Beruflich Dokumente

Kultur Dokumente

PSV 0764 CD Vent KO Drum Liquid Pump - L03

Hochgeladen von

Ebby OnyekweOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PSV 0764 CD Vent KO Drum Liquid Pump - L03

Hochgeladen von

Ebby OnyekweCopyright:

Verfügbare Formate

REV.

NO

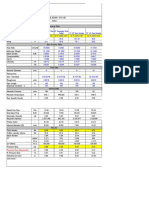

DATE 19-Jul-10 21-Jun-11 24-Oct-11 14-Feb-13 13-Mar-13 NWP 1 OF 3 PSV-0764 C/D

PREP'D NP JOA JOA RAU RAU

CHK'D SCJ SCJ SCJ KSJ YA

CALCULATION SHEET

FOR PRESSURE RELIEF VALVE

K02 K03 L01 L02 L03 Unit : Sheet : Item No. :

Project : Client : Service :

DSO Offshore CNL Vent KO Drum Liquid Pump

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44

Notes. 1. The calculated orifice size of water case is bigger than the size of oil case. Therefore the sizing case is Water case. 2. PSV type : Conventional 4. Equipment Design Pressure : 324.1 barg 5. PSV Set Pressure 124.1 barg 6. Reliving Contingencies Applicable or not N/A N/A Yes N/A N/A N/A N/A N/A N/A N/A N/A N/A 10200 (Note 1) 3. Equipment Protected : Vent K/O Drum Liquid Pump, 176-PBB-0764 A/B 2. Reference P&ID SOM-NWP1-PRO-PID-HHI-0000-00020-02 1. Objective Identify reliving contingencies and determine relieving flowrate of Pressure Relief Valve PSV-0764 C/D

No. A B C D E F G H I J K L

Case Fire (Wetted Surface Area) Fire (Unwetted Surface Area) Blocked Discharge Reflux Failure Check Valve Malfunction Tube Rupture Control Valve Failure Power Failure Gas Blowby Loss of air or gas instrument Loss of cooling Excessive heat input

Flowrate(kg/hr)

Remarks

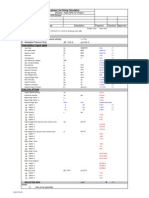

REV. NO

DATE 19-Jul-10 21-Jun-11 24-Oct-11 14-Feb-13

PREP'D NP JOA JOA RAU

CHK'D SCJ SCJ SCJ KSJ YA

CALCULATION SHEET

FOR PRESSURE RELIEF VALVE BY API RP 520 ( Blocked- Liquid)

Project : DSO Offshore Client : CNL Service : Vent KO Drum Liquid Pump

K02 K03 L01 L02 L03 Unit : Sheet :

13-Mar-13 RAU NWP 2 OF 3 Item No. : PSV-0764 C/D

Blocked Case (Sizing Case) 1 1. Cause of Overpressure 2 3 2. Relieving Condition 4 Fluid Viscosious (Y or N) N Water (Note 1) 5 6 Relief Temperature (T): 35 7 Set Pressure : 12,410 KPag 8 Over Pressure (%) : 10 % 9 Relief Pressure (P1) : 13,651 KPag 10 11 Molecular Weight of vapor (M): 12 Density at standard condition 1,000.0 kg/ 13 Required Relieving Rate (Q): 10.2 /hr 14 170.0 L/min 15 10,200 kg/hr 16 Back Pressure (P2 ) : 100.0 Kpag 17 Viscosity 0.73 cP 18 Correction Factor due to Viscosity(Kv) 1.0000 (for nonviscosious) 19 (Figure 36) 1.0037 (for viscosious) 71 20 Reynolds Number 847,584 21 22 4. Calculate required relieving area. 23 24 A = 11.78*Q (G/P1-P2) 25 KdKw KcKv 2 26 = 26.5 mm 2 27 0.0410 in 28 29 Kd = 0.65 (w/o Rup.D) Effective coefficient of discharge 30 Kw = 1 (find Kw ) 0.81% (Pb/Ps *100 Fig 31 in API 520) 31 Kc = 1 (rupture disk =0.9, others =1.0) 32 33 5. Selection of Orifice Size & Type 34 The quantity of PSV to be installed : 1 SETs 35 Inlet size X Outlet size 36 Cal. (Note 2) 1.5 * D * 3.0 37 38 39 6. Selected Orifice Area : 0.110 inch2 40 70.968 mm2 41 42 43 7. Rated Flow rate : 44 27,350 kg/hr (for nonviscosious) 45 60,297 lb/hr (for nonviscosious) 46 NOTE. 1. The above property is based on Water. 2. Orifice size selected and confirmed by Vendor.

