Beruflich Dokumente

Kultur Dokumente

RE and Dfhgrapid Product

Hochgeladen von

Ishak AnsarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

RE and Dfhgrapid Product

Hochgeladen von

Ishak AnsarCopyright:

Verfügbare Formate

Journal of Materials Processing Technology xxx (2005) xxxxxx

RE (reverse engineering) as necessary phase by rapid product development

M. Sokovic , J. Kopac

Faculty of Mechanical Engineering, University of Ljubljana, Askerceva 6, SI-1000 Ljubljana, Slovenia

Abstract The engineering design supported by CAD/CAE techniques allows optimising the product concept before manufacturing with assistance of CAM, in management for rapid product development and rapid set-up production in advance. For some product development processes reverse engineering (RE) allows to generate surface models by three-dimensional (3D)-scanning technique, and consequently this methodology permits to manufacture different parts (for cars, for household appliances) and tools (moulds, dies, press tools) in a short development period. The aim of this paper is to present a brief overview of RE as a necessary phase which provide benets to the design and production processes in advance. 2005 Elsevier B.V. All rights reserved.

Keywords: Scanning (digitising); Reverse engineering; Product design; Rapid prototyping; CAD/CAE/CAM techniques

1. Introduction Why rapid product development is necessary, asked many workers special in countries of middle and east Europe. Owners and directors of factories answer is, that the involved money in process must give maximal benet in other case they not make investment in such production. Very important production is cars manufacturing, where every of car content thousand and more pieces, which must be made as quicker and chipper is possible, by achieving of prescribed quality. By small or bigger changing of car model there are changing many of pieces too. The time of changing became shorter and shorter and requirements push all in the production chain in great hurry with time. In this case are very useful and successful the methods of reverse engineering (RE). The very important tools, which help in this process, are different scanning systems, which ensure in the short time exact dimensional description in digital concept, which is useful for direct control on machine tool in advance. We can add or change some shapes, dimensions or some functional matters and prepare CNC-code for new article [1,2].

The RE is now an accepted part of contemporary product design and manufacturing process. The RE process can be loosely dened as process that result in the creation of a mathematical model from a physical one. There are some reasons why this is necessary: - Some parts exist for which no design/manufacturing documentation exists. - In some cases it is necessary only to extract 2D prole data from the model as the complete part may be efciently modelled using these proles and a surface/solid CAD/CAM system. - Potential application area can be found in the injection moulding industry (rapid tooling, recovering broken moulds or duplicating a mould); other elds such as medical, eyewear or the toy industry [3]. All the above-cited cases have very different RE requirements; from recovering mechanical design information to design based modications. In the case of extracting mechanical design information, we will be interested in absolute tolerance contrary to the case of design based extraction where the precedent will be that of extracting design intent. In mentioned contest, the RE methodologies and techniques are absolutely necessary because allows capturing

Corresponding author. E-mail address: mirko.sokovic@fs.uni-lj.si (M. Sokovic).

0924-0136/$ see front matter 2005 Elsevier B.V. All rights reserved. doi:10.1016/j.jmatprotec.2005.04.047

M. Sokovic, J. Kopac / Journal of Materials Processing Technology xxx (2005) xxxxxx

and digitising the object surface geometry to be utilised in CAD/CAE/CAM.

2. Product development approaches Nowadays the management of engineering product design could be realised based on the two methodologies presented in Fig. 1, trough two information ows called conventional approach and non-conventional approach [4]. 2.1. Conventional approach The conventional approach to develop products with CAD/CAE/CAM techniques normally starts with the geometric modelling utilising a CAD system. The geometric model could be represented as a wire frame or as surfaces or as a solid structure. Via conceptual modelling, the generated CAD information could be exported subsequently in standard format (IGES

points/STL binary, ASCII data, DXF polyline, VDA points or IGES/STL surfaces) and imported in the same data format to CAE systems (allowing numerical model simulation) and/or to CAM systems (allowing to generate tooling trajectoriesNC-code). In a system with a unique database, the design information could be shared between every application automatically, without the need to transfer data manually, each time. 2.2. Non-conventional approach The product development by conventional approach is not applicable when the goal is to reengineer or to simulate and to optimise parts/moulds/tools already existents without information in CAD data format. Consequently, will be necessary to apply techniques that allow capturing the geometry of parts/moulds/tools (or prototypes), and to generate a conceptual numerical model that will be used in CAE and CAM systems. This process is regularly called reverse engineering [24].

