Beruflich Dokumente

Kultur Dokumente

Design of Deployment Mechanism of Solar Array On A Small Satellite

Hochgeladen von

saadajmalsultan23Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design of Deployment Mechanism of Solar Array On A Small Satellite

Hochgeladen von

saadajmalsultan23Copyright:

Verfügbare Formate

American Journal of Mechanical Engineering, 2013, Vol. 1, No. 3, 66-72 Available online at http://pubs.sciepub.

com/ajme/1/3/2 Science and Education Publishing DOI:10.12691/ajme-1-3-2

Design of the Deployment Mechanism of Solar Array on a Small Satellite

M. G. El-Sherbiny1, A. Khattab1, M.K. Kassab2,*

2

Mechanical Design and Production Eng., Cairo University, Giza, Egypt Structure Department, National authority for Remote Sensing & Space Sciences (NARSS), Cairo, Egypt *Corresponding author: mgsherbiny@yahoo.com

Received December 20, 2012; Revised May 06, 2013; Accepted May 07, 2013

Abstract This paper presents analytical simulation of drag braking during deployment of a solar array system of a

small satellite within the space environment, and helps the designer to detect problems during ground testing. The deployment mechanism (DM) is modeled by using Mechanical Desktop (MDT) software and analyzed by using Finite Element Analysis Package (ANSYS 11). Design and Stress analysis of DM is performed at the most critical points during its functioning. Several finite element analysis models were considered to verify the DM integrity. These analyses were correlated with static, modal and random vibration testing. The present work can help in checking the survival of the mechanism under realistic operating conditions and makes sure that it will perform well after an orbit insertion of the satellite.

Keywords: satellite, deployment mechanism, shoe brake, solar Array, finite element, modal analysis

The designed brake has to be checked and tested accurately before the prototype is made available [4]. In the present work the DM is modelled by using Mechanical Desktop (MDT) software and then analyzed by Finite Element Analysis Package (ANSYS 11). Simulation analysis was made to describe the dynamic behavior of the mechanism structure and to predict its natural frequencies and structure response to the worst case of Launch Vehicle (LV) loads through static, modal and random vibration analysis [5]. Mechanical structure can resonate, where small forces can result in significant deformation, and damage can be induced in the structure. Resonant vibration is mainly caused by an interaction between inertial and elastic deformations of the materials within a structure. To better understand structural vibration problems, the resonant frequencies of the structure have to be identified. Modal analysis is recognized as a technique in finding the modes of vibration of machines, and mechanisms [6].

1. Introduction

Todays engineering design needs to manage the conflicting goals, improving performance while reducing developing time and costs. In this context designers utilized the solar energy as clean renewable source for powering small satellites. Solar arrays of considerable surface area are required to provide enough power for the safe payload functioning and for the computer and the communication systems, [1]. Figure 1 shows a schematic drawing of the satellite with the solar arrays [2]. Innovative designs included foldable solar arrays to minimize size and space requirement on the launching vehicle. Self actuated deployment mechanisms utilized the stored energy in a torsion spring to drive the solar arrays during the unfolding phase after orbital insertion. In such cases the motion has to be controlled by drag braking to reduce or eliminate the shock loading at the end of the stroke. Drag brake should be of minimum size and weight but can absorb and dissipate energy enough to make gradual deployment and smooth motion until the mechanism gets to rest at the end of the stroke, without shock loadings or reactions. A special small drum brake, with frictional shoes which are forced in contact with the drum under a compressive spring force, was designed for this particular purpose [3]. Figure 2 shows an isometric drawing of the brake assembly. The brake has an estimated weight of 0.350Kg and is able to deploy the solar arrays in 2 to 3 seconds depending on the realized coefficient of friction of 0.5 in normal atmosphere and 1.0 in space environment at an altitude of 768Km.

