Beruflich Dokumente

Kultur Dokumente

2005 Aerosol Sci. Technol. Zervas E. Interlaboratory Test of Exhaust PM Using ELPI

Hochgeladen von

Makis123Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2005 Aerosol Sci. Technol. Zervas E. Interlaboratory Test of Exhaust PM Using ELPI

Hochgeladen von

Makis123Copyright:

Verfügbare Formate

This article was downloaded by: [Hellenic Open University] On: 01 July 2012, At: 00:43 Publisher: Taylor

& Francis Informa Ltd Registered in England and Wales Registered Number: 1072954 Registered office: Mortimer House, 37-41 Mortimer Street, London W1T 3JH, UK

Aerosol Science and Technology

Publication details, including instructions for authors and subscription information: http://www.tandfonline.com/loi/uast20

Interlaboratory Test of Exhaust PM Using ELPI

E. Zervas , P. Dorlhne , L. Forti , C. Perrin , J. C. Momique , R. Monier , H. Ing & B. Lopez

a b c d d a a b b c c d

Renault, 1, Alle Cornuel, Lardy, France Institut Franais du Ptrole (IFP), Rueil-Malmaison, France PSA Peugeot Citren, La Garenne-Colombes, France

Union Technique de l'Automobile, du Motocycle et du Cycle (UTAC), Autodrome de LinasMontlhry, Montlhry, France Version of record first published: 23 Feb 2007

To cite this article: E. Zervas, P. Dorlhne, L. Forti, C. Perrin, J. C. Momique, R. Monier, H. Ing & B. Lopez (2005): Interlaboratory Test of Exhaust PM Using ELPI, Aerosol Science and Technology, 39:4, 333-346 To link to this article: http://dx.doi.org/10.1080/027868290930222

PLEASE SCROLL DOWN FOR ARTICLE Full terms and conditions of use: http://www.tandfonline.com/page/terms-and-conditions This article may be used for research, teaching, and private study purposes. Any substantial or systematic reproduction, redistribution, reselling, loan, sub-licensing, systematic supply, or distribution in any form to anyone is expressly forbidden. The publisher does not give any warranty express or implied or make any representation that the contents will be complete or accurate or up to date. The accuracy of any instructions, formulae, and drug doses should be independently verified with primary sources. The publisher shall not be liable for any loss, actions, claims, proceedings, demand, or costs or damages whatsoever or howsoever caused arising directly or indirectly in connection with or arising out of the use of this material.

Aerosol Science and Technology, 39:333346, 2005 Copyright c American Association for Aerosol Research ISSN: 0278-6826 print / 1521-7388 online DOI: 10.1080/027868290930222

Interlaboratory Test of Exhaust PM Using ELPI

E. Zervas,1 P. Dorlh` ene,1 L. Forti,2 C. Perrin,2 J. C. Momique,3 R. Monier,3 H. Ing,4 and B. Lopez4

Renault, 1, All ee Cornuel, Lardy, France Institut Franc ais du P etrole (IFP), Rueil-Malmaison, France 3 PSA Peugeot Citr oen, La Garenne-Colombes, France 4 Union Technique de lAutomobile, du Motocycle et du Cycle (UTAC), Autodrome de Linas-Montlh ery, Montlh ery, France

2 1

Downloaded by [Hellenic Open University] at 00:43 01 July 2012

The Particulate Measurement Programme (PMP) works on the development of an improved method for the exhaust particulate matter (PM) measurement, which can include, if feasible and necessary, the measurement of particle number. The French PMP subgroup, composed of IFP, PSA Peugeot-Citro en, Renault, and UTAC, has dened a measurement protocol based on electrical low-pressure impactor (ELPI) and conducted an interlaboratory test to evaluate its performances. The technical program was based on tests carried out on three Euro3 passenger cars (one gasoline operating under stoichiometric conditions, one Diesel, and one Diesel equipped with a diesel particulate lter (DPF)) that were tested on the New European Driving Cycle (NEDC). The regulated pollutants are also measured, as indicators of test repeatability and good working conditions. The interlaboratory reproducibility value of the tunnel background tests is quite high (337%) due to low particle numbers. The repeatability values increase at low particle numbers independently of the vehicle used. On the NEDC, the reproducibility of total particle number is 59, 47, and 131% for the gasoline, Diesel, and DPF-equipped Diesel vehicles, respectively (compare to 67, 29, and 164% for PM collected on lters). These results show that the protocol used in this study allows a reliable measurement of exhaust particle number in the case of vehicles emitting at least two orders of magnitude more than the tunnel background. In the other cases, the measurement variability is too high, especially for regulatory purposes, without taking into account other metrological aspects, such as calibration.

INTRODUCTION Current European regulations are based on a gravimetric measurement of exhaust particles emitted from Diesel passenger cars. However, as health concerns and instrument capabilities increase, more research is focused on number and size of emitted particles. The Particle Measurement Programme (PMP) of the Working Party on Pollution and Energy (GRPE) of the United

Received 1 July 2004; accepted 31 January 2005. Address correspondence to Efthimios Zervas, Renault, 1 All ee Cornuel, 91510 Lardy, France. E-mail: efthimios.zervas@renault.com

Nations at Geneva is mandated to work on the development of an improved method for the particulate matter (PM) measurement, which can include, if feasible and necessary, the measurement of the particle number of the exhaust particles (UNECE 2001). Currently there are many methods for the particle number and size determination. The method most commonly used in the case of vehicle exhaust gas are the electrical low-pressure impactor (ELPI; Keskinen et al. 1992; Ahlvik et al. 1998; Pattas et al. 1998; Khalek 2000; Maricq et al. 2000; Witze et al. 2004), scanning mobility particle sizer (SMPS; Wang and Flagan 1990) and particle counters (Willeke and Baron 1993; Hinds 1999), but many others are also presented in literature. Burtscher (2001) and Mohr and Lehmann (2003) give a detailed description of several analytical methods. Because SMPS has an insufcient resolution time (some minutes) it cannot be used for the analysis of particle distribution on the New European Driving Cycle (NEDC). Particles are composed of solid carbonaceous matter, other solids such as metals, and adsorbed components such as water, sulphates, and volatile organic compounds (Degobert 1992). The very ne particles are not always solids but can be condensate aerosol (Lunders et al. 1998; Matter et al. 1999). Several of the methods used for the measurement of the particle number cannot distinguish the solid particles from the volatiles (Burtscher 2001). For this reason, several methods, such as thermodenuders or thermodiluters have been developed to eliminate the volatiles before measurements (Wehner et al. 2002), but as sampling conditions play a very important role on the particle size measurements (L unders et al. 1998; Khalek et al. 1999; Maricq et al. 1999; Ntziachristos and Samaras 2000) a standard procedure is not well established yet. Several authors evaluate the performances of ELPI. Marjam aki et al. (2000) evaluate the collection efciency of the impactor and the performances of the charger. Maricq et al. (2000) and Van Gulijk et al. (2003, 2004) perform a comparison between ELPI and SMPS, while Witze et al. (2004) compares ELPI with LII and TEOM. 333

334

E. ZERVAS ET AL.

Downloaded by [Hellenic Open University] at 00:43 01 July 2012

One specic point before the validation of an analytical method is the determination of its repeatability and reproducibility. Round robin test is the most adequate method for this purpose (Hoekman et al. 1995; Lanning et al. 1997; Tejada et al. 1997). However, no interlaboratory comparison on ELPI performances has yet been presented. This article presents the results of the French PMP subgroup, composed by IFP, PSA Peugeot-Citro en, Renault, and UTAC, of an interlaboratory comparison of particle number measurement using ELPI. An interlaboratory comparison of particle counters will be presented in a future article. Three Euro3 passenger cars (PC) are used in this study: a gasoline vehicle operating under stoichiometric conditions and two Diesel PC, one with and one without diesel particulate lter (DPF). A pragmatic protocol based on the European regulatory conditions (tests on the NEDC) is used. The intralaboratory variability, repeatability, and reproducibility values are presented in the case of the three vehicles. The CO2 , fuel consumption (FC), and regulated pollutants are also measured, and their repeatability and reproducibility are compared with these of the particle number. Other particular measurement aspects that can inuence the obtained results and are not very well established today (Choi et al. 2003), such as accurate day-to-day calibration of the analytical instruments, are not treated here.