Fig. 1. Sequences to manufacture engineering products (parts/moulds/tools).

M. Sokovic, J. Kopac / Journal of Materials Processing Technology xxx (2005) xxxxxx

Fig. 2. Digitising techniques for the 3D-geometries and generated data.

3. The reverse engineering process The RE process can be divided into three steps: digitising; data segmentation; data tting. The rst objective of RE methodology is to generate a conceptual model (example: surface triangulated) from a physical model: a sample (part or tool) or prototype. In this sense the 3D-scanning (digitising) techniques aided by specialised softwares for model reconstruction are necessary. 3D-scanning (digitising) is the process of gathering data from an undened three-dimensional surface. During the scanning process, an analogue-scanning probe is commanded to move back and forth (contact or non-contact) across the unknown surface. During this process, the system records information about the surface in the form of numerical datagenerates a points cloud matrix (3D-coordinates). This data may then be used to create a CNC-program to machine a replica or geometric variant of the shape. Alternatively, the data can be exported in various formats to a CAD/CAM system for further processing [2,5].

When digitising a part at least the following factors must be taken into consideration [3]: What is the model made of? What is the physical condition of the model? Need for xtures. Alignment requirements. Digitiser errors. Available digitisers. What is the required use of the resultant geometric model?

Of these factors the last one is probably the most important and in many cases not taken sufciently into consideration. 3.1. Difference between digitising and scanning The terms digitising and scanning are often used to describe the same process. Traditionally, the term digitising referred to the process of taking discrete points from a surface using a touch-trigger probe. However, with the introduction of new technologies in data capture such as laser, camera, vision and analogue probe systems, the term digitising is now used as the generic description for the process of acquiring data from undened surfaces [5,6].

Fig. 3. Different probe sensors for digitising equipments: (a) physical touching probe sensor, (b) laser beam probe and (ce) optical sensors (CCD cameras).

M. Sokovic, J. Kopac / Journal of Materials Processing Technology xxx (2005) xxxxxx

The digital points cloud could be captured from different digitising techniques (Fig. 2), classied in two main groups: - The mechanical techniques (by physical contact sensors). - The optical techniques (by non-contact with the object). Related with the rst group is normally utilised a coordinate measuring machine (CMM), or a CNC-milling machine basis, equipped with physical touching probe sensors (i.e. Retroscan or RenscanRenishaw, UK), Fig. 3a. Related with the second group, could be utilised also a CMM or a CNC-milling machine basis, but equipped with laser beam probes Renishaw (Fig. 3b), Metris LC

Fig. 5. Possibilities of use RE-methodology.

Mitutoyo, Comet T-Scan SteinbichlerGermany or associated to optical sensors (ex. CCD-cameras), Kr eonFrance (Fig. 3c), ATOS II GOM mbHGermany (Fig. 3d), Optigo 200 CogniTensIsrael, for non-contact coordinate measuring (Fig. 3e). For the second group would be also exist techniques utilising computer tomography (CT) that allows to capture also the inside object geometry [6].

Fig. 4. Example of the sequences of the reverse engineering (RE), corresponding to Fig. 1.

Fig. 6. Examples of manufactured prototypes of car parts in the second phase of R&D process [1].

