Beruflich Dokumente

Kultur Dokumente

(Tim Gilles) Automotive Engines Diagnosis Repair

Hochgeladen von

Ambangan SiregarOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

(Tim Gilles) Automotive Engines Diagnosis Repair

Hochgeladen von

Ambangan SiregarCopyright:

Verfügbare Formate

CHAPTER 13

Pistons, Rings, and Connecting Rods

487

CONNECTING RODS

Connecting rods are usually made of forged or cast steel. Some racing rods are made of forged aluminum (see Figure 13.67). Forged rods are stronger than cast rods, but casting has been improved to the point that some late-model passenger car engines use cast rods because they cost less. Rods are generally made in an I-beam shape for strength. The big end of each rod is precisely ground to achieve perfect oil clearance and crush on the rod bearings when the rod and bearing inserts are installed on the crank journal. Rod caps are not interchangeable. If they are interchanged, the oil clearances of the bearings can vary greatly and the crank might not even be able to turn.

SHOP TIP

FIGURE 13.67 A piston-and-rod assembly from a top-fuel dragster uses an aluminum spacer at each end of the piston pin. (Courtesy of Tim Gilles)

On a V-type engine, if the rods and caps were not numbered during disassembly, try to match them up as closely as possible by looking to see if the chamfers on the edge of the bore line up.

type of retaining ring coming out under the tremendous loads experienced on the piston assemblies in a 6000-horsepower engine.

SHOP TIP

Full-floating pins often fit snugly in the piston when cold. To remove the piston pin easily, first heat the piston in hot water.

Direction of Piston on Connecting Rod

Be sure to keep track of the direction the connecting rod faces in relation to the top of the piston. Pistons have a notch on the side of the piston head that faces the front of the engine (Figure 13.68).

Rod bolts usually have slightly enlarged shanks to hold them tight in the rod (Figure 13.69). The cap has precise holes that line up with this enlarged area of the bolt to prevent misalignment of the rod and cap when they are assembled. The notches cut in the rod for the bearing locating lugs usually face each other when correctly installed (Figure 13.70). Incorrect installation of the rod cap can cause uneven bearing wear (Figure 13.71).

NOTE

Overtorque of rod bolts can cause them to fail during deceleration when the load is on the bolt instead of on the rod (Figure 13.72).

SHOP TIP

A good way to keep track of piston/connecting rod direction during piston replacement is to put the piston notch to the right and then mark the side of the rod cap that is facing up with a felt marker or electric engraver. This will make it easy to install the new pistons properly. On a V-type engine, half the numbers will be up and half will be down.

Sintered Powder-Forged Fractured Rods

Some newer connecting rods are powder forged. Iron powder, graphite, and copper are precast in molds that are close to what the final rod will look like. The mixture is heated to sinter the mixture together. Then they are forged in a forging press.

Das könnte Ihnen auch gefallen

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesVon EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesBewertung: 5 von 5 Sternen5/5 (1)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreVon EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreBewertung: 4.5 von 5 Sternen4.5/5 (11)

- The Engine Tuning BibleDokument14 SeitenThe Engine Tuning BiblexerwaneNoch keine Bewertungen

- Vincent TechnicalDokument58 SeitenVincent TechnicalCiprian MaiorNoch keine Bewertungen

- Pp16aDokument86 SeitenPp16aWagih Abd El-AzizNoch keine Bewertungen

- Fundamentals of Alignment PDFDokument66 SeitenFundamentals of Alignment PDFAmal TharakaNoch keine Bewertungen

- Adjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersDokument13 SeitenAdjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersJ.d. LangleyNoch keine Bewertungen

- Camaro 5th Gen 2010-2015: How to Build and ModifyVon EverandCamaro 5th Gen 2010-2015: How to Build and ModifyBewertung: 4.5 von 5 Sternen4.5/5 (3)

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsVon EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNoch keine Bewertungen

- Vehicle Dynamics and Damping: First Revised EditionVon EverandVehicle Dynamics and Damping: First Revised EditionBewertung: 4 von 5 Sternen4/5 (2)

