Beruflich Dokumente

Kultur Dokumente

1 s2.0 S0003267013011264 Main

Hochgeladen von

Ysabel Huaccallo AguilarOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1 s2.0 S0003267013011264 Main

Hochgeladen von

Ysabel Huaccallo AguilarCopyright:

Verfügbare Formate

Accepted Manuscript

Title: Simultaneous Determination of Amino Acids and Carbohydrates in Culture Media of Clostridium Thermocellum by Valve-switching Ion Chromatography Author: Yun Fa Haiyan Yang Chengshuai Ji He Cui Xinshu Zhu Juan Du Jun Gao PII: DOI: Reference: To appear in: Received date: Revised date: Accepted date: S0003-2670(13)01126-4 http://dx.doi.org/doi:10.1016/j.aca.2013.08.033 ACA 232791 Analytica Chimica Acta 3-6-2013 8-8-2013 20-8-2013

Please cite this article as: Y. Fa, H. Yang, C. Ji, H. Cui, X. Zhu, J. Du, J. Gao, Simultaneous Determination of Amino Acids and Carbohydrates in Culture Media of Clostridium Thermocellum by Valve-switching Ion Chromatography, Analytica Chimica Acta (2013), http://dx.doi.org/10.1016/j.aca.2013.08.033 This is a PDF le of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its nal form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

Submit to Analytica Chimica Acta ACA-13-1197Rev. Highlighted Simultaneous Determination of Amino Acids and Carbohydrates in Culture Media of Clostridium Thermocellum by Valve-switching Ion Chromatography

Yun Faa,*, Haiyan Yanga, Chengshuai Jib, He Cuic, Xinshu Zhud, Juan Due, Jun Gao a,*

Public Laboratory of Bioenergy and Biofuels, Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences, No. 189 Songling Road, Qingdao 266101, China b China University of Petroleum, No.66, West Changjiang Road, Qingdao Economic & Technological Development Zone 266580, China Technical Center of Shandong Entry-Exit Inspection and Quarantine Bureau, No. 70 Qutangxia Road, Qingdao 266002, China d Metabolomics group, Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences, No. 189 Songling Road, Qingdao 266101, China

c a

* To

whom correspondence should be address.

Fax: +86-532-80662695

E-mail address: fayun@qibebt.ac.cn or gaojun@qibebt.ac.cn Corresponding address:

Public Laboratory of Bioenergy and Biofuels, Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences, No. 189 Songling Road, Qingdao, 266101, China

1

Ac ce

Tel.: +86-532-80662692

pt

ed

College of Materials Science and Engineering, Qingdao University of Science & Technology, No. 53 Zhengzhou Road, Qingdao 266042, China

an

us

cr

ip t

Page 1 of 21

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29

Simultaneous Determination of Amino Acids and Carbohydrates in Culture Media of Clostridium Thermocellum by Valve-switching Ion Chromatography

Yun Faa,*, Haiyan Yanga, Chengshuai Jib, He Cuic, Xinshu Zhud, Juan Due, Jun Gaoa,*

Public Laboratory of Bioenergy and Biofuels, Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences, No. 189 Songling Road, Qingdao 266101, China

b

An improved method for the simultaneous determination of 20 amino acids and 7 carbohydrates using one-valve switching after injection, ion chromatography, and integrated pulsed amperometric detection is proposed. The resolution of the amino acids and carbohydrates in the cation trap column was investigated. In addition, parameters including flow liquid type, flow rate, concentration, and valve-switch timing were optimized. The method is time-saving, effective, and accurate for the simultaneous separation of amino acids and carbohydrates, with a mean correlation coefficient of >0.99 and repeatability of 0.5% to 4.6% for eight replicates. The method was successfully applied in the analysis of amino acids and carbohydrates in aseptic media and in extracellular culture media of three phenotypes of Clostridium thermocellum.

Ac ce

pt

ed

Abstract

an

College of Materials Science and Engineering, Qingdao University of Science & Technology, No. 53 Zhengzhou Road, Qingdao 266042, China

us

Technical Center of Shandong Entry-Exit Inspection and Quarantine Bureau, No. 70 Qutangxia Road, Qingdao 266002, China d Metabolomics group, Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences, No. 189 Songling Road, Qingdao 266101, China

cr

China University of Petroleum, No.66, West Changjiang Road, Qingdao Economic & Technological Development Zone 266580, China

ip t

Page 2 of 21

30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

Keywords: ion chromatography; valve switching; amino acids; carbohydrates; electrochemical detector

1. Introduction Lignocellulose is the most abundant, inexpensive, and renewable resource on earth.

Great importance has been focused on the research on changing lignocellulose

biomass into regenerative fuels to address future energy needs [1-2]. Microorganisms such as Clostridium thermocellum that can directly convert cellulose into ethanol as

attention from many researchers [3-4]. To improve strains, analyze gene functions, and optimize cell systems, researchers aim to quantitatively understand the metabolism of bacteria and determine metabolic flux data. Amino acids and sugars are among the most important metabolites involved in

can reveal cellular metabolic differences under the interferences from cellular and environment. Furthermore, such analysis can explain the metabolic pathway [5]. Therefore, the accurate and efficient determination of amino acids and sugars is highly important. Cation-exchange chromatography with post-column derivatization and

spectrophotometric detection [6] as well as reversed-phase liquid chromatography with pre-column derivatization and spectrophotometric detection [7] are commonly

