Beruflich Dokumente

Kultur Dokumente

Rheological Methods in Food Process Engineering (2nd Edition)

Hochgeladen von

jmprtaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Rheological Methods in Food Process Engineering (2nd Edition)

Hochgeladen von

jmprtaCopyright:

Verfügbare Formate

RHEOLOGICAL METHODS IN

FOOD PROCESS ENGINEERING

Second Edition

Jame s F. St e ffe , Ph. D. , P. E.

Professor of Food Process Engineering

Dept. of Food Science and Human Nutrition

Dept. of Agricultural Engineering

Michigan State University

Fre e man Pre s s

2807 Still Valley Dr.

East Lansing, MI 48823

USA

Prof. James F. Steffe

209 Farrall Hall

Michigan State University

East Lansing, MI 48824-1323

USA

Phone: 517-353-4544

FAX: 517-432-2892

E-mail: steffe@msu.edu

URL: www.egr.msu.edu/~steffe/

Copyright 1992, 1996 by James F. Steffe.

All rights reserved. No part of this work may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any

means, electronic, mechanical, photocopying, recording, or other-

wise, without the prior written permission of the author.

Printed on acid-free paper in the United States of America

Second Printing

Library of Congress Catalog Card Number: 96-83538

International Standard Book Number: 0-9632036-1-4

Fre e man Pre s s

2807 Still Valley Dr.

East Lansing, MI 48823

USA

Table of Cont e nt s

Preface ix

Chapter 1. Introduction to Rheology 1

1.1. Overview ...................................................................................... 1

1.2. Rheological Instruments for Fluids .......................................... 2

1.3. Stress and Strain .......................................................................... 4

1.4. Solid Behavior ............................................................................. 8

1.5. Fluid Behavior in Steady Shear Flow ....................................... 13

1.5.1. Time-Independent Material Functions ............................ 13

1.5.2. Time-Dependent Material Functions ............................... 27

1.5.3. Modeling Rheological Behavior of Fluids ....................... 32

1.6. Yield Stress Phenomena ............................................................. 35

1.7. Extensional Flow ......................................................................... 39

1.8. Viscoelastic Material Functions ................................................ 47

1.9. Attacking Problems in Rheological Testing ............................ 49

1.10. Interfacial Rheology ................................................................. 53

1.11. Electrorheology ......................................................................... 55

1.12. Viscometers for Process Control and Monitoring ................ 57

1.13. Empirical Measurement Methods for Foods ........................ 63

1.14. Example Problems .................................................................... 77

1.14.1. Carrageenan Gum Solution ............................................. 77

1.14.2. Concentrated Corn Starch Solution ................................ 79

1.14.3. Milk Chocolate .................................................................. 81

1.14.4. Falling Ball Viscometer for Honey ................................. 82

1.14.5. Orange Juice Concentrate ................................................ 86

1.14.6. Influence of the Yield Stress in Coating Food ............... 91

Chapter 2. Tube Viscometry 94

2.1. Introduction ................................................................................. 94

2.2. Rabinowitsch-Mooney Equation .............................................. 97

2.3. Laminar Flow Velocity Profiles ................................................ 103

2.4. Laminar Flow Criteria ................................................................ 107

2.5. Data Corrections ......................................................................... 110

2.6. Yield Stress Evaluation .............................................................. 121

2.7. Jet Expansion ............................................................................... 121

2.8. Slit Viscometry ............................................................................ 122

2.9. Glass Capillary (U-Tube) Viscometers .................................... 125

2.10. Pipeline Design Calculations .................................................. 128

2.11. Velocity Profiles In Turbulent Flow ....................................... 138

2.12. Example Problems .................................................................... 141

2.12.1. Conservation of Momentum Equations ........................ 141

2.12.2. Capillary Viscometry - Soy Dough ................................ 143

2.12.3. Tube Viscometry - 1.5% CMC ......................................... 146

2.12.4. Casson Model: Flow Rate Equation ............................... 149

2.12.5. Slit Viscometry - Corn Syrup .......................................... 150

2.12.6. Friction Losses in Pumping ............................................. 152

2.12.7. Turbulent Flow - Newtonian Fluid ................................ 155

2.12.8. Turbulent Flow - Power Law Fluid ................................ 156

v

Chapter 3. Rotational Viscometry 158

3.1. Introduction ................................................................................. 158

3.2. Concentric Cylinder Viscometry .............................................. 158

3.2.1. Derivation of the Basic Equation ...................................... 158

3.2.2. Shear Rate Calculations ...................................................... 163

3.2.3. Finite Bob in an Infinite Cup ............................................. 168

3.3. Cone and Plate Viscometry ....................................................... 169

3.4. Parallel Plate Viscometry (Torsional Flow) ............................ 172

3.5. Corrections: Concentric Cylinder ............................................. 174

3.6. Corrections: Cone and Plate, and Parallel Plate ..................... 182

3.7. Mixer Viscometry ....................................................................... 185

3.7.1. Mixer Viscometry: Power Law Fluids ............................. 190

3.7.2. Mixer Viscometry: Bingham Plastic Fluids ..................... 199

3.7.3. Yield Stress Calculation: Vane Method ........................... 200

3.7.4. Investigating Rheomalaxis ................................................ 208

3.7.5. Defining An Effective Viscosity ........................................ 210

3.8. Example Problems ...................................................................... 210

3.8.1. Bob Speed for a Bingham Plastic Fluid ............................ 210

3.8.2. Simple Shear in Power Law Fluids .................................. 212

3.8.3. Newtonian Fluid in a Concentric Cylinder ..................... 213

3.8.4. Representative (Average) Shear Rate .............................. 214

3.8.5. Concentric Cylinder Viscometer: Power Law Fluid ...... 216

3.8.6. Concentric Cylinder Data - Tomato Ketchup ................. 218

3.8.7. Infinite Cup - Single Point Test ......................................... 221

3.8.8. Infinite Cup Approximation - Power Law Fluid ........... 221

3.8.9. Infinite Cup - Salad Dressing ............................................ 223

3.8.10. Infinite Cup - Yield Stress Materials .............................. 225

3.8.11. Cone and Plate - Speed and Torque Range ................... 226

3.8.12. Cone and Plate - Salad Dressing ..................................... 227

3.8.13. Parallel Plate - Methylcellulose Solution ....................... 229

3.8.14. End Effect Calculation for a Cylindrical Bob ................ 231

3.8.15. Bob Angle for a Mooney-Couette Viscometer .............. 233

3.8.16. Viscous Heating ................................................................ 235

3.8.17. Cavitation in Concentric Cylinder Systems .................. 236

3.8.18. Mixer Viscometry .............................................................. 237

3.8.19. Vane Method - Sizing the Viscometer ........................... 243

3.8.20. Vane Method to Find Yield Stresses .............................. 244

3.8.21. Vane Rotation in Yield Stress Calculation .................... 247

3.8.22. Rheomalaxis from Mixer Viscometer Data ................... 250

Chapter 4. Extensional Flow 255

4.1. Introduction ................................................................................. 255

4.2. Uniaxial Extension ...................................................................... 255

4.3. Biaxial Extension ......................................................................... 258

4.4. Flow Through a Converging Die .............................................. 263

4.4.1. Cogswells Equations ......................................................... 264

4.4.2. Gibsons Equations ............................................................. 268

4.4.3. Empirical Method ............................................................... 271

4.5. Opposing Jets .............................................................................. 272

4.6. Spinning ....................................................................................... 274

4.7. Tubeless Siphon (Fano Flow) .................................................... 276

vi

4.8. Steady Shear Properties from Squeezing Flow Data ............. 276

4.8.1. Lubricated Squeezing Flow ............................................... 277

4.8.2. Nonlubricated Squeezing Flow ........................................ 279

4.9. Example Problems ...................................................................... 283

4.9.1. Biaxial Extension of Processed Cheese Spread ............... 283

4.9.2. Biaxial Extension of Butter ................................................ 286

4.9.3. 45 Converging Die, Cogswells Method ........................ 287

4.9.4. 45 Converging Die, Gibsons Method ............................ 289

4.9.5. Lubricated Squeezing Flow of Peanut Butter ................. 291

Chapter 5. Viscoelasticity 294

5.1. Introduction ................................................................................. 294

5.2. Transient Tests for Viscoelasticity ............................................ 297

5.2.1. Mechanical Analogues ....................................................... 298

5.2.2. Step Strain (Stress Relaxation) .......................................... 299