2. Structure and Model Description

The DM is intended for fastening of solar panel to the satellite body, turning the solar panel into the working position and keeping it in this position during operation in orbit. Once the Satellite is in orbit, the Solar Arrays are deployed to function. Therefore, Mathematical Model of DM is constructed and analyzed using finite Element Computer Package (ANSYS 11) to minimize the cost of making prototypes and the time in trial and error practices. Figure 3 shows the MDT model of the designed DM brake assembly to eject the folded SA and to control its deployment under drag braking. The finite element package provides a library of structure elements, such as

American Journal of Mechanical Engineering

67

beams, shells, and solid elements. The DM is modeled by connecting elements together within the geometrical constraints, taking into consideration material properties,

and appropriate boundary conditions to describe the physical constraints.

Figure 1. Top view of the satellite with four solar arrays

Figure 2. Assembly of shoe brake

Figure 3. Isometric 3D view of the model

68

American Journal of Mechanical Engineering

Forces and moments obtained from solar array mechanism and structural analysis are given in [7]. Fx = - 1.291e-002N, Fy = - 5.33e-004 N, Fz = - 1.651e-002N. Mx = 7.28 e-003N m, My = - 5.795 e-003N m Mz = 5.745 e-003N m. FE analysis of DM is performed to make sure that the DM structure will withstand the loads at the stoppage point. It is recommended to run modal analysis to make sure the natural frequencies of SA will not coincide with the DM ones. ANSYS 11 FE package is used to make the design analysis and verify the design [8]. The method uses a complex system of points (nodes) which form a grid or a mesh. Fine mesh is used to model fine geometrical details as well as closely approximate the localized stresses and strains in areas of steep gradients or of high stress concentrations. The model represents the assembly of all components and parts of the mechanism linked together and exposed to maximum loading conditions.

Figure 4. Tetrahedral mesh of the brake mechanism

Figure 5. Total Deformation within the mechanism

2. 1. Mesh Generation

Tetrahedral elements are used as shown in Figure 4. When using high relevance of 100, and fine relevance center, the meshing leads to huge sizable number of nodes and elements. But when simplifying relevance to 60 or 50 and selecting a relevance center of medium or coarse, the meshing problem can be smoothly solved.

Using relevance of 100; and relevance center medium, one gets: No. of elements: 595160; No. of degrees of freedom (No. of Nodes): 1249356, whilst using relevance of 50; and relevance center medium, gives: No. of elements was: 90914; No. of degrees of freedom (No. of Nodes): 194640,

American Journal of Mechanical Engineering

69

Therefore the later case is more appropriate to minimize truncations and round off errors. Figure 4 shows the mesh design of the DM brake assembly.

2.2. Materials

The materials are selected to meet the requirements of each individual component. Structural steel was selected for parts: rotating shaft, screws, and joints. AISI 4130 steels and 304 stainless steels were used for drums, Gray cast iron is also used for brake shoes, Aluminum alloy AMG6 is used for movable bracket, housing cage and friction arms, whilst other commercial aluminum alloys were used for guiding bushes, and Piano wire spring DIN 17223D is used for spring elements. The mechanical, thermal and physical properties of these materials as employed in the present work are given in appendix I.

Figure 7. Equivalent Stress distribution (Von-Misses)

3. Static Analysis

The objective of static loading is to define the resulting load distribution, strains and stresses throughout the structure of mechanism components. When performing static analysis under load, static forces and moments are applied to the assembly of the mechanism components. The linear static analysis in ANSYS is used to compute stresses, strains and deformations [9]. Figure 5 represents the ANSYS static analysis from geometry definition passing through connection definition, meshing the model and up to post processing of the static structural results. It also shows the critical areas of the maximum deformation occurs on the movable bracket reaching a maximum computed value as 2,2501e-004 m. The results indicated that deformations, strains, and stresses are small and did not threaten the structure of SA and the movable bracket. Figure 6 shows the critical areas of the highest strain in the DM, and also shows the locations of applied loads and the fixed nodal points resembling fixed supports. The analysis showed that the most critical strain occurs on housing cage 2,1718e-002m/m. Figure 7 shows the critical regions or the most stressed regions in the DM. The analysis showed that the most critical stress occurs on cubic joint and its value is 2,7544e+008 Pa. Obviously the computed max shear stresses were far below the shear strength of the part and therefore the design was mechanically safe under static loading conditions.