Ac ce

amino acids and sugars in culture media of different phenotypes of C. thermocellum

pt

protein metabolism and carbon metabolism. Analysis of the concentration changes in

ed

an

fuel have an important value in the field of bio-energy, thereby attracting considerable

us

cr

ip t

Page 3 of 21

52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73

used to determine amino acids. The methods for carbohydrate analysis include mainly liquid chromatography with refractive index detection [8]. The above methods cannot determine amino acids and carbohydrates of complex samples directly and simultaneously. Anion exchange chromatography and the integrated pulsed amperometric technique have been proven as selective and sensitive methods for determining amino acids and sugars directly without derivatization [9-11]. The bi-modal integrated amperometric detection can analyze mixtures of amino acids and carbohydrates [12]. However, these mixtures cannot be simultaneously determined in

complex sample, the presence of hydroxyl amino acids or other sugars need further identification. Valoran P. Hanko et al. and Yvonne Genzel et al. successfully determined amino acids in cell culture media [13-14]. However, the co-elution between amino acids and carbohydrates remains unsolved. Therefore, sugars need to

column with an optimized long gradient elution time [17]. They applied the condition to detect amino acids and sugars in green tea and rice wine [18-19]. Nevertheless, separating sugars from amino acids requires low [NaOH]. At this condition, the electrochemical response is lower, and the use of low [NaOH] probably causes a baseline drift [20]. Petr Jandik presented a two dimensional ion chromatography (IC) approach to separate amino acids and carbohydrates using three valves and a short time of 25 min to 40 min [21]. However, quantitative analysis is difficult to perform

Ac ce

amino acids and 9 carbohydrates was demonstrated by Yu on an Amino Pac PA 10

pt

be removed prior to amino acid separation [15-16]. The simultaneous separation of 17

ed

an

this manner because under the waveform of mode for carbohydrate detection in a

us

cr

ip t

Page 4 of 21

74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95

because the extraction efficiency of the trap column decreases rapidly. At present, an in-depth quantitative analysis for real complex samples has not been reported. In this work, we achieved a precise quantitative and simultaneous analysis of amino acids and carbohydrates using valve switching with a mean correlation coefficient of >0.99 and repeatability of 0.5% to 4.6%. After injection, all additional procedures of

the system are carried out using a single 10-port valve. The resolution of the amino

acid from the carbohydrate on the trap column was investigated, and the optimum conditions for high trap efficiency were systematically studied online. The new

media and in extracellular culture media of three phenotypes of C. thermocellum.

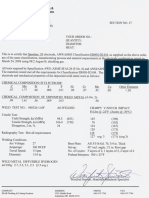

2. Experimental 2.1. Instrumentation and chromatography conditions

AS50 auto-sampler, and a 10-port valve. An HPLC system equipped with a high-pressure-double-piston pump and a refractive index detector (RID) (Yilite, Dalian, China) was used for pumping the trap solution and testing the resolution of glucose and aspartic acid on the trap column. Chromeleon software was used for system control. Carbohydrate Removal Cartridge (2 mm 15 mm, Dionex) was used as the cation-trap column. Chemical separation was performed using a CarboPac PA10 column (2 mm 250 mm, Dionex) with a guard column (2 mm 50 mm,

Ac ce

equipped with DP analytical gradient pumps, two electrochemical detectors (ED), an

pt

Analyses were conducted using an IC-3000 IC system (Dionex, Sunnyvale, CA)

ed

an

method was successfully used to determine amino acids and carbohydrates in aseptic

us

cr

ip t

Page 5 of 21

96 97 98 99 100 101 102 103 104

Dionex) and an AminoPac PA10 column (2 mm 250 mm, Dionex) with a guard column (2 mm 50 mm, Dionex). The gradient programs and the electrochemical waveforms used to separate the amino acids and the carbohydrates are listed in Tables 1 and 2. Gold electrodes were used in pH reference mode to detect the amino acids and in AgCl reference mode to

detect the carbohydrates. All amino acids and carbohydrates were separated at a flow rate of 0.25 mL min-1. The column temperature was 32.5 C.

