Beruflich Dokumente

Kultur Dokumente

99 Ejemplos Practicos de Aplicaciones Neumaticas Festo

Hochgeladen von

John Alejandro Perez PerezOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

99 Ejemplos Practicos de Aplicaciones Neumaticas Festo

Hochgeladen von

John Alejandro Perez PerezCopyright:

Verfügbare Formate

1

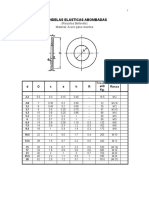

ARANDELAS ELASTICAS ABOMBADAS

(Resortes Belleville)

Material: Acero para resortes

Fza.20%

Para

Rosca

e=0

Kg.

2.2

5.5

0.3

0.15

0.45

16.5

M2

2.8

3.2

3.7

4.3

5.3

6

6.4

7.5

8.4

7

8

9

10

12

12

14

14

18

0.35

0.45

0.5

0.6

0.7

0.7

0.8

0.9

1

0.2

0.2

0.25

0.25

0.3

0.3

0.35

0.3

0.4

0.55

0.65

0.75

0.85

1

1

1.15

1.2

1.4

0.3

0.3

0.3

22

35

47

66

90

95

120

162

170

M 2.6

M3

M 3.5

M4

M5

M5

M6

M6

M8

10.5

22

1.2

0.5

1.7

0.4

250

M 10

13.5

28

1.5

0.7

2.2

0.5

420

M 12

15

17

21

25.5

28

28

34

40

45

52

1.6

1.8

2

2.2

2.5

0.7

0.8

1

1.1

1.2

2.3

2.6

3

3.3

3.7

0.5

0.6

0.7

1

1

530

580

750

930

1010

(M 14)

M 16

M 20

M 24

(M 27)

ANILLOS DE ELEVACION

d1

M 10

M 12

M 16

M 20

M 24

M 30

d2

d3

d4

bmin

e

f

h

k

l

z

tmin

25

45

25

17

8

3

45

10

17

2.2

22.5

30

54

30

20.5

10

3.5

53

12

20.5

2.5

26.5

35

63

35

27

12

4

62

14

27

3

33.5

40

72

40

30

14

5

71

16

30

3.5

37.5

50

90

50

36

18

6

90

20

36

4.5

44.5

65

108

60

45

22

7

109

24

45

5

55

230

340

700

1200

1800

3600

170

240

500

830

1270

2600

TAPONES ROSCADOS

Rosca

(Pulg.)

d

mm.

G 1/8

G 1/4

G 3/8

G 1/2

9.73

13.16

16.66

20.96

17

22

27

32

19.6

25.4

31.2

36.9

5

6

8

10

16

20

25

31

3

3

3

4

3

4

4

5.5

18

21

25

30

G 3/4

26.44

41

47.3

11

40

5.5

33

ARANDELAS DE SEGURIDAD

Dureza requerida: HRc 44-51

Rosca

d1

M2

M3

M3.5

M4

M5

M6

(M7)

M8

M10

M12

(M14)

M16

(M18)

M20

2.1

3.1

3.6

4.1

5.1

6.1

7.1

8.1

10.2

12.2

14.2

16.2

18.2

20.2

M24

M27

M30

24.5

27.5

30.5

Tol

+0.3

0

+0.4

0

+0.5

0

+0.8

0

+1

0

+1.2

0

d2

max

min

max

4.4

6.2

6.7

7.6

9.2

11.8

12.8

14.8

18.1

21.1

24.1

27.4

29.4

33.6

1

1.6

1.6

1.8

2.4

3.2

3.2

4

4.4

5

6

7

7

8

1.2

1.9

1.9

2.1

2.8

3.8

3.8

4.7

5.2

5.9

7.1

8.3

8.3

9.4

0.9

1.3

1.3

1.5

1.8

2.5

2.5

3

3.5

4

4.5

5

5

6

0.5

0.8

0.8

0.8

1.2

1.6

1.6

2

2.2

2.5

3

3.5

3.5

4

40

43

48.2

10

10

12

11.8

11.8

14.2

7

7

8

5

5

6

TORNILLOS PARA MADERA

A) Cabeza Redonda

d

d1

a

k

R1

R2

n

t

3

1.8

6

2

2.3

4.6

0.8

1.4

3.5

2.3

7

2.5

2.8

5.5

0.8

1.6

4

2.4

8

3.8

3.2

6.5

1

1.8

4.5

2.9

9

3.2

3.5

7

1

2

5

3

10

3.5

4

8

1.2

2.2

6

3.6

12

4.2

4.5

9

1.6

2.8

B) Cabeza Cuadrada o Hexagonal

d

d1

s

e

k

Rmax

8

5.6

14

19.8

6

0.6

10

7

17

24

7

0.6

12

8.4

22

31.1

9

1.2

16

11.6

27

38.2

11

1.2

7

4.2

14

5

5.5

11

1.6

3

8

5.2

16

5.5

6.5

13

2

3.5

TORNILLOS PARA MADERA

(continuacin)

C) Cabeza conica

d

d1

a

k

n

t

2.6

1.6

5.2

1.3

0.6

0.6

3

1.8

6

1.5

0.8

0.7

3.5

2.3

7

1.75

0.8

0.85

4

2.4

8

2

1

1

5

3

10

2.5

1.2

1.2

6

3.6

12

3

1.6

1.5

8

5.2

16

4

2

2

ARANDELAS

ARANDELA NORMAL

Ejecucion mg

Ejecucion m

Rosca

d1

d2

M2

M2.5

M3

(M3.5)

M4

M5

M6

(M7)

M8

M10

M12

(M14)

M16

(M18

M20

M24

(M27)

M30

2.2

2.7

3.2

3.7

4.3

5.3

6.4

7.4

8.4

10.5

13

15

17

19

21

25

28

31

5

6.5

7

8

9

10

12.5

14

17

21

24

28

30

34

37

44

50

56

0.3

0.5

0.5

0.5

0.8

1

1.6

1.6

1.6

2

2.5

2.5

3

3

3

4

4

4

ARANDELAS

ARANDELA EN ABANICO

Rosca

M2

M2.5

M3

2.2

2.8

3.2

4.5

5.5

6

0.3

0.4

0.4

M4

M5

M6

4.3

5.3

6.3

8

9

11

0.5

0.6

0.7

TORNILLOS TIPO PHILLIPS

A) Cabeza Cnica Abombada

D

c

D

k

p

R

w

m

M2.5

4.7

1.5

0.7

0.6

2.7

M3

M5

0.2

5.6

1.65

1.5

0.8

0.75

3.1

0.3

9.2

2.5

2.5

1.3

1.25

5.3

10

B) Cabeza Cnica Plana a 90

M3

M4

M5

c

D

k

p

R

m

0.2

5.6

1.65

1.5

0.8

2.9

0.3

7.5

2.2

2

1

4.4

9.2

2.5

2.5

1.3

4.6

11

C) Cabeza Cilndrica Abombada

M2.5

M3

M4

M5

M6

a

D-h13

k

R1

R2

v

w

m

1

5

2

5

0.2

1.3

0.7

2.7

1

6

2.4

6

0.3

1.6

0.8

3.1

1.2

8

3.1

8

0.4

2

1.1

4.5

1.5

10

3.8

10

0.5

2.5

1.3

5.3

2

18

4.6

12

0.6

3

1.6

7.2

12

TORNILLO SIN CABEZA CON HEXAGONO INTERIOR

M2

M3

M5

M6

M8

M10

M12

(M14)