TECHNICAL BACKGROUND OF ELPI Keskinen et al. (1992) present the operation principles of ELPI (charger, impactor cut diameters, and electrometer) and compare it with SMPS. An atomizer was used to generate an aerosol, which is measured by SMPS and ELPI. This work concludes that both instruments measure the same particle distribution. Marjam aki et al. (2000) evaluates the performances of ELPI at a nominal ow rate of 10 l/min. The impactor, charger, and their calibration using two different aerosol-generation techniques are presented. This article presents the impactor collection efciency and charger performance (both are estimated satisfactory) and the comparison of the size distribution obtained by ELPI and SMPS using a di-octyl-sebacate (DOS) aerosol. Both techniques give similar particle distribution. ELPI is used for the measurement of exhaust gasparticle number and distribution, but it is also used to estimate the particle mass. Ahlvik et al. (1998) uses ELPI to measure the particle number distribution of a passenger car (model year 1993) and a heavy-duty engine on two driving cycles (European Driving Cycle (EDC) and Federal Test Procedure (FTP) for the passenger car, and US transient cycle and European Steady-state Cycle (ESC) for the heavy-duty engine). A differential mobility analyzer (DMA) is also used for these measurements. The effective particle density is estimated from the DMA and used to estimate the particle mass from ELPI distribution; however, the authors do not examine this method deeply. The effect of dilution ratio and driving cycle on particle distribution is also

presented. Pattas et al. (1998) examine the effect of DPF on particle size distribution using ELPI. The inuence of sulphur and Ce content in the fuel on particle distribution is presented on the NEDC. It is shown that DPF decreases the particle number, but no information about repeatability is given. Shi et al. (1999) use ELPI to study the number and distribution of particles emitted from a Diesel engine tested on an 11-mode steady-state cycle. A comparison of particle emissions at different engine load and speeds is performed using ELPI and SMPS, where both techniques give similar results. The authors present that the estimated particle mass is 1.31.6 times higher than the mass collected on lters. Maricq et al. (2000) presents a comparison of particle distribution of three diesel and three gasoline vehicles (model years 19951997) operating in steady states and on the FTP and measured by SMPS and ELPI. The effective density of particles is also estimated and used to calculate the particle mass, but no comparison with the mass collected on lters is given. Tsukamoto et al. (2000) uses ELPI to measure the particle number distribution of a heavy-duty engine. The emitted particle mass is estimated from ELPI measurements and compared with the mass collected on lters. Generally, the estimated mass is 1.52 times higher than the mass collected on lters. Khalek (2000) analyzes the particle number distribution of a heavy-duty engine on FTP. Similar to Tsukamoto et al. (2000), he concludes that ELPI overestimates total mass emissions comparing to lter mass measurements. Andrews et al. (2001) estimate the particle effective density as a function of size to 1.50.2 g/cm3 . This work concludes that the estimated mass can be very different from the mass collected on lters. This difference can be very important for particles bigger than 1 m. One reason is that ELPI overestimates the particle number by up to two orders of magnitude at this particle size. Virtanen et al. (2002) estimate the particle effective density to 1.11.2 g/cm3 as a function of their size. This work suggests that dilution has a strong effect on density values. Ristim aki et al. (2002) use ELPI and SMPS to estimate the effective density of different aerosols but not of exhaust gas particles. Choi et al. (2003) use ELPI to study the emissions of nanoparticles of a HSDI diesel engine and the effect of the oxidation catalyst on mass and distribution of emitted particles. Maricq and Xu (2004) use DMA and ELPI to determine the effective density and fractal dimension of particles emitted from ames and motor vehicle exhaust gas. The effective densities of particles emitted from two diesel engines and a direct-injection SI engine are identical. However, ELPI has some limitation for particle number measurements. Van Gulijk et al. (2001, 2003) presents a list of nonideal behavior of ELPI, as particle bounce, wall or interstage loss, overloading or surface buildup, and losses due to electrostatic effects and to charger nonideal efciency. Using a steadystate speed, a continual decrease of small particles and a continual increase of bigger ones is observed. The authors explain that this is due to impactor overloading. In our point of view,

INTERLABORATORY TEST OF EXHAUST PM USING ELPI

335

TABLE 1 Main characteristics of the three passenger cars used Vehicle 1 Type Fuel Inertia class (kg) Displacement (cm3 ) Number of cylinders Valves per cylinder Injection system Combustion system Max. power (kW) Emission limits EGR type After-treatment device Renault M egane Gasoline 1130 1600 4 4 MPI 66 Euro3 TWC Vehicle 2 Vehicle 3

Peugeot 307 Peugeot 307 Diesel Diesel 1360 1360 1997 1997 4 4 2 4 Common rail Common rail HDI HDI 66 80 Euro3 Euro3 Electric closed loop Electric closed loop DOC DOC + DPF mass is poor. The limits of detection (LOD) of ELPI are found to be very close (90%) to the measured particle concentration when a particulate lter is used.

Downloaded by [Hellenic Open University] at 00:43 01 July 2012

even if a part of these changes is due to impactor overloading, an extremely constant source of particles and different analytical methods must be combined to validate these conclusions. Van Gulijk et al. (2004) present that ELPI underestimates the apparent size of particles and, as a result, that their number is overestimated. Three other program must be mentioned. ACEA conducted two important research programs studying the emissions of ne particles (ACEA 1999, 2002). In the rst study, 11 diesel and 5 gasoline vehicles were tested on NEDC and steady speeds by two laboratories. The emissions of regulated pollutants and particle number (determined by SMPS) are presented in the nal report, but no repeatability or reproducibility values are given. ELPI is not used in this work. Three diesel and four gasoline passenger cars were tested in the second program. The stability of ELPI is determined over 18 weeks (one test per week) using a reference vehicle at a steady speed of 100 km/h. Within the same laboratory, the repeatability 1.96*RSD value (Relative Standard Deviation, dened in the experimental section) is 31% (data extracted from this report). With no apparent explanation, the particle number decreases by about 35% between the beginning and the end of this program. No other repeatability results are presented. The third program is the Swiss contribution to the GRPE particle measurement program (Mohr and Lehmann 2003b). In this study, 24 particle-measurement techniques were tested using a heavy-duty engine and a combustion aerosol generator. As only one laboratory is involved, no reproducibility values can be given. The repeatability values (1.96*RSD) of ELPI during the European Transient Cycle (ETC) are 20 and 57%, respectively, for a conguration without and with a particulate lter. The respective values are 16% and 39% for the gravimetric method and 4% and 47% for the CPC. Other tests on steady-state speeds are also performed. The 1.96*RSD of the tunnel background measurements are 38% for ELPI, 55% for the gravimetric method, and 95% for the CPC. The correlation between particle number measured by ELPI or CPC and particle

EXPERIMENTAL SECTION Three passenger cars were used in this study: a gasoline PC operating under stoichiometric conditions (vehicle 1), a diesel PC (vehicle 2) and a diesel PC equipped with a DPF (vehicle 3). Table 1 provides their main characteristics. Twenty ve parts per million of commercially used, Ce-based additive were added in the fuel in the case of the DPF-equipped vehicle to decrease the necessary temperature for the DPF regeneration from about 650 to 550 C. The addition of Ce-based additive does not change the particle distribution. As fuel sulphur can inuence the nanoparticle formation due to sulphates emission, (Mohr 2003a), fuels with less than 10 ppm of sulphur were used for this study. The main characteristics of these fuels are presented in Table 2. The same lubricant, which contains less than 0.4% of sulphur, was used for all three vehicles. Three tests were performed on the NEDC (cold start) and regulated pollutants, CO2 , and fuel consumption were measured according to current European regulations (EU Directive 70/220). The experimental procedure used is the following: a cold NEDC, 24 h of conditioning at 20 C, and three cold NEDCs with a conditioning of 24 h between each cycle. The results of the last three NEDC are taken into consideration. In the case of the DPF-equipped diesel PC, a DPF regeneration is performed at each laboratory before these cycles. Number and size distribution measurements were performed using a DEKATI ELPI, covering particle cut size from 8 to 10 m. Three laboratories used an ELPI sampling of 10 l/min, while Lab 1 used an ELPI sampling of 20 l/min. As thermodenuders can induce high particle losses (OICA 2003; Zervas et al. 2004), a DEKATI ejector-type dilutor, heated at 130 C with hot

