Beruflich Dokumente

Kultur Dokumente

Tull Ahoma

Hochgeladen von

LTE002Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tull Ahoma

Hochgeladen von

LTE002Copyright:

Verfügbare Formate

Tullahoma, Tennessee Wastewater Treatment Plant

Introduction The first US large scale continuous influent, intermittent discharge variant of a Sequencing Batch Reactor wastewater treatment plant was installed in Tullahoma, Tennessee in 1985 under an Environmental Protection Agency, Innovative and Alternative Technology Grant. Process Evaluation In the late 1970s, the old Tullahoma treatment plant, which was built in 1955, was overloaded and deteriorating. The City of Tullahoma and their consultants, Barge, Waggoner, Summer and Cannon began an extensive evaluation of different treatment options for the new plant. The options evaluated were the Oxidation Ditch, In-Channel Clarifiers and the ABJ ICEAS Process. A value engineering team closely examined factors other than initial capital and operating costs, including reliability of the treatment process, degree of operational difficulty, availability of land and system footprint existing appurtenances and aesthetic considerations. As part of the evaluation, City and State officials visited Australia to see five existing ABJ ICEAS facilities and receive an objective evaluation from ICEAS plant operators and Australian government officials. During the trip, the Tennessee officials were particularly impressed by the ability of the ICEAS to accommodate widely fluctuating infiltration loads without effluent degradation. The ABJ ICEAS process was selected by the City of Tullahoma, TN and their consultants, Barge, Waggoner, Summer and Cannon as the most cost-effective wastewater treatment alternative. The ICEAS Process Developed in Australia in 1975, the ICEAS process is a continuous flow hybrid of the conventional fill and draw SBR. Unlike the conventional SBR, which discontinues flow during the settle and decant phase, raw wastewater is continuously fed into the ICEAS basin during all phases of the cycle. Short circuiting, during the decant period is prevented through the use of a baffled, pre-react wall. The continuous flow feature of the ABJ ICEAS process typically results in a basin volume that is 25-30 percent less than that required by a conventional SBR.

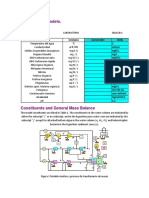

The ICEAS process accomplishes the tasks of biological oxidation, nitrification, denitrification, phosphorous release and uptake and solid/liquid separation continuously, in a single basin. The time-based operation of the ICEAS cycle is controlled automatically through a microprocessor. A typical cycle consists of three basic phases: aeration, settling and decant. In certain applications, intermittent periods of aeration and anoxic mixing are combined to promote biological nutrient removal. During the decant period of the ABJ ICEAS cycle, the top layer of clarified water is discharged through the use of a simple controlled weir type decanter. The entirely stainless steel ABJ decanter requires no valves. All flow from the ICEAS basin occurs by gravity. A pivoting scum float prevents any scum or floatables from being decanted with the treated water. The ICEAS process, though conceptually sophisticated, is simple and elegant in operation. The system uses a minimum of moving or powered components. Tullahoma Design The ICEAS facility at the Tullahoma, TN WWTP was designed according to the following parameters: Influent Conditions Average Daily Flow (Summer) 3.0 mgd Peak Daily Flow (Winter) 6.0 mgd Peak Storm Flow 9.0 mgd Super Storm Flow 12.0 mgd 220 mg/l BOD5 TSS 190 mg/l 35 mg/l NH3-N Effluent Requirements BOD5 TSS NH3-N ICEAS Process Design Criteria F:M SVI Normal Cycle Time Storm Cycle Time Super Storm Number of ICEAS Basins Basin Length Basin Width Top Water Level Summer 20 mg/l 20 mg/l 2.5 mg/l Winter 30 mg/l 30 mg/l 10 mg/l

0.08 lb./ BOD/lb. MLSS/day 150 mg/gm 4 hours 3 hours 100 minutes 2 146 ft. 177 ft. 16 ft.

The Tullahoma plant, constructed in 1985, consisted of a mechanically cleaned bar screen, tangential inflow grit chamber with classifier/screw conveyor, pump station, influent divider, two ICEAS basins, chlorination/dechlorination facilities, cascade aeration and sludge thickening/holding facilities. Plant Star-Up and Initial Operation Plant operation began in August 1985. Before construction began, the city realized they had a severe I & I problem. By the time the new plant was commissioned, they had achieved limited success with their I & I reduction program. Additionally, the BOD load to the plant was higher than anticipated. With highly variable organic loading, due to discharge received from two local tanneries and an electroplating plant, influent BOD concentrations ranged form 150 700 mg/l. In the early days, BOD peaks reached 1,100 mg/l.

