Beruflich Dokumente

Kultur Dokumente

Nextship Lean Shipbuilding

Hochgeladen von

Agus RfiaiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Nextship Lean Shipbuilding

Hochgeladen von

Agus RfiaiCopyright:

Verfügbare Formate

RAPPORT 1214

Steinar Kristoffersen

NEXTSHIP - LEAN SHIPBUILDING

State of the art and potential to be "lean" in multifariously distributed maritime design, engineering and construction

SteinarKristoffersen NEXTSHIPLEANSHIPBUILDING Stateoftheartandpotentialtobeleaninmultifariouslydistributed maritimedesign,engineeringandconstruction

Report1214 ISSN:08060789 ISBN:9788278301777 MreforskingMoldeAS December2012

Title:

NextShipLeanShipbuilding:Stateoftheartandpotentialto beleaninmultifariouslydistributedmaritimedesign, engineeringandconstruction SteinarKristoffersen 1214 2387 NextShip SteinarKristoffersen NorgesForskningsrd

Author: Reportnumber: Projectnumber: Projectname: Projectleader: Sourceoffunding:

Reportcanbeorderedfrom: MoldeUniversityCollege,library, Postbox2110,N6402MOLDE,NORWAY: Tel.:(+47)71214161, Fax:(+47)71214160, email:biblioteket@himolde.nowww.himolde.no Numberofpages: 26 Price: ISSN ISBN Abstract This report surveys a selection of historical and domain specific articles and essays pertaining to lean shipbuilding andhighvalueadding manufacturingin general.Itpurportstogiveanimpressionofthe fields state of art, with an empirical backdrop and some critical reflections, which may in the next instanceserveasavantagepointforatopologyofthisclassofmanagementideologies. NOK50, 08060789 9788278301777

Preface

This report corresponds to deliverable 4.1 Stateoftheart Report on Lean construction in shipbuilding from work package 4 of the NextShipproject. It reviews information stemming from threesources,namely i) theclassicalbackgroundliteratureofsocalledleanproductionsystems,withvariances towards lean manufacturing, lean construction, lean planning, and finally, lean shipbuilding. The literature is scarce on the area of lean shipbuilding, thus, I have supplemented the report with observations and ideas from empirical work in the STX OSV Sviknes Shipyard, which at the time was under management of Dr. Jan Emblemsvg who is also onthesteeringcommitteeofthisproject. Finally,Ihavedrawnuponethnomethodologicalanalysisofplanningassuch,whichhave been influentially published in other subject areas, in order to create a balance against thepredominantlyreductionistperspectiveofoperationalsciencelogistics.

ii)

iii)

Thus, this report represents a perspective of the potential of modern shipbuilding to become lean, which in this report will be denoted with a capital L in Lean when it signifies this particular management ideology, as well as referencing and commenting some of the pertaining literature of thefield. SteinarKristoffersen Molde,December2012

Tableofcontents

PREFACE.....................................................................................................................................3 Tableofcontents........................................................................................................................ 5 Introduction ................................................................................................................................7 TheLeanhistory......................................................................................................................... 8 TheLeanprinciples..................................................................................................................... 8 Leanmanufacturing................................................................................................................... 9 Leanconstruction..................................................................................................................... 10 Leanprojectmanagement....................................................................................................... 11 Leanshipbuilding.................................................................................................................... 12 Empiricalstudies...................................................................................................................... 13 Discussion.................................................................................................................................19 HeijunkainLeanshipbuilding......................................................................................... 21 Genchigenbutsu(investigatepersonally)inLeanshipbuilding......................................21 Hansei(reflexiveapproaches)inLeanshipbuilding........................................................21 Kaizen(continuousimprovement)inLeanshipbuilding.................................................21 Conclusion................................................................................................................................22 References................................................................................................................................26

Introduction

Thecurrentreportexaminesthestateoftheartofacademicandpractitionercontributionstowards makingshipyardconstructionworkmoreefficient.Itapproachesthequestionfromseveralangles, usingliteraturestudies,empiricalexaminationofworkintheplanningandmanagementfunctional areasofashipyard,aswellassometheoreticalandmethodologicallyinformedcriticalreflection. IthasnotbeentheobjectivetosubmitthemostvoluminousreporteverwrittenonLean.The classicalliteratureis,indeed,classicalandeasilyrecovered.Thus,thisreportdoesnotenter uncriticallyasurveyofarticlespublishedbyproponentsofLean.Instead,Ihavesoughttoexamine Leansinternal(in)consistenciesaswellastheeventualfitthatitfurnishesvisvisthemaritime domain.Themandateoftheresearchofwhichthisreportisapart,clearlypointsinthedirectionof examiningitspotentialinthatregard.TheideathesocalledLeanconstructionmaybeappliedto shipbuilding,andthatitprovidesacandidatesolutiontoincreasingefficiency,hasbeenlaunchedby manyauthors[1],butturnsouttobedifficulttoproveconsistently[2,3]. Thequestion,whichalsohasbeenaskedbeforeisofcourse,whetheritispossibleandmeaningfora shipyardtoworktowardsleanshipbuilding.Indeed,whenLeanisseenassimplyanenhancementof massproductionmethods[4],thenotherconceptualmethodssuchasagile,resilient,flexibleor, indeed,leagilemightbeequallyreadilyconsidered[5,6].Agiletechniquesaresometimestreated akintoLean,sometimesasexactlytheopposite,andusuallyasarelateddevelopment[7].Thisisa hinttowardsthelackofastableontologicalfoundation,whichinapostmodernperspectiveishardly surprisingalbeitinstarkcontractstotherealistorientationofLeanresearchingeneral[8].Hence, someexplicitlycriticalexaminationsofthenotionofLeanhasbeenreviewedaswell[9,10],withno intentionfromthisreportatthesametimetocontributetodismissingthenotionofLeanassuch. Afirstpremiseofthisreportwouldsimplybetoprovideanoverviewofstateoftheartinmodern manufacturing,includingandmainly,butnotexclusiveofLean.Itseemsunproductivetofocusonly onLeansincethepracticalimplementationofitsprinciplesvariestremendously.Atthesametime,it hasbeenanambitiontocomeacrossasbalancedwithregardstotheselectionofarticlesaswellas theportraitthatwedrawofLean. Thispaperisthereforenotgoingtotrytoestablishacommonanddefinitesetofdelineating definitions;ratheritisgoingtoprovidesufficientfootingtodecidewhenandwhythenotionofLean isbeingusedintheliterature,andwhattheeffectsoftalkingleanareinanorganizationalaswell asatheoreticalperspective.Itshouldbeclear,thus,thatthispaperisnotassuchamethods paper,insofarasitprescribesawayofbecominglean,forwhichotherarticlescanbefoundamong relatedpublications[11]. Second,analysingtheroleofknowledgemanagementandthereconciliationofdiverse organizationalculturesisgoingtobeanimportantpartofanycasestudypertainingtocomplex, highvalueaddingmanufacturingandconstruction(suchasshipbuilding)[12].Thisisbecausethe worktakingplaceinthisdomainisseenasunequivocallycompetenceandskillbased,andthe

NextShipLeanShipbuilding

transferofworkfromonestationtoanotherisnotsimplyalogisticalproblem.Theproduction processesandtheartefactsthusproducedaresufficientlycomplexfortheretobemany simultaneouspointsofviewofwhatwaswanted,whatwasdesignedand,finally,whathasbeen built[13]. Third,thisstateoftheartsurveyisgoingtobelargelypracticalandempiricallyoriented.Weare contributingtoanactionresearchendeavourinrelativelylargescale,andhenceneedtoworkout descriptionsandanalysisofthetheoreticalbackgroundthatisusefulinawiderangeofcontexts, suchasworkshopsandtrainingcoursesattheshipyards. Finally,ouraimisultimatelytosupportanddemonstratebetterplanningprocessesfor internationallydistributedshipbuildingprojects.Thismeansafocuswithcommunication,decision makingandriskmanagement.Strategicdevelopmentanddesignwillalsoneedtobetakeninto considerationwhenwestudytheLeantalking.Thismaynotleadunanimouslytowarda recommendationofLean,assuch,buthopefullyabetterunderstandingofwhatitentails.

TheLeanhistory

NotwithstandingthefactthatreportsaretobefoundofLeanappliedtoshipbuilding[14,15],Lean is,arguably,seenbymostaspredominantlyanimplementationofmassproductionorcertainlyan extension[10]. Whilstthemanycontestingviewsconcerningwhereandhowleanmayactuallybeimplemented, supporttheassumptionthatLeandoesnotfurnishaparticularlystableontology,butratheran expressionofideologicalpragmatism,thebackgroundofLeanishistoricallyclear.Leanoriginated fromtheJapaneseautomobileindustry,startingperhapsasearlyasthe1950s[16].Inorderto competewithAmericanbrands,whichhadasignificantlyhigherproductionvolumeandtherefore lowerunitcosts,amoreefficientapproachtoindustrialproductionwasnecessaryinordertobeable tomeetthemarketsexpectationswithregardstocustomizability[17].

TheLeanprinciples

Therearemanydifferentpractices,ideologiesandtechniquesthatcometogetherunderLean,asan umbrellaterm,whichusuallycomprisewhatisotherwiseknownasJustInTimeproduction principles(JIT),TotalQualityManagement(TQM,awidelyscopedpreventativemaintenance programmeandhumanresourcemanagement.Moreover,itconcernsitselfheavilywith implementationofnotionsofproductionpullandflow.Indeed,thesemanticallysharedbaggage, signifiedbyasyntacticallysimilar,yetincreasinglysemanticallydifferentinterpretationofterms, betweenLeananditspredecessors,mayhavecontributed(allegedly)totheontologicalconfusion andinternalinconsistenciesofmuchLeanliterature[18].Thechallengesgodeeper,however[ibid]:

A greater source of confusion, however, is the more substantive disagreement about what comprises lean production and how it can be measured operationally [18].

NextShipLeanShipbuilding

ItissimpleenoughtodescribetheintentionsofLeanatarelativelyabstractlevel,e.g.,that: Processesneedtohavelowoverheadtobesetupcorrectly,togetherwithatightmonitoring systemandreactivecheckandredesignoftheprocess(PlanDoCheckAct[19]). Maintenanceshouldbereactive,inthesensethatitcontributestofurtheringproductivity, ratherthanrefactoringtheproduct. ItisimperativeinLeantoengagetheemployeesonalllevels. Leanmanufacturingisalsorequiredtocompriseasetofpracticesfocusedonreducing wasandnonvalueaddedactivitiesfromthecompanysmanufacturingactivities.

Itis,however,hardtofindrepresentativeandcrediblemanagementstrategies,whichwouldadmit toaimforasetofobjectivesthatwerestarklyincontradistinctiontotheonesabove.Clearly,amore instrumentalapproachisneededtosupplementsuchprinciples.The[some]slightlymoreconcrete, andhenceimportantguidelinesoftheToyotawayareexpressedhenceforth[20]: Longtermphilosophiesshouldgovernshorttermstrategies. Createacontinuousandtransparentvalueflowthatmakesweaknessesidentifiableand repairable. Repairatoncewhenerrorsarefound. Usepullratherthanpushtoavoidstocksandoverproduction. Levelouttheworkload(Heijunka). Standardizetasks;itisneededforimprovementandempowerment. Bringproblemstothesurface,visualize. Usewellknownandfamiliartechnology. Educateleadersandemployees. Respectandchallengepartnersandsuppliers. Investigateuncertaintyandreducehumanbias,personally(Genchigenbutsu). Makedecisionsslowly;implementdecisionsrapidly. Supportrelentlessreflection(Hansei;itmayalsomeanconsideration). SupportcontinuousImprovement(Kaizen).