336

E. ZERVAS ET AL.

TABLE 2 Fuel characteristics Characteristic Density at 15 C (kg/m3 ) Viscosity at 40 C (cSt) Cetane number Flash Point ( C) Distillation ( C) Initial Boiling Point 10% 20% 50% 90% 95% Final Boiling Point E 250 C (vol%) E 300 C (vol%) E 350 C (vol%) Composition Sulphur (mg/kg) Polycyclic Hydrocarbons (wt%) Ce (ppm, the DPF vehicle only) Diesel 834 3.00 53.8 82 197 222 235 278 331 347 359 30.4 69.6 95.9 8 4.5 25 Characteristic Density at 15 C (kg/m3 ) H/C ratio Octane number (MON/RON) Distillation ( C) Initial Boiling Point 10% 20% 50% 90% 95% Final Boiling Point E 70 C (vol%) E 100 C (vol%) E 150 C (vol%) Composition Total parafns (vol%) Total olens (vol %) Total aromatics (vol%) Benzene (vol%) Polyaromatics (wt%) Total oxygenates (vol%) Sulphur (mg/kg) Lead (mg/l) Gasoline 762 1.82 89.1/100.2 34.9 62.9 77.4 107.0 144.8 154.8 184.8 15 38.3 92.5 59.4 0 49.6 1.73 4.5 <0.2 8 <2

Downloaded by [Hellenic Open University] at 00:43 01 July 2012

nitrogen or air (120 C), was used to dilute the sample gas and minimize the nucleation particles. The total length of the antistatic tube used to connect the sample probe installed on the dilution tunnel and ELPI is less than 3 meters. The experimental setup is presented in Figure 1. The four laboratories did not use the same setup of dilution tunnels: Labs 1 and 2 had the same dilution tunnel for gasoline and diesel vehicles, Lab 4 used two dilution tunnels (one for gasoline and one for diesel vehicles) but with a common sampling point, and Lab 3 had two dilution tunnels with two sampling points. These experimental facilities are representative of those used in other European laboratories. Tunnel background measurements (blanks) are performed during the 5 min before the tests to check the tunnel cleanness and during the 5 minutes at the end of the test, with engine switched off, to control the initial test conditions. The tunnel background values were not subtracted from the particle number measurements. The particle numbers of the tunnel background tests are expressed in 1/km. This is calculated from the same blank exhaust volume as a NEDC test. The intralaboratory variability (ILV) is expressed as the relative standard deviation of the measured values. The repeatability and reproducibility between the four laboratories are calculated following the ISO 5725 standards (ISO 1994). In this work,

the intralaboratory variability, reproducibility, and repeatability is expressed as 1.96*RSD (condence interval of 95%). These calculations are as follows: Mean value of each laboratory: Meani = m i, j ni [1]

Standard deviation of each laboratory: ni m i2, j ( n i (n i 1) m i, j )2

SDi =

[2]

Relative standard deviation of each laboratory: RSDi = 100 T1 =

i

SDi meani

[3] [4] [5] [6]

n i m i, j n i m i2, j

i

T2 = T3 =

i

ni

INTERLABORATORY TEST OF EXHAUST PM USING ELPI

337

Downloaded by [Hellenic Open University] at 00:43 01 July 2012

FIG. 1.

Experimental setup.

T4 =

i

n i2 (n i 1)RSDi2

i

[7] [8] T3 (k 1) T32 T4 [9]

T5 = s L2 =

T2 T3 T12 T5 T3 (k 1)

Intralaboratory variability: ILVi = 1.96 RSDi [10] [11] [12]

T5 /(T3 k ) Repeatability = 1.96 100 T1 / T3 T5 /(T3 k ) + s L 2 Reproducibility = 1.96 100 T1 /T3

where n i = the number of measurements of i laboratory, m i, j = the value of j measurements of i laboratory, and k = number of laboratories. RESULTS AND DISCUSSION Emissions of Regulated Pollutants, CO2 , and Fuel Consumption Table 3 presents the emission of regulated pollutants, CO2 , and FC of the three vehicles. In the case of CO, the mean exhaust values are 0.7, 0.22, and 0.16 g/km for the gasoline, diesel, and DPF-equipped diesel vehicle, respectively. The cor-

responding 1.96*RSD intralaboratory variability is within 215, 834%, and 1084%, respectively, for the three vehicles. The corresponding reproducibility 1.96*RSD value is 13, 21, and 113%, respectively, while the corresponding repeatability value is 11, 20, and 38%, respectively. The last reproducibility value is due to the high CO mean value of Lab2 (more than double that of the other three laboratories, probably due to the deactivation of the oxidation catalyst). Nevertheless, this value is not considered as an outlier and is not extracted form the calculations. The 1.96*RSD values are more important at lower emissions. The 1.96*RSD of intralaboratory hydrocarbon (HC) variability is within 1116, 1021, and 1050% for the gasoline, diesel, and DPF-equipped diesel vehicles, respectively. The reproducibility 1.96*RSD value is 27, 22.5, and 67%, respectively, for the three vehicles, while the corresponding repeatability value is 14, 18, and 27.5%, respectively. Once more, the last reproducibility value is due to the high HC emissions measured by Lab 2 (probably due to the deactivation of the catalyst), but this value is not considered as an outlier and is not extracted from the calculations. Like in the case of CO emissions, the RSD values are more important at lower emissions. The NOx 1.96*RSD intralaboratory variability values are within 1467, 25.5, and 57% for the gasoline, diesel and DPF-equipped diesel vehicles, respectively. The reproducibility 1.96*RSD value of these emissions is 47, 11, and 17%, respectively, for the three vehicles, while the corresponding repeatability value is 46, 4, and 6%. The gasoline vehicle has a higher

Downloaded by [Hellenic Open University] at 00:43 01 July 2012

338 HC G 0.116 0.147 0.122 0.112 0.124 11.4 15.8 13.7 14 14.2 27.2 20.8 13.2 21.4 10.4 18.3 22.6 9.8 13.8 50.2 34.9 27.5 67.2 27.5 14 35.7 67.3 45.9 47.2 3.4 2.4 3.2 5.5 4 10.9 6 7.4 5.1 6.5 6.4 16.7 88.3 0 37.2 0 60.4 67.8 12.8 5 14.4 13 12.9 29.3 0.034 0.032 0.035 0.029 0.032 0.033 0.054 0.031 0.028 0.036 0.045 0.037 0.04 0.051 0.043 0.333 0.344 0.319 0.36 0.339 0.254 0.295 0.279 0.307 0.284 0.0008 0.0011 0.001 0.0233 0.0275 0.0313 0.0313 0.0284 D D + D PF G D G D D + D PF D + D PF 0.0006 0.0007 0.001 0.001 0.0008 72 169.7 261.1 122.2 191 163.9 NOx PM G CO2 FC (in l/100 km) D D + D PF G 156.4 137.1 155.8 137.9 159.6 136.1 161.7 137.6 158.4 137.2 1.8 0.8 1.4 0.7 1.2 3.6 1.6 0.9 2.4 0.9 1.6 1.7 136.5 135.9 135.9 139.8 137 1.4 0.3 1.6 1.3 1.2 2.9 D D + D PF 6.64 5.2 6.59 5.23 6.7 5.23 6.81 5.22 6.68 5.22 1.7 0.7 1.3 0.8 1.2 2.9 1.4 1.1 2.4 0.9 1.6 1.4 5.14 5.09 5.18 5.29 5.17 1.3 0.4 1.3 1.3 1.2 3.3 0.12 0.28 0.12 0.1 0.16