5.2.3. Creep and Recovery ........................................................... 304

5.2.4. Start-Up Flow (Stress Overshoot) ..................................... 310

5.3. Oscillatory Testing ...................................................................... 312

5.4. Typical Oscillatory Data ............................................................ 324

5.5. Deborah Number ........................................................................ 332

5.6. Experimental Difficulties in Oscillatory Testing of Food ..... 336

5.7. Viscometric and Linear Viscoelastic Functions ...................... 338

5.8. Example Problems ...................................................................... 341

5.8.1. Generalized Maxwell Model of Stress Relaxation ........ 341

5.8.2. Linearized Stress Relaxation ............................................. 342

5.8.3. Analysis of Creep Compliance Data ................................ 343

5.8.4. Plotting Oscillatory Data ................................................... 348

6. Appendices 350

6.1. Conversion Factors and SI Prefixes .......................................... 350

6.2. Greek Alphabet ........................................................................... 351

6.3. Mathematics: Roots, Powers, and Logarithms ....................... 352

6.4. Linear Regression Analysis of Two Variables ........................ 353

6.5. Hookean Properties .................................................................... 357

6.6. Steady Shear and Normal Stress Difference ........................... 358

6.7. Yield Stress of Fluid Foods ........................................................ 359

6.8. Newtonian Fluids ....................................................................... 361

6.9. Dairy, Fish and Meat Products ................................................. 366

6.10. Oils and Miscellaneous Products ........................................... 367

6.11. Fruit and Vegetable Products ................................................. 368

6.12. Polymer Melts ........................................................................... 371

6.13. Cosmetic and Toiletry Products ............................................. 372

6.14. Energy of Activation for Flow for Fluid Foods .................... 374

6.15. Extensional Viscosities of Newtonian Fluids ........................ 375

6.16. Extensional Viscosities of Non-Newtonian Fluids .............. 376

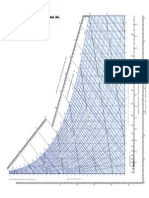

6.17. Fanning Friction Factors: Bingham Plastics .......................... 377

6.18. Fanning Friction Factors: Power Law Fluids ........................ 378

6.19. Creep (Burgers Model) of Salad Dressing ............................. 379

6.20. Oscillatory Data for Butter ...................................................... 380

6.21. Oscillatory Data Iota-Carrageenan Gel ................................. 381

6.22. Storage and Loss Moduli of Fluid Foods .............................. 382

vii

Nomenclature ......................................................................................... 385

Bibliography ........................................................................................... 393

Index ......................................................................................................... 412

viii

Pre fac e

Growth and devel opment of thi s work sprang from the need to

provi de educati onal materi al for food engi neers and food sci enti sts. The

fi rst edi ti on was concei ved as a textbook and the work conti nues to be

used i n graduate l evel courses at vari ous uni versi ti es. I ts greatest

appeal , however, was to i ndi vi dual s sol vi ng practi cal day-to-day prob-

l ems. Hence, the second edi ti on, a si gni fi cantl y expanded and revi sed

versi on of the ori gi nal work, i s ai med pri mari l y at the rheol ogi cal

practi ti oner (parti cul arl y the i ndustri al practi ti oner) seeki ng a broad

understandi ng of the subject matter. The overal l goal of the text i s to

present the i nformati on needed to answer three questi ons when faci ng

probl ems i n food rheol ogy: 1. What properti es shoul d be measured? 2.

What type and degree of deformati on shoul d be i nduced i n the mea-

surement? 3. How shoul d experi mental data be anal yzed to generate

practi cal i nformati on? Al though the mai n focus of the book i s food,

sci enti sts and engi neers i n other fi el ds wi l l fi nd the work a conveni ent

reference for standard rheol ogi cal methods and typi cal data.

Overal l , the work presents the theory of rheol ogi cal testi ng and

provi des the anal yti cal tool s needed to determi ne rheol ogi cal properti es

from experi mental data. Methods appropri ate for common food i ndustry

appl i cati ons are presented. Al l standard measurement techni ques for

fl ui d and semi -sol i d foods are i ncl uded. Sel ected methods for sol i ds are

al so presented. Resul ts from numerous fi el ds, parti cul arl y pol ymer

rheol ogy, are used to address the fl ow behavi or of food. Mathemati cal

rel ati onshi ps, deri ved from si mpl e force bal ances, provi de a funda-

mental vi ew of rheol ogi cal testi ng. Onl y a background i n basi c cal cul us

and el ementary stati sti cs (mai nl y regressi on anal ysi s) i s needed to

understand the materi al . The text contai ns numerous practi cal exampl e

probl ems, i nvol vi ng actual experi mental data, to enhance comprehen-

si on and the executi on of concepts presented. Thi s feature makes the

work conveni ent for sel f-study.

Speci fi c expl anati ons of key topi cs i n rheol ogy are presented i n

Chapter 1: basi c concepts of stress and strai n; el asti c sol i ds showi ng

Hookean and non-Hookean behavi or; vi scometri c functi ons i ncl udi ng

normal stress di fferences; model i ng fl ui d behavi or as a functi on of shear

rate, temperature, and composi ti on; yi el d stress phenomena, exten-

si onal fl ow; and vi scoel asti c behavi or. Effi ci ent methods of attacki ng

probl ems and typi cal i nstruments used to measure fl ui d properti es are

di scussed al ong wi th an exami nati on of probl ems i nvol vi ng i nterfaci al

ix

rheol ogy, el ectrorheol ogy, and on-l i ne vi scometry for control and mon-

i tori ng of food processi ng operati ons. Common methods and empi ri cal

i nstruments uti l i zed i n the food i ndustry are al so i ntroduced: Texture

Profi l e Anal ysi s, Compressi on-Extrusi on Cel l , Warner-Bratzl er Shear

Cel l , Bostwi ck Consi stometer, Adams Consi stometer, Amyl ograph,

Fari nograph, Mi xograph, Extensi graph, Al veograph, Kramer Shear

Cel l , Brookfi el d di sks and T-bars, Cone Penetrometer, Hoeppl er Vi s-

cometer, Zhan Vi scometer, Brabender-FMC Consi stometer.

The basi c equati ons of tube (or capi l l ary) vi scometry, such as the

Rabi nowi tsch-Mooney equati on, are deri ved and appl i ed i n Chapter 2.

Lami nar fl ow cri teri a and vel oci ty profi l es are eval uated al ong wi th data

correcti on methods for many sources of error: ki neti c energy l osses, end

effects, sl i p (wal l effects), vi scous heati ng, and hol e pressure. Tech-

ni ques for gl ass capi l l ary and sl i t vi scometers are consi dered i n detai l .

A secti on on pi pel i ne desi gn cal cul ati ons has been i ncl uded to faci l i tate

the constructi on of l arge scal e tube vi scometers and the desi gn of fl ui d

pumpi ng systems.

A general format, anal ogous to that used i n Chapter 2, i s conti nued

i n Chapter 3 to provi de conti nui ty i n subject matter devel opment. The

mai n foci of the chapter center around the theoreti cal pri nci pl es and

experi mental procedures rel ated to three tradi ti onal types of rotati onal

vi scometers: concentri c cyl i nder, cone and pl ate, and paral l el pl ate.

Mathemati cal anal yses of data are di scussed i n detai l . Errors due to

end effects, vi scous heati ng, sl i p, Tayl or vorti ces, cavi tati on, and cone

truncati ons are i nvesti gated. Numerous methods i n mi xer vi scometry,

techni ques havi ng si gni fi cant potenti al to sol ve many food rheol ogy

probl ems, are al so presented: sl ope and matchi ng vi scosi ty methods to

eval uate average shear rate, determi nati on of power l aw and Bi ngham

pl asti c fl ui d properti es. The vane method of yi el d stress eval uati on,

usi ng both the sl ope and si ngl e poi nt methods, al ong wi th a consi der-

ati on of vane rotati on duri ng testi ng, i s expl ored i n detai l .

The experi mental methods to determi ne extensi onal vi scosi ty are

expl ai ned i n Chapter 4. Techni ques presented i nvol ve uni axi al exten-

si on between rotati ng cl amps, bi axi al extensi onal fl ow achi eved by

squeezi ng materi al between l ubri cated paral l el pl ates, opposi ng jets,

spi nni ng, and tubel ess si phon (Fano) fl ow. Rel ated procedures,

i nvol vi ng l ubri cated and nonl ubri cated squeezi ng, to determi ne shear

fl ow behavi or are al sopresented. Cal cul ati ng extensi onal vi scosi ty from

fl ows through tapered convergences and fl at entry di es i s gi ven a

thorough exami nati on.

x

Essenti al concepts i n vi scoel asti ci ty and standard methods of

i nvesti gati ng the phenomenon are i nvesti gated i n Chapter 5. The ful l

scope of vi scoel asti c materi al functi ons determi ned i n transi ent and

osci l l atory testi ng are di scussed. Mechani cal anal ogues of rheol ogi cal

behavi or are gi ven as a means of anal yzi ng creep and stress rel axati on

data. Theoreti cal aspects of osci l l atory testi ng, typi cal data, and a

di scussi on of the vari ous modes of operati ng commerci al i nstruments

-strai n, frequency, ti me, and temperature sweep modes- are presented.

The Deborah number concept, and how i t can be used to di sti ngui sh

l i qui d from sol i d-l i ke behavi or, i s i ntroduced. Start-up fl ow (stress

overshoot) and the rel ati onshi p between steady shear and osci l l atory

properti es are al so di scussed. Conversi on factors, mathemati cal rel a-

ti onshi ps, l i near regressi on anal ysi s, and typi cal rheol ogi cal data for

food as wel l as cosmeti cs and pol ymers are provi ded i n the Appendi ces.

Nomencl ature i s conveni entl y summari zed at the end of the text and a

l arge bi bl i ography i s furni shed to di rect readers to addi ti onal i nfor-

mati on.