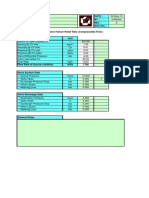

REV. NO

DATE 19-Jul-10 21-Jun-11 24-Oct-11 14-Feb-13

PREP'D NP JOA JOA RAU

CHK'D SCJ SCJ SCJ KSJ YA

CALCULATION SHEET

FOR PRESSURE RELIEF VALVE BY API RP 520 ( Blocked- Liquid)

Project : DSO Offshore Client : CNL Service : Vent KO Drum Liquid Pump

K02 K03 L01 L02 L03 Unit : Sheet :

13-Mar-13 RAU NWP 3 OF 3 Item No. : PSV-0764 C/D Blocked Case

1 1. Cause of Overpressure 2 3 2. Relieving Condition 4 Fluid Viscosious (Y or N) 5 PFD stream 6 Relief Temperature (T): 7 Set Pressure : 8 Over Pressure (%) : 9 Relief Pressure (P1) : 10 11 Molecular Weight of vapor (M): 12 Density at standard condition 13 Required Relieving Rate (Q): 14 15 16 Back Pressure (P2 ) : 17 Viscosity 18 Correction Factor due to Viscosity(Kv) 19 (Figure 36) 20 Reynolds Number 21 22 4. Calculate required relieving area. 23 24 A = 11.78*Q (G/P1-P2) 25 KdKw KcKv 2 26 = 22.1 mm 2 27 0.0342 in 28 29 Kd = 0.65 30 Kw = 1 31 Kc = 1 32 33 5. Selection of Orifice Size & Type 34 The quantity of PSV to be installed : 35 Inlet size 36 Cal. 1.5 37 38 6. Selected Orifice Area : 0.110 39 70.968 40 41 42 7. Rated Flow rate : 43 22,801 44 50,268 45 NOTE. 1. The above property is based on Oil

N 35 12,410 10 13,651

Oil KPag % KPag

(Note 1)

695.0 10.2 170.0 7,089 100.0 0.36 1.0000 1.0043 1,321,328

kg/ /hr L/min kg/hr Kpag cP (for nonviscosious) (for viscosious)

71

(w/o Rup.D) Effective coefficient of discharge (find Kw ) 0.81% (Pb/Ps *100 Fig 31 in API 520) (rupture disk =0.9, others =1.0)

1 X

SETs Outlet size

* D *

3.0

(Note 2)

inch2 mm2

kg/hr lb/hr

(for nonviscosious) (for nonviscosious)

2. Orifice size selected and confirmed by Vendor.

Das könnte Ihnen auch gefallen

- PSV Sizing Psv-414 UpdateDokument7 SeitenPSV Sizing Psv-414 UpdateBui Khoi NguyenNoch keine Bewertungen

- 3Ph Horiz Sep 2010 Weir VerA SIDokument5 Seiten3Ph Horiz Sep 2010 Weir VerA SIBrenda DavisNoch keine Bewertungen

- PSV 0600B Well Test Separator - L03Dokument6 SeitenPSV 0600B Well Test Separator - L03Ebby OnyekweNoch keine Bewertungen

- 2phase Separator Size 2010 VerAADokument22 Seiten2phase Separator Size 2010 VerAAAnonymous a4Jwz14WNoch keine Bewertungen

- Line Losses (Fittings) ΔP (ft) ΔP (ft)Dokument3 SeitenLine Losses (Fittings) ΔP (ft) ΔP (ft)ahmadlieNoch keine Bewertungen

- Gas Line Size-1Dokument12 SeitenGas Line Size-1svnaik14Noch keine Bewertungen

- CPF-010 Process Line Sizing Attachment - 0Dokument38 SeitenCPF-010 Process Line Sizing Attachment - 0goodspeed_ph100% (1)

