Beruflich Dokumente

Kultur Dokumente

Final Weld Strength Calns

Hochgeladen von

Sajal KulshresthaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Final Weld Strength Calns

Hochgeladen von

Sajal KulshresthaCopyright:

Verfügbare Formate

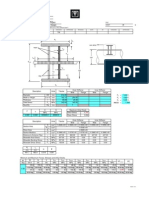

GODREJ & BOYCE MFG.CO.LTD., PRODUCT ENGINEERING DEPT., P.E.D.

, MUMBAI, INDIA WELD SIZE ADEQUACY CHECK AND STRENGTH CALCULATIONS

MDC No. : Project No. : Made by : Azhar Input Echo: Nozzle Mark Nozzle Location Corroded Thickness of Shell Required shell thickness Allowable Stress of Vessel Wall (at Design temperature) Corroded Thickness of Nozzle Required nozzle thickness Nozzle O/D Allowable Stress of Attachment (at Design temperature) Pad O/D Thickness of pad Allowable stress of pad (at Design temp) Pad to Nozzle fillet weld Weld size between Pad and Shell Area required for Reinforcement Area available in shell Area available in Nozzle wall , with Pad Area available in nozzle extention inside the vessel Area availble in reinforcing Pad Whether pad to nozzle groove weld is FPW (Y/N)? Whether the attachment inside projection present (Y/N)?

Client :Consultant :Eqpt. no. : -

Page : 0 Rev : 0 Date : 0/0/2005

Azhar

= = t = tr = Sv = tn trn do Sn dp te Sp leg Wp A A1 A2 A3 = = = = = = = = = = = = =

M1 Shell 0.230 0.308 18900 0.890 0.254 59.000 12355 25.000 0.630 20000 0.354 0.472 6.975 1.942 2.207 0.000

in in psi

Pad-Nozzle GW

Nozzle-Pad FW

in in in psi in in psi in in in2 in2 in2 in2 in2

Pad-Shell FW

Nozzle-Shell FW

Various strength paths As per UG-41.1 (a)

A5 = 7.440 = Y = N

A43

Whether the nozzle opening passes through a category A,C or D joint (Y/N) ?

= N

Nozzle I/D

Strength reduction factors

Factor E1 Joint Efficency Factor F

di = 57.22 in fr1 = Min (Sn/Sv,1 ) = Minimum of ( 12355 / 18900, 1 ) = 0.654 fr2 = Min (Sn/Sv,1 ) = Minimum of ( 12355 / 18900, 1 ) = 0.654 fr3 = Min (Min (Sn or Sp)/Sv,1) = Minimum of ( 12355 / 18900 , 20000 / 18900 , 1 ) = 0.654 fr4 = Min (Sp/Sv,1 ) = Minimum of ( 20000 / 18900, 1 ) = 1 E1 = 1 F = 1

GODREJ & BOYCE MFG.CO.LTD., PRODUCT ENGINEERING DEPT., P.E.D., MUMBAI, INDIA WELD SIZE ADEQUACY CHECK AND STRENGTH CALCULATIONS

MDC No. : Project No. : Made by : Azhar

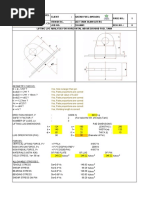

Client :Consultant :Eqpt. no. : (leg)2 x fr3 ( 0.3543 ) ^ 2 x 0.654 0.082 in2 (Wp)2 x fr4 ( 0.47244 ) ^ 2 x 1 0.223 in2

Page : 0 Rev : 0 Date 0/0/2005 A41

Area available in Nozzle to Pad fillet weld, A41 = = = Area available in Pad to Shell fillet weld, A42 = = =

A42

Check for weld size adequacy As per UW-16 (b) For Pad to Nozzle fillet weld,

tmin = Min (0.75,Thickness of the thinner of the parts joined by a fillet) tmin = Minimum of ( 0.75 , 0.89 , 0.6299 ) = 0.63 in Requred Pad to Nozzle fillet weld throat size tpnr = 0.7 x tmin or 0.25, whichever is minimum = Minimum of ( 0.7 x 0.63 , 0.25 ) tpnr = 0.25 [UG-16] in Available Pad to Nozzle fillet weld thoat size tpna = 0.7 x leg = 0.7 x 0.3543 = 0.25 Safe in tmin = Minimum of ( 0.75 , 0.6299 , 0.23 ) For Pad to Shell fillet weld, = 0.23 in Required Pad to Shell fillet weld throat size tpsr = 0.5 x tmin = 0.5 x 0.23 = 0.12 in Available Pad to Shell fillet weld throat size tpsa = 0.7 x Wp = 0.33 Safe in Weld sizes are adequate