Leanmanufacturing

ManufacturingisanalternativeperspectiveofthebackgroundofLean[21],asitdealswithlarge volumesandsmallmargins,usually(ortherefore)incombinationwithextensivereconfigurationof thefactoryandassemblyline,whichinthenextinstancemeansmorecost.However,Leandeals,it seems,historicallybetterwithvariationinsidethelargervolumes,thantraditionalmanufacturing, whichfitswiththebackgroundofitinJapaneseautomobileconstruction,wheremanufacturers neededtobecompetitiveinamarkedwherebuyershaslessmoneytospendoneachitem,but perhapscombinedwithstrongerwillsandopinionstraditionallytorequestadaptationandvariances, althoughanequallyplausibleexplanationmighthavebeenthatlargervolumesveryneededinan initialphaseofthemarket,wheremanufacturersdidnotknowwellwhatthecustomerswantedor needed.InAmericanautomobilemanufacturing,thevolumesmighthavegrownovertime,which gavetheactorsafootholdofmarkedknowledgetoproducelargerseriesofidenticalcarsthat

10

NextShipLeanShipbuilding

customerwantedtotakehomefromtheshop.ThismightnothavebeenthecaseinJapan,noratthe sameorlaterstageofdevelopment,inEurope. Thelargerseriesintotalandtheopportunitytoexplorethecustomerpreferencesinaundersupplied homemarket,mayhavegivenearlyadopterofLean,lessincentivestofocusonriskandtheneedto plantheirwayawayfrommistakes. Studyingleanmanufacturingsupplychainsinparticular,wefindthatsome,onthesurface,ignore planningandrisk(uncertainty)altogether,andinsteadfocusonotherdimensions[22]: Priceandquantityoforders Inventorydecisions Cyclelengthsandinspectionintervals Optimalbatchsizeandnumberofkanbans1 Reductionofwaste[20]: o Defectsinproduction o Overproduction o Stocks o Unnecessaryprocessing,movementofpeopleortransportofgoods o Waiting

Leanconstruction

ThetransformationofLeanfromaproductionphilosophythroughmanufacturingtoconstructionhas beenthetopicofmanypapers,e.g.[23],andmanydifferentaspectshavebeenbroughttothefore. Manufacturingwillcertainlyfullycomprisedesignandprototyping,buttheyresultsinamodelonly, whichistobemultipliedlater(andefficiently).Incontradistinctiontomanufacturing,construction onlybuildsoneexample,whichareatthesametimetheprototypeandtheproduct.Theexploration stagesthroughconceptualdesign,evaluation,engineeringandtestingareprevalent.Itmaybe claimedthatconstructionisplacebound,forinstanceinsuchawaythatthephysicalcellsthatmight beconceivedforafactorythatmovespartsandpartlyfinishedproductsaroundisreplacedbyan artefactthatisinitselfthefactoryandthusneedstomovethedefactocellwithpeopleandtools around.Interpretingconstructionquiteliterally,onemightalsoseeconstructionasanindustrial process,whichisheavilyinfluencedofitssocial,culturalandinparticular,physicalsurroundings. Also,itmaybedistinguishablefrommanufacturinginasmuchastheproducthavingtobeusedinthe placewheretheywerebuild,ratherthaninmanufacturedforusewhereandwheneverthe customerchooses[20]. WemayalsoindicatethatthestateoftheartofLeanprescribesabottomupapproachtoplanning, inwhichonesstartswithweeklyworkplansandworkupwardstotheprojectschedule.

Akanbanisamessagetransmittedmanuallyorautomaticallybackupstreaminthesupplychaintopsignify depletionofapartthatisneededtomanufacturetheproduct.

1

NextShipLeanShipbuilding

11

Communicationsaboutrequirementsanddeliverieshavetobepersonalandvisible(lakanban)and soarecommitments,whichareindividuallyrequestedandgiven[20].Moreover,inthesameproject managementphilosophy,thelookaheadtoconstraintsneedingtobealleviatedinordertocomplete thetasksasindicated,andreviseandelaboratethephaseplansandthemasterschedule[20]. Movingtoleanconstruction,wemayalsohavetotakeintodueconsiderationthatthephysicalcells ofproductionandthedesignedlayoutoftheworkshopfloorwhichmakesimplementingsomeof Leansprinciplesratherintuitive,disappears.Leanconstructionextendsthescopeandneedfor visualinspectionandhumaninterventionwithregardstoqualitycontrol,theorganizationofworkis virtualratherthanphysicalandconcurrent(re)engineeringbecomesevenmorecrucial.Its sequentialityisattenuated,comparedtomanufacturing.[24] Wewanttoaddalso,forfuturereferenceandstudyintheNextShipproject,issuesof: Strategicdevelopment[25],e.g.,ofproductlines Design[26] Planning[20] Decisionmaking[27] Riskmanagement[28]and Communicationandcollaboration[29],

whichareareasthateachandoneindividuallyhavebeenmadethetopicofresearchfromawide varietyofacademicandpractitionervantagepoints,includingLean.

Leanprojectmanagement

ApplyingLeantoprojectmanagementpracticesalsoseemstobenecessarytomakesuchguidelines relevantforshipbuilding,inasmuchastheplanningstagesandrisk[crisis]managementcomeacross ascrucial[20]: Allproductlifecyclephasesneedtobeconsidered Stagescannotbelookedatindependentlyofeachother Productandprocessdesignisconnected(whichissomeflavourofdialectics/historical materialism,perhaps),and Projectsaregovernedthroughstructuringwork(planning)andcontrollingproduction.

Targetvaluedesignisoneapproach,whichbothcomprisesmanyelementsfromlean(eliminate waste,doonlytheworkthatisrequested),butalsocomesacrossasasetofmanagementprinciples, andaphilosophythatimplementsleandesign/construction[29]: Objectiveofcostmanagement:procure(construct)forlessthanallowablecost,usinggain sharing(vs.minimizeprize) Finalcostvs.estimatingtenderlimits Costbreakdown:Cost,profitsandcontingencies(vs.anycost) Setbyfeasibilitystudy(vs.estimates)

12

NextShipLeanShipbuilding

Functionschange(innovationmaybeneeded)vs.Costchange Interdisciplinaryteams(vs.divisionoflabour) Activeclient(vs.representedordistant) Projectorganization:valuebased(vs.costbased) Operatingprinciples:Colocation(vs.projectmanagementtools) Contracts:Relational,incentivebasedvs.transactionbased Riskmanagement:Consolidatedvs.riskshiftingdownthevaluechain

Leanshipbuilding

TheNorwegianshipbuildingindustryprideitselfbybeingabletobuildadvancedvesselsfor demandingservicesoffshore,whicharedeliveredontimeandanunsurpassedquality.Thecurrent distributionofconstructionwork,typicallywiththebulkofsteelworkandweldingtocreateeither modulesoracompletehullabroad[30],maybeinterpretedasevidencethattheapproachistoo costly,however.Therearehistoricalreasonsaswellasdemographicandstructuralexplanations,for Norwayssuccessinthemaritimesector.Forinstance,thereisawellfunctioningmaritimecluster, whichinitsturnmaybebolsteredbythedistributionandactivityofports,aswellasthe geographicalvicinitytorichnaturalresources[31]. Thecompetitiveadvantagesofaregionareneverguaranteedtolast,ofcourse,andinternational capacitytodeliverhullsandmoduleswillpotentiallyformthebasisforsterncompetitioninthe future.Thus,costandspeedofdeliverywillcontinuetobesignificantareasofimprovement,inorder fortheleadintheoffshorespecializedvesselcategorytobemaintained.Itisinthisperspectivethat theturntowardsLeanshipbuildingneedstobeassessed.Thereseemstobelimitedempirical evidencethatLeanwill,assuch,cutcosts[32],however,likemostmanagementstrategies, implementationisprobablymoreimportantthattheory. ThemajorelementsofLean,intheshapethattheytakewhentheyaremadeinparticularapplicable toshipbuilding,isinoneinstancereferredtoas[33]: Preciselyspecifyingthevalueofeachspecificproduct Identifyingthesocalledvaluestreamforeachproduct Makethevalueflowuninterrupted Letthecustomerinitiatetransaction(pull) Pursueperfection,reducingeffort,time,space,cost,andmistakeswhileofferingaproduct thatkeepsonconvergingtowardstheidealforthecustomer.

Thereareseveraladditionaltraits,whichconcernLeaninconstruction(ratherthanmanufacturing), however,whichalsoneedstobeconsideredcarefullyforshipyardslookingtowardsLeanasan organizationprinciplefortheirproduction: Thesiteitselfisaresource. Theproductionfacilitieshavetobesetupanewforeachnewbuild;indeed,thebuilding projectisinitselftheproductionfacilities.

NextShipLeanShipbuilding

13

Theproductionfacilitiesaswellastheteamsandworkers,areplacedonthesiteandin relationtoanother.

Inadditiontothis,thereareotheradaptations(andeffects)ofLeanthinking(withitsoriginofLean manufacturing),thathasbeenproposedinordertopitchitmoresuitablyforconstructiontype processes: Objectivesneedtobewellandfullyunderstood. Crossfunctionalteamsmaybeconcurrentlyactiveinthevaluestream. Designislikelytobeshiftedalongthevaluestream,i.e.,itisnotalldoneupfront Cycletimesarereduced Continuousimprovementoughttobeanintegralpartoftheprocess

Theproblem,ofcourse,isthatthesearenoteasilyoperationalassertions. Onquitetheotherendofthescale,towardsconcreterecommendationsandtechniques,wefind e.g.,thenotionofmeasuringwasteandefficiencybypercentagecompletedofplannedwork(PPC) (perweek),whichispromotedbyBallard[20],togetherwiththenotion/tooloflastplannerand lookaheadplanning,using[34]: 1. PPCefficiencymetrics 2. Thelastplannerprinciple 3. Lookaheadexercises;thepurposeofwhichistosmoothenworkflowandmaintaina suitablebacklogofassignmentsthataresound,i.e.,thattheactorsthemselvesjudgetobe executableorthatthecontingenciesnecessarytomaketheactivitiessoundareidentified andworkaroundsproposed. 4. Bottomupplanning,i.e.,thatthelookaheadplanandlastplannerinputsareallowedto shapethemasterandphaseschedules. InthenextsectionweshalllookathowthehistoricaloriginandthebasictenetsofLeansislivedat aNorwegianshipyard,whichisspecializedinoffshoreservicevessels.