M. Sokovic, J. Kopac / Journal of Materials Processing Technology xxx (2005) xxxxxx Table 1 Review of the advantages and weaknesses of different scanning systems Type of scanning CCD cameras Advantages Fast It is possible to use two or three cameras simultaneously Insensible to colour of parts (additional SW-controlled light) Non-contact method; it is possible to scan of soft materials Weaknesses

Laser

In the case of special coaxial lightening it is possible to scan small diameters and high depths in the Z-axis It is possible to scan very small areas, cca 1 mm2 (one scan is enough)accuracy is about some micrometers Scanning of the at surfaces is very fast (principle of the prole projector) Precise and fast scanning in Z-axis (0.001 mm or better) Non-contact method It is possible to scan of soft materials (also liquids)

High price of equipment Accuracy decreases linear depend of the camera distance Scanning angle is equal regardless of the shape of the parts surface; in the case of very steep angles the measurement is very disgured By scanning with camera very high sharpness of visible picture is required; simultaneous scanning of close and far surface details demonstrates linear deviation of the results respect to different focus distance In the case of oily of wet parts scanning the results are disgured Dust causes fault by scanning

Very high price of equipment It is not possible to scan reective materials Scanning in X- and Y-axis is very inaccurate (0.0350.060 mm) It is not possible to scan on the area of notches or very steep surfaces because of additional reection Sensitivity to draught and dust in the air It is not appropriate to soft materials Scanning of unknown surfaces is not makes possible or process of scanning is very slow and inaccurate

Contact (classical)

Very precise in all axis (depends of the scanning equipment) Very fast scanning of geometrical well-known parts Very precise scanning of coins and similar relief Possibility of manual or automatic scanning Hand scanning equipment (measurement hand) is useful for scanning very big products such as: airplanes, ships, big machines and devices (accuracy of scanning is not drastically changes)

Contact (Renishaw Cyclone 2)

Very precise in all axis (0.001 mm) Relatively low price of apparatus It is possible to use different styli for different surfaces It is possible to scan unknown surfaces with similar accuracy compare to known ones It is possible to scan unknown steep surface (angle is very close to 90 ) very accurate Oil, liquid and dust on the surface do not disturb scanning process Scanning module works like 3D measurement deviceno problem by scanning un-perpendicular surfaces Scanning speed automatically adapt oneself to surface roughnessscanned values (coordinates in X-, Y- and Z-axes) are very accurate; direct, accurate comparison with CAD drafts is possible (resolution and accuracy are 0.002 mm also by 350 mm long probe) It is possible to use scanning SW, which is combine with appropriate controller, on the every measurement table; scanning speed is more than 20 times faster compare to classical conguration, because is not necessary to write additional program for measurement

Minimum diameter of stylus is 0.3 mm; scanning of surface roughness is not possible Is not suitable to scan soft materials Although is stylus material resistant against wear, stylus surface wears after time Scanning speed is lower (compare to non-contact scanning systems)

M. Sokovic, J. Kopac / Journal of Materials Processing Technology xxx (2005) xxxxxx

3.2. 3D-CAD redesign from digitising data The data generated during 3D-scanning, i.e. the digital points cloud data in X, Y, Z coordinates, is exported to a model reconstruction system software to be transformed in a conceptual model supported by a triangular surface geometry or by a CAD-surface data (Fig. 4). When nish the conceptual model, the subsequent procedures are similar to the conventional sequence by product development that normally starts with the geometric modelling utilising a CAD-system, see Fig. 1 [2,4]. Some of important possibilities of use the REmethodology in the practice shown in Fig. 5. 3.3. What type of sensor should be used For most applications, the best results in terms of accuracy and quality of surface nish are obtained using contact sensors. However, where very soft and fragile materials (and non-reective surface) is to be scanned, non-contact, laser or optical systems offers (Renishaw, Kr eon, ATOS II, Optigo, . . .). Contact systems have several fundamental advantages over the majority of available non-contact systems, Table 1 [2,6]. An ideal scanning device would be combination of camera, laser and contact probe supported with appropriate controller. 3.4. RE for foundry parts and tools reconstruction The use of RE methodology in the R&D study of casting parts for automotive industry allowed optimising a casting part and to manufacture the respective rapid tools for sand casting in the rst step. In the second phase, it is possible to use RE for extracting mechanical design information or design based modications. In the case of extracting mechanical design information we will be interested in absolute tolerance (Fig. 6) contrary to the case of design based extraction where the precedent will be that of extracting design intent. 4. Conclusion The product (parts, moulds, tools) development via integrated reverse engineering is a recent methodology in re-

