Beruflich Dokumente

Kultur Dokumente

Bullwhip

Hochgeladen von

Mohammad FaizanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bullwhip

Hochgeladen von

Mohammad FaizanCopyright:

Verfügbare Formate

Bullwhip effect

From Wikipedia, the free encyclopedia

Illustration of the bullwhip effect: The final customer places an order (whip) and order fluctuations build up upstream the supply chain.

The bullwhip effect (or whiplash effect) is an observed phenomenon in forecast-driven distribution channels. It refers to a trend of larger and larger swings in inventory in response to changes in demand, as one looks at firms further back in the supply chain for a product. The concept first appeared inJay Forrester's Industrial Dynamics (1961) and thus it is also known as the Forrester effect. Since the oscillating demand magnification upstream asupply chain is reminiscent of a cracking whip, it became known as the bullwhip.

Causes

Bullwhip effect

Because customer demand is rarely perfectly stable, businesses must forecast demand to properly position inventory and other resources. Forecasts are based on statistics, and they are rarely perfectly accurate. Because forecast errors are a given, companies often carry an inventory buffer called "safety stock". Moving up the supply chain from end-consumer to raw materials supplier, each supply chain participant has greater observed variation in demand and thus greater need for safety stock. In periods of rising demand, down-stream participants increase orders. In periods of falling demand, orders fall or stop, thereby not reducing inventory. The effect is that variations are amplified as one moves upstream in the supply chain (further from the customer). This sequence of events is well simulated by the Beer

Distribution Game which was developed by MIT Sloan School of Management in the 1960s. The causes can further be divided into behavioral and operational causes: [edit]Behavioral

causes

misuse of base-stock policies misapplication of trinomial theorem misperceptions of feedback and time delays panic ordering reactions after unmet demand perceived risk of other players' bounded rationality

[edit]Operational

causes

dependent demand processing Forecast Errors adjustment of inventory control parameters with each demand observation

Lead time Variability (forecast error during replenishment lead time) lot-sizing/order synchronization consolidation of demands transaction motive quantity discount

trade promotion and forward buying anticipation of shortages allocation rule of suppliers shortage gaming (including dereliction under Benford's law) Lean and JIT style management of inventories and a chase production strategy

[edit]Consequences In addition to greater safety stocks, the described effect can lead to either inefficient production or excessive inventory as the producer needs to fulfill the demand of its predecessor in the supply chain. This also leads to a low utilization of the distribution channel. In spite of having safety stocks there is still the hazard of stock-outs which result in poor customer service. Furthermore, the Bullwhip effect leads to a row of financial costs. Next to the (financially) hard measurable consequences of poor customer services and the damage of public image and loyalty an organization has to cope with the ramifications of failed fulfillment which can lead to contract penalties. Moreover the hiring and dismissals of employees to manage the demand variability induce further costs due to training and possible lay-offs. [edit]Countermeasures Theoretically the bullwhip effect does not occur if all orders exactly meet the demand of each period. This is consistent with findings of supply chain experts who have recognized that the Bullwhip Effect is a problem in forecast-driven supply chains, and careful management of the effect is an important goal

for Supply Chain Managers. Therefore it is necessary to extend the visibility of customer demand as far as possible. One way to achieve this is to establish a demand-driven supply chain which reacts to actual customer orders. In manufacturing, this concept is called kanban. This model has been successfully implemented in Wal-Mart's distribution system. Individual Wal-Mart stores transmit point-of-sale (POS) data from the cash register back to corporate headquarters several times a day. This demand information is used to queue shipments from the Wal-Mart distribution center to the store and from the supplier to the Wal-Mart distribution center. The result is near-perfect visibility of customer demand and inventory movement throughout the supply chain. Better information leads to better inventory positioning and lower costs throughout the supply chain. Barriers to the implementation of a demand-driven supply chain include the necessary investment in information technology and the creation of a corporate culture of flexibility and focus on customer demand. Another prerequisite is that all members of a supply chain recognize that they can gain more if they act as a whole which requires trustful collaboration and information sharing. Methods intended to reduce uncertainty, variability, and lead time: Vendor Managed Inventory (VMI) Just In Time replenishment (JIT) Strategic partnership Information sharing smooth the flow of products coordinate with retailers to spread deliveries evenly reduce minimum batch sizes smaller and more frequent replenishments

eliminate pathological incentives every day low price policy restrict returns and order cancellations order allocation based on past sales instead of current size in case of shortage

Das könnte Ihnen auch gefallen

- Advantages N Disadvantages of Fixed Xchange RateDokument3 SeitenAdvantages N Disadvantages of Fixed Xchange RateMohammad FaizanNoch keine Bewertungen