Empiricalstudies

WehaveattendedseveralmeetingsatSTXOSV(aswellasothershipyardspreviously)concerningthe productionprocessingeneral,documentationandplanningmorespecifically.Inthefollowing itemizedlistofobservation,theimpressionsfromourfieldworkislinkedtoLeanguidelines: Thenotesindicatethatshipbuilding,ingeneral,aswellasobservablyatSTXOSV,mightstill altogetherbealongstepawayfromtrulyimplementingLeanproductionphilosophies,inasmuchas: Referencedprinciple 1. Longtermphilosophiesdo notgovernshorttermstrategies Comment ThetasksassignedtoanassemblyyardinNorwayisnotlong termstrategicallydecided,butratherajudgmentofcapacity intheshortterm,whichismadebytheboardofthegroup ratherthanthedirectorofthelocalyard.Thisdoesnotseem

14

NextShipLeanShipbuilding

2. Creatingacontinuousflowis hamperedbytheproductassite natureofconstructionatthe shipyard

3. Usingpullratherthan pushtoavoidstocksand overproduction,mayjeopardize supplysecurity

tobepartofalongtermphilosophy. ThesocalledToyotawaycallsforacontinuousflow,whichis theconceivednoninterruptedandmonotonouslyforward drivennatureofaprocess.Itisproblematictoimplementina settingthathassomeverylarge(andrelativelyfew)critical processstepsormachinesinplace,whichistypicallythecase forshipbuildingwithitscranesanddocks.Typically,a situationwasdescribedtousinoneofourmeetings,which entailedtheblockageofphysicalmovementofonemodule byworkonanother.Finally,strivingforcontinuousflow wouldseemalsoseemtotrytoreducethechangeorders, sincetheybydefinitionintroducesbackflows.Suchback flows,ontheotherhand,areassociatedinshipbuildingwith highvalueworkcarryingbettermarginsthanworkthat proceedsaccordingtoplan,andhenceitmaybemore difficulttoeliminate,notwithstandingthattherewasnotany indicationsgiventhattherelationshipbetweencontinuous flowandlucrativebackflowshadbeenexploredindetail. Also,therewasadistinctculturalexplicationofthe differencesbetweenyardsinNorwayande.g.,Romania, whichinwhichthelocalyardsweredescribedashavingmore ofanartisan(incontrasttoindustrial)historyandhence, intuitiveeyeforshipbuilding,whichmadelocalworkers understandintentionbetter.Thisisanotionalapproach, whichinadditiontravelspoorlysincedistanceanddifferences (culturalorotherwise)makesitmoredifficultto communicate.Thispartofourfieldworkobservation, regardingcommunicationisnottheonlypertaining component.Inadditioniswasrecountedhowthedrawings wereneverfinished,forvariousreasons,3Ddrawingsare poorlytranslatedinto2Dinstructions,sincetheformeris concludedinamoreholisticway.Themainpointtonotice hereisnottheexplanations,butratherthattheexpectations, whichthusreifiedthenotionofaculturaldifference,wasthat thesteelyardsinRomanianeededprecisedrawingsand instructionsinordertodotheirworkwithoutwasteoftime andmaterials,whilsttheNorwegianyardsexcelledexactlyin managingwellwithoutthosedetaileddrawings.Thesame argumentcoversplansandplanningaswell,andisobservable bythestatementthatideally,ourmangerswanttobe handedaplanthatsaysbuildship,andthenon informativenessofplanning.Thelattercanbeseenintwo way,firstthatplansareusuallyreusedonthemacrolevel, whentheylooklikecomponentlists,andrelativelystaticand noncommunicativeonthelowerlevels.Again,theissuesof communicationisbroughttothefore. Theneedtosecuredeliveriesofverylargeandsometimes complex(orboth)goods,whicharenotnecessarilyavailable fromaproductionlinewithunlimitedcapacity(suchas thrusters,streamers,lightingandsubseacapacity),stocksare necessaryinshipproduction

NextShipLeanShipbuilding 4. Theworkloadisprobably quiteconjuncturedependent (makingHeijunkaunrealistic)

15

Theworkloadisatthemacrolevelnotunderthecontrolof theshipyard,itmayjustasmuchbeseenasduetotheoil price(alittlecrudelystated,butstill),andinadditionthe boardoftheSTXOSVgroupdecidedonshortnoticewhere andwhentoallocatenewbuildstotheyards.Ontopofthis, repairsandmodificationsarisefrequently;theaftermarketis importantaswell. Eveniferrorsareknown,theymaynotberepairedatonce, 5. Repairingatoncewhen errorsarefoundmaybeincalculable sincethecostofrepairisexcessivecomparedtothecostof delays.Forinstance,asteelplatewhichiscuttosmallmay vs.risk,costandthefuture developmentoftechnologiesand onlyberepairedbywelding,anoperationwhichmaywait policies. untilassemblysincetheamountofweldingworkneededis likelytobedefendable.Ontheotherhand,thebroken processmighthavebeenrepaired,butonlyiftheerroris recurringormoreexpensivethandelaysofthisparticular constructionproject.Moreover,itisinthatlightoneneeds againtoinspecttheculturaldifferences(drawingona valuationofaccuracyvs.independenceofworkersvs.the costofmanhours),indeedallowingittoreflectbackonthe reasonforusingthesubcontractedinaccuratecutterinthe firstplace.Ifanimprovedprocessraisedthecost,itseems reasonabletoexpectthatthecustomerwilllookaroundfor otheroptions,whicharecheaper.Ontheotherhand,later buildsmayrequiredifferentsubcontractingpoliciesor productionprocessesandnewtechnology(forautomating welding,e.g.),maybeinplaceanyway,sothatinthisregard, theuncertaintyofmakingtheerrorcorrectiondecisionis higherthanitmightseematfirstglance.Forinstance,the groupmaydecidetotenderworkatanindependentyard later,inwhichcasetherepairofflawedcuttingwouldhave tobeseenasawasteinitself,underLeanterminology. Giventhattheworkplaceisalsothestorageandpartofthe 6. Standardizedtasksare constructedmechanicalstructure;thatitdevelopstherefore neededforimprovementand throughoutaprocesswhichissubjecttovariationduetothe empowerment,butmaybeelusive paradoxofvariationofpartsifstockiseliminatedvs.thelack ofslackinspaceandsuppliersproductioncapacity,which maybestrained,aswellasthemanpowerdemandwhichis greatoverall,butnotusuallyastaticresource(peoplewillbe sick,takeholidaysandretire,require(re)trainingorattendto theirfamiliesduringprojectsthatgoonforayearormore), tasksarelesslikelytobestandardizable. 7. Bringingproblemstothe Theinitialresponsefromsubjectsthatwehavetalkedtoin surfacemayreduceflexibilityand theshipbuildingindustryhasthroughouttheprojectperiod trust beenthateverythingisundercontrol.Thisis understandable.Productsarecomplex;constructionis completelydelegatedandorders,aswellasfundingrelieson trust.Ontheotherhand,problemsdo,infactarise,and henceitmaybeconcludedthatincreasedtransparency reducesflexibility.Visualization(anddocumentationin general)mustbeseeninlightofthis. 8. Usingknowntechnologyis Thetraditionofshipbuildingasamanualcraftcomesthrough

16 sometimesseenasbackwardsand defensive

NextShipLeanShipbuilding

clearlywhenwediscusstheusageofintegrationservicehubs, suchasthoseimplementedontopofSharepoint(eventually tobecomplementedorreplacedbyAveva).Thetoolsseem tobelessfamiliartomanagementthanmightbeexpected,if, indeed,theplanningandprocessmanagementaspectsofthe jobisbeingupgradedtosupportleanconstructionandnext generationplanningtechniques.Ontheotherhand, managementisexpectedtoexploitthecommercialpotential ofnewtechnology. 9. Educateleadersand Inourfieldwork,STXOSVhasprovidedanaccount,artefacts employeestakestimeandispartof anddemonstrationsofacompetenceorientedmanagement alargerdynamics style,inwhichpeopleareconstantlymadeawareofthecore elementsofleanshipbuilding.TheinterpretationofLean(at themanagementside)variesfromtextbookexplication, however,andforemenandworkersdifferinthenextinstance evenwithinwhattheyhavebeentaught.Evaluationofthe learningoutcomeseemsnecessary. TherelationshipbetweentheSTXOSVyard(s)inNorwayand 10. Respectandchallenge theirRomanianpartneryardsseemtostillbeinginformation, partnersandsuppliers;thisisan anditwasbeingcharacterizedbydifferencesinhistory, ideal(human)ambitionthatis tradition,cultureandtechnology,aswellaseconomy.Thefull alwayschallenging. ramificationsofthishasnotbeenexploredordescribedby ourproject,sofar,butthisiscertainlyoneissuethatshould beputontheagenda.Thiswasnoindicationthatstrategicor operationalmanagementhadfundamentallydifferentvalues fromtheiremployeesandsubcontractorslocally. ThemanagementofSTXOSVhasadeeppersonal 11. Investigatepersonally (Genchigenbutsu);thisseemstobe involvementandiswillingandabletocarryoutnecessary bolsteredbyastrongmanagement researchandanalysisactivities,insofaraswehavebeenable todiscover. culture Wehavenotbeenabletodiscerndetailsaboutthedecision 12. Makedecisionsslowly, makingprocess,buttherehavebeenindicationsgoingboth implementthemrapidly;decision ways,ontheconcreteandinstancebasedlevelofallocating makingandtherealizationof jobs(buildsandrepairs)totheyards,aswellasvarying decisionsismultifaceted commitmenttoleanamongmiddlelevelmanagement, whichmayindicatethatthedecisioninfavourofthe approachmightneedevenbetteranchoring. 13. Supportrelentlessreflection Wedonothavethenecessaryinsighttoassertthatthelevel (Hansei)and ofreflectionisneitherunsupportednorrelentless.The participationofSTXOSVintheNextShipprojectisapositive sign. 14. Supportcontinuous TheactivitiesofSTXOSVthatwearebeingexposedtoinour Improvement(Kaizen) researchareapositivesigninthemselves. Similarly,wemaymoveontowardevenmoreconcreterecommendationsofimplementingleanin construction,adheringtomoreoperationalguidelines: Referencedguideline 15. Preciselyspecifyingthevalueof eachspecificproduct Comment Thiselementisprobablyinneedofadaptationand translationtothespecificcircumstancesofshipyards.Whatis

NextShipLeanShipbuilding

17

16. Identifyingthesocalledvalue streamforeachproduct

17. 18.

19.

20.

forinstance,eachproduct? Thisispossiblyimplementedintheearnedvalueapproach toplanning,however,wedidnotfinditwidely operationalizedduringourshortfieldstudyandvisits.This shouldbefurtherresearched. Makethevalueflow Today,thereareinterruptions,ascommentedabove,largely uninterrupted duetoextraneousfactorswhicharenoteasilyeliminated. Letthecustomerinitiate Inasmuchastheentirevaluechainneedstobehandled transaction(pull) insidethesameparadigm,itcanbenecessarytonotethat eventhecustomerdoesnotinaonesidefashion,representa definiteandunequivocalpull.Shipsaresometimesordered tosecureaslotintheproductioncapacitysystem,moreover, ownerknowthatthesales/contractingeffortsthattheyhave tostart(andconclude)beforeshipsarefinished,mayrequire thespecificationstoberewritten,andsodoestheyard.Ona lower(moredownstream)level,theyarditselfhastoorder workandpartsbeforethedrawingshavebeenfinally approbated,eveniftheyknowthisislikelytoleadto redesigns.Acompletelynonconcurrentengineeringlifecycle wouldtaketoolongtimetocomplete.Theyardalsohasto secureproductioncapacitywithsuppliers,andthus,order mightneedtobeplacedinaslightpushratherthanwait untiltheyarepulled.Theproductinquestionisnotonly(or evenmainly)aphysicalartefactthatisneededinaconcrete andgivenform,thesaleseffortsmaybeinitiatedfurther upstream,byadesignoffice,consultantsoreventheyard itself,iftheyhavecontractedashipfromthemselvestocover byriskandbeliefthattheintherighttimeabuyerwillbe available. Theideathatthereexistsoneidealproductforthecustomer Pursueperfection,reducing seemsambitious,inasituationwheremarketdemand, effort,time,space,cost,and financingandtechnologyvary.Thesecorefactorsneedtobe mistakeswhileofferinga productthatkeepson analysedwithregardstodecisionmakingunderuncertainty convergingtowardstheidealfor andperhapsinrelationshiptoeachother,inparticular.One thecustomer. mayingeneralsuspectthatuncertaintyislargelyignored [35],whichmay[ibid]bebroughttotheforeinsuch analyticalendeavors,whichcomplementthetraditional planningorientation. Objectivesarewellandfully Wehavehadnoopportunitytogatherinformationaboutthe understood extenttowhichobjectivesareshared,butwereceived indicationthatthegroupstructuremightbemorebrittlethan nameandlogomightindicate.Yardswithinagroup (notwithstandingtherelationshipwithsuppliersandpartners whoalsohavecompetitivebidsgoingwithotheryards)may inthefuturebecompetitorsagain(weweretold),inthe eventofabreakupofthegroup,andtheemployeesare awareofit.Moreover,wedoneedtoaskiftheobjectivesof managementwhowantsamorepredictableprocessandless expensivevesselsproducedinsemiseries,aresharedbytheir staff,suppliersandsubcontractors,andindeed,ifitisshared bythecustomer.

