Beruflich Dokumente

Kultur Dokumente

Mechatronics

Hochgeladen von

Aamir Hasan KhanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Mechatronics

Hochgeladen von

Aamir Hasan KhanCopyright:

Verfügbare Formate

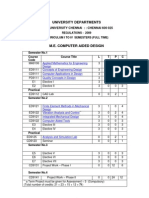

UNIVERSITY DEPARTMENTS

ANNA UNIVERSITY CHENNAI : : CHENNAI 600 025

REGULATIONS - 2009 CURRICULUM I TO IV SEMESTERS (FULL TIME)

M.E. MECHATRONICS

SEMESTER I SL. COURSE No CODE THEORY 1 MA9119 2 MR9111 MR9112 3 MR9113 MR9114 4 5 E1 6 E2 PRACTICAL 7 MF9125 COURSE TITLE Numerical Methods & Graph Theory Sensors in Automation Concepts in Mechanical Engineering Concepts in Electronics Engineering Fluid Power Automation Elective I Elective II Automation Lab TOTAL SEMESTER II SL. COURSE No CODE THEORY 1 MR9121 2 MF9124 3 MR9122 4 MR9123 5 E3 6 E2 PRACTICAL 7 MR9124 COURSE TITLE Industrial Robotics MEMS & Nanotechnology Microcontroller & PLC Control System Engineering Elective III Elective IV Microcontroller Lab L 3 3 3 3 3 3 0 TOTAL 18 T 0 0 0 0 0 0 0 0 P 0 0 0 0 0 0 3 3 C 3 3 3 3 3 3 2 20 L 3 3 3 3 3 3 0 18 T 1 0 0 0 0 0 0 1 P 0 0 0 0 0 0 3 3 C 4 3 3 3 3 3 2 21

SEMESTER III SL. COURSE No CODE THEORY 1 E5 2 E6 3 E7 PRACTICAL 4 MR9131 COURSE TITLE Elective V Elective VI Elective VII Project Phase I TOTAL L 3 3 3 0 9 T 0 0 0 0 0 P 0 0 0 12 12 C 3 3 3 6 15

SEMESTER IV SL. COURSE No CODE PRACTICAL 1 MR9141 COURSE TITLE Project Phase II TOTAL L 0 0 T 0 0 P 24 24 C 12 12

TOTAL CREDITS TO BE EARNED FOR THE AWARD OF THE DEGREE = 68

ELECTIVES FOR M.E.MANUFACTURING ENGINEERING SL. No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 COURSE CODE MR9150 MF9162 QE9114 MR9152 MR9153 MR9154 MR9155 MR9156 MR9157 MR9158 MR9159 MR9160 MR9161 MR9162 MF9163 MF9161 MR9164 MF9153 COURSE TITLE Industrial Instrumentation Artificial Intelligence Metrology and Inspection Machine Vision and Applications Mechatronics elements and programming of CNC machines Automotive Electronics Opto Electronic Instrumentation Machine Tool Control and Condition Monitoring Network and Distribution System Medical Electronics and Instrumentation Real Time Embedded System Mechatronics System Design Telematics Mechatronics for Aircraft Lean Manufacturing system and Implementation Non-Destructive Evaluation Material Handling, Storage And Assembly Automation Materials Management & Logistics L 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 T 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 P 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 C 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3

MA 9119

NUMERICAL METHODS AND GRAPH THEORY

L T P C 3 0 0 3

AIM: To solve some engineering models and problems by using Numerical Analysis and Graph Theoretical concepts. OBJECTIVES: The engineers will have an exposure on various topics such as Systems of Equation, Interpolation and Numerical Integration, Initial and Boundary Value Problems, Fundamentals of Graphs, Graphs Algorithms to understand their applications in engineering problems. UNIT I SYSTEMS OF EQUATIONS 12

Simultaneous linear equations Direct method LU decomposition methods - Gauss elimination, Gauss Jordan methods Iterative methods Jacobi and Gauss-Seidel methods. UNIT II INTERPOLATION AND INTEGRATION 12

Hermites interpolation Cubic Spline Interpolation Gaussian Numerical Integration Trapezoidal and Simpson rules Newton-Cotes formula Gaussian quadrature cubature. UNIT III NUMERICAL METHODS FOR ODE 12

Single step methods multi step methods Taylor series and Euler methods Runge Kutta method of fourth order Multi step methods Adams-Bashforth, Milnes Predictor-Corrector methods Boundary value problems by Finite difference method. UNIT IV FUNDAMENTALS OF GRAPHS 12

Graphs sub graphs - Complements Graph isomorphism vertex degree: Eulerian graphs Planar graphs Hamiltonian paths, tree and Cut-sets. UNIT V TREES AND ALGORITHMS 12

Kruskals algorithm Dijkstras shortest path algorithm, Prims algorithm Transport Networks. TOTAL : 60 PERIODS TEXT BOOKS: 1. Jain, M.K., Iyengar, S.R.K., and Jain, R.K., Numerical Methods for Scientific & Engineering computation, Wiley Eastern Ltd., 1987. 2. Froberg, C.E. Numerical Mathematics, The Benjamin/Cummings Publishing Co., Inc., 1985. 3. Grimaldi R.P., Discrete and Combinatorial Mathematics, Pearson Education Inc., 1999. REFERENCES: 1. Froberg, C.E. Numerical Mathematics, The Benjamin/Cummings Publishing Co., Inc., 1985. 2. Jain, M.K., Iyengar, S.R.K., and Jain, R.K., Numerical Methods for Scientific & Engineering computation, Wiley Eastern Ltd., 1987. 3. Bondy, J.A. and Murthy, U.S.R., Graph Theory with Applications, Macmillan,

MR 9111

SENSORS IN AUTOMATION

L T P C 3 0 0 3

AIM: To impart knowledge on various types of sensors and transducers for Automation in Manufacturing Engineering. OBJECTIVE: To study basic concepts of various sensors and transducers in Manufacturing Engineering To develop knowledge in selection of suitable sensor in manufacturing requirement UNIT I INTRODUCTION 9 Definition Measurement Techniques Classification of errors Error analysis Static and dynamic characteristics of transducers Performance measures of sensors Classification of sensors calibration techniques Potentiometer strain gauges optical encoders. UNIT II INDUCTANCE AND CAPACITANCE TRANSDUCER 9 LVDT RVDT Synchro Microsyn Applications: Pressure, position, angle and acceleration. Capacitance circuitry Feed back type condenser microphone frequency modulating oscillator circuit Dynamic capacitance variation A.C. Bridge for Amplitude Modulation Applications: Proximity, microphone, pressure, displacement. UNIT III PIEZOELECTRIC & MAGNETIC SENSORS 9 Piezoelectric Materials and properties Modes of deformation Multimorphs Environmental effects Applications: Accelerometer, ultrasonic. Magnetic Sensors types, principle, requirement and advantages: Magneto resistive Hall effect - Eddy current. RADIATION AND ELECTRO CHEMICAL SENSORS AND APPLICATIONS 9 Photo conductive cell, photo voltaic, Photo resistive Fiber optic sensors X-ray and Nuclear radiation sensors Electrochemical sensors: Electrochemical cell, polarization, sensor Electrodes and electroceramics in Gas Media. UNIT V RECENT TRENDS IN SENSORS AND APPLICATIONS 9 Film sensors micro-scale sensors Particle measuring systems Applications and case studies of Sensors in Automobile Engineering, Aeronautics, Machine tools and Manufacturing processes TOTAL: 45 PERIODS REFERENCES: 1. Patranabis D.,Sensor and Actuators, Prentice Hall of India (Pvt) Ltd., 2005. 2. Renganathan S.,Transducer Engineering, Allied Publishers (P) Ltd., 2003 3. Ernest O. Doeblin, Measurement system, Application and design, , Tata McGraw Hill Publishing Company Ltd., Fiftieth Edition, 2004 4. Bradley D.A., and Dawson, Burd and Loader, Mechatronics, Thomson Press India Ltd., 2004 5. Bolton W., Mechatronics, Thomson Press, 2003. UNIT IV

MR 9112

CONCEPTS IN MECHANICAL ENGINEERING

L TPC 3 0 0 3

AIM: To impart knowledge of basic mechanical engineering to the students. OBJECTIVE: To make the students to understand the concepts, design, construction and properties of mechanical elements UNIT I MECHANISMS 11 Definition Machine and Structure Kinematic link, pair and chain classification of Kinametic pairs Constraint & motion - Degrees of freedom Slider crank Single and double Crank rocker mechanisms Inversions applications. Kinematic analysis and synthesis of simple mechanisms Determination of velocity and acceleration of simple mechanisms. UNIT II TRANSMISSION SYSTEMS 12 Types of friction friction in screw and nuts pivot and collar thrust bearings collar bearing plate and disc clutches belt (flat & vee) and rope drives creep in belts Jockey pulley open and crossed belt drives Ratio of tensions Effect of centrifugal and initial tension condition for maximum power transmission basics of brakes, journal and rolling element bearings hydrostatic and aerostatic bearings recirculating ball screw and nut assembly. UNIT III VIBRATION 8 Free, forced and damped vibrations of single degree of freedom systems force transmitted to supports vibration Isolation vibration absorption torsional vibration of shafts single and multirotor systems geared shafts critical speed of shafts. UNIT IV DESIGN OF MACHINE ELEMENTS 7

Design of shafts Springs screw and fasteners Gear profile and geometry nomenclature of spur & helical gears worm and worm wheel. UNIT V MACHINE TOOLS 7 Machine tool construction-features operations of lathe, milling machine, drilling machine Drive system for machine tools mechanical, hydraulic and electric stepped and variable speeds spindle speeds and feed drives-linear and reciprocation motion generation. TOTAL: 45 PERIODS REFERENCES: 1. Bansal Dr.R.K.Theory of Machines Laxmi Publications (P) ltd., New Delhi 2001. 2. G.C.Sen . and A. Bhattacharya, Principles of machine tools , New Central book Agency, 1999. 3. Joseph Edward Shigley, Charles R.Mischke, Mechanical Engineering Design Mcgraw Hill International Edition, 1992. 4. S.G. Kulkarni, Machine Design, Tata McGraw Hill,2003. 5. Malhotra .D.R. and Gupta .H.C. The Theory of machines Satya Prakasam, Tech. India Publications, 1989. 6. Acherkan.N, Machine tool Design , vol 3, MIR Publishers, 1978

