Beruflich Dokumente

Kultur Dokumente

TYCAN Screening Solutions

Hochgeladen von

GustavoOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TYCAN Screening Solutions

Hochgeladen von

GustavoCopyright:

Verfügbare Formate

Screening Solutions by Screening Specialists

Introduction

Founded in 1930, W.S. TYLER CANADA operates a Screening Media (TYLER) and a Vibrating Screen Division (TYCAN) under one roof for over 75 years. The company philosophy is to provide Screening Solutions by Screening Specialists. Today, W.S. TYLER CANADA is part of the family owned Haver Group and the only company in the world capable of supplying all aspects of the renowned screening circle. The screening circle is a given necessity for any customer that aims to separate his products according to size. The screening circle contains the following components:

W.S.Tyler Canada TYCAN

4. Service: The screening media and the vibrating screen must be dened as a complete screening system. TYCAN understands that responsibility and as a result offers far reaching services, such as the self developed vibration analysis. Using such milestone technologies we are today capable of ensuring complete synchronization between screening media and vibrating machine with the help of automatically generated improvement recommendations. To ensure the quality of the recommendation results, we again require the particle analysis and thus the screening circle closes to form a complete rotation.

1. Particle Analysis: the basis for any screening process is the understanding of the size distribution within the feed material as well as the desired product. TYLER offers all aspects of particle analysis, beginning with standard sieves over traditional laboratory shakers such as the famous ROTAP to the technology of Computerized Particle Analysis (CPA).

The Screening Circle

3. Vibrating Screens: The particle sizes of the feed material as well as the required cut sizes determine the necessary drive technology and physical size of the vibrating screen. TYCANs engineering department is a very international team. As a result the customer benets from this wide range of experience and process studies with screening solutions that are extraordinary and unprecedented in the history of the screening industry. Using tools such as FEA and 3-D CAD systems, TYCANs promise is to develop customized solutions according to product application and customer specication.

2. Screening Media: The results of the particle analysis and the material characteristics determine the opening and the composition of the screening surface. TYLER offers a full line of screening media, starting with woven wire cloth, engineered rubber and polyurethane systems to self cleaning screens and perforated plate. TYLER understands the impact media changes can have on protecting the vibrating screen itself.

For planning, designing, engineering and manufacturing complete Screening Solutions, W.S. TYLER CANADA is always the right partner. Our decades of experience in providing all aspects of the screening circle ensure that you are receiving:

Screening Solutions by Screening Specialists

Eccentric Shaft Systems (4-bearing Technology)

The NCLASS

The TYCAN N-Class is commonly used as a primary screen targeted at increasing the throughput and the efciencies of the primary crusher in very heavy duty and aggressive environments. Capable of handling particles as big as 78 x 39 x 39 and screening at cut sizes of to 12 it is ideal for very demanding industries such as mining or crushed stone. This operation principle consists of the use of a shaft and four bearings. The vibration motion is worked into the shaft in form of single eccentricity, allowing for equipment operation with consistent amplitude, independent of the load fed to the screen. Due to the constant dynamic operating conditions and consequently the very high G-Forces generated by the technical principle of the vibrating screen, product particles are consistently launched out of the classication openings of the media creating a self-cleaning effect, which minimizes material clogging and pegging.

N-CLASS in a typical layout

PRINCIPAL CHARACTERISTICS: Consistent amplitude Constant dynamic, load independent operating conditions, Adjustable frequency Dry and humid classication Cuts of up to approximately 12 High classication capacity and better classication efciencies Use of perforated plates up to 4 with conical opening as classication media Allows for various classication deck congurations Allows for the classication of viscous and sticky products Does not transmit vibrations into the structure Width of up to 8 ft. Length of up to 22 ft Optional full or partial dust enclosure Allows for immediate stoppage (either by electric brake or by reversal) eliminating residual vibrations N-CLASS Scalper screen Model ESS 2400 x 5000

Double Eccentric Shaft Systems (4-bearing Technology)