4. Modal Analysis of DM

Modal analysis and testing is used to identify the vibration modes and their natural frequencies, and to provide the structural matrices, which is required for the dynamic analysis of the assembly. Thus the basic structural dynamic data, as obtained accurately from a valid test provides a true identification of the structural behavior at the modes of interest. These derived matrices are based on the measured contributions of the mass, stiffness and damping properties at the modes of interest, taking into considerations the actual boundary conditions. These data is introduced into a finite element model of the structure, for subsequent problem solving, or re-designing the mechanism for better dynamic response [9]. Modal analysis was performed to the model of DM using ANSYS 11 software and the model has been solved for the first 5 modes. Figure 8 and Figure 9 show the resulting first two modes of vibration. This analysis is also used to gain better understanding of DM behavior and response to environmental conditions which of course, lead to better planning of the experimental testing. The normal modes obtained from the FEA for DM model before testing, represent fairly reasonable estimation of the DM Eigen frequencies and mode shapes. This information is used to plan the real testing; that is, to determine excitation conditions, shaker locations and accelerometer locations.

Figure 6. Areas of highly localized strains

Figure 8. First mode shape of DM structure at fn = 0.25236 Hz

70

American Journal of Mechanical Engineering

compression spring with a value of 733.18Pa. These stresses are far below the material failure limits, do not form threatening for DM, and implies that DM can withstand vibration loads well after an orbit insertion of the satellite.

Figure 9. Second mode shape of DM structure at fn = 0.31372 Hz

5. Random Analysis

Figure 10. PSD Acceleration versus Frequency

The fundamental nature of random vibration are needed to verify design, develop and produce cost effective and lightweight mechanisms that are capable of operating in various environments with high degree of reliability. The characteristic of random vibration is non-periodic and it can be considered as a series of overlapping sinusoidal curves [9,10,11]. In this environment all the exciting frequencies within a given bandwidth are excited at the same time. One of the different types of curves that can be used to show the random vibration input requirements is the Power Spectral Density (PSD) curve. Table (1) shows the PSD data. This is also shown in log-log scale with power spectral density (G2/Hz) along the ordinate vertical axis and frequency (Hz) along the horizontal abscissa axis. It should be noted that acceleration is represented as root mean square (RMS) and it is the area under the random vibration curve. Figure 10 shows the shaped random vibration input curve for the DM model.

Table (1). PSD Acceleration vs. Frequency Frequency Hz 10,0 25,0 50,0 80,0 130,0 160,0 190,0 225,0 270,0 310,0 PSD Acceleration (m/sec ) /Hz 1,0 1,3 1,0 3,1 1,6 2,8 1,2 2,0 2,8 5,0

Figure 11. Stress distribution on the DM model

Deformations occurred under the effect of frequencies load at all directions (X, Y, and Z) and the resulting deformations due to velocity and acceleration loads did not represent a threat to any of the DM components. Figure 12, Figure 13 and Figure 14 show the deformation due to directional displacement, velocity and acceleration along the X axis.

Figure 11 shows the resulting stresses of DM analysis and it is seen that stress distribution values have occurred at scale factor 1 sigma, and probability of 68.3% of the time at X-axis direction. It also, shows that the maximum effect of frequencies occurs on Torsion Spring and

Figure 12. Deformation due to displacement of DM mechanism on X axis

American Journal of Mechanical Engineering [4]