MR 9113

CONCEPTS IN ELECTRONICS ENGINEERING

L T P C 3 0 0 3

AIM: To understand the basics and working principles of electronic components and their applications OBJECTIVE: This course is intended for learning the Fundamentals, properties and applications of Electronic Components, Characteristics and applications of all types of power circuits, principles and operations of Operational Amplifiers. This course is also gives the ideas of Digital Electronics and all types of Analog and Digital Modulation techniques. UNIT I ELECTRONIC COMPONENTS AND DEVICES 9 Resistors, Capacitors, Inductors, Transformers Properties, types and applications; Junction diodes, Zener diodes, Bipolar transistors, Field Effect transistors, Unijunction Transistors, MOS Devices, LEDs Characteristics and applications; Feedback amplifiers, Oscillators, Power amplifiers. UNIT II POWER CIRCUITS 6 Rectifiers and Filters; Regulated Power Supply Switching Power Supplies, Thermal Considerations, Thyristor Devices SCR, DIAC, TRIAC, QUADRAC operating mechanism, characteristics and applications. UNIT III OPERATIONAL AMPLIFIERS 12 Principles, Specifications, Ideal characteristics, Arithmetic Operations using OpAmps, Integrator, Differentiator, Comparator, Schmitt Trigger, Instrumentation Amplifier, Active filters, Linear Rectifiers, Waveform Generators, D/A converters. UNIT IV DIGITAL ELECTRONICS 12 Number systems Logic gates Boolean algebra Simplification of Boolean functions using Map method. Tabulation method Combinational logic circuits: Full adder, Code Converters, Multiplexers, Decoders Sequential logic circuits: Flipflops, Counters, Shift registers A/D Converters. UNIT V COMMUNICATION PRINCIPLES 6 Modulation: Need, Principles, Types Analog Modulation, AM, FM Digital Modulation: PWM, PCM, FSK Demodulation techniques Transmitters and receivers.

TOTAL: 45 PERIODS REFERENCES: 1. Jocob Mill Man, Micro electronics Digital and Analog circuits & Systems McGraw-Hill 2004. 2. Fanco, design with Operational amplifiers and Analog Integrated Circuits, TMH, 2005 3. Taub and Schilling, Principles of Communicating systems, 3rd edition TMH, 2005 4. Ray & Chaudary, Linear Integrated Circuits, New Age 1991. 5. Malvino & Leach, Digital Principals & application, TMH 2002

MR 9114

FLUID POWER AUTOMATION

L T P C 3 0 0 3

AIM: To impart knowledge in the area of hydraulics, pneumatic and fluid power components and its functions. OBJECTIVE: To make the students to learn the basic concepts of hydraulics and pneumatics and their controlling elements in the area of manufacturing process. To train the students in designing the hydraulics and pneumatic circuits using ladder diagram.

UNIT I INTRODUCTION 5 Need for Automation, Hydraulic & Pneumatic Comparison ISO symbols for fluid power elements, Hydraulic, pneumatics Selection criteria. UNIT II FLUID POWER GENERATING/UTILIZING ELEMENTS 8 Hydraulic pumps and motor gears, vane, piston pumps-motors-selection and specification-Drive characteristics Linear actuator Types, mounting details, cushioning power packs construction. Reservoir capacity, heat dissipation, accumulators standard circuit symbols, circuit (flow) analysis. UNIT III CONTROL AND REGULATION ELEMENTS 8 Direction flow and pressure control valves-Methods of actuation, types, sizing of ports-pressure and temperature compensation, overlapped and underlapped spool valves-operating characteristics-electro hydraulic servo valves-Different typescharacteristics and performance. UNIT IV CIRCUIT DESIGN 10 Typical industrial hydraulic circuits-Design methodology Ladder diagram-cascade, method-truth table-Karnaugh map method-sequencing circuits-combinational and logic circuit. UNIT V ELECTRO PNEUMATICS & ELECTRONIC CONTROL OF HYDRAULIC AND PNEUMATIC CIRCUITS 7 Electrical control of pneumatic and hydraulic circuits-use of relays, timers, counters, Ladder diagram. Programmable logic control of Hydraulics Pneumatics circuits, PLC ladder diagram for various circuits, motion controllers, use of field busses in circuits. Electronic drive circuits for various Motors.

TOTAL: 45 PERIODS REFERENCES: 1. Antony Esposito, Fluid Power Systems and control Prentice-Hall, 1988 2. Herbert R. Merritt, Hydraulic control systems, John Wiley & Sons, Newyork, 1967 3. Dudbey.A.Peace, Basic Fluid Power, Prentice Hall Inc, 1967 4. Peter Rohner, Fluid Power logic circuit design. The Macmillan Press Ltd.,London, 1979 5. E.C.Fitch and J.B.Suryaatmadyn. Introduction to fluid logic, McGraw Hill, 1978. 6. W.Bolton, Mechatronics, Electronic control systems in Mechanical and Electrical Engineering Pearson Education, 2003. 7. Peter Rohner, Fluid Power Logic Circuit Design, Mcmelan Prem, 1994.

MF 9125

AUTOMATION LAB

L T P C 0 0 4 2

AIM: To impart knowledge in the area of hydraulics and pneumatic components and its functions. OBJECTIVE: To make the students to learn the basic concepts of hydraulics and pneumatics and its applications in the area of manufacturing process. 1. To simulate the various hydraulics and pneumatics circuits 2. Study of Sensors and Transducers. Potentiometer, Strain gauge, Torque, LVDT, Hall-effect, speed, Vibration, Pressure. 3. Study of Temperature Transducer. 4. Study of optical Transducer. 5. Exercises on Operational amplifier circuits. 6. Study of Fiber optic sensors. 7. Electronic Power controls of DC and AC motors. 8. Study of Hydraulic and Pneumatic components. 9. Exercise on Hydraulic circuits. 10. Exercise on Electro hydraulic circuits. 11. Study of Electro Pneumatic Sequencing circuits. 12. Study of Hydraulic and Pneumatic Circuits using simulation software. 13. Exercise on Hydraulic and Pneumatic circuits using PLC.

MR 9121

INDUSTRIAL ROBOTICS

L T P C 3 0 0 3

AIM: To impart knowledge in the area of mechanical design, sensors and programming of industrial robots. OBJECTIVE: To make the students to learn about the mechanical design of robots, various sensors and its application in the area of industrial robotics. UNIT I INTRODUCTION

10 Types of Industrial Robots, definitions classifications based on work envelope Generations configurations and control loops, co-ordinate system need for robot basic parts and functions specifications. UNIT II MECHANICAL DESIGN OF ROBOT SYSTEM 12 Robot motion Kinematics of Robot motion Direct and Indirect kinematics Homogeneous transformations linkages and joints mechanism method for location and orientation of objects drive systems end effectors types, selection, classification and design of grippers gripper force analysis. UNIT III SENSORS 8 Functions of Sensors Position and proximitys sensing tactile sensing sensing joint forces vision system object recognition and image transformation safety monitoring sensor systems image analysis application of image processing. UNIT IV ROBOT PROGRAMMING & AI TECHNIQUES 8 Types of Programming Teach pendant programming Basic concepts in A1 techniques Concept of knowledge representations Expert system and its components. UNIT V ROBOTIC WORK CELLS AND APPLICATIONS OF ROBOTS 7 Robotic cell layouts Inter locks Humanoid robots Micro robots Application of robots in surgery, Manufacturing industries, space and underwater. TOTAL: REFERENCES: 1. Yoram Koren Robotics, McGraw Hill 1992 2. Groover.M.P. Industrial Robotics, Prentice Hall, 1992 3. Janakiraman P.A. Robotics and Image Processing, Tata McGraw Hill, 1995 45 PERIODS

MF 9124 MICRO ELECTRO MECHANICAL SYSTEMS AND NANO TECHNOLOGY L T P C 3 0 0 3 AIM: To inspire the students to expect to the trends in manufacturing micro components and measuring systems to nano scale. OBJECTIVES: To expose the students to the evolution of micro electromechanical systems, to the various fabrication techniques and to make students to be award of micro actuators. Also to impart knowledge to the students about nano materials and various nano measurements techniques. UNIT I OVER VIEW OF MEMS AND MICROSYSTEMS 6 Definition historical development fundamentals properties, micro fluidics, design and fabrication micro-system, microelectronics, working principle and applications of micro system. MATERIALS, FABRICATION PROCESSES AND MICRO SYSTEM PACKAGING 10 Substrates and wafers, silicon as substrate material, mechanical properties of Si, Silicon Compounds silicon piezo resistors, Galium arsenide, quartz, polymers for MEMS, conductive polymers. Photolithography, photo resist applications, light sources, in implantation, diffusion process exudation thermal oxidation, silicon diode, chemical vapour deposition, sputtering - deposition by epitoxy etching bulk and surface machining LIGA process Micro system packaging considerations packaging levels of micro system packaging die level, device level and system level. UNIT III MICRO DEVICES AND MATERIALS 8 Sensors classification signal conversion ideal characterization of sensors micro actuators, mechanical sensors measurands displacement sensors, pressure and flow sensors, micro actuators smart materials applications. UNIT IV SCIENCE OF NANO MATERIALS 10 Classification of nano structures effect of the nanometer length scale effects of nano scale dimensions on various properties structural, thermal, chemical, mechanical, magnetic, optical and electronic properties effect of nanoscale dimensions on biological systems. Fabrication methods Top down processes bottom up process. UNIT V CHARACTERIZATION OF NANO MATERIALS 11 Nano-processing systems Nano measuring systems characterization analytical imaging techniques microscopy techniques, electron microscopy scanning electron microscopy, transmission electron microscopy, transmission electron microscopy, scanning tunneling microscopy, atomic force microscopy, diffraction techniques spectroscopy techniques Raman spectroscopy, 3D surface analysis Mechanical, Magnetic and thermal properties Nano positioning systems. TOTAL: 45 PERIODS UNIT II

10

REFERENCES: 1. Tai Ran Hsu, MEMS and Microsystems Design and Manufacture, Tata-McGraw Hill, New Delhi, 2002. 2. Mark Madou Fundamentals of Microfabrication, CRC Press, New York, 1997. 3. Norio Taniguchi, Nano Technology, Oxford University Press, New York, 2003 4. The MEMS Hand book, Mohamed Gad-el-Hak, CRC Press, New York, London. 5. Charles P Poole, Frank J Owens, Introduction to Nano technology, John Wiley and Sons, 2003 6. Julian W. Hardner Micro Sensors, Principles and Applications, CRC Press 1993.

