Beruflich Dokumente

Kultur Dokumente

Style 2900 Data Sheet

Hochgeladen von

Ricardo OrdoñezOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Style 2900 Data Sheet

Hochgeladen von

Ricardo OrdoñezCopyright:

Verfügbare Formate

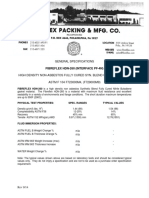

Garlock 2900/2950

MATERIAL PROPERTIES* Color: Composition: 1 Fluid Services : 2 Temperature , F (C) Minimum: Continuous Max: Maximum: 2 Pressure , Maximum, psig (bar): 2 P x T (max.) , psig x F (bar x C) 1/32 and 1/16": 1/8": TYPICAL PHYSICAL PROPERTIES ASTM F36 ASTM F36 ASTM F38 ASTM F152 ASTM F1315 ASTM F433 ASTM D149

*

2900 Black, 2950 Green Aramid fibers with a nitrile binder Water, aliphatic hydrocarbons, oils and gasoline -100 (-75) +400 (+205) +700 (+371) 1000 (70) 350,000 (12,000) 250,000 (8,600)

ASTM F586

ASTM F104

Compressibility, range, %: Recovery, %: Creep Relaxation, %: Tensile, Across Grain, psi (N/mm2): Density, lbs./ft.3 (grams/cm3): Thermal Conductivity (K), W/mK (Btu.in./hr.ft.2F): Dielectric Properties, range, volts/mil. Sample conditioning 3 hours at 250F: 96 hours at 100% Relative Humidity: Design Factors "m" factor: "y" factor, psi (N/mm2): Line Call Out:

7-17 50 25 1500 (10) 105 (1.68) 0.29-0.38 (2.00-2.65) 1/16" 1/8" 342(3) 254(3) 26 28 1/16" & Under 1/8" (4) (4) 4.5 7.0 3000(4) (20.7) 4000(4) (27.6) F712102A9B5E33K5L101M5

SEALING CHARACTERISTICS* ASTM F37B Fuel A 500 (3.5) 9.8 (0.7) 0.6 ml/hr. ASTM F37B Nitrogen 3000 (20.7) 30 (2) 1.2 ml/hr.

Gasket Load, psi (N/mm2): Internal Pressure, psig (bar): Leakage

*

IMMERSION PROPERTIES - ASTM F146 Fluid Resistance after Five Hours ASTM #1 Oil ASTM IRM #903

300F (150C) 300F (150C)

ASTM Fuel A

70-85F (20-30C)

ASTM Fuel B

70-85F (20-30C)

Thickness Increase, (%) Weight Increase, (%) Tensile Loss, (%)

Notes:

0-5 0-10 -

0-15 0-35

0-5 0-10 -

0-10 0-20 -

This is a general guide and should not be the sole means of selecting or rejecting this material. ASTM test results in accordance with ASTM F-104; properties based on 1/32" (0.8mm) sheet thickness unless otherwise mentioned. * Values do not constitute specification Limits

1 2

See Garlock chemical resistance guide.

Based on ANSI RF flanges at our preferred torque. When approaching maximum pressure, continuous operating temperature, minimum temperature or 50% of maximum PxT, consult Garlock Applications Engineering. Minimum temperature rating is conservative.

3 4 5

Indicates current arced around and not through gasket. Dielectric higher than indicated unless otherwise mentioned. These values are from style 2950. Style 2900 has higher values.

A9: Leakage in Fuel A (Isooctane), Gasket Load = 500psi (3.5N/mm2), Pressure = 9.8psig (0.7bar): Typical = 0.25ml/hr, Max = 1.5ml/hr. A9: Leakage in Nitrogen, Gasket Load = 3,000psi (20.7N/mm2), Pressure = 30psig (2bar): Typical = 1.0ml/hr, Max = 2.5ml/hr.