71

Figure 13. Deformation due to velocity on X axis

Friswell, M. I., Mottershead J. E., Finite Element Model Updating in Structural Dynamics Dept. of Mechanical Engineering, University of Swansea, Swansea, U.K. Springer, Solid Mechanics and Its Applications, Vol. 38, P292. 1996. [5] Shibabrat N., Wrik M., Experimental Modal Testing for Estimating the Dynamic Properties of a Cantilever Beam , Department of Civil Engineering , Jadavpur University, Kolkato700 032. http://fosonlietne.org/Thought/CA-77.pdf. [6] Bart B. Wim H. and Jan D.; Modern Solutions for Ground Vibration Testing of Large Aircraft; LMS International, Leuven, Belgium, SAE International Journal of Aerospace, April, 2009, Vol. 1, No. 1, pp. 732-742, 2009. [7] EgyptSat-1 Project, Satellite Preliminary Design. Composition and main Characteristics, Doc. No. EGS YZH RPT 01400 issue 2. 2007. [8] ANSYS, Inc. Release 11.0 Documentation for ANSYS. [9] Sudharsan, M; Structural Design and Analysis of a lightweight Composite Sandwich Space Radiator Panel Msc. Thesis, Office of Graduate Studies of Texas A&M University, USA, December 2003. [10] Neville F. Rieger; the Relation between Finite Element Analysis and Modal Analysis; Stress Technology Incorporated, Rochester, New York. 2008. [11] Fufa, B.; Zaho, C.; and Wensheag, M.; Modeling and Simulation of Satellite Solar Panel Deployment and Locking Information Technology Journal 9 (3): pp. 600-604, 2010.

Appendix I

Table 1. Properties of Structural Steel Structural Young's Modulus 2,e+011 Pa Poisson's Ratio 0,3 Density 7850, kg/m3 Tensile Yield Strength 2,5e+008 Pa Tensile Ultimate Strength 4,6e+008 Pa Thermal Thermal Conductivity 60,5 W/m C Specific Heat 434, J/kg C Table 2. Properties of Aluminum Alloy Structural Young's Modulus 7,1e+010 Pa Poisson's Ratio 0,33 Density 2770, kg/m3 Tensile Yield Strength 2,8e+008 Pa Tensile Ultimate Strength 3,1e+008 Pa Thermal Specific Heat 875, J/kg C Table 3. Properties of Steel Standard AISI 4130 Structural Young's Modulus Poisson's Ratio Density 2,e+005 Pa 0,3 7700, kg/m3

Figure 14. Deformation due to acceleration on the X axis

6. Conclusion

Linear static analysis of the DM is performed using FE analysis on ANSYS software and the deformation and displacement are computed. The modal analysis was conducted and the first five resonance frequencies (mode shapes) are calculated. Results obtained from Random vibration analysis revealed that the maximum stresses occurred on Torsion Spring and Compression Spring with a value of 733.18Pa. The FE analysis of the proposed design of the DM for SA of a small satellite showed that the model survived vibration loads, moments, and forces at operating conditions similar to those expected after an orbit insertion of the satellite. The present work also shows that the designed small shoe brake can be used to control the unfolding and protect the solar panels from shock loads and damage at the end of the deployment.

Table 4. Properties of Stainless Steel 316 Structural Young's Modulus 1,93e+011 Pa 0,31 7750,kg/m3 2,07e+008 Pa 5,86e+008 Pa 15,1W/m C 480,J/kg C Poisson's Ratio Density Tensile Yield Strength Tensile Ultimate Strength Thermal Thermal Conductivity Specific Heat

References

[1] [2] [3]

Heylen W., Lammens S., Sas P.,: Modal Analysis Theory and Testing, Katholieke Universiteit, Leuven, 1997. Egypt Sat-1 Project, Satellite Preliminary Design. Album of Drawings. Doc. No. EGS YZH RPT 01801, NARS, EGYPT, 2007. Kassab, M. Design, Analysis, Manufacturing, and Testing of a Deployment Mechanism for Solar Panel of a Small Satellite ; Ph.D. thesis, Faculty of Engineering, Cairo University, Egypt, December 2011.