MR 9124

MICROCONTROLLER LAB

L TP C 3 0 0 3

1. Programming exercises on 8051 Microcontroller. 2. Programming exercises on PLC. 3. Programming exercises on PIC Microcontroller. 4. PIC and 8051 Microcontroller simulation exercises. 5. Exercises on A/D and D/A converter interfacing. 6. Exercises on PC Interface with Microcontroller. 7. Exercises on Pick and place Robotic interfacing. 8. Exercises on Pulse width Modulation using Microcontrollers (DC motor control). 9. Exercise on stepper motor interfacing. 10. Data Acquisition system using Microcontroller. 11. Exercises on servo motor interfacing. 12. Mini Project with Microcontroller. MR 9122 MICROCONTROLLER & PROGRAMMABLE LOGIC CONTROLLERS LTPC 3003 AIM: To understand the programming interfacing and microcontrollers and programmable logic controller. OBJECTIVE: This course is intended for learning the Introduction and Architecture of Microcontroller, Fundamentals of Assembly language Programming, Programming of Microcontroller and Interfacing of Micrcontroller. This course is also gives the ideas of Fundamentals. Architecture and Operations of programmable logic controller, Problem solving using logic ladder diagrams and communication in PLCs. UNIT- I INTRODUCTION TO MICRO CONTROLLER 6 applications of various

Architecture of Microcontroller CISC and RISC - : 8051 family, - PIC 16FXXX family Memory organization Addressing modes Fundamentals of Assembly language Programming Instruction to Assembler Compiler and IDE Introduction to Embedded systems.

11

UNIT II PROGRAMMING OF MICROCONTROLLER 12 Instruction set Addressing modes Programming- Timer/Counter, Interrupts Serial communication of 8051 and PIC family-program examples. UNIT- III INTERFACING OF MICROCONTROLLER 9

Interfacing of Memory-key board-Displays- ADC and DAC-stepper motors with 8051 and PIC family using Assembly language programming. UNIT- IV INTRODUCTION TO PROGRAMMABLE LOGIC CONTROLLER 6

Fundamentals of programmable logic controller Functions of PLCs PLC operations Evaluation of the modern PLC State Based Design Memory Serial communication Human machine Interfacing Selection of PLC Features of PLC. UNIT - V PLC PROGRAMMING 12

Architecture Basics of PLC programming Developing Fundamental wiring diagrams Problem solving using logic ladder diagrams communication in PLCs Programming Timers programming counters.. TOTAL : 45 PERIODS REFERENCES 1. Muhammad Ali Mazidi and Janice Gillispic Mazdi, The 8051 Microcontroller and Embedded Systems Pearson Education, Inc 2006. 2. John B. Peatman, Design with Micro controllers, McGraw Hill International, USA, 2005. 3. Kenneth Hint, and Daniel Tabak, Micro controllers, Architecture, Implementation and programming, McGraw Hill International, USA, 1992. 4. Kenneth J. Aylala, The 8051 Micro controller, the Architecture and Programming applications:2003. 5. Frank D. Petro Zella, Programmable logic controller McGraw Hill Publications, 1998. 6. James W. Stewart, The 8051 Micro controller hardware, software and interfaciung, regents Prentice Hall, 2003. 7. John B. Peatman, PIC programing, McGraw Hill International, USA, 2005.

MR 9123

CONTROL SYSTEM ENGINEERING

LT P C 30 0 3

AIM: To understand the various types of control systems and their design and specifications OBJECTIVE: This course is intended for learning the all types of Control Systems and their Representations. Block diagrams, Time and Frequency domain specifications, stability of control systems and stability criterion. This course is also gives the ideas of Analysis and Design of State Variables and components of control systems.

12

UNIT I SYSTEMS AND THEIR REPRESENTATION 9 Basic elements in Control Systems Mathematical Models Mechanical translational Mechanical rotational Electrical systems Transfer functions Block diagrams. Reduction techniques signal flow graph Thermal Hydraulic Pneumatic Systems. UNIT II TIME AND FREQUENCY RESPONSE 9 Time domain specifications-types of test inputs-I and II order systems-responsegeneralized error series-steady state error-frequency domain specifications-polarplot-bode plot UNIT III STABILITY OF CONTROL SYSTEMS 9

Characteristic equation-location of roots in S plane for stability Routh Hurwitz criterion-root locus technique construction-Gain and phase margin-Nyquist stability criterion. UNIT IV STATE VARIABLE ANALYSIS AND DESIGN 9 Concepts of state variables and state model state models for linear continuous time systems Solution of state equations Concepts of controllability and observability State variables and Linear Discrete time systems problems. UNIT V CONTROL SYSTEM COMPONENTS 9

Servomotor-stepper motor- synchro -resolver- amplidyne - planar motor: types, principle, Application and Selection Passive Compliances TOTAL : 45 PERIODS REFERENCES: 1. K.ogata, :modern controls engineering Prentice Hall of India Pvt. Ltd., New Delhi, 2005. 2. B.C. kuo, Automatic Control Systems, Prentice Hall of India Pvt. Ltd., New Delhi, 2004 3. I.J.Nagrath and Gopal. Control system engineering, new age international (P) Ltd., 2006. 4. A. Nagoor Kani, Control Systems, RBA publications (P) Ltd., 2007. 5. M. Gopal, Control Systems priniciples and Design Tata MV Graw Hill Publishing Ltd, 2003 MR 9150 INDUSTRIAL INSTRUMENTATION L 3 AIM: To understand and know the measurements of various industrial instruments and data presentation systems. OBJECTIVE: This course is intended for learning the Pressure Measurement. All types of Flow Measurements, All types of temperature, humidity, strain and vibration measurements, classification and characteristics of Data Presentation Systems. T 0 P 0 C 3

13

UNIT I

PRESSURE MEASUREMENT

Pressure Standards Dead weight gauge, Manometers Elastic elements: Diaphragms, Bellows, Bourdon tubes Low pressure measurement: McLeod gauge, Knudsen gauge, Thermocouple and Pirani gauge, lonization gauge High pressure measurement I/P and P/I Converters, Transmitters. UNIT II FLOW AND LEVEL MEASUREMENTS 9

Head-type flow meters: Orifice, Venturi, Nozzle Rotameter Anemometers: Hot wire and Hot film Electromagnetic flowmeters Turbine flowmeter Ultrasonic Flowmeter Electric methods for level measurement: Resistance switching type, Conductance probe type, Capacitance type Ultrasonic, Nuclear Radiation methods of Level measurement. UNIT III TEMPERATURE AND HUMIDITY MEASUREMENT 9

Temperature Standards Range Resistance Temperature Detectors (RTDs), Two wire and Three wire configuration Thermocouples: Lead and Cold Junction Compensation Techniques Radiation pyrometers Humidity measurements Transmitters. UNIT IV STRAIN AND VIBRATION MEASUREMENTS 6

Stress strain relation Strain measurement considerations Static and Dynamics Measurements Calibration of Strain gauges Load Cells Vibration Measurements. UNIT V DATA PRESENTATION SYSTEMS 12

Classification Characteristics Digital display elements, LEDs, LCDs, - Dot matrix systems, alphanumeric displays Graphic display: CRT Recording: Chart recorders, CRO, X-Y Recorders, Printers, Magnetic recorders, Digital recording techniques Signal conditioning methods Data Acquisition Systems Data Loggers Outline and Features of PC Based Instruments Virtual Instruments.

TOTAL: 45 PERIODS

REFERENCES 1. 2. 3. 4. Ernest O.Doebelin, Measurement systems Application and Design, International Student Edition, IV Edition, McGraw-Hill Book Company, 1998. R.K.Jain, Mechanical and Industrial Measurements, Khanna Publishers, New Delhi, 1999. B.C.Nakra and K.K.Chaudary, Instrumentation Measurement and Analysis, Tata McGraw-Hill Publishing Company Ltd., New Delhi, 1985. D.Patranabis, Principles of Industrial Instrumentation, Tata McGraw-Hill Publishing Ltd., New Delhi, 1999.

14

MF 9162

ARTIFICIAL INTELLIGENCE L 3 T 0 P 0 C 3

AIM: To understand the various types and applications of Fuzzy Logics and Artificial Neural Networks. OBJECTIVE: This course is intended for learning the basic concepts, Operations and Principles of Fuzzy Logic, applications of various Fuzzy Logic systems, architecture and Taxonomy of Neural Networks. This course is also gives the ideas of ANN Architectures, Genetic Algorithms. Meta Heuristic techniques and Applications in Design and Manufacturing. UNIT I INTRODUCTION TO FUZZY LOGIC 8

Basic concepts in Fuzzy Set theory Operations of Fuzzy sets Fuzzy relational equations Propositional, Predicate Logic Inference Fuzzy Logic Principles Fuzzy inference Fuzzy Rule based systems Fuzzification and defuzzification Types. UNIT II FUZZY LOGIC APPLICATIONS 10

Fuzzy logic controllers Principles Various industrial Applications of Fuzzy logic control Adaptive Fuzzy systems Fuzzy Decision making Fuzzy classification Fuzzy pattern Recognition Image Processing applications Fuzzy optimization. UNIT III INTRODUCTION TO ARTIFICIAL NEURAL NETWORKS 8

Fundamentals of Neural networks Neural network architectures Learning methods Taxonomy of Neural Network Architectures Standard back propagation Algorithms Selection of various parameters Variations. UNIT IV OTHER ANN ARCHITECTURES 10

Associative memory Exponential Bidirectional Associative Memory Adaptive Resonance Theory Introduction Adaptive Resonance Theory 1 Adaptive Resonance Theory 2 Applications Kohen Self organizing maps counter propagation networks Industrial Applications. UNIT V RECENT ADVANCES 10

Fundamentals of Genetic Algorithms Hybrid systems Meta heuristic techniques like simulated Annealing, Tabu Search, Ant colony optimization, Perpetual self organizing, Artificial immune systems Applications in Design and Manufacturing. TOTAL: 45 PERIODS REFERENCES: 1. Klir, G.J. Yuan Bo, Fuzzy sets and Fuzzy Logic: Theory and Applications, Prentice Hall of India Pvt. Ltd., 1997.

