Beruflich Dokumente

Kultur Dokumente

Berghof Filtration Concept

Hochgeladen von

skthen72Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Berghof Filtration Concept

Hochgeladen von

skthen72Copyright:

Verfügbare Formate

Innovative Berghof filtration concept to quicken Asian-Pacific pulse

Market requires robust and flexible waste water treatment The often coined German term Deutsche Grndlichkeit is hard to translate, but incorporates all the good characteristics we sell with our products including: quality, thoroughness and reliability. This not only makes BMW and Mercedes Benz highly coveted brands, but also the Berghof Group, says General Manager Eric Wildeboer of Berghof Membrane Technology. What we do in our highly specialized field of work, is trying to support our partners the best we can with innovative, extremely flexible products of the highest quality. The story of the family-owned Berghof Group started in 1966 as a research centre in the field of electrochemistry, membrane filtration and plastic technology in the south of Germany. Today the Berghof Group is a long-term partner in the development and realization of pioneering work with more than 220 experts and specialists in eight product areas. The strength of the joint network between the different product areas lies in the synergy between the diverse technology skills of the innovation hub that is Berghof. Within the Berghof Group, Membrane Technology is one of the fastest growing divisions. Since 1975 Berghof Membrane Technology has developed and manufactured its own tubular membrane modulesand technology for a wide range of applications. From 1990 to 2003 Berghof offered turnkey solutions to end-users. Beginning in 2004 the company changed to strictly offering products and extensive knowledge and training to OEM-customers only. This strategy has built longterm partnerships in their global network. Today 95 % of Berghofs membrane business is related to membrane bio-reactor technology (MBR) for mainly the industrial market. Since 2012, Berghof has experienced a strong growth for its products outside of the MBR market as well. Innovation and high flexibility towards customers is Berghofs fundamental strategy for the current growth curve. Global water scarcity is an increasing issue, as it is the quest for renewable energy. With that in mind, Berghof has developed a new, flexible, low energy filtration concept called the Berghof BioPulse, as shown in the image below.

Eric Wildeboer says: It seems that with this BioPulse concept we are exactly fulfilling our customers needs. The market demands a reliable, robust and flexible concept that is able to produce high quality water under all circumstances at the most economical conditions at any time. We have combined the

strength of submerged and side stream membrane technology into a new innovative sidestream concept, which is a low energy concept with easy operation and maintenance. The submerged membrane system may be saving energy but offers little flexibility when the system requires adjustment, e.g. when waste water quality is changing or fouling potential is increasing. Berghof is currently installing the latest BioPulse MBR systems at two major sites with zero liquid discharge requirements: The largest bio-ethanol project in Europe, is related to the production of the second generation bio-fuels and renewable energy. More than 95 % of the waste water resulting from the production process needs to be recycled (zero liquid discharge) into high-purity water. After two years of extensive pilot research a comprehensive treatment scheme has been designed which consists of anaerobic digestion, aerobic biological treatment in combination with Berghof tubular ultrafiltration (UF) products, a multi-stage, reverseosmosis plant and evaporation. The UF-design is based on the flexible, low energy Berghof BioPulse concept. Two identical UF lines are treating a total of 180 m/h of waste water and filtering it into 150 m/h purified UF permeate and 30 m/h concentrate. Each UF line is equipped with 72 ten inch, four meter long membrane modules based on 5 mm and 8 mm diameter backwashable, low energy PVDF membranes. The unique features are backwashable membranes with 8 mm diameter, making Berghof the only supplier of this technological feature. Berghof is also the sole producer of 10-inch 4 m long XL-modules, which enables its OEM-partners further savings in plant construction and footprint. The UF modules are operated at a very low variable velocity. With this flexibility Berghof is able to control fouling and produce the designed waste water amount under optimum conditions at any time. This is what Berghof customers have been asking for. The periodical cleaning of the PVDF membranes is carried out by backflushing. The particle-free UF permeate is further recycled into process water, using reverse osmosis and evaporation. The second BioPulse system is being installed at the largest solar-thermal power plant in North America. Due to critical fouling components in the feed water Berghofs customer has selected the robust and reliable, low energy BioPulse concept. A total of 6720 m/d of water will be treated in eight double skids. Each equipped with ten pieces 10-inch diameter 4 m long modules using 5 mm backwashable low energy PVDF Berghof membranes. Start-up is expected to be at the end of 2013. The next generation of BioPulse is already under development and will save operators ubiquitous adjustment activities. A joint development between Berghof Automation and Berghof Membrane Technology should lead to a smart, self-regulating BioPulse software program. The software, containing the entire Berghof membrane know-how gathered over the last 30 years, will do the fine tuning itself. The system will automatically anticipate process changes at any time. Berghof is convinced that this feature will lead to further savings for customers. The main focus is to support its partners in achieving an excellent reference on their projects.