Despite these unexpected hurdles, the effluent BOD and TSS criteria were met within 20 days of start-up. Nitrification proceeded a bit more slowly as the plant was not seeded. By January 1986, full nitrification was being accomplished on a daily basis. Plant Upgrade From nearly the day of start-up, the Tullahoma WWTP performed exceptionally well, never exceeding permit requirements, while operating within and even up to 30 percent higher than its design flow capacity. In fact, due to the high I & I, it was not uncommon for the plant to receive peak flows in excess of 20 mgd. During a period spanning from 1993-1995, the city of Tullahoma expanded and upgraded their wastewater treatment plant to allow processing of the high storm flows, along with some additional upgrading. The upgrade included additional piping and a new computer system with a SCADA package, larger headworks, including a new bar screen and grit chamber, the addition of two 30 mgd screw pumps, addition of a pre-aeration basin, a new 48 million gallon equalization basin and upgrade of the chlorine disinfection system. Under the new plant configuration, flows up to 15 mgd are received directly by the ICEAS basin. Flows in excess of 15 mgd are diverted to the equalization basin. Another large part of the plant upgrade involved retrofit of the original jet aeration system with a high efficiency SANITAIRE fine bubble membrane grid aeration system, in the interest of energy savings. As a result of the aeration retrofit, the large jet pumps required by the jet system were eliminated. The elimination of the jet pumps reduced maintenance costs and saved over 3000 kWh/day in power costs. Power costs were also reduced due to the jet aeration blowers being replaced with smaller blowers due to the lower air requirement of the fine bubble system. On-Going Operation Since its start-up in 1985, the Tullahoma, TN WWTP has never been out of compliance. The plant typically produces an ultra high quality effluent with single digit effluent BOD5 and TSS concentrations and effluent NH3-N concentration less than 1 mg/l. The Tullahoma, TN WWTP was the first plant in the US to use the ICEAS process. Currently, there are over 200 ICEAS facilities operating in the US and over 400 installations operating throughout the world. Tullahoma, TN is not only the oldest ABJ ICEAS installation, but also after nearly 15 years of operation, a showcase facility. The plant is a true testimony to the effectiveness of the ABJ ICEAS process and dedicated operators.

ABJ ICEAS reactor with SANITAIRE fine bubble membrane diffuser system replaced jet aeration system.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- ZH - 2005 RCDokument99 SeitenZH - 2005 RCLTE002Noch keine Bewertungen

- High PerformanceDokument3 SeitenHigh PerformanceLTE002Noch keine Bewertungen

- Soil WashingDokument19 SeitenSoil WashingLTE002Noch keine Bewertungen

- Cal Methodology - Energy Saving - Electrical - HouseholdDokument15 SeitenCal Methodology - Energy Saving - Electrical - HouseholdLTE002Noch keine Bewertungen

- Biomass To Ethanol ProcessDokument132 SeitenBiomass To Ethanol ProcessLTE002Noch keine Bewertungen

- Simulation of High-Speed FillingDokument13 SeitenSimulation of High-Speed FillingLTE002Noch keine Bewertungen

- Trigger Sprayer Dynamic Systems ModelDokument5 SeitenTrigger Sprayer Dynamic Systems ModelLTE002Noch keine Bewertungen

- Paper - 5 Noise MinimizationDokument5 SeitenPaper - 5 Noise MinimizationLTE002Noch keine Bewertungen

- 49 Structure Porosity of Flocculated ADDokument8 Seiten49 Structure Porosity of Flocculated ADLTE002Noch keine Bewertungen

- Paper - 84 Magnetic FormingDokument8 SeitenPaper - 84 Magnetic FormingLTE002Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ALPEMA Responses To Requirements in API 668 Feb2022Dokument4 SeitenALPEMA Responses To Requirements in API 668 Feb2022TreeNoch keine Bewertungen

- Kivul Oya Reservoir Project ECBADokument32 SeitenKivul Oya Reservoir Project ECBAVijaykanth ViveNoch keine Bewertungen

- Agua Ing PDFDokument29 SeitenAgua Ing PDFbenabdallah131Noch keine Bewertungen

- Iron in Cereal: Separation of MixturesDokument2 SeitenIron in Cereal: Separation of MixturesliebofreakNoch keine Bewertungen

- A New Scheme For Ammonia and Fertilizer GenerationDokument14 SeitenA New Scheme For Ammonia and Fertilizer GenerationChiaoNoch keine Bewertungen

- Steam Cleaner Ks Professional Line OdontosteamDokument4 SeitenSteam Cleaner Ks Professional Line OdontosteamEhab AlzabtNoch keine Bewertungen

- Material and Energy BalanceDokument26 SeitenMaterial and Energy Balancem9m2070Noch keine Bewertungen

- Appendix Sizing The Building Water Supply and Distribution Piping SystemsDokument36 SeitenAppendix Sizing The Building Water Supply and Distribution Piping SystemsMahmood BadawiNoch keine Bewertungen