TABLE 3 Average, for each laboratory, emission of regulated pollutants, CO2 (in g/km) and fuel consumption (in L/100 km), intralaboratory variability (IVL), repeatability (RPT), and reproducibility (RPD) 1.96 RSD values (%) for the three vehicles used

CO

(g/km)

D + D PF

Lab 1 0.67 Lab 2 0.73 Lab 3 0.67 Lab 4 0.73 MEAN 0.7 ILV (%) Lab 1 11 Lab 2 2.6 Lab 3 11.9 Lab 4 15.2 RPT (%) 11.2 RPD (%) 13.1

0.2 0.24 0.23 0.22 0.22

33.9 10 18.2 8.1 20.4 21.3

24.9 10.3 84.1 41.1 37.6 113.1

G, gasoline vehicle; D, diesel vehicle; D + DPF, DPF-equipped diesel vehicle.

INTERLABORATORY TEST OF EXHAUST PM USING ELPI

339

Downloaded by [Hellenic Open University] at 00:43 01 July 2012

intralaboratory variability, repeatability, and reproducibility (lower 1.96*RSD values) than the two diesel ones due to lower emissions. The PM emissions are less repeatable than the previous pollutants in the case of the low-emitting vehicles. The 1.96*RSD intralaboratory variability values are within 3788 (with the measurements of only two laboratories), 514, and 72261% for the gasoline, diesel, and DPF-equipped diesel vehicles, respectively. The reproducibility 1.96*RSD value of these emissions is 67, 29, and 164%, respectively, for the three vehicles, while the corresponding repeatability value is 60, 12.7, and 191%. The gasoline vehicle and the DPF-equipped diesel vehicle have high RSD values due to their very low emissions, which are similar to the tunnel backgrounds. The repeatability of CO2 and fuel consumption is better than this of the regulated pollutants: the 1.96*RSD intralaboratory variability values are less than 2.4%, with no signicant differences between CO2 and FC values. The reproducibility and repeatability 1.96*RSD values of these emissions ranged from 1.2 to 3.6%. The 1.96*RSD ILV values increase with the decrease of the mean emitted value in the case of CO, HC, NOx, and PM emis-

FIG. 3. Particle number of the tunnel background tests before and after each NEDC for the four laboratories and the three vehicles used.

sions (Figure 2). This correlation seems independent of the vehicle and technology used, even if more data are necessary to validate this statement. Within the observed range, this correlation is not valid in the case of CO2 and FC. Particle Number of the Tunnel Background Tests Figure 3 presents the particle number of the tunnel backgrounds, before and after the tests, for the four laboratories and the three vehicles used. The particle number is quite similar before and after each NEDC, indicating that the tunnel is found at its initial stage after each cycle. The difference of the tunnel temperature before and after the tests is less than 5 C; moreover, particle numbers after the tests are not systematically higher than before the tests. These statements indicate that there is no particle desorption from the higher tunnel temperature after each NEDC. The tunnel background values before tests are used in the rest of this work. Figure 4 presents the particle number of the tunnel background tests as a function of laboratory. This number depends on the tunnel used at each laboratory, but it is generally around 1 1011 1/km. The particle number observed in the Lab 3 gasoline tunnel is the lowest due to its cleanness. The higher numbers of the diesel tunnel are due to the particle deposit on the

FIG. 2. 1.96 RSD intralaboratory variability values versus the mean value of the regulated pollutants (in g/km), CO2 (in g/km), and fuel consumption (in l/100 km) of the three vehicles used (PM: particulate matter).

340

E. ZERVAS ET AL.

Downloaded by [Hellenic Open University] at 00:43 01 July 2012

FIG. 4. Tunnel background tests. Lower bars: tunnel background particle numbers measured at each laboratory (mean of three tests); mean value of all tests and ELPI limits of detection and quantication (LOD = 5.3 1010 1/km/LOQ = 1.59 1011 1/km) for the three vehicles used. Upper bars: 1.96 RSD of each laboratory ILV (left bars), and reproducibility and repeatability (right bars). Lab 3 has two tunnels, one for gasoline vehicles (3G) and one for diesel vehicles (3D).

FIG. 5. Lower bars: particle number (in 1/km) of the gasoline vehicle measured at each laboratory (mean of 3 tests), mean value of all tests and ELPI limits of detection and of quantication (LOD = 5.3 1010 1/km/LOQ = 1.59 1011 1/km). Blank = mean of all four laboratories blanks for this vehicle. Upper bars: blank reproducibility 1.96 RSD values (left bars), 1.96 RSD intralaboratory variability values (middle bars), and reproducibility and repeatability 1.96 RSD values (right bars).

walls during the tests and the dropping during the measurements (Andrews et al. 2000). All of these tests are not very repeatable due to the low particle number; repeatability is also very dependent on the tests performed previously due to the dropping of the deposed particles (Andrews et al. 2000). For each laboratory, the 1.96*RSD intralaboratory variability values are within 43 and 153%. Mohr (2003b) presents an ILV of 38%, but for a heavy-duty engine. The reproducibility 1.96*RSD value of tunnel background tests is 200%, while repeatability 1.96*RSD is 163%. Figure 4 shows that the particle number of blank measurements is very near or even below the ELPI LOD or limits of quantication (LOQ = 3 LOD), which are 5.3 1010 and 1.5 1011 1/km, respectively. Particle Number on the NEDC Figure 5 presents the particle number of the gasoline vehicle emitted on the NEDC. The mean total particle number measured is 1.3 1012 1/km, the same order of magnitude as ACEA (2002). The 1.96*RSD values are quite high due to low particle numbers (Zervas et al. 2004). The intralaboratory 1.96*RSD variability values are 2469%, while the corresponding reproducibility and repeatability values are 59 and 45%. These values are much lower than those of the tunnel background tests of this vehicle, which is 174%. The mean total particle number of the diesel vehicle without DPF is two orders of magnitude higher than the particle number of the gasoline vehicle: 1.3 1014 1/km (Figure 6), as already

FIG. 6. Lower bars: particle number (in 1/km) of the diesel vehicle measured at each laboratory (mean of 3 tests), mean value of all tests and ELPI limits of detection and of quantication (LOD = 5.3 1010 1/km/LOQ = 1.59 1011 1/km). Blank = mean of all four laboratories blanks for this vehicle. Upper bars: blank reproducibility 1.96 RSD values (left bars), 1.96 RSD intralaboratory variability values (middle bars), and reproducibility and repeatability 1.96 RSD values (right bars).

INTERLABORATORY TEST OF EXHAUST PM USING ELPI

341

Downloaded by [Hellenic Open University] at 00:43 01 July 2012

FIG. 7. Lower bars: particle number (in 1/km) of the DPF-equipped diesel vehicle measured at each laboratory (mean of 3 tests), mean value (MV) of all tests, and ELPI limits of detection and of quantication (LOD = 5.3 1010 1/km/LOQ = 1.59 1011 1/km). Blank = mean of all four laboratories blanks for this vehicle. Upper bars: blank reproducibility 1.96 RSD values (left bars), 1.96 RSD intralaboratory variability values (middle bars), and reproducibility and repeatability 1.96 RSD values (right bars).