Table 1 Gradient conditions Gradient conditions for the amino acids Time (min) 0 2 8 11 18 21 23 42 42.1 44.1 44.2 60 0 76 76 64 64 40 44 14 14 20 20 76 76 97 97 60 %H2O %NaOH (250 mM) 24 24 36 36 20 16 16 16 80 80 24 40 40 70 70 8 %NaAC (1 M) Curve

pt

Ac ce

24 3 3

Gradient conditions for the carbohydrates

20 30

40

40 45 50

60 10 10 20

40 70 70

50.1 52 52.1 60

80 80 3 3

20 97 97

105

Table2. Detection conditions

ed

20 20

M

8 5 8 8 5 8 8 5 8

an

Page 6 of 21

us

cr

ip t

Wave form for amino acids Time (ms) 0 40 50 210 220 460 470 560 570 580 590 600 0 200 400 410 420 430 440 500 Potential (V) vs. pH 0.13 0.13 0.28 0.28 0.61 0.28 0.28 1.67 1.67 0.93 0.13 0.1 0.1 0.1 2 2 0.6 0.1 0.1 0.61

Wave form for carbohydrates

106 107 108 109 110 111 112 113 114 115

All the solutions were prepared in 18 M.cm water (Milli-Q) with a 0.22 m nylon membrane filter. Formic acid and acetic acid were purchased from Aladdin (Shanghai, China). Sodium hydroxide (50% w/w, certified grade) was obtained from Acros Organics (New Jersey, USA); sodium acetate (purity, >99%) was procured from Sigma-Aldrich (St. Louis, MO, USA); and the amino acid and carbohydrate standards were supplied by AccuStandard (St. New Haven, CT, USA). In this study, we selected L-norleucine and lactose as the internal standards. All the samples were obtained from cultures of C. thermocellum at 60 C.

Ac ce

pt

2.2. Preparation of reagents, standards, and samples

ed

an

Page 7 of 21

us

cr

ip t

116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135

Approximately 1.0 mg mL-1 internal standards were added to the samples before pre-treatment. The cells and the extracellular matrix were delaminated by centrifugation at 12,000 rpm for 10 min at 4 C. The cells were treated for other analysis. The supernatants were diluted 10 times with water and filtered using 0.22m nylon membrane prior to IC analysis. 2.3. Valve-switching program

All the procedures of the system were carried out using a single 10-port valve and three pumps interconnected by a narrow poly (ether-ether-ketone) tubing system (Fig.

were 0.127 mm in inner diameter (I.D.). The other parts of the tubing system were 0.254 mm in I.D., and the volumes of loop1 and loop2 were 25 and 200 L, respectively.

The steps in the valve-switching program (Fig. 1) follow. Step 1 represents sample

phase, where amino acids and carbohydrates are eluted from the trap column and Loop 2, respectively; separated on anion-exchange columns; and detected by the EDs. Step 4 involves re-equilibration, where the trap solution is equilibrated in the trap column, and both anion-exchange columns are being re-equilibrated prior to their next analysis. The timing and the status of valves were listed in Table 3.

Ac ce

trap column and carbohydrates are intercepted into Loop 2. Step 3 is the analysis

pt

loading. Step 2 is the sample injection stage, where amino acids are extracted on the

ed

an

1). T1 was 39.4 mm long, whereas T2 and T3 were both 5.5 mm long. T1, T2, and T3

us

cr

ip t

Page 8 of 21

137 138 139 140

Fig. 1. Sketch map of the valve-switching program. Continuous black lines represent closed status of the path flow, and arrows indicate the flow direction. Table 3 The timing and the status of valves Procedure Step1 Step2 Step3 Step4 Time(min) -4.5 0 1.2 10.2-60.0 Status of injecting valve(6-port) load

an

inject inject inject

141 142 143 144 145 146 147 148 149 150

Status1: port1 connected to port2, port 3 connected to port4, port5 connected to port6, port7 connected to port8,

port9 connected to port10.

b

port8 connected to port9.

2.4. Method validation

The method was validated for precision, sensitivity, linearity, and reproducibility. Repeatability (the relative standard deviation) was determined using eight replicates of 1.00 mg L-1 standard mixture. Reproducibility was determined using three replicates of three concentrations of 0.05, 0.20, and 1.00 mg L-1. Linear regression

9

Ac ce

Status2: port1 connected to port10, port2 connected to port3, port4 connected to port5, port6 connected to port7,

pt

ed

us

Status of switching valve(10-port) Status1a Status1 Status2b Status1

cr

136

ip t

Page 9 of 21

151 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 167 168 169 170 171 172

calibration curves were calculated by plotting the peak area ratios of the external and internal standards versus the concentration of the external standards. Accuracy of the method was confirmed using an amino acid analyzer (Sykam 433D, Germany) with a LCA K07/Li column (4.6 mm 150 mm, Sykam) and a UV detector. 3. Results and discussion 3.1. The choice of trap solution

Water, buffer solution, and acids are used as eluent for cation exchange chromatography [22-24]. Using acid solution directly as the trap solution is beneficial

formic acid and acetic acid were tested online as trap solutions on a cation exchanger. Using acetic acid as trap solution, leucine and isoleucine co-eluted with a long tail on the methionine peak. Using formic acid as trap solution, a satisfactory chromatogram and >90% trap recovery of aspartic acid were obtained. Therefore, formic acid was

To obtain the highest trap efficiency of amino acids and complete separation of amino acids and carbohydrates, we studied their resolution on the cation exchange trap column.