72

American Journal of Mechanical Engineering

Table 5. Properties of Aluminum Alloy AMG6 Structural Young's Modulus Poisson's Ratio Density Thermal Specific Heat 875,J/kg C Density Tensile Ultimate Strength Thermal 2,06e+011Pa 0,29 7850,kg/m3 Thermal Specific Heat 450,J/kg C Thermal Conductivity Specific Heat 52,W/m C 447,J/kg C 7200,kg/m3 2,4e+008Pa 7,1e+010 Pa 0,33 2770,kg/m3 Young's Modulus Poisson's Ratio 1,1e+011Pa 0,28 Table 7. Properties of Gray Cast Iron Structural

Table 6. Properties of Piano Wire Steel DIN 17223D Structural Young's Modulus Poisson's Ratio Density

Das könnte Ihnen auch gefallen

- STM Paper PDFDokument73 SeitenSTM Paper PDFAlrack sinner75% (4)

- DiodeDokument22 SeitenDiodeSaurabh Mittal100% (1)

- Design of The Deployment Mechanism of Solar Array PDFDokument8 SeitenDesign of The Deployment Mechanism of Solar Array PDFShoaib IqbalNoch keine Bewertungen

- M Jayakumar Paper (17142691331)Dokument12 SeitenM Jayakumar Paper (17142691331)N V DhandapaniNoch keine Bewertungen

- Development of A Lightweight Tubular Space FrameDokument7 SeitenDevelopment of A Lightweight Tubular Space FrameJony M. TemnikarNoch keine Bewertungen

- Analysis and Validation of Eicher 11.10 ChassisDokument4 SeitenAnalysis and Validation of Eicher 11.10 ChassisdessaivipulNoch keine Bewertungen

- An Optimization Analysis On An Automotive Component With Fatigue Constraint Using Hyperworks Software For Environmental SustainabilityDokument5 SeitenAn Optimization Analysis On An Automotive Component With Fatigue Constraint Using Hyperworks Software For Environmental SustainabilitySahaya GrinspanNoch keine Bewertungen

- Functional Simulation of Harmonic Drive With S.M.A. Wave GeneratorDokument5 SeitenFunctional Simulation of Harmonic Drive With S.M.A. Wave GeneratorBizau ViorelNoch keine Bewertungen

- About The Preliminary Design of The Suspension SPRDokument7 SeitenAbout The Preliminary Design of The Suspension SPRalinNoch keine Bewertungen

- Fatigue Life Estimation of Chassis Frame FESMDokument7 SeitenFatigue Life Estimation of Chassis Frame FESMRtdpDinuNoch keine Bewertungen

- Static Analysis of Spur Gear Using FEMDokument6 SeitenStatic Analysis of Spur Gear Using FEMSameOldHatNoch keine Bewertungen

- Assessment of Dynamic Parameters of Heavy-Duty GearsDokument6 SeitenAssessment of Dynamic Parameters of Heavy-Duty GearsMohammad HosseiniNoch keine Bewertungen

- Design and Clamping Force Analysis of Vacuum Fixture To Machine Aerospace ComponentsDokument6 SeitenDesign and Clamping Force Analysis of Vacuum Fixture To Machine Aerospace ComponentssaaNoch keine Bewertungen

- Analysis of Fatigue Characteristics of Gears Based On Ncode DesignlifeDokument6 SeitenAnalysis of Fatigue Characteristics of Gears Based On Ncode DesignlifeTUTUNoch keine Bewertungen

- Stress and displacement analysis of axial flow impulse turbine rotor bladeDokument8 SeitenStress and displacement analysis of axial flow impulse turbine rotor bladecena3135Noch keine Bewertungen

- Optimization of Engine Mounting Bracket Using FEA Mr. Pramod Walunje Prof. V.K. KurkuteDokument4 SeitenOptimization of Engine Mounting Bracket Using FEA Mr. Pramod Walunje Prof. V.K. KurkuteFabian CaizaNoch keine Bewertungen

- Design Sensitivity Analysis of Air-Lubricated Slider BearingsDokument3 SeitenDesign Sensitivity Analysis of Air-Lubricated Slider BearingsDeepak SharmaNoch keine Bewertungen

- Fatigue Life of A Mining Dump Truck...Dokument9 SeitenFatigue Life of A Mining Dump Truck...Esteban FaundezNoch keine Bewertungen

- Comparative Analysis of Vehicle Suspension System in Matlab-Simulink and Msc-Adams With The Help of Quarter Car ModelDokument8 SeitenComparative Analysis of Vehicle Suspension System in Matlab-Simulink and Msc-Adams With The Help of Quarter Car ModelHemanth KrishnaNoch keine Bewertungen