M16

M20

1.05

0.9

1.8

1.5

2.9

2.5

1.6

0.15

0.5

2

0.25

0.5

3

0.4

0.75

3.5

3.02

3.06

3.5

0.5

1

4.7

4.02

4.07

5

0.6

1.25

5.8

5.02

5.08

6

0.8

1.5

7

6.02

6.09

8

1

1.75

7

6.02

6.09

8

1

2

9.4

8.03

8.1

10

1.1

2

11.7

10.03

10.12

12

1.2

2.5

smi n

smax

tmin

z1

z2

13

TORNILLO SIN CABEZA CON RANURA

M2

M3

M4

M5

M6

M8

M10

M12

nnom

nmin

nmax

t

b

z

0.3

0.5

0.6

0.8

1.2

1.6

1

0.4

1

3.6

0.6

1.4

4.8

0.8

1.7

6

0.8

2

7.2

1

2.5

9.6

1.2

3

12

1.5

3.5

14

2

14

TUERCAS ALMENADAS

d1

(M7)

M8

M10

M12

11

13

17

19

12.7

15

19.6

21.9

8

9.5

12

15

5.5

6.5

8

10

2

2.5

2.8

3.5

17

M16

24

27.7

19

13

4.5

22

M20

30

34.6

22

16

4.5

28

15

TUERCAS AUTOBLOQUEANTES

emin

m1 min

m2

M3

5.5

6.08

2.7

2.4

M6

M8

M10

M12

10

13

17

19

11.05

14.38

18.90

21.10

8

9.5

11.5

14

4.5

6

7

9

5

6.5

8

10

Nota: el efecto autobloqueante desaparece luego de 3 4 montajes por deterioro

del anillo plstico.

16

TUERCAS EN T

8

10

12

14

(16)

18

22

tol

-0.3

-0.5

-0.3

-0.6

M6

M8

M10

M12

(M14)

M16

M20

13

15

18

22

25

28

34

tol

0

-0.5

1.6

10

12

14

16

18

20

28

6

6

7

8

9

10

14

0

-0.5

+1

0

2.5

tol

0

-0.5

0.3

0.09

0.36

0.11

0.42

0.21

17

RANURAS EN T

Cota Nominal

A

5

6

8

10

12

14

Tolerancia

H8

H12

+0.018

0

+0.022

0

+0.027

0

+0.12

0

+0.15

0

+0.18

0

18

Tol

10

+1

0

11

14.5

16

19

23

+1.5

0

5

7

7

8

9

+2

0

30

22

+0.033

28

36

0

+0.039

42

Tol

max

+0.5

0

10

13

18

21

25

28

11

15

17

20

23

36

30

45

38

+1

0

16

+0.25

46

56

+4

0

20

25

+3

56

71

48

61

68

32

85

74

36

+4

0

95

84

106

94

+0.3

0

90

+5

0

40

min max

+3

0

80

+0.046

0

37

+0.21

0

12

+2

0

48

54

1.6

g

Tol

0.6

1.6

2.5

2

1) Ranuras maquinadas: H8 para guias, H12 para fijacin.

2) Escoger hmax que permita maquinado posterior sobre la mesa.

0

-0.3

0

-0.5

0

-0.8

0

-1

max

0.3

0.12

0.15

1.6

0.18

0.5

0.21

2.5

4

6

0.25

0.30

1.0

1.2

Rosca

Tuerca

T

Tornillo

T

M4

M5

M5

M6

M8

M10

M12

M6

M8

M10

M12

M12

M16

M16

M20

M20

M24

M30

M24

M30

M36

M36

M42

M42

M48

M48

18

LONGITUDES NORMALIZADAS DE TORNILLOS Y ROSCAS

Rosca mtrica ISO

Longitud del tornillo

Escalonamiento

0.5 mm

1 mm

2 mm

2...3 mm Terminan en 0 2 5 8

5 mm

10 mm

20 mm

Longitud

Tornillo1)

2

2.5

3

4

5

6

(7)

8

9

10

12

14

16

(18)

20

(85)

90

95

100

(105)

110

115

120

(125)

130

140

150

160

170

180

Lmites

2...2.5 mm

3...10 mm

12...20 mm

22...40 mm

45...125 mm

130...200 mm

>200 mm

Longitud de rosca parcial 2)

Frmula para long

b1

2d+6 mm

b2

2d+12 mm

b3

2d+25mm

3d+10 mm

b4

Long

Tornillo1)

22

25

(28)

30

(32)

35

(38)

40

45

50

55

60

(65)

70

(75)

80

190

200

220

240

260

280

300

1) Evitar las longitudes entre parntesis

2) Excepto los bulones para acero y tornillos sin cabeza parcial roscados.

3) Salvo indicacin, los tornillos a ranura M1...M1.4 son totalmente roscados.

long tornillo

125 mm

>125...200 mm

>200 mm

Tornillos a ranurar

solo si M1.6

19

LONGITUDES NORMALIZADAS DE TORNILLOS Y ROSCAS

Rosca mtrica ISO

(Contunuacin)

LONGITUD DE ROSCA PARCIAL2)

Rosca

d

1.6

1.8

2

2.2

2.5

3

3.5

4

5

6

7

8

10

12

14

16

18

20

22

24

27

30

33

36

39

42

b1

b2

b3

b4

9

10

10

10

11

12

13

14

16

18

20

22

26

30

34

38

42

46

50

54

60

66

72

78

84

90

24

26

28

32

36

40

44

48

52

56

60

66

72

78

84

90

96

49

53

57

61

65

69

73

79

85

91

97

103

109

15

15

16

17

18

19

20

22

25

28

31

34

40

46

52

58

64

70

Rosca

d

45

48

52

56

60

64

68

72x6

76x6

80x6

85x6

90x6

95x6

100x6

105x6

110x6

115x6

120x6

125x6

130x6

140x6

150x6

b1

b2

b3

96

102

-

102

108

116

124

132

140

148

156

164

172

182

192

-

115

121

129

137

145

153

161

169

177

185

195

205

215

225

235

245

255

265

275

285

305

325

1) Evitar las longitudes entre parntesis

2) Excepto los bulones para acero y tornillos sin cabeza parcial roscados.