Today Berghof Membrane Technology operates worldwide and has meanwhile over 500 successful operational references. In terms of technology Berghof envisions a further fast growth in the industrial market. The worldwide trend is towards a robust and reliable treatment with the most economical conditions for a wide range of industrial applications. In addition, Berghof focuses on the decentralized markets for containerized sewage treatment plants. The company is confident that their innovative compact BioPulse design will exactly meet the customers needs. Cost for sewer systems continue to rise and Berghofs membrane technology has been proven cost-effective all over the world. In 2004 Berghof started an exclusive partnership with TriHigh Membrane Technology as distributor for the Chinese market. TriHigh offers a fast and professional local OEM-service, which is the strength of Berghof. Today it covers over 75 % of the industrial market for sidestream technology in China. Markets in which Berghof is strongly represented are landfill leachate, oilfield, coal industry, fermentation, tobacco industry, mining, etc. This year Berghof Membrane Technology has expanded its focus on the Asia-Pacific market. The company is looking for new partners in the Asia-Pacific region and would love to share its know-how. Come and join Berghof! Contact: Eric Wildeboer, Managing Director Berghof Membrane Technology,

eric.wildeboer@berghof.com

Das könnte Ihnen auch gefallen

- Water Desalination ReportDokument4 SeitenWater Desalination Reportskthen72Noch keine Bewertungen

- Lecture37 PDFDokument6 SeitenLecture37 PDFNico Aumento Jr.Noch keine Bewertungen

- EDR Technical Training-PublicDokument80 SeitenEDR Technical Training-PublicHassan Feki100% (1)

- Assignment On Industrial Relation of BDDokument12 SeitenAssignment On Industrial Relation of BDKh Fahad Koushik50% (6)

- Pipes On DeckDokument34 SeitenPipes On DeckNataly Janataly100% (1)

- TSM Strapping (Tank Calibration)Dokument2 SeitenTSM Strapping (Tank Calibration)skthen72Noch keine Bewertungen

- Uf Tech ManualDokument18 SeitenUf Tech ManualVemulapalli SaibabuNoch keine Bewertungen

- Lamella Clarifier Leopold TexlerDokument4 SeitenLamella Clarifier Leopold TexlerAntony ThanosNoch keine Bewertungen

- Water Treatment Plant Performance Evaluations and OperationsVon EverandWater Treatment Plant Performance Evaluations and OperationsNoch keine Bewertungen

- Case Study: A Modular, Scalable & Highly-Efficient Seawater Desalination SolutionDokument4 SeitenCase Study: A Modular, Scalable & Highly-Efficient Seawater Desalination Solutionwahyu raharjoNoch keine Bewertungen

- Presentation - Jeddah Airport 2 ISTP (KOM)Dokument44 SeitenPresentation - Jeddah Airport 2 ISTP (KOM)Mana DiaaNoch keine Bewertungen

- Microsoft Word - Festo Rain Water Harvesting Flow ChartDokument5 SeitenMicrosoft Word - Festo Rain Water Harvesting Flow Chartjeykumar.BalannairNoch keine Bewertungen

- Membrane ManualDokument181 SeitenMembrane ManualPranjal KulkarniNoch keine Bewertungen

- Simple Sewage: Treatment SolutionsDokument10 SeitenSimple Sewage: Treatment SolutionsAnonymous oUoJ4A8xNoch keine Bewertungen

- Report of Membrane Bioreactor System (MBR) For Wastewater TreatmentDokument10 SeitenReport of Membrane Bioreactor System (MBR) For Wastewater TreatmentJulie MahadiNoch keine Bewertungen

- Memcor UF CS CP Changi Singapore 45 D03679 enDokument2 SeitenMemcor UF CS CP Changi Singapore 45 D03679 enRiannaNoch keine Bewertungen

- 4-MCran Membrane CleaningDokument41 Seiten4-MCran Membrane CleaningKhalid AbdelRahimNoch keine Bewertungen

- Containerisedmbrsystem EngDokument12 SeitenContainerisedmbrsystem EngNermeen ElmelegaeNoch keine Bewertungen

- Memcor UF Product Data Sheet CPII MemRackDokument2 SeitenMemcor UF Product Data Sheet CPII MemRackDio MiNoch keine Bewertungen

