Beruflich Dokumente

Kultur Dokumente

Parametric Analysis and Optimization of Turning Operation by Using Taguchi Approach

Hochgeladen von

IJMEROriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Parametric Analysis and Optimization of Turning Operation by Using Taguchi Approach

Hochgeladen von

IJMERCopyright:

Verfügbare Formate

International Journal of Modern Engineering Research (IJMER)

www.ijmer.com Vol. 3, Issue. 4, Jul - Aug. 2013 pp-2154-2156 ISSN: 2249-6645

www.ijmer.com 2154 | Page

Mr. Manoj Kumar Sahoo

Department of Mechanical Engineering, Lakhmi Chand Institute of Technology, Bilaspur

ABSTRACT: Every day scientists are developing new materials and for each new material, we need economical and

efficient machining. Turning process is the one of the methods to remove material from cylindrical and non-cylindrical

parts. Stainless steel is a widely used material in day to day applications. This paper deals with the optimization of turning

process by the effects of machining parameters applying Taguchi methods so as to improve the quality of manufactured

goods, and engineering development of designs for studying variation. There are three machining parameters i.e., Spindle

speed, Feed rate and Depth of cut. Experiments are done by varying one parameter and keeping other two fixed so maximum

value of each parameter was obtained. Taguchi orthogonal array is designed with three levels of turning parameters with

the help of software Minitab 16. In the first run nine experiments are performed and material removal rate (MRR) is

calculated. When experiments are repeated in second run again MRR is calculated. Taguchi method stresses the importance

of studying the response variation using the signaltonoise (S/N) ratio, resulting in minimization of quality characteristic

variation due to uncontrollable parameter. The metal removal rate was considered as the quality characteristic with the

concept of "the larger-the-better. S/N ratio values are calculated by taking the help of software Minitab 16. The MRR values

measured from the experiments and their optimum value for maximum material removal rate. It is also predicted that

Taguchi method is a good method for optimization of various machining parameters as it reduces the number of

experiments.

KEYWORDS: Turning, Material Removal Rate, AISI 304 Steel, Taguchi, Minitab16

I. INTRODUCTION

Experimental work includes the turning operation which is performed on the HMT NH26 lathe machine. The input

parameters are taken as spindle speed, feed and depth of cut whereas the output parameter is taken as material removal rate.

The values taken for spindle speed (in rpm) are 220, 350 and 540, the values for feed (in mm/rev) are 0.388, 0.418 and

0.462, and for depth of cut (in mm) the values are taken as 0.9, 1.0 and 1.1. The experiments are performed by HSS tool on

AISI 304 steel bar work piece of 40 mm diameter and 60 mm length.

Table 1.1: Composition of AISI 304 Steel

Element C Mn Si Cr Ni P S

Weight % 0.08 2 1 18-20 8-10 0.045 0.03

I.1.1 MATERIAL REMOVAL RATE: Material Removal Rate (MRR) Measurement From the initial and final weight of

job, MRR is calculated and the relation is given below:

TimeTaken

t FinalWeigh ght InitialWei

MRR

=

II. LITERATURE REVIEW

Liu et al. (2006), has made use of the basic thermo mechanical properties and the molecular mechanical theory of friction.

The main aim is to extend the knowledge of minimum chip thickness values to as many materials as possible when these

materials are put to wide range of cutting conditions. [1]

H S Yoon et al., has proposed an orthogonal cutting force model based on slip-line field model for micro machining. Two

material flow processes are being considered- chip formation process and ploughing. The paper takes into account the effects

of parameters like effective rake angle, depth of deformation and minimum chip thickness. [2]

Z J Zhou et al. (1996), has taken up the case of ultra precision machining to study the effect of diamond tool sharpness on

cutting surface integrity and minimum chip thickness. Good surface integrity is an essential requirement of machining

processes. Good surface integrity implies smaller surface roughness and smaller residual stresses combined with high

dimensional accuracy. However, the accuracy of the relative motion between the cutting edge and the work piece governs

the achievable machining accuracy. So, the performance of machine tools needs to be studied. [3]

III. MATERIALS AND METHODS

III.1 TURNING OPERATION

Turning is the removal of metal from the outer diameter of a rotating cylindrical work piece. Turning is used to

reduce the diameter of the work piece, usually to a specified dimension, and to produce a smooth finish on the metal. Often

the work piece will be turned so that adjacent sections have different diameters. Turning is the machining operation

performed on lathe that produces cylindrical parts.