15

2. Jacek M. Zurada, Introduction to Artificial Neural Systems Jaico Publishing House, 1994 3. Simon Haykin, Neural Networks A comprehensive foundation, Prentice Hall, 2nd Edition, 1998. 4. Laurene Fausett, Fundamentals of Neural Networks, Architectures, Algorithms and Applications, Prentice Hall, Englewood cliffs, 1994. 5. S. Rajasekaran, GA Vijayalakshmi Pai, Neural Networks, Fuzzy Logic and Genetic Algorithms, Prentice Hall of India Private Limited, 2003. QE9114 METROLOGY AND INSPECTION L 3 AIM: To enable the learner to get familiar with the fundamental and advanced aspects of manufacturing metrology and quality control. OBJECTIVE: To make the learner to design and fabricate inspection methods and systems in corporating electronic systems for inspection and quality control in engineering. UNIT I FUNDAMENTALS AND CONCEPTS IN METROLOGY 9 T 0 P 0 C 3

Standards of measurement Analog and digital measuring instruments-comparators Limits, Fits and Tolerances Gauge design Angular measurements Surface Roughness Form errors and measurements. UNIT II INSPECTION AND GENERAL MEASUREMENTS 12

Inspection of gears and threads Tool makers microscope Universal measuring machine use of Laser interferometer in machine tool Inspection use of laser in on-line Inspection Laser micrometer Laser Alignment telescope. UNIT III OPTO ELECTRONICS IN ENGINEERING INSPECTION 6

Use of opto electronics in Tool wear measurement Micro hole measurement and surface Roughness Applications in In-Process measurement and on line Inspection. UNIT IV MACHINE VISION 9

Fundamentals of Image Processing Steps involved in Image Processing Machine Vision applications in manufacturing and metrology. UNIT V COORDINATE METROLOGY AND QUALITY CONTROL 9

Co-ordinate measuring machines Applications and case-studies of CMM in Inspection Use of Computers in quality control Control charts Reliability. TOTAL: 45 PERIODS REFERENCES

16

1. Jain R.K. Engineering Metrology Khanna Publishers 2000 2. Robert G. Seippel Opto Electronics for technology and engineering Prentice Hall New Jersey 1989. 3. Anil.K.Jain Fundamentals of digital Image Processing Prentice Hall of India Pvt. Ltd., - 2004 4. Dale.H. Besterfield Total Quality Management Pearson Education Asia 2002 5. Manuals of C.M.M. and systems. MR 9152 MACHINE VISION AND APPLICATIONS L 3 AIM: To impart knowledge on image processing and machine vision applications OBJECTIVE: To understand and apply the machine vision analysis and applications. UNIT I INTRODUCTION 9 T 0 P 0 C 3

Human vision Machine vision and computer vision benefits of machine vision Block diagram and function of machine vision system implementation of industrial machine vision system. UNIT II IMAGE ACQUISITION 12

Scene constraints-lighting sources, types and setups Lighting parameters working principle Analog and Digital Cameras General problem in capturing the image selection of camera optics in camera. UNIT III IMAGE PROCESSING 9

Image formation filtering technique Pixel processing Processing of binary and grey scale images Operators types segmentation edge detection Morphology. UNIT IV IMAGE ANALYSIS 6

Feature extraction-decision making pattern recognition colour image processing 3D image processing. UNIT V MACHINE VISION APPLICATION 9

Machine vision applications in manufacturing, electronics, printing, pharmaceutical, textile and Bio medical field - Case studies TOTAL: 45 PERIODS REFERENCES

17

1. Springer, Digital Image Processing, 2003 2. Milan Sonka, Vaclav Hlavac, Roger Boyle, Image Processing Analysis and machine vision publisher, 1995. 3. Richard.O.Duda, Peter.E.Hurt, Pattern Classification and Scene Analysis Publishers, 2000. 4. Rafael C.Gonzales, Richard.E.Woods, Digital Image Processing Publishers, 1992. 5. Nello Zuech, Understanding and Applying Machine Vision Marcel dekker Inc. 2000. MR 9153 MECHATRONICS ELEMENTS AND PROGRAMMING OF CNC MACHINES L T P C 3 0 0 3 AIM: To introduce the application of Mechatronics in machine tools. OBJECTIVE: To explain in detail about the various Mechatronics elements in CNC machines and also programming of CNC machines. UNIT I INTRODUCTION OF NC, CNC, DNC AND ADAPTIVE CONTROL

Classification of machine tools types, functions and processes - fundamentals of NC and CNC technologies Adaptive control - types, application and benefits - general configuration of adaptive control and function reasons for process change - practical problems with adaptive control - example for feedback and adaptive control. UNIT II MECHATRONIC ELEMENTS IN CNC MACHINE TOOLS 9

CNC systems - configuration of the CNC system interfacing monitoring diagnostics - machine data - compensations for machine accuracies - PLC in CNC PLC programming for CNC, steps in programming and case studies - machine structure -types of loads on CNC machine - guide ways and types - mechanical transmission elements - elements for rotary motion to linear motion - ball screw and types - roller screw and types - rack and pinion - various torque transmission elements - requirements of feed drives and spindle drive. UNIT III MECHATRONICS ELEMENT IN CNC MEASURING SYSTEM AND TOOLING 12 Measuring systems - feedback devices - velocity feedback - analog and digital position feedback - rotary and linear. Tooling - requirement and planning - preset, qualified and semi qualified tools. Fixtures requirement - unified and modular fixtures - tool identification - touch trigger probe- tool coding - EEPROM tools.

18

Tool condition monitoring - various indirect and direct methods. Identification and gauging of work piece. Tool locking system - ball lock mechanism and contact pressure monitoring. Automatic tool changing system - types and benefits - tool magazine sensors in CNC. UNIT IV CNC PROGRAMMING 14

Machine axes identification - primary, secondary and tertiary - manual CNC programming - Milling programming fundamentals - compensation and offset in milling -fixed cycles in milling - repetitive programming - loops, sub programs and macros. Turning programming fundamentals - compensation and offset in turning fixed cycles in turning. Computer assisted programming in APT - basic geometry definition - cutter motion definition - postprocessor statements - generation and execution of APT programs. UNIT V TESTING AND MAINTENANCE OF CNC MACHINES 5

Verification of technical specification and functional aspects, Verification during idle running & machine tool and the work piece accuracy - Installation of CNC machines Maintenance of CNC machines - machine elements hydraulic elements - electrical and electronic elements maintenance schedules. TOTAL: 45 PERIODS REFERENCES: 1. Jonathan Lin,S.C., Computer Numerical Control (From Programming to Networking), Delmar Publishers Inc., 2000. 2. HMT Limited, Mechatronics, Tata Mcgraw-Hill Publishing Co Ltd, 2002. 3. Groover,M.P., Automation, Production System and CIM, Prentice Hall of India Pvt. Ltd, 2003. 4. Grahamt.Smith, Advanced Machining: The Handbook of Cutting Technology, IFS Publications Ltd., 1989 5. Sehrawatt,M.S., and Narang,J.S., CNC Machine, Dhanpat Rai And Co, 2002. 6. Jayakumar,V., and Mahendran,B., Computer Aided Manufacturing, Lakshmi Publications 2005. 7. Radhakrishnan,P., CNC Machine, New Central Book Agency, 2000. 8. Stenerson and Curran, Computer Numerical Control-Operation and Programming, PHI Learning Pvt. Ltd., 2008.

19

MR 9154

AUTOMOTIVE ELECTRONICS L 3 T 0 P 0 C 3

AIM: To understand the design and specifications of various automotive electronic control systems. OBJECTIVE: This course is intended for learning the Fundamentals of Automobile Engineering, Automotive applications of all types of sensors and actuators systems. This course is gives the brief ideas of automotive engines, Engine control functions, Fuel delivery systems. All types of transmission control systems, Electromagnetic Interference and Electronic Dashboard Instruments. UNIT I FUNDAMENTALS OF AUTOMOTIVE ELECTRONICS 6

Introduction to Automobile Engineering, Automotive Engines, Automotive Control Systems Components of Electronic Engine Management Current trends in Automobiles. UNIT II AUTOMOTIVE SENSORS AND ACTUATORS 9

Introduction Basic Arrangement Automotive applications of Pressure, Flow, Temperature sensors Position, Speed and Acceleration Sensors Exhaust gas sensors Engine knock, Engine torque sensors Automotive actuators. UNIT III AUTOMOTIVE ENGINE CONTROL SYSTEMS I: ENGINE CONTROL

12

Objectives Spark Ignition Engines: Engine control functions, Engine control modes, Fuel delivery systems, MPFI, Ignition Systems, Diagnostics Compression Ignition Engines Emission control. UNIT IV Automotive Transmission Control Systems II 12

Transmission control Cruise control Braking control Traction control Suspension control Steering control Stability control Integrated engine control. UNIT V AUTOMOTIVE MONITORING AND DIAGNOSTICS 6

Electromagnetic Interference (EMI) Suppression Electromagnetic Compatibility Electronic Dashboard Instruments On board and off board Diagnostics Security and warning Systems.

TOTAL: 45 PERIODS REFERENCES: 1. William B.Ribbens, Understanding Automotive Electronics 5th Edition, Butterworth, Heinemann Wobum, 1998.

20

2. Tom Weather Jr and Cland C. Hunter, Automotive Computers and Control System Prentice Hall Inc., New Jersey. 3. Young A.P. and Griffths, L., Automobile Electrical Equipment English Language Book Society and New Press. 4. Crouse, W.H. Automobile Electrical Equipment, McGraw Hill Book Co Inc., New York, 1955. 5. Robert N Brady, Automotive Computers and Digital Instrumentation, Areston Book Prentice Hall, Eagle Wood Cliffs, New Jersey, 1988. 6. T. Mellard, Automotive Electronics. 7. R.K. Jurgen, Automotive Electronics Handbook, McGraw Hill 2nd Edition.