FIG. 8. Lower curve: intralaboratory standard deviation (1.96 SD) of particle number versus particle number on the NEDC. Upper curve: intralaboratory 1.96 SD of particle number of each ELPI stage. All points for the three vehicles used.

presented (ACEA 2002; Zervas et al. 2004). The intralaboratory 1.96*RSD variability values are 1020%. These values are lower than the corresponding values of the gasoline vehicle due to higher particle number (Figure 5). The corresponding reproducibility and repeatability 1.96*RSD values are 47 and 14%, quite low compared to the values of this vehicle tunnel background tests, which is 166%. It must be noted that this vehicle is representative of the current European eet (Euro3). Figure 8 presents that the mean total particle number of the DPF-equipped diesel vehicle is lower than the particle number of the two previous ones: 1.8 1011 1/km, as already presented (ACEA 2002; Zervas et al. 2004). The intralaboratory 1.96*RSD variability values are within 18135%, while the corresponding reproducibility and repeatability values are 131 and 96%. These last values are quite close to the tunnel background tests of this vehicle, which is 137%. The variability values are higher than the values of the diesel vehicle due to the lower particle numbers (Figure 3). It must be noted that the particulate emissions of this vehicle are representative of the emissions of the future European passenger cars. The particle number of this vehicle is very close or even lower than the ELPI limits of detection or quantication, which induces high values of reproducibility (as in the case of mass measurements). These high values of reproducibility might not be adapted for regulatory purposes. There are some correlations between the 1.96*RSD values and particle number. The lower curve of Figure 8 shows that the

intralaboratory standard deviation (1.96*SD) of the measured total particle number on the NEDC is linear with this number, independent of the vehicle and technology used, indicating that the error of this number determination using ELPI is quite constant (Zervas et al. 2004). The same linear relation also exists in the case of particle number 1.96*SD at each ELPI stage (upper curves of Figure 8). Figure 9 presents the ELPI 1.96*RSD ILV, reproducibility, and repeatability values as a function of particle number for the three vehicles tested. Upper curves show that reproducibility and repeatability values increase at low particle numbers. The order observed is tunnel backgrounds blanks > Diesel + DPF > Gasoline > Diesel. The DPF-equipped diesel vehicle emits slightly more particles that the blanks, but the 1.96*RSD reproducibility and repeatability values present a very important increase between these two points. This statement indicates that ELPI repeatability is critical for future vehicles. The lower curves present the intralaboratory variability. The points are more scattered, but three blocks of points are observed: one with low 1.96*RSD values due to high particle numbers (Diesel vehicle), one with intermediary particle numbers and 1.96*RSD values (gasoline vehicle), and one with very disperse 1.96*RSD values due to very low particle numbers. This last block corresponds to DPF-equipped Diesel vehicle and blanks of the three vehicles. This statement indicates that even within the same laboratory the 1.96*RSD values are very dispersed in the case of future vehicles. A probable correlation between repeatability of emitted particle numbers and each laboratory is searched but no tendency is found.

342

E. ZERVAS ET AL.

Downloaded by [Hellenic Open University] at 00:43 01 July 2012

FIG. 9. Lower curves: ELPI 1.96 RSD intralaboratory variability values as a function of each laboratory average particle number, for the three vehicles used and the tunnel background tests of each vehicle. Upper curves: ELPI 1.96 RSD reproducibility and repeatability values as a function of the average particle number, for the three vehicles used and the tunnel background tests.

Mean Particle Size Distribution Figure 10 presents the mean particle size distribution of the three vehicles. These distributions are quite similar for the four laboratories. Furthermore, size distribution shows that there is no nucleation during the measurements. The particle numbers emitted from the gasoline vehicle (mean value of all tests) are about one order of magnitude higher than particle numbers of tunnel blanks, up to about 300 nm (Figure 11, lower curves). For bigger particles, the ratio between exhaust gas particles and tunnel background ones drops to only two. The particle number of the diesel vehicle is, on the entire distribution, 23.5 orders of magnitude higher than the particle number of the tunnel blank measurements, while the particle number of the DPF-equipped diesel vehicle remains very close to the blank measurements for the entire distribution, especially in the area of very ne particles. For the three vehicles tested, the maximum of this ratio is observed at the third ELPI stage (63109 nm). Upper curves of Figure 11 present the ratio between the mean number of emitted particles and ELPI LOD; the limits of quantication are also presented. It is clearly shown that the particle numbers of tunnel blanks of the DPF-equipped diesel PC and of the upper part of the gasoline PC distribution are very close or even lower to the LOD and LOQ. The repeatability 1.96*RSD values of each ELPI stage are 4182, 0.6188, and 18259%, respectively, for the gasoline, diesel, and DPF-equipped diesel vehicles. These values remain lower than 133, 35, and 211%, respectively, for the three vehicles at the four rst stages of the ELPI, where the majority of the

FIG. 10. Mean particle size distribution of the tunnel background (average of all tests), and of the gasoline PC (lower curves), diesel PC (middle curves), and DPF-equipped diesel PC (upper curves) measured at each laboratory (mean of 3 tests).

particles are measured (99, 96, and 97%, respectively, for the three vehicles). The corresponding reproducibility 1.96*RSD values are 63178, 20161, and 129208%. Comparison Between the Particle Number and Mass ELPI gives the particle distribution, but some authors calculate the particle mass from this distribution. To achieve it the particle density must be rst determined. Different particle densities are used in literature: an average density of 1.0 g/cm3 (Shi et al. 1999; Tsukamoto et al. 2000), or 1.7 g/cm3 (Ulfvarson et al. 1997), or 0.5 g/cm3 (Witze et al. 2004). But particle density is a function of size (Ulfvarson et al. 1997; Ahlvik 1998; Andrews et al. 2001, Virtanen et al. 2002, Witze et al. 2004). The smaller particles are spherical, and the effective diameter determines the particle density. The larger the particles are the more primary particles they contain, leading to much lower values of effective density (Ahlvik et al. 1998). The values of 1 g/cm3 at 50 nm and 0.3 g/cm3 at 300 nm (Witze et al. 2004), or 1.50.2 g/cm3 (Andrews et al. 2001), or 1.20.3 g/cm3 (Maricq et al. 2004) or 1.60.2 g/cm3 (Ahlvik et al. 1998), or 1.11.2 g/cm3 (Virtanen et al. 2002) are suggested.

INTERLABORATORY TEST OF EXHAUST PM USING ELPI

343

Downloaded by [Hellenic Open University] at 00:43 01 July 2012

FIG. 11. Lower curves: ratio between the mean numbers of the particles emitted from each vehicle and the number of the tunnel background tests. Upper curves: ratio between the mean particle numbers and the ELPI LOD.

A correlation between the particle mass obtained from calculations and the mass measured on lters is performed. The conclusions of Tzsukamoto et al. (2000) are that an average density cannot be assumed for all particle size and that ELPI, due to the several assumptions used (same density of particles

of each size, each particle size of each stage, charge efciency, etc.), generally predicts 1.52 times more particle mass. Shi et al. (1999) found that ELPI and SMPS predict 1.31.6 times more mass than this collected on lters. Khalek (2000) also concludes that ELPI overestimates the total mass emissions comparing to lter mass measurements in the case of a heavy-duty engine. Andrews et al. (2001) conclude that estimated mass can be very different from the mass collected on lter. Witze et al. (2004) use only the rst 6 ELPI stages and an empirical method to adjust particle density to the mass obtained on the lters. The correlation between the particle mass estimated from ELPI and the mass collected on lters is presented here. For the estimation of particle mass from ELPI, the following procedure is used: the particle mass is the sum of the particle mass of each stage over the NEDC. The particle mass of each stage is calculated as the product of particle numbers and the effective density of each stage. The density values of Ahvil et al. (1998) are used for these estimations. Two methods are applied: using all or only the rst six ELPI stages, as Witze et al. (2004). These results are presented in Figure 12. This gure is divided in four parts. Lower part of this gure presents the particle mass estimated from ELPI versus this collected on lters when all ELPI stages are taken into consideration. The lower, upper, and mean (dened as Di = mean upper) diameter of each ELPI stage is used for these calculations. The upper curves present the same estimations using only the six rst stages. As the emissions of diesel vehicle are much higher comparing to the other two vehicles, the right part of this gure presents the estimation of

FIG. 12. Comparison between particle mass collected on lters and estimated from ELPI using the lower, mean, and upper diameter for each stage. Lower curves: all ELPI stages. Upper curves: six rst ELPI stages.