- Thesis On Fretting Fatigue in Railway AxlesDokument6 SeitenThesis On Fretting Fatigue in Railway Axlespamelasmithlittlerock100% (2)

- 05 Ijetmr19 A01 612 PDFDokument8 Seiten05 Ijetmr19 A01 612 PDFShahnewaz BhuiyanNoch keine Bewertungen

- Deformation Analysis of a 3-Axis Gantry System Using FEADokument4 SeitenDeformation Analysis of a 3-Axis Gantry System Using FEAŽan PjerNoch keine Bewertungen

- Abaqus Fem Analysis of The Postbuckling Behaviour of Composite PDF E1094Dokument4 SeitenAbaqus Fem Analysis of The Postbuckling Behaviour of Composite PDF E1094FabricioNoch keine Bewertungen

- Integrated Landing Gear System PDFDokument14 SeitenIntegrated Landing Gear System PDFMario Di PisaNoch keine Bewertungen

- 3-D Modelling AND Finite Element Analysis OF EOT Crane: Abhinay Suratkar, Vishal ShuklaDokument4 Seiten3-D Modelling AND Finite Element Analysis OF EOT Crane: Abhinay Suratkar, Vishal ShuklaNaresh DesaiNoch keine Bewertungen

- Weight Reduction of Planetary Gearbox Pedestal Using Finite Element AnalysisDokument4 SeitenWeight Reduction of Planetary Gearbox Pedestal Using Finite Element AnalysisPrabhakar PurushothamanNoch keine Bewertungen

- Point MobilityDokument10 SeitenPoint MobilityPadma JaNoch keine Bewertungen

- Me161011 Lab 4Dokument11 SeitenMe161011 Lab 4Muhammad HamzaNoch keine Bewertungen

- Fatigue Life Prediction For Automobile Coil Spring Using Modal AnalysisDokument6 SeitenFatigue Life Prediction For Automobile Coil Spring Using Modal Analysisvivashwanth paiNoch keine Bewertungen

- SM3357Dokument13 SeitenSM3357Glorius CarmenNoch keine Bewertungen

- 5.eng Design and Analysis of Helical Springs in Two Wheeler Suspension SystemDokument14 Seiten5.eng Design and Analysis of Helical Springs in Two Wheeler Suspension SystemImpact JournalsNoch keine Bewertungen

- Analysis of Flywheel: Akshay P. Punde, G.K.GattaniDokument3 SeitenAnalysis of Flywheel: Akshay P. Punde, G.K.GattaniKelsey RyanNoch keine Bewertungen

- Modeling of The Suspension of A Passenger Bus by Finite Element SoftwareDokument3 SeitenModeling of The Suspension of A Passenger Bus by Finite Element SoftwarePrasad KhatiNoch keine Bewertungen

- Matecconf Eureca2020 03001Dokument13 SeitenMatecconf Eureca2020 03001Putra JokoNoch keine Bewertungen

- Finite Element Analysis of Cylinder Piston Impact Based On ANSYS/LS-DYNADokument4 SeitenFinite Element Analysis of Cylinder Piston Impact Based On ANSYS/LS-DYNAAshutosh KumarNoch keine Bewertungen

- Stress Behaviour Improvement of Automobile Flywheel Under High Centrifugal ForcesDokument6 SeitenStress Behaviour Improvement of Automobile Flywheel Under High Centrifugal ForcesParag NaikNoch keine Bewertungen

- System Simulation of Belt ConveyorsDokument9 SeitenSystem Simulation of Belt Conveyorsharishkumar.ravichandranNoch keine Bewertungen

- Mathematical Modelling and Shape Optimisation of Front Damper Mount of Ashok Leyland 1612 Truck Using 3d Finite Element MethodDokument7 SeitenMathematical Modelling and Shape Optimisation of Front Damper Mount of Ashok Leyland 1612 Truck Using 3d Finite Element MethodtheijesNoch keine Bewertungen