search and development phase. If is today this methodology additionally integrated with new rapid manufacturing technologies such as high speed machining (HSM) and ve-axis milling, allows manufacturing time reduction and associated costs for product development and management. For these production methodologies and techniques the 3D-scanning (digitising) is the initial activity to capture the product geometries. This paper shows some possibilities of use and benet from utilising the RE-methodologies and techniques in production process, especially in the case when exists parts without 3D-CAD support. In this contest, RE is absolutely necessary because allows capturing and digitising the object surface geometry to be utilised in CAD/CAE/CAM. In the paper is also given some interesting information about characteristics (advantages and weaknesses) of different scanning systems (contact or non-contact). Therefore, the RE-process (integrated with the recent rapid prototyping and/or rapid tooling technologies) is granted by numerical simulation the process and product optimisation to increase the nal product quality, lead to increase the competitiveness in the different cases (car parts production, production of parts for household appliance, rapid tool making for these parts).

References

[1] J. Kopac, M. Sokovic, Prototype workshop rst step for a successful ow of orders at automotive industry Innovative Automotive Technology IAT03, Koper/Portoro z, April 2425, 2003, pp. 459467 (in Slovene). [2] M. Sokovic, 3D-scanningmain phase by reverse engineering, Euroteh 3 (3) (2004) 8390 (in Slovene). [3] T. Herbertson, Reverse engineering, in: Fourth International Conference on Industrial Tools ICIT 2003, April 8th12th, Bled, Slovenia, 2003, pp. 419422. [4] J.C. Ferreira, et al., Integrated product and tooling development via reverse engineering methodologies and rapid prototyping techniques, in: 3o Congresso Brasilerio de Gestao de Desenvolvimento de Produto, 2527 Setembro de, Florianopolis, Brasil, 2001. [5] N.N., Scanning Systems for Reverse Engineering, Renishaw Apply Innovation, H-2000-3120-04-B, Renishaw plc, UK. [6] Web sites of different producers of digitising (scanning) equipments: www.renishaw.com, www.metris.com, www.steinbichler.de, www. kreon3d.com, www.gom.com, www.cognitens.com.

Das könnte Ihnen auch gefallen

- The Development of Computational Model Through Reverse Engineering - Side Mirror Case StudyDokument18 SeitenThe Development of Computational Model Through Reverse Engineering - Side Mirror Case StudywanameiNoch keine Bewertungen

- Rapid Technology in Dental Biomechanics Vrtanoski Gligorce, Andonovic VladanDokument6 SeitenRapid Technology in Dental Biomechanics Vrtanoski Gligorce, Andonovic VladanGligorcheNoch keine Bewertungen

- Unit 2Dokument34 SeitenUnit 2sai venkatsharmaNoch keine Bewertungen

- M2. Mechanical RE RevIIDokument40 SeitenM2. Mechanical RE RevIIhani100% (1)

- Reverse Engineering - A General Review PDFDokument5 SeitenReverse Engineering - A General Review PDFIsmael Aguilar100% (1)

- 18me4105 - Additive Manufacturing Key & Scheme of Evaluation Dec-2022Dokument13 Seiten18me4105 - Additive Manufacturing Key & Scheme of Evaluation Dec-2022srinivas kanakalaNoch keine Bewertungen

- Free-Form Surface Models Generation Using Reverse Engineering Technique-An Investigation PDFDokument7 SeitenFree-Form Surface Models Generation Using Reverse Engineering Technique-An Investigation PDFmetallobNoch keine Bewertungen

- Project Report On Reverse Engineering: Guide: Prof Biswanath DoloiDokument31 SeitenProject Report On Reverse Engineering: Guide: Prof Biswanath DoloiBIPLAB MONDALNoch keine Bewertungen