344

E. ZERVAS ET AL.

TABLE 4 The a , b, and r 2 of the best-t lines y = ax + b of the estimated versus measured particle mass a All ELPI stages Upper diameter Mean diameter Lower diameter First six ELPI stages Upper diameter Mean diameter Lower diameter 15.60 6.85 0.917 4.92 2.61 0.454 b 0.016 0.0066 0.0008 0.0048 0.0026 0.0005 r2 0.90 0.92 0.95 0.96 0.95 0.93

and 11 times more for the gasoline and Diesel+DPF vehicles respectively), while the use of the rst six ELPI stages estimates lower mass (in average 47 and 78% less mass than the measured one for the gasoline and diesel + DPF vehicles respectively); the use of mean diameter gives similar results as the upper one (2.6 and 4.3 times more mass for the gasoline and Diesel + DPF vehicle, respectively, when all ELPI stages are taken into account; while the 6 rst stages give respectively 73% and 89% less mass); and the use of lower diameter estimates lower mass than the measured one in all cases (all ELPI stages: 71 and 96% less mass than the measured one for the gasoline and diesel + DPF vehicles, respectively; 6 rst ELPI stages: 53 and 98%, respectively, less mass). A coefcient can be applied to each stage density and adjust the estimated values to the measured ones. This method can give slightly better results, but only in the case of the diesel PC, while the estimated emissions of gasoline and diesel + DPF vehicle are not improved. For all the above reasons, the use of ELPI results is not recommended for the estimation of particle mass. Comparison Between the Reproducibility and Repeatability of Regulated Pollutants and Particle Number Measurements Using ELPI Figure 13 presents the reproducibility and repeatability of regulated pollutants and particle numbers determined by ELPI. The CO2 and FC corresponding values are very low and are not

Downloaded by [Hellenic Open University] at 00:43 01 July 2012

the diesel vehicle, while the left one the estimation of the gasoline and diesel + DPF passenger cars. The best-t lines y = ax + b and the coefcient of determination (r 2 ) of the estimated versus measured values are calculated for each diameter. Table 4 presents the values of a , b, and r 2 for these congurations. From a macroscopic point of view, the use of upper and mean diameter gives much higher particle mass than the measured one; the use of lower diameter using only the six rst ELPI stages estimates very lower mass. The use of lower diameter using all ELPI stages gives the quite good best-t line: y = 0.917*x 0.0008, with r 2 = 0.95, and it could predict the measured mass. However, if each vehicle is examined in detail, the obtained results are less good. In the case of the diesel vehicle, Figure 12 shows that globally the estimated and measured mass points are found on a straight line. However:

the use of upper diameter estimates higher mass than the measured one (in average 14 times more mass than the measured one when all the ELPI stages are taken into account, while the 6 rst stages give, on average, 4.6 times more mass), the use of mean diameter also estimates higher mass than the measured one (in average 6.3 times more mass than the measured one when all the ELPI stages are taken into account, while the 6 rst stages give in average 2.4 times more mass), and the use of lower diameter estimates lower mass than the measured one (in average 15% less than the measured mass when all the ELPI stages are taken into account, while the 6 rst stages give in average 68% less mass than the measured one). In the case of the low-emitting particles passenger cars, Figure 12 shows that ELPI cannot estimate the measured mass. The points are too dispersed. Moreover:

the use of upper diameter estimates higher mass than the measured one in the case of all ELPI stages (6.6

FIG. 13. Reproducibility (R1) and repeatability (R2) of CO, HC, NOx, PM (in g/km), and ELPI particle number of the tunnel background tests (Number Blank) and on the NEDC (1/km, Number ELPI) for the three vehicles used. G, gasoline; D, diesel; D + DPF, DPF-equipped diesel vehicle.

INTERLABORATORY TEST OF EXHAUST PM USING ELPI

345

presented in this gure. The 1.96*RSD of particle emissions determined by lters is, for each vehicle, higher than for the other three regulated pollutants. This difference is not very important in the case of the diesel vehicle: reproducibility of 14% and repeatability of 30% against 1224% for the other pollutants. As the other two vehicles emit very low particle mass, these differences become quite important: 61 and 69% for the PM emissions versus 1247% for the other three pollutants in the case of the gasoline vehicle, and 165 and 190% against 6114% for the DPF-equipped diesel passenger car. The ELPI reproducibility over the entire NEDC is not very different from that of PM emissions: 68, 29, and 164% for the PM determination against 59, 47, and 131% for the ELPI, for the three vehicles, respectively; the corresponding repeatability values are 61, 14 and 190% for the PM versus 45, 14, and 96% for ELPI.

Downloaded by [Hellenic Open University] at 00:43 01 July 2012

CONCLUSIONS The French subgroup of the Particulate Measurement Programme, composed by IFP, PSA Peugeot-Citro en, Renault, and UTAC, conducted an interlaboratory test on the determination of exhaust particle number using ELPI. Three Euro3 passenger carsone gasoline operating under stoichiometric conditions, one diesel, and one DPF-equipped dieselare tested on the NEDC. Only the metrological aspects related to repeatability and detection limits are studied here, without touching on other features not well established today, such as calibration of analytical instruments. The results of this study show the following:

indicating that the error of this number determination is quite constant. On the entire NEDC, the reproducibility of total particle number determined by ELPI is 59, 47, and 131% for the gasoline, diesel, and DPF-equipped diesel vehicles, respectively. These values are quite similar to those of the mass particle determination. The particle number emitted from the DPF-equipped diesel engine is very close or even lower to ELPI LOD and LOQ. ELPI can be used, with some approximations, to estimate the mass of emitted particles, but only for Euro3 Diesel passenger cars, and it fails to estimate the emitted mass of the low-particle-emitting vehicles. Even if size distribution is given by ELPI with insufcient reliability, it allows to check that there is no nucleation mode due to inadequate dilution parameters. These results show that the protocol used in this study allows the reliable measurement of exhaust particle number in the case of vehicles emitting at least two orders of magnitude more than the tunnel background. In the other cases, the measurement variability is too high, especially for regulatory purposes.

REFERENCES

ACEA. (1999). ACEA Programme on Emissions of Fine Particles from Passenger Cars, Report, December 1999. www.acea.be. ACEA. (2002). ACEA Programme on Emissions of Fine Particles from Passenger Cars 2, Report, July 2002, www.acea.be. Ahlvik, P., Ntziachristos, L., Keskinen, J., and Virtanen, A. (1998). Real Time Measurements of Diesel Particle Size Distribution with an Electrical Lowpressure Impactor, SAE Tech. Paper Ser. 980410. Andrews, G. E., Clarke, A. J., Rojas, N. Y., Gregory, D., and Sale, T. (2000). Diesel Particle Size Distribution Changes along a Practical Exhaust System during Cold Start in Passenger Car IDI Diesel, SAE Technical Paper Series. 2000-01-0514. Andrews, G. E., Clarke, A. G., Rojas, N. Y., Sale, T., and Gregory, D. (2001). Diesel Particle Size Distribution: The Conversion of Particle Number Size Distribution to Mass Distribution, SAE Technical Papers Series 2001-011946. Burtscher, H. (2001). Literature Study on Tailpipe Particulate Emission Measurement for Diesel Engines, Report for the PMP, www.akpf.org/pub/ burtscher bericht.pdf Choi, B. C., Jang, S. H., and Juhng, W. N. (2003). ELPI Measurement of Particulate Matter from HSDI Diesel Engine with Diesel Oxidation Catalyst, SAE Technical Paper Series 2003-01-3159. Degobert, P. (1992). Automobile et Pollution. Eds Technip, Paris. Hinds, W. C. (1999). Aerosol Technology. J. Wiley and Sons, New York. Hoekman, S. K., Stanley, R. M., Clark, W. L., Siegel, W. O., Schlenker, A. M., and Biller, W. F. (1995). CRC Speciated Hydrocarbon Emissions Analysis Round Robin Test Program, SAE Technical Papers Series 950780. ISO (1994). ISO 5725-2 AFNOR, Paris. Keskinen, J., Pietarinen, K., and Lehtimaki, M. (1992). Electrical Low Pressure Impactor, J. Aerosol Sci. 23:353360. Khalek, I. A., Kittelson, D., and Brear, F. (1999). The Inuence of Dilution Conditions on Diesel Exhaust Particle Size Distribution Measurements, SAE Technical Paper Series 1999-01-1142.