J.F. Steffe

June, 1996

xi

De dic at ion

To Susan, Justi nn, and Dana.

xiii

Chapt e r 1 . Int roduc t ion t o Rhe ology

1.1. Overview

The fi rst use of the word "rheol ogy"i s credi ted toEugene C. Bi ngham

(ci rca 1928) who al so descri bed the motto of the subject as

("panta rhei ," from the works of Heracl i tus, a pre-Socrati c Greek phi -

l osopher acti ve about 500 B.C.) meani ng "everythi ng fl ows" (Rei ner,

1964). Rheol ogy i s now wel l establ i shed as the sci ence of the deformati on

and fl ow of matter: I t i s the study of the manner i n whi ch materi al s

respond to appl i ed stress or strai n. Al l materi al s have rheol ogi cal

properti es and the area i s rel evant i n many fi el ds of study: geol ogy and

mi ni ng (Cri stescu, 1989), concrete technol ogy (Tattersal l and Banfi l l ,

1983), soi l mechani cs (Haghi ghi et al ., 1987; Vyal ov, 1986), pl asti cs

processi ng (Deal y and Wi ssburn, 1990), pol ymers and composi tes

(Nei l sen and Landel , 1994; Yanovsky, 1993), tri bol ogy (study of l ubri -

cati on, fri cti on and wear), pai nt fl ow and pi gment di spersi on (Patton,

1964), bl ood (Di ntenfass, 1985), bi oengi neeri ng (Skal ak and Chi en,

1987), i nterfaci al rheol ogy (Edwards et al ., 1991), structural materi al s

(Cal l i ster, 1991), el ectrorheol ogy (Bl ock and Kel l y, 1988), psychor-

heol ogy (Drake, 1987), cosmeti cs and toi l etri es (Laba, 1993b), and

pressure sensi ti ve adhesi on (Saunders et al ., 1992). The focus of thi s

work i s food where understandi ng rheol ogy i s cri ti cal i n opti mi zi ng

product devel opment efforts, processi ng methodol ogy and fi nal product

qual i ty. To the extent possi bl e, standard nomencl ature (Deal y, 1994)

has been used i n the text.

One can thi nk of food rheol ogy as the materi al sci ence of food. There

are numerous areas where rheol ogi cal data are needed i n the food

i ndustry:

a. Process engi neeri ng cal cul ati ons i nvol vi ng a wi de range of equi p-

ment such as pi pel i nes, pumps, extruders, mi xers, coaters, heat

exchangers, homogeni zers, cal enders, and on-l i ne vi scometers;

b. Determi ni ng i ngredi ent functi onal i ty i n product devel opment;

c. I ntermedi ate or fi nal product qual i ty control ;

d. Shel f l i fe testi ng;

e. Eval uati on of food texture by correl ati on to sensory data;

f. Anal ysi s of rheol ogi cal equati ons of state or consti tuti ve equati ons.

Many of the uni que rheol ogi cal properti es of vari ous foods have been

summari zed i n books by Raoand Steffe (1992), and Wei pert et al . (1993).

2 Chapter 1. Introduction to Rheology

Fundamental rheol ogi cal properti es are i ndependent of the i nstru-

ment on whi ch they are measured so di fferent i nstruments wi l l yi el d

the same resul ts. Thi s i s an i deal concept and di fferent i nstruments

rarel y yi el d i denti cal resul ts; however, the i dea i s one whi ch di sti n-

gui shes true rheol ogi cal materi al properti es from subjecti ve (empi ri cal

and general l y i nstrument dependent, though frequentl y useful )

materi al characteri zati ons. Exampl es of i nstruments gi vi ng subjecti ve

resul ts i ncl ude the fol l owi ng (Bourne, 1982): Fari nograph, Mi xograph,

Extensograph, Vi scoaml yograph, and the Bostwi ck Consi stometer.

Empi ri cal testi ng devi ces and methods, i ncl udi ng Texture Profi l e

Anal ysi s, are consi dered i n more detai l i n Sec. 1.13.

1.2. Rheological Instruments for Fluids

Common i nstruments, capabl e of measuri ng fundamental rheol og-

i cal properti es of fl ui d and semi -sol i d foods, may be pl aced i nto two

general categori es (Fi g. 1.1): rotati onal type and tube type. Most are

commerci al l y avai l abl e, others (mi xer and pi pe vi scometers) are easi l y

fabri cated. Costs vary tremendousl y from the i nexpensi ve gl ass capi l -

l ary vi scometer to a very expensi ve rotati onal i nstrument capabl e of

measuri ng dynami c properti es and normal stress di fferences. Sol i d

foods are often tested i n compressi on (between paral l el pl ates), tensi on,

or torsi on. I nstruments whi ch measure rheol ogi cal properti es are cal l ed

rheometers. Vi scometer i s a more l i mi ti ng term referri ng to devi ces

that onl y measure vi scosi ty.

Rotati onal i nstruments may be operated i n the steady shear (con-

stant angul ar vel oci ty) or osci l l atory (dynami c) mode. Some rotati onal

i nstruments functi on i n the control l ed stress mode faci l i tati ng the

col l ecti on of creep data, the anal ysi s of materi al s at very l ow shear rates,

and the i nvesti gati on of yi el d stresses. Thi s i nformati on i s needed to

understand the i nternal structure of materi al s. The control l ed rate

mode i s most useful i n obtai ni ng data requi red i n process engi neeri ng

cal cul ati ons. Mechani cal di fferences between control l ed rate and con-

trol l ed stress i nstruments are di scussed i n Sec. 3.7.3. Rotati onal sys-

tems are general l y used toi nvesti gate ti me-dependent behavi or because

tube systems onl y al l ow one pass of the materi al through the apparatus.

A detai l ed di scussi on of osci l l atory testi ng, the pri mary method of

determi ni ng the vi scoel asti c behavi or of food, i s provi ded i n Chapter 5.

1.2 Rheological Instruments for Fluids 3

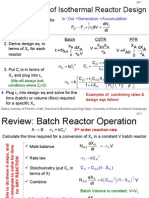

Figure 1.1. Common rheological instruments divided into two major categories:

rotational and tube type.

There are advantages and di sadvantages associ ated wi th each

i nstrument. Gravi ty operated gl ass capi l l ari es, such as the Cannon-

Fenske type shown i n Fi g. 1.1, are onl y sui tabl e for Newtoni an fl ui ds

because the shear rate vari es duri ng di scharge. Cone and pl ate systems

are l i mi ted to moderate shear rates but cal cul ati ons (for smal l cone

angl es) are si mpl e. Pi pe and mi xer vi scometers can handl e much l arger

parti cl es than cone and pl ate, or paral l el pl ate, devi ces. Probl ems

associ ated wi th sl i p and degradati on i n structural l y sensi ti ve materi al s

are mi ni mi zed wi th mi xer vi scometers. Hi gh pressure capi l l ari es

operate at hi gh shear rates but general l y i nvol ve a si gni fi cant end

pressure correcti on. Pi pe vi scometers can be constructed to wi thstand

the ri gors of the producti on or pi l ot pl ant envi ronment.

Rotational Type

Parallel Plate Cone and Plate

Concentric Cylinder

Mixer

Tube Type

Pipe Glass Capillary High Pressure Capillary

4 Chapter 1. Introduction to Rheology

Al l the i nstruments presented i n Fi g. 1.1 are "vol ume l oaded"devi ces

wi th contai ner di mensi ons that are cri ti cal i n the determi nati on of

rheol ogi cal properti es. Another common type of i nstrument, known as

a vi brati onal vi scometer, uses the pri nci pl e of "surface l oadi ng"where

the surface of an i mmersed probe (usual l y a sphere or a rod) generates

a shear wave whi ch di ssi pates i n the surroundi ng medi um. A l arge

enough contai ner i s used soshear forces donot reach the wal l and refl ect

back to the probe. Measurements depend onl y on abi l i ty of the sur-

roundi ng fl ui d to damp probe vi brati on. The dampi ng characteri sti c of

a fl ui d i s a functi on of the product of the fl ui d vi scosi ty (of Newtoni an

fl ui ds) and the densi ty. Vi brati onal vi scometers are popul ar as i n-l i ne

i nstruments for process control systems (see Sec. 1.12). I t i s di ffi cul t to

use these uni ts to eval uate fundamental rheol ogi cal properti es of non-

Newtoni an fl ui ds (Ferry, 1977), but the subjecti ve resul ts obtai ned often

correl ate wel l wi th i mportant food qual i ty attri butes. The coagul ati on

ti me and curd fi rmness of renneted mi l k, for exampl e, have been suc-

cessful l y i nvesti gated usi ng a vi brati onal vi scometer (Sharma et al .,

1989).

I nstruments used to eval uate the extensi onal vi scosi ty of materi al s

are di scussed i n Chapter 4. Pul l i ng or stretchi ng a sampl e between

toothed gears, sucki ng materi al i nto opposi ng jets, spi nni ng, or

expl oi ti ng the open si phon phenomenon can generate data for cal cu-

l ati ng tensi l e extensi onal vi scosi ty. I nformati on to determi ne bi axi al

extensi onal vi scosi ty i s provi ded by compressi ng sampl es between

l ubri cated paral l el pl ates. Shear vi scosi ty can al so be eval uated from

unl ubri cated squeezi ng fl ow between paral l el pl ates. A number of

methods are avai l abl e tocal cul ate an average extensi onal vi scosi ty from

data descri bi ng fl ow through a convergence i nto a capi l l ary di e or sl i t.