Load to be carried by welds [Fig. UG-41.1 Sketch (a)]: W = [A - A1 + 2tnfr1(E1t - Ftr)]Sv Total weld load = [6.9747-1.9423+ 2 x 0.89 x 0.654.(1 x 0.23-1 x 0.30803)] x 18900 [UG-41(b)(2)] = 93396 lb W1-1 = [A2 + A5 + A41 + A42] x Sv Weld load for strength path 1-1 = [2.20689 + 7.44 + 0.082 + 0.223 ] x 18900 [UG-41(b)(1)] = 188091 lb >W W2-2 = [A2 + A3 + A41 + A43 + 2tntfr1] x Sv Weld load for strength path 2-2 = [2.20689 + 0 + 0.082 + + 2 x 0.89 x 0.23 x 0.654 ] x 18900 [UG-41(b)(1)] = 48320 lb W3-3 = [A2 + A3 + A5 + A41 + A42 + A43 + 2tntfr1] x Sv Weld load for strength path 3-3 = [2.20689 +0+ 7.44 + 0.082 + 0.223 + + 2 x 0.89 x 0.23 x 0.654 ] x 18900 [UG-41(b)(1)] = 193151 lb >W Since the weld load W calculated by UG-41(b)(2) is smaller than W1-1 & W3-3. W may be used in place of W11 & W3-3 for comparing the weld capacity to weld load. Strength of connection elements: Outward nozzle wled shear

Outer element weld shear

Wonws = = = Woews = =

p/2 x do x leg x min(Sn,Sp) x 0.49 3.14 / 2 x 59 x 0.3543 x 12355 x 0.49 198683 lb p/2 x dp x Wp x min(Sv,Sp) x 0.49 3.14 / 2 x 25 x 0.47244 x 18900 x 0.49

GODREJ & BOYCE MFG.CO.LTD., PRODUCT ENGINEERING DEPT., P.E.D., MUMBAI, INDIA WELD SIZE ADEQUACY CHECK AND STRENGTH CALCULATIONS

MDC No. : Project No. : Made by : Azhar Nozzle wall shear

Element groove weld tension

Nozzle groove weld tension

Client :Page : 0 Consultant :Rev : 0 Eqpt. no. : Date : 0/0/2005 = 171729 lb Wnws = p/2 x (do + di)/2 x tn x (Sn) x 0.70 = 3.14 / 2 x (59 + 57.22) / 2 x 0.89 x 12355 x 0.70 = 702233 lb Wegwt = p/2 x (do) x te x min(Sn,Sp) x 0.74 = 3.14 / 2 x 59 x 0.6299 x 12355 x 0.74 = 533455 lb Wngwt = p/2 x do x t x min(Sv,Sn) x 0.74 = 3.14 / 2 x 59 xB 0.23 x 12355 x 0.74 = 194784 lb [UG-41.1(a)] 1-1 = = = 2-2 = = = 3-3 = = = Woews + Wnws 171729 + 702233 873962 lb Wonws + Wegwt + Wngwt 198683 + 533455 + 194784 926922 lb Woews + Wngwt 171729 + 194784 366513 lb

Ref.

Check for strength paths:

Stronger than W1-1, Pass

Stronger than W2-2, Pass

Stronger than W3-3, Pass

Also, paths are stronger than the required strength of W = 93396 lb. Thus the design is adequate.

