Beruflich Dokumente

Kultur Dokumente

MgSo4 Test

Hochgeladen von

Utpal MondalOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MgSo4 Test

Hochgeladen von

Utpal MondalCopyright:

Verfügbare Formate

Standard Test Method for Soundness of Aggregates by Use of Magnesium Sulfate (ASTM C 88)

MgSO4 Solution Preparation : 1) Take 1400 g of the Heptahydrate Magnesium Sulfate (MgSO47H2O) 2) Mix it Well in 1 liter of distilled water at 25 to 30 C. 3) Thoroughly stir the mixture during the addition of the salt and stir the solution at frequent intervals until used 4) To reduce evaporation and prevent contamination, keep the solution covered at all times when access is not needed. 5) Allow the solution to cool to at (21 1C). 6) Again stir, and allow the solution to remain at the designated temperature for at least 48 h before use. 7) Prior to each use, break up the salt cake, if any, in the container, stir the solution thoroughly. 8) Check the Specific Gravity. It should be between 1.295 to 1.308. 9) Discard a discolored solution, or filter it and check for specific gravity. 10) Solution is ready to use.

Note : it is recommended that the heptahydrate salt be used and in an amount of not less than 1400 g/litre of water because an excess of crystals be present.

Test Procedure : Fine Aggregates Sample Preparation: 1) Take 2500 gm fine aggregates passing 100% of 4.75 mm sieve. 2) Wash it 300 mic sieve thoroughly and dry to constant mass. 3) Sieve it & prepare sample on following basic. a) 600 mic passing & 300 mic retained 120 gm b) 1.18 mm passing & 600 mic retained 120 gm c) 2.36 mm passing & 1.18 mm retained 120 gm d) 4.75 mm passing & 2.36 mm retained 120 gm 4) Re-sieve to refusal on same sieve and take sample 1000.1 gm of each part. Note : Should the sample have less than 30% retained on the 300 m sieve, it is deemed to be too fine and no test is done on any fraction. If any fraction constitutes less than 5% of the sample, it shall not be tested. Procedure: 1) Place each fraction in a separate suitable wire basket / Container. 2) Immerse the samples in the prepared solution for 16 to 18 h in such a manner that the solution covers them to a depth of at least 15 mm @ 211 C. 3) After the immersion period, remove the samples from the solution, drain for 30 5 min., and place in drying oven at 1105C for 6 to 8 h. Constant mass will be considered to be achieved when the loss is less than 0.1% of sample mass in 4 h of drying. 4) After achieving constant mass, allow samples to cool to room temp. and immerse in solution. 5) Repeat the process of alternate immersion and drying for 5 cycles. 6) After completion of the final cycle, and after the sample has cooled, wash the sample free from the magnesium sulphate as determined by the reaction of the wash water with a 3% (by mass) barium chloride (BaCl2). 6) Wash by circulating hot tap water (40 to 60C) in their containers. 7) After the MgSO4 has been removed, dry the samples to a constant weight at 110 5.0C. 8) Sieve the fine aggregate over the same sieve on which it was retained before the test, nesting the sieves so that the finest is on the top and the coarsest is on the bottom. 9) Weigh the material retained on each sieve.

Das könnte Ihnen auch gefallen

- Pharmacy Calculation Workbook: 250 Questions to Prepare for the NAPLEX and PTCB ExamVon EverandPharmacy Calculation Workbook: 250 Questions to Prepare for the NAPLEX and PTCB ExamBewertung: 5 von 5 Sternen5/5 (1)

- Soundness Test For AggregateDokument3 SeitenSoundness Test For AggregateMastani BajiraoNoch keine Bewertungen

- Soundness Test by Use of Magnesium SulfateDokument9 SeitenSoundness Test by Use of Magnesium Sulfatesterces011Noch keine Bewertungen

- Soundness Test of Aggregates: by Use of Sodium Sulfate or Magnesium Sulfate ASTM C-88 Aashto T104Dokument19 SeitenSoundness Test of Aggregates: by Use of Sodium Sulfate or Magnesium Sulfate ASTM C-88 Aashto T104Mj AustriaNoch keine Bewertungen

- Experiment No 8 Soundness TestDokument6 SeitenExperiment No 8 Soundness Testfaiz19aaNoch keine Bewertungen

- Soundness of Aggregates by Use of Sodium Sulfate or Magnesium SulfateDokument34 SeitenSoundness of Aggregates by Use of Sodium Sulfate or Magnesium SulfateFaith GandaNoch keine Bewertungen