Aspartic acid is acidic and easy to elute from the trap column because of its weak interaction with the cation-exchange resin. Therefore, the retention behaviors of aspartic acid and glucose were investigated as representative compounds. If baseline separation of aspartic acid and glucose is obtained, isolation on the trap column would

10

Ac ce

3.2. Resolution of carbohydrates and amino acids on the cation exchanger

pt

the better choice as the trap solution given the analysis condition.

ed

an

for amino acid retention on the cation exchanger in hydrogen form [16]. In this work,

us

cr

ip t

Page 10 of 21

173 174 175 176 177 178 179 180

be successful. We tested the resolution of 20 mg L-1 glucose and 10 mg L-1 aspartic acid on the trap column at different formic acid concentrations (0, 1.0, 3.0, 4.0, 5.0, 8.0, and 15.0 mM) and flow rates (0.02, 0.05, 0.10, 0.15, 0.20, 0.25, and 0.50 mL min-1) (Fig. 2). The 3.0 mM formic acid provided the best resolution. In addition, we checked the equilibration time of the trap column at 0.05, 0.10, and 0.15 mL min-1. The time values were 85, 45, and 25 min, respectively. Although the resolution

increased as the flow rate decreased, the most time-saving condition was at 0.10 mL min-1 with a resolution 2.0.

181 182 183 184 185 186 187

Fig. 2. Curve of resolution of aspartic acid and glucose with different flow rates and concentrations

3.3. Switching time of the 10-port valve We used 20 mg/L glucose as standard and a 200 L tube as Loop 2 to set the cut window (the switching time of the 10-port valve) on the optimum conditions in the section 3.2. We tested the peak area of glucose in different time (0.6, 0.7, 0.8, 0.9, 1.0, 1.1, 1.2, 1.3, 1.4, 1.5, 1.6, 1.7, 1.8, 2.2, 2.5min) on CarbonPac PA 10 column. The

11

Ac ce

pt

ed

an

Page 11 of 21

us

cr

ip t

188 189 190 191 192 193 194 195 196 197 198 199 200 201 202

peak value of the area was at 1.20 min. In the experiment that followed, 1.20 min was used as the switching time. 3.4. Optimum conditions of the method As described above, the optimum analysis conditions include 3 mM formic acid solution as the liquid of the trap column at 0.10 mL min-1 flow rate, 1.20 min as the

switching time of 10-port valve. We tested the recoveries of 20 amino acids and 7 sugars (~1.0 mg mL-1 each amino acid and ~2.0 mg mL-1 each carbohydrate as standard mixture) under the optimum conditions. The results are satisfactory, with a

3.5. Evaluation of the new method

Fig. 3A1 shows severe co-elution in the direct injection of the same mixture onto a single column. Threonine and serine were found in the waveform for the carbohydrates as shown as Fig. 3B1. However, Fig. 3A2 and 3B2 displayed good

203 204

Fig. 3. Comparison of two methods for amino acid and carbohydrate standard mixture analysis. 12

Ac ce

pt

separation without interference between the amino acids and the carbohydrates.

ed

an

Page 12 of 21

mean value of 99.3% and scope of 91.3% to 109%.

us

cr

ip t

205 206 207 208 209 210 211 212 213 214 215 216 217 218 219 220 221 222 223 224 225 226

Chromatogram A1: direct injection of standard mixture on Amino Pac PA10 column. Chromatogram B1: direct injection of standard mixture on CarboPac PA10 column. Chromatogram A2 and B2: direct single injection of standard mixture by the new method on Amino Pac PA10 column and CarboPac PA10 column. Peak identities are given in Table 3.

The linearity of response was tested for the 25 L injections of 0.01, 0.05, 0.10, 0.25, 0.50, 1.00, 2.50, 5.00, and 10.00 mg L-1 standard mixtures. Moreover, the linear

range is described in Table 3. The mean correlation coefficient of the calibration

Repeatability for the eight replicates of 1.00 mg L-1 standard mixture was 0.50% to 4.60%. Reproducibility for the three replicates of 0.05, 0.20, and 1.00 mg L-1 standard mixture was 0.67% to 5.45%.

The accuracy of this method was confirmed using post column derivatization and

data 1) with valve-switching IC and with post-column derivatization in an amino acid analyzer, respectively. A comparison among data 2, data 3, and data 1 in Table 3 shows almost similar results. The average relative errors were 4.34% and 2.84%, respectively. The relative error for the seven carbohydrates ranged from 0.50% to 5.00%.