- A Cyber-Physical Methodology To Automate Robotized Finishing ProcessesDokument17 SeitenA Cyber-Physical Methodology To Automate Robotized Finishing ProcessesJames MorenoNoch keine Bewertungen

- Application of Reverse Engineering Techniques in Mechanics System ServicesDokument9 SeitenApplication of Reverse Engineering Techniques in Mechanics System ServicesRaul AndresNoch keine Bewertungen

- Additive Manufacturing ProcessesDokument27 SeitenAdditive Manufacturing ProcessesAizrul ShahNoch keine Bewertungen

- Reverse EngineeringDokument27 SeitenReverse Engineeringzeyadhr70Noch keine Bewertungen

- DS48 257 PDFDokument8 SeitenDS48 257 PDFjwpaprk1Noch keine Bewertungen

- Implementation of 3D Optical Scanning Technology ForDokument13 SeitenImplementation of 3D Optical Scanning Technology ForDinesh KumarNoch keine Bewertungen

- Reverse Engineering Using A Knowledge-Based Approach: Alexandre DuruptDokument17 SeitenReverse Engineering Using A Knowledge-Based Approach: Alexandre DuruptAparna DuggiralaNoch keine Bewertungen

- AMTA UNIT 1 CompleteDokument11 SeitenAMTA UNIT 1 CompleteAdula RajasekharNoch keine Bewertungen

- Materials Today: Proceedings: Robin H. Helle, Hirpa G. LemuDokument8 SeitenMaterials Today: Proceedings: Robin H. Helle, Hirpa G. LemuRaj PatelNoch keine Bewertungen

- Application of Cad in RP TechnologyffDokument13 SeitenApplication of Cad in RP TechnologyffPushkar FegadeNoch keine Bewertungen

- AMTA UNIT5 CompleteDokument20 SeitenAMTA UNIT5 CompleteAdula RajasekharNoch keine Bewertungen

- Unit 1Dokument35 SeitenUnit 1narasimhanaiduNoch keine Bewertungen

- Advanced Simulation of NC Turning OperationsDokument13 SeitenAdvanced Simulation of NC Turning OperationsSri VathsenNoch keine Bewertungen

- Comp GraDokument7 SeitenComp GraCassiano FerriNoch keine Bewertungen

- Modeling and Problem Solving Techniques for EngineersVon EverandModeling and Problem Solving Techniques for EngineersNoch keine Bewertungen

- Application of CAD/CAE & Rapid Prototyping Technology in Medical FieldDokument5 SeitenApplication of CAD/CAE & Rapid Prototyping Technology in Medical FieldRizwanNoch keine Bewertungen

- Advanced Manufacturing Systems Assignment 1 FaraiDokument10 SeitenAdvanced Manufacturing Systems Assignment 1 Faraifatsoe1Noch keine Bewertungen

- Reverse Engineering and Its Application in Rapid Prototyping and Computer Integrated ManufacturingDokument8 SeitenReverse Engineering and Its Application in Rapid Prototyping and Computer Integrated ManufacturingRomdhane Ben KhalifaNoch keine Bewertungen

- UNIT1,3Dokument14 SeitenUNIT1,3Sagar BatraNoch keine Bewertungen

- CADCAM MinDokument91 SeitenCADCAM MinBandi KumarreddyNoch keine Bewertungen

- Reverse EngineeringDokument13 SeitenReverse Engineeringprashant6942100% (3)

- Development of An Integrated Laser-Based Reverse Engineering and Machining SystemDokument6 SeitenDevelopment of An Integrated Laser-Based Reverse Engineering and Machining SystemAmrik SinghNoch keine Bewertungen

- Additive Manufacturing UNIT-1Dokument11 SeitenAdditive Manufacturing UNIT-1ENGINEERING MECHANICSNoch keine Bewertungen

- Cad BookDokument86 SeitenCad BookGopi RaguNoch keine Bewertungen

- Cost of Photochemical Machining: Rajkumar Roy, David Allen, and Oscar ZamoraDokument10 SeitenCost of Photochemical Machining: Rajkumar Roy, David Allen, and Oscar ZamoraBayu Wigha AnugrahNoch keine Bewertungen