- EFI BasicsDokument168 SeitenEFI BasicsBryanMaes100% (1)

- 2016-Harley-Davidson-Street-Bob Owners ManualDokument193 Seiten2016-Harley-Davidson-Street-Bob Owners ManualCristiano TavaresNoch keine Bewertungen

- Automotive Transmission NewDokument147 SeitenAutomotive Transmission NewhodvmkvecautoNoch keine Bewertungen

- Body Repair Manual PDFDokument170 SeitenBody Repair Manual PDF2663bNoch keine Bewertungen

- The Basics of Valvetrain TechnologyDokument9 SeitenThe Basics of Valvetrain TechnologyChristina SchultzNoch keine Bewertungen

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Von EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Bewertung: 3 von 5 Sternen3/5 (4)

- Vanpelt Flathead Catalog2015Dokument68 SeitenVanpelt Flathead Catalog2015skidbar100% (1)

- RB26 Head PortingDokument24 SeitenRB26 Head PortingJam Bab0% (1)

- The Design of Competition EnginesDokument546 SeitenThe Design of Competition EnginesJoão Victor Paschoal PoletiNoch keine Bewertungen

- Manual Transmission/Transaxle: Service and Repair 1. Transmission DisassembleDokument72 SeitenManual Transmission/Transaxle: Service and Repair 1. Transmission DisassembleRodriitec Y sus Rodrigos100% (1)

- Tech Talks Wheel AlignmentDokument20 SeitenTech Talks Wheel Alignmentdionisio emilio reyes jimenez100% (2)

- 2009-2011 DS Service Manual PDFDokument416 Seiten2009-2011 DS Service Manual PDFDaemionNoch keine Bewertungen

- Offroad Suspension Setup Guide: 4/5 Harford Street PO Box 833 Penrith NSW 2750Dokument12 SeitenOffroad Suspension Setup Guide: 4/5 Harford Street PO Box 833 Penrith NSW 2750AndrésNoch keine Bewertungen

- Building High Performance Engines 2Dokument26 SeitenBuilding High Performance Engines 2lone_anarchistNoch keine Bewertungen

- Automotive FundamentalsDokument53 SeitenAutomotive FundamentalssebsrayNoch keine Bewertungen

- L1 Blue Composite Booklet WEBDokument36 SeitenL1 Blue Composite Booklet WEBcarlosve87Noch keine Bewertungen

- How To Tune and Modify Motorcycle Engine Management SystemsDokument1 SeiteHow To Tune and Modify Motorcycle Engine Management SystemsJuan AguinigaNoch keine Bewertungen

- Contents:: Name:Veeravalli Sunil Varma ROLL NO:17221A0371Dokument9 SeitenContents:: Name:Veeravalli Sunil Varma ROLL NO:17221A0371Sunil Varma VeeravalliNoch keine Bewertungen

- 200-01-3546 Racing Engine Design Options Investigated by Engine SimulationDokument16 Seiten200-01-3546 Racing Engine Design Options Investigated by Engine SimulationGregF1Noch keine Bewertungen

- Sae Technical Paper Series: Lonny L. Thompson, Jon K. Lampert and E. Harry LawDokument12 SeitenSae Technical Paper Series: Lonny L. Thompson, Jon K. Lampert and E. Harry LawSrikanth SridharanNoch keine Bewertungen

- Camshaft and Valvetrain BasicsDokument10 SeitenCamshaft and Valvetrain BasicsRamesh RamasamyNoch keine Bewertungen

- Brake Handbook - Fred PuhnDokument178 SeitenBrake Handbook - Fred PuhnGuilherme Pfeilsticker78% (9)

- Application GuideDokument31 SeitenApplication GuidejavierNoch keine Bewertungen

- The BG Tuning ManualDokument13 SeitenThe BG Tuning Manuald_u_i_l_i_o100% (1)

- EFI Basics PDFDokument168 SeitenEFI Basics PDFgene_buckets100% (2)