The F-CLASS

The TYCAN F-CLASS is the number one vibrating screen for classication in the heavy mining, mineral and crushed stone industries. The positive circle-throw motion of the F-CLASS is developed by a counterbalanced double eccentric shaft, which is supported by four double spherical roller screen bearings. Rubber mounting units dynamically balance by isolating the vibrating body from the stationary base frame. The shaft is supported on the base by side arm assemblies that are also isolated on rubber mounting units. The F-CLASS free oating action permits the shaft to nd its natural center of rotation without strain or thrust on the bearings. This feature minimizes maintenance and downtime and prolongs the life of the bearings. PRINCIPAL CHARACTERISTICS: Consistent amplitude Constant dynamic, load independent operating conditions Adjustable frequency at speeds of 750 to 1050 RPM Dry and humid classication Solid HUCK bolted construction Hands Free tube housing assembly for easy bearing exchange Allows for various classication deck congurations of up to 3 decks Allows for the classication of viscous and sticky products Does not transmit vibrations into the structure Installed at angles of 15 to 25 degrees Width of up to 8 ft (2500mm) Length of up to 24 ft (7500mm) Optional full or partial dust enclosure Optional ball tray for classication of ne and sticky material F-CLASS model 900

TYCAN F-CLASS in a typical layout

Counterbalanced double eccentric shaft assembly

Concentric Shaft Systems (Two-bearing Technology)

The T-CLASS

The TYCAN T-CLASS vibrating screen with eld proven features makes it a versatile performer. It is designed to be a rugged dependable vibrating screen for use in the screening of a wide variety of materials. The circle throw motion of the T-CLASS Series is developed by a counterbalanced shaft assembly, which is supported by two double spherical roller screen bearings. The circle throw action has proven to be very effective in moving coarse material to the top of the bed so that the nes and near mesh particles may pass through the media openings. The T-CLASS Series provides fast and accurate sizing of materials. The T-CLASS Series modular design and the use of standard components result in savings because TYCAN fabricates and assembles machines customized to the application by using standard stock components. This standardization of components also results in readily available spare parts. The T-CLASS simple design combined with its rugged construction results in minimum maintenance and downtime. T-CLASS model 990M on ROSTA elements

Hands Free Tube Assembly

Typical layout of a T-CLASS with Twin Shaft Assembly PRINCIPAL CHARACTERISTICS: Extremely versatile and maintenance friendly Easy change of Amplitude Adjustable frequency at speeds of 750 to 1050 RPM Dry and humid classication Solid HUCK bolted construction Hands Free tube housing construction for easy bearing exchange Cut sizes from 6 inches to 20 mesh Allows for various classication deck congurations of up to 4 12 decks Installed at angles of 10 to 25 degrees Width of up to 8 ft Length of up to 24 ft Optional full or partial dust enclosure Optional ball tray for classication of ne and sticky material Optional Twin Shaft Assembly for Heavy Duty Applications

Horizontal Screening Systems

The L-CLASS

The TYCAN L-CLASS is designed to operate horizontally and is engineered for various service applications. Its a superior performer in sizing, washing, conveying, and dewatering of materials of intermediate cut size. The L-CLASS is ideal for wet or dry applications and meets demand in existing or planned plants where headroom is limited. The gearless, demountable vibrator emits minimum noise levels, well below minimum noise levels, and can be mounted overhead or under slung of the screen body dependent on space restrictions. The L-CLASS four bearing, stroke-throw vibrating screen is easy to maintain because of its readily replaceable parts and solid HUCK bolted construction. For applications requiring extended bearing life-times the L-Class is also available with our dependable and rugged Exciter Technology. PRINCIPAL CHARACTERISTICS: Dual alloy steel counterweight concentric shafts Self-synchronizing drive design Extremely versatile drive head with option of overhead or under slung design Adjustable frequency at speeds of 750 to 1050 RPM Dry and humid classication Solid HUCK bolted construction Cut sizes from 3 inches to 20 mesh Allows for various classication deck congurations of up to 3 decks Installed at angles of 3 to 6 degrees Width of up to 8 ft (2500mm) Length of up to 20 ft (7500mm) Optional full or partial dust enclosure Optional ball tray for classication of ne and sticky material L-CLASS model 6x16 (2000mm x 5000mm) 1D

L-CLASS model 6x16 (2000mm x 5000mm) 2D

Horizontal Screening Systems

The XLCLASS

Todays markets have increasingly been demanding higher production rates in form of bigger machines as well as superior machine availability. Traditional shaft driven technology reaches its limitations at a determined width due to the mechanical deection of the shaft resulting in unacceptable bearing lifetimes. TYCANs solution to the markets demands and the technological limitations of the shaft technology is the exciter driven XL-Class. The exciter is a completely incased drive unit consisting of short shafts supported by closely positioned bearings. Mounted on a specially designed over head bridge the exciter technology allows TYCANs XL-Class to be built at widths in excess of 8ft addressing the market need for bigger machines. Due to carefully chosen bearing sizes in combination with maintenance friendly lubrication via oil the demand for availability is addressed by bearing lifetimes as high as 50,000 hours (application dependant). Not only does the XLClass set new standards in its drive principle but also in its body design. Enabling forces of more than 5g (application dependant) the XL-Class is engineered using state of the art Finite Element Analysis technology (FEA). FEA enables structural calculations by simulating the machines dynamic behavior in form of a 3D model. The results of the simulation allow the determination of resulting tensions and natural frequencies to assure a technologically optimized and economically sound design.