- SBI Work CompletionDokument1 SeiteSBI Work CompletionMohammad FaizanNoch keine Bewertungen

- DissertationDokument110 SeitenDissertationJacobsonson ChanNoch keine Bewertungen

- Tender: 1) Technical Bid 2) Commercial/Price BidDokument1 SeiteTender: 1) Technical Bid 2) Commercial/Price BidMohammad FaizanNoch keine Bewertungen

- A Study of Diet Cokery in Hotel: TopicDokument5 SeitenA Study of Diet Cokery in Hotel: TopicMohammad FaizanNoch keine Bewertungen

- English Quran Plain TextDokument314 SeitenEnglish Quran Plain TextGeorges GengeNoch keine Bewertungen

- Gold StandardsDokument13 SeitenGold StandardsMohammad FaizanNoch keine Bewertungen

- Matrix School of Management Studies: List of Students of Msms Batch 2012-14Dokument12 SeitenMatrix School of Management Studies: List of Students of Msms Batch 2012-14Mohammad FaizanNoch keine Bewertungen

- New Microsoft Office Word DocumentDokument3 SeitenNew Microsoft Office Word DocumentMohammad FaizanNoch keine Bewertungen

- National Youth Tobacco Survey (NYTS)Dokument1 SeiteNational Youth Tobacco Survey (NYTS)Mohammad FaizanNoch keine Bewertungen

- Ankush Project (Repaired)Dokument55 SeitenAnkush Project (Repaired)Mohammad Faizan60% (5)

- Objective: Product Is Outlined. Industry and Independent Research Supports The DualDokument4 SeitenObjective: Product Is Outlined. Industry and Independent Research Supports The DualMohammad FaizanNoch keine Bewertungen

- Criteria For Project Report: Students Will Be Evaluated On Following PointsDokument1 SeiteCriteria For Project Report: Students Will Be Evaluated On Following PointsMohammad FaizanNoch keine Bewertungen

- Consumer Behaviour & Purchase Process Analysis - Cigarette IndustryDokument3 SeitenConsumer Behaviour & Purchase Process Analysis - Cigarette IndustryMohammad Faizan100% (1)

- Shrikant Gonepalliwar Summer CVDokument2 SeitenShrikant Gonepalliwar Summer CVMohammad FaizanNoch keine Bewertungen

- Criteria For Project Report: Students Will Be Evaluated On Following PointsDokument1 SeiteCriteria For Project Report: Students Will Be Evaluated On Following PointsMohammad FaizanNoch keine Bewertungen

- Industrial Policy 1991Dokument15 SeitenIndustrial Policy 1991Mohammad FaizanNoch keine Bewertungen

- Taxation: Concept, Nature and Characteristics of Taxation and TaxesDokument11 SeitenTaxation: Concept, Nature and Characteristics of Taxation and TaxesMohammad FaizanNoch keine Bewertungen

- New Microsoft Office Word DocumentDokument1 SeiteNew Microsoft Office Word DocumentMohammad FaizanNoch keine Bewertungen

- Commodity MarketDokument9 SeitenCommodity MarketMohammad FaizanNoch keine Bewertungen

- Front PageDokument10 SeitenFront PageMohammad FaizanNoch keine Bewertungen

- About Godfrey Phillips IndiaDokument17 SeitenAbout Godfrey Phillips IndiaMohammad FaizanNoch keine Bewertungen

- MNGT Accounting-Theory NotesDokument28 SeitenMNGT Accounting-Theory NotesMohammad FaizanNoch keine Bewertungen

- Corporate Social Responsibility: AwardsDokument3 SeitenCorporate Social Responsibility: AwardsMohammad FaizanNoch keine Bewertungen

- Features of International BusinessDokument1 SeiteFeatures of International BusinessMohammad FaizanNoch keine Bewertungen

- Farhaan 2Dokument115 SeitenFarhaan 2Mohammad FaizanNoch keine Bewertungen

- New Microsoft Word DocumentDokument2 SeitenNew Microsoft Word DocumentMohammad FaizanNoch keine Bewertungen

- A Study of Diet Cokery in Hotel: TopicDokument5 SeitenA Study of Diet Cokery in Hotel: TopicMohammad FaizanNoch keine Bewertungen

- Master of International Business: AdmissionDokument1 SeiteMaster of International Business: AdmissionMohammad FaizanNoch keine Bewertungen

- Agreement On AgricultureDokument16 SeitenAgreement On AgricultureMohammad FaizanNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Financial Management (Problems)Dokument12 SeitenFinancial Management (Problems)Prasad GowdNoch keine Bewertungen

- Chapter 12 QADokument6 SeitenChapter 12 QAShamara ZamanNoch keine Bewertungen

- Harvard Business School: Balncing Online and Offline Marketing Case AnalysisDokument3 SeitenHarvard Business School: Balncing Online and Offline Marketing Case AnalysisUma ShankarNoch keine Bewertungen