Das könnte Ihnen auch gefallen

- Davit Arm Support Plate CheckDokument56 SeitenDavit Arm Support Plate CheckHafizi HZnumismatic100% (5)

- Godrej & Boyce calculations for weld strength and size of RIL equipmentDokument10 SeitenGodrej & Boyce calculations for weld strength and size of RIL equipmentSajal KulshresthaNoch keine Bewertungen

- Welding Calculations For Base PlateDokument116 SeitenWelding Calculations For Base PlateSyedZainAli100% (2)

- NRPOD Tapti Expansion Project Deck Ring Stiffener DesignDokument5 SeitenNRPOD Tapti Expansion Project Deck Ring Stiffener Designtekstep7Noch keine Bewertungen

- Base Plate CalculationDokument7 SeitenBase Plate CalculationLcm TnlNoch keine Bewertungen

- Cone Design Tool: Pressure Vessel Engineering LTDDokument1 SeiteCone Design Tool: Pressure Vessel Engineering LTDrina2393Noch keine Bewertungen

- Welding CalculationsDokument14 SeitenWelding Calculationsjitulpatil100% (6)

- Section VIII CalDokument19 SeitenSection VIII CalPradeep Kothapalli100% (1)

- Calculation of left and right saddle supports for offshore tankerDokument12 SeitenCalculation of left and right saddle supports for offshore tankerrustamriyadiNoch keine Bewertungen

- Platform Cleat CalculationDokument1 SeitePlatform Cleat Calculationmiteshpatel191Noch keine Bewertungen

- Walkway Support Structure DesignDokument6 SeitenWalkway Support Structure Designaakash prabhuNoch keine Bewertungen

- Weldment Strength Excel CalculationsDokument38 SeitenWeldment Strength Excel CalculationsRAMSINGH CHAUHAN100% (4)

- LIFTING LUG Weld Check KGDokument4 SeitenLIFTING LUG Weld Check KGjoerijiNoch keine Bewertungen

- ASME B16.5 Class 150 & 300 Flanges Studbolt LengthDokument3 SeitenASME B16.5 Class 150 & 300 Flanges Studbolt LengthbakellyNoch keine Bewertungen

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDokument4 SeitenBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNoch keine Bewertungen

- Square Blind Flange With Stiffener ULDokument5 SeitenSquare Blind Flange With Stiffener ULjoeriji100% (1)

- Design of I-Shape Column Base PlateDokument6 SeitenDesign of I-Shape Column Base PlatebuildconNoch keine Bewertungen

- Davit Cal 2251B Davit Arm CalculationDokument4 SeitenDavit Cal 2251B Davit Arm Calculationnitin400Noch keine Bewertungen

- Saddle Baseplate Joint Weld Strength CalculationDokument58 SeitenSaddle Baseplate Joint Weld Strength CalculationSyedZainAliNoch keine Bewertungen

- CALCULATION FOR BLIND PLATE HYDROTEST MESHDokument7 SeitenCALCULATION FOR BLIND PLATE HYDROTEST MESHDenny Syamsuddin100% (1)

- Weld Consumable CalculatorDokument7 SeitenWeld Consumable CalculatoretienetergolinoNoch keine Bewertungen

- Cone Weight CalculationDokument10 SeitenCone Weight CalculationRajesh OwaiyarNoch keine Bewertungen

- Lifting TrunionDokument1 SeiteLifting TrunionRUDHRA DHANASEKAR0% (1)

- Gasket Dimension (ASME B16.5 & B16.47)Dokument4 SeitenGasket Dimension (ASME B16.5 & B16.47)amaNoch keine Bewertungen

- Fillet Welding CalculationDokument6 SeitenFillet Welding Calculationulul khanNoch keine Bewertungen

- Welding consumables and metal requirements for pipe jointsDokument6 SeitenWelding consumables and metal requirements for pipe jointsNabihah NurulhudaNoch keine Bewertungen

- 44.lifting Lug With Collar CalculationDokument44 Seiten44.lifting Lug With Collar CalculationAnonymous AyDvqg100% (1)

- Weld Calculation Equivalent To BoltsDokument3 SeitenWeld Calculation Equivalent To Boltskalpanaadhi100% (2)

- Design of Flanges - Full-Face Gasket 2010Dokument29 SeitenDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- ASME Code VIII Div. I Edition 2004Dokument4 SeitenASME Code VIII Div. I Edition 2004Akshat JainNoch keine Bewertungen

- Design Calculations For Pressure VesselsDokument54 SeitenDesign Calculations For Pressure VesselsEdgar A. Arredondo QuirozNoch keine Bewertungen