- Static Analysis, Design Modification and Modal Analysis of Structural Chassis FrameDokument5 SeitenStatic Analysis, Design Modification and Modal Analysis of Structural Chassis FrameGopinath ChakrabortyNoch keine Bewertungen

- Ansys Analysis-Trolley Beam 3T1Dokument13 SeitenAnsys Analysis-Trolley Beam 3T1Ye Wint ThuNoch keine Bewertungen

- Journal-Analysis of Semi Circular-Arch Truses Using I-DeasDokument7 SeitenJournal-Analysis of Semi Circular-Arch Truses Using I-DeascurrjekNoch keine Bewertungen

- Design and Analysis of Twin Motor Planetary Gear Drive For Dual Speed and Safety Optimization in Hoist ApplicationDokument5 SeitenDesign and Analysis of Twin Motor Planetary Gear Drive For Dual Speed and Safety Optimization in Hoist ApplicationIJIRSTNoch keine Bewertungen

- Landing GearDokument12 SeitenLanding GearcmpmarinhoNoch keine Bewertungen

- Design and Analysis of Steering Knuckle 2019 PDFDokument9 SeitenDesign and Analysis of Steering Knuckle 2019 PDFsanjeev105Noch keine Bewertungen

- 5.accidental Car Impact Analysis and CFDDokument6 Seiten5.accidental Car Impact Analysis and CFDprojectzfourNoch keine Bewertungen

- Rotordynamic Design Optimization of A Steam Turbine Rotor Bearing SystemDokument72 SeitenRotordynamic Design Optimization of A Steam Turbine Rotor Bearing SystemTarkan KaragozNoch keine Bewertungen

- Optimization of Car Rim Using OptiStructDokument6 SeitenOptimization of Car Rim Using OptiStructsujaydsouza1987Noch keine Bewertungen

- Stress Distribution Analysis of Rear Axle Housing by Using Finite Elements AnalysisDokument10 SeitenStress Distribution Analysis of Rear Axle Housing by Using Finite Elements AnalysisrubantoNoch keine Bewertungen

- Analysis of Fly WheelDokument5 SeitenAnalysis of Fly Wheelfsilassie8012Noch keine Bewertungen

- Midas Civil - Analysis ReferenceDokument400 SeitenMidas Civil - Analysis ReferenceMohd FaizalNoch keine Bewertungen

- Fatigue Life of AA7075Dokument10 SeitenFatigue Life of AA7075Murali SiddarthNoch keine Bewertungen

- OSA Poster Design Improvement SigmaConsultancyDokument6 SeitenOSA Poster Design Improvement SigmaConsultancySanchit GuptaNoch keine Bewertungen

- Use and Benefits of Kinematics Inversion of Single Slider Mechanism A Review PaperDokument5 SeitenUse and Benefits of Kinematics Inversion of Single Slider Mechanism A Review PaperRockerss RockerssNoch keine Bewertungen

- Design, Analysis and Simulation of A Composite BulkheadDokument5 SeitenDesign, Analysis and Simulation of A Composite BulkheadThota Sri K HarithaNoch keine Bewertungen

- 8 Kamaland RahmanDokument11 Seiten8 Kamaland RahmanBinh NghiemNoch keine Bewertungen

- Dynamic Damage and FragmentationVon EverandDynamic Damage and FragmentationDavid Edward LambertNoch keine Bewertungen

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsVon EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNoch keine Bewertungen

- Luran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)Dokument3 SeitenLuran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)rosebifNoch keine Bewertungen

- Government Engineering College Surveying Lab ManualDokument26 SeitenGovernment Engineering College Surveying Lab ManualNittin BhagatNoch keine Bewertungen

- Sallyport MBI Bifold BrochureDokument6 SeitenSallyport MBI Bifold BrochureameraldaherNoch keine Bewertungen

- Excellent Hex Key Wrench: English VersionDokument54 SeitenExcellent Hex Key Wrench: English Versionmg pyaeNoch keine Bewertungen

- Lab Sheet - Infiltration TestDokument8 SeitenLab Sheet - Infiltration TestDINAMARIANASAMUJI0% (1)