3) Salvo indicacin, los tornillos a ranura M1...M1.4 son totalmente roscados.

20

CABEZAS DE TORNILLOS Y TUERCAS HEXAGONALES

(Rosca mtrica ISO)

Rosca

d

1

1.2

1.4

1.6

1.8

2

2.2

2.5

3

3.5

4

5

6

8

10

12

14

16

18

20

22

24

27

30

33

36

39

normal

s

2.5

3

3

3.2

3.5

4

4.5

5

5.5

6

7

8

10

11

13

17

19

22

24

27

30

32

36

41

46

50

55

60

k

0.8

0.8

1

1.1

1.2

1.4

1.6

1.7

2

2.4

2.8

3.5

4

5

5.5

7

8

9

10

12

13

14

15

17

19

21

23

25

c

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.2

0.2

0.2

0.2

0.3

0.3

0.3

0.3

0.4

0.4

0.4

0.4

0.4

0.4

0.6

0.6

0.6

0.6

0.6

0.6

s

22

24

27

30

32

36

-

Gruesa1)

Delgada2)

(evitar)

(evitar)

k

9

10

12

13

14

15

-

c

0.4

0.4

0.4

0.4

0.4

0.6

-

s

8

10

10

13

17

19

22

24

27

30

32

36

41

46

50

55

k

3.5

4

4

5.5

7

8

9

10

12

13

14

15

17

19

21

23

m

normal

c

0.2

0.3

0.3

0.3

0.3

0.4

0.4

0.4

0.4

0.4

0.4

0.6

0.6

0.6

0.6

0.6

evitar

0.5d

0.8d

1d

1.5d

1

1

1.2

1.2

1.4

1.7

1.8

2

2.5

3

3.5

4

5

5.5

6

7

8

9

10

12

13

15

15

18

19

0.8

1

1.2

1.3

1.4

1.6

1.8

2

2.4

2.8

3.2

4

5

5.5

6.5

8

10

11

13

15

16

18

19

22

24

26

29

31

2

2.2

2.5

3

3.5

4

5

6.5

6.5

8

10

13

13

16

19

19

23

23

26

29

32

35

38

15

18

21

24

27

30

33

36

40

45

50

54

60

3)

21

CABEZAS DE TORNILLOS Y TUERCAS HEXAGONALES

(Rosca mtrica ISO)

(continuacin)

Rosca

d

42

45

48

52

56

60

64

68

72

76

80

85

1)

2)

3)

4)

5)

m

s

65

70

75

80

85

90

95

100

105

110

115

120

k

26

28

30

33

35

38

40

43

45

48

50

54

c

0.6

0.6

1

1

1

1

1

1

1

1

1

1.6

Para reducir presin especfica.

Para tornillos de freno, etc.

Adicionada a ISO

No es norma ISO

15 en tuercas de m = 0.5 d

0.5d

21

22

24

26

28

30

32

34

36

38

40

42

Rosca

0.8d

d

90

34

95

36

100

38

105

42

110

45

115

48

120

51

125

54

130

58

140

61

150

64

68

m

s

130

135

145

150

155

165

170

180

185

200

210

k

57

60

63

66

69

72

76

79

82

88

95

3)

c 0.5d 0.8d

1.6

45

72

1.6

48

76

1.6

50

80

1.6

84

1.6

88

1.6

92

1.6

96

2.5

100

2.5

104

2.5

112

2.5

120

22

EXTREMIDADES DE TORNILLOS-ROSCA METRICA ISO

1)

Achaflanado

Pivote perforado

pivote Abombado

Abombado

Pivote corto

Cono Int.

Con Punta

Pivote Normal

Pivote a punta

3)

Rosca

z1 4)

(1.5P)

z3

z4

z5

z6

z7

z8

z9

d1

d2

d3

d4

W

min

1

1.2

1.4

1.6

1.8

2

2.2

2.5

3

3.5

4

5

6

7

8

10

12

14

16

18

20

0.4

0.4

0.5

0.5

0.5

0.6

0.6

0.7

0.8

0.9

1

1.2

1.5

1.5

1.8

2.2

2.5

3

3

3.5

3.5

1

1

1

1

1

1

1.2

1.5

1.5

1.8

2

2.5

3

3

4

4

1.5

2

2

2.5

2.5

3

3

3.5

4.5

5

5.5

7

7

9

9

9

1.2

1.2

1.2

1.2

1.2

1.2

1.5

2

2

2.5

3

3.5

3.5

4.5

4.5

4.5

0.1

0.2

0.2

0.25

0.25

0.25

0.3

0.35

0.4

0.45

0.45

0.6

0.7

0.8

1

1

1.25

1.5

1.75

2

2

0.65

0.8

0.8

1

1.25

1.5

1.5

1.5

2

2

3

3

3

3

0.5

0.6

0.7

0.8

0.9

1

1.1

1.25

1.5

1.75

2

2.5

2.5

2.5

3

4

5

5

6

6.6

7

0.4

0.5

0.7

0.9

1

1.2

1.6

1.8

2.3

2.5

3

3.5

4

4.5

4.5

5

0.5

0.7

0.7

0.7

0.9

1

1.3

1.5

2

2.2

2.5

3.5

4

5

5.5

7

8.5

10

12

13

15

0.6

0.8

0.8

1

1.2

1.6

1.6

2

2.5

3.2

3.2

4

4

4

1.2

1.4

1.9

2

2.5

3

4

5

6

8

8

10

12

14

1

2

2

2

2

4

4

5

6

0.1

0.1

0.1

0.1

0.1

0.1

0.2

0.2

0.3

0.3

0.3

0.3

0.4

0.4

0.4

0.5

0.6

0.8

0.8

0.8

1

1.2

1.6

1.6

1.8

2

2.5

2.5

3

4

5

5

6

6

6

1)

2)

3)

4)

Extremo sin exigencia especial

Puede diaminuir en tornillos foramados

Vlido para roscas ordinarias y finas salvo algunos valores de Z1

Puede agrandarse Z1 hasta 2.(Paso) en roscas formadas

23

EXTREMIDADES DE TORNILLOS-ROSCA METRICA ISO

(Continuacin)

4)

3)