- Gas Line Sizing - Api 14E Input Description Unit: General DataDokument13 SeitenGas Line Sizing - Api 14E Input Description Unit: General DataSamuel Onyewuenyi100% (1)

- FGCP Line Sizing CalculationsDokument86 SeitenFGCP Line Sizing CalculationsToyinNoch keine Bewertungen

- PSV Sizing TableDokument14 SeitenPSV Sizing TablebadelitamariusNoch keine Bewertungen

- Line SizeDokument3 SeitenLine Sizeintania660% (1)

- Gas - Line SizingDokument2 SeitenGas - Line SizingSeema SiddiquaNoch keine Bewertungen

- Line Sizing - 2PHASEDokument11 SeitenLine Sizing - 2PHASEEbby Onyekwe100% (1)

- Line Sizing LiqDokument12 SeitenLine Sizing LiqDana GuerreroNoch keine Bewertungen

- CPF-010 Utility Line Sizing Attachment - 0Dokument31 SeitenCPF-010 Utility Line Sizing Attachment - 0goodspeed_phNoch keine Bewertungen

- Template Gas Line SizingDokument11 SeitenTemplate Gas Line SizingRindie AuroraNoch keine Bewertungen

- 2 Phase Horizontal Flow Line Sizing Cal-AUHDokument15 Seiten2 Phase Horizontal Flow Line Sizing Cal-AUHMike DukasNoch keine Bewertungen

- 3phase Separator Size 2010 VerADokument24 Seiten3phase Separator Size 2010 VerACristina BarbulescuNoch keine Bewertungen

- Control Valve Hydraulics-GasDokument6 SeitenControl Valve Hydraulics-GasganeshdhageNoch keine Bewertungen

- PSV Sizing (Liquid)Dokument2 SeitenPSV Sizing (Liquid)Saeid Rahimi Mofrad50% (2)

- Blowdown OrificeDokument2 SeitenBlowdown OrificeOmprakaash MokideNoch keine Bewertungen

- DJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDokument37 SeitenDJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDIANTORONoch keine Bewertungen

- WS-CA-PR-024 - Atmospheric & Low Preesure Tank VentingDokument4 SeitenWS-CA-PR-024 - Atmospheric & Low Preesure Tank Ventinghhvg100% (1)

- Pump (English) TemplateDokument1 SeitePump (English) TemplateMichael HaiseNoch keine Bewertungen

- Scrubber Design (Packed Column)Dokument11 SeitenScrubber Design (Packed Column)soreksatuNoch keine Bewertungen

- All Sep CalcDokument22 SeitenAll Sep Calcbharathscds100% (3)

- Orifice Sizing TemplateDokument2 SeitenOrifice Sizing TemplaterajeevjayanathNoch keine Bewertungen

- Strainer Screen & Mesh Selection GuideDokument4 SeitenStrainer Screen & Mesh Selection Guidelenasko0% (1)

- Relief Valve Version 1Dokument37 SeitenRelief Valve Version 1ChakerZagrouba100% (2)

- D-1309 Sizing Calc Sht1Dokument1 SeiteD-1309 Sizing Calc Sht1NKNoch keine Bewertungen

- PSV SizingDokument6 SeitenPSV SizingBui Khoi Nguyen100% (1)

- Gas Line Sizing by API 14E Method Revision #: ??: Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, TeesDokument4 SeitenGas Line Sizing by API 14E Method Revision #: ??: Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, Teesusaid saifullahNoch keine Bewertungen

- Line SizingDokument7 SeitenLine SizingKips AksNoch keine Bewertungen

- Line Sizing (Liquid)Dokument22 SeitenLine Sizing (Liquid)Muthuselvi Shanmugaraj100% (1)

- Gas Line SizingDokument11 SeitenGas Line SizingEbby OnyekweNoch keine Bewertungen

- Cvsize (Control Valve Sizing)Dokument8 SeitenCvsize (Control Valve Sizing)EslamSheblNoch keine Bewertungen

- Line Sizing For Liquid, (DO IT OWN)Dokument11 SeitenLine Sizing For Liquid, (DO IT OWN)sumitNoch keine Bewertungen

- Seperator Sizing v3Dokument5 SeitenSeperator Sizing v3camasa2011Noch keine Bewertungen