- Polycold Edwards Data Sheet Maxcool 4000HDokument2 SeitenPolycold Edwards Data Sheet Maxcool 4000HadrianioantomaNoch keine Bewertungen

- Plumbing Key AnswerDokument7 SeitenPlumbing Key AnswerStanley Scott ArroyoNoch keine Bewertungen

- Metroplex Resolution On ALCO/Mohawk Harbor Redevelopment ProjectDokument118 SeitenMetroplex Resolution On ALCO/Mohawk Harbor Redevelopment ProjectAndrew PuglieseNoch keine Bewertungen

- Samsung Rt78ctbww User ManualDokument48 SeitenSamsung Rt78ctbww User Manualmerna atefNoch keine Bewertungen

- Best Articles Ever - Want To Know - Complete Archive - News Articles-3,950Dokument3.950 SeitenBest Articles Ever - Want To Know - Complete Archive - News Articles-3,950Keith KnightNoch keine Bewertungen

- Datos para El Modelo.: Determinantes UnidadesDokument8 SeitenDatos para El Modelo.: Determinantes UnidadesVaNe Arzayus TrujilloNoch keine Bewertungen

- Sodium Arsenite, Powder MSDS: Section 1: Chemical Product and Company IdentificationDokument6 SeitenSodium Arsenite, Powder MSDS: Section 1: Chemical Product and Company IdentificationNur ChayatiNoch keine Bewertungen

- Big Performance! The New Range of Kärcher Pumps.: Professional Pump Systems For The House and GardenDokument28 SeitenBig Performance! The New Range of Kärcher Pumps.: Professional Pump Systems For The House and GardenAromaBox AromakozmetikaNoch keine Bewertungen

- Civil Engineering and Environmental ScienceDokument2 SeitenCivil Engineering and Environmental ScienceNyel SaduesteNoch keine Bewertungen

- Emalex 602: Safety Data SheetDokument6 SeitenEmalex 602: Safety Data SheetShahbaz QureshiNoch keine Bewertungen

- SWOT Analysis: SWOT Analysis of Pakistan With Respect To Energy Sector 1. Strengths of Energy SectorDokument4 SeitenSWOT Analysis: SWOT Analysis of Pakistan With Respect To Energy Sector 1. Strengths of Energy SectorSumra MaqboolNoch keine Bewertungen

- JU-001-04-0222-0000-00-1C-0001 - WBS Mina JustaDokument15 SeitenJU-001-04-0222-0000-00-1C-0001 - WBS Mina JustaAzul BlueNoch keine Bewertungen

- Design and Fabrication of Pressing Steam Boiler PDFDokument14 SeitenDesign and Fabrication of Pressing Steam Boiler PDFAjil XavierNoch keine Bewertungen

- Portofolio Bahasa Inggris: Disusun Oleh: Gigih Satria Pradana Xii Ips 1 0030551620 / 20231339Dokument18 SeitenPortofolio Bahasa Inggris: Disusun Oleh: Gigih Satria Pradana Xii Ips 1 0030551620 / 20231339Hanan Halim AbdullahNoch keine Bewertungen

- Mobil 600 W Super Cylinder OilDokument10 SeitenMobil 600 W Super Cylinder Oilluis carlos Mendoza AriasNoch keine Bewertungen

- Physics PressureDokument35 SeitenPhysics Pressuresai yadaNoch keine Bewertungen

- Aashto T-85Dokument6 SeitenAashto T-85kampNoch keine Bewertungen

- Pro II SimulationDokument5 SeitenPro II Simulationrasnowmah2012Noch keine Bewertungen

- Rainwater Harvesting 101 - Your How-To Collect Rainwater GuideDokument13 SeitenRainwater Harvesting 101 - Your How-To Collect Rainwater GuideNitheesh KumarNoch keine Bewertungen

- Peigao Duan, Xiujun Bai, Yuping Xu, Aiyun Zhang, Feng Wang, Lei Zhang, Juan MiaoDokument9 SeitenPeigao Duan, Xiujun Bai, Yuping Xu, Aiyun Zhang, Feng Wang, Lei Zhang, Juan MiaoyemresimsekNoch keine Bewertungen

- Water Supply and Distribution System in The PhilippineDokument5 SeitenWater Supply and Distribution System in The PhilippineJea May CallejoNoch keine Bewertungen

- Section A: Reading Read The Following Texts Carefully and Then Answer Section A in The Question Paper. Text 1: Ice Swimming in TromsøDokument5 SeitenSection A: Reading Read The Following Texts Carefully and Then Answer Section A in The Question Paper. Text 1: Ice Swimming in TromsøAdrielle DeenNoch keine Bewertungen