- Imperial Piping Weight Load Calculation WorkbookDokument13 SeitenImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- Reinforcement Pad DesignDokument3 SeitenReinforcement Pad DesignAkshat JainNoch keine Bewertungen

- Storage Vessel DesignDokument4 SeitenStorage Vessel DesignArpit ThumarNoch keine Bewertungen

- Wind Calculation SheetDokument32 SeitenWind Calculation SheetaauppalNoch keine Bewertungen

- Hot Forming Brochure from J Bown & CoDokument9 SeitenHot Forming Brochure from J Bown & CoClayton Kok100% (3)

- Lifting Lug Calcs (Frame)Dokument5 SeitenLifting Lug Calcs (Frame)Mudasir MughalNoch keine Bewertungen

- Heat Treatment Requirement Heat Treatment Requirement: o o o oDokument2 SeitenHeat Treatment Requirement Heat Treatment Requirement: o o o ofizanlaminNoch keine Bewertungen

- Flange CalculationsDokument3 SeitenFlange CalculationssanjaysyNoch keine Bewertungen

- Welding CalculationDokument16 SeitenWelding CalculationbrintopvNoch keine Bewertungen

- Design of Flat Head For HydrotestDokument12 SeitenDesign of Flat Head For HydrotestSAGARNoch keine Bewertungen

- LIFTING LUG CALCULATIONDokument2 SeitenLIFTING LUG CALCULATIONhuangjlNoch keine Bewertungen

- Clip PlatformDokument24 SeitenClip Platformwisnu_bayusaktiNoch keine Bewertungen

- PIPE Sizes and Sch. TABLEDokument1 SeitePIPE Sizes and Sch. TABLEs.vijayaraghavanNoch keine Bewertungen

- Lifting Lug Calculation 4april2018Dokument2 SeitenLifting Lug Calculation 4april2018Diosdado Mingi Jr.Noch keine Bewertungen

- Shell Type Boiler CalculationsDokument17 SeitenShell Type Boiler Calculations9913489806Noch keine Bewertungen

- 2 A Davit CalculationDokument30 Seiten2 A Davit CalculationKarina RoquelNoch keine Bewertungen

- Design CalcDokument308 SeitenDesign CalcPeja Jusoh100% (1)

- Double V Weld CalculationDokument8 SeitenDouble V Weld CalculationHgagselim SelimNoch keine Bewertungen

- Lifting LugDokument5 SeitenLifting LugFarid Tata100% (1)

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Dokument35 SeitenDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainNoch keine Bewertungen

- Metric Bolt Torque - Thread StrengthDokument7 SeitenMetric Bolt Torque - Thread StrengthbakellyNoch keine Bewertungen

- Davit CalcDokument4 SeitenDavit CalcrustamriyadiNoch keine Bewertungen

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADokument1 Seite2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanNoch keine Bewertungen

- Design Calculations For Anchor BoltDokument1 SeiteDesign Calculations For Anchor BoltAkshat JainNoch keine Bewertungen

- Final Weld Strength CalnsDokument5 SeitenFinal Weld Strength CalnsamachmouchiNoch keine Bewertungen

- 321 Chapter 5 Splice DesignDokument91 Seiten321 Chapter 5 Splice DesignHemant Ramesh NarkarNoch keine Bewertungen

- Moment Connection Beam Column IS & BS SECTION FOR IS800Dokument29 SeitenMoment Connection Beam Column IS & BS SECTION FOR IS800pjuvvadi86% (7)

- Tailing Lug Calculations-01Dokument2 SeitenTailing Lug Calculations-01Sajal KulshresthaNoch keine Bewertungen

- Strainer Information PDFDokument6 SeitenStrainer Information PDFmahdiNoch keine Bewertungen

- FAB Yearend Spend Campaign Oct Jan2020 TnC1Dokument1 SeiteFAB Yearend Spend Campaign Oct Jan2020 TnC1Satyanarayana MukkuNoch keine Bewertungen

- Enjoy 2% Cashback: Use Your Samba Credit Card at Kalyan Jewellers andDokument1 SeiteEnjoy 2% Cashback: Use Your Samba Credit Card at Kalyan Jewellers andSajal KulshresthaNoch keine Bewertungen