18 21. Crossfunctionalteamsare concurrentlyactiveinthevalue stream 22. Designisshiftedalongthevalue stream,i.e,.notalldoneup front

NextShipLeanShipbuilding

Wehavereasontobelievethatthisisthecase.

23. Cycletimesarereduced

24. Lookahead,thepurposeof whichistosmoothenworkflow andmaintainasuitablebacklog ofassignmentsthataresound, i.e.,thattheactorsthemselves judgetobeexecutableorthat thecontingenciesnecessaryto maketheactivitiessoundare identifiedandworkarounds proposed. 25. Bottomupplanning,i.e.,that thelookaheadplanandlast plannerinputsareallowedto shapethemasterandphase schedules.

Thisisacriticalissue,whichweperceivedwasdefactothe casealready(i.e.,thesteelyardsandoutfittershadto improviseandadapttodealwiththedynamicsofthe supplies,technologyandincompletenessofdrawingsat certainstages).Ontheotherhand,tensionisraised, potentially.Managementwillwanttoimplementa predictableprocess,which,giventhatitisoneoff(largely) onecannotexpect.Repeatconstruction(manufacturing)may betunesandempiricallyestimatedwithprecision,butthe sameishardlythecaseforbig,uniqueprojects. Theremaybealackofrealisminherentintheusageofthe termleanshipbuilding,atleastunlessonemanagestounite aroundagoalofbuildingmanycopied,simplerdesigns, comprisingmorestandardizedsolutionsandmainstream componentsandtechnology. Thislevelofrationalityandoversightisdefinitelyanaimto strivefor,however,itmaybedifficulttoachievegiventhe incompletenessofinformation(whichpointstowardsa judgementofnonsoundactivities)vs.amultistakeholder universeinwhicheachactorisnot,asitwere,freetomake suchcallsindependentofotherandmorepowerfulagents.

Thisisanexpression,asweseeit,oftheneedinplanningto beresponsiveonthetopofanappreciationofinterteam communication[36,37],whichhasbeenrelativewell attendedtoaspartoftheleanliterature.

Oneofthecurrentmostprecariousneedofamodernshipyard,istobeabletomonitor,recordand analyseprogress,insofarasthatsetsthemupforbeingabletodeliverthevesselthatwasspecified onthedatethatitwaspromised.Wehavealsoshownthatitisanindustrywhichisvariable,indeed thatitmakesagoodearningfromchangeorders,withintheNorwegianmaritimeclusterthatit needstobeinnovativeandresponsive,inordertocompetewithlowcostcountries,andhencethat Leanmaynotbethemostappropriatewayforward,accordingtosomeresearch[19].Onbehalfof Lean,ontheotherhand,itmaybeseenasencouragingthatotherprojectsofasimilarnaturehave enjoyedgreatsuccesswithLean,allegedly,andthatmeasureshavethusbeenproposedtodealwith theinherentcomplexitiesofsmalllot,highcomplexityandvalueaddingengineertoorderand manufacturing,suchaslastplanner,weeklyworkplans,lookaheadprocesses,phaseschedulingand evaluation(learningfromfailure)[20].

NextShipLeanShipbuilding

19

StateoftheartofLeantodaymayalsobeseenasplayingapivotalroleinthetransitionfromvery traditional,mechanisticandtopdownpreemptyingapproachprojectmanagement,intoanagile andsituatedapproachtoprojectmanagement,whichistypicallydescribedasmoreorganicand bottomup(sourced).Classicalprojectmanagement,thus,isbasedontheassumptionthattheplan somehowdoesreflectthestateofaffairs,andthatchangingtheplanwill(contribute)tochanging thatexternalworld.Hence,italsofollowsthatiftheplanisinaccurateorwrong,itisduetoerrors, lackofinsightorinformationorachangeofdirection,andthatitneedstobecontinuouslyupdated inordertoserveasamapoffutureprocessesaswell.Theoppositeperspectiveofplanning,whichis notparticularlynewanymoreeither,isthatplansareresourcesthatmoreorlessproductivelyare usedbymembersoftheorganizationtoindicate,andindeed,planwhattheywanttodo,butthatin actuallydoingtheyrespondtotheconcreteanddetailedcircumstancesofthesettingthattheyare in,matchingthemapwiththenewrealityratherthantheotherwayaround.Hence,amapmaybea moreorlessaccuraterepresentationofwhathasbeengoingon,butitisnotusefulinanormative way[38]. ThemostcrucialaspectsofProjectManagement2.0,whichiswherethistransitionistheprojected toendup,istoestablish[39]: Asharedglobalawarenessofadynamicsituation:Thisentailsrichandmeaningful informationbeingexchangedcontinuouslybetweenmembersoftheorganization,whomay havetobeadvancedusersofcommunicationsolutioninordertogetthedatathattheyneed withoutsufferinginformationoverload. Rapidresponsestounexpectedevents,whichismadepossiblebyhighlymotivatedand competentworkerscombininglocalresourcesbasedonaglobaloverview,andtheurgeto createvaluefortheclientandminimizewaste,henceadheringalsototheprinciplesoflean construction. Thereis,arguably,arelationshiptoplans,whenauthorstalkaboutinspectionintervals,and clearly,thelengthsofcyclesaswellastestingandinspectionrepresentapproachesto dealingwithuncertaintyandrisk.Batchsizesandthenumbersofkanbansarealso,according tosomeresearchers,likeParveenandRao[22],linkedtotheconsiderationthatreworkcan andwilltakeplace.

Thus,evenintheleancaseofSTXOSV,itmightbefruitfultolookattheinvestmentneededto maintainoptimalinventoryandthemutualauditingprocedures(MAP2),whichinvolveinspection, testing,rework,etc.,notlikewaste,butratherasawayofminimizingit. Doingawaywiththetools/vehiclestominimizewastebasedonamisguidedapprehensionthatthese areinthemselveswasteispotentiallyasourceofevenmorewaste.

Discussion

Shipbuildersseemreluctanttoimplementthetightintegrationofthesupplychainsthatisnecessary forjustintimetowork.Itcouldbebecausetheyworryaboutlackofconfidentialityorthecostof

2

ThiscouldperhapsbeaconceptualcontributionofNextShip

20

NextShipLeanShipbuilding

communication[22].IncontractstoParveenandRao[ibid],however,wehypothesizethattheco ordinationcostsactuallyincreaseiftheydonot. Qualitycontrolisacorepartoflean,weventurethatthisisaccordingtoverynarrowqualitycriteria, meaninglowvariance.TheNorwegianshipbuildingmodel,however,affordsvariationand improvisation,inordertostayinnovative.Thisisanother,nontranslatablequalitynotion,totheone thatiscommonlydiscussedinlean. Therehavebeenotherissuesdiscussedelsewhereaswell,e.g.,therelationshipbetweenthesupply chainandenduserdemand,whichcannotbeindependentofeachotherforleanmanufacturingto bepossible,accordingtosome[40].Similarly,Cochranetal.claims[41]: Manufacturingneedstohaveasharedcoordinationmechanism,whichcontributesto reconcilethemanufacturingstrategy. Manufacturingneedstobeaccommodatingtherequiredflexibility.

WecannothelpnoticingthestatementfromSTXOSVmanagersthatsalesandmarketingacceptand placeordersatyards,regardlessoftheircapacityandcurrentworkingrelationshipfurtherupstream towardsthehullyardsandmanufacturingprocesses,whichintentionallyarenotpitchedtowards flexibility(althoughtheNorwegianyardsare),whichmayimplicateapermanentstateofconflict, whichLeancannotpossiblyalleviate.WemayalsohavetoaskiftheNorwegianapproachassuchis aturnagainstleansinceitbufferssupplierscontactthroughthemakerslist,i.e.,stops communicationdirectlybetweensuppliersandthecustomer[42]. Lookingatthejustintimeaspectofleanshipbuilding,itseemsthattheadvantagesofreduced inventories,reducedleadtimes,higherqualityreducedscrapandreworkrates,anabilitytokeepto schedules,increasedflexibility,easierautomationandbetterutilizationofworkersandequipment [22,p.183],donotreallyapplyinthisdomain,sinceobjectivethecostofanywouldbenegligible comparedtothecostofaship,withoneexception(whichiscontradictorytotheothers),andthatis tokeeptheschedule.Wemayreferagaintothefieldwork,wherewehaveheardmanagersatSTX OSVseveraltimesquotingtheimportancenever,everlettingthefinaldeliverydateslip. Shipbuildingmaybeaparticularlychallengingdomainontowhichtoimplementleansystems[43], sincetheycomefromatraditionoffixedpriceandtimecontracts,whichisatriskbothwithregards totherealizationcostandprofitabilityfortheyard,butalsobecausewhenrequirementschange,the variationorders,whichmay,indeed,disruptthescheduleandinterferewithcapacitiesplannedfor otherprojects,arestillanopportunityfortheyardtoincreasetheprofitabilityoftheproject[20]. KarolisandOterhalsincontrast,recommendsimplification,visualizationandinformationflow[43]as anapproachtoimproveefficiency.Theyalsocommentonthelackofcontrolofphasesandtheir transition,andassertthatthis []meansasignificantincreaseinprojectcost,disruptionofworkflowandplannedworksequence, overburdeningofworkforce,whichultimately,canresultinlatedeliveryofthefinalproduct[43p. 325].

NextShipLeanShipbuilding

21

Thissupportsoursuspicionthatacontradictionofobjectivesmaystronglyinferencewiththeplanof becomingLeanamongNorwegianspecializedshipyards.Abriefdiscussionofsomecoreissuesand aspectsofthisiscertainlywarranted.

HeijunkainLeanshipbuilding

TherehavebeenevenmorerecentpaperspublishedonLeaninshipbuildinghowever,e.g.[44],in whichitisclaimedthat Whereastheonesidedweldingtechnologyisimplementedinthepanellinesoftheshipyardsofmost WesternEuropeancountries,thisinandofitselfisnotleanmanufacturing.Theimplementationof onepieceflowasopposedtocreatinglargebedplatesandthenplacingthelongitudinalsandwelding isrequired.Determiningstepsnecessarytotransformtraditionalpanelassemblytoleanonepiece flowmanufacturingisnecessary.Thewastethatisinherentintraditionalpanellinesandwhichcan beeliminatedinleanpanellinesincludesoverproduction,waiting,unnecessarymotions, overprocessing,transportandinventories,anddefects[ibid,p.2021]. Itisclaimed,inparticular,byKolietal.,thatitisnecessarytotransformthetraditionalshipblock assemblyprocesswithaleaneronepieceflow,inwhichuniformplatesareoutfittedandwielded withlongitudinalsbeforetheyareassembled,ratherthantheotherwayaround.Thisaffordsrobotic wieldingandleveledproductiontoalargerextend,duetoanequalingoftakttimeswhenpanelsare notassembleduntilthetransverseribshavetobemounted.

