch keine Bewertungen

- Part VI (E) - Piling Work SafetyDokument26 SeitenPart VI (E) - Piling Work SafetyBinz100% (2)

- JSA Jackhammer RemovalDokument3 SeitenJSA Jackhammer Removalbashirdarak80% (5)

- Tower Crane Installation SOP SummaryDokument3 SeitenTower Crane Installation SOP SummaryRashidi RahmanNoch keine Bewertungen

- Jsa For Dismantel of StructureDokument2 SeitenJsa For Dismantel of StructureBaiju SinghNoch keine Bewertungen

- EARTHWORKS SAFETYDokument4 SeitenEARTHWORKS SAFETYsatti100% (2)

- JHA PlumberDokument3 SeitenJHA PlumberEko Susanto100% (1)

- Grounding System Jsa 2008Dokument4 SeitenGrounding System Jsa 2008Aldrin100% (5)

- JSA For Kerb Stone in Process AreaDokument3 SeitenJSA For Kerb Stone in Process AreaMohammed Minhaj100% (1)

- Excavations JSA Final 2015Dokument5 SeitenExcavations JSA Final 2015jithin shankarNoch keine Bewertungen

- Job Safety Analysis: Page 1 of 4Dokument4 SeitenJob Safety Analysis: Page 1 of 4RakeshkasarlaNoch keine Bewertungen

- JSA For HDPE Liner Fusion Welding2Dokument6 SeitenJSA For HDPE Liner Fusion Welding2Mohammed Minhaj100% (8)

- Mie Hse Jha 004 - Installation of TransformerDokument5 SeitenMie Hse Jha 004 - Installation of TransformerLuqman Osman67% (6)

- Pa Hsec 02 040 002 F03Dokument4 SeitenPa Hsec 02 040 002 F03Abdul KhaliqNoch keine Bewertungen

- Slip Form Construction Safety AnalysisDokument5 SeitenSlip Form Construction Safety Analysisputrasejahtra50% (2)

- Job Safety Analysis - Clinker StorageDokument4 SeitenJob Safety Analysis - Clinker StorageMohammed MinhajNoch keine Bewertungen

- Chipping Work (Manually)Dokument1 SeiteChipping Work (Manually)ChandruNoch keine Bewertungen

- Jsa Working at Height (Maintenance & Cleaning)Dokument2 SeitenJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (1)

- JSA For Blower Cyclone and Duct Installation - Revision 004Dokument8 SeitenJSA For Blower Cyclone and Duct Installation - Revision 004WilsonNoch keine Bewertungen

- JSA For Concrete PouringDokument1 SeiteJSA For Concrete PouringHSE fahadNoch keine Bewertungen

- Bricks Messonary Work Job Hazard AnalysisDokument2 SeitenBricks Messonary Work Job Hazard AnalysisMc Evans Magallanes100% (1)

- Job Safety Analysis WorksheetDokument7 SeitenJob Safety Analysis WorksheetMohamedSaidNoch keine Bewertungen

- cONSTRUCTION WORK JSADokument21 SeitencONSTRUCTION WORK JSAMohammed AlshehhiNoch keine Bewertungen

- Glass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETDokument3 SeitenGlass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETusman rasheed100% (1)

- Boom Lift PDFDokument2 SeitenBoom Lift PDFcityofdarwingisNoch keine Bewertungen

- Job Hazard Analysis DemolitionDokument2 SeitenJob Hazard Analysis DemolitionvinothNoch keine Bewertungen

- JSA FOR STEEL ERECTIONDokument7 SeitenJSA FOR STEEL ERECTIONRajuNoch keine Bewertungen

- Confined Spaces: Job Safety AnalysisDokument2 SeitenConfined Spaces: Job Safety Analysismalimsaidi_160040895Noch keine Bewertungen

- JSA NO 2-Piling WorkDokument3 SeitenJSA NO 2-Piling WorkKarthik GanesanNoch keine Bewertungen

- EF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Dokument5 SeitenEF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Anis Uddin100% (2)

- JSA Manual Excavation and Cable LayingDokument3 SeitenJSA Manual Excavation and Cable Layingimran100% (1)

- JSA For Piping-Hydro TestDokument10 SeitenJSA For Piping-Hydro TestMuthu AlaguRajNoch keine Bewertungen

- Job Safety Analysis for ElectriciansDokument2 SeitenJob Safety Analysis for ElectriciansDeny SafariNoch keine Bewertungen

- Job Safety Analysis - Cement SiloDokument9 SeitenJob Safety Analysis - Cement SiloMohammed Minhaj100% (1)

- JSA Cable Pulling and Laying WorksDokument6 SeitenJSA Cable Pulling and Laying Workskabir100% (1)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Dokument3 SeitenKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNoch keine Bewertungen

