Beruflich Dokumente

Kultur Dokumente

Cryocooler

Hochgeladen von

Yasir AliCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cryocooler

Hochgeladen von

Yasir AliCopyright:

Verfügbare Formate

Course: ME 657 Measurement of Refrigeration Effect on Single Stage Pulse Tube Cryocooler Name: Roll No: Cryocooler: A Cryocooler

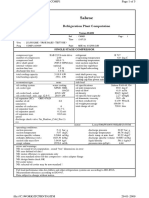

is a device or ensemble of equipment for producing refrigeration effect at temperature less than 120 K. Basic Principle of Pulse Tube Cryocooler: Pressurization and depressurization of any closed volume from a point on its periphery sets up temperature gradients in the volume. Working of Pulse Tube Cryocooler: During the pressure buildup, the high pressure gas admits through the Regenerator, where it is cooled to the cold end temperature Tc. As this gas enters the Pulse Tube through the heat exchanger, HX1, it compresses the gas that is already in the Tube nearly adiabatically, thus acting as Gas Piston, so that the temperature of this gas increases. At the hot end the temperature is maintained at room temperature by the circulation of water in the HX2, hence the gas looses certain amount of heat and temperature becomes equal to room temperature. During the expansion phase, the gas expands to lower temperature than the temperature while entering. This temperature difference gives rise to refrigeration effect. Objectives of the Experiment: 1. To understand the working the Single Stage Pulse Tube Refrigeration System with the instrumentation like vacuum and temperature measurement. 2. To plot A) Cooldown curve and B) Refrigeration load V/s. Temperature. List of components and accessories of Pulse Tube Refrigeration System: Components: 1. Compressor 2. After-cooler 3. Regenerator 4. Cold End Heat Exchanger 5. Pulse Tube 6. Hot End Heat Exchanger 7. Inertance tube 8. Reservoir Accessories: 1. Compressor Power Supply (Dimmerstat). 2. Vacuum System ( Turbo Molecular Pump and Rotary Pump (RP) Unit / Diffusion Pump and Rotary Pump Unit) 3. Vacuum Gauges (Pirani Gauge, Penning Gauge) 4. Temperature Sensors and Indicators. 5. Heater with DC power Supply. Accessories Details: 1. Rotary Pump: Atmospheric to 10 -3 2. Diffusion Pump: 10 -3 to 10 -6 mbar. 3. Turbo Molecular Pump: Operating Speed : 27067 to 27083 rpm for 10 -6 mbar. 4. Vacuum Gauges: Pirani: Atmospheric to 10 -3 Penning: 10 -3 to 10 -6 mbar. 5. Temperature Sensor: Silicon Diode: 4 K to 325 K. 6. Temperature Indicator: Lakeshore Model-340.

Course: ME 657 Measurement of Refrigeration Effect on Single Stage Pulse Tube Cryocooler Procedure: 1. Start the Vacuum system and obtain a vacuum in the jacket of the Pulse Tube unit of the order of 10 -6 mbar (15 20 min.). 2. Switch on the Compressor power supply (Dimmerstat) and slowly increase the input power to 100 W. 3. Observe temperature at a time step of 5 min. till it reaches 125 K (approx. 25 min.). 4. Increase slowly the Compressor power to 200 W and observe temperature till 100 K will be attained (approx. 20 min.). Similarly, increase the power to 300 W and observe till temperature reaches to minimum value (approx. 40 min.) 5. Plot the Cooldown Curve. 6. After attaining min. temperature, apply Refrigeration load (DC Power Supply) for 80 K (i.e. apply the power till temperature becomes stable at 80 K; approx. 15 min.). 7. Repeat the procedure for 90 and 100 K (approx. 15 min. each). 8. Plot the curve for Refrigeration load V/s. Temperature. 9. Comment on the results and write your conclusion. 10. Viva. Observations: Charging Pressure (bar) Ambient Temperature (K) Jacket Vacuum (mbar) Observation Table: A) Cooldown Curve : Compressor Input Power = 100 W Compressor Input Power = 200 W Compressor Input Power = 300 W Time (min) Temperature (K) Time (min) Temperature (K) Time (min) Temperature (K) 5 10 15 20 125 100 B) Refrigeration Load: Temperature (K) Refrigeration Load (W) = V*I 0 (No Load) 80 90 100 Conclusion:

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Bell 429 Helicopter - High Resolution PanelDokument1 SeiteBell 429 Helicopter - High Resolution Panelguicordova0% (1)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 4 Diffusion+ficks PDFDokument107 Seiten4 Diffusion+ficks PDFYasir AliNoch keine Bewertungen

- CFD Containment ModelingDokument32 SeitenCFD Containment ModelingMetalloyNoch keine Bewertungen

- Pressure Drop and Vacuum One LessonDokument3 SeitenPressure Drop and Vacuum One LessonYasir AliNoch keine Bewertungen

- Law of FlowDokument7 SeitenLaw of FlowYasir AliNoch keine Bewertungen

- HeaT Transfer Heat ExchangersDokument37 SeitenHeaT Transfer Heat ExchangersYasir AliNoch keine Bewertungen

- Physics PortionDokument7 SeitenPhysics PortionYasir AliNoch keine Bewertungen

- Notification of Revised Pay Scales 2015 KPKDokument6 SeitenNotification of Revised Pay Scales 2015 KPKYasir AliNoch keine Bewertungen

- Speed of SoundDokument13 SeitenSpeed of SoundYasir AliNoch keine Bewertungen

- A Virial Coefficient Analysis of Helium Adsorption IsothermsDokument10 SeitenA Virial Coefficient Analysis of Helium Adsorption IsothermsYasir AliNoch keine Bewertungen

- Ministry of Law Justice and Human Rights Pakistan Jobs Application Form 2015Dokument1 SeiteMinistry of Law Justice and Human Rights Pakistan Jobs Application Form 2015Yasir AliNoch keine Bewertungen

- Lecture5 B PETDokument26 SeitenLecture5 B PETYasir AliNoch keine Bewertungen

- Solutions To The Diffusion EquationDokument18 SeitenSolutions To The Diffusion EquationYasir AliNoch keine Bewertungen

- Virial Coe Cient: 1 DerivationDokument3 SeitenVirial Coe Cient: 1 DerivationYasir AliNoch keine Bewertungen

- Us 12e pr1263Dokument1 SeiteUs 12e pr1263Janaka MangalaNoch keine Bewertungen

- Prediction of The Light CP-even Higgs-Boson Mass of The MSSM: Towards The ILC PrecisionDokument13 SeitenPrediction of The Light CP-even Higgs-Boson Mass of The MSSM: Towards The ILC PrecisionYasir AliNoch keine Bewertungen

- ISB Rev1 (Final August 2008)Dokument70 SeitenISB Rev1 (Final August 2008)Yasir AliNoch keine Bewertungen

- Nee48 - GBL 7.0Dokument2 SeitenNee48 - GBL 7.0Rafael OrtizNoch keine Bewertungen

- Graded Seals, Quartz To Pyrex, Quartz To Stainless SteelDokument2 SeitenGraded Seals, Quartz To Pyrex, Quartz To Stainless SteelYasir AliNoch keine Bewertungen

- Introduction To Statistical ThermodynamicsDokument29 SeitenIntroduction To Statistical ThermodynamicsYasir AliNoch keine Bewertungen

- Refrigeration and Air-Conditioning - S K MondalDokument0 SeitenRefrigeration and Air-Conditioning - S K MondalShaheen S. RatnaniNoch keine Bewertungen

- System Procedure For Id FanDokument9 SeitenSystem Procedure For Id Fansprotkar100% (1)