- Chapter 4 AccountingDokument22 SeitenChapter 4 AccountingChan Man SeongNoch keine Bewertungen

- Project-Six Sigma - FlipkartDokument4 SeitenProject-Six Sigma - Flipkartsomeswara prasad k.mNoch keine Bewertungen

- Findings: "A Study On Customer Satisfaction of MILMA Products Among Households in Aluva Municipality"Dokument5 SeitenFindings: "A Study On Customer Satisfaction of MILMA Products Among Households in Aluva Municipality"anil mathewNoch keine Bewertungen

- Reply of Inqury LetterDokument5 SeitenReply of Inqury Letteralfrindu PratamaNoch keine Bewertungen

- Analysis of Mutual Funds in IndiaDokument78 SeitenAnalysis of Mutual Funds in Indiadpk1234Noch keine Bewertungen

- Global or Local Strategies? Mcdonald'S Turkey Example: Sertaç HAMZADokument21 SeitenGlobal or Local Strategies? Mcdonald'S Turkey Example: Sertaç HAMZALAM HUỲNH NHẬTNoch keine Bewertungen

- Anw Internship Report FINALDokument83 SeitenAnw Internship Report FINALRonysars50% (2)

- Deprication and Fixed AssetsDokument7 SeitenDeprication and Fixed AssetsManjeet KaurNoch keine Bewertungen

- Pidilite Case StudyDokument3 SeitenPidilite Case StudyNilanjan SamantaNoch keine Bewertungen

- Business HWDokument7 SeitenBusiness HWPeanut ButterNoch keine Bewertungen

- Group A-18 TCS Report Relation With MicroeconomicsDokument4 SeitenGroup A-18 TCS Report Relation With MicroeconomicsHarsh ShrivastavNoch keine Bewertungen

- 2024 Influencer Marketing Trends ReportDokument42 Seiten2024 Influencer Marketing Trends Reportkarthik83.v209Noch keine Bewertungen

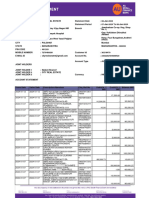

- Bank Statements AY 2020-21Dokument21 SeitenBank Statements AY 2020-21rohit madeshiyaNoch keine Bewertungen

- CH 17Dokument6 SeitenCH 17Rabie HarounNoch keine Bewertungen

- Pricing StrategiesDokument14 SeitenPricing StrategiesMica ReaNoch keine Bewertungen

- 08 Jan 2024 - 514002AccStmtDownloadReportDokument12 Seiten08 Jan 2024 - 514002AccStmtDownloadReportshas2sriNoch keine Bewertungen

- Red Hot Selling - Paul GoldnerDokument238 SeitenRed Hot Selling - Paul GoldnerBibleNut777Noch keine Bewertungen

- Consignment QuestionDokument2 SeitenConsignment QuestionADITYA JAGTAPNoch keine Bewertungen

- Fe FormulasDokument7 SeitenFe FormulasJonathan Garcia GomezNoch keine Bewertungen

- Pertama. Bandung. Linda Karya: Daftar PustakaDokument7 SeitenPertama. Bandung. Linda Karya: Daftar PustakaNaqiya SalsabilaNoch keine Bewertungen

- LEGO ReportDokument23 SeitenLEGO Reportimola_józsa100% (2)

- What Is A Good Way To Look For Undervalued Stocks - QuoraDokument12 SeitenWhat Is A Good Way To Look For Undervalued Stocks - QuoraAchint KumarNoch keine Bewertungen

- Banking Industry in IndiaDokument18 SeitenBanking Industry in IndiaSajna NadigaddaNoch keine Bewertungen

- 13 Chapter V (Swot Analysis and Compitetor Analysis)Dokument3 Seiten13 Chapter V (Swot Analysis and Compitetor Analysis)hari tejaNoch keine Bewertungen

- Gildan Activewear Inc Is A Montreal Based Company That Manufactures and PDFDokument1 SeiteGildan Activewear Inc Is A Montreal Based Company That Manufactures and PDFhassan taimourNoch keine Bewertungen

- MBA Semester-I: Work Allotment Schedule Subject Code Subject Instructor 18MBA11 18MBA12 18MBA13 18MBA14 18MBA15 18MBA16Dokument1 SeiteMBA Semester-I: Work Allotment Schedule Subject Code Subject Instructor 18MBA11 18MBA12 18MBA13 18MBA14 18MBA15 18MBA16Mrudhula RaniNoch keine Bewertungen

- Riset PasarDokument20 SeitenRiset PasarAulia Mifta HCNoch keine Bewertungen