21

MR 9155

OPTO - ELECTRONIC INSTRUMENTATION L 3 T 0 P 0 C 3

AIM: To understand the basic concepts, properties and applications of optical fibers and lasers. OBJECTIVE: This course is intended for learning the Principles of light propagation through a fiber, types and properties of fibers. Fiber optic sensors, types of modulators, Industrial Application of Optical Fibers, Measurements of pressure, temperature, current, voltage liquid level and strain. This course is also gives the ideas of Fundamentals and characteristics of lasers, properties of lasers, All types of laser, Industrial Application of Lasers and Medical Applications of Optical Fibers and lasers. UNIT I OPTICAL FIBERS AND THEIR PROPERTIES 9

Principles of light propagation through a fiber types of fibers and their properties transmission characteristics of optical fiber absorption losses scattering losses dispersion optical fiber measurement optical sources optical detectors LED LD PIN and APD UNIT II INDUSTRIAL APPLICATION OF OPTICAL FIBERS 9

Fiber optic sensors fiber optic instrumentation system types of modulators detectors application in instrumentation interferometric method of measurement of length moir fringes measurements of pressure, temperature, current, voltage liquid level and strain fiber optic gyroscope polarization maintaining fibers. UNIT III LASER FUNDAMENTALS 9

Fundamental characteristics of lasers three level and four level lasers properties of laser laser modes resonator configuration Q-switching and mode locking cavity dumping types of laser: gas lasers, solid lasers, liquid lasers and semi conductor lasers. UNIT IV INDUSTRIAL APPLICATION OF LASERS 9

Laser for measurement of distance, length velocity, acceleration, current voltage and atmospheric effect material processing laser heating, welding melting and trimming of materials removal and vaporization. UNIT V HOLOGRAM AND MEDICAL APPLICATION 9

Holography basic principle: methods: holographic interferometry and applications, holography for non destructive testing holographic components medical applications of lasers, laser and tissue interaction laser instruments for surgery, removal of tumors of vocal cords, brain surgery, plastic surgery, gynecology and oncology. TOTAL: 45 PERIODS

22

REFERENCES: 1. Ghatak A.K. and Thiagarajar K, Optical electronics foundation book, TMH, New Delhi, 1991 Keiser G, Optical Fiber Communication, McGraw Hill, 1991. 2. John and Harry, Industrial lasers and their applications McGraw Hill, 1974. 3. John F Read, Industrial applications of lasers, Academic Press, 1978 4. MonteRoss, Laser applications, McGraw-Hill 1968. MR 9156 MACHINE TOOL CONTROL AND CONDITION MONITORING L T P 3 0 0

C 3

AIM: To impart knowledge on machine tool control and conditioning monitoring. OBJECTIVE: To introduce various types of machine tool control and various condition monitoring techniques. UNIT I OVERVIEW OF AUTOMATIC CONTROL IN MACHINE TOOLS 11

Open loop and closed loop system in machine tools- process model formulationtransfer function-control actions-block diagram representation of mechanical pneumatic and electrical systems. Process computer - peripherals-Data logger-Direct digital control-Supervisory computer control. UNIT II DRIVE SYSTEMS AND FEED BACK DEVICES IN MACHINE TOOLS 9 Hydraulic and Pneumatic drives, Electrical drives A.C. Motor, D.C. Motor, Servo motor and Stepper motor. Feed back devices - Syncro, resolver, diffraction gratings, potentiometer, Inductosyn and encoders-application in machine tools. UNIT III ADAPTIVE CONTROL AND PLC 10

Adaptive control-types ACC, ACO, Real time parameter estimation, Applications adaptive control for turning, milling, grinding and EDM. Programmable logic controller-Functions-Applications in machine tools. UNIT IV VIBRATION, ACOUSTIC EMISSION / SOUND. 8

Primary & Secondary signals, Online and Off-line monitoring. Fundamentals of Vibration, Sound, Acoustic Emission. Machine Tool Condition Monitoring through Vibration, Sound, Acoustic Emission, Case Studies UNIT V CONDITION MONITORING, THROUGH OTHER TECHNIQUES 7

Visual & temperature monitoring, Leakage monitoring, Lubricant monitoring, condition monitoring of Lube and Hydraulic systems, Thickness monitoring, Image processing techniques in condition monitoring. TOTAL: 45 PERIODS

23

REFERENCES: 1. Manfred Weck, Hand Book of Machine Tools Vol.3, John Wiley & Sons, 1984. 2. Sushil Kumar Srivstava, Industrial Maintenance ManagementS.Chand & Company Ltd., New Delhi, 1998. 3. Mikell P.Groover, Automation Production system and Computer Integrated Manufacturing, Prentice Hall of India Pvt. Ltd., 1995. MR 9157 NETWORKS AND DISTRIBUTION SYSTEMS L 3 AIM: To impart the knowledge of networking and distribution systems to the students OBJECTIVE: This course is intended for learning the Introduction to networks, definition of layers, reference models, Different Architectural Protocols and Standards, different protocols, Network interconnection, Distribution system models, and distribution file system. UNIT I NETWORK FUNDAMENTALS 6 T 0 P 0 C 3

Introduction to networks, definition of layers, services, interfaces and protocols, communication themes, switching techniques-circuit switched, package switched and message switched networks reference models, (OSI, TCP/IP, ATM) layers and duties comparison of models. UNIT II ARCHITECTURAL PROTOCOLS AND STANDARDS 9

Physical Layer-General Description, Characteristics, Signalling Limits, Media Types and Comparison, Topologies, Examples of Physical Layer (RS232-C, ISDN, ATM, SONNET) Data link layer sliding window protocols, A104A protocols, LAN protocols Performance, specification and verification IEEE-Standards. UNIT III NETWORK INTERCONNECTION 6

Internet working interconnection issues, bridges-transparent & source routing bridges, routers, flow and congestion command algorithms, gateways - Network security Internet protocols. UNIT IV DISTRIBUTED SYSTEMS 12 Models: Hardware concepts-software concepts-claint server modelscommunication: Layout protocals-Remote procedure call-Remote object invocationmessage oriented communication-synchronization Mechanism: clock-logical clocksElection Algorithms-mutual exclusion- Case study:Amoeba-Mach-Chorus. UNIT V DISTRIBUTED FILE SYSTEM 12 Design:File service interface-Directory server Interface- Implementation:File useagesystem structure-Caching replication- Trends in distributed file systems: New

24

Hardware-scalability-Wide Multimedia.

area

networking-Mobile

users-Fault

tolerances-

TOTAL: 45 PERIODS REFERENCES: 1. Stallings, S.W. Data and computer communications, IV Edition, Prentice Hall of India, 2006. 2. Tanenbaum, A.S. Computer Networks, Prentice Hall of India, III Edition, 2006. 3. Keiser, Local Area Network, Tata Mc GrawHill, 1999. 4. Kesav S. An engineering approach to computer networking, Addision Wesley, 1999. 5. Comerd E-Internetowrking with TCP/IP(Volume 1), Principles, Protocols and architecture, III Edition, Prentice Hall of Indoa, 1999. 6. Forauzan B, - Introduction to Data Communication & Networking McGraw Hill 1998. 7. Tanenbaum, A.S, Marten vansteen.Distributed systems principles and paradigms Prentice Hall of India, 2006. 8. Tanenbaum, A.S, Distributed operating systems Pearson Educatoon, 1995. MR 9158 MEDICAL ELECTRONICS AND INSTRUMENTATION L 3 AIM: To understand the concepts and operations of various medical electronic instruments. OBJECTIVE: This course is intended for learning the brief review of human physiology and anatomy, different types of sensors used I biomedicine, selection criteria for transducers and electrodes, different types Electro-Physiological Measurement, Measurement of blood pressure, gas volume, flow rate of CO2 and O2 in exhaust air, Medical Imaging Parameter Measurements, Cardiac pacemakers, defibrillators ventilators and Therapetic devices. UNIT I ANATOMY, PHYSIOLOGY AND TRANSDUCERS 9 T 0 P 0 C 3

Brief review of human physiology and anatomy cell and their structures electrical mechanical and chemical activities action and resting potential different types of electrodes sensors used in biomedicine selection criteria for transducers and electrodes necessity for low noise pre-amplifiers differential amplifiers Chopper amplifiers electrical safety grounding and isolation. UNIT II ELECTRO PHYSIOLOGICAL MEASUREMENT 9

ECG EEG EMG - ERG lead system and recording methods typical waveforms applications. UNIT III NON-ELECTRICAL PARAMETER MEASUREMENTS 9

25

Measurement of blood pressure blood flow cardiac output cardiac rate heart sound measurement of gas volume flow rate of CO2 and O2 in exhaust air pH of blood ESR and GSR measurements. UNIT IV MEDICAL IMAGING PARAMETER MEASUREMENTS 9

X-Ray machine computer aided tomography magnetic resonance imaging system ultra sonography endoscopy different types of telemetry system laser in biomedicine. UNIT V ASSISTING AND THERAPETIC DEVICES 9

Cardiac pacemakers defibrillators ventilators muscle stimulators diathermy introduction to artificial kidney artificial heart heart lung machine limb prosthetics orthotics elements of audio and visual aids. TOTAL:45 PERIODS

REFERENCES 1. Webster J.G., Medical Instrumentation: Application and Design, 3rd Edition, John Wiley and Son, 1999. 2. Khandpur R.S. Hand book of Biomedical instrumentation and Measurements, Tata McGraw-Hill New Delhi 1987. 3. Geddes and Baker, Principles of Applied Biomedical Instrumentation, John Wiley and Sons, USA, 1975. 4. Well G. Biomedical Instrumentation and Measurements, Prentice Hall, New Jersey, 1980. 5. Koryla J., Medical and Biological Application of Electro chemical devices John Wiley and Sons, Chichester, 1980 6. Wise D.L., Applied Bio-sensors, Butterworth USA, 1989 7. Jackson and Webster, Medicine and Clinical Engineering Prentice Hall, New Delhi, 1979.

26

MR 9159

REAL TIME EMBEDDED SYSTEM L 3 T 0 P 0 C 3

AIM: To impart knowledge in the area of real time embedded system. OBJECTIVE: To teach and understand about the definitions, high level language descriptions of software for embedded system. UNIT I INTRODUCTION TO EMBEDDED SYSTEMS 6

Definitions Brief overview of micro-controllers, microprocessors and DSPs, Typical classification and application scenarios of embedded systems. UNIT II EMBEDDED SYSTEM COMPONENTS AND INTERFACE 9

Embedded processors Memory Devices Interface and Peripherals Power and its Management. UNIT III EMBEDDED SYSTEM DESIGN AND DEVELOPMENT 9

Design Methods and techniques Models and languages State Machine and state tables in embedded design High level language descriptions of S/W for embedded system, Java based embedded system design Simulation and Emulation of embedded systems. UNIT IV REAL TIME MODELS, LANGUAGE AND OPERATING SYSTEMS 12

Event based, process based and graph based models, Petrinet models-Real time languages The real time Kernel, OS tasks, task states, task scheduling, interrupt processing, clocking communication and synchronization, control blocks, memory requirements and control, kernel services Real time languages and their features. UNIT V CASE STUDIES IN REAL TIME EMBEDDED INSTRUMENTS 9

Specific examples of time-critical and safety-critical embedded systems applications in automotives, aerospace, medicine and manufacturing. TOTAL: 45 PERIODS REFERENCES 1. Ball S.R., Embedded microprocessor Systems Real World Design, Prentice Hall, 1996 2. Herma K., Real Time Systems Design for distributed Embedded Applications, Kluwer Academic, 1997. 3. Gassle.J., Art of Programming embedded systems, Academic Press, 1992.