- Auto Material CamshaftDokument30 SeitenAuto Material CamshaftHardik ShahNoch keine Bewertungen

- MT Jan-Feb 08 Engine BalancingDokument6 SeitenMT Jan-Feb 08 Engine BalancingTony Foale100% (1)

- Chapter5 Efi SystemDokument74 SeitenChapter5 Efi SystemDavid Perez NavarroNoch keine Bewertungen

- Automotive Braking SystemDokument20 SeitenAutomotive Braking SystemTapan Sen BiswalNoch keine Bewertungen

- Understanding Crankshaft BalancingDokument5 SeitenUnderstanding Crankshaft BalancingVontrex DergonNoch keine Bewertungen

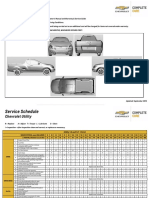

- Service Schedule: Chevrolet UtilityDokument5 SeitenService Schedule: Chevrolet UtilityJamie Whittle100% (2)

- Porsche Panamera S e Hybrid PDFDokument80 SeitenPorsche Panamera S e Hybrid PDFPancho RiveraNoch keine Bewertungen

- Rearend Gear GuideDokument18 SeitenRearend Gear GuideJam BabNoch keine Bewertungen

- Carb Quick Guide - S&S CycleDokument4 SeitenCarb Quick Guide - S&S Cycledevdatt persaudNoch keine Bewertungen

- Suspension Set Up Explained: The Components, Where Are They and What Do They DoDokument5 SeitenSuspension Set Up Explained: The Components, Where Are They and What Do They Doaf00712210Noch keine Bewertungen

- Parking BrakesDokument16 SeitenParking BrakesPanagiotis MakadasisNoch keine Bewertungen

- Holley 2 Barrell Carb 350cfmDokument12 SeitenHolley 2 Barrell Carb 350cfmjaydoo100% (1)

- Hayabusa 2012Dokument2 SeitenHayabusa 2012gosiamailNoch keine Bewertungen

- Inside The TTX Theory and DesignDokument44 SeitenInside The TTX Theory and DesignHarsh Narang100% (2)

- PagesDokument96 SeitenPagesAndré MoreiraNoch keine Bewertungen

- Automotive Encyclopedia Goodheart-WillcoxDokument6 SeitenAutomotive Encyclopedia Goodheart-Willcoxamanapartrs67% (3)

- CEV 2013 Technical Rules Moto3Dokument7 SeitenCEV 2013 Technical Rules Moto3Steve DarcyNoch keine Bewertungen

- Flow Pattern in Horizontal TubeDokument1 SeiteFlow Pattern in Horizontal TubeAmbangan SiregarNoch keine Bewertungen

- Flow Pattern in Horizontal TubeDokument1 SeiteFlow Pattern in Horizontal TubeAmbangan SiregarNoch keine Bewertungen

- AsuDokument1 SeiteAsuAmbangan SiregarNoch keine Bewertungen

- Higher Algebra - Hall & KnightDokument593 SeitenHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- 한국항만 (영문)Dokument38 Seiten한국항만 (영문)hiyeonNoch keine Bewertungen

- SANDWICH Elisa (Procedure) - Immunology Virtual Lab I - Biotechnology and Biomedical Engineering - Amrita Vishwa Vidyapeetham Virtual LabDokument2 SeitenSANDWICH Elisa (Procedure) - Immunology Virtual Lab I - Biotechnology and Biomedical Engineering - Amrita Vishwa Vidyapeetham Virtual LabsantonuNoch keine Bewertungen

- CrimDokument29 SeitenCrimkeziahmae.bagacinaNoch keine Bewertungen

- AIP 2020 FINAL JuneDokument5 SeitenAIP 2020 FINAL JuneVINA ARIETANoch keine Bewertungen

- Volcanoes Sub-topic:Volcanic EruptionDokument16 SeitenVolcanoes Sub-topic:Volcanic EruptionVhenz MapiliNoch keine Bewertungen

- RS2 Stress Analysis Verification Manual - Part 1Dokument166 SeitenRS2 Stress Analysis Verification Manual - Part 1Jordana Furman100% (1)