The reproducibility 1.96*RSD values are 13, 21, and 113%, respectively, for the three vehicles in the case of CO; 27, 23, and 67% in the case of HC; 47, 11, and 17% in the case of NOx; and 68, 29, and 164% in the case of particles collected on lters. For these pollutants, the intralaboratory variability 1.96*RSD values increase quite regularly with the decrease of the mean emitted values, independently of the vehicle and technology used. The reproducibility 1.96*RSD values of CO2 emissions and fuel consumption are always less than 3.6% and much lower than the RSD values of the regulated pollutants. There is very little difference between the 1.96*RSD values of CO2 and FC. There is no obvious link between the 1.96*RSD values of CO2 emission or fuel consumption and the vehicle used or the mean value. There is no effect of the ELPI sampling volume, between 10 and 20 l/min, as the results of the Lab 1 are similar to these of the other laboratories. The reproducibility 1.96*RSD of the tunnel background tests is quite high (200%), due to low particle numbers, very close to the ELPI detection limits. The 1.96*SD of the measured particle number (on the NEDC or at each ELPI stage) is linear with this number, independently of the vehicle and technology used,

346

E. ZERVAS ET AL. Ristim aki, J., Virtanen, A., Marjam aki, M., Rostedt, A., and Keskinen, J. (2002). On-line Measurement of Size Distribution and Effective Density of Submicron Aerosol Particles, J. Aerosol Sci. 33:15411557. Shi, J. P., Harrison, R. M., and Brear, F. (1999). Particle Size Distribution from a Modern Heavy Duty Diesel Engine, Sci. Total Environ. 235:305307. Tejada, S. B., Clark, W., and Biller, W. F. (1997). CRC Carbonyl Emissions Analysis Round Robin ProgramPhase II, SAE Technical Paper Series 971609. Tsukamoto, Y., Goto, Y., and Odaka, M. (2000). Continuous Measurement of Diesel Particulate Emissions by an Electrical Low-Pressure Impactor, SAE Technical Paper Series 2000-01-1138. Ulfvarson, U., Figler, B., and Krantz, S. (1997). Diesel Engine Development is Guided by Inadequate Particle Sampling, SAE Technical Paper Series 970759. UNECE. 2001. GRPE Particle Measurement Programme. Programme Overview. http://www.unece.org/trans/main/wp29/wp29wgs/wp29grpe/infpapers 42.html Van Gulijk, C., Marijnissen, J. C. M., Makkee, M., and Moulijn, J. A. (2001). Restriction for the ELPI in Diesel Particulate Measurements, J. Aerosol Sci. 32:11171130. Van Gulijk, C., Marijnissen, J. C. M., Makkee, M., and Moulijn, J. A. (2003). The Choice of Instrument (ELPI and/or SMPS) for Diesel Soot Particulate Measurements, SAE Technical Paper Series 2003-01-0784. Van Gulijk, C., Marijnissen, J. C. M., Makkee, M., Moulijn, J. A., and SchmidtOtt, A. (2004). Measuring Diesel Soot with a Scanning Mobility Particle Sizer and an Electrical Low-Pressure Impactor: Performance Assessment with a Model for Fractal Like Agglomerates, J. Aerosol Sci. 35:633655. Virtanen, A., Ristim aki, J., Marjama aki, M., Vaaraslahti, K., and Keskinen, J. (2002). Effective Density of Diesel Exhaust Particles as a Function of Size, SAE Technical paper series 2002-01-0056. Wang, S. C., and Flagan, R. C. (1990). Scanning Electrical Mobility Spectrometer, Aerosol Sci. Technol. 13:230240. Wehner, B., Philippin, S., and Wiedensohler, A. (2002). Design and Calibration of a Thermodenuder with an Improved Heating Unit to Measure the SizeDependant Volatile Fraction of Aerosol Particles, J. Aerosol Sci. 33:1087 1093. Willeke, K., and Baron, P. A. (1993). Aerosol Measurement, Principles, Techniques and Applications. Van Nostrand Reinhold, New York. Witze, P. O., Chase, R. E., Maricq, M. M., Podsiadlik, D. H., and Xu, N. (2004). Time-resolved Measurement of Exhaust PM for FTP-75: Comparison of LII, ELPI and TEOM Techniques, SAE Technical Paper Series 2004-01-0964. Zervas, E., Dorlh` ene, P., Daviau, R., and Dionnet, B. (2004). Repeatability of Fine Particle Measurement of Diesel and Gasoline Vehicles Exhaust Gas, SAE Technical Paper Series 2004-01-1983.

Downloaded by [Hellenic Open University] at 00:43 01 July 2012

Khalek, I. A. (2000). Characterization of Particle Size Distribution of a Heavyduty Diesel Engine during FTP Transient Cycle Using ELPI, SAE Technical Paper Series 2000-01-2001. Lanning, L. A., Clark, W. L., Siegel, W. O., Hoekman, S. K., Stanley, R. M., and Biller, W. F. (1997). CRC Hydrocarbon Emissions Analysis Round Robin Test Program Phase II, SAE Technical Papers Series 971608. L unders, H., Kr uger, M., Stommel, P., and L uers, B. (1998). The Role of Sampling Conditions in Particle Size Measurements, SAE Technical Paper Series 981374. Maricq, M. M., Chase, R. E., Podsiadlik, D. H., and Vogt, R. (1999). Vehicle Exhaust Particle Size Distributions: A Comparison of Tailpipe and Dilution Tunnel Measurements, SAE Technical Paper Series 1999-01-1461. Maricq, M. M., Podsiadlik, D. H., and Chase, R. E. (2000). Size Distributions of Motor Vehicle Exhaust PM: A Comparison between ELPI and SMPS Measurements, Aerosol Sci. Technol. 33:239260. Maricq, M. M., and Xu, N. (2004). The Effective Density and Fractal Dimension of Soot Particles from Premixed Flames and Motor Vehicle Exhaust, Aerosol Sci. 35:12511274. Marj amaki, M., Keskinen, J., Chen, D. R., and Pui, D. Y. H. (2000). Performance Evaluation of the Electrical Low Pressure Impactor (ELPI), J. Aerosol Sci. 31:249261. Matter, U., Siegman, H. C., and Burtcher, H. (1999). Dynamic Field Measurements of Submicron Particles from Diesel Engines, Environ. Sci. Technol. 33:19461952. Mohr, M., Lehmann, U., and Margaria, G. (2003a). ACEA Programme on the Emissions of Fine Particulates from Passenger Cars (2). Part 2. Effect of Sampling Conditions and Fuel Sulphur Content on the Particle Emission, SAE Technical Paper Series 2003-01-1890. Mohr, M., and Lehmann, U. (2003). Comparison Study of Particle Measurement Systems for Future Type Approval Application, Research Report no 202779, Eidgen ossiche Materialpr ufungs und Forschungsanstalt (EMPA), D ubendorf Switzerland, Mai 2003, http://www.empa.ch/plugin/ template/empa/*/20987//l=1 Ntziachristos, L., and Samaras, Z. (2000). Sampling Conditions Effects on Realtime Particle Measurements from a Light Duty Vehicle, SAE Technical Paper Series 2000-01-2049. OICA. (2003). Industry Comments on the Proposed Particulate Measurement Techniques. OICA contribution to PMP, http://www.unece.org/trans/main/ wp29/wp29wgs/wp29grpe/grpeinf45.html Pattas, K., Kyriakis, N., Samaras, Z., Pistikopoulos, P., and Ntziachristos, L. (1998). Effect of DPF on Particulate Size Distribution Using an Electrical Low Pressure Impactor, SAE Technical Paper Series 980544.