27

4. Gajski, D.D. Vahid, F., Narayan S., Specification and Design of Embedded Systems, PTR Prentice Hall, 1994. 5. Intel manual on 16 bit embedded controllers, Santa Clara, 1991 6. C.M. Krishna, Kang G. Shin, Real Time systems, McGraw Hill 1997 7. Raymond J.A. Buhr, Donaid L, Balley: An Introduction to Real time Systems, Prentice Hall international, 1999. MR 9160 MECHATRONICS SYSTEM DESIGN L 3 AIM: To understand the basic concepts, properties and interfacing off controls and drives in Mechatronics System Design. OBJECTIVE: This course is intended for learning the Mechatronics systems and their design process. Different types of Controls and Drives, Real time interfacing, data acquisition system, sensors for condition monitoring, mechanitronic controlin automated manufacturing. De-icing temperature control system and skip control of a CD player. This course is also gives the case studies on design of mechatronics product, pick and place robot, car park barriers, car engine management and bar code reader. UNIT I SYSTEMS AND DESIGN 9 T 0 P 0 C 3

Mechatronics systems Integrated design issue in Mechatronics Mechatronic key elements, Mechatronics approach Adaptive control and distributed control system Design process Type of design Integrated product design Mechanism, load condition, design and flexibility structures man machine interface, industrial design and ergonomics, information transfer, safety. UNIT II CONTROL AND DRIVES 9

Control devices Electro hydraulic control devices, electro pneumatic proportional controls Rotational drives pneumatic motors: continuous and limited rotation Hydraulic motor: continuous and limited rotation motion converters, fixed ratio, invariant motion profile, variators. UNIT III REAL TIME INTERFACING 9

Real time interface Introduction, Elements of a data acquisition and control system, over view of I/O process, installation of I/O card and software Installation of the application software over framing. UNIT IV CASE STUDIES I 9

Case studies on data acquisition testing of transportation surface materials transducer calibration system for automotive application Strain gauge weighing system solenoid force Displacement calibration system Rotary optical encoder controlling temperature of a hot/cold reservoir sensors for condition monitoring mechatronic control in automated manufacturing.

28

UNIT V

CASE STUDIES II

Case studies on data acquisition and control thermal cycle fatigue at a ceramic plate PH control system. De-icing temperature control system skip control of a CD player Auto focus camera. Case studies on design of mechatronics product pick and place robot car park barriers car engine management bar code reader.

TOTAL: 45 PERIODS REFERENCES 1. Brian morriss, Automated manufacturing Systems Actuators Controls, sensors and Robotics, McGraw Hill International Edition, 1995. 2. Bolton, Mechatronics Electronic control systems in mechanical and electrical engineering, 2nd edition, Addison Wesley Longman Ltd., 1999. 3. Devadas Shetty, Richard A.Kolkm, Mechatronics system design, PWS publishing company, 1997. 4. Bradley, D. Dawson, N.C.Burd and A.J. Loader, Mechatronics: Electronics in product and process, Chapman and Hall, London, 1991 5. Gopal, Sensors A comprehensive survey Vol I & Vol VIII, BCH publisher, New York. MR 9161 TELEMATICS L 3 AIM: To impart the knowledge in the area of Telematics. OBJECTIVE: This course is intended for learning the applications of telemetry, in either commercial or defense/space organizations. Applications include telemetry as applied to control and monitoring of space vehicles as well as telecommunications, automotive testing, in-plant industrial system control and electrical power transmission telemetry systems. T 0 P 0 C 3

UNIT I

INTRODUCTION

Types of telemetry systems - Basic radio telemetry system - Radio Frequency (RF) Link - Components of telemetry system - Antennas - Near-Earth and Deep Space Applications - Telemetry standards - Understanding dB: Decibels, Power Ratio, Voltage Ratio, dB Conversions. UNIT 2 TELEMETRY TECHNIQUES 12

Carrier Modulation - Amplitude and Frequency Modulation (AM and FM) -FM: Ground Station, Frequencies, Techniques, Modulation Index Spectra - Guard Bands - FM Channel Mixing - Signal Sampling - Pulse Amplitude Modulation

29

(PAM), PAM Ground Station -PCM Encoder -- PCM Ground Station - Data Bus: ARINC-429 - MIL-STD-1553 - IRIG-106, Chapter 8 (1553 and 429) Recent Updates - MIL-STD-1553 Future - Other Buses UNIT 3 THE COMPUTER AND THE TELEMETRY SYSTEM 12

Data Words - Data Transfer Mechanisms - PC Computers - Getting Data to Disk - Buffer Servicing: CVT vs. Data Driven - Bus Standards - PC Systems PC Software Environment: Portability and Ruggedness - Buses: ISA, PCMCIA (PC Card) - PCI, VME - USB, FireWire (IEEE 1394) - SCSI (Internal), Fibre Channel - ATA and Serial ATA RAID and Networked Storage - Networking Growth - Ethernet: Rates, Components, Physical Medium - Fiber Connectors - Software Protocols UDP vs. TCP - Data Flow Down - Display Devices - Graphics Display Engines: Tabular, Bar Charts, Strip Charts, Alarm Pages, Quick Look - IADS ILIAD - LabView - MatLab - Global Majic - Quinn Curtis - DataViews Parameter Databases - Telemetry Attribute Transfer Standards (TMATS) "Hard" Programming (Patch Panels) - Strip charts RF Transmission: UHF Bands - Digital Signal Transmission - Popular Modulation Types - Antennas - Bit Error Rate (BER) - System BER Testing Future VisionsJTRS UNIT 4 MISSION PLANNING AND DATA MINING 7

Mission Planning - Work Breakdown Structure - Mission Support Process The Next Challenge (Data Mining) - Data Mining Tool Requirements - brief discussion of future trends, including iNet. UNIT - 5 APPLICATIONS 8

Applications in healthcare, fleet management, intelligent transportation, automotive, advanced manufacturing, supply chain management and defence & security as case studies to explain the deployment and effectiveness of telematic systems.

TOTAL : 45 PERIODS REFERENCE:

1. Telemetry Systems Engineering, Frank Carden, Russ Jedlicka, Robert Henry, Artech House Publishers Boston, MA, USA, ISBN-13: 9781580532570. 2. Practical Radio Engineering and Telemetry for Industry, David Bailey, Elsevier, ISBN-13: 978-0-7506-5803-4. 3. Telematics and Transport Behaviour (Advances in Spatial Science) by Peter Nijkamp, G. Pepping, D. Banister, Springer-Verlag Telos (May 1996) ISBN-13: 978-3540609193.

30

4. Handbook of Telemetry and Remote Control by Elliot L Gruenberg, McGraw-Hill, 1967. MR 9162 MECHATRONICS FOR AIRCRAFT L T 3 0 AIM: To understand the Design, Architecture and Operations of Aircraft Systems OBJECTIVE: This course is intended for learning the architecture and design of Avionics systems, components of airplane, sensors and actuation systems in Aircraft, Testing methodologies and Aircraft navigation systems. This course is gives the ideas of air speed, air temperature, Angle of attack measurements, pressure, torque, fuel flow, engine vibration, monitoring and integration of GPS and INS utilization of navigation systems in aircraft. UNIT I AVIONICS SYSTEM ARCHITECTURE & DESIGN 9 P 0 C 3

Need for Avionics in Civil and Military aircraft and Space systems, integrated avionics, Avionics system architecture, design and evaluation. Fault tolerant systems - hardware, and software, Future architecture. Data buses- MIL-STD-1553B, ARINC-429 and 629, STANAG-3910 and 3838, DOD-STD-1773, HSDB, CAN bus, Avionics Full Duplex Switched Ethernet (AFDX) comparison of buses UNIT II CONFIGURATION OF AIRPLANE AND ITS COMPONENTS 9

Fundamentals - components of an airplane and their functions - motions of a plane Cockpit displays - MFDs, MFK, HUD, DVI, HOTAS, Helmet mounted display, UNIT III AIRCRAFT SENSORS AND ACTUATION SYSTEMS 9

Gyroscope- Principles , Gyro equations, Rate Gyros - Rate integration and free Gyro, Vertical and Directional Gyros, Laser Gyroscopes, Accelerometers. Types of actuation systems-Linear and non-linear actuation system, modeling of actuation systems, Servo-loop analysis actuator design - testing methodologies, Performance testing equipments for sensors and actuation systems.

UNIT IV

AIRCRAFT INSTRUMENTS

12

Air data instruments-airspeed, altitude, Vertical speed indicators. Static Air temperature, Angle of attack measurement. Direct reading compass, magnetic heading reference system-detector element, Pressure , temperature fuel quantity and engine power measurement and control instruments-measurement of RPM, manifold pressure, torque, exhaust gas temperature, EPR, fuel flow, engine vibration, monitoring. Electrical Power requirement for Military and Civil standards. Solar battery design. UNIT V AIRCRAFT NAVIGATION SYSTEMS 6

31

Inertial Navigation Satellite navigation - GPS -system description -basic principles position and velocity determination-signal structure-DGPS, Integration of GPS and INS-utilization of navigation systems in aircraft TOTAL: 45 PERIODS REFERENCES: 1. Collinson R.P.G. Introduction to Avionics, Chapman and Hall, 1996 2. Cary R .Spitzer, The Avionics Handbook,Crc Press, 2000. 3. Pallet, E.H.J. 'Aircraft Instruments & Integrated systems', Longman Scientific and Technical, McGraw-Hill, 1992. 4. Myron Kyton, Walfred Fried, Avionics Navigation Systems, John Wiley & Sons,1997 5. Pallett, E.H.J. Aircraft instruments, principles and applications, Pitman publishing Ltd., London, 1981.