- Gas-Liquid Line SizingDokument1 SeiteGas-Liquid Line Sizingagusnnn100% (2)

- Cakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DataDokument6 SeitenCakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DatasterlingNoch keine Bewertungen

- Flash Tank Calculation ReportDokument29 SeitenFlash Tank Calculation Reporttauqeer100% (1)

- Line Sizing (SI) Gas PhaseDokument10 SeitenLine Sizing (SI) Gas PhaseRian Intan SaputraNoch keine Bewertungen

- Ejercicio 246 PSV438 RESUELTODokument2 SeitenEjercicio 246 PSV438 RESUELTOHumberto Ivan Gonzales TapiaNoch keine Bewertungen

- Power CalculationDokument4 SeitenPower CalculationGunasekaranNoch keine Bewertungen

- Control Valve Sizing - EXXON Calculation MethodDokument14 SeitenControl Valve Sizing - EXXON Calculation Methodm0% (1)

- Control Valve SizingDokument3 SeitenControl Valve SizingN. S. PanditNoch keine Bewertungen

- Sizing of Pressure Safety Valve: Project Name ClientDokument7 SeitenSizing of Pressure Safety Valve: Project Name ClientAmit Bansal100% (1)

- Inlet Separator Design APIDokument8 SeitenInlet Separator Design APIIlham Dwiyanto Emzar100% (1)

- 16 - Gas Line SizingDokument11 Seiten16 - Gas Line SizingJunaid MateenNoch keine Bewertungen

- RD 810Dokument73 SeitenRD 810Ashish MishraNoch keine Bewertungen

- Control Valve Failure Relief Rate - Gas ServiceDokument3 SeitenControl Valve Failure Relief Rate - Gas ServiceSaeid Rahimi Mofrad100% (1)

- M-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionDokument2 SeitenM-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionAJAY1381Noch keine Bewertungen

- Seperator Sizing Sheet (Ken Arnold)Dokument2 SeitenSeperator Sizing Sheet (Ken Arnold)Hani KirmaniNoch keine Bewertungen

- Centrifugal Pump Calculation Summary Sheet: ConfidentialDokument3 SeitenCentrifugal Pump Calculation Summary Sheet: ConfidentialPrafitri KurniawanNoch keine Bewertungen

- Steam Pressure DropDokument8 SeitenSteam Pressure DropDavid Muñoz CastroNoch keine Bewertungen

- 7810-8110-Ca-1540-651-001 - HP FG KodDokument68 Seiten7810-8110-Ca-1540-651-001 - HP FG Kodgopal krishnan0% (1)

- Heat Transfer Coeficient in ReactorDokument2 SeitenHeat Transfer Coeficient in ReactorDavid LambertNoch keine Bewertungen

- Vertical Separator SizingDokument4 SeitenVertical Separator SizingnemprrNoch keine Bewertungen

- PSV Sizing Psv-402 Update PsetDokument7 SeitenPSV Sizing Psv-402 Update PsetBui Khoi NguyenNoch keine Bewertungen

- CALIB053 - Mathcad 15 EquationsDokument8 SeitenCALIB053 - Mathcad 15 Equationsilie_vlassaNoch keine Bewertungen

- LPG Pipeline MeteringDokument7 SeitenLPG Pipeline MeteringDinesh Pinto100% (1)

- Fisher Specification Manager User ManualDokument28 SeitenFisher Specification Manager User Manualtareq.sefatNoch keine Bewertungen

- Narrative For Proposed Pressure Regulator Sizing CalculationsDokument7 SeitenNarrative For Proposed Pressure Regulator Sizing CalculationsEbby OnyekweNoch keine Bewertungen

- Epf Water TreatmentDokument1 SeiteEpf Water TreatmentRenzoNoch keine Bewertungen

- Restriction Orifice Plate Calculator GasDokument25 SeitenRestriction Orifice Plate Calculator GaseshraghianNoch keine Bewertungen

- OLGA Core and Modules: Compositional Tracking ModuleDokument3 SeitenOLGA Core and Modules: Compositional Tracking ModulePasquale CutriNoch keine Bewertungen

- Leaflet MOOC Oil & GasDokument2 SeitenLeaflet MOOC Oil & GasEbby OnyekweNoch keine Bewertungen