Rosca

z1

(1.5P)

z3

z4

z5

z6

z7

z8

z9

d1

d2

d3

d4

W

min

22

24

27

30

33

36

39

42

45

48

52

56

60

64

68

3.5

4.5

4.5

5

5

6

6

6.5

6.5

7.5

7.5

8

8

9

9

4

5

5

6

6

6

7

7

8

8

9

10

10

12

12

11

11

12

14

14

14

18

18

18

18

18

18

22

22

22

5.5

5.5

-

2.5

2.5

-

3

4

-

8

8

-

6

6

7

8

9

10

11

12

12

12

12

12

-

17

18

21

23

26

28

30

32

35

38

42

45

48

52

56

5

5

5

6.3

6.3

6.3

6.3

8

8

8

8

8

10

10

10

16

16

-

6

8

-

1

1

1.2

1.2

1.6

1.6

2

2

2

2

2.5

2.5

2.5

3

3

7

7

7

8.5

8.5

8.5

8.5

10

10

10

10

10

12

12

12

1) Extremo sin exigencia especial

2) Puede diaminuir en tornillos foramados

3) Vlido para roscas ordinarias y finas salvo algunos valores de Z1

4) Puede agrandarse Z1 hasta 2.(Paso) en roscas formadas

24

TIPOS DECABEZA Y LLAVES CORRESPONDIENTES

DIMENSIONES Y TOLERANCIAS

CABEZAS

LLAVES

Diam

nom

Cabeza

s

1)

m, mg,

m

g

mg,

2)

g

3)

Llave

s1

Maq.

Sin

4)

maq

Juego

s1 -s

m, mg, g

m

Llave

Maq

s

Tol

Tol

Tol

Tol

Tol

Tol

min

inf

inf

sup

sup

max

sup

inf

2.5

0

-0.10

+0.02 +0.08

0.02

0.18

3

0

-0.10

+0.02 +0.08

0.02

0.18

3.2

0

-0.12

+0.02 +0.08

0.02

0.20

3.5

0

-0.12

+0.02 +0.12

0.02

0.24

4

0

-0.12

+0.02 +0.12

0.02

0.24

4.5

0

-0.12

+0.02 +0.12

0.02

0.24

5

0

-0.12

+0.02 +0.12

0.02

0.24

5.5

0

-0.12

+0.02 +0.12

0.02

0.24

6

0

-0.12

+0.03 +0.15

0.03

0.27

7

0

-0.15

+0.03 +0.15

0.03

0.30

8

0

-0.15

+0.03 +0.15

0.03

0.30

(9)

0

-0.22

+0.03 +0.15

0.03

0.37

10

0

-0.22 -0.36 +0.04 +0.19 +0.24

0.04

0.41

(11)

0

-0.27 -0.43 +0.04 +0.19 +0.24

0.04

0.46

(12)

0

-0.27 -0.43 +0.04 +0.24 +0.30

0.04

0.51

13

0

-0.27 -0.43 +0.04 +0.24 +0.30

0.04

0.51

(14)

0

-0.27 -0.43 +0.05 +0.27 +0.35

0.05

0.54

17

0

-0.27 -0.43 +0.05 +0.30 +0.40

0.05

0.57

19

0

-0.33 -0.52 +0.06 +0.36 +0.46

0.06

0.69

22

0

-0.33 -0.84 +0.06 +0.36 +0.46

0.06

0.69

24

0

-0.33 -0.84 +0.06 +0.36 +0.46

0.06

0.69

27

0

-0.33 -0.84 +0.08 +0.48 +0.58

0.08

0.81

30

0

-0.33 -0.84 +0.08 +0.48 +0.58

0.08

0.81

32

0

-0.39 -1.00 +0.08 +0.48 +0.58

0.08

0.87

36

0

-0.62 -1.00 +0.10 +0.60 +0.70

0.10

1.22

41

0

-0.62 -1.00 +0.10 +0.60 +0.70

0.10

1.22

46

0

-0.62 -1.00 +0.10 +0.60 +0.70

0.10

1.22

50

0

-0.62 -1.00 +0.10 +0.60 +0.70

0.10

1.22

55

0

-0.74 -1.20 +0.20 +0.72 +0.92

0.12

1.46

60

0

-0.74 -1.20 +0.20 +0.72 +0.92

0.12

1.46

1) Tolerancias h12 para s=...8, h13 para s=9...32, h14 para s=36...60

2) Tolerancia h14 para s=...19. h15 para s19

3) Vlido para llaves maquinadas o no

4) Slo para llaves cerradas

Medida angular

Cuadrado

Hexagonal

e1

e2

e3

e4

e4

mg, g

m

mg, g

llave

no

maq

max

min

max

min

max

min

min

0.60

0.67

0.73

0.73

0.78

0.83

0.98

1.30

1.30

1.42

1.42

1.58

1.70

1.70

1.70

1.70

2.12

2.12

3

3.5

3.7

4

4.5

5

6

7

7

8

9

10

12

13

14

15

16

19

22

25

28

32

35

38

42

48

53

58

65

70

3.5

4.2

4.5

4.9

5.7

6.4

7.1

7.8

8.5

9.9

11.3

12.7

14.1

15.6

17.0

18.4

19.8

24.0

26.9

31.1

33.9

38.2

42.4

45.3

50.9

58.0

65.1

70.7

77.8

84.8

3.3

3.9

4.2

4.6

5.3

5.9

6.5

7.1

8

9

10

12

13

14

16

17

18

22

25

28

32

36

40

42

48

54

60

65

72

80

2.9

3.5

3.7

4.0

4.6

5.2

5.8

6.4

6.9

8.1

9.2

10.4

11.5

12.7

13.8

15.0

16.2

19.6

21.9

25.4

27.7

31.2

34.6

36.9

41.6

47.3

53.1

57.7

63.5

69.3

2.71

3.28

3.48

3.82

4.38

4.95

5.51

6.08

6.64

7.74

8.87

9.92

11.1

12.1

13.3

14.4

15.5

18.9

21.1

24.5

26.8

30.1

33.5

35.7

40.0

45.6

51.3

55.8

61.3

67.0

10.9

11.9

13.1

14.2

15.3

18.7

20.9

23.9

26.2

29.6

33.0

35.0

39.6

45.2

50.9

55.4

60.8

66.4

25

TORNILLOS DE CABEZA CONICA A 90

Rosca mrica ISO

Rosca

d

1

1.2

1.4

1.6

2

2.2

2.5

3

3.5

4

4.5

5

6

8

10

12

14

16

18

20

Normal

a1)

2.2

2.65

3.1

3.5

4.4

4.85

5.5

6.3

7.35

8.4

9

10

12

16

20

24

28

32

36

40

k

0.6

0.7

0.85

0.95

1.2

1.35

1.5

1.65

1.9

2.2

2.25

2.5

3

4

5

6

7

8

9

10

Abombada

n

t1

nom

min

0.25

0.3

0.3

0.4

0.5

0.6

0.6

0.8

0.8

1

1

1.2

1.6

2

2.5

3

3

4

4

5

0.2

0.24

0.28

0.3

0.4

0.44

0.5

0.6

0.7

0.8

0.9

1

1.2

1.6

2

2.4

2.8

3.2

3.6

4

a1)