- SOUNDNESSDokument2 SeitenSOUNDNESSibad ullahNoch keine Bewertungen

- Detailed Protocol 2Dokument2 SeitenDetailed Protocol 2Martha Lucia CepedaNoch keine Bewertungen

- Analytical Procedure For Total Sulphate ContentDokument1 SeiteAnalytical Procedure For Total Sulphate ContentPrashant DevdaNoch keine Bewertungen

- 2.3 Analytical Method 2.3.1 PH TestDokument9 Seiten2.3 Analytical Method 2.3.1 PH TestSusi MulyaniNoch keine Bewertungen

- Soundness of Aggregate by U Se of Sodium Sulfate or Magnésium SulfateDokument10 SeitenSoundness of Aggregate by U Se of Sodium Sulfate or Magnésium SulfatesitrakiniavoNoch keine Bewertungen

- ABIN6975603 ManualDokument12 SeitenABIN6975603 ManualAhmed AliNoch keine Bewertungen

- Experiment 2 Determination of Sulfate (As %SO3) in A Soluble SampleDokument4 SeitenExperiment 2 Determination of Sulfate (As %SO3) in A Soluble SampleCharmaine Dela Cruz0% (1)

- This Protocol Describes The Production of Competent Yeast Cells For Lithium AcetateDokument7 SeitenThis Protocol Describes The Production of Competent Yeast Cells For Lithium AcetateMohd AimanNoch keine Bewertungen

- Haccp Procedures and Micro TestingDokument20 SeitenHaccp Procedures and Micro TestingUttam Kumar DashNoch keine Bewertungen

- Handout For Workshop (DAY 01) (KSBT)Dokument7 SeitenHandout For Workshop (DAY 01) (KSBT)Michael KahnwaldNoch keine Bewertungen

- Mashal 069Dokument6 SeitenMashal 069Fayyaz AhmadNoch keine Bewertungen

- EPA Method 160 1Dokument3 SeitenEPA Method 160 1Gustavo Leonardo Huidobro MussoNoch keine Bewertungen

- Procedure For Doc PadlaDokument5 SeitenProcedure For Doc PadlaAnna H. NavarroNoch keine Bewertungen

- Method 1:0: Preparation of The Sample For AnalysisDokument4 SeitenMethod 1:0: Preparation of The Sample For AnalysisgabisoNoch keine Bewertungen

- Protocol For Bigdye Preparing Sequencing SamplesDokument4 SeitenProtocol For Bigdye Preparing Sequencing SamplesDaniel FilhoNoch keine Bewertungen

- Chapter Two FavourDokument18 SeitenChapter Two FavourStephanie ChidinmaNoch keine Bewertungen

- Acid Detergent Fiber Procedure (ADF) : 1. ApplicationDokument4 SeitenAcid Detergent Fiber Procedure (ADF) : 1. ApplicationFarai FaustosNoch keine Bewertungen

- Sandwich ELISA Kit For Dysferlin: ABIN6955479Dokument11 SeitenSandwich ELISA Kit For Dysferlin: ABIN6955479Trd FFNoch keine Bewertungen

- Rat Tumor Necrosis Factor α (TNF-α) ELISA KitDokument8 SeitenRat Tumor Necrosis Factor α (TNF-α) ELISA KitSamuelNoch keine Bewertungen

- Molybdenite Concentrates: Procedure For The Assaying ofDokument12 SeitenMolybdenite Concentrates: Procedure For The Assaying ofMiguel Castillo LeyvaNoch keine Bewertungen

- (Intended Use) : Instruction ManualDokument8 Seiten(Intended Use) : Instruction ManualTPNoch keine Bewertungen

- AOAC 935.29 Moisture in MaltDokument1 SeiteAOAC 935.29 Moisture in MaltCarmen LinaresNoch keine Bewertungen

- Soundness TestDokument2 SeitenSoundness TestDeven PatleNoch keine Bewertungen

- Suspensibility WPDokument2 SeitenSuspensibility WPNadeem Mirza100% (1)

- 308 2017 Application Note Determination of Oil Content in Seed Samples 0Dokument8 Seiten308 2017 Application Note Determination of Oil Content in Seed Samples 0Hà Thị Thanh TịnhNoch keine Bewertungen

- Aashto T-104 PDFDokument10 SeitenAashto T-104 PDFthauwui8650% (2)

- Jar Test For Determining Optimum Coagulant DosageDokument2 SeitenJar Test For Determining Optimum Coagulant DosageTauseef TariqNoch keine Bewertungen

