Beruflich Dokumente

Kultur Dokumente

AcousticEye G3 - User Manual - V6 PDF

Hochgeladen von

Dan-jones TudziOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AcousticEye G3 - User Manual - V6 PDF

Hochgeladen von

Dan-jones TudziCopyright:

Verfügbare Formate

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

AcousticEye Dolphin G3 Tube Inspection System USER MANUAL

This manual applies to a complete testing system comprised of a Main Control and Analysis unit (AEMUN-30000) and an Acoustic Probe (AEPRB-30000)

CE Authorised Representative: Acoustic Eye International Attn: Gijs Cremer Eindhoven Mail address: PO Box 205 3830 AE Leusden, The Netherlands Visit address: Arnhemseweg 87 Leusden, The Netherlands Telephone: +31 33 4453114

-1-

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Revisions Record Rev. 1 2 3 4 5 6 Description of Change Initial release Add calibration tube Change CE authorized rep. Version 3.3 Release Minor changes Version 3.4 Release Revision Date 24-03-11 12-05-11 10-08-11 05-12-11 21-02-12 6-06-12 Revised By Roy Shtainman Roy Shtainman Roy Shtainman Roy Shtainman Roy Shtainman Roy Shtainman

Created By:

Roy Shtainman Willy Grunfeld

Tech Support Manager Quality Manager

15-Mar-11

Reviewed By:

24-March-11

-2-

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Table of Contents 1

1.1 1.2 1.3

INTRODUCTION .................................................................................................................... - 4 SCOPE ....................................................................................................................................... - 4 INTENDED USE ........................................................................................................................... - 4 ENCLOSURE ................................................................................................................................ - 4 -

2

2.1 2.2

TEST SYSTEM COMPONENTS. ........................................................................................... - 5 MAIN MEASUREMENT AND TEST UNIT .......................................................................................... - 5 OPERATOR INTERFACE ................................................................................................................ - 5 -

3

1.3

POWER CONSUMPTION ....................................................................................................... - 6 OVERVOLTAGE CONDITIONS ........................................................................................................ - 6 -

4

4.1 4.2

PHYSICAL AND ENVIRONMENTAL CHARACTERISTICS ............................................ - 6 DIMENSIONS AND WEIGHT ........................................................................................................... - 6 EQUIPMENT SPECIFICATIONS ...................................................................................................... - 7 -

5

5.1 5.2 5.3 5.4

QUICK START GUIDE ........................................................................................................... - 9 REMOVING EQUIPMENT FROM THE CARRYING CASE, SET-UP ......................................................... - 9 ATTACHING A TUBE ADAPTER TIP TO THE PROBE......................................................................... - 11 CONNECTING TO A POWER OUTLET ............................................................................................ - 17 TURNING THE SYSTEM ON .......................................................................................................... - 18 -

6

6.1 6.2 6.3 6.4 6.5

OPERATION INSTRUCTIONS ............................................................................................ - 20 PROBE LEDS ............................................................................................................................ - 20 PRELIMINARY TESTS .................................................................................................................. - 22 SETUP PRE MEASUREMENT ..................................................................................................... - 32 MEASUREMENT ......................................................................................................................... - 60 REPORT POST MEASUREMENT ................................................................................................. - 64 -

APPENDIX I PACKAGING INSTRUCTIONS, CABLE ARRANGEMENT ........................ - 77 APPENDIX II INSTRUCTIONS FOR ASSEMBLING EXTERNAL SEALING SPONGE ON ADAPTORS. ............................................................................................................. - 81 APPENDIX III MISCELLANEUOS ........................................................................................... - 87 APPENDIX IV PC HW BUTTONS ............................................................................................. - 87 APPENDIX V PROBE SCREEN NOTOFICATIONS .............................................................. - 87 APPENDIX VI SPECIFICATIONS AND STANDARDS ......................................................... - 87 -3-

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Introduction

1.1 Scope

This manual provides the specifications and instructions for the safe and effective operation of Acousticeyes Dolphin G3 Tube Inspection System, a NDT testing and evaluation solution for tubular systems using Acousticeyes proprietary Acoustic Pulse Reflectometry (APR) technology . The system consists of a main measurement and control unit referred to as the MCU, a hand-held measurement probe referred to as Dolphin Probe and a calibration tube. While it covers basic instructions for performing tests and generating a basic test report, it is intended to be used primarily as an installation and operation instructions manual, not a substitute for the operators training course offered by Acousticeye. This training offered by Acousticeye provides the skill and know-how necessary for analyzing and interpreting the data obtained from measurements and for obtaining the best possible assessment of the condition of the target tubing system. Note: Screen shots provided in this manual are based on version 3.0 of the application software (PTS) and may differ slightly from the actual screen shots in your particular version.

1.2

Intended Use

The system is designed for on-site inspection and evaluation of faults such as holes, pits, erosion, partial blockages etc. in tubular systems (material independent), in process industries such as power plants, refineries and the like, by means of the injection of acoustic pulses through one open end of the tube under test, and analysis of the reflected waves.

1.3 Enclosure

The test set is enclosed in one carrying case which provides protection for the contained system components during air and ground transportation, storage and handling. For operation the system components are removed from their carrying case (Refer to section 5) -4-

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Test System components.

2.1 Main Measurement , Test Unit and Calibration Tube

The main unit is contained within a metal enclosure with a removable top panel and contains the following main components: iEi Panel PC industrial computer iEi Lithium Battery Pack (BAT-LI-4S2P3800A) Rating: 14,8V DC, 3800 mAh, Maximum Charging Voltage/Current 16.8Vdc/2000mA

Amplifier Maya sound card

Dolphin Probe A formed plastic housing containing: Microphone Speaker LCD screen

Calibration tube: A 1.5 meter in length, faultless and plugged aluminum tube.

2.2 Operator interface

The operator interfaces with the tester primarily through the computer and specifically its GUI (Graphic User Interface), an integral part of the operation software. Hardware interfaces consist of a push button switch and 4 indicator LEDs located on the probe handle. The push button switch initiates the test by generating the acoustic wave and capturing of the reflected signals. The LED functions are as follows: -5-

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Blue: Ready for taking a measurement (or step to the next measurement) Yellow: Measurement in process Red: Last measurement was not taken properly probably due to a sealing problem. If applicable please repeat the measurement. There is also an indication on the SW interface. Green: Last measurement was taken properly.

Power consumption

Installation category II, IEC 60364-4-443 Power Input: Dual voltage system (110V/220V).