- Determining The Pressure Drop To Be Used in A Control Valve Sizing CalculationDokument2 SeitenDetermining The Pressure Drop To Be Used in A Control Valve Sizing CalculationAntonio LebrunNoch keine Bewertungen

- Allied Valve Diers Two Phase Flow Required DataDokument3 SeitenAllied Valve Diers Two Phase Flow Required DataEbby OnyekweNoch keine Bewertungen

- OpenSourceSoftwareInfo PogoplugPCDokument18 SeitenOpenSourceSoftwareInfo PogoplugPCcdla14Noch keine Bewertungen

- Chevron Job TitleDokument2 SeitenChevron Job TitleEbby OnyekweNoch keine Bewertungen

- Ogbuiyi YolandaDokument13 SeitenOgbuiyi YolandaEbby OnyekweNoch keine Bewertungen

- ACS11Dokument3 SeitenACS11Ebby OnyekweNoch keine Bewertungen

- InstructionDokument23 SeitenInstructionEbby OnyekweNoch keine Bewertungen

- Pressure Changers On Aspen PlusDokument19 SeitenPressure Changers On Aspen PlusAlexReituNoch keine Bewertungen

- Oil Characterization 1Dokument16 SeitenOil Characterization 1Muhammad Kabir MusaNoch keine Bewertungen

- 7405Dokument8 Seiten7405Ebby OnyekweNoch keine Bewertungen

- Super Euro 2016 WallchartDokument1 SeiteSuper Euro 2016 WallchartYogi Prianda PutraNoch keine Bewertungen

- What Is Hydrocarbon DewPointDokument2 SeitenWhat Is Hydrocarbon DewPointEbby OnyekweNoch keine Bewertungen

- Crude Tower Simulation-HYSYS v8.6Dokument42 SeitenCrude Tower Simulation-HYSYS v8.6EstrellaNoch keine Bewertungen

- Mooc Sustainable Mobility Example of Working Timetable: 1h 20minDokument1 SeiteMooc Sustainable Mobility Example of Working Timetable: 1h 20minEbby OnyekweNoch keine Bewertungen

- Full Time Enm202 2014 CWDokument9 SeitenFull Time Enm202 2014 CWEbby OnyekweNoch keine Bewertungen

- Pressure Drop CalculationDokument30 SeitenPressure Drop CalculationEbby Onyekwe100% (1)

- Exercise A - Transfer of FluidDokument2 SeitenExercise A - Transfer of FluidEbby OnyekweNoch keine Bewertungen

- Spec Speed PrimerDokument11 SeitenSpec Speed PrimerEbby OnyekweNoch keine Bewertungen

- Minimum Expense Form 2015-2016: School of Graduate StudiesDokument2 SeitenMinimum Expense Form 2015-2016: School of Graduate StudiesEbby OnyekweNoch keine Bewertungen

- Book 1Dokument2 SeitenBook 1Ebby OnyekweNoch keine Bewertungen

- Corrosion Management For Seawater Injection SystemsDokument5 SeitenCorrosion Management For Seawater Injection SystemszaxaderNoch keine Bewertungen

- Pollutants and Ways To Reduce ThemDokument1 SeitePollutants and Ways To Reduce ThemEbby OnyekweNoch keine Bewertungen

- PSV Sizing ProcedureDokument1 SeitePSV Sizing ProcedureEbby OnyekweNoch keine Bewertungen

- Gear Adendum Modification CoefficientDokument8 SeitenGear Adendum Modification CoefficientRobert StuartNoch keine Bewertungen

- Apf188088 enDokument130 SeitenApf188088 enJavier LópezNoch keine Bewertungen

- Is Thicker Gasket Material Better Than ThinnerDokument2 SeitenIs Thicker Gasket Material Better Than ThinnerSteven LiparotoNoch keine Bewertungen

- Experiment - 06 - ViscosityDokument7 SeitenExperiment - 06 - Viscosityadimegha0% (1)

- Important Questions Sem1 PhysicsDokument2 SeitenImportant Questions Sem1 Physicsprashanth kumar100% (1)

- Seleccion Chiller AguaDokument60 SeitenSeleccion Chiller AguaÓscar Alfonso Gómez SepúlvedaNoch keine Bewertungen