- Reverse Engineering-Unit 1 NotesDokument19 SeitenReverse Engineering-Unit 1 Notessarthak.aggarwal.ug20Noch keine Bewertungen

- Cadcam LabDokument83 SeitenCadcam LabRachit VemulaNoch keine Bewertungen

- Reverse Engineering of Freeform Surfaces A Methodology For Threshold Definition in Selective SamplingDokument8 SeitenReverse Engineering of Freeform Surfaces A Methodology For Threshold Definition in Selective SamplingmetallobNoch keine Bewertungen

- Introduction To Reverse Engineering: October 2007Dokument10 SeitenIntroduction To Reverse Engineering: October 2007Sudeep Kumar Singh100% (1)

- CADM Year Questions, Unit 4,5Dokument28 SeitenCADM Year Questions, Unit 4,5Johnson PaulNoch keine Bewertungen

- Digital Modeling and Rapid PrototypingDokument28 SeitenDigital Modeling and Rapid PrototypingAnonymous mzF3JvyTJsNoch keine Bewertungen

- What Is Reverse Engineering?Dokument15 SeitenWhat Is Reverse Engineering?Kuldeep GautamNoch keine Bewertungen

- Yusuf WESIC2003 Paper PDFDokument6 SeitenYusuf WESIC2003 Paper PDFSalehNoch keine Bewertungen

- Unit 1 ADMDokument43 SeitenUnit 1 ADMCHINTAKINDI VENKATAIAH RAGHUVAMSHINoch keine Bewertungen

- Cad-Cam Manual PDFDokument34 SeitenCad-Cam Manual PDFM.Saravana Kumar..M.E100% (2)

- Reverse Engineering Based Methodology For Modelling Cutting ToolsDokument9 SeitenReverse Engineering Based Methodology For Modelling Cutting ToolsbobbyNoch keine Bewertungen

- CAD CAM CIM Lab ManualDokument44 SeitenCAD CAM CIM Lab Manualgoku.animaxNoch keine Bewertungen

- شبیه سازی 3Dokument6 Seitenشبیه سازی 3muhammadaliNoch keine Bewertungen

- 15AE308J - Design Lab Manual New 2020Dokument43 Seiten15AE308J - Design Lab Manual New 2020rushan ahmedNoch keine Bewertungen

- Sciencedirect: Additive Manufacturing of Fixture For Automated 3D Scanning - Case StudyDokument6 SeitenSciencedirect: Additive Manufacturing of Fixture For Automated 3D Scanning - Case StudyraharjoNoch keine Bewertungen

- Rapid Prototyping - WikipediaDokument15 SeitenRapid Prototyping - WikipediaChalla varun KumarNoch keine Bewertungen

- Reverse Engineering: Submitted ToDokument24 SeitenReverse Engineering: Submitted Tovarun.119100% (1)

- A CAD-CAE-Integrated Injection Mold Design SystemDokument13 SeitenA CAD-CAE-Integrated Injection Mold Design SystemaenymaNoch keine Bewertungen

- Crankshaft Design Excel SheetDokument7 SeitenCrankshaft Design Excel SheetSHADABNoch keine Bewertungen

- ME2309 CAD CAM Lab ManualDokument36 SeitenME2309 CAD CAM Lab Manualkumar km100% (1)

- Reverse Engineering of Pump Casing and ImpellerDokument12 SeitenReverse Engineering of Pump Casing and ImpellerEmad BadrNoch keine Bewertungen

- Model Prediction of Defects in Sheet Metal Forming ProcessesDokument12 SeitenModel Prediction of Defects in Sheet Metal Forming Processeschandra jemyNoch keine Bewertungen

- Reverse Engineering of Mechanical DevicesDokument5 SeitenReverse Engineering of Mechanical DevicesTensingh RajaNoch keine Bewertungen

- Micro-Specific Design Flow For Tool-Based Microtechnologies: TechnicalpaperDokument6 SeitenMicro-Specific Design Flow For Tool-Based Microtechnologies: TechnicalpaperlipinkhareendranNoch keine Bewertungen