3.1 Overvoltage conditions

Overvoltage Category II type of supply for connection of equipment

4

4.1

Physical and Environmental characteristics Dimensions and weight Weight: Gross (In carrying case/trolley) MCU Probe: 18 kg (39.7 lbs) Net (Removed from carrying case) 8kg 1kg

4.1.1

4.1.2

Dimensions

Trolley: 56 x 45.5 x 26.5 cm The trolley incorporates built in wheels and 2 handles, one for lifting and another for pulling, to enhance portability and handling. 4.1.3 Accessory stowage The carrying case (trolley) has provisions for the stowage of all the accessories. -6-

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

These are designed to prevent damage to the accessories and probe during transit. 4.2 Equipment Specifications

# 1.

Specification Overall size (L x W x H)

Spec Limits 33 x 28 x 14 cm (MCU) 25 x 14 x 12 cm (probe)

Tested to

Comments

Size of carrying case

56 x 45.5 x 26.5 cm

Weight :

8kg (MCU) 1 kg (probe) 18 kg (Inside carrying case) MIL-PRF-28822, Procedure: 4.5.5.1.1 for Class 2

2.

Temperature, Operating Temperature, Storage

-100C to +500 -200C to +700 RH: up to 95%

3.

Humidity

MIL-PRF-28822, Procedure 4.5.5.1.1.2 MIL-PRF-28822, Procedure 4.5.5.2

4.

Altitude Operating: Altitude nonoperating:

0 to 4000m (03123feet) 0 to 10000m (0-32800 feet) IPX0

5.

Ingress

IEC 60529 -7-

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Specification Protection Enclosed in carrying case

Spec Limits IP67 (1 meter) submersion for 30 minutes) Class 2 :15-55 Hz. 15 min./axis cycling+10 min. dwell@ resonance frequency (or 33 Hz if no resonance found) for each of the 3 axis Drop height of 30 cms on each of the 6 faces and 4 corners for a total of 10 drops. N/A

Tested to

Comments

6.

Sinusoidal Vibration/ Transportability

MIL-PRF-28822 , 4.5.5.3.2 for Class 2

In carrying case

7.

Transit drop test

MIL-PRF-28822, 4.5.5.4.2 for Class 2, MIL-PRF-28822, Procedure 4.5.6.3 CISPR 11, CLASS 1 IEC 6100-3-2 , 3-3,4-2 , -4-3,-4-4, -4-5, -4-6 & -4-11 FCC Part 15, Subpart B, CLASS A

In carrying case

8. 9.

Explosive Atmosphere EMC

Detailed in Test Report EN 61326-1

10.

SAFETY

Detailed in Test Report EN 61010-1:01 IEC 61010 UL 61010-1 CSA C22.2 610101-04+GI1

Safety evaluated to +40 0 C max. ambient

-8-

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

5 5.1

Quick Start Guide Removing equipment from the carrying case, set-up

Open the carrying case and remove the main unit.

Fig. 1

-9-

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Fig. 2

Fig. 3

Place the main unit on a suitable workbench or table top. In case no suitable table is available, place the main unit on the carrying case. - 12 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

5.2

Attaching a tube adapter tip to the probe

The probe mechanically interfaces with the inspected tube by means of an adapter and a rubber sponge seal. According to the tubes to be inspected, select an adapter that matches the tubes diameter. Please use the get recommended adaptor wizard on the SW after inserting the inspected tube OD and wall thickness the application recommends the most fitted adaptor to be used can be identified by code: -RDP (Regular Diameter Probe): - Type AXX - cylindrical adaptors. - Type BXX - conical adaptors with perforated tips. -LDP (Large Diameter Probe): Type LDP_XXX Note: It is important to use only adapters and seals supplied by AcousticEye. See instructions for attaching the rubber sponge to the adapter in Appendix II. In order to choose the right adapter make sure that the adapters OD is a bit smaller then the measured tube ID.

- 11 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Attaching an adaptor to a RDP Probe:

Fig. 4

Fig. 5

- 12 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Fig. 6

Fig. 7

Fig. 8

- 13 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Attaching an adaptor to a LDP Probe:

Fig. 7a

Fig. 8a

- 14 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Fig. 9a

Fig. 7a

- 15 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Connect the probe to the main unit panel. Connect the probe cable to the probe. Pay attention to the connector orientation.

Fig. 9

Connect the other end of the cable to the main unit.

Fig. 10

- 16 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

5.3

Connecting to a power outlet

Connect the power cord to the top panel of the main unit (next to the ON/OFF switch) See Fig. 11.

Fig. 11

Connect the power cord to the mains (Its important to ensure proper grounding!)

Fig. 12

- 17 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

5.4

Turning the system on

Switch on the main unit power switch located on the upper panel

Fig. 13

- 18 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Launching the software Double click on the PTS icon located on the desktop using the supplied stylus.

Fig. 14

Make sure that the status line indicates that the software is ready (Fig 12A)

Fig 14A

- 19 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Operation Instructions

6.1.1 Probe LEDs

During system initialization, all the 4 LEDs at the back of the probe are turned on. A blue LED light on the gauge indicates that the initialization is over and the system is ready to take measurements.

Fig. 15

Notes about functions of the probe controls and indicators: The lower button initiates a measurement The upper button skips a tube (can be used in case of a plugged tube for example) and it increases the measurement counter by 1, all 4 LEDs flicker once when applied. - 22 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

LED colors and their meaning: o BLUE: software is ready, press button at will o YELLOW: measurement in course, dont move o RED: Last measurement was not taken properly probably due to a sealing problem. If applicable please repeat the measurement (after deleting last measurement and reducing the counter). There is also an indication on the SW interface. o GREEN: Last measurement was taken properly.

6.1.2 Initial Templates

Upon initialization or when a new session is created, the user is prompted to choose a session template. The available templates are: Regular Diameter Probe - Standard Measurement Tube dimensions: 5/16 to 1.5 Tube length: Over 6 meters. Regular Diameter Probe - Short Measurement Tube dimensions: 5/16 to 1.5 Tube length: Up to 6 meters. Large Diameter Probe - Standard Measurement Tube dimensions: 1.5 to 4 Tube length: No limitation

- 21 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.2 Preliminary Tests 6.2.1 Perform Hardware Test

In order to verify the system functionality, perform one test measurement in the air by clicking in the upper menu: Advanced -> Perform Hardware test.

Verify that you can hear the sound wave and that the test result was positive. In case the HW test failed

Try restarting the system. If the problem persists Dont use the system and contact AcousticEye Support promptly.

- 22 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.2.2 Perform Calibration Verification

The second part of the inspection preliminary tests is verifying the probe calibration. This test should be performed following a successful Hardware test. The test is performed using the supplied calibration tube a 1.5 meter in length, Faultless and plugged from one side, aluminum tube. The non-plugged side has an interface to the system probe. This test verifies the probe calibration and if needed recalibrates it. This procedure must be performed on site before conducting any inspection session. Its recommended to climate the probe to the site environmental conditions 1 hour before performing the calibration (due to temperature changes between storing to operating locations). Connecting the calibration tube RDP: Open the probe bolt.