1.3. Stress and Strain

Si nce rheol ogy i s the study of the deformati on of matter, i t i s essenti al

to have a good understandi ng of stress and strai n. Consi der a rectan-

gul ar bar that, due to a tensi l e force, i s sl i ghtl y el ongated (Fi g. 1.2). The

i ni ti al l ength of the bar i s and the el ongated l ength i s where

wi th representi ng the i ncrease i n l ength. Thi s deformati on

may be thought of i n terms of Cauchy strai n (al so cal l ed engi neeri ng

strai n):

L

o

L

L L

o

+ L L

1.3 Stress and Strain 5

[1.1]

or Hencky strai n (al so cal l ed true strai n) whi ch i s determi ned by

eval uati ng an i ntegral from to :

[1.2]

Figure 1.2. Linear extension of a rectangular bar.

Cauchy and Hencky strai ns are both zero when the materi al i s

unstrai ned and approxi matel y equal at smal l strai ns. The choi ce of

whi ch strai n measure to use i s l argel y a matter of conveni ence and one

can be cal cul ated from the other:

[1.3]

i s preferred for cal cul ati ng strai n resul ti ng from a l arge deformati on.

Another type of deformati on commonl y found i n rheol ogy i s si mpl e

shear. The i dea can be i l l ustrated wi th a rectangul ar bar (Fi g. 1.3) of

hei ght . The l ower surface i s stati onary and the upper pl ate i s l i nearl y

di spl aced by an amount equal to . Each el ement i s subject to the same

l evel of deformati on so the si ze of the el ement i s not rel evant. The angl e

of shear, , may be cal cul ated as

c

L

L

o

L L

o

L

o

L

L

o

1

L

o

L

L

o

L

dL

L

ln(L/L

o

)

L L

0

h

ln(1 +

c

)

h

h

L

6 Chapter 1. Introduction to Rheology

[1.4]

Wi th smal l deformati ons, the angl e of shear (i n radi ans) i s equal to the

shear strai n (al so symbol i zed by ), .

Figure 1.3. Shear deformation of a rectangular bar.

Figure 1.4. Typical stresses on a material element.

Stress, defi ned as a force per uni t area and usual l y expressed i n

Pascal (N/m

2

), may be tensi l e, compressi ve, or shear. Ni ne separate

quanti ti es are requi red to compl etel y descri be the state of stress i n a

materi al . A smal l el ement (Fi g. 1.4) may be consi dered i n terms of

tan()

L

h

tan

h

L

11

21

23

22

33

1

2

3

x

x

x

1.3 Stress and Strain 7

Cartesi an coordi nates ( ). Stress i s i ndi cated as where the fi rst

subscri pt refers to the ori entati on of the face upon whi ch the force acts

and the second subscri pt refers to the di recti on of the force. Therefore,

i s a normal stress acti ng i n the pl ane perpendi cul ar to i n the

di recti on of and i s a shear stress acti ng i n the pl ane perpendi cul ar

to i n the di recti on of . Normal stresses are consi dered posi ti ve when

they act outward (acti ng to create a tensi l e stress) and negati ve when

they act i nward (acti ng to create a compressi ve stress).

Stress components may be summari zed as a stress tensor wri tten

i n the form of a matri x:

[1.5]

A rel ated tensor for strai n can al so be expressed i n matri x form. Basi c

l aws of mechani cs, consi deri ng the moment about the axi s under

equi l i bri um condi ti ons, can be used to prove that the stress matri x i s

symmetri cal :

[1.6]

so

[1.7]

[1.8]

[1.9]

meani ng there are onl y si x i ndependent components i n the stress tensor

represented by Eq. [1.5].

Equati ons that show the rel ati onshi p between stress and strai n are

ei ther cal l ed rheol ogi cal equati ons of state or consti tuti ve equati ons. I n

compl ex materi al s these equati ons may i ncl ude other vari abl es such as

ti me, temperature, and pressure. A modul us i s defi ned as the rati o of

stress to strai n whi l e a compl i ance i s defi ned as the rati o of strai n to

stress. The word rheogram refers toa graph of a rheol ogi cal rel ati onshi p.

x

1

, x

2

, x

3

ij

11

x

1

x

1

23

x

2

x

3

ij

11

12

13

21

22

23

31

32

33

1

1

1

1

]

ij

ji

12

21

31

13

32

23

8 Chapter 1. Introduction to Rheology

1.4. Solid Behavior

When force i s appl i ed to a sol i d materi al and the resul ti ng stress

versus strai n curve i s a strai ght l i ne through the ori gi n, the materi al i s

obeyi ng Hookes l aw. The rel ati onshi p may be stated for shear stress

and shear strai n as

[1.10]

where i s the shear modul us. Hookean materi al s do not fl ow and are

l i nearl y el asti c. Stress remai ns constant unti l the strai n i s removed

and the materi al returns to i ts ori gi nal shape. Someti mes shape

recovery, though compl ete, i s del ayed by some atomi sti c process. Thi s

ti me-dependent, or del ayed, el asti c behavi or i s known as anel asti ci ty.

Hookes l aw can be used to descri be the behavi or of many sol i ds (steel ,

egg shel l , dry pasta, hard candy, etc.) when subjected to smal l strai ns,

typi cal l y l ess than 0.01. Large strai ns often produce bri ttl e fracture or

non-l i near behavi or.

The behavi or of a Hookean sol i d may be i nvesti gated by studyi ng

the uni axi al compressi on of a cyl i ndri cal sampl e (Fi g. 1.5). I f a materi al

i s compressed so that i t experi ences a change i n l ength and radi us, then

the normal stress and strai n may be cal cul ated:

[1.11]

[1.12]

Figure 1.5 Uniaxial compression of a cylindrical sample.

12

G

G

22

F

A

F

(R

o

)

2

c

h

h

o

R

h

h

o

R R

h

Initial Shape Compressed Shape

o

o

1.4 Solid Behavior 9

Thi s i nformati on can be used to determi ne Youngs modul us ( ), al so

cal l ed the modul us of el asti ci ty, of the sampl e:

[1.13]

I f the deformati ons are l arge, Hencky strai n ( ) shoul d be used to

cal cul ate strai n and the area term needed i n the stress cal cul ati on

shoul d be adjusted for the change i n radi us caused by compressi on:

[1.14]

A cri ti cal assumpti on i n these cal cul ati ons i s that the sampl e remai ns

cyl i ndri cal i n shape. For thi s reason l ubri cated contact surfaces are

often recommended when testi ng materi al s such as food gel s.

Youngs modul us may al so be determi ned by fl exural testi ng of

beams. I n one such test, a canti l ever beam of known l ength (a) i s

defl ected a di stance (d) when a force (F) i s appl i ed to the free end of the

beam. Thi s i nformati on can be used to cal cul ate Youngs modul us for

materi al s havi ng a rectangul ar or ci rcul ar crossecti onal area (Fi g. 1.6).

Si mi l ar cal cul ati ons can be performed i n a three-poi nt bendi ng test (Fi g.

1.7) where defl ecti on (d) i s measured when a materi al i s subjected to a

force (F) pl aced mi dway between two supports. Cal cul ati ons are si ghtl y

di fferent dependi ng on wether-or-not the test materi al has a rectangul ar

or ci rcul ar shape. Other si mpl e beam tests, such as the doubl e canti l ever

or four-poi nt bendi ng test, yi el d comparabl e resul ts. Fl exural testi ng

may have appl i cati on to sol i d foods havi ng a wel l defi ned geometry such

as dry pasta or hard candy.

I n addi ti on to Youngs modul us, Poi ssons rati o ( ) can be defi ned

from compressi on data (Fi g. 1.5):

[1.15]

Poi ssons rati o may range from 0 to 0.5. Typi cal l y, vari es from 0.0 for

ri gi d l i ke materi al s contai ni ng l arge amounts of ai r to near 0.5 for l i qui d

l i ke materi al s. Val ues from 0.2 to 0.5 are common for bi ol ogi cal

materi al s wi th 0.5 representi ng an i ncompressi bl e substance l i ke potato

E

E

22

22

F

(R

o

+ R)

2

lateral strain

axial strain

R/R

o

h/h

o

10 Chapter 1. Introduction to Rheology

fl esh. Ti ssues wi th a hi gh l evel of cel l ul ar gas, such as appl e fl esh, woul d

have val ues cl oser to 0.2. Metal s usual l y have Poi sson rati os between

0.25 and 0.35.

Figure 1.6 Deflection of a cantilever beam to determine Youngs modulus.

Figure 1.7 Three-point beam bending test to determine Youngs modulus (b, h,

and D are defined on Fig. 1.6).

E = 4Fa /(dbh )

E = 64Fa /(3d D )

Rectangular Crossection Circular Crossection

3 3 4 3

h

b D

d

F

a

E = Fa /(4dbh )

E = 4Fa /(3d D )

Rectangular Crossection Circular Crossection

4 3

3 3

F

d

a

1.4 Solid Behavior 11

I f a materi al i s subjected to a uni form change i n external pressure,

i t may experi ence a vol umetri c change. These quanti ti es are used to

defi ne the bul k modul us ( ):

[1.16]

The bul k modul us of dough i s approxi matel y Pa whi l e the val ue for

steel i s Pa. Another common property, bul k compressi bi l i ty, i s

defi ned as the reci procal of bul k modul us.