Das könnte Ihnen auch gefallen

- 2005 Fuel Zervas E. Formation of Organic Acids From Propane, Isooctane and Toluene Isooctane FlamesDokument10 Seiten2005 Fuel Zervas E. Formation of Organic Acids From Propane, Isooctane and Toluene Isooctane FlamesMakis123Noch keine Bewertungen

- 06 - 2002 - Environ.-sci.-Technol. - Zervas-E. - Emission of Alcohols and CarbonylsDokument8 Seiten06 - 2002 - Environ.-sci.-Technol. - Zervas-E. - Emission of Alcohols and CarbonylsMakis123Noch keine Bewertungen

- 07 2003 Environ. Sci. Technol. Zervas E. Emissions of Regulated Pollutants From A Spark Ignition EngineDokument7 Seiten07 2003 Environ. Sci. Technol. Zervas E. Emissions of Regulated Pollutants From A Spark Ignition EngineMakis123Noch keine Bewertungen

- 04 2001 Atmos. Environ. Zervas E. Emission of Specific Pollutants From A Compression Ignition EngineDokument6 Seiten04 2001 Atmos. Environ. Zervas E. Emission of Specific Pollutants From A Compression Ignition EngineMakis123Noch keine Bewertungen

- 05 2001 Environ. Sci. Technol. Zervas E. C1 C5 Organic Acid Emissions From An SI EngineDokument6 Seiten05 2001 Environ. Sci. Technol. Zervas E. C1 C5 Organic Acid Emissions From An SI EngineMakis123Noch keine Bewertungen

- 01 1999 J. Air Waste Manage. Assoc. Zervas E. The Influence of Gasoline Formulation On Specific Pollutant EmissionsDokument11 Seiten01 1999 J. Air Waste Manage. Assoc. Zervas E. The Influence of Gasoline Formulation On Specific Pollutant EmissionsMakis123Noch keine Bewertungen

- 03 2000 Atmos. Environ. Zervas E. Organic Acids Emissions From Natural Gas Fed EnginesDokument9 Seiten03 2000 Atmos. Environ. Zervas E. Organic Acids Emissions From Natural Gas Fed EnginesMakis123Noch keine Bewertungen

- 54-2010 - SAE Paper 2010-01-2224 - MethaneDokument8 Seiten54-2010 - SAE Paper 2010-01-2224 - MethaneMakis123Noch keine Bewertungen

- 103-2015 - 10th PESXM - Extremes GreeceDokument8 Seiten103-2015 - 10th PESXM - Extremes GreeceMakis123Noch keine Bewertungen

- Wet Oxidation of 2-Chlorophenol in Aqueous SolutionsDokument10 SeitenWet Oxidation of 2-Chlorophenol in Aqueous SolutionsMakis123Noch keine Bewertungen

- 52-2010 - ECC - Climate Changes - Sun ActivityDokument9 Seiten52-2010 - ECC - Climate Changes - Sun ActivityMakis123Noch keine Bewertungen

- 50-2010 - ECC - 2010 - EU CO2 RegulationsDokument22 Seiten50-2010 - ECC - 2010 - EU CO2 RegulationsMakis123Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- BPSK SimulinkDokument13 SeitenBPSK SimulinkpootommyNoch keine Bewertungen

- Psychrometric Chart - Us and Si UnitsDokument1 SeitePsychrometric Chart - Us and Si UnitsRaden_Rici_Abi_1914Noch keine Bewertungen

- FR-8x Editor Eng01 WDokument8 SeitenFR-8x Editor Eng01 WRadulian Daniel100% (1)

- MILL Series GB-1007 01Dokument20 SeitenMILL Series GB-1007 01Ady IonutNoch keine Bewertungen

- WEISER Locks and HardwareDokument24 SeitenWEISER Locks and HardwareMaritime Door & WindowNoch keine Bewertungen

- EN RotomaticDokument4 SeitenEN RotomaticnajeerwNoch keine Bewertungen

- Dynamic Cone Penetrometers: In-Situ CBR in 10 Minutes With Dual-Mass DcpsDokument2 SeitenDynamic Cone Penetrometers: In-Situ CBR in 10 Minutes With Dual-Mass Dcpsd'Hell CaesarNoch keine Bewertungen

- Air-Bag: (1) Connector InformationDokument34 SeitenAir-Bag: (1) Connector InformationbakriramziNoch keine Bewertungen

- Comparative Study of Nylon and PVC Fluidized Bed Coating On Mild SteelDokument12 SeitenComparative Study of Nylon and PVC Fluidized Bed Coating On Mild SteelWaqqas ChaudhryNoch keine Bewertungen

- OTE Maintenance Inspection For Grinding Eng WebDokument2 SeitenOTE Maintenance Inspection For Grinding Eng WebjadetorresNoch keine Bewertungen

- TD Quintolubric 888 68Dokument2 SeitenTD Quintolubric 888 68Haitham YoussefNoch keine Bewertungen

- Selenium-75 Sources and Source Holders: ApplicationsDokument2 SeitenSelenium-75 Sources and Source Holders: ApplicationsTanpreet SinghNoch keine Bewertungen

- Lecure Two. ReactorsDokument56 SeitenLecure Two. ReactorsSophia WambuiNoch keine Bewertungen

- Bubbling Kun NiDokument7 SeitenBubbling Kun NiBelen CRNoch keine Bewertungen

- ASTM F 412 - 01a Standard Terminology Relating To Plastic Piping Systems1Dokument13 SeitenASTM F 412 - 01a Standard Terminology Relating To Plastic Piping Systems1JORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- How Is Electrical Energy MeasuredDokument4 SeitenHow Is Electrical Energy MeasuredSonya ReddyNoch keine Bewertungen

- Tutorial - 05 - Excavation Settle 3DDokument13 SeitenTutorial - 05 - Excavation Settle 3DAlejandro Camargo SanabriaNoch keine Bewertungen

- Mega PostDokument5 SeitenMega PostandreyfgNoch keine Bewertungen

- AB-522 Standard Pneumatic Test Procedure RequirementsDokument16 SeitenAB-522 Standard Pneumatic Test Procedure RequirementsShank HackerNoch keine Bewertungen

- Huawei ACU2 Wireless Access Controller DatasheetDokument12 SeitenHuawei ACU2 Wireless Access Controller Datasheetdexater007Noch keine Bewertungen

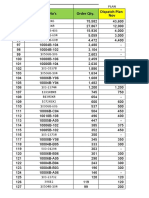

- Order Qty Vs Dispatch Plan - 04 11 20Dokument13 SeitenOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPNoch keine Bewertungen

- RT L2 General Examination PaperDokument4 SeitenRT L2 General Examination PaperdaddadNoch keine Bewertungen

- Determination of The Solubility Product Constant of Silver AcetateDokument8 SeitenDetermination of The Solubility Product Constant of Silver AcetateSara Al AzemNoch keine Bewertungen

- 21-3971-CLA - DisenŞo Preliminar Cimentacion - Normal SoilDokument4 Seiten21-3971-CLA - DisenŞo Preliminar Cimentacion - Normal SoilJose ManzanarezNoch keine Bewertungen

- Ude My For Business Course ListDokument51 SeitenUde My For Business Course ListShehroz BhuttaNoch keine Bewertungen

- Project AgreementDokument6 SeitenProject AgreementRowin DizonNoch keine Bewertungen

- CovestroDokument2 SeitenCovestroRonaldo CamargoNoch keine Bewertungen

- 100ah - 12V - 6FM100 VISIONDokument2 Seiten100ah - 12V - 6FM100 VISIONBashar SalahNoch keine Bewertungen

- Sjoblom, J. - Handbook of Emulsion Technology PDFDokument731 SeitenSjoblom, J. - Handbook of Emulsion Technology PDFdcharlies92% (13)