Fig. 16

- 23 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Fig. 17

Take off the probe membrane

Fig. 18

- 24 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Fig. 19

Attach the calibration tube to the probe (note the tube end orientation).

Fig. 20

- 25 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Connecting the calibration tube LDP: Take off the probe membrane

Fig. 16a

Fig. 17a

- 26 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Attach the calibration tube to the probe (note the tube end orientation).

Fig. 18a

- 27 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Back on the PTS application; go to Advanced->Probe->Probe Calibration

A note will be displayed

The procedure status is displayed at the bottom left status bar

- 28 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

When done a completion note will be displayed

In case the probe calibration fails: a. Verify that the calibration tube is attached properly to the probe. b. Quiet any external noise or vibration sources. c. Repeat the calibration process. d. If fails again, Restart the main unit. e. Place the probe and the calibration tube tip on a soft (shock observing) ground f. Repeat the calibration process.

- 29 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Disconnect the calibration tube from the probe.

Dont forget to reinstall the probe membrane.

- 32 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

The Set-up, Measuring and Report Workflow The PTS application is operated by means of the three main tabs and applicable sub-tabs described below. Main Tabs a) Setup for the pre-measurement steps. b) Measurement for taking measurements. c) Report for the post measurement analysis and report generation The basic workflow is to go through the tabs from left to right start with the main tab on the left (setup), go over all its sub tabs from left to right. When finished, move to the next main tab Measurement.

- 31 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.3 Setup Pre measurement

6.3.1 Tube sheet map creation In the PTS application there are several methods of creating a tube sheet map and choosing the tube ordering. Here is a description of the most common method using a digital photo: Take a digital photo of the measured equipment and place it on the systems computer. TIPS FOR TAKING PICTURES OF TUBE SHEETS Use a good quality camera, having at least 5 mega pixels resolution with optical zoom capabilities Use flash photography under all circumstances, even at full sunlight, unless there are safety limitations. Position the camera in front of the tube sheet, holding the camera centered (in line with the tube sheet center) The distance between the camera and the tube sheet should be at least 45 times the diameter of the tube sheet. Make sure that most of the picture frame is occupied by the tube sheet. Come closer to the tube sheet or use optical zoom if necessary to achieve that goal.

Open the Map builder sub application

Go to file->New

- 32 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Double click on the path at the Picture File Name field to open a browse window. Navigate to the image taken, open it, and then double click on the Create Map button. The equipments photos will be shown on screen.

- 33 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

There are 2 ways of performing the tubes detection on the digital image manually or automatically. 6.3.1.1 Manual tube detection on the MapBuilder Check the add button at the bottom left corner. Then start clicking on the tubes, according to the tube ordering you want to use. Note: The circle size can be adjusted by changing the value of the Radius field, right to the Mode field. To delete or select a certain tube use the Delete/Add/Select menu at the Mode field. To zoom in or out, use the keyboard +/- keys or the mouse scroll wheel. To move the picture, use the arrow keys.

After the tube map is ready, choose file->save to custom, then choose a map name.

- 34 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Close the Map builder application. The tube map is set.

- 35 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.3.1.2 Automatic tube detection on the MapBuilder While preparing a map in Map Builder, it is possible to automatically detect the tubes holes in the map, without clicking on them one by one: Load the equipment map Choose the Path selection mode:

On the top menu, click Tube detection -> Custom

- 36 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Click on the map to create a region of interest for the searching process.

- 37 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Click on the Set button in Region of interest Zoom in onto the map, and select 2 points on the diameter of some tube.

- 38 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Click on the Set button in Diameter Click Search

- 39 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Note: if a message that there is not enough memory for the operation is displayed, try selecting smaller portions of the map at a time, until the map is completed The Search further button can be clicked to perform a deeper search. Remaining tubes may be filled in manually by changing the Mode at the lef tbottom part of the screen to Add, and changing the selection mode to Rectangle by right clicking on the map, and choosing Selection type - > Rectangle Note: The tube radius may be changed to see if the tubes are obscuring some suspicious area. Note: Using the Tube detection mechanism obliges the use of Tube Ordering (Row-Column-Zone ordering) before saving the map.

- 42 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.3.2 Row Column Zone Annotation 6.3.2.1 Row Column Zone Support - Map Builder After building the tubes map, the tubes can be ordered by rows, columns and zones. There are 2 methods to set Row Column Zone info for a given picture: A) Automatic B) Manual 6.3.2.1.1 Automatic In the top menu, click Tube ordering -> Custom

For regular maps as the above one, using the Automatic tube ordering should be enough. By looking at the above map, the user can see that it is best to divide it by Columns (vertical), so the Advance at angle by parameter should be set to columns as well as the colorized by parameter.

- 41 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Mark the first tube (the tube you want to define as (0,0)) and press set. The first tube ID box should be filled in with a number.

- 42 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Select two adjacent tubes (select the second one by pressing and holding the ctrl button). Then press the set button. A number representing an angle should appear in the angle box.

- 43 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Press the apply button. The presented coloring help verify that the ordering was done properly. Zoom in the better verify it. Once done, go to file->save to custom, and specify a name for the map.

- 44 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Note: If the tube set in First tube ID is not located in one of the maps corners, the program will display a message and select on the map the tubes that can be set as the first tube.

- 45 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.3.2.1.2 Manual If the Automatic method didnt provide the desired results, the Row Column Zone properties can be set using the Manual method.

For example, in the following map, select the first column, then in the bottom Orientation panel set the C field to 1, select the desired starting point (Top at the above example) and click Apply. To determine the coloring orientation, on the top menu, click Tube ordering -> Custom and set the Colorize by parameter. By leaving the R field empty, the user indicates to the software to automatically fill in the R values into the selected tubes. After setting the first column, select the second column, set the C field to 2 and click Apply. - 46 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Repeat the procedure for the entire map. If the map is at a certain angle, the tubes for each row or column can be chosen by the Path selection mode.

- 47 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Then click several times to bound the desired Row or column:

- 48 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Then right click again and choose Select from path

- 49 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Once the user has selected the desired column, he can click Apply and repeat the action for the remaining columns. Note: To set different zones to the map, select the tubes at the needed zone, clear the R, C fields, set the Z value, and click Apply

Once done, go to file->save to custom, and specify a name for the map.