2.2

2.65

3.1

3.5

4.4

4.85

5.5

6.3

7.35

8.4

9

10

12

16

20

24

28

32

36

40

1) Terico amin=1.75d

Consultar dimensiones exactas para cada caso.

k

0.6

0.7

0.85

0.95

1.2

1.35

1.5

1.65

1.9

2.2

2.25

2.5

3

4

5

6

7

8

9

10

t2

nom

min

0.25

0.3

0.35

0.4

0.5

0.55

0.6

0.75

0.9

1

1.1

1.25

1.5

2

2.5

3

3.5

4

4.5

5

0.25

0.3

0.3

0.4

0.5

0.6

0.6

0.8

0.8

1

1

1.2

1.6

2

2.5

3

3

4

4

5

0.35

0.4

0.5

0.55

0.7

0.75

0.9

1.05

1.2

1.4

1.55

1.75

2.1

2.8

3.5

4.2

4.9

5.6

6.3

7

26

TORNILLOS DE CABEZA CILINDRICA

Tamao de la cabeza - Rosca mtrica ISO

Cabeza

Cilndrica

Cab Cil

Reducida

Cabeza

Abombada

Hexgono

Interior

Dimensiones en mm

Rosca

d

1

1.2

1.4

1.6

2

2.2

2.5

3

3.5

4

4.5

5

6

8

10

12

14

16

18

20

22

24

27

30

33

36

39

42

45

48

52

a1

k1

2

2.3

2.6

3

3.8

4

4.5

5.5

6

7

8

8.5

10

13

16

18

21

24

27

30

-

0.7

0.8

0.9

1

1.3

1.5

1.6

2

2.4

2.6

3.1

3.3

3.9

5

6

7

8

9

10

11

-

t1

nom

min

0.25

0.3

0.3

0.4

0.5

0.6

0.6

0.8

0.8

1

1

1.2

1.6

2

2.5

3

3

4

4

5

-

0.28

0.32

0.36

0.4

0.52

0.6

0.64

0.8

0.96

1.04

1.24

1.32

1.56

2

2.4

2.8

3.2

3.6

4

4.4

-

a2

k1

1.2

1.5

1.8

2

2.5

3

3.8

4.5

5

6

7.2

10

12

-

0.7

0.8

0.9

1

1.3

1.6

2

2.4

2.6

3.3

3.9

5

6

-

t1

nom

min

0.25

0.3

0.3

0.4

0.5

0.6

0.8

0.8

1

1.2

1.6

2

2.5

-

0.28

0.32

0.36

0.4

0.52

0.64

0.8

0.96

1.04

1.32

1.56

2

2.4

-

a3

k2

5

6

7

8

9

10

12

16

20

-

1.5

1.8

2.1

2.4

2.7

3

3.6

4.8

6

-

t2

nom

min

0.6

0.8

0.8

1

1

1.2

1.6

2

2.5

-

0.6

0.72

0.84

0.96

1.08

1.2

1.44

1.92

2.4

-

a1

k3

5.5

7

8.5

10

13

16

18

21

24

27

30

33

36

40

45

50

54

58

63

68

72

78

3

4

5

6

8

10

12

14

16

18

20

22

24

27

30

33

36

39

42

45

48

52

2.5

3

4

5

6

8

10

12

14

14

17

17

19

19

22

24

27

27

32

32

36

36

t3

min

1.3

2

2.7

3.3

4.3

5.5

6.6

7.8

8.8

9.8

10.7

11.3

12.9

15.1

17.1

18.8

20.8

22.9

25

27.1

29.1

31.9

27

REDONDEADOS EN LA CABEZA

Rosca Mtrica ISO

Rosca

d

1

1.2

1.4

1.6

1.8

2

2.2

2.5

3

3.5

4

5

6

7

8

10

12

14

16

18

20

22

24

27

30

33

36

39

Ejecucin1)

m, mg

R min

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.2

0.2

0.25

0.25

0.4

0.4

0.6

0.6

0.6

0.6

0.8

0.8

0.8

1

1

1

1

1

R max

0.2

0.2

0.2

0.2

0.3

0.3

0.3

0.3

0.3

0.3

0.35

0.35

0.4

0.4

0.6

0.6

1.1

1.1

1.1

1.1

1.2

1.2

1.2

1.7

1.7

1.7

1.7

1.7

damax

1.4

1.6

1.8

2

2.4

2.6

2.8

3.1

3.6

4.1

4.7

5.7

6.8

7.8

9.2

11.2

14.2

16.2

18.2

20.2

22.4

24.4

26.4

30.4

33.4

36.4

39.4

42.4

Ejecucin

g

R min

0.2

0.25

0.25

0.4

0.4

0.6

0.6

0.6

0.6

0.8

0.8

0.8

1

1

1

1

1

R max

0.5

0.6

0.6

1.1

1.1

1.6

1.6

1.6

1.6

2.2

2.2

2.2

2.7

2.7

2.7

3.2

3.2

damax

6

7.2

8.2

10.2

12.2

15.2

17.2

19.2

21.2

24.4

26.4

28.4

32.4

35.4

38.4

42.4

45.4

Rosca

d

42

45

48

52

56

60

64

68

72

76

80

85

90

95

100

105

110

115

120

125

130

140

150

Ejecucin1)

m, mg

R min

1.2

1.2

1.6

1.6

2

2

2

2

2

2

2

2

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

R max

1.8

1.8

2.3

2.3

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

3.5

4

4

4

4

4

4

4

4

4.5

damax

45.6

48.6

52.6

56.6

63

67

71

75

79

83

87

92

97

102

108

113

118

123

128

133

138

148

159

Ejecucin

g

R min

1.2

1.2

1.6

1.6

2

2

2

2

2

2

2

2

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

R max

3.3

3.8

4.3

5.3

5.5

5.5

5.5

5.5

5.5

5.5

6

6

6

6.5

6.5

6.5

6.5

6.5

6.5

6.5

7.5

8

8

damax

48.

52.

56

62

67

71

75

79

83

87

92

97

102

108

113

118

123

128

133

138

145

156

166

1) La precision domensional, el estado superficial y las tolerancias de fabricacion

dependen de la calidad de ejecucion

m = media

g = grosera o basta

mg = semi-grosera

28

MOMENTOS DE APRIETE - CARGAS ADMISIBLES

Nota: Los momentos deapriete varan fuertemente segun el estado de las

superficies de apoyo y su lubricacin. Los valores de la tabla (indicativos

solamente) se obtienen con coeficiente de rozamiento =0.1

Las cargas mximas tienen en cuenta los momentos de apriete o de montaje y la

precompresin segn la tabla siguiente.