MF 9163 LEAN MANUFACTURING SYSTEM AND IMPLEMENTATION L 3 AIM: To introduce the concepts of lean manufacturing system. OBJECTIVES: To study the various tools for lean manufacturing (LM). To apply the above tools to implement LM system in an organization. INTRODUCTION TO LEAN MANUFACTURING 7 T 0 P 0 C 3

UNIT I

Conventional Manufacturing versus Lean Manufacturing Principles of Lean Manufacturing Basic elements of lean manufacturing Introduction to LM Tools. UNIT II CELLULAR MANUFACTURING, JIT, TPM 9

Cellular Manufacturing Types of Layout, Principles of Cell layout, Implementation. JIT Principles of JIT and Implementation of Kanban. TPM Pillars of TPM, Principles and implementation of TPM. UNIT III SET UP TIME REDUCTION, TQM, 5S, VSM 10

Set up time reduction Definition, philosophies and reduction approaches. TQM Principles and implementation. 5S Principles and implementation - Value stream mapping - Procedure and principles. UNIT IV SIX SIGMA 9

32

Six Sigma Definition, statistical considerations, variability reduction, design of experiments Six Sigma implementation UNIT V CASE STUDIES 10 Various case studies of implementation of lean manufacturing at industries. TOTAL: 45 PERIODS REFERENCES: 1. Design and Analysis of Lean Production Systems, Ronald G. Askin & Jeffrey B. Goldberg, John Wiley & Sons, 2003 2. Rother M. and Shook J, 1999 Learning to See: Value Stream Mapping to Add Value and Eliminate Muda , Lean Enterprise Institute, Brookline, MA. 3. Mikell P. Groover (2002) Automation, Production Systems and CIM.

MF 9161

NON-DESTRUCTIVE EVALUATION L T 3 0

P 0

C 3

AIM: To stress the importance of NDT in engineering. OBJECTIVES: To introduce all types of NNDT and their applications in Engineering.

UNIT I Non-Destructive Testing: An Introduction, Visual Inspection & Liquid Penetrant Testing 6 Introduction to various non-destructive methods, Comparison of Destructive and Non destructive Tests, Visual Inspection, Optical aids used for visual inspection, Applications. Physical principles, procedure for penetrant testing, Penetrant testing materials, Penetrant testing methods-water washable, Post Emulsification methods, Applications

UNIT II EDDY CURRENT TESTING & ACOUSTIC EMISSION 10

Principles, Instrumentation for ECT, Absolute, differential probes, Techniques High sensitivity techniques, Multi frequency, Phased array ECT, Applications. Principle of AET, Instrumentation, Applications - testing of metal pressure vessels, Fatigue crack detection in aerospace structures. 33

UNIT III

MAGNETIC PARTICLE TESTING & THERMOGRAPHY

10

Principle of MPT, procedure used for testing a component, Equipment used for MPT, Magnetizing techniques, Applications. Principle of Thermography, Infrared Radiometry, Active thermography measurements, Applications Imaging entrapped water under an epoxy coating, Detection of carbon fiber contaminants. UNIT IV ULTRASONIC TESTING & RADIOGRAPHY 10

Principle, Ultrasonic transducers, Ultrasonic Flaw detection Equipment, Modes of display A- scan, B-Scan, C- Scan, Applications, Inspection Methods - Normal Incident Pulse-Echo Inspection, Normal Incident Throughtransmission Testing, Angle Beam Pulse-Echo testing, Applications of Normal Beam Inspection in detecting fatigue cracks, Inclusions, Slag, Porosity and Intergranular cracks. Principle of Radiography, Effect of radiation on Film, Radiographic imaging, Inspection Techniques Single wall single image, Double wall Penetration, Multiwall Penetration technique, Real Time Radiography UNIT V CASE STUDIES, COMPARISON AND SELECTION OF NDT METHODS 9

Case studies on defects in cast, rolled, extruded, welded and heat treated components. Comparison and selection of various NDT techniques. Codes, standards, specification and procedures. TOTAL: 45 PERIODS

REFERENCES: 1. Baldev Raj, Jeyakumar,T., Thavasimuthu,M., Practical Non Destructive Testing Narosa publishing house, New Delhi, 2002

2. Krautkramer. J., Ultra Sonic Testing of Materials, 1st Edition, Springer Verlag Publication, New York, 1996. 3. Peter J. Shull Non Destructive Evaluation: Theory, Techniques and Application Marcel Dekker, Inc., New York, 2002 4. www.ndt.net

34

MR 9164

MATERIAL HANDLING, STORAGE AND ASSEMBLY AUTOMATION L 3 T 0 P 0 C 3

AIM: To make the learner to understand the importance of layout and the productivity improvements due to the automation of material handling storage and assembly. OBJECTIVE: To make the learner to develop skills of analyzing the automation concepts and develop the need based design and fabrication of automated materials handling, storage and assembly system. UNIT I INTRODUCTION TO LAYOUT 9

Techniques for Analysing material flow Assembly chart Operation process chart multi process chart flow process chart flow diagram man machine chart two handed process chart string diagram Travel chart Visualizing Layout Drafting and sketching template and 3-D Block models. UNIT II MATERIAL HANDLING 9

Overview of material handling equipment Considerations in material handling system design 10 principles of material handling Industrial trucks AGV systems mobile Robots Mono Rails and other Rail Guided Vehicles Conveyors systems Cranes and Hoists Analysis of Material transport systems. UNIT III STORAGE SYSTEM 9

Storage system performance storage location strategies Conventional storage methods and equipments Automated storage systems. Engineering Analysis of Automated storage systems - AS/RS. UNIT IV SYSTEMS TRANSFER LINES AND AUTOMATED MANUFACTURING 8

Fundamentals of Automated production lines Application of Automated production lines Analysis of Transfer lines with no internal storage Analysis of Transfer lines with internal storage buffer. UNIT V AUTOMATED ASSEMBLY SYSTEMS 9

Fundamentals of Automated Assembly systems Design for Automated Assembly Quantitative Analysis of Assembly systems Automatic data capture - over view of Automatic identification methods. Bar-code techniques other Automatic Identification Systems.

TOTAL: 45 PERIOD

35

REFERENCES: 1. 2. 3. 4. 5. Mikell.P.Groover Automation, Production System and Computer integrated manufacturing, prentice Hall of India Pvt. Ltd., New Delhi 2003 S.Kant. Vajpayee Principles of Computer Integrated Manufacturing, Prentice Hall of India Pvt. Ltd., 2006. G.K. Agarwal Plant Layout and material handling M/s Jain Brothers, Delhi 2000 Mulcahy.D.E. Material handling hand book McGraw Hill, New York 1999 Kulwiec R.A. Editor Material Handling Hand book 2nd Edition, JohnWiely & Sons Inc., New York 1985.

36

MF 9153

MATERIALS MANAGEMENT AND LOGISTICS L 3 T 0 P 0 C 3

AIM: To introduce to the students the various functions of materials management and logistics OBJECTIVE: To make the students familiar with the various concepts and functions of material management, so that the students will be in a position to manage the materials management department independently. UNIT I INTRODUCTION 6

Introduction to materials management Objectives Functions Operating Cycle Value analysis Make or buy decisions. UNIT II MANAGEMENT OF PURCHASE 7

Purchasing policies and procedures Selection of sources of supply Vendor development Vendor evaluation and rating Methods of purchasing Imports Buyer Seller relationship Negotiations. UNIT III MANAGEMENT OF STORES AND LOGISTICS 12

Stores function Location Layout Stock taking Materials handling Transportation Insurance Codification Inventory pricing stores management safety warehousing Distribution linear programming Traveling Salesman problems Network analysis Logistics Management. UNIT IV Materials Planning 10

Forecasting Materials requirements planning Quantity Periodic Deterministic models Finite production. UNIT V Inventory Management 10

ABC analysis Aggregate planning Lot size under constraints Just in Time (JIT) system. Total: 45 REFERENCES 1. Lamer Lee and Donald W.Dobler, Purchasing and Material Management, Text and cases, Tata McGraw Hill, 1996. 2. Gopalakrishnan.P, Handbook of Materials Management, Prentice Hall of India, 1996. 3. Guptha P.K. and Manmohan, Problems in Operations Research, Suttan Chand & Sons, 2003.

37

4. Dr. R. Kesavan, C.Elanchezian and T.SundarSelwyn, Engineering Management Eswar Press 2005. 5. Dr.R. Kesavan, C.Elanchezian and B.Vijaya Ramnath, Production Planning and Control, Anuratha Publications, Chennai, 2008. 6. G. Reghuram, N. Rangaraj, Logistics and supply chain management cases and concepts, Macmillan India Ltd., 2006.

38

Das könnte Ihnen auch gefallen

- Instrumentation EngineeringDokument34 SeitenInstrumentation Engineeringvaithy1990Noch keine Bewertungen

- Engineering Surveying: Theory and Examination Problems for StudentsVon EverandEngineering Surveying: Theory and Examination Problems for StudentsBewertung: 4.5 von 5 Sternen4.5/5 (24)

- Smart Electrical and Mechanical Systems: An Application of Artificial Intelligence and Machine LearningVon EverandSmart Electrical and Mechanical Systems: An Application of Artificial Intelligence and Machine LearningRakesh SehgalNoch keine Bewertungen

- Mechanisms: Kinematic Analysis and Applications in RoboticsVon EverandMechanisms: Kinematic Analysis and Applications in RoboticsNoch keine Bewertungen

- Artificial Intelligence and Machine Learning in Smart City PlanningVon EverandArtificial Intelligence and Machine Learning in Smart City PlanningVedik BasettiNoch keine Bewertungen

- M.E. Refrigeration and Air Conditioning SyllabusDokument38 SeitenM.E. Refrigeration and Air Conditioning SyllabusJoswa Caxton75% (4)

- Machine Learning and Data Science in the Power Generation Industry: Best Practices, Tools, and Case StudiesVon EverandMachine Learning and Data Science in the Power Generation Industry: Best Practices, Tools, and Case StudiesPatrick BangertNoch keine Bewertungen

- Introduction to Bond Graphs and their ApplicationsVon EverandIntroduction to Bond Graphs and their ApplicationsBewertung: 5 von 5 Sternen5/5 (1)