- 52 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.3.2.2 Row Column Zone Support PTS

PTS supports Row Column Zone tube identifiers. If a user wishes to work without Row-Col-Zone, he can only use the R ( row ) values, by right clicking on the ,measurements list and choosing Measurement name format

- 51 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

The N value at the 2D map tube drawings represents the order by which the tubes need to be measured. This order will change if the user changes the Advance by field at Measurements name control panel. The Advance by field at Measurements name control panel will also determine the way that the defect tables and measurement list are sorted. As always, there is a backward compatibility which means PTS can load older sessions. The user can also use the D field (Description) to type free text at certain measurements. By selecting tubes in the 2D map, the corresponding tubes in the measurement list will be selected. If tubes selected in the 2D map dont exist in the measurement list, they will be immediately unselected. By clicking on a single tube in the 2D map, the tube Zone-Row-Column information will be set at the Measurement name control panel. An existing measurement can be renamed by right clicking on it and selecting Rename. The Zone-Row-Column-Description info in the Measurement name control will be set in the measurements name. After the map is finalized, use file->save to custom in order to save the map to the main application. Close the map builder.

- 52 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Back on the main application, the first step is to open a new session and to name it. Go to file->new and then file->save as; choose a unique name and location for this session. Note: The measurements are saved automatically to the hard-drive as they are taken (no data is lost due to a crash/outage problem). By default all measurements are saved to a temporary directory on disk as they are made Path\TempDir_XX In order to avoid overwriting this temporary directory use the Rename or the Save As options. The Save As button can be used to make a copy of the measurements, but will entail copying large amounts of data to the new directory, cluttering the disk and taking some time to execute.

- 53 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.3.3 Setting the tube map Go to Setup tab, then Map sub tab. Under Facilities drop down menu, choose custom. Then at the System Type drop down menu, choose the map you have created. Click the Apply bottom. Note: To Zoom in/out or move the map use the relevant keyboard keys.

Other mapping options will be introduced in the hands-on training part of the course.

- 54 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.3.4 Setting up tube parameters Go to the Parameters sub tab. Insert the temperature, tube length, outer diameter, wall thickness and probe adaptor code in the corresponding fields. Note: - Pay close attention to the units in each parameter. - The unit type (metric/US) can be changed using the preferences->units in the menu bar. - When moving to the measurement tab for the first time, the system will ask you to fill in the 5 parameters mentioned above. Filling in these parameters correctly is crucial for proper system performance. These parameters affect the final analysis (report generation). However, they dont affect the raw data acquisition meaning that in order to perform a measurement you can insert dummy values, but before generating a report you must insert the parameters accurately. The tube length should be taken from the measurements signals after finishing the job, go to report->signals, right click ->select all measurements. The average tube length is the one you should use. When inspecting U-Tubes set the U-Tubes parameter to yes.

- Checking the show advanced box, opens a list of all the advanced parameters. Dont change those values without consulting with AcousticEye support first! - Restoring the parameters list (both basic and advanced) to its default values, can be done by choosing Advanced-> Database -> Restore default values, in the upper menu.

- 55 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.3.4.1 Choosing the proper adaptor The application has a wizard that assist the user in choosing the proper adaptor. After inserting the tube OD and Wall Thickness, choose the Get recommended adaptor button. The system will suggest the proper adaptor code to be picked from the system set.

- 56 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.3.4.2 Measuring the inspection temperature Since the speed of sound is affected by the air temperature inside the tube, it is important to measure and update it on the software. Measuring the temperature inside the tube can be performed simply by measuring the temperature of the tube wall with a surface thermometer (under the assumption that on steady state conditions both should be equal).

The requirements from the thermometer are: Note: The temperature update affects only the location reporting accuracy and not the system sensitivity. The thermometer is not supplied with the system. Accuracy: Up to 5 degrees Celsius variation (2.5 Celsius). Surface thermometer: the measurement is done on the tube wall. Time to a steady reading: 1 minute.

- 57 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

After taking the trouble to enter all setup parameters, you might like to export them to a file of their own Next time you start a session you can save time by importing previous settings Heres how to do it:

o Export:

Import:

Note: these parameters are saved with all the measurements of a particular session

6.3.5 Inspection details Fill in the relevant fields to appear in the final report. Free text summary can also be edited. The name of the company performing the inspection and its logo can be applied both will appear in the header on top of each report page.

- 58 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.3.6 License update

In order to operate, the program requires a valid license that needs to be updated every 90 days. There are two ways to update the license: When internet connection is available, clicking the Update button will cause the program to connect to the AcousticEye server and retrieve a 90 days license and a software update if available. 21 days before the license expiration date a proper message will be displayed to the user. If the license expires, the program will cease to work until the license is updated. When internet connection is not available, clicking the Import license button will prompt the user for a license file. Such .lic file can be sent to the user by email.

6.3.7 Export Click DB When Internet connection is not available, and the user wants to send an activity report to AcousticEye, an activity file can be exported to be later sent by mail.

- 59 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.4

Measurement You should keep 3 goals in mind as you make measurements: You probably want to go through measurements of as many tubes as possible in a given time You definitely want to synchronize the measurement label in the software with the actual tube that has been measured Finally you should use the built in safeguards to make sure that the measurements are good (this will be explained below in detail)

6.4.1 Conducting a reference measurement Move to the Measurement tab. Insert the probe tube adaptor into the tube marked as 1 in the tube map, verifying a good seal. When ready press the lower button on the probe or use the software button. The reference measurement is much longer then all the others (about 45 seconds), and during it the system performs a volume optimization to the excitation signal. Once done the volume parameter will be updated by the chosen value. After getting the blue LED indication (meaning that the reference is done), press the push button again or use the software Measure button to take another measurement of the first tube (marked with red circle).

- 62 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.4.2 Taking the tubes measurements Go over all the tubes you wish to measure using the probe push button or the software Measure button. Wait for the blue LED indication before moving on to the next tube. The system gives an indication whether the measurement was taken properly (sealing considerations). 2 indications are given in parallel: 1. Probe indication Green indication stands for a good measurement; red indication together with a "bad sealing" error message stands for a bad measurement. 2. GUI indication at the measurements window on the right, under the QC column. Stands for a measurement taken properly. measurement. Stands for a bad

In case of a bad measurement a warning message appears:

- 61 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

In case of a bad measurement indication, if applicable improve the sealing and repeat the measurement.

Example (Bad Sealing):

During work it is recommended to use the 2D sub-tab in order to validate your position on the tube map. To view the acoustic signal, just switch to the Signals sub-tab.

- 62 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.4.2.1 Deleting a measurement To delete a measurement, mark it with the cursor then right click->delete selected. The counter value will be decreased automatically.