Momentos de apriete admisibles en roscas ordinarias (Kg.m)

Calidad

tornillo

M4

M5

M6

5.6

8.8

10.9

12.9

0.12

0.25

0.35

0.40

0.23

0.48

0.68

0.80

0.40 0.95

0.85 2.0

1.15 2.8

1.40 3.3

M8

M10 M12 M16 M20 M24 M27 M30 M36

1.8

3.8

5.5

6.6

3.1

6.5

9.2

11

7.5 14.5

16 30.5

22.5 43

27

52

26

54

77

93

36

77

107

129

49

105

148

180

86

182

257

310

Momentos de apriete admisibles en roscas finas (Kg.m)

Calidad

tornillo

M8x1

M10x1.25

5.6

8.8

10.9

12.9

0.95

2.0

2.8

3.2

1.7

3.7

5.3

6.4

M12x1.25 M16x1.5 M20 x1.5

3.1

6.6

9.4

11.1

7.4

15.7

22

26

14.8

31.5

44.5

53

M24x2

M30x2

M36x1.5

24.5

52

74

88

49

105

148

178

90

191

268

322

Cargas dinmicas admisibles (kg)

Calidad

tornillo

M4

M5

M6

M8

5.6

8.8

30

60

80

160

130

260

280

575

480

960

700

1475

1400

2960

2200

4700

3200

6800

4130

8800

10.9

140

280

450

900

1520

2280

4230

6600

9600

12.9

190

380

560

1150

1850

2700

5100

7850

1140

0

1235

0

1485

0

M10 M12 M16 M20 M24 M27 M30 M36

5570

1080

0

1515

0

1840

0

7400

1565

0

2200

0

2650

0

Cargas estticas admisibles (kg)

Calidad

tornillo

M4

M5

M6

M8

M10 M12 M16 M20 M24 M27 M30 M36

5.6

8.8

110

230

175

370

250

530

440

930

625

1330

960

2040

1880

4000

2870

6100

4200

8900

10.9

320

520

740

1300

1860

2850

5600

8600

12.9

380

630

890

1570

2240

3440

6750

1030

0

1250

0

1500

0

5400

1150

0

1610

0

1940

0

6300

1340

0

1880

0

2260

0

9600

2030

0

2840

0

3430

0

29

PRECOMPRESION-PRESION ESPECIFICA

Precompresin (Kg) antes de servicio, originado por el momento de apriete

Calidad

tornillo

M4

M5

M6

M8

M10 M12 M16 M20 M24 M27 M30 M36

5.6

200

320

450

825

1300

1900

3540

5475

7950

8.8

420

680

970

1750

2780

4050

7500

10.9

590

955

1350

2480

3900

5700

12.9

710

1150

1620

2970

4700

6800

1055

0

1270

0

1170

0

1650

0

1980

0

1695

0

2380

0

2860

0

1035

0

2200

0

3090

0

3700

0

1260

0

2700

0

3790

0

4600

0

1840

0

3900

0

5500

0

6600

0

Presin especfica (Kg/mm2) bajo la cabeza segn el mom. de apriete (Torn

Hexag)

Calidad

tornillo

M4

M5

M6

M8

M10 M12 M16 M20 M24 M27 M30 M36

5.6 8.8 9.7 11.2 11.9 12.3 17.1

8.8 18.7 20.6 24.2 25.9 26.2 36.5

10.9 27.4 29 33.7 36

37 51.5

12.9 32

35 40.5 43 44.5 61.5

18

38

53

64

16.7 16.3 18.8 17.1 16.8

36

35

40

37 35.8

50.5 49

56 51.5 50

60.5 59

67 62.5 60

30

MOMENTO MAXIMO SEGUN EL MATERIAL DE LAS PIEZAS A ENSAMBLAR

Mom apriete admisible para Al, latn, bronce, Ac37, Ac37K, etc. (

Calidad

tornillo

M4

M5

M6

5.6

8.8

10.9

12.9

0.12

0.25

0.32

0.32

0.23

0.48

0.60

0.60

0.40 0.95

0.85 1.9

0.85 1.9

0.85 1.9

M8

M4

M5

M6

5.6

8.8

10.9

12.9

0.12

0.25

0.35

0.40

0.23

0.48

0.68

0.80

0.40 0.95

0.85 2.0

1.15 2.7

1.20 2.7

M8

1.8

3.6

3.6

3.6

3.1

4.5

4.5

4.5

7.5

10.5

10.5

10.5

14.5 26

21.5 38.5

21.5 38.5

21.5 38.5

36

48

48

48

M4

M5

M6

5.6

8.8

10.9

12.9

0.12

0.25

0.35

0.40

0.23

0.48

0.68

0.80

0.40 0.95

0.85 2.0

1.15 2.8

1.40 3.3

M8

Kg/mm2)

49

72

72

72

el35

86

128

128

128

Kg/mm2)

M10 M12 M16 M20 M24 M27 M30 M36

1.8

3.8

5.2

5.2

3.1

6.3

6.3

6.3

7.5 14.5

14.7 30

14.7 30

14.7 30

26

54

54

54

36

67

67

67

Momento admisible para 42CrMo4, 31NiCr14, Fundicin, etc. (

Calidad

tornillo

el25

M10 M12 M16 M20 M24 M27 M30 M36

Momento admisible para Aceros C45. Ac60K, 9SMnPb28K, etc. (

Calidad

tornillo

49

100

100

100

86

180

180

180

50 Kg/mm )

2

el

M10 M12 M16 M20 M24 M27 M30 M36

1.8

3.8

5.5

6.6

3.1

6.5

9.0

9.0

7.5

16

21

21

14.5

30.5

43

43

26

54

77

77

36

77

96

96

49

105

144

144

86

182

257

257

Das könnte Ihnen auch gefallen

- Tablas de TornillosDokument30 SeitenTablas de TornillosgabNoch keine Bewertungen

- Representación de RoscasDokument19 SeitenRepresentación de RoscasJhamadZegarraMedranoNoch keine Bewertungen

- Representación de RoscasDokument14 SeitenRepresentación de RoscasMarcos Calderon FloresNoch keine Bewertungen

- Roscas DibujoDokument7 SeitenRoscas DibujoAngel VazquezNoch keine Bewertungen

- ROSCASDokument17 SeitenROSCASAnonymous lEmVFI100% (1)

- Catalogo Sabater-Fundimol P22y23Dokument2 SeitenCatalogo Sabater-Fundimol P22y23Heidys YohanaNoch keine Bewertungen

- Tuercas EsDokument43 SeitenTuercas Eselcaballodorado12121100% (1)

- MICRO Catalogo Cn10Dokument13 SeitenMICRO Catalogo Cn10Julian TagliariniNoch keine Bewertungen

- Tabla de Dosificaciones y AcerosDokument2 SeitenTabla de Dosificaciones y Aceroscamilo6mora100% (1)