- Steam Systems Product Offerings: For Industrial / Commercial SystemsDokument2 SeitenSteam Systems Product Offerings: For Industrial / Commercial SystemsDavid C TalledoNoch keine Bewertungen

- Electric Motor EE ST and L - EEA Comment Attended 22 July 2015Dokument193 SeitenElectric Motor EE ST and L - EEA Comment Attended 22 July 2015gomeraNoch keine Bewertungen

- Scan Brush Semi Automatic Screen Filters Technical DataDokument5 SeitenScan Brush Semi Automatic Screen Filters Technical DataChristian Ve GaNoch keine Bewertungen

- Aviation PhysicsDokument3 SeitenAviation PhysicsNelson Cervantes ArasNoch keine Bewertungen

- CE Test-1 PDFDokument93 SeitenCE Test-1 PDFKundan SinghNoch keine Bewertungen

- Ball Mill Heat Balance ExplanationDokument4 SeitenBall Mill Heat Balance ExplanationVisnu Sankar67% (3)

- Causes of CarryoverDokument3 SeitenCauses of CarryoverRajesh SarkarNoch keine Bewertungen

- 03.shaft ComponentsDokument185 Seiten03.shaft ComponentsClio 77Noch keine Bewertungen

- Chapter-2 (Steel Design)Dokument22 SeitenChapter-2 (Steel Design)danica ledesmaNoch keine Bewertungen

- An Infinite Row of Collinear Cracks in An Infinite Elastic SheetDokument5 SeitenAn Infinite Row of Collinear Cracks in An Infinite Elastic SheetXI CHENNoch keine Bewertungen

- Example 84Dokument58 SeitenExample 84youceftliNoch keine Bewertungen

- Calculation On The Heat Transfer Correlations and Simulation Verification For Typical LNG Open Rack VaporizerDokument6 SeitenCalculation On The Heat Transfer Correlations and Simulation Verification For Typical LNG Open Rack VaporizerabdoNoch keine Bewertungen

- Proiect Lemn - Facultatea de Constructii IasiDokument24 SeitenProiect Lemn - Facultatea de Constructii IasiIordana-Paula ManoleNoch keine Bewertungen

- 1422 Chapt 15 ThermodynamicsDokument40 Seiten1422 Chapt 15 Thermodynamicstomm01Noch keine Bewertungen

- Edm-760 Quick Reference Guide: How To Use Leanfind (Page 13)Dokument59 SeitenEdm-760 Quick Reference Guide: How To Use Leanfind (Page 13)jpzemogNoch keine Bewertungen

- Uk - Datasheets - 18032010vsmall FileDokument60 SeitenUk - Datasheets - 18032010vsmall FileEka Jayalaksana0% (1)

- 12 06 Digital Turbine Governor PDFDokument5 Seiten12 06 Digital Turbine Governor PDFRidwanvascoNoch keine Bewertungen

- WP-8.5.1-02 Role of RWCDokument3 SeitenWP-8.5.1-02 Role of RWCNitin SharmaNoch keine Bewertungen

- Turcon Glyd Ring T: Double Acting Rubber Energized Plastic Faced SealDokument14 SeitenTurcon Glyd Ring T: Double Acting Rubber Energized Plastic Faced SealPhong DuongNoch keine Bewertungen

- Full File at Https://testbanku - eu/Solution-Manual-for-Engineering-Mechanics-Dynamics-2nd-Edition-by-TongueDokument273 SeitenFull File at Https://testbanku - eu/Solution-Manual-for-Engineering-Mechanics-Dynamics-2nd-Edition-by-TongueMontoya UrquizaNoch keine Bewertungen

- Resumen Ingles 29-09-2020Dokument3 SeitenResumen Ingles 29-09-2020Jordin BarreraNoch keine Bewertungen

- High Mast and Octagonal Poles CatalogueDokument5 SeitenHigh Mast and Octagonal Poles CatalogueakhilNoch keine Bewertungen

- Load and Stress Distribution in Screw Threads With Modified WashersDokument11 SeitenLoad and Stress Distribution in Screw Threads With Modified WashersminakirolosNoch keine Bewertungen

- Control Chapter 1Dokument19 SeitenControl Chapter 1Wilmar Antonio Zuluaga ArangoNoch keine Bewertungen