Note on labeling: Measurements can be are labeled as follows: [R] = Row [C] = Column [Z] = Zone [N] = Tube number (a continuous counter following the measuring sequence) If a user wishes to work without Row-Col-Zone, he can only use the R ( row ) values, by right clicking on the ,measurements list and choosing Measurement name format

- 63 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.5

Report post measurement

In the report main tab you will see the following sub-tabs:

Options: Analyzing all the measurements or only selected tubes Signals: On this screen signals can be Displayed and analyzed using several important features Noise margins, Thresholds (per defect type), Subtract of calibration. Defects table: All detected defects are listed in separated tabs based on their type. Filtering can be done as well. Final report: Printing a report and 3 dimensional representations. 6.5.1 Before report generation Before generating an inspection report, you need to verify that the following steps were completed: 1. Parameters All the tube and adaptor parameters were inserted correctly. If needed, the relevant advanced parameters (primarily detection thresholds), were adjusted.

2. Optimal visual reference was selected Before running a final analysis we need to choose an optimal visual reference. If a good reference tube is available we can just use it as a reference. In order to do so just measure it as was explained in section 6.4.1. Or just click on the tube measurement, then right click ->change reference to>the selected measurement.

- 64 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Since in most cases a reference tube will not be available, we need to choose a different reference method averaging. To do so, in the measurement tab, click on one of the tubes ->right click->select all measurements, then clear off the bad measurements from the group (bad sealing, plugged tubes). Once done: right click->change reference to->the average of selected measurements. Since the measurement quality status depends on the reference tube, the system will ask whether to recalculate the tubes QC status.

Note: Indications of the measurements that participated in the creation of the Reference and Noise can be seen in the R N columns.

- 65 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.5.2 Generating a report

6.5.2.1 System interpretation Go to Report -> options Choose the measurements that you want to analyze (All/selected only). Choose whether the inspected tubes are U-Tubes When the U-Tubes analysis mode is selected, the automatic analysis splits the tubes into length based groups (marked "GXX"):

Choose whether to impose reference tubes on small statistics sessions, creating a reference tube by averaging is meaningless. The visual reference is imposed to be used in the automatic analysis as well.

Press the

To stop the report analysis, click the Abort button. When finished a completion message will appear. - 66 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

In the defects table tab you can see all the detected defects, separated into tabs based on their type. Filtering based on the column attribute can be done as well.

In the Signals tab, measurements can be displayed and analyzed manually using several features Thresholds, noise, subtract calibration, Filter view.

- 67 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.5.2.2 User interpretation

Now comes the final part of the analysis the user reviews the system report and verifies the findings. Go to the signals tab, choose the measurement you want to analyze, its signal will appear on the screen. All the defects that were detected in this tube will be listed below the signal on separated tabs, based on their type.

Clicking on an indication will zoom in on its location on the signal.

- 68 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Now, the user can decide whether to approve or decline the system classification and add its graph to the final report

And simply continue to the next indication by using the dedicated arrow key

The tube condition can be classified as well if needed.

Free text can be inserted in the comments column. Notes: Assigned keyboard buttons to improve usability during the analysis. The list is shown when clicking on the button.

- 69 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Load last saved in Defects Table screen: o Clicking this button will load the last saved defect table. o The defect table is saved automatically every few minutes or when the Apply button is clicked, or when the session is closed.

At any defects table scheme, right clicking on an indication will enable the following options: o Approve/Decline Selected indications can be applied simultaneity using the Ctrl key. o Delete to delete the indications o Add new insert a new defect to the marked tube, based on the user manual analysis. o Move to Move the current classification to any of the other options. o Approve/Decline all All the indications in the same tube/class (depends on your viewing scheme) will be approved/declined. o Add/Remove graph from all o Approve without adjacent fault filtering - approve very close faults. o Properties Defect ID, tube ID and the defect location and amplitude attributes are displayed

- 72 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Filters views: In order to increase defect delectability while using the automatic analysis, the system applies 5 types of filters Low/Low_BP/High/High_BP/None. In order to let the user verify the defect using the same filter that was used by the system the filter at which this defect was detected is listed at the detection filter column and the user can toggle between the filters to optimize the defect verification.

The same defect will look totally different under different filters: A hole:

LPF:

HPF:

BPF: - 71 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

In order to know how a certain defect type looks under a certain view filter, the user can apply the theoretical defect signatures at the right click options menu:

- 72 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Signals screen options: o Displaying multiple signals can be done using the Ctrl key (one by one), or the shift key (selecting a group of signals). o Zooming can be done using the + - keys; panning can be done using the arrow keys. o Right click on a line (signal or a threshold) will color it orange momentarily and display its text o Other right click options: View all will zoom out to the entire signal length Undo zoom will return to the last zoom step Save as image save the current screen capture

Show holes/Pitting/Erosions/Blockages signatures Shows the theoretical defect type signatures under the selected view filter with various sizes. Hide defect signatures Hides the selected signatures. Deselect from measurement list unselect the tube from the highlighted measurements list.

- 73 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

6.5.2.3 Printing the report

After the user has finished going over all the reports and verifying the system classification, its time to print the report. Under report->Final report->Issue report, the user can: Choose some report printing options Add pictures to the report to appear after the 2D colored map (Usually this option is useful for displaying some zoomed in zones of a big heat exchanger.

In order to print the report, all you need to do is press the Issue report button.

- 74 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

A report (at the chosen format) will be displayed; the chosen signal graphs will appear in the report as well.

- 75 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Pie charts summarizing the malfunctions can be viewed at the final report tab.

The pie chart is also added to the HTML/PDF report.

- 76 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

APPENDIX I PACKAGING INSTRUCTIONS, CABLE ARRANGEMENT

There are two cables: the external power cord and a second cable for the connection of the main control unit (computer) to the probe. The cables are packaged in the carrying case, inside a cell located under the main control unit. In order to re-pack the cables follow the instructions below. STEP 1: open (lift) the cell plastic cover. STEP 2: probe-main unit arrangement. components: cable, plastic cable drum (Fig. 2.1).

Fig. 2.1 A. Place the connector in its place using the cable locator bracket (Fig.2.2)

- 77 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Fig. 2.2 B. Start rolling tightly the cable on the internal drum tube (Fig. 2.3)

Fig. 2.3 C. Final configuration of the rolling cable should be as shown (Fig.2.4)

Fig. 2.4

- 78 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

STEP 3: place the cable in its place as shown (Fig. 3)

Fig. 3

- 79 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

STEP 4: Internal Suitcase arrangement Is displayed at the image below (Fig. 4.1)

Fig. 4.1

- 82 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

APPENDIX II INSTRUCTIONS FOR ASSEMBLING EXTERNAL SEALING SPONGE ON ADAPTORS.