- (Intended Use) : Instruction ManualDokument8 Seiten(Intended Use) : Instruction ManualTPNoch keine Bewertungen

- AASHTO T-104 (Año 2007)Dokument10 SeitenAASHTO T-104 (Año 2007)Roberto VasquezNoch keine Bewertungen

- Competent Cells Low Temp MethDokument2 SeitenCompetent Cells Low Temp MethJose ManuelNoch keine Bewertungen

- Sorghum Quality ParametersDokument37 SeitenSorghum Quality ParametersnarayananNoch keine Bewertungen

- Determination of Total Suspended SolidsDokument2 SeitenDetermination of Total Suspended Solidstanmay_envs100% (1)

- 3.2. S.4.2 Analytical ProcedureDokument8 Seiten3.2. S.4.2 Analytical ProcedureRaul JimenezNoch keine Bewertungen

- K-Sdam DataDokument12 SeitenK-Sdam Data2nmzgbvk6cNoch keine Bewertungen

- Competition ELISA Kit For Arginine Vasopressin: ABIN6953918Dokument11 SeitenCompetition ELISA Kit For Arginine Vasopressin: ABIN6953918ullifannuriNoch keine Bewertungen

- Low Level Measurement of Cadmium in Foods: AA-97 May 1990Dokument5 SeitenLow Level Measurement of Cadmium in Foods: AA-97 May 1990ابزار دقیقNoch keine Bewertungen

- Immunoflourescence Procedures: Normal Sera For Immunohistochemistry Buffers General SolutionsDokument1 SeiteImmunoflourescence Procedures: Normal Sera For Immunohistochemistry Buffers General SolutionsMohd Helmy MokhtarNoch keine Bewertungen

- Material and MethodsDokument9 SeitenMaterial and MethodsNaga BhushanNoch keine Bewertungen

- DNA Extraction (Using The Omega Biotek E.Z.N.A. Mollusc DNA Kit)Dokument3 SeitenDNA Extraction (Using The Omega Biotek E.Z.N.A. Mollusc DNA Kit)xicoalexandreNoch keine Bewertungen

- EPA Method - 418 - 1-Total Petroleum HydrocarbonsDokument3 SeitenEPA Method - 418 - 1-Total Petroleum HydrocarbonsMeetika GuptaNoch keine Bewertungen

- Western Blot Protoco1 - UpdateDokument4 SeitenWestern Blot Protoco1 - UpdateMichael DaleyNoch keine Bewertungen

- Ammoniacal Nitrogen Analysis EPA Method 350.1Dokument6 SeitenAmmoniacal Nitrogen Analysis EPA Method 350.1cherry0% (1)

- Detection of DNA Fragmentation: Toxicology LabDokument5 SeitenDetection of DNA Fragmentation: Toxicology Labamaal ramadanNoch keine Bewertungen

- ACFrOgA4vMgj582kVwOj24JX0HRoLncETTiCmvayF-NkYDz4zFD-3InaLDzXQ P4kqee7wVAtbFehpka C 8R-Uxs4B3spyaF27u9MRssKiaQvK3BdHr 3T3chD2fZpdhB T1H5Xc0MdvVHyPKXdDokument3 SeitenACFrOgA4vMgj582kVwOj24JX0HRoLncETTiCmvayF-NkYDz4zFD-3InaLDzXQ P4kqee7wVAtbFehpka C 8R-Uxs4B3spyaF27u9MRssKiaQvK3BdHr 3T3chD2fZpdhB T1H5Xc0MdvVHyPKXdTecnico FisicoquimicaNoch keine Bewertungen

- Glomalin ExtractDokument2 SeitenGlomalin ExtractBashbouryNoch keine Bewertungen

- Total Suspended SolidsDokument3 SeitenTotal Suspended SolidsOpata OpataNoch keine Bewertungen

- Experimental ReportDokument2 SeitenExperimental ReportJun Ming SunNoch keine Bewertungen

- IMOA AssayingMoConcentratesDokument13 SeitenIMOA AssayingMoConcentratesPUTODIXONVOL2Noch keine Bewertungen

- Soundness TestDokument3 SeitenSoundness TestYasirNoch keine Bewertungen

- Mbpracticas LabDokument6 SeitenMbpracticas LabRosa VelásquezNoch keine Bewertungen

- MELUH Yeast ChIP ProtocolDokument8 SeitenMELUH Yeast ChIP ProtocolsurendrasrawanNoch keine Bewertungen