- GE EDI O&M Manual - 10jul06Dokument14 SeitenGE EDI O&M Manual - 10jul06Geancarlo GutierrezNoch keine Bewertungen

- Uf Toray PresentationDokument54 SeitenUf Toray PresentationPrateek VermaNoch keine Bewertungen

- Standard MBR Units PDFDokument9 SeitenStandard MBR Units PDFWilmer Martelo Sarabia100% (1)

- 2014 Berghof Membrane TechnologyDokument53 Seiten2014 Berghof Membrane TechnologyVictor DominguezNoch keine Bewertungen

- 1 Designing A Reverse Osmosis Plant For Desalination of Agricultural Drainage WaterDokument14 Seiten1 Designing A Reverse Osmosis Plant For Desalination of Agricultural Drainage Waterabdo magdyNoch keine Bewertungen

- Kubota SMU General Information PDFDokument6 SeitenKubota SMU General Information PDFJulio TovarNoch keine Bewertungen

- KEE MBBR BrochureDokument6 SeitenKEE MBBR Brochureseragak100% (1)

- Hyflux Standard Membrane Systems Brochure - Ver5.1 - ENDokument40 SeitenHyflux Standard Membrane Systems Brochure - Ver5.1 - ENIGNyomanAnomWijayaNoch keine Bewertungen

- MBR C0 IntroductionDokument4 SeitenMBR C0 IntroductionAlfonso José García LagunaNoch keine Bewertungen

- Flint WTP O-M Manual With SOPs 553219 7Dokument83 SeitenFlint WTP O-M Manual With SOPs 553219 7Omkar BharankarNoch keine Bewertungen

- SUEZ Hand Book For Industrial Water TreatmentDokument1 SeiteSUEZ Hand Book For Industrial Water TreatmentJahidul IslamNoch keine Bewertungen

- HP Deskjet Printer Supply ChainDokument19 SeitenHP Deskjet Printer Supply ChainJose Barnon86% (7)

- Boiler Inspection MaintenanceDokument5 SeitenBoiler Inspection Maintenanceskthen72Noch keine Bewertungen

- Pre TreatmentDokument65 SeitenPre TreatmentSagar SewlaniNoch keine Bewertungen

- HYDRAcap MAX Presentation - Abril 2012Dokument32 SeitenHYDRAcap MAX Presentation - Abril 2012PC VSNoch keine Bewertungen

- Summary Report: RO System Flow DiagramDokument3 SeitenSummary Report: RO System Flow Diagramjugal ranaNoch keine Bewertungen

- IMO - PowerpointDokument16 SeitenIMO - PowerpointMahen Fernando100% (3)

- Biomod: Packaged Moving Bed Biofilm ReactorDokument4 SeitenBiomod: Packaged Moving Bed Biofilm ReactorAlvaro Huete100% (1)

- Case History - MBR Plant Achieves Higher Flow With PermaCareDokument4 SeitenCase History - MBR Plant Achieves Higher Flow With PermaCareSandeep K TiwariNoch keine Bewertungen

- UNA-620A - Operating InstructionREV02 by B.bennettDokument27 SeitenUNA-620A - Operating InstructionREV02 by B.bennettcysauts100% (2)

- Comparison of CCGT For System Stability StudiesDokument7 SeitenComparison of CCGT For System Stability Studiesskthen72Noch keine Bewertungen

- 1295 - Offer 50 KLD Package Type STP 27.08.2022 - RemovedDokument11 Seiten1295 - Offer 50 KLD Package Type STP 27.08.2022 - RemovedsanjeevNoch keine Bewertungen

- KUBOTA Submerged Membrane Unit Optional Parts: Lifting Tool Guide SetDokument1 SeiteKUBOTA Submerged Membrane Unit Optional Parts: Lifting Tool Guide SetmutazsalihNoch keine Bewertungen

- 40 KLD MBR QuoteDokument15 Seiten40 KLD MBR QuoteV Narasimha RajuNoch keine Bewertungen

- SWTP Operation ManualDokument131 SeitenSWTP Operation ManualKASHIFNoch keine Bewertungen

- CAP 15 - 3 Design of Water Resource Recovery Facilities, Sixth Edition Nitrogen-Removal-Sidestream-Process-DesignDokument4 SeitenCAP 15 - 3 Design of Water Resource Recovery Facilities, Sixth Edition Nitrogen-Removal-Sidestream-Process-DesignNICOLAS SANCHEZ GOMEZNoch keine Bewertungen

- 2010 SMR ClarifierDokument60 Seiten2010 SMR ClarifierRohan KakdeNoch keine Bewertungen