STEP 1: clean the adaptor tip & tip base (sealing sponge bonding surface) with ethanol as shown in Fig. 1.

Fig. 1

- 81 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

STEP 2: find the right sealing sponge on the sealing sponge plate and remove it from the plate. As shown in Fig. 2.1 & 2.2

Fig. 2.1

- 82 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Fig. 2.2 STEP 3: remove the internal part of the sealing sponge ring. As shown in Fig. 3

Fig. 3 STEP 4: remove the adhesive protective wrapping. As shown in Fig. 4

- 83 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Fig. 4

- 84 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

STEP 5: place the sponge ring on the adaptor tip. As shown in Fig. 5

Fig. 5

- 85 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

STEP 6: turn the ring clockwise till the bonding surface touches the tip base. As shown in Fig. 6 Notice: You must turn the sponge ring on the adaptor tip in order to make the sponge come closer to the adaptor bonding surface.

Fig. 6

- 86 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

APPENDIX III MISCELLANEUOS

1. Report -> Signals screen

Check here to see a graphical representation of the noise margin Check here to order to get the exact estimation for a specific fault

Check here to see a subtraction of the calibration from the measured signal

Check here to see a graphical representation of the various defect types thresholds

- 87 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

2. File menu

New Open a new session file (under Path\TempDir_0), need to be renamed in order not to be over written by a later session. Load Load an existing session file Save As File is copied and saved to a chosen name. Compress to zip is used for reducing raw data size before sending on the net. Use default setting (without checking any box) unless asked otherwise. Rename renaming current session name.

Import/Export setup parameters Is used to import/Export an existing parameter file from/to an external folder for future use. Note that the parameters file must be named ArgumentsDB.xml

- 88 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

APPENDIX IV PC HW Buttons

From right to left: Screen on/off Increase brightness Decrease brightness Increase volume (not in use) Decrease volume (not in use) Auto screen brightness Mute power alert buzzer

- 89 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

APPENDIX V Probe screen notifications

In order improve the system usability by decreasing the use of the main unit during the measurement acquisition phase Most of the measurement control process was mirrored to the probe screen. Almost all the user notifications appear on the probe screen and the user can operate the system using the probe only. Here are the complete scenarios and the handling from the probe: Legend: Low = lower probe button Up = Upper probe button -> = Pressing a probe button

HW TEST During hardware test - on the probe: performing hardware test. At the end: Hardware test succeeded / hardware test failed. CALIBRATION During calibration: calibrating probe. At the end: Ready. REFERENCE During Reference: measuring If a Reference exists: Ref exists. Low=OK -> Perform new Ref? Low=OK UP=NO Regular measurement Measuring: R[ ]C[ ] At the end: SNR:___. Next: R[ ]C[ ]. Repeating an existing Measurement - meas exists. Low = OK-> Remeasure ? Low=yes UP=NO Problematic measurement - problematic meas. Low=OK -> UP=Continue. Low=Repeat

- 92 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

Bad sealing - Bad sealing. Low=OK - > UP=Continue. Low=Repeat

Bad measurement - After 3 attempts: Meas failed. Low=Ok -> Next: R[ ]C[ ] -> Measuring

Example (Bad Sealing):

- 91 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

APPENDIX VI - REFERENCED EC DIRECTIVES, SPECIFICATIONS AND STANDARDS

The following documents referenced in this manual are pertinent only in the quoted context and to the extent specified. UNIVERSAL SERIAL BUS REVISION 2.0 SPECIFICATION IEC 61010-1EDITION 2.0 200102 SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT FOR MEASUREMENT, CONTROL AND LABORATORY USE PART 1: GENERAL REQUIREMENTS ELECTRICAL EQUIPMENT FOR MEASUREMENT, CONTROL AND LABORATORY USE EMC REQUIREMENTS PART 1: GENERAL REQUIREMENTS SAFETY INFORMATION TECHNOLOGY EQUIPMENT, INCLUDING ELECTRICAL BUSINESS EQUIPMENT GENERAL SPECIFICATION FOR TEST EQUIPMENT FOR USE WITH ELECTRICAL AND ELECTRONIC EQUIPMENT Department of Defense Test Method Standard for Environmental Engineering Considerations and Laboratory Tests

IEC 61326-1EDITION 1.0 200512

UL 1950

MIL-PRF-28800F

MIL-STD-810F

- 92 -

Product Management

AcousticEye G3 Tube Inspection System User Manual Doc#: UTM00006 Rev: 6 Date: 6 June 2012

EU DIRECTIVE 2006/95/EC EU DIRECTIVE 2004/108/EC EU DIRECTIVE 2002/95/EC

Low Voltage Directive EMC RESTRICTION ON HAZARDUOUS SUBSTANCES - ROHS

- 93 -

Das könnte Ihnen auch gefallen

- Final Draft en Iso Fdis 15548-2 - 2007Dokument39 SeitenFinal Draft en Iso Fdis 15548-2 - 2007gorkembaytenNoch keine Bewertungen

- 88 D 340 nh3 Storage Tank Sept 10 2014 2Dokument9 Seiten88 D 340 nh3 Storage Tank Sept 10 2014 2mohamed abd eldayemNoch keine Bewertungen

- 243 Standard Practice For Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes.Dokument7 Seiten243 Standard Practice For Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes.Ali MohsinNoch keine Bewertungen

- Casting Definitions and TerminologyDokument15 SeitenCasting Definitions and TerminologyCharlie ChongNoch keine Bewertungen

- G S Earth WireDokument10 SeitenG S Earth WiresaratNoch keine Bewertungen

- Ost Specifications State A Requirement For Conducting This Check, But Do Not Provide A ProcedureDokument6 SeitenOst Specifications State A Requirement For Conducting This Check, But Do Not Provide A ProcedureshifaNoch keine Bewertungen

- Tta Power 2015 Vi 001Dokument31 SeitenTta Power 2015 Vi 001Trịnh Quốc TuyếnNoch keine Bewertungen

- Liquid Penetrant TestingDokument22 SeitenLiquid Penetrant TestingNishant SinghNoch keine Bewertungen

- Vacuum Box Test Procedure: PurposeDokument4 SeitenVacuum Box Test Procedure: Purposesaravan1891Noch keine Bewertungen

- Radiography Testing: RT PrincipleDokument6 SeitenRadiography Testing: RT PrincipleAvish ShahNoch keine Bewertungen

- 'AMIGO' Product InfoDokument5 Seiten'AMIGO' Product InfoNicoreac Monica PaulaNoch keine Bewertungen

- Radiation Safety Program 2Dokument16 SeitenRadiation Safety Program 2Ahmed shabanNoch keine Bewertungen