- Thumb RuleDokument4 SeitenThumb RulenishadNoch keine Bewertungen

- Abdali Area: Jordan District Cooling Case StudyDokument13 SeitenAbdali Area: Jordan District Cooling Case StudymohamadNoch keine Bewertungen

- Wke Series - Installation InstructionsDokument7 SeitenWke Series - Installation InstructionsTim GlassettNoch keine Bewertungen

- Lennox MS8C-MS8H Mini-Split SystemsDokument4 SeitenLennox MS8C-MS8H Mini-Split SystemsChristian Chalco GonzalesNoch keine Bewertungen

- HVAC AcroymnsDokument6 SeitenHVAC AcroymnsglenlcyNoch keine Bewertungen

- Air Handling System in Pharmaceutical ManufacturingDokument86 SeitenAir Handling System in Pharmaceutical ManufacturingVamsiDeepakNoch keine Bewertungen

- Hyundai R320Lc 7Dokument587 SeitenHyundai R320Lc 7magno schimitNoch keine Bewertungen

- Heat Exchanger Network PPK TugasDokument15 SeitenHeat Exchanger Network PPK TugasogiNoch keine Bewertungen

- Case StudyDokument6 SeitenCase StudyB 02 Kavya DcruzNoch keine Bewertungen

- Yukon 0904Dokument4 SeitenYukon 0904Việt Đặng XuânNoch keine Bewertungen

- Ghoubali Et Al. 2017Dokument15 SeitenGhoubali Et Al. 2017Francisco OppsNoch keine Bewertungen

- Grafik PsicrometricDokument3 SeitenGrafik PsicrometricDwi CahyoNoch keine Bewertungen

- WarmFlo Plenum Electric Heaters BrochureDokument2 SeitenWarmFlo Plenum Electric Heaters Brochuree-ComfortUSANoch keine Bewertungen

- Noakhali Gold Foods LTD.: List of Machinenary Equipment For NGFLDokument1 SeiteNoakhali Gold Foods LTD.: List of Machinenary Equipment For NGFLaktaruzzaman bethuNoch keine Bewertungen

- 303-03 Engine Cooling 2.3L EcoBoost - Diagnosis and Testing - Engine CoolingDokument21 Seiten303-03 Engine Cooling 2.3L EcoBoost - Diagnosis and Testing - Engine CoolingCARLOS LIMADANoch keine Bewertungen

- Embraco Standard Aftermarket Portfolio PDFDokument2 SeitenEmbraco Standard Aftermarket Portfolio PDFJOR4CHNoch keine Bewertungen

- Group 1 Experiment 2 Eh2203aDokument17 SeitenGroup 1 Experiment 2 Eh2203aAbdullah FarhanNoch keine Bewertungen

- RAC AssignmentDokument7 SeitenRAC AssignmentSoumikSabyasachi50% (2)

- Mcac TSM 2008 02Dokument94 SeitenMcac TSM 2008 02Eng . Moiead SlemanNoch keine Bewertungen

- Penawaran Harga COLDSTORAGEDokument1 SeitePenawaran Harga COLDSTORAGEChannel ArifNoch keine Bewertungen

- Your User Manual Honeywell EvohomeDokument2 SeitenYour User Manual Honeywell EvohomecmartinherrNoch keine Bewertungen

- Air Handling UnitDokument44 SeitenAir Handling Unitpostboxsg100% (1)

- BE EngGuide RooftopSeries10ZHZJZR PDFDokument207 SeitenBE EngGuide RooftopSeries10ZHZJZR PDFvirtech1Noch keine Bewertungen

- Flue Gas SystemDokument56 SeitenFlue Gas SystemAmit PrajapatiNoch keine Bewertungen

- NHsoft VPDokument5 SeitenNHsoft VPBASEM NOMAN ALI MOHAMMEDNoch keine Bewertungen

- Rac Problems Set 1Dokument6 SeitenRac Problems Set 1Mohammad Umair100% (1)