Table 4 Repeatability, reproducibility, correlation coefficient, linear range and data comparison

13

Ac ce

same sample (prepared using 19 amino acid standards which concentration listed in

pt

UV detection for 19 amino acids. Data 2 and data 3 were obtained by analyzing the

ed

an

reached 0.99. Repeatability and reproducibility were also investigated (Table 3).

us

cr

ip t

Page 13 of 21

Serial number 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 a b c d e f g

Correlation Analyte coefficient (n=6) Arginine Lysine Glutamine Asparagine Alanine Threonine Glycine Valine Serine Proline Isoleucine Leucine Methionine Histidine Phenylalanine Glutamic acid Aspartic acid Cytine Tyrosine Tryptophan Trehalose Arabinose Galactose Glucose Mannose Ribose 0.9844 0.9974 0.9996 0.9992 0.9994 0.9985 0.9991 0.9897 0.9984 0.9980 0.9985 0.9987 0.9979 0.9906 0.9986 0.9993 0.9981 0.9864 0.9985 0.9975 0.9995 0.9999 0.9999 0.9999 0.9999 Y=2.2647X+0.5309 Y=1.3588X-0.1135 Y=2.1601X-0.0425 Y=5.5032X+0.1239 Y=2.3712X-0.0567 Y=3.233X-0.1285 Y=2.4867X-0.1037 Y=1.8913X+0.0908 Y=2.1319X-0.0254 Y=3.293X-0.2051 Y=1.0801X0.0856 Y=0.8693X-0.0823 Y=2.7365X-0.187 Y=6.6014X+0.9758 Y=6.9946X+0.0203 Y=0.6773X+0.0186 Y=1.3429X-0.0511 Y=2.7317X-0.4972 Y=3.0703X-0.1335 Y=3.2886X-0.312 Regression equation

Linear range (mg L-1) 0.052.00 0.052.50 0.052.50 0.051.00 0.052.50 0.055.00 0.051.00 0.055.00 0.055.00 0.055.00 0.055.00 0.055.00 0.051.00 0.051.00 0.052.50 0.055.00 0.055.00 0.052.50 0.051.00

Repeatability (%,n=8) 2.26 2.05 2.44 2.42 2.53 2.91 2.30 4.69 2.66 2.65 3.35 2.88 2.43

Reproducibility (%) 4.42 2.60 1.59 1.61 1.32 2.12 1.82 3.61 1.89 2.77 3.13 3.77 2.77

Data1a (mg L-1) 2.00 2.00 2.00 2.00 2.00 2.00 2.00

Data2b (mg L-1) 1.93 1.98 2.09 1.94 1.89 1.90 1.90

Data3c (mg L-1) 1.93 1.99 2.05 2.08 2.07 2.02 1.99 1.95 1.99 1.96 1.90 2.12 2.01 1.97 1.96 2.05 2.02 -1.95 2.14 --------

cr

2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 -2.00 2.00 4.00 4.00 4.00 4.00 4.00 4.00 4.00

us

3.88 5.45 3.02 2.53 4.13 2.40 4.28 5.60 0.67 1.40 1.27 2.77 1.10 2.92

an

1.98 2.59 2.47 2.61 2.42 2.41 3.40 3.87 0.42 0.50 0.51 1.05 0.48 3.44

ed

0.052.50

Y=1.2677X-0.0273 Y=1.8355X-0.0027 Y=2.7257X-0.0217

0.0510.00 0.0510.00 0.0510.00 0.0510.00 0.0510.00 0.0510.00 0.0510.00

pt

Y=3.5603X+0.0429 Y=1.4789X-0.0203

Ac ce

0.9738

Y=1.4123X+0.4782 Y=1.7305X-0.0869

Cellobiose

0.9998

227 228 229 230 231 232 233

a

Data 1 is the actual concentration of the sample prepared using standards. Data 2 was obtained by the new method with valve switching for the sample mentioned above.

Data 3 was obtained by post-column derivatization using an amino acid analyzer for the same sample.

3.6. Sample analysis The proposed method was used to analyze amino acids and carbohydrates in aseptic

14

ip t

1.86 1.90 1.89 1.87 1.88 1.88 2.01 1.90 1.91 2.03 -2.06 1.91 3.98 4.07 4.03 4.06 4.05 3.96 3.80

Page 14 of 21

234 235 236 237 238 239 240 241 242 243 244 245 246 247

medium and the corresponding medium of three phenotypes of C. thermocellum (CT). The three phenotypes included a wild-type strain (WT), an ethanol-tolerant strain with 0% ethanol addition (ET0), and an ethanol-tolerant strain with 3% ethanol addition (ET3), respectively. The chromatogram of the four samples obtained in the system (Fig. 4) demonstrates a complete separation of the carbohydrates from the amino

acids. Table 4 lists the average contents of amino acids and carbohydrates in four types of fermentation medium for three replicates. The data indicated that three phenotypes could consume glucose and release valine, etc. However, the consumption

ET0 and ET3 released arginine, which showed that most of the arginine is synthesized in ethanol-tolerant strains. The deduction is consistent with that reported in 2011 by Shao [25]. A similar case was observed in tyrosine, where ET3 released the most tyrosine. The concentration changes in glucose and cellobiose of the three phenotypes

248 249 250

Fig. 4 Chromatograms of standard mixtures and four samples using the proposed method. Chromatogram A1 and B1: direct single injection of standard mixture; Chromatogram A2 and B2: aseptic medium;

15

Ac ce

pt

demonstrated the differences in carbon source uptake.

ed

an

of arginine, tyrosine, and cellobiose was quite different. WT could use arginine, but

us

cr

ip t

Page 15 of 21

251 252 253 254 255 256 257

Chromatogram A3 and B3: wild-type strain of Clostridium thermocellum by (WT-CT); Chromatogram A4 and B4: ethanol-tolerant strain with 0% ethanol addition (ET0); Chromatogram A5 and B5: ethanol-tolerant strain with 3% ethanol addition (ET3). i1 and i2 denote L-norleucine and lactose as the internal standards. Other peak identities and the analyte amounts are given in Table 4.