Parametric Analysis and Optimization of Turning Operation

by Using Taguchi Approach

International Journal of Modern Engineering Research (IJMER)

www.ijmer.com Vol. 3, Issue. 4, Jul - Aug. 2013 pp-2154-2156 ISSN: 2249-6645

www.ijmer.com 2155 | Page

The cutting tool material used in this experiment is high speed steel (HSS). The work piece taken for this

experiment is AISI 304 steel bar of 40 mm diameter and 60 mm length. Experiment has been performed on HMT NH26

LATHE. Table 3.1 shows the experimental data:

Table 3.1: Observation of first run of experiment

Spindle

Speed

(rpm)

Feed

(mm/rev)

Depth of Cut

(mm)

Time

(sec)

Initial

wt. (gm)

Final wt.

(gm)

Difference

(gm)

MRR 1

(gm/sec)

220 0.388 1.1 16 737 714 23 1.44

220 0.418 1 15 757 738 19 1.27

220 0.462 0.9 11.7 762 744 18 1.53

350 0.388 1 9.9 762 740 22 2.20

350 0.418 0.9 9 758 740 18 2.00

350 0.462 1.1 8 784 766 18 2.25

540 0.388 0.9 7 753 746 7 0.99

540 0.418 1.1 7.1 758 742 16 2.25

540 0.462 1 6.5 727 716 11 1.72

Table 3.2: Observation of second run of experiment

Spindle

Speed

(rpm)

Feed

(mm/rev)

Depth of Cut

(mm)

Time

(sec)

Initial

wt. (gm)

Final wt.

(gm)

Difference

(gm)

MRR 2

(gm/sec)

220 0.388 1.1 15.66 714 692 22 1.40

220 0.418 1 15.41 738 718 20 1.30

220 0.462 0.9 11.71 744 726 18 1.54

350 0.388 1 10.00 740 718 22 2.20

350 0.418 0.9 8.75 740 722 18 2.06

350 0.462 1.1 8.13 766 748 18 2.21

540 0.388 0.9 6.10 746 740 6 0.98

540 0.418 1.1 6.54 742 728 14 2.14

540 0.462 1 6.39 716 704 12 1.88

I I I .1.1 TAGUCHI METHOD

Taguchi method is a powerful tool for the design of high quality systems. It provides simple, efficient and

systematic approach to optimize design for performance, quality and cost. Taguchi method is efficient method for designing

process that operates consistently and optimally over a variety of conditions. Taguchi approach to design of experiments

easy to adopt and apply for users with limited knowledge of statics, hence gained wide popularity in the engineering and

scientific community. The desired cutting parameters determined by handbook. Cutting parameters are reflected on surface

roughness, surface texture and dimensional deviation on turned product. Taguchi method is especially suitable for industrial

use but can also be used for scientific research.

I I I .1.1.1 DESI GN OF ORTHOGONAL ARRAY

Taguchi Orthogonal Array is designed in Minitab16 to calculate S/N ratio and Means.

I I I .1.1.1. ANALYSI S OF THE SI GNAL TO NOI SE (S/N) RATI O

In the Taguchi approach, the term signal represents the desired value (mean) for the output characteristics and term

noise represents the undesirable value (standard deviation) for the output

characteristics. Therefore, S/N ratio is the ratio of mean to the standard deviation. Taguchi uses the S/N ratio to measure the

quality characteristics deriving from desired value. The S/N ratio is defined as given equation.

the larger the better

It is when the occurrences of some undesirable product characteristics is to be maximized. It is given by

(

(

=

2

1 1

10 log 10 /

y n

N S

IV. RESULTS & DISCUSSION

After finding all the observation as given in Table 3.1 and 3.2, S/N ratio and Means are calculated and various

graph for analysis is drawn by Minitab 16 software using Taguchi Method.