- Floormap3d MFL Tank Inspection PDFDokument4 SeitenFloormap3d MFL Tank Inspection PDFassurendran0% (1)

- Ultrasonic ExaminationDokument14 SeitenUltrasonic ExaminationLiliNoch keine Bewertungen

- ACFM Applications1Dokument12 SeitenACFM Applications1naoufel1706Noch keine Bewertungen

- Corrosion Mapping With Phased Array UltrasonicsDokument27 SeitenCorrosion Mapping With Phased Array UltrasonicsIvan MauricioNoch keine Bewertungen

- NDT Certification Systems:: Written PracticeDokument3 SeitenNDT Certification Systems:: Written PracticeKhaled MeraashliNoch keine Bewertungen

- Brinell Hardness of Metallic Materials: Standard Test Method ForDokument32 SeitenBrinell Hardness of Metallic Materials: Standard Test Method ForJeffersonCruzNoch keine Bewertungen

- Magnetic Flux Leakage (MFL) TechnologyDokument4 SeitenMagnetic Flux Leakage (MFL) TechnologyShakirNoch keine Bewertungen

- Electromagnetic Testing-EMT-MFLT Chapter 9-LibreDokument228 SeitenElectromagnetic Testing-EMT-MFLT Chapter 9-Libresafeer ahmad100% (1)

- Daily Lrut Report: Lrut Instrument Lrut Probe TechniqueDokument1 SeiteDaily Lrut Report: Lrut Instrument Lrut Probe TechniqueSang Nguyen QuangNoch keine Bewertungen

- Scope of WorksDokument3 SeitenScope of WorksGovindraj KrishnanNoch keine Bewertungen

- BPF-V-270 Test Separator-Cm-Pvir-Xxxxx-20Dokument32 SeitenBPF-V-270 Test Separator-Cm-Pvir-Xxxxx-20Agung Prastyo WibowoNoch keine Bewertungen

- Standard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodDokument7 SeitenStandard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodMauricio FernándezNoch keine Bewertungen

- Guided Wave Presentation NDT Global 1Dokument41 SeitenGuided Wave Presentation NDT Global 1Ahmed LepdaNoch keine Bewertungen

- Corrosion Evaluation by RTDokument6 SeitenCorrosion Evaluation by RTMassimo FumarolaNoch keine Bewertungen

- 7.2.eddy Current Testing-Part2Dokument19 Seiten7.2.eddy Current Testing-Part2Mohanad Almalah100% (1)

- ECT Inspection Technique: Setup and CalibrationDokument19 SeitenECT Inspection Technique: Setup and CalibrationAbhishek DevarajNoch keine Bewertungen

- 11 TechCorr GWUTDokument52 Seiten11 TechCorr GWUTSefliadi StNoch keine Bewertungen

- Ultrasonic Crack PDFDokument11 SeitenUltrasonic Crack PDFHector BeaujonNoch keine Bewertungen

- ELIOS 2 Technical Specifications v1Dokument5 SeitenELIOS 2 Technical Specifications v1Alexey LipovatyiNoch keine Bewertungen

- Silverwing B Scan ReportDokument46 SeitenSilverwing B Scan ReportpjhollowNoch keine Bewertungen

- An Introduction To Long-Range Screening Using Guided WavesDokument8 SeitenAn Introduction To Long-Range Screening Using Guided WavesVikas TiwariNoch keine Bewertungen

- UT of Pressure Vessel Construction WeldsDokument30 SeitenUT of Pressure Vessel Construction WeldsKashif KaziNoch keine Bewertungen

- MSDS MtbeDokument5 SeitenMSDS MtbeViệt HàNoch keine Bewertungen

- Dmta 20017 01en Rev e Hydroform UserDokument88 SeitenDmta 20017 01en Rev e Hydroform UserGhaithNoch keine Bewertungen

- Basic Principles of Eddy Current InspectionDokument58 SeitenBasic Principles of Eddy Current Inspectiondavid eduardo arteaga faubla100% (1)

- Tubulars NDT TechniqueDokument22 SeitenTubulars NDT TechniqueCepi Sindang KamulanNoch keine Bewertungen

- Liquid Penetrant Testing ProcedureDokument2 SeitenLiquid Penetrant Testing ProcedureManivannanMudhaliarNoch keine Bewertungen

- IRISDokument67 SeitenIRISArinze7Noch keine Bewertungen

- MT Asme Sec V Article 7Dokument18 SeitenMT Asme Sec V Article 7mohamedNoch keine Bewertungen

- E570-97 Flux Leakage Ferro TubularDokument6 SeitenE570-97 Flux Leakage Ferro TubularAsif HameedNoch keine Bewertungen

- Tube Inspection InsertDokument2 SeitenTube Inspection InsertManish SharmaNoch keine Bewertungen

- UCI Hardness TestersDokument3 SeitenUCI Hardness TestersMuhammad AdilNoch keine Bewertungen

- Penetrants TESTINGDokument86 SeitenPenetrants TESTINGsankaran_muthukumarNoch keine Bewertungen

- NDT of Welded Steel Tanks1 PDFDokument4 SeitenNDT of Welded Steel Tanks1 PDFBulut Yildiz100% (1)

- Instruction IRIS Tube Inspection EngDokument47 SeitenInstruction IRIS Tube Inspection EngVasilyNoch keine Bewertungen

- CN-11-Section 11 Teletest Functional Tests and Troubleshooting Rev0.1 PDFDokument18 SeitenCN-11-Section 11 Teletest Functional Tests and Troubleshooting Rev0.1 PDFTĩnh Hồ TrungNoch keine Bewertungen

- PSL 30 Log of Pre Cert ExperienceDokument5 SeitenPSL 30 Log of Pre Cert Experiencenarutothunderjet216Noch keine Bewertungen

- Non Destructive TestingDokument182 SeitenNon Destructive TestingAravindNoch keine Bewertungen

- Lrut Special AplicationDokument20 SeitenLrut Special AplicationAbdur Rahim100% (1)

- Info Sheet Iris Inspection of TubesDokument2 SeitenInfo Sheet Iris Inspection of TubesCepi Sindang KamulanNoch keine Bewertungen

- Eagle 2000 PDFDokument4 SeitenEagle 2000 PDFErick OlavarriaNoch keine Bewertungen

- AITIS Company ProfileDokument7 SeitenAITIS Company ProfileassurendranNoch keine Bewertungen

- RESUMEDokument3 SeitenRESUMENikhatRizaviNoch keine Bewertungen

- NDT For Roller CoasterDokument5 SeitenNDT For Roller Coasterluqman syakirNoch keine Bewertungen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- Oprators Manual CMS9000V3.0 Software MonitorDokument58 SeitenOprators Manual CMS9000V3.0 Software MonitorCristhian Josué RápaloNoch keine Bewertungen