- CBD Credit Card Cashback T&CsDokument2 SeitenCBD Credit Card Cashback T&CsSajal KulshresthaNoch keine Bewertungen

- Grade 1 Science WorksheetDokument3 SeitenGrade 1 Science WorksheetSajal KulshresthaNoch keine Bewertungen

- Ellipsoidal Head Dimensional CharacteristicsDokument2 SeitenEllipsoidal Head Dimensional CharacteristicsSajal KulshresthaNoch keine Bewertungen

- Strainer Information PDFDokument6 SeitenStrainer Information PDFmahdiNoch keine Bewertungen

- Grade 1Dokument2 SeitenGrade 1Sajal KulshresthaNoch keine Bewertungen

- Arabian Oryx Physical FeaturesDokument4 SeitenArabian Oryx Physical FeaturesSajal KulshresthaNoch keine Bewertungen

- FirstRewardsCatalogue PDFDokument9 SeitenFirstRewardsCatalogue PDFSajal KulshresthaNoch keine Bewertungen

- Pressure VesselsDokument9 SeitenPressure VesselsSajal KulshresthaNoch keine Bewertungen

- Modal Mass IDokument8 SeitenModal Mass ISajal KulshresthaNoch keine Bewertungen

- Hotl ListDokument1 SeiteHotl ListSajal KulshresthaNoch keine Bewertungen

- Close Bank Account RequestDokument1 SeiteClose Bank Account RequestlogisrinivasNoch keine Bewertungen

- Form 15G TDS waiverDokument2 SeitenForm 15G TDS waiverPalaniappan Meyyappan83% (6)

- Form No. 15 H: Bar Code: PanDokument2 SeitenForm No. 15 H: Bar Code: PanSajal KulshresthaNoch keine Bewertungen

- Trunnion PDFDokument7 SeitenTrunnion PDFSajal KulshresthaNoch keine Bewertungen

- Seismic Design Lec 2 PDFDokument32 SeitenSeismic Design Lec 2 PDFGuillermo Cordero100% (1)

- The Damage Could Have Been Greater Had He Not Stopped Himself From Paying The Fourth and Final InstalmentDokument1 SeiteThe Damage Could Have Been Greater Had He Not Stopped Himself From Paying The Fourth and Final InstalmentSajal KulshresthaNoch keine Bewertungen

- Harrington Manual Trolleys and Hoists Product Specification FormDokument1 SeiteHarrington Manual Trolleys and Hoists Product Specification FormSajal KulshresthaNoch keine Bewertungen

- Walnut CakeDokument1 SeiteWalnut CakeSajal KulshresthaNoch keine Bewertungen

- Spark Resistance HoistDokument4 SeitenSpark Resistance HoistSajal KulshresthaNoch keine Bewertungen

- WRC 107Dokument3 SeitenWRC 107Aqeel BismaNoch keine Bewertungen

- Input EchoDokument10 SeitenInput EchoSajal KulshresthaNoch keine Bewertungen

- Common Ions Anions and CationsDokument2 SeitenCommon Ions Anions and CationsSajal KulshresthaNoch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- WJM Technologies: Excellence in Material JoiningDokument5 SeitenWJM Technologies: Excellence in Material JoiningA K SinghNoch keine Bewertungen

- AlgurgDokument1 SeiteAlgurgSajal KulshresthaNoch keine Bewertungen

- AccountClosureRequest NewDokument1 SeiteAccountClosureRequest NewSajal KulshresthaNoch keine Bewertungen

- Exchanger CostingDokument2 SeitenExchanger CostingSajal KulshresthaNoch keine Bewertungen

- 3 Steel Grating Catalogue 2010 - SERIES 1 PDFDokument6 Seiten3 Steel Grating Catalogue 2010 - SERIES 1 PDFPablo MatrakaNoch keine Bewertungen

- The Invisible Hero Final TNDokument8 SeitenThe Invisible Hero Final TNKatherine ShenNoch keine Bewertungen

- Osora Nzeribe ResumeDokument5 SeitenOsora Nzeribe ResumeHARSHANoch keine Bewertungen

- Rescue Triangle PDFDokument18 SeitenRescue Triangle PDFrabas_Noch keine Bewertungen

- Marksmanship: Subject: III. Definition of TermsDokument16 SeitenMarksmanship: Subject: III. Definition of TermsAmber EbayaNoch keine Bewertungen