- Determination of The PH Value of Water Using A PH MeterDokument7 SeitenDetermination of The PH Value of Water Using A PH MeterRome Dionisio Komicho100% (1)

- Procedures: Experiment 1. Reagents RequiredDokument2 SeitenProcedures: Experiment 1. Reagents RequiredAmrita MishraNoch keine Bewertungen

- 6 11 3-A-AmylaseDokument3 Seiten6 11 3-A-Amylasesml03137355727Noch keine Bewertungen

- Information Brochure M.sc. B.tech.Dokument3 SeitenInformation Brochure M.sc. B.tech.Utpal MondalNoch keine Bewertungen

- Asphalt General SpecDokument39 SeitenAsphalt General SpecUtpal MondalNoch keine Bewertungen

- Scheme Details: Outright SaleDokument1 SeiteScheme Details: Outright SaleUtpal MondalNoch keine Bewertungen

- Asphalt Special SpecDokument16 SeitenAsphalt Special SpecUtpal MondalNoch keine Bewertungen

- Ncat 1087 ManualDokument69 SeitenNcat 1087 ManualSreekanthNoch keine Bewertungen

- MDD OmcDokument2 SeitenMDD OmcUtpal Mondal100% (1)

- Quality Week - Agenda PDFDokument1 SeiteQuality Week - Agenda PDFUtpal MondalNoch keine Bewertungen

- Alccofine 1203Dokument1 SeiteAlccofine 1203Utpal MondalNoch keine Bewertungen

- Summary of Excavated Soil Sample Results Dated 27.10.13Dokument4 SeitenSummary of Excavated Soil Sample Results Dated 27.10.13Utpal MondalNoch keine Bewertungen

- C 11 - R0 Sand Equivalent Value - Barka Batching PlantDokument1 SeiteC 11 - R0 Sand Equivalent Value - Barka Batching PlantUtpal Mondal100% (1)

- 4th WEEK SEPTDokument8 Seiten4th WEEK SEPTUtpal MondalNoch keine Bewertungen

- C 09 - R0 Los Angeles Abrasion - Barka Batching PlantDokument5 SeitenC 09 - R0 Los Angeles Abrasion - Barka Batching PlantUtpal MondalNoch keine Bewertungen

- Class Cement Content (Kg/Cum) Admixture Qty (Ltr/Cum) % Weight of Cement ContentDokument1 SeiteClass Cement Content (Kg/Cum) Admixture Qty (Ltr/Cum) % Weight of Cement ContentUtpal MondalNoch keine Bewertungen

- Preparation of Concrete Cubes: Concrete Batching Plant, BarkaDokument1 SeitePreparation of Concrete Cubes: Concrete Batching Plant, BarkaUtpal MondalNoch keine Bewertungen

- 01 TM 014 C40 20 MS Concrete Mix ProportionsDokument1 Seite01 TM 014 C40 20 MS Concrete Mix ProportionsUtpal Mondal100% (1)

- 01 TM 013 C30 20 08 06 2013 Mix ProportionDokument1 Seite01 TM 013 C30 20 08 06 2013 Mix ProportionUtpal MondalNoch keine Bewertungen

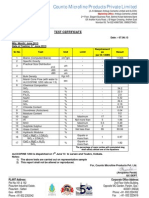

- Material Test July 2013: Concrete Batching Plant - BarkaDokument2 SeitenMaterial Test July 2013: Concrete Batching Plant - BarkaUtpal MondalNoch keine Bewertungen

- Boolean Algebra & Karnaugh Maps: Points To RememberDokument8 SeitenBoolean Algebra & Karnaugh Maps: Points To RememberUtpal MondalNoch keine Bewertungen

- Testing: Coarse Aggregate Specific GravityDokument16 SeitenTesting: Coarse Aggregate Specific GravityUtpal MondalNoch keine Bewertungen

- Technip Separations PDFDokument9 SeitenTechnip Separations PDFProcess EngineerNoch keine Bewertungen

- Amphotericin BDokument14 SeitenAmphotericin BJuan David BastidasNoch keine Bewertungen

- Organic ReactionDokument9 SeitenOrganic Reactionliska ramdanawatiNoch keine Bewertungen

- Hess's Law Bond Enthalpies 5.3 (22 Marks) : 1a. (1 Mark)Dokument6 SeitenHess's Law Bond Enthalpies 5.3 (22 Marks) : 1a. (1 Mark)sennaNoch keine Bewertungen

- Unit-2 Water ChemistryDokument15 SeitenUnit-2 Water ChemistryKunjal singhNoch keine Bewertungen