International Journal of Modern Engineering Research (IJMER)

www.ijmer.com Vol. 3, Issue. 4, Jul - Aug. 2013 pp-2154-2156 ISSN: 2249-6645

www.ijmer.com 2156 | Page

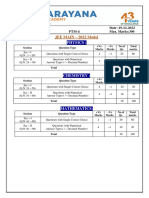

Table 4.1: Experiment Results and corresponding S/N ratios:

S.No.

Spindle Speed

(rpm)

Feed

(mm/rev)

Depth of

Cut (mm)

MRR 1

(gm/sec)

MRR2

(gm/sec)

S/N Ratio

1 220 0.388 1.1 1.44 1.40 2.80549

2 220 0.418 1 1.27 1.30 3.69201

3 220 0.462 0.9 1.53 1.54 2.44400

4 350 0.388 1 2.20 2.20 5.57042

5 350 0.418 0.9 2.00 2.06 5.90939

6 350 0.462 1.1 2.25 2.21 8.48077

7 540 0.388 0.9 0.99 0.98 1.38411

8 540 0.418 1.1 2.25 2.14 5.54248

9 540 0.462 1 1.72 1.88 4.84202

Since, the greater S/N value corresponds to a better performance; therefore, the optimal level of the machining parameters is

the level with the greatest value.

Fig 1. Effect of turning parameters on MRR for Means

Fig 2. Effect of turning parameters on MRR for S/N ratio

V. CONCLUSIONS

The effect of parameters spindle speed on the metal removal rate values is shown above figure for S/N ratio. Its

effect is increasing with increase in spindle speed upto 350 rpm beyond that it is decreasing. So the optimum spindle speed is

level 2 i.e. 350 rpm.

The effect of parameters feed rate on the metal removal rate values is shown above figure S/N ratio. Its effect is

increasing with increase in feed rate. So the optimum feed rate is level 3 i.e. 0.462 mm/rev.

The effect of parameters depth of cut on the metal removal rate values is shown above figure for S/N ratio. Its effect is

decreasing with increase in depth of cut. So the optimum depth of cut is level 3 i.e. 1.1 mm.

REFERENCES

[1]. Liu X., DeVor R.E. and Kapoor S.G., An Analytical Model for the Prediction of Minimum Chip Thickness in Micromachining,

Journal of Manufacturing Science and Engineering, MAY 2006, Vol. 128, pp. 474-481.

[2]. H.S. Yoon, K.F. Ehmann, A Slip-line field model for orthogonal micro-machining processes, Department of Mechanical

Engineering, Northwestern University, IL, U.S.A.

[3]. Z.J. Yuan , M. Zhou, S. Dong, Effect of diamond tool sharpness on minimum cutting thickness and cutting surface integrity in

ultra precision machining, Journal of Materials Processing Technology 62 (1996), pp. 327-330.

[4]. Krishankant, Jatin Taneja, Mohit Bector, Rajesh Kumar, Application of Taguchi Method for Optimizing Turning Process by the

effects of Machining Parameters, International Journal of Engineering and Advanced Technology, ISSN: 2249 8958, Volume-2,

Issue-1, October 2012, pp. 263-274.

[5]. Ashish Yadav, Ajay Bangar, Rajan Sharma, Deepak Pal, Optimization of Turning Process Parameters for Their Effect on En 8

Material Work piece Hardness by Using Taguchi Parametric Optimization Method International Journal of Mechanical and

Industrial Engineering (IJMIE), ISSN No. 2231 6477, Volume-1, Issue-3, 2012, pp. 36-40.