- BS en 12285-1-2003 (2006)Dokument162 SeitenBS en 12285-1-2003 (2006)dahzahNoch keine Bewertungen

- 04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFDokument8 Seiten04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFVic KeyNoch keine Bewertungen

- Journal of Water Process Engineering: SciencedirectDokument8 SeitenJournal of Water Process Engineering: SciencedirectOmar GameelNoch keine Bewertungen

- Flat Plate Membrane Bioreactor (MBR) System TrainingDokument56 SeitenFlat Plate Membrane Bioreactor (MBR) System TrainingmarvilouNoch keine Bewertungen

- Fs-Bio-010-Mbr A20160202Dokument25 SeitenFs-Bio-010-Mbr A20160202GREENLAB ECL TECHNoch keine Bewertungen

- Book of Abstracts: Philippine Projects To The Intel International Science and Engineering FairDokument84 SeitenBook of Abstracts: Philippine Projects To The Intel International Science and Engineering FairJimarie BithaoNoch keine Bewertungen

- Reverse Osmosis Design GuidelinesDokument2 SeitenReverse Osmosis Design Guidelineswacsii ccasullaNoch keine Bewertungen

- Teknofanghi Monoscrew Pump - CatalougeDokument4 SeitenTeknofanghi Monoscrew Pump - CatalougeKarim ShamashergyNoch keine Bewertungen

- Hydranautics - Nitto Membrane Applications, Case Studies, Lessons LearntDokument37 SeitenHydranautics - Nitto Membrane Applications, Case Studies, Lessons Learntkalyan patilNoch keine Bewertungen

- Air Reverse OsmosisDokument12 SeitenAir Reverse Osmosisirdawan100% (2)

- Prensentation Slides For Industry BriefingDokument40 SeitenPrensentation Slides For Industry BriefingkunalkhubaniNoch keine Bewertungen

- Handling Dairy Milk House WastewaterDokument31 SeitenHandling Dairy Milk House WastewaterAndreea CalcanNoch keine Bewertungen

- Technical Specifications TR-3.0 E IngeDokument10 SeitenTechnical Specifications TR-3.0 E Ingegowri shankarNoch keine Bewertungen

- AWW December 2017Dokument68 SeitenAWW December 2017prabal rayNoch keine Bewertungen

- Mono BeltDokument4 SeitenMono BeltAlexandru IgnatNoch keine Bewertungen

- FINAL Floc Design Waila Option3Dokument38 SeitenFINAL Floc Design Waila Option3dpkNoch keine Bewertungen

- Lesson 17 - Activated SludgeDokument8 SeitenLesson 17 - Activated SludgeShane RodriguezNoch keine Bewertungen

- Process Flow Diagram Hospital E.T.P: EP Bio CompositesDokument2 SeitenProcess Flow Diagram Hospital E.T.P: EP Bio CompositesRohan Chaugule100% (1)

- MBBR Design CalculationDokument5 SeitenMBBR Design CalculationPANDIARAJ KARUPPATHEVARNoch keine Bewertungen

- 7 - Pre-Treatments To Reduce Fouling of Low Pressure Microfiltration (MF) Membranes PDFDokument10 Seiten7 - Pre-Treatments To Reduce Fouling of Low Pressure Microfiltration (MF) Membranes PDFRinaAprianiAapNoch keine Bewertungen

- TorayDokument8 SeitenTorayWildan Novaldi IrawanNoch keine Bewertungen

- ACO Passavant - Technical Handbook and Product CatalogueDokument24 SeitenACO Passavant - Technical Handbook and Product CatalogueACO PassavantNoch keine Bewertungen

- Electrical 2x18MW Rev0Dokument12 SeitenElectrical 2x18MW Rev0skthen72Noch keine Bewertungen

- ProfSurv Asset Management Apr06Dokument5 SeitenProfSurv Asset Management Apr06skthen72Noch keine Bewertungen

- Sojitz & Toshiba Won Thai Bing 2 CFPP (1,200MW)Dokument3 SeitenSojitz & Toshiba Won Thai Bing 2 CFPP (1,200MW)skthen72Noch keine Bewertungen

- 031 Hoznedl M-FTDokument9 Seiten031 Hoznedl M-FTskthen72Noch keine Bewertungen

- FR Notice Dec 2012 PDFDokument5 SeitenFR Notice Dec 2012 PDFskthen72Noch keine Bewertungen

- 0010 - Rewa PSGDokument24 Seiten0010 - Rewa PSGskthen72Noch keine Bewertungen

- F 2397 Trucking Firm enDokument3 SeitenF 2397 Trucking Firm enskthen72Noch keine Bewertungen