- Zener DataDokument2 SeitenZener Dataapi-27149887Noch keine Bewertungen

- Asme B36.10M-2018Dokument36 SeitenAsme B36.10M-2018امينNoch keine Bewertungen

- 1855OME - Instruction Manual - Kinney Oil Mist EliminatorsDokument15 Seiten1855OME - Instruction Manual - Kinney Oil Mist EliminatorsahmedNoch keine Bewertungen

- TDS2000 Rig Systems DiagramsDokument13 SeitenTDS2000 Rig Systems DiagramsBaskar KannaiahNoch keine Bewertungen

- IEC CsODESDokument2 SeitenIEC CsODESArun KumarNoch keine Bewertungen

- Experion Scada PinDokument7 SeitenExperion Scada PinKhalid AliNoch keine Bewertungen

- Catalog Advantys AS-I IP20-IP67 - 803510 - DIA3ED2040909EN - 200408Dokument30 SeitenCatalog Advantys AS-I IP20-IP67 - 803510 - DIA3ED2040909EN - 200408Jean MarzanNoch keine Bewertungen

- Suvarnabhumi Airport Trial OperationDokument4 SeitenSuvarnabhumi Airport Trial Operationfwmching0% (1)

- Lab5 AnswerSheetDokument3 SeitenLab5 AnswerSheetnislam57Noch keine Bewertungen

- Switching Theory and Logic Design PDFDokument159 SeitenSwitching Theory and Logic Design PDFSai TejaswiniNoch keine Bewertungen

- Huawei EHuawei - Erelay - Solution - OverviewRelay Solution OverviewDokument31 SeitenHuawei EHuawei - Erelay - Solution - OverviewRelay Solution Overviewtariq8283% (6)

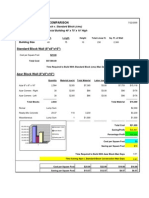

- AZAR Block CostcomparisonDokument8 SeitenAZAR Block CostcomparisontckittuNoch keine Bewertungen

- Assessment Clo1 Clo2 Clo3 Clo4 Clo5 Plo1 Plo2 Plo2 Plo1Dokument12 SeitenAssessment Clo1 Clo2 Clo3 Clo4 Clo5 Plo1 Plo2 Plo2 Plo1Ma Liu Hun VuiNoch keine Bewertungen

- Setting vpn1Dokument10 SeitenSetting vpn1Unink AanNoch keine Bewertungen

- 03.job Specification Instrumentaton PDFDokument27 Seiten03.job Specification Instrumentaton PDFshareyhouNoch keine Bewertungen

- XHLE Long Coupled Centrifugal Pump EnglishDokument8 SeitenXHLE Long Coupled Centrifugal Pump Englishgagi1994brahimNoch keine Bewertungen

- Saint Gobain - CertainTeed Roofing ShinglesDokument14 SeitenSaint Gobain - CertainTeed Roofing ShinglesJagriti KashyapNoch keine Bewertungen

- PVT Correlations McCain - ValkoDokument17 SeitenPVT Correlations McCain - ValkoAlejandra Maleja RivasNoch keine Bewertungen

- 2014 Solder Joint ReliabilityDokument18 Seiten2014 Solder Joint ReliabilitychoprahariNoch keine Bewertungen

- 01-01 Boltec S - SafetyDokument30 Seiten01-01 Boltec S - SafetyALVARO ANTONIO SILVA DELGADONoch keine Bewertungen

- Design of A Fluidized Drum GranulatorDokument6 SeitenDesign of A Fluidized Drum GranulatorditchcheNoch keine Bewertungen

- Online Institute Reporting Slip of The Application Number - 200310422837 PDFDokument1 SeiteOnline Institute Reporting Slip of The Application Number - 200310422837 PDFRohith RohanNoch keine Bewertungen

- RCC BEAM DESIGN AND SERVICEABILITYDokument15 SeitenRCC BEAM DESIGN AND SERVICEABILITYprashmceNoch keine Bewertungen

- Grounding and JumperingDokument16 SeitenGrounding and Jumperingferreiramarco56Noch keine Bewertungen