When two materi al constants descri bi ng the behavi or of a Hookean

sol i d are known, the other two can be cal cul ated usi ng any of the fol -

l owi ng theoreti cal rel ati onshi ps:

[1.17]

[1.18]

[1.19]

Numerous experi mental techni ques, appl i cabl e to food materi al s, may

be used to determi ne Hookean materi al constants. Methods i ncl ude

testi ng i n tensi on, compressi on and torsi on (Mohseni n, 1986; Pol a-

kowski and Ri pl i ng, 1966; Dal l y and Ri pl ey, 1965). Hookean properti es

of typi cal materi al s are presented i n the Appendi x [6.5].

Li near-el asti c and non-l i near el asti c materi al s (l i ke rubber) both

return to thei r ori gi nal shape when the strai n i s removed. Food may

be sol i d i n nature but not Hookean. A compari son of curves for l i near

el asti c (Hookean), el astopl asti c and non-l i near el asti c materi al s (Fi g.

1.8) shows a number of si mi l ari ti es and di fferences. The el astopl asti c

materi al has Hookean type behavi or bel ow the yi el d stress ( )but fl ows

to produce permanent deformati on above that val ue. Margari ne and

butter, at room temperature, may behave as el astopl asti c substances.

I nvesti gati on of thi s type of materi al , as a sol i d or a fl ui d, depends on

the shear stress bei ng above or bel ow (see Sec. 1.6 for a more detai l ed

di scussi on of the yi el d stress concept and Appendi x [6.7] for typi cal yi el d

stress val ues). Furthermore, to ful l y di sti ngui sh fl ui d from sol i d l i ke

behavi or, the characteri sti c ti me of the materi al and the characteri sti c

ti me of the deformati on process i nvol ved must be consi dered si mul ta-

K

K

change in pressure

volumetric strain

change in pressure

(change in volume/original volume)

10

6

10

11

1

E

1

3G

+

1

9K

E 3K(1 2) 2G(1 + )

3K E

6K

E 2G

2G

o

12 Chapter 1. Introduction to Rheology

neousl y. The Deborah number has been defi ned to address thi s i ssue.

A detai l ed di scussi on of the concept, i ncl udi ng an exampl e i nvol vi ng

si l l y putty (the "real sol i d-l i qui d") i s presented i n Sec. 5.5.

Figure 1.8. Deformation curves for linear elastic (Hookean), elastoplastic and

non-linear elastic materials.

Food rheol ogi sts al so fi nd the fai l ure behavi or of sol i d food (parti c-

ul arl y, bri ttl e materi al s and fi rm gel s) to be very useful because these

data someti mes correl ate wel l wi th the concl usi ons of human sensory

panel s (Hamann, 1983; Montejano et al ., 1985; Kawanari et al ., 1981).

The fol l owi ng termi nol ogy (taken from Ameri can Soci ety for Testi ng and

Materi al s, Standard E-6) i s useful i n descri bi ng the l arge deformati on

behavi or i nvol ved i n the mechani cal fai l ure of food:

el asti c l i mi t - the greatest stress whi ch a materi al i s capabl e of sus-

tai ni ng wi thout any permanent strai n remai ni ng upon compl ete

rel ease of stress;

proporti onal l i mi t - the greatest stress whi ch a materi al i s capabl e of

sustai ni ng wi thout any devi ati on from Hookes Law;

compressi ve strength - the maxi mum compressi ve stress a materi al

i s capabl e of sustai ni ng;

shear strength - the maxi mum shear stress a materi al i s capabl e of

sustai ni ng;

tensi l e strength - the maxi mum tensi l e stress a materi al i s capabl e

of sustai ni ng;

yi el d poi nt - the fi rst stress i n a test where the i ncrease i n strai n

occurs wi thout an i ncrease i n stress;

o

Linear Elastic Elastoplastic Non-Linear Elastic

Permanent

Deformation

12 12 12

1.5.1 Time-Independent Material Functions 13

yi el d strength - the engi neeri ng stress at whi ch a materi al exhi bi ts

a speci fi ed l i mi ti ng devi ati on from the proporti onal i ty of stress to

strai n.

A typi cal characteri sti c of bri ttl e sol i ds i s that they break when gi ven

a smal l deformati on. Fai l ure testi ng and fracture mechani cs i n struc-

tural sol i ds are wel l devel oped areas of materi al sci ence (Cal l i ster, 1991)

whi ch offer much to the food rheol ogi st. Eval uati ng the structural

fai l ure of sol i d foods i n compressi on, torsi on, and sandwi ch shear modes

were summari zed by Hamann (1983). Jagged force-deformati on rel a-

ti onshi ps of crunchy materi al s may offer al ternati ve texture cl assi fi -

cati on cri teri a for bri ttl e or crunchy foods (Ul bri cht et al ., 1995; Pel eg

and Normand, 1995).

1.5. Fluid Behavior in Steady Shear Flow

1.5.1. Time-Independent Material Functions

Viscometric Functions. Fl ui ds may be studi ed by subjecti ng them

to conti nuous sheari ng at a constant rate. I deal l y, thi s can be accom-

pl i shed usi ng two paral l el pl ates wi th a fl ui d i n the gap between them

(Fi g. 1.9). The l ower pl ate i s fi xed and the upper pl ate moves at a

constant vel oci ty ( ) whi ch can be thought of as an i ncremental change

i n posi ti on di vi ded by a smal l ti me peri od, . A force per uni t area

on the pl ate i s requi red for moti on resul ti ng i n a shear stress ( ) on

the upper pl ate whi ch, conceptual l y, coul d al so be consi dered to be a

l ayer of fl ui d.

The fl ow descri bed above i s steady si mpl e shear and the shear rate

(al so cal l ed the strai n rate) i s defi ned as the rate of change of strai n:

[1.20]

Thi s defi ni ti on onl y appl i es to streaml i ne (l ami nar) fl ow between

paral l el pl ates. I t i s di rectl y appl i cabl e to sl i di ng pl ate vi scometer

descri bed by Deal y and Gi acomi n (1988). The defi ni ti on must be

adjusted to account for curved l i nes such as those found i n tube and

rotati onal vi scometers; however, the i dea of "maxi mum speed di vi ded

by gap si ze"can be useful i n esti mati ng shear rates found i n parti cul ar

appl i cati ons l i ke brush coati ng. Thi s i dea i s expl ored i n more detai l i n

Sec. 1.9.

u

L/t

21

d

dt

d

dt

L

h

_

,

u

h

14 Chapter 1. Introduction to Rheology

Figure 1.9. Velocity profile between parallel plates.

Rheol ogi cal testi ng to determi ne steady shear behavi or i s conducted

under l ami nar fl ow condi ti ons. I n turbul ent fl ow, l i ttl e i nformati on i s

generated that can be used to determi ne materi al properti es. Al so, to

be meani ngful , data must be col l ected over the shear rate range

appropri ate for the probl em i n questi on whi ch may vary wi del y i n

i ndustri al processes (Tabl e 1.1): Sedi mentati on of parti cl es may i nvol ve

very l ow shear rates, spray dryi ng wi l l i nvol ve hi gh shear rates, and

pi pe fl ow of food wi l l usual l y occur over a moderate shear rate range.

Extrapol ati ng experi mental data over a broad range of shear rates i s

not recommended because i t may i ntroduce si gni fi cant errors when

eval uati ng rheol ogi cal behavi or.

Materi al fl ow must be consi dered i n three di mensi ons to compl etel y

descri be the state of stress or strai n. I n steady, si mpl e shear fl ow the

coordi nate system may be ori ented wi th the di recti on of fl ow sothe stress

tensor gi ven by Eq. [1.5] reduces to

[1.21]

h

VELOCITY PROFILE

FORCE

AREA

u

u = 0

1

2

x

x

ij

11

12

0

21

22

0

0 0

33

1

1

1

1

]

1.5.1 Time-Independent Material Functions 15

Table 1.1. Shear Rates Typical of Familiar Materials and Processes

Situation (1/s) Application

Sedimentation of particles in 10

-6

- 10

-3

Medicines, paints, spices in

a suspending liquid salad dressing

Leveling due to surface ten- 10

-2

- 10

-1

Frosting, paints, printing inks

sion

Draining under gravity 10

-1

- 10

1

Vats, small food containers,

painting and coating

Extrusion 10

0

- 10

3

Snack and pet foods, tooth-

paste, cereals, pasta, poly-

mers

Calendering 10

1

- 10

2

Dough Sheeting

Pouring from a bottle 10

1

- 10

2

Foods, cosmetics, toiletries

Chewing and swallowing 10

1

- 10

2

Foods

Dip coating 10

1

- 10

2

Paints, confectionery

Mixing and stirring 10

1

- 10

3

Food processing

Pipe flow 10

0

- 10

3

Food processing, blood flow

Rubbing 10

2

- 10

4

Topical application of creams

and lotions

Brushing 10

3

- 10

4

Brush painting, lipstick, nail

polish

Spraying 10

3

- 10

5

Spray drying, spray painting,

fuel atomization

High speed coating 10

4

- 10

6

Paper

Lubrication 10

3

- 10

7

Bearings, gasoline engines

Si mpl e shear fl ow i s al so cal l ed vi scometri c fl ow. I t i ncl udes axi al

fl ow i n a tube, rotati onal fl ow between concentri c cyl i nders, rotati onal

fl ow between a cone and a pl ate, and torsi onal fl ow (al so rotati onal )

between paral l el pl ates. I n vi scometri cfl ow, three shear-rate-dependent

materi al functi ons, col l ecti vel y cal l ed vi scometri c functi ons, are needed

to compl etel y establ i sh the state of stress i n a fl ui d. These may be

descri bed as the vi scosi ty functi on, , and the fi rst and second normal

stress coeffi ci ents, and , defi ned mathemati cal l y as

[1.22]

[1.23]

1

(

)

2

(

)

f (

)

21

1

f (

)

11

22

(

)

2

N

1

(

)

2

16 Chapter 1. Introduction to Rheology

[1.24]

The fi rst ( ) and second ( ) normal stress di fferences are

often symbol i cal l y represented as and , respecti vel y. i s al ways

posi ti ve and consi dered to be approxi matel y 10 ti mes greater than .