Das könnte Ihnen auch gefallen

- Assessment of Steganography Using Image Edges For Enhancement in SecurityDokument11 SeitenAssessment of Steganography Using Image Edges For Enhancement in SecurityIJMERNoch keine Bewertungen

- X Chromosomal MinerDokument7 SeitenX Chromosomal MinerIJMERNoch keine Bewertungen

- Thermodynamic Analysis of Cooled Blade Gas Turbine Cycle With Inlet FoggingDokument9 SeitenThermodynamic Analysis of Cooled Blade Gas Turbine Cycle With Inlet FoggingIJMERNoch keine Bewertungen

- An Efficient Algorithm Based On Modularity OptimizationDokument6 SeitenAn Efficient Algorithm Based On Modularity OptimizationIJMERNoch keine Bewertungen

- The Combining Approach of Svms With Ant Colony Networks: An Application of Network Intrusion DetectionDokument8 SeitenThe Combining Approach of Svms With Ant Colony Networks: An Application of Network Intrusion DetectionIJMERNoch keine Bewertungen

- Survey On Data Mining and Its Area of ApplicationDokument6 SeitenSurvey On Data Mining and Its Area of ApplicationIJMERNoch keine Bewertungen

- Historiography and Caste OppressionDokument5 SeitenHistoriography and Caste OppressionIJMERNoch keine Bewertungen

- Synthesis and Characterization of Partial Blended Green Polymer ElectrolytesDokument6 SeitenSynthesis and Characterization of Partial Blended Green Polymer ElectrolytesIJMERNoch keine Bewertungen

- Understanding The Behavior of Band-Pass Filter With Windows For Speech SignalDokument7 SeitenUnderstanding The Behavior of Band-Pass Filter With Windows For Speech SignalIJMERNoch keine Bewertungen

- Stabilization of Waste Soil at Karur Dump Yard by Using Polypropylene FiberDokument5 SeitenStabilization of Waste Soil at Karur Dump Yard by Using Polypropylene FiberIJMERNoch keine Bewertungen

- Converting Daily Solar Radiation Tabulated Data With Different Sky Conditions Into Analytical Expression Using Fourier Series TechniqueDokument9 SeitenConverting Daily Solar Radiation Tabulated Data With Different Sky Conditions Into Analytical Expression Using Fourier Series TechniqueIJMERNoch keine Bewertungen

- The Dynamics of Two Harvesting Species With Variable Effort Rate With The Optimum Harvest PolicyDokument9 SeitenThe Dynamics of Two Harvesting Species With Variable Effort Rate With The Optimum Harvest PolicyIJMERNoch keine Bewertungen

- Biorthogonal Nonuniform Multiwavelet Packets Associated With Nonuniform Multiresolution Analysis With Multiplicity DDokument6 SeitenBiorthogonal Nonuniform Multiwavelet Packets Associated With Nonuniform Multiresolution Analysis With Multiplicity DIJMERNoch keine Bewertungen

- A Study On Corrosion Inhibitor of Mild-Steel in Hydrochloric Acid Using Cashew WasteDokument6 SeitenA Study On Corrosion Inhibitor of Mild-Steel in Hydrochloric Acid Using Cashew WasteIJMERNoch keine Bewertungen

- An Use of Fuzzy Logic For Development and Analysis of Rainfall - Runoff ModelDokument8 SeitenAn Use of Fuzzy Logic For Development and Analysis of Rainfall - Runoff ModelIJMERNoch keine Bewertungen

- Space Ball 2D GameDokument7 SeitenSpace Ball 2D GameIJMERNoch keine Bewertungen

- Effects of Heat, Mass Transfer and Viscous Dissipation On Unsteady Flow Past An Oscillating Infinite Vertical Plate With Variable Temperature Through Porous MediumDokument7 SeitenEffects of Heat, Mass Transfer and Viscous Dissipation On Unsteady Flow Past An Oscillating Infinite Vertical Plate With Variable Temperature Through Porous MediumIJMERNoch keine Bewertungen

- Liquefaction Susceptibility Evaluation of Hyderabad SoilDokument7 SeitenLiquefaction Susceptibility Evaluation of Hyderabad SoilIJMERNoch keine Bewertungen