- Neural Network Systems Techniques and Applications: Advances in Theory and ApplicationsVon EverandNeural Network Systems Techniques and Applications: Advances in Theory and ApplicationsNoch keine Bewertungen

- Anna UniversityDokument26 SeitenAnna UniversityNagasubramaniyan SankaranarayananNoch keine Bewertungen

- Me Manufacturing Curriculum-2Dokument11 SeitenMe Manufacturing Curriculum-2Arun KumarNoch keine Bewertungen

- Anna Univ Syllabus For EIE 3rd To 8th Sem Syllabus - WWW - Annaunivedu.infoDokument58 SeitenAnna Univ Syllabus For EIE 3rd To 8th Sem Syllabus - WWW - Annaunivedu.infosudentsideaNoch keine Bewertungen

- Anna Univ Part Time Mech SylabusDokument69 SeitenAnna Univ Part Time Mech SylabusmayilsamythangarajuNoch keine Bewertungen

- M.E. MANUFACTURING ENGINEERING AU SyllabusDokument35 SeitenM.E. MANUFACTURING ENGINEERING AU SyllabusJoswa CaxtonNoch keine Bewertungen

- Me Manufacturing CurriculumDokument37 SeitenMe Manufacturing CurriculumJeyaram kumarNoch keine Bewertungen

- B.E. CSEgbDokument98 SeitenB.E. CSEgbjyotsnaroopNoch keine Bewertungen

- B.E. CseDokument114 SeitenB.E. Cseselva136832Noch keine Bewertungen

- ManufacturingDokument35 SeitenManufacturingMichael EnglishNoch keine Bewertungen

- ME Avionics SyllabusDokument42 SeitenME Avionics SyllabusSam ThomasNoch keine Bewertungen

- UploadedFile 129816616088888750Dokument35 SeitenUploadedFile 129816616088888750Jeyaram KumarNoch keine Bewertungen

- Anna University Curriculum for ME Manufacturing EngineeringDokument34 SeitenAnna University Curriculum for ME Manufacturing EngineeringAnantha NarayananNoch keine Bewertungen

- ME8791 Mechatronics 01 - by WWW - Learnengineering.inDokument125 SeitenME8791 Mechatronics 01 - by WWW - Learnengineering.inLAKKANABOINA LAKSHMANARAONoch keine Bewertungen

- B.E. Automobile Engg.Dokument63 SeitenB.E. Automobile Engg.Vijil RajNoch keine Bewertungen

- Karanataka State Open University: M Tech in Mechanical (Computer Integrated Manufacturing)Dokument35 SeitenKaranataka State Open University: M Tech in Mechanical (Computer Integrated Manufacturing)nav1278Noch keine Bewertungen

- Me Manufacturing EngineeringDokument33 SeitenMe Manufacturing EngineeringsumikannuNoch keine Bewertungen

- Printing Iii To Viii PDFDokument62 SeitenPrinting Iii To Viii PDFRaja PrabhuNoch keine Bewertungen

- Annauniversity ICE VI VIIIDokument48 SeitenAnnauniversity ICE VI VIIIismailpasha_1987Noch keine Bewertungen

- M.E. CAD/CAM CURRICULUM AND SYLLABUS AT ANNA UNIVERSITYDokument27 SeitenM.E. CAD/CAM CURRICULUM AND SYLLABUS AT ANNA UNIVERSITYBhuvanesh KumarNoch keine Bewertungen

- 4th semester syllabusDokument10 Seiten4th semester syllabussaravanan.ma0611Noch keine Bewertungen

- M.E. Applied Electronics Curriculum and SyllabusDokument39 SeitenM.E. Applied Electronics Curriculum and SyllabusVENKINoch keine Bewertungen

- ANNA UNIVERSITY PART TIME ECE CURRICULUMDokument167 SeitenANNA UNIVERSITY PART TIME ECE CURRICULUMganathippu1Noch keine Bewertungen

- ManuDokument67 SeitenManuidocipetchennaiNoch keine Bewertungen

- Internal CombustionDokument26 SeitenInternal CombustionakbsrajNoch keine Bewertungen

- Mechanical EngineeringDokument23 SeitenMechanical EngineeringAntony AshleyNoch keine Bewertungen

- Puter Integrated Manufacturing SyllabusDokument41 SeitenPuter Integrated Manufacturing SyllabusJoswa CaxtonNoch keine Bewertungen

- Anna University Manufacturing Engineering CurriculumDokument67 SeitenAnna University Manufacturing Engineering CurriculumBhuvanesh PonnanNoch keine Bewertungen

- Syllabus For Applied ElectronicsDokument28 SeitenSyllabus For Applied ElectronicsvinayakbondNoch keine Bewertungen

- Syl Lab I MechanicalDokument231 SeitenSyl Lab I MechanicalSachin SilmanaNoch keine Bewertungen

- Sem 3 SyallabusDokument12 SeitenSem 3 SyallabusVishwadeep PaulNoch keine Bewertungen

- University DepartmentsDokument33 SeitenUniversity DepartmentsPn KrizhhNoch keine Bewertungen

- ECE Syllabus Anna University (CEG, MIT)Dokument86 SeitenECE Syllabus Anna University (CEG, MIT)Pon Krithikha100% (1)

- ANNA UNIVERSITY TIRUCHIRAPPALLI PART TIME MECHANICAL ENGINEERING REGULATIONS 2007Dokument73 SeitenANNA UNIVERSITY TIRUCHIRAPPALLI PART TIME MECHANICAL ENGINEERING REGULATIONS 2007செல்வ குமார்Noch keine Bewertungen

- 2nd Semester SyllabusDokument6 Seiten2nd Semester SyllabusNitin RathoreNoch keine Bewertungen

- ME Engineering Design-2013 Syllabus Anna UnivDokument28 SeitenME Engineering Design-2013 Syllabus Anna Univshibumankulath4727Noch keine Bewertungen

- M.E. Engineering DesignDokument47 SeitenM.E. Engineering DesignSms RajaNoch keine Bewertungen

- M.Tech. Programme in Mechatronics, IIT PatnaDokument13 SeitenM.Tech. Programme in Mechatronics, IIT PatnaNPMYS23Noch keine Bewertungen

- Anna University:: Chennai 600 025 Curriculum 2004 B.Tech. Information Technology Semester Iii Code No. Course Title L T P M TheoryDokument39 SeitenAnna University:: Chennai 600 025 Curriculum 2004 B.Tech. Information Technology Semester Iii Code No. Course Title L T P M TheorySutha BalaNoch keine Bewertungen

- M.E. Applied Electronics Curriculum and Syllabus 2013-17Dokument50 SeitenM.E. Applied Electronics Curriculum and Syllabus 2013-17jayj_5Noch keine Bewertungen

- M.E Design 2008 SyllabusDokument35 SeitenM.E Design 2008 SyllabusmeindyaNoch keine Bewertungen

- M.tech SyllabusDokument22 SeitenM.tech Syllabusrajeev_kumar365Noch keine Bewertungen

- ANNA UNIVERSITY M.E. COMPUTER AIDED DESIGN REGULATIONSDokument50 SeitenANNA UNIVERSITY M.E. COMPUTER AIDED DESIGN REGULATIONSJoswa CaxtonNoch keine Bewertungen

- Multidimensional Systems: Signal Processing and Modeling Techniques: Advances in Theory and ApplicationsVon EverandMultidimensional Systems: Signal Processing and Modeling Techniques: Advances in Theory and ApplicationsNoch keine Bewertungen

- Automation in Mining, Mineral and Metal Processing: Proceedings of The 3Rd Ifac Symposium, Montreal, Canada 18-20 August 1980Von EverandAutomation in Mining, Mineral and Metal Processing: Proceedings of The 3Rd Ifac Symposium, Montreal, Canada 18-20 August 1980J. O'SheaNoch keine Bewertungen

- New Trends in Observer-based Control: A Practical Guide to Process and Engineering ApplicationsVon EverandNew Trends in Observer-based Control: A Practical Guide to Process and Engineering ApplicationsOlfa BoubakerNoch keine Bewertungen

- Activity Based ManagementDokument62 SeitenActivity Based ManagementJoswa CaxtonNoch keine Bewertungen

- 3G Prepaid Datacard ServiceDokument4 Seiten3G Prepaid Datacard ServiceShiva RamNoch keine Bewertungen

- University Departments: Anna University Chennai:: Chennai 600 025Dokument47 SeitenUniversity Departments: Anna University Chennai:: Chennai 600 025tauqeerabbasNoch keine Bewertungen

- Anna University ME Quality Engineering CurriculumDokument39 SeitenAnna University ME Quality Engineering CurriculumJoswa CaxtonNoch keine Bewertungen

- M.E. Product Design & DevelopmentDokument50 SeitenM.E. Product Design & DevelopmentJoswa CaxtonNoch keine Bewertungen

- M.E. Industrial Engineering SyllabusDokument46 SeitenM.E. Industrial Engineering SyllabusJoswa CaxtonNoch keine Bewertungen

- ANNA UNIVERSITY M.E. COMPUTER AIDED DESIGN REGULATIONSDokument50 SeitenANNA UNIVERSITY M.E. COMPUTER AIDED DESIGN REGULATIONSJoswa CaxtonNoch keine Bewertungen

- Regu2009 ChennaiDokument17 SeitenRegu2009 ChennaipsnasabariNoch keine Bewertungen

- M.E. Internal Combustion Engineering SyllabusDokument35 SeitenM.E. Internal Combustion Engineering SyllabusJoswa CaxtonNoch keine Bewertungen

- University departments and course details for M.E. Energy EngineeringDokument44 SeitenUniversity departments and course details for M.E. Energy EngineeringJoswa CaxtonNoch keine Bewertungen

- Puter Integrated Manufacturing SyllabusDokument41 SeitenPuter Integrated Manufacturing SyllabusJoswa CaxtonNoch keine Bewertungen

- BE/Btech Cgpa Calculator - Anna University Affiliated CollegesDokument6 SeitenBE/Btech Cgpa Calculator - Anna University Affiliated CollegesJoswa CaxtonNoch keine Bewertungen

- AutomobileDokument33 SeitenAutomobilemarinerajesh3022Noch keine Bewertungen

- Mathemagics Workbook - Chapter OneDokument7 SeitenMathemagics Workbook - Chapter OneJoswa CaxtonNoch keine Bewertungen