Das könnte Ihnen auch gefallen

- Crgo MTCDokument4 SeitenCrgo MTCGupta Gupta100% (1)

- Gas Sweetening and Processing Field ManualVon EverandGas Sweetening and Processing Field ManualBewertung: 4 von 5 Sternen4/5 (7)

- Garlock 700Dokument1 SeiteGarlock 700Jairo ArroyoNoch keine Bewertungen

- Garlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsDokument1 SeiteGarlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsRicardo Perez VerdugoNoch keine Bewertungen

- Garlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsDokument1 SeiteGarlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsChristian SanhuezaNoch keine Bewertungen

- Garlock Style 706 Data SheetDokument1 SeiteGarlock Style 706 Data SheetArturo Gasperin BarrigaNoch keine Bewertungen

- 3510 Off White Gylon Data SheetDokument1 Seite3510 Off White Gylon Data SheetJose CarlosNoch keine Bewertungen

- Garlock 9900 Data Sheet PDFDokument1 SeiteGarlock 9900 Data Sheet PDFMartin Andrew TugadeNoch keine Bewertungen

- Garlock Blue Gard 3000 Data SheetDokument1 SeiteGarlock Blue Gard 3000 Data SheetMatheus TorresNoch keine Bewertungen

- Garlock 3504 Blue Gylon Data SheetDokument1 SeiteGarlock 3504 Blue Gylon Data SheetdanielbustNoch keine Bewertungen

- Garlock Style 5500 Spec Sheet - (NA) 2016-11 ENDokument1 SeiteGarlock Style 5500 Spec Sheet - (NA) 2016-11 ENALONSO GOMEZNoch keine Bewertungen

- Garlock Style 9900 Spec Sheet - (NA) 2021-09 ENDokument1 SeiteGarlock Style 9900 Spec Sheet - (NA) 2021-09 ENDrojanle MezbraNoch keine Bewertungen

- 3504 Blue Gylon Data Sheet PDFDokument1 Seite3504 Blue Gylon Data Sheet PDFYnuzneNoch keine Bewertungen

- Garlock Style 700 Spec Sheet - (NA) 2016-11 enDokument1 SeiteGarlock Style 700 Spec Sheet - (NA) 2016-11 enMarín HernándezNoch keine Bewertungen

- Garlock GYLON 3500Dokument1 SeiteGarlock GYLON 3500echavarriNoch keine Bewertungen

- Garlock Style 3000 Spec Sheet - (NA) 2016-11 enDokument1 SeiteGarlock Style 3000 Spec Sheet - (NA) 2016-11 enalan2003_1_29040Noch keine Bewertungen

- Garlock Hi TempDokument4 SeitenGarlock Hi Temprock starNoch keine Bewertungen

- Klinger C4401 PDFDokument2 SeitenKlinger C4401 PDFArtur MkrtchyanNoch keine Bewertungen

- Garlock Graph Lock 3125ssDokument1 SeiteGarlock Graph Lock 3125ssJhon AlarconNoch keine Bewertungen

- Klingersil C 4300Dokument2 SeitenKlingersil C 4300Feri KaruanaNoch keine Bewertungen

- Hopelen PP Homopolymer General Information: DescriptionDokument1 SeiteHopelen PP Homopolymer General Information: DescriptionBrijesh PatelNoch keine Bewertungen

- Garlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 enDokument1 SeiteGarlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 ennmosilvaNoch keine Bewertungen

- 8600 Aramid-Inorganic/SBR Rubber Binder: ApplicationDokument2 Seiten8600 Aramid-Inorganic/SBR Rubber Binder: ApplicationIrving Alan Uc FernandezNoch keine Bewertungen

- Ifg 5500Dokument1 SeiteIfg 5500Amir100% (1)

- Compressed Sheet With Carbon Fibers, NBR Binder: ApplicationDokument2 SeitenCompressed Sheet With Carbon Fibers, NBR Binder: ApplicationEmmanuelNoch keine Bewertungen

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFDokument1 SeiteGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFalan2003_1_29040Noch keine Bewertungen

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 enDokument1 SeiteGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 enAndres Rodriguez HerreraNoch keine Bewertungen

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFDokument1 SeiteGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFalan2003_1_29040Noch keine Bewertungen

- 7797 - Premium Grade Neoprene Rubber SheetDokument1 Seite7797 - Premium Grade Neoprene Rubber SheetIsabel López TresgalloNoch keine Bewertungen

- Thermoseal Klingersil C-4401Dokument2 SeitenThermoseal Klingersil C-4401timwright999Noch keine Bewertungen

- Garlock GYLON Style 3510 Spec Sheet - (NA) 2016-12 ENDokument1 SeiteGarlock GYLON Style 3510 Spec Sheet - (NA) 2016-12 ENSu Kil SungNoch keine Bewertungen