- Alstom in VietnamDokument4 SeitenAlstom in Vietnamskthen72Noch keine Bewertungen

- 1MDB Powers To The Top: BusinessDokument7 Seiten1MDB Powers To The Top: Businessskthen72Noch keine Bewertungen

- The General Election FactorDokument12 SeitenThe General Election Factorskthen72Noch keine Bewertungen

- F 9250 Wellstar enDokument2 SeitenF 9250 Wellstar enskthen72Noch keine Bewertungen

- F 1754 Graettinger enDokument2 SeitenF 1754 Graettinger enskthen72Noch keine Bewertungen

- Acronyms, Abbreviations and Glossary Acronyms and AbbreviationsDokument37 SeitenAcronyms, Abbreviations and Glossary Acronyms and Abbreviationsskthen72Noch keine Bewertungen

- Emeach 5460 enDokument2 SeitenEmeach 5460 enskthen72Noch keine Bewertungen

- Exp.1 (Screening) Group1Dokument16 SeitenExp.1 (Screening) Group1itokki otoyaNoch keine Bewertungen

- Defining The Audiovisual IndustryDokument20 SeitenDefining The Audiovisual IndustryAyoub Ait MahmoudNoch keine Bewertungen

- Argumentative E-WPS OfficeDokument6 SeitenArgumentative E-WPS OfficeoneNoch keine Bewertungen

- Best of SEO#1 SEO Training & Content Marketing Course 2022Dokument2 SeitenBest of SEO#1 SEO Training & Content Marketing Course 2022Oscar MascarenoNoch keine Bewertungen

- 1Dokument7 Seiten1gosaye desalegnNoch keine Bewertungen

- ME232 Thermodynamics 2 Quiz 1 - P1&P3 Complete SolutionDokument2 SeitenME232 Thermodynamics 2 Quiz 1 - P1&P3 Complete Solutioncarlverano0428Noch keine Bewertungen

- PepsiCo Strategic Plan Design PDFDokument71 SeitenPepsiCo Strategic Plan Design PDFdemereNoch keine Bewertungen

- ECON 202 Optional Problem SetDokument3 SeitenECON 202 Optional Problem SetAnthony SabarilloNoch keine Bewertungen

- Activity Diagram 1Dokument14 SeitenActivity Diagram 1Yousef GamalNoch keine Bewertungen

- 5 Axis Lesson 2 PDFDokument36 Seiten5 Axis Lesson 2 PDFPC ArmandoNoch keine Bewertungen

- Midterm Fin Oo4Dokument82 SeitenMidterm Fin Oo4patricia gunio100% (1)

- GG&G 2012 CatDokument111 SeitenGG&G 2012 Cattyrant88Noch keine Bewertungen

- Pablo EscobarDokument21 SeitenPablo EscobarTalha WaqasNoch keine Bewertungen

- Orphanage Project ProposalDokument3 SeitenOrphanage Project ProposaldtimtimanNoch keine Bewertungen

- Ojsadmin, 12 ZhangG 19Dokument14 SeitenOjsadmin, 12 ZhangG 19Kristel MitraNoch keine Bewertungen

- AttitudeDokument24 SeitenAttitudeisratazimNoch keine Bewertungen

- SANAKO Study700 V 500 BrochureDokument4 SeitenSANAKO Study700 V 500 BrochureDwi PrihantoroNoch keine Bewertungen

- St10 Flasher DLL: Stmicroelectronics ConfidentialDokument10 SeitenSt10 Flasher DLL: Stmicroelectronics Confidentialeshwarp sysargusNoch keine Bewertungen

- Peir Nts Section 8 BeDokument14 SeitenPeir Nts Section 8 BethamestunnelNoch keine Bewertungen

- Vocabulary List Year 6 Unit 10Dokument2 SeitenVocabulary List Year 6 Unit 10Nyat Heng NhkNoch keine Bewertungen

- Retail Scenario in IndiaDokument10 SeitenRetail Scenario in IndiaSeemaNegiNoch keine Bewertungen

- Technical Schedule World BankDokument249 SeitenTechnical Schedule World BankPramod ShastryNoch keine Bewertungen

- Micro Economics SummaryDokument62 SeitenMicro Economics SummaryEVS PRADEEPNoch keine Bewertungen

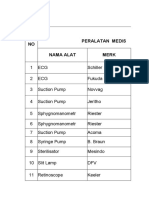

- Daftar Kalibrasi Peralatan MedisDokument34 SeitenDaftar Kalibrasi Peralatan Medisdiklat rssnNoch keine Bewertungen