Table 5 Results of actual samples Serial number 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 a Analyte Arginine Lysine Glutamine Asparagine Alanine Threonine Glycine Valine Serine Proline Isoleucine Leucine Methionine Histidine Phenylalanine Glutamic acid Aspartic acid Cytine Tyrosine Aseptic medium (mg L-1) 5.78 3.91 1.28 8.14 2.50 7.24 3.36 7.05 1.42 1.06 7.01 7.81 7.24 CT-WT (mg L-1) 4.93 9.40 2.73 9.94 24.89 6.24 3.20 CT-ET0 (mg L-1) 6.21

us

6.05 2.14 9.44 21.04 7.07 3.49 16.46 19.14 15.50 10.13 12.41 11.53 ND 1.57 47.76 30.22 23.59

a

an M

1.01 ND 2.43 46.02 29.90 17.16

a

20.65

21.33

16.84

ed

10.71 17.40

pt

0.69

2.08

Ac ce

29.81 28.62 36.71

196.75 5.22 26.92 ND ND

274.92 5.56 23.09 ND ND

255.06 5.72 22.60 ND ND

20 b c d e f g

Tryptophan Trehalose Arabinose Galactose Glucose Mannose Ribose Cellobiose

2193.70 ND 83.59 571.25

209.20 ND 98.75

192.80 ND 77.02

272.25

447.25

258 259

ND: Not detected 16

cr

a a a

ip t

CT-ET3 (mg L-1) 10.95 5.85 1.42 9.32 22.78 9.34 4.37 23.49 18.70 14.78 14.21 16.92 ND ND 1.36 46.01 26.85 12.94 538.87a 5.95 15.03 ND ND 248.92a ND 84.70 2156.80a

Page 16 of 21

260 261 262 263 264 265 266 267 268 269 270 271 272 273 274 275 276 277 278

Data of samples that were diluted 250 times

CT-WT: wild-type strain of Clostridium thermocellum CT-ET0: ethanol-tolerant strain of Clostridium thermocellum 0% ethanol addition CT-ET3: ethanol-tolerant strain of Clostridium thermocellum 3% ethanol addition

4. Conclusions

This study demonstrates an effective, accurate, and completely automated method

for the simultaneous determination of amino acids and carbohydrates with no co-elution. The method has to do with a trapping column, trapping under the correct

analysis are satisfactory and highly valuable for metabolomics research. Acknowledgements

This project is supported by the National Special Fund for Major Research Instrumentation Development (No. 2012YQ090229), the Instrument Functional

2011SJGZ06, 2012SJGZ12, and 2012424012). The authors are grateful to Professor Shifen Mou, Engineer Renyong Li, and Engineer Xiangchun Li for the valuable discussions.

17

Ac ce

yg2010072), and the Shandong Provincial Technology Development Plan Fund (No.

pt

Exploitation and Technical Innovation Fund, Chinese Academy of Sciences (No.

ed

an

conditions, valve timing, and two column separations. Results of actual sample

us

cr

ip t

Page 17 of 21

278 279 280 281 282 283 284 285 286 287 288 289 290 291 292 293 294 295 296 297 298 299

References

[1] C.Weber, A.Farwick, F.Benisch, D.Brat, H.Dietz, T.Subtil, E.Boles, Appl. Microbiol. Biot., 87 (2010) 1315. [2] H.G.Qiu, L.X.Sun, J.K.Huang, S.Rozelle, Renew Sust. Energ. Rev., 16 (2012) 3104. [3] A.L. Demain, M. Newcomb, J.H.D. Wu, Microbiology and Molecular Biology Reviews, 69 (2005) 154.

[4] L.R.Lynd, W.H.van Zyl, J.E.McBride, , M.Laser, Curr. Opin. Biotech., 16 (2005) 583.

[5] G.A. Pope, D.A. MacKenzie, M.Defernez, M.A.M.M. Aroso, L.J. Fuller,F.A. Mellon, W.B.

(2007) 679.

[6] F.D. Macchi, F.J. Shen, F.G. Kech, R.J. Harris, In C. Cooper, N. Packer, K. Williams, Methodsin Molecular Biology, Vol 159: Amino Acid Analysis Protocols, Humana Press Inc,Totowa NJ, 2001, pp.30.