Genchigenbutsu(investigatepersonally)inLeanshipbuilding

ThetraditionofNorwegianshipyardsisformanagementtobedelegatedtotheforemenandco ordinatorsofindividualbuilds.Expereincefromtheprelimiaryinvestigationscarriedoutaspartof theactionresearchpartofNextShipaswellasother,relatedprojectsatMreforskningMoldeAS, indicatesthatthereispotentialtoimplementGenchigenbutsuaspartofaLeanstrategy.Onthe otherhand,wewerealsotoldinexplicittermsthatstrategicmanagementandthelargescale resourceallocationdecisions(wheretobuild,whentobidandcommission,etc.)weremadeone sidedlybytheboardofdirectorsoftheshipyardgroup,ratherthanlocalmanagement.Thus,there seemstoberoomforaleanerapproach,indeed,ifthisisjudgedtobeamoreimportantstrategic imperativethanshorttermmeetingtherequirementsofthemarket.

Hansei(reflexiveapproaches)inLeanshipbuilding

Hanseimeansreflectionandconsideration,whichindicatesaconsciousnessofworkandimpactthat workhasonitssurroundings.Atleastpointingtowardstheneedforawiderperspectiveonlearning andimprovement,wemightforthisLeanguidelinebeabletoindicateaneedtolookatthewider ecologyofthesupplychainandaimtosupportmutuallybeneficiallearningacrosssitesandfirms, whicharepartnersorcustomersuppliers[45].

Kaizen(continuousimprovement)inLeanshipbuilding

IntheambitionofKaizen(continuousimprovement),thereisusuallyanorientationtowards encouragingandsupportingallworkersininputtingsuggestionstohowasteporaprocessmaybe improved.Similarlytohansei,itmayinsomeinstancesprovemoredifficulttobolstersuchfeedback fromthefactoryfloow,whenincitementprogrammesandcompanyculturesareasdifferentasthey

22

NextShipLeanShipbuilding

seembetweenahullyardinRomaniaandanassemblyyardinNorway.Itseemsproductiveinorder toachievesuchlearning(fromeachother),especiallyonadeeper,doublelooplevel[46]thatexplicit mechanismsbebutinplacetobridgethedifferencesbetweentheyards.

Conclusion

Thequestionneedstobeasked,thus,inconclusionofthisreport,whyshipbuildingseemstobe differentfromothertypesofconstructionandengineeringwork,whenitcomestoimplementing leanprinciples. WehaveinLeanseenpromotedanotionofsocalledsoundactivities,and it seems reasonable to

assume that the presence of each of the seven conditions for sound production will affect the ability to be lean. These activity constraints are, in summary [47]:

Informationneedstobepresentinduetime,sothateverybodycanplantheirworkproperly; Previousactivitieshavetobecompletedasplannedpreventsreleaseresourcesuponcompletion; Sufficientmanningreducesthepossibilityofstress,improvisationandnontaktperformance;Taktis thefixedpaceallotmentofresources,whichissufficienttodealwiththemaximumcomplexitiesof anygivensubsetofoperation,anditisanotionthathavealsobeenstudiedwithregardsto implementingLeaninshipbuilding[15]. Therightequipmentandaproperandwellorganizedconstructionsitealsoreducetheriskof disruptions. Ithasbeenclaimedthatsoundactivitiesperhapsmakeiteasiertostayinthespaceofnonchaos [48].Itmightbetemptingtherefore,toconcludethatboxinginactivitiesinasounderlandscape willmakethemleaner,however,oneneedstocarefullyinvestigatethedistinctlyintractablenature ofshipbuildingandthechallengesthereof: Thesiteandtheproductevolvingthroughouttheprojectintoamerger,inasmuchasthe product(i.e.,avessel)initselfalsobecomesthespaceavailabletoplanandconductthe work(theprocess)aswellasstoringpartsandtools,eventhelodgingofworkers.The externalworkplace(factory)compriseslarge,inflexiblestructuressuchascranes,docks, quaysand Duetotheoneoffnaturedesign,engineeringandsupplychainmanagementtakesplacein parallel.Evenofsistershipsthelearningeffectisreduced,since o Theworkspaceisunique(yardsusuallycannotaccommodateanassemblylineof manyships)duetosize,andworkprocessesonthemicrolevelcertainly,dependson thedynamicsofthebuildingtakingplacetocreateproductthatencompassesthe workitself. o Thebuildingscheduleissufficientlylonglastingtoontheonhandexpecttheoptimal priceperformancemixofcomponentstochangeduetotechnologicaldevelopment andrenegotiationofprices,andthechangeofassignmentsbytheownerdueto

NextShipLeanShipbuilding

23

changingmarketcondition,whichintheirturnimplicateschangestothe requirementspecification.Indeed,ownersmayinhightimesordershipssimplyto havetheminthepipeline,thusavoidingtohavetobattleforlimitedyardcapacity onceworkorderscomesin.Onealsohastobearinmindthatthesekindsofchanges areusuallytheresultofcontractualchangeorders(COs),whichareprofitableforthe yard. Ahighpercentageofthevalueaddedworkcomprisesprefabricationandoutfittingof moduleselsewhere,beforetheyareshippedtothecommissioningyardforassemblyand testing.Moreover,engineeringtoalargeextenddepartsfromapartslistandalistof supplierswhohavealonglasting,functioningrelationshipwiththeyard.Therobustnessand engineeringabilityofpartsaswellassafetyofdeliveriesareprobablyparamounttocost andspeedofdelivery. Acloselyrelatedpointtothepreviousisthattheadvantageofgeographicalproximity betweenactorsinasupplychainnetwork,eveninaglobalindustry.Thismaybeduetothe innovativenessandcompetitivenatureofthebusiness,whichleadstosignificant customizationthroughoutthephases.

Itmightseemthatthefundamentallogisticalequationissomewhatdifferent,withregardstoat leastsomeofthesoundnessfactorsrecountedabove. Ourpaperclearlypointstowardssimilarfindingstothosethatsomeauthorsreportfromthebuilding andconstructionindustry[9].Theyreportthattheremovalofcapacityfromthesystemthatisa resultofLeansambitiontoreducewasteandincreasetheutilizationdegreeofworkers,alsoremove flexibilitytodealwithinherentcomplexityanduncertainty.Ontheotherhand,wehavealso complementedanddeepenedthisforourdomainspecifically,forinstancebypointingtothe differencesbetweenahostoffactorsthatissometimesglossedasculturaldifference.Ishasbeen simpletoseethatthestrategicambitionofdevelopingaleanandlowcoststeelyard,whichhas voluminousandtraditionallytieredorganizationsabroad,sitspoorlywiththeoppositeheritageand pridetobepredominantlyadesignandassemblyyardathome,intermsofroleandmanagement structuralmodelling ThisreportisintendedtoprovideinputtoafurtherdiscussionoftheseissuesintheNextShip project,toevenmoreclearlyestablishthefundamentaldifferences(andsimilarities)ofthemaritime clusteractivitiesandfirmsinourregionvs.moretrivialconstructionanddegreesofmass manufacturing.Thereare,inconclusion,manywaysofbecominglean,anditisinterpretedand implementeddifferentlydependingonitstargetdomainandambition.Moreover,thescopeofthe implementationprocess,e.g.,withregardstothedegreeofwhichitincludestheentiresupplychain, isvariableandinfluential.Indeed,forfurtherresearchthisdimensionshouldinandbyitselfbe includedasaresearchtopic,asshouldotherreasonsandeffectsofcompaniesandtheirmanagers claimingthatLeanconstitutesoneoftheircorevaluesandintentions.

24

NextShipLeanShipbuilding

References

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] S.Bertelsen,"LeanConstruction:Whereareweandhowtoproceed,"LeanConstruction Journal,vol.1,p.46,2004. H.Thomas,M.Horman,R.Minchin,andD.Chen,"ImprovingLaborFlowReliabilityforBetter ProductivityasLeanConstructionPrinciple,"JournalofConstructionEngineeringand Management,vol.129,pp.251261,2003. H.Thomas,M.Horman,U.deSouza,andI.Zavski,"ReducingVariabilitytoImprove PerformanceasaLeanConstructionPrinciple,"JournalofConstructionEngineeringand Management,vol.128,pp.144154,2002. D.A.MouraandR.C.Botter,"Canashipyardworktowardsleanshipbuildingoragile manufacturing?,"inSustainableMaritimeTransportationandExploitationofSeaResources, RizzutoandG.Soares,Eds.,edLondon:Taylor&FrancisGroup,2012. I.Cabral,A.Grilo,andV.CruzMachado,"AdecisionmakingmodelforLean,Agile,Resilient andGreensupplychainmanagement,"InternationalJournalofProductionResearch,vol.50, pp.48304845,2012/09/012012. J.BenNaylor,M.M.Naim,andD.Berry,"Leagility:Integratingtheleanandagile manufacturingparadigmsinthetotalsupplychain,"InternationalJournalofProduction Economics,vol.62,pp.107118,1999. A.Gunasekaran,"Agilemanufacturing:Aframeworkforresearchanddevelopment," InternationalJournalofProductionEconomics,vol.62,pp.87105,1999. D.SeymourandJ.Rooke,"Theroleofethnographyintheimplementationoflean construction,"presentedatthe9thInt.GroupforLeanConstructionConf.,2001. A.Fearne,"Efficiencyversuseffectivenessinconstructionsupplychains:thedangersof leanthinkinginisolation,"SupplyChainManagement,vol.11,p.283,2006. B.Dankbaar,"LeanProduction:Denial,ConfirmationorExtensionofSociotechnicalSystems Design?,"HumanRelations,vol.50,pp.567584,1997. G.AnandandR.Kodali,"Developmentofaframeworkforimplementationoflean manufacturingsystems,"InternationalJournalofManagementPractice,vol.4,pp.95116, 2010. L.Argote,S.L.Beckman,andD.Epple,"ThePersistenceandTransferofLearninginIndustrial Settings,"ManagementScience,vol.36,pp.140154,February1,19901990. H.MoystandB.Das,"FactorsAffectingShipDesignandConstructionLeadTimeandCost," JournalofShipProduction,vol.21,pp.186194,2005. P.C.Koenig,H.Narita,andK.Baba,"LeanProductionintheJapaneseShipbuilding Industry?,"JournalofShipProduction,vol.18,pp.167174,2002. J.K.LikerandT.Lamb,"WhatisLeanShipConstructionandRepair?,"JournalofShip Production,vol.18,pp.121142,2002. C.Berggren,"LeanProduction.TheEndofHistory?,"Work,Employment&Society,vol.7, pp.163188,June1,19931993. M.Holweg,"Thegenealogyofleanproduction,"JournalofOperationsManagement,vol.25, pp.420437,2007. R.ShahandP.T.Ward,"Defininganddevelopingmeasuresofleanproduction,"Journalof OperationsManagement,vol.25,pp.785805,2007. O.Salem,J.Solomon,A.Genaidy,andI.Minkarah,"LeanConstruction:FromTheoryto Implementation,"JournalofManagementinEngineering,vol.22,pp.168175,2006/10/01 2006. G.BallardandI.Tommelein,"Leanmanagementmethodsforcomplexprojects,"Engineering ProjectOrganizationJournal,vol.2,pp.8596,2012/06/012012.