- E1 Tornillos PDFDokument1 SeiteE1 Tornillos PDFJoseElHerreroNoch keine Bewertungen

- Pernos y ArandelasDokument49 SeitenPernos y ArandelashlopezNoch keine Bewertungen

- CilindrosDokument21 SeitenCilindrosMajitito Taipe ANoch keine Bewertungen

- Pares de Apriete (MA) para Conexiones de Lumbrera: MontajeDokument2 SeitenPares de Apriete (MA) para Conexiones de Lumbrera: MontajeplvillarrealNoch keine Bewertungen

- Planilla de Aceros Casa M.S. CASA (B)Dokument7 SeitenPlanilla de Aceros Casa M.S. CASA (B)Daniel Carapaz JiménezNoch keine Bewertungen

- Representación de RoscasDokument17 SeitenRepresentación de RoscasFernando Nahuel AmatoNoch keine Bewertungen

- BoquillerosDokument181 SeitenBoquillerosSergio MenchùNoch keine Bewertungen

- Proyecto Mecanica - Wulfrano292558 - Tinoco (No Se Sus Otros Nombre o Clave) - Pulido (No Se Sus Otros Nombre o Clave)Dokument17 SeitenProyecto Mecanica - Wulfrano292558 - Tinoco (No Se Sus Otros Nombre o Clave) - Pulido (No Se Sus Otros Nombre o Clave)wulfrano sanchezNoch keine Bewertungen

- FT Vitalintl Tecle Manual 0.25T 50TDokument1 SeiteFT Vitalintl Tecle Manual 0.25T 50TQuiroa, Antonio J0% (1)

- Partes de Un Plano EstructuralDokument4 SeitenPartes de Un Plano EstructuraleduardoooNoch keine Bewertungen

- PiñonesDokument10 SeitenPiñonesFrancisco Javier Orellana ContrerasNoch keine Bewertungen

- Catálogo de Piñones MartinDokument12 SeitenCatálogo de Piñones MartinDavid EstrellaNoch keine Bewertungen

- Sae 100 R1at (Gates)Dokument1 SeiteSae 100 R1at (Gates)Darío GertenbachNoch keine Bewertungen

- Cancamos PDFDokument2 SeitenCancamos PDFVictor Sebastian Flores OñateNoch keine Bewertungen

- Tolerancias Norma Iso Acabados A FrioDokument1 SeiteTolerancias Norma Iso Acabados A FrioJoaoNoch keine Bewertungen

- GANTDokument10 SeitenGANTLenin HBravoNoch keine Bewertungen

- ALFA LAVAL Unique-SSV-Manually-Operated-Manually-RegulatingDokument4 SeitenALFA LAVAL Unique-SSV-Manually-Operated-Manually-RegulatingJenny TrujilloNoch keine Bewertungen

- HidrologíaDokument5 SeitenHidrologíaRoberto RiosNoch keine Bewertungen

- Catalogo Cancamos OPACDokument4 SeitenCatalogo Cancamos OPACmetal tuzaroNoch keine Bewertungen

- f11.04 Brocas Machos y TerrajasDokument5 Seitenf11.04 Brocas Machos y TerrajasluisNoch keine Bewertungen

- Seleccion de Chavetas y Dimensionamiento de ChaveterosDokument2 SeitenSeleccion de Chavetas y Dimensionamiento de ChaveterosAlejandroNoch keine Bewertungen

- Catálogo KALFLEXDokument45 SeitenCatálogo KALFLEXgregorio cabrera floridoNoch keine Bewertungen

- Tornillos HexagonalesDokument1 SeiteTornillos HexagonalessergioNoch keine Bewertungen

- Catalogo Losacero T-DeckDokument10 SeitenCatalogo Losacero T-DeckOto Cuyuch100% (1)

- Calculo VigasDokument7 SeitenCalculo VigasRubén F Dalla VecchiaNoch keine Bewertungen

- Lista Pariñas - Cto, Tub, CondDokument38 SeitenLista Pariñas - Cto, Tub, CondPablo Alexis García de la CruzNoch keine Bewertungen

- Longitud de Desarrollo, Ganchos EstándarDokument3 SeitenLongitud de Desarrollo, Ganchos EstándarLUIS JAVIER GÓMEZ DIAZNoch keine Bewertungen

- Planilla de Hierros 1 SR QUISAGUANODokument10 SeitenPlanilla de Hierros 1 SR QUISAGUANOpedro ortizNoch keine Bewertungen

- Catalogo de Cadenas InviernoDokument16 SeitenCatalogo de Cadenas InviernoEdson Arroyo Condori100% (1)

- CN10 Micro-AutomaciónDokument10 SeitenCN10 Micro-AutomaciónGabrielMontielNoch keine Bewertungen

- v3 Mdba2i6hpcDokument1 Seitev3 Mdba2i6hpcLINOVA CANoch keine Bewertungen

- Tolerante ISO AlezajeDokument4 SeitenTolerante ISO Alezajealin.butunoi86567% (6)

- CHAVETAS PLANAS, Tablas, PosicionamientoDokument2 SeitenCHAVETAS PLANAS, Tablas, Posicionamientojose manuel gomez jimenez100% (3)

- TuercasDokument22 SeitenTuercasWilson Javier Ruiz AlvarezNoch keine Bewertungen

- Catalogo IpeDokument2 SeitenCatalogo IpeJhon Sebastian Reyes DiazNoch keine Bewertungen

- Dibujo Técnico. Normalización Industrial. Elementos de Uniones Desmontables: Tornillos, Tuercas, Arandelas, Esparragos, PernosDokument37 SeitenDibujo Técnico. Normalización Industrial. Elementos de Uniones Desmontables: Tornillos, Tuercas, Arandelas, Esparragos, Pernosricardobrtlm91% (74)

- Tablas UNE-EN ISO 286 2011Dokument39 SeitenTablas UNE-EN ISO 286 2011Beatriz IturraldeNoch keine Bewertungen

- THW 90 PDFDokument2 SeitenTHW 90 PDFLU MafaNoch keine Bewertungen

- Aguilar Paúl - Tabla de Corte y Soldadura PDFDokument3 SeitenAguilar Paúl - Tabla de Corte y Soldadura PDFkevin sanchezNoch keine Bewertungen

- Idoc - Pub Calculo de Consumo de Material de SoldaduraDokument17 SeitenIdoc - Pub Calculo de Consumo de Material de SoldaduraJosé Luis Albanés ArévaloNoch keine Bewertungen

- Parker Tube Catalog 4300examin1.page479Dokument1 SeiteParker Tube Catalog 4300examin1.page479oscarn_036Noch keine Bewertungen