- Job Safety Analysis: Manual ExcavationDokument2 SeitenJob Safety Analysis: Manual Excavationfdfddf dfsdfNoch keine Bewertungen

- Job Safetyanalysis: Traffic Control & FlaggingDokument2 SeitenJob Safetyanalysis: Traffic Control & Flaggingnasrul draco100% (1)

- Job Safety Analysis (JSA) - Night Work DateDokument2 SeitenJob Safety Analysis (JSA) - Night Work Datenabeel100% (2)

- 0 JsaDokument54 Seiten0 JsaRavi AmarlapudiNoch keine Bewertungen

- JSA For Lifting of RebarsDokument5 SeitenJSA For Lifting of RebarsNiraNoch keine Bewertungen

- JSA - Anchor Bolt and Template Lifting From Ground To Elevated Work PlatformDokument6 SeitenJSA - Anchor Bolt and Template Lifting From Ground To Elevated Work PlatformRaju KhalifaNoch keine Bewertungen

- JSA for Grinding WorkDokument5 SeitenJSA for Grinding WorkM M PRADHANNoch keine Bewertungen

- JSA - Installation of U G PipingDokument11 SeitenJSA - Installation of U G PipingOws Anish100% (1)

- Removing Staircase with Crane Lifts SteelDokument3 SeitenRemoving Staircase with Crane Lifts Steelmarvin100% (1)

- Jsa PCC & RCCDokument2 SeitenJsa PCC & RCCNilesh koliNoch keine Bewertungen

- Jsa Water Proofing For DHADokument13 SeitenJsa Water Proofing For DHAAnonymous YmINeSIFNoch keine Bewertungen

- Job Safety Analysis: Night Work at SiteDokument2 SeitenJob Safety Analysis: Night Work at SiteSaiyad RiyazaliNoch keine Bewertungen

- 06 Earthworks, Blinding, Screeding, Water Proofing, Form Work, Reinforcement, Concreting and Cur2Dokument6 Seiten06 Earthworks, Blinding, Screeding, Water Proofing, Form Work, Reinforcement, Concreting and Cur2Hilbrecht De PedroNoch keine Bewertungen

- 09 JSA For Excavation and Blinding at Pump House 1 & 3Dokument4 Seiten09 JSA For Excavation and Blinding at Pump House 1 & 3Hilbrecht De Pedro100% (1)

- 07 JSA For Concreting at Outfall AreaDokument4 Seiten07 JSA For Concreting at Outfall AreaHilbrecht De PedroNoch keine Bewertungen

- JSA For Geotechnical Investigation at OffshoreDokument5 SeitenJSA For Geotechnical Investigation at OffshoreHilbrecht De PedroNoch keine Bewertungen

- JSA For Soil ImprovementDokument4 SeitenJSA For Soil ImprovementHilbrecht De Pedro100% (1)

- 04 Jsa For Camp Constn & Associated FacilitysDokument5 Seiten04 Jsa For Camp Constn & Associated FacilitysHilbrecht De Pedro100% (1)

- 07 JSA For Concreting at Outfall AreaDokument4 Seiten07 JSA For Concreting at Outfall AreaHilbrecht De PedroNoch keine Bewertungen

- 04 Jsa For Camp Constn & Associated FacilitysDokument5 Seiten04 Jsa For Camp Constn & Associated FacilitysHilbrecht De Pedro100% (1)

- 09 JSA For Excavation and Blinding at Pump House 1 & 3Dokument4 Seiten09 JSA For Excavation and Blinding at Pump House 1 & 3Hilbrecht De Pedro100% (1)

- 02 JSA For Bathymatic SurveyDokument3 Seiten02 JSA For Bathymatic SurveyHilbrecht De Pedro100% (1)

- 06 Earthworks, Blinding, Screeding, Water Proofing, Form Work, Reinforcement, Concreting and Cur2Dokument6 Seiten06 Earthworks, Blinding, Screeding, Water Proofing, Form Work, Reinforcement, Concreting and Cur2Hilbrecht De PedroNoch keine Bewertungen

- G.R. No. L-72873 PDFDokument2 SeitenG.R. No. L-72873 PDFbrecht1980Noch keine Bewertungen

- Luzon Surety Co Vs de GarciaDokument2 SeitenLuzon Surety Co Vs de GarciaJedyne Tejada67% (3)

- Advance Notes On Criminal Law Book 2Dokument83 SeitenAdvance Notes On Criminal Law Book 2Hilbrecht De PedroNoch keine Bewertungen

- Spoken ArabicDokument95 SeitenSpoken ArabicHilbrecht De Pedro100% (1)

- FSK Demodulator With PLLDokument5 SeitenFSK Demodulator With PLLHema100% (1)

- Opentbs Demo: Merge Data With A ChartDokument4 SeitenOpentbs Demo: Merge Data With A Charteduarditom1Noch keine Bewertungen