NextShipLeanShipbuilding [21] [22] [23] [24] [25] [26] [27] [28] [29] [30] [31] [32] [33] [34] [35] [36] [37] [38] [39] [40]

25

S.Kumar,D.Choe,andS.Venkataramani,"AchievingcustomerserviceexcellenceusingLean PullReplenishment,"InternationalJournalofProductivityandPerformanceManagement, vol.62,pp.85109,2013. M.ParveenandT.V.V.L.N.Rao,"Anintegratedapproachtodesignandanalysisoflean manufacturingsystem:aperspectiveofleansupplychain,"InternationalJournalofServices andOperationsManagement,vol.5,pp.175208,2009. F.Jacobs,J.E.Folkestad,andS.Glick,"ReviewofConstructionLeanResearchStudiesin SupportofLeanTransformationtotheConstructionOperatingPlatform,"Journalof EnterpriseTransformation,vol.2,pp.157176,2012/07/012012. O.Paez,S.Salem,J.Solomon,andA.Genaidy,"Movingfromleanmanufacturingtolean construction:Towardacommonsociotechnologicalframework,"HumanFactorsand ErgonomicsinManufacturing&ServiceIndustries,vol.15,pp.233245,2005. G.Manville,R.Greatbanks,R.Krishnasamy,andD.W.Parker,"Criticalsuccessfactorsfor LeanSixSigmaprogrammes:aviewfrommiddlemanagement,"InternationalJournalof Quality&ReliabilityManagement,vol.29,pp.720,2012. M.Solesvik,SimulationandOptimizationinCollaborativeShipDesign:InnovativeApproach CooperativeDesign,Visualization,andEngineeringvol.7467,2012. M.Celik,C.Kahraman,S.Cebi,andI.D.Er,"Fuzzyaxiomaticdesignbasedperformance evaluationmodelfordockingfacilitiesinshipbuildingindustry:ThecaseofTurkish shipyards,"ExpertSystemswithApplications,vol.36,pp.599615,2009. D.Aloini,"Supplychainmanagement:areviewofimplementationrisksintheconstruction industry,"BusinessProcessManagementJournal,vol.18,p.735,2012. D.Zimina,G.Ballard,andC.Pasquire,"Targetvaluedesign:usingcollaborationandalean approachtoreduceconstructioncost,"ConstructionManagementandEconomics,vol.30, pp.383398,2012/05/012012. M.Z.SolesvikandP.Westhead.,"Partnerselectionforstrategicalliances:Casestudyinsights fromthemaritimeindustry.,"IndustrialManagement+DataSystemsvol.110,pp.841860, 2010. Y.C.Chang,"TheImpactofMaritimeClusters,"inOceanGovernance.Awayforward,ed: SpringerNetherlands,2012,pp.103109. L.Koskela,"Movingonbeyondleanthinking,"LeanConstructionJournal,vol.1,pp.2437, 2004. J.P.WomackandD.T.[ones,"BeyondToyota:HowtoRootOutWasteandPursue Perfection,"HARVARDBUSINESSREVIEWpp.140,SeptemberOctober1996. A.Mossman,G.Ballard,andC.Pasquire,"Thegrowingcaseforleanconstruction," ConstructionResearchandInnovation,vol.2,pp.3034,2011. T.Ruefli,"Strategiccontrolofcorporatedevelopmentunderambiguouscircumstances," Managementscience,vol.27,p.1158,1981. J.M.WorleyandT.L.Doolen,"Theroleofcommunicationandmanagementsupportina leanmanufacturingimplementation,"ManagementDecision,vol.44,pp.228245,2006. H.M.PerumalPuvanasvaran,TangSaiHong,MuhamadMohd.Razali,"Therolesof communicationprocessforaneffectiveleanmanufacturingimplementation,"Journalof IndustrialEngineeringandManagement,vol.2,2009. L.A.Suchman,Plansandsituatedactions:theproblemofhumanmachinecommunication: CambridgeUniversityPress,1987. R.E.Levitt,"Towardsprojectmanagement2.0,"EngineeringProjectOrganizationJournal, vol.1,pp.197210,2011/09/012011. J.B.Naylor,M.M.Naim,andD.Berry,"Leagility:Integratingtheleanandagile manufacturingparadigmsinthetotalsupplychain,"InternationalJournalofProduction Economics,vol.62,pp.107118,1999.

26 [41] [42] [43] [44] [45] [46] [47]

NextShipLeanShipbuilding

[48]

D.S.Cochran,W.Eversheim,G.Kubin,andM.L.Sesterhenn,"Theapplicationofaxiomatic designandleanmanagementprinciplesinthescopeofproductionsystemsegmentation," InternationalJournalofProductionResearch,vol.38,pp.13771396,2000/04/012000. A.ReichhartandM.Holweg,"Leandistribution:concepts,contributions,conflicts," InternationalJournalofProductionResearch,vol.45,pp.36993722,2007/08/152007. K.DugnasandO.Oterhals,"StateoftheArtShipbuilding:TowardsUniqueandIntegrated LeanProductionSystems,"presentedattheTheInternationalGroupforLeanConstruction WorldConference(IGLC16),Manchester,2008. D.Koli,N.Fafandjel,andA.Zamarin,"LeanManufacturingMethodologyforShipyards," Brodogradnja,vol.63,pp.1829,March2012. D.H.T.Walker,"InnovationandValueDeliverythroughSupplyChainManagement,"in ConstructionInnovationandProcessImprovement,ed:WileyBlackwell,2012,pp.125153. C.Argyris,"Singleloopanddoubleloopmodelsinresearchondecisionmaking.," AdministrativeScienceQuarterly,vol.21,pp.363375,Sept.1976. M.A.Thomassen,D.Sander,K.A.Barnes,andA.Nielsen,"Experienceandresultsfrom implementingleanconstructioninalargeDanishcontractingfirm,"inProceedingsofthe 11thAnnualConferenceonLeanConstruction,VirginiaTech,Blacksburg,July22nd24th, 2003. J.Rasmussen,"Riskmanagementinadynamicsociety:amodellingproblem,"Safetyscience, vol.27,p.183,1997.

PUBLIKASJONER AV FORSKERE TILKNYTTET HGSKOLEN I MOLDE OG MREFORSKING MOLDE AS

www.himolde.no www.mfm.no

2010 - 2012

Publikasjoner utgitt av hgskolen og Mreforsking kan kjpes/lnes fra Hgskolen i Molde, biblioteket, Postboks 2110, 6402 MOLDE. Tlf.: 71 21 41 61, epost: biblioteket@himolde.no

NASJONAL / NORDISK PUBLISERING

Egenrapportserie

Kristoffersen, Steinar (2012): NextShip Lean Shipbuilding. State of the art and potential to belean in multifariouslty distributed maritime design, engineering and construction. Rapport / Mreforsking Molde AS nr. 1214. Molde. Mreforsking Molde AS. 26 s. Pris: 50,Oterhals, Oddmund (2012): Nyfrakt II. Sluttrapport. Rapport / Mreforsking Molde AS nr. 1213. Molde. Mreforsking Molde AS. 13 s. Pris: 50,Oterhals, Oddmund; Hjelle, Harald M.; Hervik, Arild og Brthen, Svein (2012): Nyfrakt II. Virkemidler for fornying av nrskipsflten. Rapport / Mreforsking Molde AS nr. 1212. Molde. Mreforsking Molde AS. 19 s. Pris: 50,Kristoffersen, Steinar (2012) Safe and robust content distribution.: challenges and solutions related to internetbased sharing of business critical documentation. Rapport / Mreforsking Molde AS nr. 1211. Molde. Mreforsking Molde AS 50 s. Pris: 100,Brthen, Svein; Hagen, Kre P.; Hervik, Arild; Larsen, Odd I.; Pedersen, Karl R.; Rekdal, Jens; Tveter, Eivind og Zhang, Wei (2012): Alternativ finansiering av transportinfrastruktur. Noen utvalgte problemstillinger. Rapport / Mreforsking Molde AS nr. 1210. Molde. Mreforsking Molde AS. 92 s. Pris: 100, Oterhals, Oddmund; Brthen, Svein og Husdal, Jan (2012) Diagnose for kystlogistikken i Midt-Norge Forprosjekt. Rapport / Mreforsking Molde AS nr. 1209. Molde. Mreforsking Molde AS 62 s. Pris: 100,Rekdal, Jens; Larsen, Odd I.; Steinsland, Christian og Zhang, Wei (2012) Eksempler p analyser av Kprising med TraMod_By : konsekvenser av tidsdifferensierte bompengesatser i Oslo, Bergen og Trondheim. Rapport / Mreforsking Molde AS nr. 1208. Molde. Mreforsking Molde AS. Dugnas, Karolis og Oterhals, Oddmund (2012) Logistikkoptimalisering i Villa-gruppen : kartlegging og forbedring av logistikkprosesser. Rapport / Mreforsking Molde AS nr. 1207 KONFIDENSIELL. Molde. Mreforsking Molde AS. 53 s. Rekdal, Jens; Larsen, Odd I.; Stensland, Christian, Zhang, Wei og Hamre, Tom N. (2012) TraMod_By del 2. Delrapport 2 : eksempler p anvendelse. Rapport / Mreforsking Molde AS nr. 1206. Molde. Mreforsking Molde AS. Pris: 150,Brthen, Svein; Halpern, Nigel og Williams, George (2012) The Norwegian Air Transport Market in the Future. Some possible trends and scenarios. Rapport / Mreforsking Molde AS nr. 1205. Molde: Mreforsking Molde AS. 82 s. Pris: 100,Hervik, Arild; Brin, Lasse og Bergem, Bjrn G. (2012) Resultatmling av brukerstyrt forskning 2010. Rapport / Mreforsking Molde AS nr. 1204. Molde: Mreforsking Molde AS. 129 s. Pris: 150,-