- Sujetador de RoscasDokument44 SeitenSujetador de RoscasBraulio Benavides HuapayaNoch keine Bewertungen

- Catalago Acero Sider PeruDokument4 SeitenCatalago Acero Sider PeruAlbertNoch keine Bewertungen

- F 01 7721 Mechanical Tee RevE. RevG SPADokument4 SeitenF 01 7721 Mechanical Tee RevE. RevG SPArobertperez19897167Noch keine Bewertungen

- M1AA02PRACTTORN2022Dokument9 SeitenM1AA02PRACTTORN2022Avril AlejandraNoch keine Bewertungen

- Diseño de estructuras de concreto armadoVon EverandDiseño de estructuras de concreto armadoBewertung: 5 von 5 Sternen5/5 (2)

- Métodos de unión y desunión de elementos fijos estructurales. TMVL0309Von EverandMétodos de unión y desunión de elementos fijos estructurales. TMVL0309Bewertung: 5 von 5 Sternen5/5 (1)

- Los Actos de Comercio-1Dokument5 SeitenLos Actos de Comercio-1Juan Samuel Perez MarquezNoch keine Bewertungen

- Parcial - Escenario 4 - PRIMER BLOQUE-TEORICO-PRACTICO - VIRTUAL - MATEMÁTICAS FINANCIERAS - (GRUPO B02)Dokument9 SeitenParcial - Escenario 4 - PRIMER BLOQUE-TEORICO-PRACTICO - VIRTUAL - MATEMÁTICAS FINANCIERAS - (GRUPO B02)angie perezNoch keine Bewertungen

- Guia 6Dokument20 SeitenGuia 6Jorge Costilla QuirozNoch keine Bewertungen

- Programación de Aula - Dirección de Servicios de Restauraciónrv - 2019 - OkDokument23 SeitenProgramación de Aula - Dirección de Servicios de Restauraciónrv - 2019 - OkPer Varez100% (1)

- Formación Profesional Dual: Servicio Nacional de Adiestramiento en Trabajo IndustrialDokument16 SeitenFormación Profesional Dual: Servicio Nacional de Adiestramiento en Trabajo IndustrialJunior Sinche RecinesNoch keine Bewertungen

- 2-Analisis de Muda y Balance de CargasDokument34 Seiten2-Analisis de Muda y Balance de CargasElba Margarita Cruz RiosNoch keine Bewertungen

- Contab Costos Prac-1Dokument1 SeiteContab Costos Prac-1ariane alvis sanchezNoch keine Bewertungen

- Anexo de SolicitudDokument3 SeitenAnexo de SolicitudCristian Cortegana RabanalNoch keine Bewertungen

- Apuntes Regulación Jurídica Del MercadoDokument37 SeitenApuntes Regulación Jurídica Del MercadoDebora BerriosNoch keine Bewertungen

- Ejemplo Publicidad Diplomado Con CostoDokument2 SeitenEjemplo Publicidad Diplomado Con CostoMateo GarzonNoch keine Bewertungen

- Ibsen Fuentes DanielDokument77 SeitenIbsen Fuentes DanielKatherine CalderonNoch keine Bewertungen

- Ensayo de Compresión A Ladrillos de Barro CocidoDokument8 SeitenEnsayo de Compresión A Ladrillos de Barro CocidoCristina Maria Gutierrez SosaNoch keine Bewertungen

- Catalogo de Valvulas Bendix PDFDokument81 SeitenCatalogo de Valvulas Bendix PDFJuan Carlos Fuentes80% (5)

- Cuaderno de Trabajo - Nivelación Matemática (DUOC UC)Dokument272 SeitenCuaderno de Trabajo - Nivelación Matemática (DUOC UC)Alexander Patricio Escobar Pinto78% (32)

- 04 Riesgos Relacionados Con La SeguridadDokument78 Seiten04 Riesgos Relacionados Con La Seguridadrebeco190Noch keine Bewertungen

- Trabajo Final Fundamentos 2Dokument22 SeitenTrabajo Final Fundamentos 2Jessica BritoNoch keine Bewertungen

- 1-Apuntes Ensayos Proctor y CBRDokument17 Seiten1-Apuntes Ensayos Proctor y CBRMilton Millanao MontecinoNoch keine Bewertungen

- Documentación Modulos Vs ComponentesDokument19 SeitenDocumentación Modulos Vs ComponentesChristianQuirozPlefkeNoch keine Bewertungen

- 03 Informe Tecnico Produccion Nacional Ene 2023Dokument51 Seiten03 Informe Tecnico Produccion Nacional Ene 2023Diario PerúNoch keine Bewertungen

- Mapa Mental Sem 3 FinalDokument1 SeiteMapa Mental Sem 3 FinalAndrea Rojas CamargoNoch keine Bewertungen

- TP 4 - 100% SociedadesDokument5 SeitenTP 4 - 100% Sociedadesnicolasaugustopg100% (3)

- Teoria de ControlDokument1 SeiteTeoria de Controljohn valecillosNoch keine Bewertungen

- Comparacion de PreciosDokument4 SeitenComparacion de PreciosRicardo VásquezNoch keine Bewertungen

- PP Identidad CorporativaDokument2 SeitenPP Identidad CorporativaVeverito Sanhueza JimenezNoch keine Bewertungen

- Cuarto Informe de Gobierno - Administración 2009-2015 - Gobierno Del Estado de Nuevo LeónDokument108 SeitenCuarto Informe de Gobierno - Administración 2009-2015 - Gobierno Del Estado de Nuevo LeónGobierno de Nuevo LeónNoch keine Bewertungen

- Efecto de Las Variables Del Procedimiento de Soldadura Sobre Las Propiedades Mecánicas y La Resistencia A La Corrosión en Depósitos de Soldadura de Aceros Inoxidables SupermartensíticosDokument384 SeitenEfecto de Las Variables Del Procedimiento de Soldadura Sobre Las Propiedades Mecánicas y La Resistencia A La Corrosión en Depósitos de Soldadura de Aceros Inoxidables SupermartensíticosPUGBA PUGNoch keine Bewertungen

- 1.2 Similitudes y Diferencias Entre Sistemas de Producción y de Servicios.Dokument6 Seiten1.2 Similitudes y Diferencias Entre Sistemas de Producción y de Servicios.Jose alejandro jdnNoch keine Bewertungen

- Memoria Señalizacion SEDE SACHACADokument17 SeitenMemoria Señalizacion SEDE SACHACAleslieNoch keine Bewertungen

- Rfi N°02 - Detalle Constructivo de Caja de RegistroDokument1 SeiteRfi N°02 - Detalle Constructivo de Caja de RegistroLUISNoch keine Bewertungen

- Fo Tema 2 2-5a EvidenciaDokument10 SeitenFo Tema 2 2-5a EvidenciaMony Hernandez0% (1)