- Reverse Engineering of Mechanical DevicesDokument4 SeitenReverse Engineering of Mechanical DevicesChethan Rao HNoch keine Bewertungen

- 2008-Manufacturing Complexity Evaluation For Additive andDokument12 Seiten2008-Manufacturing Complexity Evaluation For Additive andsachinkashidNoch keine Bewertungen

- CIM Module 2Dokument64 SeitenCIM Module 2Mohanakumara K CNoch keine Bewertungen

- CR 3-23 A-FGJ-A-E-HQQE: Position Qty. Description Single PriceDokument7 SeitenCR 3-23 A-FGJ-A-E-HQQE: Position Qty. Description Single PriceIshak AnsarNoch keine Bewertungen

- Postcoital ContraceptionDokument6 SeitenPostcoital ContraceptionIshak AnsarNoch keine Bewertungen

- Cover Sheet: Print Form Clear FormDokument1 SeiteCover Sheet: Print Form Clear FormIshak AnsarNoch keine Bewertungen

- Hund T FindingsDokument4 SeitenHund T FindingsIshak AnsarNoch keine Bewertungen

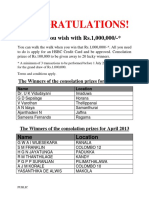

- Congratulations!: Live As You Wish With Rs.1,000,000Dokument1 SeiteCongratulations!: Live As You Wish With Rs.1,000,000Ishak AnsarNoch keine Bewertungen

- Calendar 2012 BlackDokument1 SeiteCalendar 2012 BlackIshak AnsarNoch keine Bewertungen

- C02-Fundamentals of Financial Accounting: Sample Exam PaperDokument15 SeitenC02-Fundamentals of Financial Accounting: Sample Exam PaperIshak AnsarNoch keine Bewertungen

- Department of Electronic Engineering: Final Year Project ReportDokument59 SeitenDepartment of Electronic Engineering: Final Year Project ReportIshak AnsarNoch keine Bewertungen

- Central Bank of Sri Lanka: Premier Financial InstitutionDokument1 SeiteCentral Bank of Sri Lanka: Premier Financial InstitutionIshak AnsarNoch keine Bewertungen

- Project Titles and Supervisors-2011Dokument24 SeitenProject Titles and Supervisors-2011Ishak AnsarNoch keine Bewertungen

- Semi Log Graph Paper BWDokument1 SeiteSemi Log Graph Paper BWIshak AnsarNoch keine Bewertungen

- Of Intrinsic Validity - A Study On The Relevance of Pūrva Mīmā SāDokument29 SeitenOf Intrinsic Validity - A Study On The Relevance of Pūrva Mīmā SāDanillo Costa LimaNoch keine Bewertungen

- AbstractDokument25 SeitenAbstractMargledPriciliaNoch keine Bewertungen

- 12 - Pauline Ethics - Paulinian StewardshipDokument5 Seiten12 - Pauline Ethics - Paulinian StewardshipJinky Bago AcapuyanNoch keine Bewertungen

- Legal OpinionDokument2 SeitenLegal OpinionJovz BumohyaNoch keine Bewertungen

- STSDokument37 SeitenSTSIrenejoy Ramirez0% (1)

- Empathy Map: WHO Are We Empathizing With? What Do They Need To DO?Dokument1 SeiteEmpathy Map: WHO Are We Empathizing With? What Do They Need To DO?Ioana PintilieNoch keine Bewertungen

- Filip CHICHEVALIEV REVIEW OF THE PUBLIC HEALTH LAW IN THE CONTEXT OF WHO POLICIES AND DIRECTIONSDokument15 SeitenFilip CHICHEVALIEV REVIEW OF THE PUBLIC HEALTH LAW IN THE CONTEXT OF WHO POLICIES AND DIRECTIONSCentre for Regional Policy Research and Cooperation StudiorumNoch keine Bewertungen