Rekdal, Jens; Larsen, Odd I.; Lkketangen, Arne og Hamre, Tom N. (2012): TraMod_By Del 1: Etablering av nytt modellsystem. Rapport / Mreforsking Molde AS nr. 1203. Molde: Mreforsking Molde AS. 176 s. Pris: 200,Brthen, Svein; Saeed, Naima; Sunde, yvind; Husdal, Jan; Jensen, Arne and Sorkina, Edith (2012): Customer and Agent Initiated Intermodal Transport Chains. Rapport / Mreforsking Molde AS nr. 1202. Molde: Mreforsking Molde AS. 153 s. Pris: 150,Brthen, Svein; Draagen, Lars; Eriksen, Knut S.; Husdal; Jan, Kurtzhals, Joakim H. og Thune-Larsen, Harald (2012): Mulige endringer i lufthavnstrukturen samfunnskonomi og ruteopplegg. Rapport / Mreforsking Molde AS nr. 1201. Molde: Mreforsking Molde AS. 125 s. Pris: 150,Kristoffersen, Steinar (2011): Complete Documentation for Commissioning. Knowledge and document management in ship building. Rapport / Mreforsking Molde AS nr. 1111. Molde: Mreforsking Molde AS. 32 s. Pris: 50,Hervik, Arild; Oterhals, Oddmund; Bergem, Bjrn G. og Johannessen, Gran (2011): NCE Maritime klyngeanalyse 2011. Status for maritime nringer i Mre og Romsdal. Rapport / Mreforsking Molde AS nr. 1110. Molde: Mreforsking Molde AS. 35 s. Pris: 50,Fillingsnes, Anne Berit; Sandy, Marit og Ulvund, Ingeborg (2011): Ny praksismodell i sykehjem. Rapport fra et samarbeidsprosjekt mellom Molde kommune, Kristiansund kommune og Hgskolen i Molde. Rapport / Mreforsking Molde AS nr. 1109. Molde: Mreforsking Molde AS. 50 s. Pris: 100,Oterhals, Oddmund; Johannessen, Gran og Hervik, Arild (2011): STX OSV. Ringvirkninger av verftsvirksomheten i Norge. Rapport / Mreforsking Molde AS nr. 1108. Molde: Mreforsking Molde AS. 28 s. Pris: 50,Hjelle, Harald M. og B, Ola (2011): Implementering av IT-systemer i verdikjeden for frossen fisk. Sluttrapport for FIESTA-prosjektet . Rapport / Mreforsking Molde AS nr. 1107. Molde: Mreforsking Molde AS. 124 s. Pris: 150,Rekdal, Jens (2011): Konsekvensutredning; Mseide Vedde Gseid. Delrapport: Trafikkanalyse og samfunnskonomisk kalkyle for Borgundfjordtunnelen. Rapport / Mreforsking Molde AS nr. 1106. Molde: Mreforsking Molde AS. 112 s. Pris: 150,Hjelle, Harald M. og B, Ola (2011): Sporbarhet, RFID og frossen fisk. Om potensialet til innfring av RFIDbasert sporingsteknologi i forsyningskjeden for frossen fisk. Rapport / Mreforsking Molde AS nr. 1105. Molde: Mreforsking Molde AS. 51 s. Pris: 100,Sandsmark, Maria og Hervik, Arild (2011): Internasjonalisering av merkevarer i petroleumsnringen i MidtNorge. Rapport / Mreforsking Molde AS nr. 1104. Molde: Mreforsking Molde AS. 41 s. Pris: 50,Bremnes, Helge; Hervik, Arild og Sandsmark, Maria (2011): Merkevarer i petroleumsnringen i Midt-Norge. Rapport / Mreforsking Molde AS nr. 1103. Molde: Mreforsking Molde AS. 41 s. Pris: 50,Hervik, Arild; Brin, Lasse og Bergem, Bjrn (2011): Resultatmling av brukerstyrt forskning 2009. Rapport / Mreforsking Molde AS nr. 1102. Molde: Mreforsking Molde AS. 105,[42] s. Pris. 150.Oterhals, Oddmund (2011): shipINSIDE Vurdering av et nytt konsept for skipsinnredning. Mreforsking Molde AS nr. 1101. Molde: Mreforsking Molde AS. 25 s. Pris: 50,Rapport /

Hervik, Arild; Oterhals, Oddmund; Bjrn G. Bergem og Johannessen, Gran (2010): Status for maritime nringer i Mre og Romsdal 2010. Lysere ordresituasjon med utflating av aktivitetsnivet. Rapport / Mreforsking Molde AS nr. 1011. Molde: Mreforsking Molde AS. 28 s. Pris: 50,Oterhals, Oddmund (2010): Samseiling i Bodregionen.Pilotprosjekt for utprving av rederisamarbeid. Rapport / Mreforsking Molde AS nr. 1010. Molde: Mreforsking Molde AS. 24 s. Pris: 50,-

Hjelle, Harald M. (2010): FIESTA-skolen. Etterutdanning tett p egen verdikjede. Rapport/Mreforsking Molde AS nr. 1009. Molde: Mreforsking Molde AS. 25, 91, [7] s. Pris: 150,Halpern, Nigel and Brthen, Svein (2010): Catalytic impact of airports in Norway. Rapport/Mreforsking Molde AS nr. 1008. Molde: Mreforsking Molde AS. 112 s. Pris: 150,Oterhals, Oddmund; Hervik, Arild; Tobro, Roar og Brin, Lasse (2010): Markedskarakteristika og logistikkutfordringer ved offshore vindkraftutbygging. Rapport/Mreforsking Molde AS nr. 1007. Molde: Mreforsking Molde AS. 35 s. Pris: 50,Merkert, Rico and Pagliari, Romano (Cranfield University); Odeck, James; Brthen, Svein; Halpern, Nigel and Husdal, Jan (2010): Benchmarking Avinors Efficiency a Prestudy. Report / Mreforsking Molde AS no 1006. Molde: Mreforsking Molde AS. 74 p. Price: 100,Hervik, Arild; Brin, Lasse og Bergem, Bjrn (2010): Resultatmling av brukerstyrt forskning 2008. Rapport / Mreforsking Molde AS nr. 1005. Molde: Mreforsking Molde AS. 145 s. Pris: 150,Oterhals, Oddmund; Hervik, Arild; ksenvg, Jan Erik (Kontali Analyse) og Johannessen, Gran (2010): Verdiskaping og samspill i marine nringer p Nordmre. Rapport / Mreforsking Molde AS nr. 1004. Molde: Mreforsking Molde AS. 35 s. Pris: 50,Oterhals, Oddmund (2010): Odim Abas. Verdikjedebeskrivelse og styringsmodell for prosjektgjennomfring. Rapport / Mreforsking Molde AS nr. 1003. Molde: Mreforsking Molde AS. 38 s. KONFIDENSIELL. Johannessen, Gran; Hervik, Arild (2010): Inntektsoverfringsmodell for lokale bil- og btruter. Rapport / Mreforsking Molde AS nr. 1002. Molde: Mreforsking Molde AS. 74 s. Pris: 100,Brthen, Svein; Husdal, Jan (2010): Fjerning av terreng hindre ved Kirkenes lufthavn, Hybuktmoen. Samfunnskonomisk analyse. Rapport / Mreforsking Molde AS nr. 1001. Molde: Mreforsking Molde AS. 53 s. Pris: 100,-

ARBEIDSRAPPORTER / WORKING REPORTS

Oterhals, Oddmund (2012) Nyfrakt II. Vareeierdeltakelse og kontraktsmegling. Arbeidsrapport / Mreforsking Molde AS nr. M 1202. Mreforsking Molde AS. 12 s. Pris: 50,Rye, Mette (2012): Merkostnad i privat sektor i sone 1a og 4a etter omlegging av differensiert arbeidsgiveravgift : estimat for 2012. Arbeidsrapport / Mreforsking Molde AS nr. M 1201. Molde: Mreforsking Molde AS 19 s. Pris: 50,Bremnes, Helge; Kristoffersen, Steinar og Sandsmark, Maria (2011): Evaluering av IKT-investeringer et forprosjekt. Arbeidsrapport / Mreforsking Molde AS nr. M 1103. Molde: Mreforsking Molde AS. 18 s. Pris: 50,Hervik, Arild; Hekland, Jon og Brin, Lasse (2011): Fiskeri- og havbruksnringens forskningsfond (FHF). Screening av eksisterende erfaringer internasjonalt med mling/kartlegging av effekter av forskning innen fiskeri- og havbrukssektoren. Arbeidsrapport / Mreforsking Molde AS nr. M 1102. Molde: Mreforsking Molde AS. 25 s. Pris: 50,Rye, Mette (2011): Merkostnad i privat sektor i sone 1a og 4a etter omlegging av differensiert arbeidsgiveravgift. Estimat for 2011. Arbeidsrapport / Mreforsking Molde AS nr. M 1101. Molde: Mreforsking Molde AS. 17 s. Pris: 50,Dugnas, Karolis og Oterhals, Oddmund (2010): Vareflyt og lageroptimalisering i Stokke AS. Arbeidsrapport / Mreforsking Molde AS nr. M 1003. KONFIDENSIELL. Molde: Mreforsking Molde AS. 52 s. Hervik, Arild og Brin, Lasse (2010): En empirisk tilnrming til kvantifisering av eksterne virkninger fra FoUinvesteringer Arbeidsrapport / Mreforsking Molde AS nr. M 1002. Molde: Mreforsking Molde AS. 59 s. Pris: 100,-

Bjarnar, Ove; Haugen, Kjetil; Hervik, Arild; Olstad, Asmund, Oterhals, Oddmund og Risnes, Martin (2010): Nyskaping og nringsutvikling i nringslivet i Mre og Romsdal. Sluttrapport. Arbeidsrapport / Mreforsking Molde AS nr. M 1001. Molde: Mreforsking Molde AS. 15 s. Pris: 50,-

TFS 2012-12-11

Forfatter/MreforskingMoldeAS Forskrifteneindsverklovengjelderformaterialetidennepublikasjonen.Materialeter publisertforatduskalkunnelesedetpskjermenellerfremstilleeksemplartilprivat bruk.Utenspesielleavtalermedforfatter/MreforskingMoldeASerallannen eksemplarfremstillingogtilgjengelighetsgjringbaretillattslengedetharhjemmelilov elleravtalemedKopinor,interesseorganforrettshaveretilndsverk.

MREFORSKING MOLDE AS Britvegen 4, NO-6410 Molde Telefon +47 71 21 40 00 Telefaks +47 71 21 42 99 mfm@himolde.no www.mfm.no

HGSKOLEN I MOLDE Postboks 21 10, NO-6402 Molde Telefon +47 71 21 40 00 Telefaks +47 71 21 41 00 post@himolde.no www.himolde.no

Das könnte Ihnen auch gefallen

- EVRO - PROFIL-Steel Profile CatalogDokument12 SeitenEVRO - PROFIL-Steel Profile CatalogOleksandrMISNoch keine Bewertungen

- Suzuki OBM PropellersDokument4 SeitenSuzuki OBM PropellersRomie HarieNoch keine Bewertungen

- Toyota Way Kaizen Volume 11Dokument8 SeitenToyota Way Kaizen Volume 11mohjiffryNoch keine Bewertungen

- Lamb T.World-Class Shipbuil.2001.TRANS PDFDokument24 SeitenLamb T.World-Class Shipbuil.2001.TRANS PDFairlanggaputraNoch keine Bewertungen

- ShipbuildingDokument2 SeitenShipbuildingfiskalNoch keine Bewertungen

- Virtual Manufacturing Concept For ShipbuildingDokument16 SeitenVirtual Manufacturing Concept For ShipbuildingsimalaraviNoch keine Bewertungen

- Shipbuilding Profiles en 0806Dokument10 SeitenShipbuilding Profiles en 0806lunavy01Noch keine Bewertungen

- L1 - 2 - Shipyard Productivity PDFDokument33 SeitenL1 - 2 - Shipyard Productivity PDFattiori fabriceNoch keine Bewertungen

- Boat Building BooksDokument3 SeitenBoat Building BooksVelmohanaNoch keine Bewertungen

- Presentation Total Productive Maintenance (TPM)Dokument14 SeitenPresentation Total Productive Maintenance (TPM)jaanus143Noch keine Bewertungen

- Kaizen Continuous Improvement TrainingDokument7 SeitenKaizen Continuous Improvement TrainingMadeleine ThomasNoch keine Bewertungen

- ShipbuildingDokument5 SeitenShipbuildinghemanthvdkNoch keine Bewertungen

- Advanced OutfittingDokument43 SeitenAdvanced OutfittingChandan Kumar100% (3)

- L1 - 1 - Shipbuilding ProcessDokument22 SeitenL1 - 1 - Shipbuilding Processhector_547Noch keine Bewertungen

- Lean Six Sigma in ShipbuildingDokument11 SeitenLean Six Sigma in ShipbuildingChristopher Garcia0% (1)