- Brushed Axial Fans: VA85-A101-96A Performance DiagramDokument3 SeitenBrushed Axial Fans: VA85-A101-96A Performance DiagramJaskaran SinghNoch keine Bewertungen

- IP Dect AP 8340 R150 DatasheetDokument3 SeitenIP Dect AP 8340 R150 DatasheetAsnake TegenawNoch keine Bewertungen

- Azubuko v. Motor Vehicles, 95 F.3d 1146, 1st Cir. (1996)Dokument2 SeitenAzubuko v. Motor Vehicles, 95 F.3d 1146, 1st Cir. (1996)Scribd Government DocsNoch keine Bewertungen

- 280Dokument6 Seiten280Alex CostaNoch keine Bewertungen

- Applying problem solving techniques to routine computer issuesDokument2 SeitenApplying problem solving techniques to routine computer issuesBirhanu Atnafu0% (1)

- 8 - Vibration - F22-Vibration Isolation and AbsorptionDokument26 Seiten8 - Vibration - F22-Vibration Isolation and Absorptionالأردني JordanianNoch keine Bewertungen

- Relocation Guide Version 5.6 - New BrandingDokument29 SeitenRelocation Guide Version 5.6 - New BrandingEndika AbiaNoch keine Bewertungen

- Techniques For Optimal Placement of Electric Vehicle Charging Stations A ReviewDokument5 SeitenTechniques For Optimal Placement of Electric Vehicle Charging Stations A Reviewkumar_ranjit6555Noch keine Bewertungen

- Francisco v. Boiser PDFDokument12 SeitenFrancisco v. Boiser PDFPia Christine BungubungNoch keine Bewertungen

- Theory of Elinor OstromDokument5 SeitenTheory of Elinor OstromSanjana KrishnakumarNoch keine Bewertungen

- GT2-71D Amplifier Unit Data SheetDokument3 SeitenGT2-71D Amplifier Unit Data SheetKenan HebibovicNoch keine Bewertungen

- Neeraj Kumar: Nokia Siemens Networks (Global SDC Chennai)Dokument4 SeitenNeeraj Kumar: Nokia Siemens Networks (Global SDC Chennai)Kuldeep SharmaNoch keine Bewertungen

- Vda. de Consuegra v. Government Service Insurance System (1971)Dokument1 SeiteVda. de Consuegra v. Government Service Insurance System (1971)Andre Philippe RamosNoch keine Bewertungen

- FFT FundamentalsDokument27 SeitenFFT FundamentalsVivien VilladelreyNoch keine Bewertungen

- Aaliyah Lachance Resume - DecDokument2 SeitenAaliyah Lachance Resume - Decapi-240831551Noch keine Bewertungen

- Long-Range FM Transmitter With Variable Power OutputDokument2 SeitenLong-Range FM Transmitter With Variable Power OutputHaspreet SinghNoch keine Bewertungen

- Create Config Files Python ConfigParserDokument8 SeitenCreate Config Files Python ConfigParserJames NgugiNoch keine Bewertungen

- Basics of Directional-Control ValvesDokument11 SeitenBasics of Directional-Control ValvesJosh LeBlancNoch keine Bewertungen

- Factors for Marketing Success in Housing SectorDokument56 SeitenFactors for Marketing Success in Housing SectorNhyiraba Okodie AdamsNoch keine Bewertungen

- Aartv Industrial Training ReportDokument48 SeitenAartv Industrial Training ReportRupal NaharNoch keine Bewertungen

- (Lecture 10 & 11) - Gearing & Capital StructureDokument18 Seiten(Lecture 10 & 11) - Gearing & Capital StructureAjay Kumar TakiarNoch keine Bewertungen

- Tool Selection For Rough and Finish CNC Milling OpDokument4 SeitenTool Selection For Rough and Finish CNC Milling Opmatic91Noch keine Bewertungen

- Bend Steel in Steel BarDokument3 SeitenBend Steel in Steel BarMir Masood ShahNoch keine Bewertungen

- Final IEQC MICRODokument10 SeitenFinal IEQC MICROWMG NINJANoch keine Bewertungen

- NBA Stats 2021/22: All Player Statistics in one PageDokument14 SeitenNBA Stats 2021/22: All Player Statistics in one PageTimmy GNoch keine Bewertungen

- Manufacturing and Service TechnologiesDokument18 SeitenManufacturing and Service Technologiesajit123ajitNoch keine Bewertungen

- Weiss Salt Spray and Corrosion Testing BrochureDokument7 SeitenWeiss Salt Spray and Corrosion Testing BrochureMiorita_13Noch keine Bewertungen

- 3 Axis AccelerometerDokument9 Seiten3 Axis AccelerometerResearchDesignLabNoch keine Bewertungen