Measurement of i s di ffi cul t; fortunatel y, the assumpti on that

i s usual l y sati sfactory. The rati oof , known as the recoverabl e shear

(or the recoverabl e el asti c strai n), has proven to be a useful parameter

i n model i ng di e swel l phenomena i n pol ymers (Tanner, 1988). Some

data on the val ues of fl ui d foods have been publ i shed (see Appendi x

[6.6]).

I f a fl ui d i s Newtoni an, i s a constant (equal to the Newtoni an

vi scosi ty) and the fi rst and second normal stress di fferences are zero.

As approaches zero, el asti c fl ui ds tend to di spl ay Newtoni an behavi or.

Vi scoel asti c fl ui ds si mul taneousl y exhi bi t obvi ous fl ui d-l i ke (vi scous)

and sol i d-l i ke (el asti c) behavi or. Mani festati ons of thi s behavi or, due

to a hi gh el asti c component, can be very strong and create di ffi cul t

probl ems i n process engi neeri ng desi gn. These probl ems are parti cu-

l arl y preval ent i n the pl asti c processi ng i ndustri es but al so present i n

processi ng foods such as dough, parti cul arl y those contai ni ng l arge

quanti ti es of wheat protei n.

Fi g. 1.10 i l l ustrates several phenomena. Duri ng mi xi ng or agi tati on,

a vi scoel asti cfl ui d may cl i mb the i mpel l er shaft i n a phenomenon known

as the Wei ssenberg effect (Fi g. 1.10). Thi s can be observed i n home

mi xi ng of cake or chocol ate browni e batter. When a Newtoni an fl ui d

emerges from a l ong, round tube i nto the ai r, the emergi ng jet wi l l

normal l y contract; at l ow Reynol ds numbers i t may expand toa di ameter

whi ch i s 10 to 15% l arger than the tube di ameter. Normal stress di f-

ferences present i n a vi scoel asti c fl ui d, however, may cause jet expan-

si ons (cal l ed di e swel l ) whi ch are two or more ti mes the di ameter of the

tube (Fi g. 1.10). Thi s behavi or contri butes to the chal l enge of desi gni ng

extruder di es toproduce the desi red shape of many pet, snack, and cereal

foods. Mel t fracture, a fl ow i nstabi l i ty causi ng di storted extrudates, i s

al soa probl em rel ated to fl ui d vi scoel asti ci ty. I n addi ti on, hi ghl y el asti c

fl ui ds may exhi bi t a tubel ess si phon effect (Fi g. 1.10).

2

f (

)

22

33

(

)

2

N

2

(

)

2

11

22

22

33

N

1

N

2

N

1

N

2

N

2

N

2

0

N

1

/

12

N

1

(

1.5.1 Time-Independent Material Functions 17

Figure 1.10. Weissenberg effect (fluid climbing a rotating rod), tubeless siphon

and jet swell of viscous (Newtonian) and viscoelastic fluids.

The recoi l phenomena (Fi g. 1.11), where tensi l e forces i n the fl ui d

cause parti cl es to move backward (snap back)when fl ow i s stopped, may

al so be observed i n vi scoel asti c fl ui ds. Other i mportant effects i ncl ude

drag reducti on, extrudate i nstabi l i ty, and vortex i nhi bi ti on. An excel -

l ent pi ctori al summary of the behavi or of vi scoel asti c pol ymer sol uti ons

i n vari ous fl ow si tuati ons has been prepared by Boger and Wal ters

(1993).

Normal stress data can be col l ected i n steady shear fl ow usi ng a

number of di fferent techni ques (Deal y, 1982): exi t pressure di fferences

i n capi l l ary and sl i t fl ow, axi al fl ow i n an annul us, wal l pressure i n

concentri ccyl i nder fl ow, axi al thrust i n cone and pl ate as wel l as paral l el

pl ate fl ow. I n general , these methods have been devel oped for pl asti c

mel ts (and rel ated pol ymeri c materi al s) wi th the probl ems of the pl asti c

i ndustri es provi di ng the mai n dri vi ng force for change.

VISCOUS FLUID VISCOELASTIC FLUID

WEISSENBERG

EFFECT

TUBELESS

SIPHON

JET SWELL

18 Chapter 1. Introduction to Rheology

Cone and pl ate systems are most commonl y used for obtai ni ng

pri mary normal stress data and a number of commerci al i nstruments

are avai l abl e to make these measurements. Obtai ni ng accurate data

for food materi al s i s compl i cated by vari ous factors such as the presence

of a yi el d stress, ti me-dependent behavi or and chemi cal reacti ons

occurri ng duri ng processi ng (e.g., hydrati on, protei n denaturati on, and

starch gel ati ni zati on). Rheogoni ometer i s a term someti mes used to

descri be an i nstrument capabl e of measuri ng both normal and shear

stresses. Detai l ed i nformati on on testi ng vi scoel asti c pol ymers can be

found i n numerous books: Bi rd et al . (1987), Barnes et al . (1989), Bogue

and Whi te (1970), Darby (1976), Macosko (1994), and Wal ters (1975).

Figure 1.11. Recoil phenomenon in viscous (Newtonian) and viscoelastic fluids.

Vi scometri c functi ons have been very useful i n understandi ng the

behavi or of syntheti c pol ymer sol uti ons and mel ts (pol yethyl ene, pol y-

propyl ene, pol ystyrene, etc.). From an i ndustri al standpoi nt, the vi s-

cosi ty functi on i s most i mportant i n studyi ng fl ui d foods and much of

the current work i s appl i ed to that area. To date, normal stress data

for foods have not been wi del y used i n food process engi neeri ng. Thi s

i s partl y due tothe fact that other factors often compl i cate the eval uati on

of the fl ui d dynami cs present i n vari ous probl ems. I n food extrusi on,

for exampl e, fl ashi ng (vapori zati on) of water when the product exi ts the

START

STOP

RECOIL

VISCOUS FLUID VISCOELASTIC FLUID

START

STOP

1.5.1 Time-Independent Material Functions 19

di e makes i t di ffi cul t topredi ct the i nfl uence of normal stress di fferences

on extrudate expansi on. Future research may create si gni fi cant

advances i n the use of normal stress data by the food i ndustry.

Mathematical Modelsfor Inelastic Fluids. The el asti c behavi or of

many fl ui d foods i s smal l or can be negl ected (materi al s such as dough

are the excepti on) l eavi ng the vi scosi ty functi on as the mai n area of

i nterest. Thi s functi on i nvol ves shear stress and shear rate: the rel a-

ti onshi p between the two i s establ i shed from experi mental data.

Behavi or i s vi sual i zed as a pl ot of shear stress versus shear rate, and

the resul ti ng curve i s mathemati cal l y model ed usi ng vari ous functi onal

rel ati onshi ps. The si mpl est type of substance to consi der i s the New-

toni an fl ui d where shear stress i s di rectl y proporti onal to shear rate [for

conveni ence the subscri pt on wi l l be dropped i n the remai nder of the

text when deal i ng excl usi vel y wi th one di mensi onal fl ow]:

[1.25]

wi th bei ng the constant of proporti onal i ty appropri ate for a Newtoni an

fl ui d. Usi ng uni ts of N, m

2

, m, m/s for force, area, l ength and vel oci ty

gi ves vi scosi ty as Pa s whi ch i s 1 poi seui l l e or 1000 centi poi se (note: 1

Pa s = 1000 cP = 1000 mPa s; 1 P = 100 cP). Dynami c vi scosi ty and

coeffi ci ent of vi scosi ty are synonyms for the term "vi scosi ty"i n referri ng

to Newtoni an fl ui ds. The reci procal of vi scosi ty i s cal l ed fl ui di ty.

Coeffi ci ent of vi scosi ty and fl ui di ty are i nfrequentl y used terms.

Newtoni an fl ui ds may al so be descri bed i n terms of thei r ki nemati c

vi scosi ty ( ) whi ch i s equal to the dynami c vi scosi ty di vi ded by densi ty

( ). Thi s i s a common practi ce for non-food materi al s, parti cul arl y

l ubri cati ng oi l s. Vi scosi ty conversi on factors are avai l abl e i n Appendi x

[6.1].