- A Modified PSO Based Solution Approach For Economic Ordered Quantity Problem With Deteriorating Inventory, Time Dependent Demand Considering Quadratic and Segmented Cost FunctionDokument14 SeitenA Modified PSO Based Solution Approach For Economic Ordered Quantity Problem With Deteriorating Inventory, Time Dependent Demand Considering Quadratic and Segmented Cost FunctionIJMERNoch keine Bewertungen

- Improved Aodv Routing in Wireless Sensor Networks Using Shortest Path Routing.Dokument6 SeitenImproved Aodv Routing in Wireless Sensor Networks Using Shortest Path Routing.IJMERNoch keine Bewertungen

- MHD Flow of A Non-Newtonian Fluid Through A Circular TubeDokument10 SeitenMHD Flow of A Non-Newtonian Fluid Through A Circular TubeIJMERNoch keine Bewertungen

- Heuristics For Routing and Spectrum Allocation in Elastic Optical Path NetworksDokument13 SeitenHeuristics For Routing and Spectrum Allocation in Elastic Optical Path NetworksIJMERNoch keine Bewertungen

- The Reality of Application of Total Quality Management at Irbid National University From The Perspective of AcademiciansDokument8 SeitenThe Reality of Application of Total Quality Management at Irbid National University From The Perspective of AcademiciansIJMERNoch keine Bewertungen

- Increasing Efficiency of Wireless Sensor Network Using Decentralized ApproachDokument6 SeitenIncreasing Efficiency of Wireless Sensor Network Using Decentralized ApproachIJMERNoch keine Bewertungen

- "Analysis of Mechanical Properties of Carbon Fiber Polymer Composite Materials Used As Orthopaedic Implants".Dokument8 Seiten"Analysis of Mechanical Properties of Carbon Fiber Polymer Composite Materials Used As Orthopaedic Implants".IJMERNoch keine Bewertungen

- Combined PWM Technique For Asymmetric Cascaded H-Bridge Multilevel InverterDokument10 SeitenCombined PWM Technique For Asymmetric Cascaded H-Bridge Multilevel InverterIJMERNoch keine Bewertungen

- Biokinetic Study of Fish Processing Industrial Effluent Treatment in FBBRDokument4 SeitenBiokinetic Study of Fish Processing Industrial Effluent Treatment in FBBRIJMERNoch keine Bewertungen

- Data Mining For Fraud DetectionDokument4 SeitenData Mining For Fraud DetectionIJMERNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Fcu Valve Honeywel PDFDokument6 SeitenFcu Valve Honeywel PDFRyn YahuFNoch keine Bewertungen

- Review Rachna WasteDokument9 SeitenReview Rachna WasteSanjeet DuhanNoch keine Bewertungen

- Describe an English lesson you enjoyed.: 多叔逻辑口语,中国雅思口语第一品牌 公共微信: ddielts 新浪微博@雅思钱多多Dokument7 SeitenDescribe an English lesson you enjoyed.: 多叔逻辑口语,中国雅思口语第一品牌 公共微信: ddielts 新浪微博@雅思钱多多Siyeon YeungNoch keine Bewertungen

- Dynamic Shear Modulus SoilDokument14 SeitenDynamic Shear Modulus SoilMohamed A. El-BadawiNoch keine Bewertungen

- 05-11 Trainer Interview QuestionsDokument8 Seiten05-11 Trainer Interview QuestionsqulaityNoch keine Bewertungen

- Placa 9 - SHUTTLE A14RV08 - 71R-A14RV4-T840 - REV A0 10ABR2012Dokument39 SeitenPlaca 9 - SHUTTLE A14RV08 - 71R-A14RV4-T840 - REV A0 10ABR2012Sergio GalliNoch keine Bewertungen

- Ahmed Amr P2Dokument8 SeitenAhmed Amr P2Ahmed AmrNoch keine Bewertungen

- Pressure-Dependent Leak Detection Model and Its Application To A District Water SystemDokument13 SeitenPressure-Dependent Leak Detection Model and Its Application To A District Water SystemManjul KothariNoch keine Bewertungen