- ROTALIGN Ultra Shaft Handbook ALI 9.855 01 12 en Web PDFDokument176 SeitenROTALIGN Ultra Shaft Handbook ALI 9.855 01 12 en Web PDFDan-jones TudziNoch keine Bewertungen

- Practical Use of Dynamic Vibration AbsorbersDokument4 SeitenPractical Use of Dynamic Vibration AbsorbersDan-jones TudziNoch keine Bewertungen

- Operating Deflection ShapeDokument9 SeitenOperating Deflection ShapeDan-jones TudziNoch keine Bewertungen

- Fukui PSV Catlogue 1 PDFDokument73 SeitenFukui PSV Catlogue 1 PDFDan-jones Tudzi100% (1)

- Model A7 With Mechanical Seal: Installation, Operation, Maintenance and Storage ManualDokument38 SeitenModel A7 With Mechanical Seal: Installation, Operation, Maintenance and Storage ManualDan-jones TudziNoch keine Bewertungen

- Compressor Station Piping Noise Interim Report FinalDokument41 SeitenCompressor Station Piping Noise Interim Report FinalalbertofgvNoch keine Bewertungen

- Fukui PSV Catlogue 1 PDFDokument73 SeitenFukui PSV Catlogue 1 PDFDan-jones Tudzi100% (1)

- A380-LEVEL I - ATA 31 Indicating - Recording SystemsDokument70 SeitenA380-LEVEL I - ATA 31 Indicating - Recording SystemsGuy100% (1)

- Cyberpunk 2020 - Datafortress 2020 - AppleseedDokument30 SeitenCyberpunk 2020 - Datafortress 2020 - AppleseedGeraint BrownNoch keine Bewertungen

- Ipm650 PDFDokument5 SeitenIpm650 PDFJAHDLNoch keine Bewertungen

- FitTrack BloodLinkDokument7 SeitenFitTrack BloodLinkInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- ANSYS Simulation of MRI Device For ComplianceDokument45 SeitenANSYS Simulation of MRI Device For Compliancej_c_garcia_dNoch keine Bewertungen

- Gtu Micro Processor PracticalDokument79 SeitenGtu Micro Processor Practicalbaba100% (1)

- Operation Guide 5522: Things To Check Before Using The Watch About This ManualDokument7 SeitenOperation Guide 5522: Things To Check Before Using The Watch About This Manualfirdaus_stNoch keine Bewertungen

- Design of 400kV200kV SSDokument62 SeitenDesign of 400kV200kV SSAbinav AggarwalNoch keine Bewertungen

- Kassia Webb - Resume Updtd 11 Dec 2016Dokument4 SeitenKassia Webb - Resume Updtd 11 Dec 2016api-322501460Noch keine Bewertungen

- Siko Product OverviewDokument20 SeitenSiko Product OverviewMECING LTDANoch keine Bewertungen

- Power Plant Manual 1Dokument8 SeitenPower Plant Manual 1Khoirul WaladNoch keine Bewertungen

- Color Palettes For Graphic DesignDokument19 SeitenColor Palettes For Graphic DesignClarence Tuazon FloresNoch keine Bewertungen

- LTE Parameter - Ue State HandlingDokument39 SeitenLTE Parameter - Ue State HandlingSatria Wibowo100% (5)

- ADMS Assignment Spring 2011Dokument8 SeitenADMS Assignment Spring 2011muneermuhammadNoch keine Bewertungen

- Service Manual: ChassisDokument66 SeitenService Manual: ChassisAsnake TegenawNoch keine Bewertungen

- Boarding Pass (Web Check In) WWW - Goindigo.In: Ms Jasda Ramchandani Jaipur (T2) 6E 783 08 Aug 20Dokument1 SeiteBoarding Pass (Web Check In) WWW - Goindigo.In: Ms Jasda Ramchandani Jaipur (T2) 6E 783 08 Aug 20Kscsiddhant KscsiddhantNoch keine Bewertungen

- Audio Engineering Advice - January2023 2023 V1.6Dokument31 SeitenAudio Engineering Advice - January2023 2023 V1.6jeremy hartigNoch keine Bewertungen

- FsDokument8 SeitenFskrishnacfp232Noch keine Bewertungen

- OTIS E311-CIRCUITO - (69 PG)Dokument69 SeitenOTIS E311-CIRCUITO - (69 PG)Samuel AcevedoNoch keine Bewertungen

- MCA 2020 - List of Applicants Shortlisted For Interview (F) - 30 May 2020Dokument21 SeitenMCA 2020 - List of Applicants Shortlisted For Interview (F) - 30 May 2020shatabdi mukherjeeNoch keine Bewertungen

- Cad/Cam Softwares: A Presentaton OnDokument35 SeitenCad/Cam Softwares: A Presentaton OnVaibhav AroraNoch keine Bewertungen

- SQL CCDokument457 SeitenSQL CCManish SinghNoch keine Bewertungen

- MC Line: Multifunction Three Phase Overvoltage / Undervoltage RelayDokument3 SeitenMC Line: Multifunction Three Phase Overvoltage / Undervoltage RelayCerduardo Chanchisco Roga RojasNoch keine Bewertungen

- Keyboard Shortcuts Windows 7 and 8Dokument3 SeitenKeyboard Shortcuts Windows 7 and 8Feral ErraticNoch keine Bewertungen

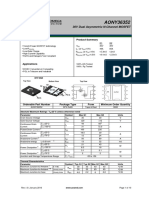

- AONY36352: 30V Dual Asymmetric N-Channel MOSFETDokument10 SeitenAONY36352: 30V Dual Asymmetric N-Channel MOSFETrobertjavi1983Noch keine Bewertungen

- Renub Research: Published: May, 2012Dokument12 SeitenRenub Research: Published: May, 2012api-114525849Noch keine Bewertungen

- Remotecontrol: Urc-A6Dokument47 SeitenRemotecontrol: Urc-A6Josue TrochezNoch keine Bewertungen

- Making A Quick Water Material in 3ds Max.: by Gerardo I. RamirezDokument3 SeitenMaking A Quick Water Material in 3ds Max.: by Gerardo I. Ramirezpalanisamy744Noch keine Bewertungen

- Installing-Uninstall Oracle 10g Database SoftwareDokument6 SeitenInstalling-Uninstall Oracle 10g Database SoftwareSarath SivanNoch keine Bewertungen

- REspuestas Quiz CP4AUTOMATIONDokument10 SeitenREspuestas Quiz CP4AUTOMATIONMax Lee100% (1)