[9] A.P. Clarke, P. Jandik, R.D. Rocklin, Y. Liu, N. Avdalovic, Anal. Chem. 71 (1999) 2781. [10]M. Raessler, B. Wissuwa, A. Breul, W. Unger, T.J. Grimm, Agr. Food. Chem. 56 (2008) 7654. [11] M.P. Olson1, L.R. Keating, W.R. LaCourse, Anal. Chim. Acta 652 (2009) 204. [12] P. Jandik, A.P. Clarke, N. Avdalovic, D.C. Andersen, J. Cacia, J. Chromatogr. B. 732 (1999) 201. [13] V.P. Hanko, J.S. Rohrer, Anal. Biochem. 324 (2004) 38. [14] Y. Genzel, S. Konig, U. Reichl, Anal. Biochem. 335 (2004) 125.

18

Ac ce

[8] Z. El Rassi, J. Chromatogra. A. 720 (1996) 118.

pt

[7] R. Rebane, K. Herodes, Anal. Chim. Acta. 672 (2010) 84.

ed

an

Dunn, M. Brown, R. Goodacre, D.B. Kell, M.E. Marvin, E.J. Louis, I.N. Roberts,Yeast. 24

us

cr

Page 18 of 21

ip t

300 301 302 303 304 305 306 307 308 309 310 311 312 313 314

[15] P. Jandik, J. Cheng, D. Jensen, S. Manz, N. Avdalovic, J. Chromatogr. B. 758 (2001) 196. [16] Y.S. Ding, H. Yu, S.F. Mou, J. Chromatogr. A. 997 (2003) 160. [17] Y.S. Ding, H. Yu, S.F. Mou, J. Chromatogr. A. 966 (2002) 97. [18] Y.S. Ding, H. Yu, S.F. Mou, J. Chromatogr. A. 982 (2002) 244. [19] H. Yu, Y.S. Ding, S.F. Mou, Chromatographia. 57 (2003) 728.

[20] Dionex, Thermo scientific Application Notes and Updates, AN150, (2003).

[21] P. Jandik, J. Cheng, in L. Bhattacharyya, J.S. Rohrer (Eds.), Application of Ion Chromatogaphy for Pharmaceutical and Biological Products, J. Willy & Sons. Inc. New

[22] S. Moore, D.H. Spackman, W.H. Stein, Anal. Chem. 30 (1958) 1190. [23] D.L. Buchanan, R.T. Markiw, Anal. Chem. 32 (1960) 1407. [24] P.B. Hamilton, Anal. Chem. 35 (1963) 2064.

[25] X.J. Shao, B. Raman, M.J. Zhu, J.R. Mielenz, S.D. Brown, A.M. Guss, L.R. Lynd, Appl.

19

Ac ce

pt

Microbiol. Biotechnol. 92 (2011) 652.

ed

an

Jersey, 2012, pp. 364.

us

cr

ip t

Page 19 of 21

314 315 316 317 318 319 320 321 322 323

Graphical abstract Highlights A highly selective and sensitive IC method was developed and validated.

Only a single valve and cation-trapping column were used for condition optimization. 20 amino acids and 7 sugars were separated simultaneously without co-elution.

The method was applied to the medium of clostridium thermocellum successfully. The work built a new analysis platform for water-soluble metabolites.

20

Ac ce

pt

ed

an

Page 20 of 21

us

cr

ip t

Ac ce pt e d M an us cr

ip

Page 21 of 21

Das könnte Ihnen auch gefallen

- We M10Dokument2 SeitenWe M10Vivek SNoch keine Bewertungen

- Journal of CO Utilization: Pedro Sa Nchez-Camacho, Issis C. Romero-Ibarra, Heriberto PfeifferDokument7 SeitenJournal of CO Utilization: Pedro Sa Nchez-Camacho, Issis C. Romero-Ibarra, Heriberto PfeifferYsabel Huaccallo AguilarNoch keine Bewertungen

- 1 s2.0 S0306454913003332 MainDokument19 Seiten1 s2.0 S0306454913003332 MainYsabel Huaccallo AguilarNoch keine Bewertungen

- Synthesis of Schiff Bases by Aromatic Amine Condensation With 3,3 - Bithiophenes-2,2 and 4,4 - DicarbaldehydesDokument5 SeitenSynthesis of Schiff Bases by Aromatic Amine Condensation With 3,3 - Bithiophenes-2,2 and 4,4 - DicarbaldehydesYsabel Huaccallo AguilarNoch keine Bewertungen

- Systematics of Metal-Insulator Interfacial Energies: A New Rule For Wetfing and Strong Catalyst-Support InteractionsDokument11 SeitenSystematics of Metal-Insulator Interfacial Energies: A New Rule For Wetfing and Strong Catalyst-Support InteractionsYsabel Huaccallo AguilarNoch keine Bewertungen

- THE Particles On Graphite: Motions of IronDokument7 SeitenTHE Particles On Graphite: Motions of IronYsabel Huaccallo AguilarNoch keine Bewertungen

- Analytical BiochemistryDokument8 SeitenAnalytical BiochemistryYsabel Huaccallo AguilarNoch keine Bewertungen

- Refinement of A Radioreceptor Binding Assay For Nicotinic Acid Adenine Dinucleotide PhosphateDokument11 SeitenRefinement of A Radioreceptor Binding Assay For Nicotinic Acid Adenine Dinucleotide PhosphateYsabel Huaccallo AguilarNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 11 Iajps11072017Dokument7 Seiten11 Iajps11072017Baru Chandrasekhar RaoNoch keine Bewertungen