- MC4 CoCU 6 - Welding Records and Report DocumentationDokument8 SeitenMC4 CoCU 6 - Welding Records and Report Documentationnizam1372100% (1)

- Dragons ScaleDokument13 SeitenDragons ScaleGuilherme De FariasNoch keine Bewertungen

- Entrepreneurial MotivationDokument18 SeitenEntrepreneurial MotivationRagavendra RagsNoch keine Bewertungen

- Rare Watches (Christie's) 16. 05. 2016.Dokument236 SeitenRare Watches (Christie's) 16. 05. 2016.Simon LászlóNoch keine Bewertungen

- Royal British College Dancesport TeamDokument10 SeitenRoyal British College Dancesport TeamAnna rose CabatinganNoch keine Bewertungen

- Science9 Q4 Week2Dokument16 SeitenScience9 Q4 Week2Maria Josie Lopez TumlosNoch keine Bewertungen

- Abdominal Migraine and HomoeopathyDokument17 SeitenAbdominal Migraine and HomoeopathyDr. Rajneesh Kumar Sharma MD HomNoch keine Bewertungen

- Collins Ks3 Science Homework Book 3Dokument5 SeitenCollins Ks3 Science Homework Book 3g3pz0n5h100% (1)

- On The Wings of EcstasyDokument79 SeitenOn The Wings of Ecstasygaya3mageshNoch keine Bewertungen

- Furniture AnnexDokument6 SeitenFurniture AnnexAlaa HusseinNoch keine Bewertungen

- Materials Management - 1 - Dr. VP - 2017-18Dokument33 SeitenMaterials Management - 1 - Dr. VP - 2017-18Vrushabh ShelkarNoch keine Bewertungen

- New Microsoft Word DocumentDokument3 SeitenNew Microsoft Word DocumentAditya ShanbhagNoch keine Bewertungen

- Review Course 2 (Review On Professional Education Courses)Dokument8 SeitenReview Course 2 (Review On Professional Education Courses)Regie MarcosNoch keine Bewertungen

- Calendar of Activities A.Y. 2015-2016: 12 Independence Day (Regular Holiday)Dokument3 SeitenCalendar of Activities A.Y. 2015-2016: 12 Independence Day (Regular Holiday)Beny TawanNoch keine Bewertungen

- DatuinMA (Activity #5 - NSTP 10)Dokument2 SeitenDatuinMA (Activity #5 - NSTP 10)Marc Alen Porlaje DatuinNoch keine Bewertungen

- 00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentDokument4 Seiten00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentFaizal AbdullahNoch keine Bewertungen

- MATH 304 Linear Algebra Lecture 9 - Subspaces of Vector Spaces (Continued) - Span. Spanning Set PDFDokument20 SeitenMATH 304 Linear Algebra Lecture 9 - Subspaces of Vector Spaces (Continued) - Span. Spanning Set PDFmurugan2284Noch keine Bewertungen

- DC Generator - Construction, Working Principle, Types, and Applications PDFDokument1 SeiteDC Generator - Construction, Working Principle, Types, and Applications PDFGokul GokulNoch keine Bewertungen

- Handout Waste Catch BasinDokument2 SeitenHandout Waste Catch BasinJonniel De GuzmanNoch keine Bewertungen

- ING C1 CO JUN2016 CorrectorDokument6 SeitenING C1 CO JUN2016 CorrectoraciameNoch keine Bewertungen

- Intercultural Personhood and Identity NegotiationDokument13 SeitenIntercultural Personhood and Identity NegotiationJoão HorrNoch keine Bewertungen

- 全新全真题库一 PDFDokument36 Seiten全新全真题库一 PDFTzarlene100% (1)

- 3DS 2017 GEO GEMS Brochure A4 WEBDokument4 Seiten3DS 2017 GEO GEMS Brochure A4 WEBlazarpaladinNoch keine Bewertungen

- HAF350A User ManualDokument14 SeitenHAF350A User ManualUEENoch keine Bewertungen