- Chapter 1 - IntroductionDokument42 SeitenChapter 1 - IntroductionShola ayipNoch keine Bewertungen

- BỘ GIÁO DỤC VÀ ĐÀO TẠO ĐỀ THI HỌC PHẦN KINH TẾ VĨ MÔDokument5 SeitenBỘ GIÁO DỤC VÀ ĐÀO TẠO ĐỀ THI HỌC PHẦN KINH TẾ VĨ MÔPhạm Thu NgaNoch keine Bewertungen

- JR Hydraulic Eng. Waterways Bed Protection Incomat BelfastDokument2 SeitenJR Hydraulic Eng. Waterways Bed Protection Incomat Belfastpablopadawan1Noch keine Bewertungen

- 9AKK101130D1664 OISxx Evolution PresentationDokument16 Seiten9AKK101130D1664 OISxx Evolution PresentationfxvNoch keine Bewertungen

- Little Book of Effective WritingDokument44 SeitenLittle Book of Effective Writingshalashvili100% (1)

- Electrocardiography - Wikipedia, The Free EncyclopediaDokument18 SeitenElectrocardiography - Wikipedia, The Free Encyclopediapayments8543Noch keine Bewertungen

- Tupperware India's Perception StudyDokument10 SeitenTupperware India's Perception StudyAnmol RahangdaleNoch keine Bewertungen

- STERNOL Specification ToolDokument15 SeitenSTERNOL Specification ToolMahdyZargarNoch keine Bewertungen

- Main Hoon Na - WikipediaDokument8 SeitenMain Hoon Na - WikipediaHusain ChandNoch keine Bewertungen

- 01 Design of Flexible Pavement Using Coir GeotextilesDokument126 Seiten01 Design of Flexible Pavement Using Coir GeotextilesSreeja Sadanandan100% (1)

- EMMS SpecificationsDokument18 SeitenEMMS SpecificationsAnonymous dJtVwACc100% (2)

- Dr. Malik's Farms BrochureDokument18 SeitenDr. Malik's Farms BrochureNeil AgshikarNoch keine Bewertungen

- Choose the Best WordDokument7 SeitenChoose the Best WordJohnny JohnnieeNoch keine Bewertungen

- Plant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirDokument20 SeitenPlant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirSharad KokateNoch keine Bewertungen

- Chemical Cleaning Products Are Destroying The Ecosystem and Your Septic Tank - Organica BiotechDokument14 SeitenChemical Cleaning Products Are Destroying The Ecosystem and Your Septic Tank - Organica BiotechKrispin FongNoch keine Bewertungen

- Wsi PSDDokument18 SeitenWsi PSDДрагиша Небитни ТрифуновићNoch keine Bewertungen

- Complete Hemi Sync Gateway Experience ManualDokument43 SeitenComplete Hemi Sync Gateway Experience Manualapi-385433292% (92)

- Legal Principles and The Limits of The Law Raz PDFDokument33 SeitenLegal Principles and The Limits of The Law Raz PDFlpakgpwj100% (2)

- Castel - From Dangerousness To RiskDokument10 SeitenCastel - From Dangerousness To Riskregmatar100% (2)

- ThesisDokument250 SeitenThesislax mediaNoch keine Bewertungen

- Assessing Eyes NCM 103 ChecklistDokument7 SeitenAssessing Eyes NCM 103 ChecklistNicole NipasNoch keine Bewertungen

- Presentation On Ich Topics & Guidelines With A Special Reference ToDokument79 SeitenPresentation On Ich Topics & Guidelines With A Special Reference ToVidyaNoch keine Bewertungen

- Indian Institute OF Management, BangaloreDokument20 SeitenIndian Institute OF Management, BangaloreGagandeep SinghNoch keine Bewertungen

- No.6 Role-Of-Child-Health-NurseDokument8 SeitenNo.6 Role-Of-Child-Health-NursePawan BatthNoch keine Bewertungen

- Manual - Sentron Pac Profibus Do Modul - 2009 02 - en PDFDokument106 SeitenManual - Sentron Pac Profibus Do Modul - 2009 02 - en PDFDante Renee Mendoza DelgadoNoch keine Bewertungen