- GUARD DOG™ UV119 Light StabilizerDokument2 SeitenGUARD DOG™ UV119 Light StabilizerXuân Giang NguyễnNoch keine Bewertungen

- International Journal of Pharmtech Research: Burn Wound Healing Activity of Hydrolyzed Virgin Coconut OilDokument7 SeitenInternational Journal of Pharmtech Research: Burn Wound Healing Activity of Hydrolyzed Virgin Coconut OilLion PamungkasNoch keine Bewertungen

- Why Plastic Parts FailDokument4 SeitenWhy Plastic Parts FailGowtham Kae KaeNoch keine Bewertungen

- Gmail FWD - 1ST QUARTER GENERAL CHEMISTRY 1 SUMMATIVE TESTDokument6 SeitenGmail FWD - 1ST QUARTER GENERAL CHEMISTRY 1 SUMMATIVE TESTGaby DuranNoch keine Bewertungen

- FL 2020-04-13 Toksikologi PelarutDokument44 SeitenFL 2020-04-13 Toksikologi PelarutRandi kautNoch keine Bewertungen

- Hydration of AminesDokument4 SeitenHydration of AminesinejattNoch keine Bewertungen

- DOE Gasification Program OverviewDokument148 SeitenDOE Gasification Program OverviewJohn DalkiaNoch keine Bewertungen

- Nitoseal 280: Constructive SolutionsDokument2 SeitenNitoseal 280: Constructive SolutionshasanalharisalaydrusNoch keine Bewertungen

- Passivation: Corrosion ProtectionDokument51 SeitenPassivation: Corrosion ProtectiondangminhNoch keine Bewertungen

- AS024 PT Sophia Ellen FurnitureDokument6 SeitenAS024 PT Sophia Ellen FurnitureLukman AlmalikiNoch keine Bewertungen

- ZI-CHEM Coagulant Flocculant Product Summary 18 List 1Dokument2 SeitenZI-CHEM Coagulant Flocculant Product Summary 18 List 1Ari WijayaNoch keine Bewertungen

- Difference Between Wax and OilDokument26 SeitenDifference Between Wax and OilJessa Mae Malinao100% (2)

- Physical Chemistry Practical: Laboratory ManualDokument22 SeitenPhysical Chemistry Practical: Laboratory ManualSoham MukherjeeNoch keine Bewertungen

- Checkpoint ChemistryDokument18 SeitenCheckpoint ChemistryNgoc Quang NguyenNoch keine Bewertungen

- A - General IndexDokument24 SeitenA - General IndexzargeenaNoch keine Bewertungen

- Public Note of Genrx PharmaDokument26 SeitenPublic Note of Genrx Pharmatowaf57520Noch keine Bewertungen

- Carbon Dioxide Capture by Amines Increasing The Efficiency by Amine Structure Modification PDFDokument2 SeitenCarbon Dioxide Capture by Amines Increasing The Efficiency by Amine Structure Modification PDFJorgeSantosAquinoNoch keine Bewertungen

- LCM Catalouge PDFDokument20 SeitenLCM Catalouge PDFRSD Water SolutionNoch keine Bewertungen

- UV-4024 MSDS (英文版)Dokument4 SeitenUV-4024 MSDS (英文版)urbaezNoch keine Bewertungen

- CHEM 1307 Exam 1 Practice Problems: C CL P K NDokument5 SeitenCHEM 1307 Exam 1 Practice Problems: C CL P K NPayal PawarNoch keine Bewertungen

- Ole2 BufferDokument19 SeitenOle2 BufferKherulJefriJamenNoch keine Bewertungen

- ORGHEM LAB HydrocarbonsDokument11 SeitenORGHEM LAB HydrocarbonsJasmine CatanaNoch keine Bewertungen

- AP X-Super Lube Cj-4Dokument1 SeiteAP X-Super Lube Cj-4Sami KahtaniNoch keine Bewertungen

- 2423 e 3Dokument21 Seiten2423 e 3Abdel Rahman MohamedNoch keine Bewertungen

- Return of the God Hypothesis: Three Scientific Discoveries That Reveal the Mind Behind the UniverseVon EverandReturn of the God Hypothesis: Three Scientific Discoveries That Reveal the Mind Behind the UniverseBewertung: 4.5 von 5 Sternen4.5/5 (52)

- 10% Human: How Your Body's Microbes Hold the Key to Health and HappinessVon Everand10% Human: How Your Body's Microbes Hold the Key to Health and HappinessBewertung: 4 von 5 Sternen4/5 (33)