- GARCH (1,1) Models: Ruprecht-Karls-Universit at HeidelbergDokument42 SeitenGARCH (1,1) Models: Ruprecht-Karls-Universit at HeidelbergRanjan KumarNoch keine Bewertungen

- Activity 2Dokument5 SeitenActivity 2DIOSAY, CHELZEYA A.Noch keine Bewertungen

- Surge Arrester PresentationDokument63 SeitenSurge Arrester PresentationRamiro FelicianoNoch keine Bewertungen

- Libro INGLÉS BÁSICO IDokument85 SeitenLibro INGLÉS BÁSICO IRandalHoyos100% (1)

- Machine Design REE 302: CH 1: Introduction To Mechanical Engineering DesignDokument26 SeitenMachine Design REE 302: CH 1: Introduction To Mechanical Engineering DesignDull PersonNoch keine Bewertungen

- EF3e Intplus Filetest 10aDokument4 SeitenEF3e Intplus Filetest 10aLin Shufen100% (1)

- STFC-2023 International E - conference-BITDokument6 SeitenSTFC-2023 International E - conference-BITRanilprabhu MNoch keine Bewertungen

- Assistant Bookkeeper Resume Sample - Best Format - Great Sample ResumeDokument4 SeitenAssistant Bookkeeper Resume Sample - Best Format - Great Sample ResumedrustagiNoch keine Bewertungen

- Xii - STD - Iit - B1 - QP (19-12-2022) - 221221 - 102558Dokument13 SeitenXii - STD - Iit - B1 - QP (19-12-2022) - 221221 - 102558Stephen SatwikNoch keine Bewertungen

- Tensile Strength of Ferro Cement With Respect To Specific SurfaceDokument3 SeitenTensile Strength of Ferro Cement With Respect To Specific SurfaceheminNoch keine Bewertungen

- Zoom g2 1nu Manual Do Utilizador PDFDokument56 SeitenZoom g2 1nu Manual Do Utilizador PDFEliude Gonçalves FerreiraNoch keine Bewertungen

- 8 Lesson 13 Viking FranceDokument2 Seiten8 Lesson 13 Viking Franceapi-332379661Noch keine Bewertungen

- R67068.0002 2 HB Profibus-Schnittstelle en KueblerDokument42 SeitenR67068.0002 2 HB Profibus-Schnittstelle en KueblerSabari StunnerNoch keine Bewertungen

- Tree Based Machine Learning Algorithms Decision Trees Random Forests and Boosting B0756FGJCPDokument109 SeitenTree Based Machine Learning Algorithms Decision Trees Random Forests and Boosting B0756FGJCPJulio Davalos Vasquez100% (1)

- Bio 104 Lab Manual 2010Dokument236 SeitenBio 104 Lab Manual 2010Querrynithen100% (1)

- Company Profile PT. Geo Sriwijaya NusantaraDokument10 SeitenCompany Profile PT. Geo Sriwijaya NusantaraHazred Umar FathanNoch keine Bewertungen

- Gastone Petrini: Strutture e Costruzioni Autarchiche Di Legno in Italia e Colonie Caratteri e CriterDokument9 SeitenGastone Petrini: Strutture e Costruzioni Autarchiche Di Legno in Italia e Colonie Caratteri e CriterPier Pasquale TrausiNoch keine Bewertungen

- Catalog NeosetDokument173 SeitenCatalog NeosetCarmen Draghia100% (1)

- IFN 554 Week 3 Tutorial v.1Dokument19 SeitenIFN 554 Week 3 Tutorial v.1kitkataus0711Noch keine Bewertungen

- Identification of PolymersDokument11 SeitenIdentification of PolymersßraiñlĕsšȜĭnšteĭñNoch keine Bewertungen

- U2 LO An Invitation To A Job Interview Reading - Pre-Intermediate A2 British CounciDokument6 SeitenU2 LO An Invitation To A Job Interview Reading - Pre-Intermediate A2 British CounciELVIN MANUEL CONDOR CERVANTESNoch keine Bewertungen

- Daily Lesson Log (English)Dokument8 SeitenDaily Lesson Log (English)Julius Baldivino88% (8)