Newtoni an fl ui ds, by defi ni ti on, have a strai ght l i ne rel ati onshi p

between the shear stress and the shear rate wi th a zero i ntercept. Al l

fl ui ds whi ch do not exhi bi t thi s behavi or may be cal l ed non-Newtoni an.

Looki ng at typi cal Newtoni an fl ui ds on a rheogram (Fi g. 1.12) reveal s

that the sl ope of the l i ne i ncreases wi th i ncreasi ng vi scosi ty.

Van Wazer et al . (1963)di scussed the sensi ti vi ty of the eye i n judgi ng

vi scosi ty of Newtoni an l i qui ds. I t i s di ffi cul t for the eye to di sti ngui sh

di fferences i n the range of 0.1 to 10 cP. Smal l di fferences i n vi scosi ty

are cl earl y seen from approxi matel y 100 to 10,000 cP: somethi ng at 800

cP may l ook twi ce as thi ck as somethi ng at 400 cP. Above 100,000 cP

i t i s di ffi cul t to make vi sual di sti ncti ons because the materi al s do not

21

/

20 Chapter 1. Introduction to Rheology

Figure 1.12. Rheograms for typical Newtonian fluids.

pour and appear, to the casual observer, as sol i ds. As poi nts of reference

the fol l owi ng represent typi cal Newtoni an vi scosi ti es at room temper-

ature: ai r, 0.01 cP; gasol i ne (petrol ), 0.7 cP; water, 1 cP; mercury, 1.5

cP; coffee cream or bi cycl e oi l , 10 cP; vegetabl e oi l , 100 cP; gl ycerol , 1000

cP; gl yceri ne, 1500 cP; honey, 10,000 cP; tar, 1,000,000 cP. Data for

many Newtoni an fl ui ds at di fferent temperatures are presented i n

Appendi ces [6.8], [6.9], and [6.10].

A general rel ati onshi p to descri be the behavi or of non-Newtoni an

fl ui ds i s the Herschel -Bul kl ey model :

[1.26]

where i s the consi stency coeffi ci ent, i s the fl ow behavi or i ndex, and

i s the yi el d stress. Thi s model i s appropri ate for many fl ui d foods.

Eq. [1.26] i s very conveni ent because Newtoni an, power l aw (shear-

thi nni ng when or shear-thi ckeni ng when ) and Bi ng-

ham pl asti c behavi or may be consi dered as speci al cases (Tabl e 1.2, Fi g.

1.13). Wi th the Newtoni an and Bi ngham pl asti c model s, i s commonl y

cal l ed the vi scosi ty ( ) and pl asti c vi scosi ty ( ), respecti vel y. Shear-

thi nni ng and shear-thi ckeni ng are al so referred to as pseudopl asti c and

di l atent behavi or, respecti vel y; however, shear-thi nni ng and

0 5 10 15 20

0

0.5

1

1.5

2

2.5

3

Shear Rate, 1/s

40% fat cream, 6.9 cP

olive oil, 36.3 cP

castor oil, 231 cP

0 5 10 15 20

0

0.5

1

1.5

2

2.5

3

Shear Rate, 1/s

S

h

e

a

r

S

t

r

e

s

s

,

P

a

40% fat cream, 6.9 cP

olive oil, 36.3 cP

castor oil, 231 cP

K(

)

n

+

o

K n

o

0 < n < 1 1 < n <

K

pl

1.5.1 Time-Independent Material Functions 21

shear-thi ckeni ng are the preferred terms. A typi cal exampl e of a

shear-thi nni ng materi al i s found i n the fl ow behavi or of a 1% aqueous

sol uti on of carrageenan gum as demonstrated i n Exampl e Probl em

1.14.1. Shear-thi ckeni ng i s consi dered wi th a concentrated corn starch

sol uti on i n Exampl e Probl em 1.14.2.

Table 1.2. Newtonian, Power Lawand BinghamPlastic Fluids as Special Cases of

the Herschel-Bulkley Model (Eq. [1.26])

Fluid K n Typical Examples

Herschel-Bulkley > 0 0 < n < > 0 minced fish paste,

raisin paste

Newtonian > 0 1 0 water, fruit juice,

milk, honey, vegeta-

ble oil

shear-thinning > 0 0 < n < 1 0 applesauce, banana

(pseudoplastic) puree, orange juice

concentrate

shear-thickening > 0 1 < n < 0 some types of

(dilatent) honey, 40% raw

corn starch solution

Bingham plastic > 0 1 > 0 tooth paste, tomato

paste

An i mportant characteri sti c of the Herschel -Bul kl ey and Bi ngham

pl asti c materi al s i s the presence of a yi el d stress ( ) whi ch represents

a fi ni te stress requi red to achi eve fl ow. Bel ow the yi el d stress a materi al

exhi bi ts sol i d l i ke characteri sti cs: I t stores energy at smal l strai ns and

does not l evel out under the i nfl uence of gravi ty to form a fl at surface.

Thi s characteri sti c i s very i mportant i n process desi gn and qual i ty

assessment for materi al s such as butter, yogurt and cheese spread. The

yi el d stress i s a practi cal , but i deal i zed, concept that wi l l recei ve addi -

ti onal di scussi on i n a l ater secti on (Sec. 1.6). Typi cal yi el d stress val ues

may be found i n Appendi x [6.7].

o

22 Chapter 1. Introduction to Rheology

Figure 1.13. Curves for typical time-independent fluids.

Figure 1.14. Rheogram of idealized shear-thinning (pseudoplastic) behavior.

Newtonian

Shear-Thickening

Shear-Thinning

Herschel-Bulkley

Bingham

S

h

e

a

r

S

t

r

e

s

s

,

P

a

Shear Rate, 1/s

S

h

e

a

r

S

t

r

e

s

s

,

P

a

Shear Rate, 1/s

Lower Region

Upper Region

Middle Region

Slope =

Slope =

1.5.1 Time-Independent Material Functions 23

Shear-thi nni ng behavi or i s very common i n frui t and vegetabl e

products, pol ymer mel ts, as wel l as cosmeti c and toi l etry products

(Appendi ces [6.11], [6.12], [6.13]). Duri ng fl ow, these materi al s may

exhi bi t three di sti nct regi ons (Fi g. 1.14): a l ower Newtoni an regi on

where the apparent vi scosi ty ( ), cal l ed the l i mi ti ng vi scosi ty at zero

shear rate, i s constant wi th changi ng shear rates; a mi ddl e regi on where

the apparent vi scosi ty ( ) i s changi ng (decreasi ng for shear-thi nni ng

fl ui ds) wi th shear rate and the power l aw equati on i s a sui tabl e model

for the phenomenon; and an upper Newtoni an regi on where the sl ope

of the curve ( ), cal l ed the l i mi ti ng vi scosi ty at i nfi ni te shear rate, i s

constant wi th changi ng shear rates. The mi ddl e regi on i s most often

exami ned when consi deri ng the performance of food processi ng equi p-

ment. The l ower Newtoni an regi on may be rel evant i n probl ems

i nvol vi ng l ow shear rates such as those rel ated to the sedi mentati on of

fi ne parti cl es i n fl ui ds. Val ues of for some vi scoel asti c fl ui ds are gi ven

i n Tabl e 5.4.

Numerous factors i nfl uence the sel ecti on of the rheol ogi cal model

used to descri be fl ow behavi or of a parti cul ar fl ui d. Many model s, i n

addi ti on to the power l aw, Bi ngham pl asti c and Herschel -Bul kl ey

model s, have been used torepresent the fl ow behavi or of non-Newtoni an

fl ui ds. Some of them are summari zed i n Tabl e 1.3. The Cross,

Rei ner-Phi l i ppoff, Van Wazer and Powel l -Eyri ng model s are useful i n

model i ng pseudopl asti c behavi or over l ow, mi ddl e and hi gh shear rate

ranges. Some of the equati ons, such as the Modi fi ed Casson and the

General i zed Herschel -Bul kl ey, have proven useful i n devel opi ng

mathemati cal model s to sol ve food process engi neeri ng probl ems (Ofol i

et al ., 1987) i nvol vi ng wi de shear rate ranges. Addi ti onal rheol ogi cal

model s have been summari zed by Hol dsworth (1993).