- Inexhaust Gasket SpecificationsDokument1 SeiteInexhaust Gasket Specificationsmuhammad0umar-4Noch keine Bewertungen

- Ficha Tecnica Teadit 1082Dokument2 SeitenFicha Tecnica Teadit 1082damianNoch keine Bewertungen

- Um180821 TDS Tpu 95a RB V11Dokument3 SeitenUm180821 TDS Tpu 95a RB V11Steven DonosoNoch keine Bewertungen

- Castrol Alphasyn HTX Range: DescriptionDokument2 SeitenCastrol Alphasyn HTX Range: DescriptionKurniawanNoch keine Bewertungen

- Na NM gf300Dokument4 SeitenNa NM gf300Bảo Trung LêNoch keine Bewertungen

- Gasket Flanged Teadit Na1040Dokument1 SeiteGasket Flanged Teadit Na1040hijodebudasNoch keine Bewertungen

- PG 23Dokument1 SeitePG 23azeem bilalNoch keine Bewertungen

- 9122 - Nitrile Rubber Data SheetDokument1 Seite9122 - Nitrile Rubber Data SheetAlpeteNoch keine Bewertungen

- Style 2925: Product DataDokument1 SeiteStyle 2925: Product DataAlexander López VillavicencioNoch keine Bewertungen

- y 130영문 (Astm)Dokument1 Seitey 130영문 (Astm)qshakimNoch keine Bewertungen

- Ba SDokument2 SeitenBa SFajar SodiqNoch keine Bewertungen

- Garlock 22 Red SBR Rubber Sheet Data SheetDokument1 SeiteGarlock 22 Red SBR Rubber Sheet Data SheetkasebNoch keine Bewertungen

- YCA.23X.34 Bourdon GageDokument2 SeitenYCA.23X.34 Bourdon Gagejanvierhotben3983Noch keine Bewertungen

- Hopelen PP Homopolymer General Information: DescriptionDokument2 SeitenHopelen PP Homopolymer General Information: DescriptionKormanyos JoppeNoch keine Bewertungen

- Aluminium 2014 t6 2014 t651Dokument3 SeitenAluminium 2014 t6 2014 t651Agung Sapto AjiNoch keine Bewertungen

- Beater-Add Specs HDN 260 (Rev. 9-14)Dokument1 SeiteBeater-Add Specs HDN 260 (Rev. 9-14)Ronald José Zavarce FloresNoch keine Bewertungen

- 75 SDDokument3 Seiten75 SDCheker HaddedNoch keine Bewertungen

- Non-Asbestos Gasketing Material: Compressed Fibre Jointing SheetsDokument4 SeitenNon-Asbestos Gasketing Material: Compressed Fibre Jointing SheetsdangomezvNoch keine Bewertungen

- Nylatron® 4.6 - BoedekerDokument6 SeitenNylatron® 4.6 - BoedekerMas ZuhadNoch keine Bewertungen

- AP ArmaFlex SA FSSA SheetRoll - Sub.EN - US.2021Dokument4 SeitenAP ArmaFlex SA FSSA SheetRoll - Sub.EN - US.2021DJNoch keine Bewertungen

- TechData - PUDokument3 SeitenTechData - PUJaime PeñabrañaNoch keine Bewertungen

- Ficha Mang Oxiacetileno BalflexDokument1 SeiteFicha Mang Oxiacetileno BalflexJUANPANIAGUANoch keine Bewertungen

- Temasil NG: CSF Sheet JointingDokument3 SeitenTemasil NG: CSF Sheet JointingTài TrầnNoch keine Bewertungen

- BS7531 Grade X. MASTERDokument1 SeiteBS7531 Grade X. MASTERKishor JadhavNoch keine Bewertungen

- Specification Sheet: Deltapi N Series Pneumatic Transmitters Model NAA Differential Pressure TransmitterDokument4 SeitenSpecification Sheet: Deltapi N Series Pneumatic Transmitters Model NAA Differential Pressure TransmitterMohammad HosseinNoch keine Bewertungen

- 1.9.1.2-80T - 18 8 Stainless SteelDokument4 Seiten1.9.1.2-80T - 18 8 Stainless SteelDevan ShanmughaNoch keine Bewertungen

- SikaGrout-215 2011-11 - 1Dokument2 SeitenSikaGrout-215 2011-11 - 1Fajar SodiqNoch keine Bewertungen