- Why We Die: The New Science of Aging and the Quest for ImmortalityVon EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityBewertung: 4 von 5 Sternen4/5 (5)

- When the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisVon EverandWhen the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Masterminds: Genius, DNA, and the Quest to Rewrite LifeVon EverandMasterminds: Genius, DNA, and the Quest to Rewrite LifeNoch keine Bewertungen

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldVon EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldBewertung: 4 von 5 Sternen4/5 (597)

- Who's in Charge?: Free Will and the Science of the BrainVon EverandWho's in Charge?: Free Will and the Science of the BrainBewertung: 4 von 5 Sternen4/5 (65)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincVon EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincBewertung: 3.5 von 5 Sternen3.5/5 (137)

- A Brief History of Intelligence: Evolution, AI, and the Five Breakthroughs That Made Our BrainsVon EverandA Brief History of Intelligence: Evolution, AI, and the Five Breakthroughs That Made Our BrainsBewertung: 4.5 von 5 Sternen4.5/5 (6)

- The Molecule of More: How a Single Chemical in Your Brain Drives Love, Sex, and Creativity--and Will Determine the Fate of the Human RaceVon EverandThe Molecule of More: How a Single Chemical in Your Brain Drives Love, Sex, and Creativity--and Will Determine the Fate of the Human RaceBewertung: 4.5 von 5 Sternen4.5/5 (517)

- Tales from Both Sides of the Brain: A Life in NeuroscienceVon EverandTales from Both Sides of the Brain: A Life in NeuroscienceBewertung: 3 von 5 Sternen3/5 (18)

- Gut: the new and revised Sunday Times bestsellerVon EverandGut: the new and revised Sunday Times bestsellerBewertung: 4 von 5 Sternen4/5 (393)

- Buddha's Brain: The Practical Neuroscience of Happiness, Love & WisdomVon EverandBuddha's Brain: The Practical Neuroscience of Happiness, Love & WisdomBewertung: 4 von 5 Sternen4/5 (216)

- All That Remains: A Renowned Forensic Scientist on Death, Mortality, and Solving CrimesVon EverandAll That Remains: A Renowned Forensic Scientist on Death, Mortality, and Solving CrimesBewertung: 4.5 von 5 Sternen4.5/5 (397)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionVon EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionBewertung: 4 von 5 Sternen4/5 (812)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildVon EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildBewertung: 4.5 von 5 Sternen4.5/5 (44)

- Seven and a Half Lessons About the BrainVon EverandSeven and a Half Lessons About the BrainBewertung: 4 von 5 Sternen4/5 (111)

- Gut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)Von EverandGut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)Bewertung: 4 von 5 Sternen4/5 (411)

- Fast Asleep: Improve Brain Function, Lose Weight, Boost Your Mood, Reduce Stress, and Become a Better SleeperVon EverandFast Asleep: Improve Brain Function, Lose Weight, Boost Your Mood, Reduce Stress, and Become a Better SleeperBewertung: 4.5 von 5 Sternen4.5/5 (16)

- The Other Side of Normal: How Biology Is Providing the Clues to Unlock the Secrets of Normal and Abnormal BehaviorVon EverandThe Other Side of Normal: How Biology Is Providing the Clues to Unlock the Secrets of Normal and Abnormal BehaviorNoch keine Bewertungen

- Undeniable: How Biology Confirms Our Intuition That Life Is DesignedVon EverandUndeniable: How Biology Confirms Our Intuition That Life Is DesignedBewertung: 4 von 5 Sternen4/5 (11)

- Darwin's Doubt: The Explosive Origin of Animal Life and the Case for Intelligent DesignVon EverandDarwin's Doubt: The Explosive Origin of Animal Life and the Case for Intelligent DesignBewertung: 4.5 von 5 Sternen4.5/5 (39)

- Human: The Science Behind What Makes Your Brain UniqueVon EverandHuman: The Science Behind What Makes Your Brain UniqueBewertung: 3.5 von 5 Sternen3.5/5 (38)

- Moral Tribes: Emotion, Reason, and the Gap Between Us and ThemVon EverandMoral Tribes: Emotion, Reason, and the Gap Between Us and ThemBewertung: 4.5 von 5 Sternen4.5/5 (116)

- The Consciousness Instinct: Unraveling the Mystery of How the Brain Makes the MindVon EverandThe Consciousness Instinct: Unraveling the Mystery of How the Brain Makes the MindBewertung: 4.5 von 5 Sternen4.5/5 (93)