- Quality Costs and AssessmentsDokument22 SeitenQuality Costs and AssessmentsPreetham Vincent Lobo100% (1)

- SHIP PRODUCTION AND MANAGEMENT: KEY CONCEPTSDokument7 SeitenSHIP PRODUCTION AND MANAGEMENT: KEY CONCEPTSASPIN RAJNoch keine Bewertungen

- Guide Lean ManufacturingDokument16 SeitenGuide Lean ManufacturingSofia MazzaNoch keine Bewertungen

- Planning and Production Control 2012Dokument60 SeitenPlanning and Production Control 2012Mahmoud ElsokkariNoch keine Bewertungen

- Lean Shipbuilding I EngDokument7 SeitenLean Shipbuilding I EngGanesh FakatkarNoch keine Bewertungen

- White Paper Shipbuilding - EnglDokument19 SeitenWhite Paper Shipbuilding - EnglRENGANATHAN PNoch keine Bewertungen

- TextbookrevcsmallDokument359 SeitenTextbookrevcsmallngungtuandoNoch keine Bewertungen

- DFMA GuidelinesDokument15 SeitenDFMA GuidelinesSaurabh TripathiNoch keine Bewertungen

- Construction MonitoringDokument34 SeitenConstruction MonitoringMat LautNoch keine Bewertungen

- Ketchikan Shipyard Improvements Plan CompleteDokument230 SeitenKetchikan Shipyard Improvements Plan CompleteOpó Ishak Bawias Adare100% (1)

- Estimating The Cost-Ship RepairDokument29 SeitenEstimating The Cost-Ship RepairMohammad Sholikhan Arif100% (1)

- Push VsPull SlideSet9Dokument44 SeitenPush VsPull SlideSet9Aditya PalNoch keine Bewertungen

- Ship Repair Project Management ToolsDokument3 SeitenShip Repair Project Management ToolsFernandoNoch keine Bewertungen

- Going Beyond LeanDokument7 SeitenGoing Beyond Leanลูกหมู ตัวที่สามNoch keine Bewertungen

- Agile & Lean ManufacturingDokument39 SeitenAgile & Lean ManufacturingHassan Aziz100% (1)

- 6 Esential Elements of Ship ProductionDokument18 Seiten6 Esential Elements of Ship Productionryan310393Noch keine Bewertungen

- Processes in ShipbuildingDokument215 SeitenProcesses in Shipbuildingnicdam100% (1)

- 342546Dokument336 Seiten342546y_596688032Noch keine Bewertungen

- Implementation of Lean Principles To Improve The Operations of A Sales Warehouse in The Manufacturing IndustryDokument9 SeitenImplementation of Lean Principles To Improve The Operations of A Sales Warehouse in The Manufacturing Industryb4rtm4nNoch keine Bewertungen

- Concepts of Modern ShipbuildingDokument257 SeitenConcepts of Modern ShipbuildingGEORGE.K.CNoch keine Bewertungen

- The RULES of WORK A Practical Engineering Guide To ErgonomicsDokument189 SeitenThe RULES of WORK A Practical Engineering Guide To ErgonomicsMabano Alit EnriqueNoch keine Bewertungen

- Lean Manufacturing Transformation for ShipyardsDokument12 SeitenLean Manufacturing Transformation for ShipyardsLukman Tarigan SumatraNoch keine Bewertungen

- Modern shipbuilding techDokument17 SeitenModern shipbuilding techSwapnil Rupaye100% (2)

- Japanese Shipbuilding Industry and Lean Production MethodsDokument45 SeitenJapanese Shipbuilding Industry and Lean Production MethodsJim GrayNoch keine Bewertungen

- NM209 - Marine Design Production - v01Dokument123 SeitenNM209 - Marine Design Production - v01Euclides CagniniNoch keine Bewertungen

- The Second Toyota ParadoxDokument19 SeitenThe Second Toyota Paradoxheartbreakid32Noch keine Bewertungen

- Lean Manufacturing and It's Implementation in Automotive IndustryDokument48 SeitenLean Manufacturing and It's Implementation in Automotive IndustryshenoyniteshNoch keine Bewertungen

- Lean ThinkingDokument14 SeitenLean ThinkingPrashanth Abhi100% (1)

- Shipbuilding and Ship Repair PM Awareness - 2nd EditionDokument58 SeitenShipbuilding and Ship Repair PM Awareness - 2nd EditionFernando RemolinaNoch keine Bewertungen

- Shipyard Engineering Production PlanningDokument45 SeitenShipyard Engineering Production PlanningtyuNoch keine Bewertungen

- Risk Management For Ship Repair ProjectsDokument9 SeitenRisk Management For Ship Repair ProjectssyughiNoch keine Bewertungen

- Big Ship ShipbuildingDokument37 SeitenBig Ship ShipbuildingPeter John PackiarajNoch keine Bewertungen

- IhopDokument65 SeitenIhopphoe_nix_chimeraNoch keine Bewertungen

- Lean Project Management A Complete Guide - 2020 EditionVon EverandLean Project Management A Complete Guide - 2020 EditionNoch keine Bewertungen

- Lean ManufacturingDokument90 SeitenLean ManufacturingSasa TesijaNoch keine Bewertungen

- Unblocking BottlenecksDokument3 SeitenUnblocking BottlenecksMaggie GonzalesNoch keine Bewertungen

- Shipbuilding Process 1Dokument53 SeitenShipbuilding Process 1tiwaripur100% (1)

- Why Standard Work Is Not StandardDokument7 SeitenWhy Standard Work Is Not StandardangrainadillaNoch keine Bewertungen

- The Lean Handbook Journey: Make - Up Flows CultureDokument26 SeitenThe Lean Handbook Journey: Make - Up Flows CultureMuhammad Mubeen Iqbal PuriNoch keine Bewertungen

- Achieving Operational Excellence While Slashing Costs: 10 Things You Must Get RightDokument12 SeitenAchieving Operational Excellence While Slashing Costs: 10 Things You Must Get RightWilson Perumal & Company100% (1)

- Cost of QualityDokument24 SeitenCost of QualityMuhammad HamidNoch keine Bewertungen

- UNCTAD Equipment Quay Gantry CraneDokument18 SeitenUNCTAD Equipment Quay Gantry CranelephuongdongNoch keine Bewertungen

- Political Change and the Rise of Labour in Comparative Perspective: Britain and Sweden 1890-1920Von EverandPolitical Change and the Rise of Labour in Comparative Perspective: Britain and Sweden 1890-1920Noch keine Bewertungen

- Design of YachtDokument77 SeitenDesign of YachtMelissa Rios100% (1)

- Analysis of Estimations, Quotations and Actual Costs Related To Dry-DockingDokument47 SeitenAnalysis of Estimations, Quotations and Actual Costs Related To Dry-DockingeajNoch keine Bewertungen

- Maritime Reporter MediaDokument6 SeitenMaritime Reporter MediaAgus RfiaiNoch keine Bewertungen

- Perception Earned Value MGMTDokument72 SeitenPerception Earned Value MGMTOnelson FdfgNoch keine Bewertungen

- CH 7 - Earned Value ManagementDokument53 SeitenCH 7 - Earned Value ManagementAgus RfiaiNoch keine Bewertungen

- World Shipbuilding Trends (ShipTek)Dokument29 SeitenWorld Shipbuilding Trends (ShipTek)Algebralph MondayNoch keine Bewertungen

- Primavera P6 Exercise WorksheetDokument35 SeitenPrimavera P6 Exercise Worksheetdyeyson3095% (19)

- What New Primavera P6 R8 3 - May 2013 SlidesDokument59 SeitenWhat New Primavera P6 R8 3 - May 2013 SlidesAgus RfiaiNoch keine Bewertungen

- CFER Canada Transatlantic Nov23Dokument19 SeitenCFER Canada Transatlantic Nov23Agus RfiaiNoch keine Bewertungen

- Kaiser P6 r8 Basic Navigation User Guide v1.1 PDFDokument39 SeitenKaiser P6 r8 Basic Navigation User Guide v1.1 PDFAgus RfiaiNoch keine Bewertungen

- Okeanos Explorer Fact SheetDokument2 SeitenOkeanos Explorer Fact SheetAgus RfiaiNoch keine Bewertungen

- 11 18 AmphibiousShipsDokument28 Seiten11 18 AmphibiousShipsAgus Rfiai100% (1)

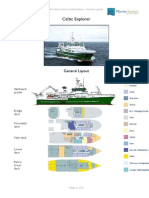

- Celtic Explorer SpecificationsDokument5 SeitenCeltic Explorer SpecificationsAgus RfiaiNoch keine Bewertungen

- MV Equator SpecificationDokument2 SeitenMV Equator SpecificationAgus RfiaiNoch keine Bewertungen

- Planning For Business Growth GuideDokument71 SeitenPlanning For Business Growth GuideUZNAPMNoch keine Bewertungen

- Estimating The Cost of New Construction PDFDokument39 SeitenEstimating The Cost of New Construction PDFrakeshrana1974Noch keine Bewertungen

- 02 Newbuilding ADokument18 Seiten02 Newbuilding AAgus RfiaiNoch keine Bewertungen

- 1 003Dokument0 Seiten1 003Bayu EkosaputroNoch keine Bewertungen

- Celtic Explorer SpecificationsDokument5 SeitenCeltic Explorer SpecificationsAgus RfiaiNoch keine Bewertungen

- Effects of PSPC on Shipbuilding Industry CostsDokument15 SeitenEffects of PSPC on Shipbuilding Industry CostsdineshbankarNoch keine Bewertungen

- Ifs ShipbuildingDokument6 SeitenIfs ShipbuildingAgus RfiaiNoch keine Bewertungen

- LCC Analysis ToolkitDokument9 SeitenLCC Analysis ToolkitAgus RfiaiNoch keine Bewertungen

- Establishing Weight Control For New ShipuildingDokument22 SeitenEstablishing Weight Control For New ShipuildingAgus RfiaiNoch keine Bewertungen

- Gmdss Guide: Furuno Electric Co., LTDDokument8 SeitenGmdss Guide: Furuno Electric Co., LTDtibalinajadelene67% (3)

- Effects of PSPC on Shipbuilding Industry CostsDokument15 SeitenEffects of PSPC on Shipbuilding Industry CostsdineshbankarNoch keine Bewertungen

- GP 17500 eDokument2 SeitenGP 17500 eAgus RfiaiNoch keine Bewertungen

- Integrating the Shipbuilding Business ModelDokument13 SeitenIntegrating the Shipbuilding Business ModelRyan HammondNoch keine Bewertungen

- SD 1.3.2 Cost EstimateDokument29 SeitenSD 1.3.2 Cost EstimateMatheus Siqueira100% (1)

- Ship FinanceDokument6 SeitenShip FinanceAgus RfiaiNoch keine Bewertungen

- Weather Fax For Navnet or PC ApplicationsDokument1 SeiteWeather Fax For Navnet or PC ApplicationsAgus RfiaiNoch keine Bewertungen

- Plato's Theory of Imitationalism in ArtDokument10 SeitenPlato's Theory of Imitationalism in ArtKath StuffsNoch keine Bewertungen

- The Leadership Quarterly: Chester A. Schriesheim, Joshua B. Wu, Cecily D. CooperDokument12 SeitenThe Leadership Quarterly: Chester A. Schriesheim, Joshua B. Wu, Cecily D. CooperRajib DharNoch keine Bewertungen

- Persuasive Communication PDFDokument15 SeitenPersuasive Communication PDFRaman KulkarniNoch keine Bewertungen