The Casson equati on has been adopted by the I nternati onal Offi ce

of Cocoa and Chocol ate for i nterpreti ng chocol ate fl ow behavi or. The

Casson and Bi ngham pl asti c model s are si mi l ar because they both have

a yi el d stress. Each, however, wi l l gi ve di fferent val ues of the fl ui d

parameters dependi ng on the data range used i n the mathemati cal

anal ysi s. The most rel i abl e val ue of a yi el d stress, when determi ned

from a mathemati cal i ntercept, i s found usi ng data taken at the l owest

shear rates. Thi s concept i s demonstrated i n Exampl e Probl em 1.14.3

for mi l k chocol ate.

o

24 Chapter 1. Introduction to Rheology

Apparent Viscosity. Apparent vi scosi ty has a preci se defi ni ti on. I t

i s, as noted i n Eq. [1.22], shear stress di vi ded by shear rate:

[1.27]

Wi th Newtoni an fl ui ds, the apparent vi scosi ty and the Newtoni an

vi scosi ty ( ) are i denti cal but for a power l aw fl ui d i s

[1.28]

Table 1.3. Rheological Models to Describe the Behavior of Time-

independent Fluids

Model (Source) Equation

*

Casson (Casson, 1959)

Modified Casson (Mizrahi and Berk,

1972)

Ellis (Ellis, 1927)

Generalized Herschel-Bulkley (Ofoli et

al., 1987)

Vocadlo (Parzonka and Vocadlo, 1968)

Power Series (Whorlow, 1992)

Carreau (Carreau, 1968)

Cross (Cross, 1965)

Van Wazer (Van Wazer, 1963)

Powell-Eyring (Powell and Eyring, 1944)

Reiner-Philippoff (Philippoff, 1935)

*

and are arbitrary constants and power indices, respectively, determined

from experimental data.

f (

f (

)

K(

)

n

K(

)

n 1

0.5

(

o

)

0.5

+ K

1

(

)

0.5

0.5

(

o

)

0.5

+ K

1

(

)

n

1

K

1

+ K

2

()

n

1

n

1

(

o

)

n

1

+ K

1

(

)

n

2

(

o

)

1/n

1

+ K

1

_

,

n

1

K

1

+ K

2

()

3

+ K

3

()

5

K

1

+ K

2

()

3

+ K

3

()

5

+ (

o

1 + (K

1

)

21

]

(n 1)/2

+

o

1 + K

1

(

)

n

o

1 + K

1

+ K

2

(

)

n

1

+

K

1

1

K

2

_

,

sinh

1

(K

3

+

o

1 + (()

2

/K

1

)

_

K

1

, K

2

, K

3

n

1

, n

2

1.5.1 Time-Independent Material Functions 25

Apparent vi scosi ti es for Bi ngham pl asti c and Herschel -Bul kl ey fl ui ds

are determi ned i n a l i ke manner:

[1.29]

[1.30]

decreases wi th i ncreasi ng shear rate i n shear-thi nni ng and Bi ngham

pl asti c substances. I n Herschel -Bul kl ey fl ui ds, apparent vi scosi ty wi l l

decrease wi th hi gher shear rates when , but behave i n the

opposi te manner when Apparent vi scosi ty i s constant wi th

Newtoni an materi al s and i ncreases wi th i ncreasi ng shear rate i n

shear-thi ckeni ng fl ui ds (Fi g. 1.15).

Figure 1.15. Apparent viscosity of time-independent fluids.

A si ngl e poi nt apparent vi scosi ty val ue i s someti mes used as a

measure of mouthfeel of fl ui d foods: The human percepti on of thi ckness

i s correl ated tothe apparent vi scosi ty at approxi matel y 60 s

-1

. Apparent

vi scosi ty can al sobe used to i l l ustrate the axi om that taki ng si ngl e poi nt

tests for determi ni ng the general behavi or of non-Newtoni an materi al s

may cause seri ous probl ems. Some qual i ty control i nstruments desi gned

for si ngl e poi nt tests may produce confusi ng resul ts. Consi der, for

f (

)

K(

) +

o

K +

o

f (

)

K(

)

n

+

o

K(

)

n 1

+

o

0<n <1.0

n >1.0.

Shear Rate, 1/s

A

p

p

a

r

e

n

t

V

i

s

c

o

s

i

t

y

,

P

a

s

Shear-Thickening

Shear-Thinning

Herschel-Bulkley

Bingham

Newtonian

Time-Independent Fluids

( 0 < n < 1.0 )

26 Chapter 1. Introduction to Rheology

exampl e, the two Bi ngham pl asti c materi al s shown i n Fi g. 1.16. The

two curves i ntersect at 19.89 1/s and an i nstrument measuri ng the

apparent vi scosi ty at that shear rate, for each fl ui d, woul d gi ve i denti cal

resul ts: = 1.65 Pa s. However, a si mpl e exami nati on of the materi al

wi th the hands and eyes woul d show them to be qui te di fferent because

the yi el d stress of one materi al i s more than 4 ti mes that of the other

materi al . Cl earl y, numerous data poi nts (mi ni mum of twofor the power

l aw or Bi ngham pl asti c model s) are requi red to eval uate the fl ow

behavi or of non-Newtoni an fl ui ds.

Figure 1.16. Rheograms for two Bingham plastic fluids.

Solution Viscosities. I t i s someti mes useful to determi ne the vi sco-

si ti es of di l ute syntheti c or bi opol ymer sol uti ons. When a pol ymer i s

di ssol ved i n a sol vent, there i s a noti ceabl e i ncrease i n the vi scosi ty of

the resul ti ng sol uti on. The vi scosi ti es of pure sol vents and sol uti ons

can be measured and vari ous val ues cal cul ated from the resul ti ng data:

[1.31]

[1.32]

0 10 20 30 40 50 60

0

20

40

60

80

100

Shear Rate, 1/s

S

h

e

a

r

S

t

r

e

s

s

,

P

a

Yield Stress = 25.7 Pa

Plastic Viscosity = .36 Pa s

Yield Stress = 6.0 Pa

Plastic Viscosity = 1.35 Pa s

Bingham Plastic Fluids

relative viscosity

rel

solution

solvent

specific viscosity

sp

rel

1

1.5.2 Time-Dependent Material Functions 27

[1.33]

[1.34]

[1.35]

where i s the mass concentrati on of the sol uti on i n uni ts of g/dl or

g/100ml . Note that uni ts of reduced, i nherent, and i ntri nsi c vi scosi ty

are reci procal concentrati on (usual l y deci l i ters of sol uti on per grams of

pol ymer). The i ntri nsi c vi scosi ty has great practi cal val ue i n mol ecul ar

wei ght determi nati ons of hi gh pol ymers (Severs, 1962; Morton-Jones,

1989; Grul ke, 1994). Thi s concept i s based on the Mark-Houwi nk

rel ati on suggesti ng that the i ntri nsi c vi scosi ty of a di l ute pol ymer

sol uti on i s proporti onal to the average mol ecul ar wei ght of the sol ute

rai sed to a power i n the range of 0.5 to 0.9. Val ues of the proporti onal i ty

constant and the exponent are wel l known for many pol ymer-sol vent

combi nati ons (Progel f and Throne, 1993; Rodri quez, 1982). Sol uti on

vi scosi ti es are useful i n understandi ng the behavi or of some bi opol ymers

i ncl udi ng aqueous sol uti ons of l ocust bean gum, guar gum, and car-

boxymethyl cel l ul ose (Rao, 1986). The i ntri nsi c vi scosi ti es of numerous

protei n sol uti ons have been summari zed by Rha and Pradi pasena

(1986).

1.5.2. Time-Dependent Material Functions

I deal l y, ti me-dependent materi al s are consi dered tobe i nel asti cwi th

a vi scosi ty functi on whi ch depends on ti me. The response of the sub-

stance to stress i s i nstantaneous and the ti me-dependent behavi or i s

due to changes i n the structure of the materi al i tsel f. I n contrast, ti me

effects found i n vi scoel asti c materi al s ari se because the response of

stress to appl i ed strai n i s not i nstantaneous and not associ ated wi th a

structural change i n the materi al . Al so, the ti me scal e of thi xotropy may

be qui te di fferent than the ti me scal e associ ated wi th vi scoel asti ci ty:

The most dramati c effects are usual l y observed i n si tuati ons i nvol vi ng

short process ti mes. Note too, that real materi al s may be both ti me-

dependent and vi scoel asti c!

reduced viscosity

red

sp

C

inherent viscosity

inh

ln

rel

C

intrinsic viscosity

int

sp

C

1

1

]C 0

C

28 Chapter 1. Introduction to Rheology

Figure 1.17. Time-dependent behavior of fluids.

Separate termi nol ogy has been devel oped to descri be fl ui ds wi th

ti me-dependent characteri sti cs. Thi xotropi c and rheopecti c materi al s

exhi bi t, respecti vel y, decreasi ng and i ncreasi ng shear stress (and

apparent vi scosi ty)over ti me at a fi xed rate of shear (Fi g. 1.17). I n other

words, thi xotropy i s ti me-dependent thi nni ng and rheopexy i s ti me-

dependent thi ckeni ng. Both phenomena may be i rreversi bl e, reversi bl e

or parti al l y reversi bl e. There i s general agreement that the term

"thi xotropy" refers to the ti me-dependent decrease i n vi scosi ty, due to

sheari ng, and the subsequent recovery of vi scosi ty when sheari ng i s

removed (Mewi s, 1979). I rreversi bl e thi xotropy, cal l ed rheomal axi s or

rheodestructi on, i s common i n food products and may be a factor i n

eval uati ng yi el d stress as wel l as the general fl ow behavi or of a materi al .

Anti -thi xotropy and negati ve thi xotropy are synonyms for rheopexy.

Thi xotropy i n many fl ui d foods may be descri bed i n terms of the

sol -gel transi ti on phenomenon. Thi s termi nol ogy coul d appl y, for

exampl e, to starch-thi ckened baby food or yogurt. After bei ng man-

ufactured, and pl aced i n a contai ner, these foods sl owl y devel op a three

di mensi onal network and may be descri bed as gel s. When subjected to

shear (by standard rheol ogi cal testi ng or mi xi ng wi th a spoon), structure

i s broken down and the materi al s reach a mi ni mum thi ckness where

Thixotropic

Time-Independent

Rheopectic

S

h

e

a

r

S

t

r