- Berryman, Sylvia - Galen and The Mechanical Philosophy - Apeiron, 35, 3 - 2002 - 235-254Dokument20 SeitenBerryman, Sylvia - Galen and The Mechanical Philosophy - Apeiron, 35, 3 - 2002 - 235-254the gatheringNoch keine Bewertungen

- Nigredo by KeiferDokument3 SeitenNigredo by KeiferchnnnnaNoch keine Bewertungen

- Accessing Transit As Universal DesignDokument14 SeitenAccessing Transit As Universal DesignValeria Sousa de AndradeNoch keine Bewertungen

- Yusrina Nur Amalia - 15 U-068 - LP VHSDokument17 SeitenYusrina Nur Amalia - 15 U-068 - LP VHSYusrina Nur AmaliaNoch keine Bewertungen

- Case Study Thank You For Smoking 1Dokument3 SeitenCase Study Thank You For Smoking 1api-419017133Noch keine Bewertungen

- Lecture MethodDokument6 SeitenLecture MethodBhawana AjmeradubeyNoch keine Bewertungen

- Contemporary Bildungsroman: A Study of Psycho-Sociological Aspects of Father-Son Relationship in Khaled Hosseini's The Kite RunnerDokument10 SeitenContemporary Bildungsroman: A Study of Psycho-Sociological Aspects of Father-Son Relationship in Khaled Hosseini's The Kite RunnerMarwa Bou HatoumNoch keine Bewertungen

- NEBOSH Unit IGC1 - Helicopter View of Course: © RRC InternationalDokument1 SeiteNEBOSH Unit IGC1 - Helicopter View of Course: © RRC InternationalKarenNoch keine Bewertungen

- To The Philosophy Of: Senior High SchoolDokument25 SeitenTo The Philosophy Of: Senior High SchoolGab Gonzaga100% (3)

- Environmental Philo. SterbaDokument4 SeitenEnvironmental Philo. SterbaJanbert Rebosura100% (1)

- KTC Employee Orientation (Jan.15.2020)Dokument8 SeitenKTC Employee Orientation (Jan.15.2020)Kirby C. LoberizaNoch keine Bewertungen

- Scientific Stock Speculation by CH DowDokument110 SeitenScientific Stock Speculation by CH DowAbdullah18100% (1)

- Environmental Phase I Checklist (ASTM E 1527-05 / X4) (Indicate With A "Y" or "N" Whether The Info. Is Included in The Phase I)Dokument3 SeitenEnvironmental Phase I Checklist (ASTM E 1527-05 / X4) (Indicate With A "Y" or "N" Whether The Info. Is Included in The Phase I)partho143Noch keine Bewertungen

- Group DiscussionDokument22 SeitenGroup DiscussionrachealllNoch keine Bewertungen

- Risk Related Decision Making 2014 HS088Dokument25 SeitenRisk Related Decision Making 2014 HS088nmandic100% (1)

- LFCH10Dokument28 SeitenLFCH10sadsad100% (2)

- The Life and Works of Rizal - Why Study RizalDokument4 SeitenThe Life and Works of Rizal - Why Study RizalTomas FloresNoch keine Bewertungen

- Hegel and The OtherDokument333 SeitenHegel and The OtherJulianchehNoch keine Bewertungen

- Learning To Memories Script at SchoolDokument3 SeitenLearning To Memories Script at SchoolJen VenidaNoch keine Bewertungen

- 2013 01 Doctoral Thesis Rainer LENZDokument304 Seiten2013 01 Doctoral Thesis Rainer LENZSunnyVermaNoch keine Bewertungen

- PTO2 Reflection Rolando EspinozaDokument3 SeitenPTO2 Reflection Rolando Espinozaleonel gavilanesNoch keine Bewertungen

- 9 Zagala, Neil - ModelDokument57 Seiten9 Zagala, Neil - ModelNeil ZagalaNoch keine Bewertungen

- Nanna-About The Soul Life of Plants-Gustav Theodor FechnerDokument47 SeitenNanna-About The Soul Life of Plants-Gustav Theodor Fechnergabriel brias buendia100% (1)