- 11.drug StudyDokument1 Seite11.drug StudyFreisanChenMandumotanNoch keine Bewertungen

- CE4105 Surface Production Operations: Operasi Produksi Permukaan Hidrokarbon / Operasi Hulu Minyak Dan GasDokument41 SeitenCE4105 Surface Production Operations: Operasi Produksi Permukaan Hidrokarbon / Operasi Hulu Minyak Dan GasRickyWisaksonoNoch keine Bewertungen

- Oxidation and Reduction Reactions in Organic ChemistryDokument9 SeitenOxidation and Reduction Reactions in Organic ChemistryTarun Lfc Gerrard100% (1)

- Rework Procedure For Bga ModulesDokument8 SeitenRework Procedure For Bga ModulesexwilliamNoch keine Bewertungen

- Nta Abhyas Test-65 CDokument5 SeitenNta Abhyas Test-65 CMIITY EDUNoch keine Bewertungen

- Heavy Metal - Metalsorb eDokument4 SeitenHeavy Metal - Metalsorb ehclpmNoch keine Bewertungen

- Evaporation Rate of Solvents PDFDokument2 SeitenEvaporation Rate of Solvents PDFsyamlokNoch keine Bewertungen

- Ras Al Khaimah Cement CompanyDokument351 SeitenRas Al Khaimah Cement CompanyHerwin NavarreteNoch keine Bewertungen

- Reference Only: I Pus Pond StreetDokument132 SeitenReference Only: I Pus Pond StreetJagdish ShindeNoch keine Bewertungen

- Industrial Crops & Products: SciencedirectDokument8 SeitenIndustrial Crops & Products: SciencedirectJyotsana DwivediNoch keine Bewertungen

- Radioactive Contamination at The Jana Elementary School Hazelwood MODokument26 SeitenRadioactive Contamination at The Jana Elementary School Hazelwood MOArmi EasterbyNoch keine Bewertungen

- SigmazincDokument8 SeitenSigmazincHaresh BhavnaniNoch keine Bewertungen

- Protons, Neutrons, and Electrons Practice WorksheetDokument3 SeitenProtons, Neutrons, and Electrons Practice WorksheetAnthony Gio L. AndayaNoch keine Bewertungen

- Bs en 357 - 2004 Glass-Frp ClassDokument16 SeitenBs en 357 - 2004 Glass-Frp ClassKwong chi hoNoch keine Bewertungen

- Stepan Pol Ps 2352Dokument2 SeitenStepan Pol Ps 2352A MahmoodNoch keine Bewertungen

- Proposed OS&E Requirement - Measuring Ozone DosageDokument3 SeitenProposed OS&E Requirement - Measuring Ozone DosageProteina QuitinaseNoch keine Bewertungen

- Teflon Industrial Bakeware Brochure PDFDokument8 SeitenTeflon Industrial Bakeware Brochure PDFKNoch keine Bewertungen

- RNA Structure, Functions WebDokument25 SeitenRNA Structure, Functions WebEmad ManniNoch keine Bewertungen

- Project Report Final-1Dokument33 SeitenProject Report Final-1Sahil ChelatNoch keine Bewertungen

- FDA-356h 508 (6.14)Dokument3 SeitenFDA-356h 508 (6.14)sailaja_493968487Noch keine Bewertungen

- AsdDokument3 SeitenAsdMuStafaAbbasNoch keine Bewertungen

- Kaowool Board Low Temperature PDFDokument2 SeitenKaowool Board Low Temperature PDFmaxibarrios72Noch keine Bewertungen

- Bab 4 ObjektifDokument9 SeitenBab 4 ObjektifFida NordinNoch keine Bewertungen

- Gas Practice QuestionsDokument6 SeitenGas Practice QuestionsJames DellavaNoch keine Bewertungen

- ESAB Welding & Cu Ing Products: A515 516 4 In. Thick 2 In. Root GapDokument1 SeiteESAB Welding & Cu Ing Products: A515 516 4 In. Thick 2 In. Root Gapalok987Noch keine Bewertungen

- Clay Notes (4th Sem)Dokument21 SeitenClay Notes (4th Sem)SamNoch keine Bewertungen

- Back To Basics ... : Material Selection and Heat TreatmentDokument8 SeitenBack To Basics ... : Material Selection and Heat TreatmentMuhammad Faisal FirdausNoch keine Bewertungen

- Major Intermediates in Organophosphate Synthesis (PCL, Pocl, PSCL, and Their Diethyl Esters) Are Anticholinesterase Agents Directly or On ActivationDokument7 SeitenMajor Intermediates in Organophosphate Synthesis (PCL, Pocl, PSCL, and Their Diethyl Esters) Are Anticholinesterase Agents Directly or On ActivationYancy JuanNoch keine Bewertungen

- Heat Capacity Lab ReportDokument8 SeitenHeat Capacity Lab ReportLiHong Khaw100% (1)