XL-CLASS 8 x 20 (2400mm x 6000mm) 2D

XL-CLASS 8 x 24 (2400mm x 7500mm) 1D dewatering

Traditionally developed for the mining industries such as copper and iron ore the XL-Class is also nding its way into

construction materials such as sand, crushed stone and aggregates due to its impressive payback and maintenance friendliness.

PRINCIPAL CHARACTERISTICS: Driven by oil lubricated, easily interchangeable exciter units Bearing lifetime of up to 50,000 (application dependant) Adjustable frequency at speeds of 750 to 1050 RPM Versatility in stroke by weight additions to the exciter counterweight Allows for various classication deck congurations of up to 3 decks Can be installed of 15 degrees Width in excess of 14 ft (4000mm) Length in excess of 36 ft (11000mm)

XL-CLASS Exciter Technology

Horizontal Screening Systems

The XL-CLASS Banana

Certain applications call for versatility in changeability of screening surface angles. TYCAN answers this market demand with the XL-Class Custom Slope Deck, designed to provide high yield and efciency in screening. Larger angles of inclination in the feeding area offer a speed gain in the material ow, which assures a reduced height in the screening layer and allows ne materials to easily pass through the screening media. Subsequent changes in the inclination angles of the media along the screen structure assure a reduction of ow speed allowing the nal layer thickness to increase, thus insuring accurate sizing performance at the screens discharge end. The Custom Slope Deck screens mechanical structure is strong and solid and entirely equipped with Huckbolts, providing high operating capacity and low maintenance cost.

XL-CLASS Banana-type 8 x 24 (2400mm x 7500mm) PRINCIPAL CHARACTERISTICS: Linear Free Vibrating System with Exciters Strength and Reliability High efciency in screening Easy to operate and to install Material in non-laminate format Designed specically for granulometric applications with high concentrations of under-sized materials

Drive system: The drive system of the Banana vibrating screen consists of exciters which are essentially composed of counterweights attached to a rigid shaft that seats in special bearings. These bearings were developed for vibrating equipment and have a useful life of 50,000 working hours or more (application dependant).

Larger angles allow a speed gain in the material ow

De-Watering Systems

D-CLASS exciter driven

Discharged, dewatered product

The D-CLASS

The TYCAN D-Class was mainly conceived for the iron ore industry in order to minimize the percentage of water residue in the product, enabling a substantial improvement in the handling, transport and piling up of ore. Used for dewatering of various products, the equipment works to allow for better material compacting and consequent water expulsion. Depending on the machine size and application, one of the free linear motion drive assemblies is used. Apart from the characteristics of the free linear motion screen, the dewatering screen has the following features: D-CLASS Unbalanced motor driven

PRINCIPAL CHARACTERISTICS: Heavy construction Use of polyurethane screen media or rubber Totally rubber covered for protection against abrasion

High Speed Screening Systems

S-CLASS 4 x 8 (1200mm x 2500mm)

The S-CLASS

S-CLASS is a versatile high speed circle-throw movement machine designed for medium and ne screening of very difcult wet or dry materials such as sands, gravel, lime, coal, chemicals, fertilizers, gold and metal ores. The S-CLASS is a tough two bearing machine with exibility to meet demanding and changeable screening conditions. The vibration of the S-CLASS is developed by a counterbalanced shaft assembly which is supported by two double spherical roller screen bearings mounted in ductile iron bearing housings at each end of the vibrator assembly. The vibrator is located over top of the vibrating screen body and is demountable for service. The circle-throw motion produced by the vibrating head is transferred into a forward inclined ellipti-

cal action on the screen surface at the feed end and into a backward inclined ellipse at the discharge end. This special design creates high transport velocities at the feed end and lower ones at the discharge end. This causes a quick and equal distribution of the material on the rst third of the screen deck and a sharper screening at the last third.

Demountable vibrator head assembly

PRINCIPAL CHARACTERISTICS: Alloy steel counterweighted shaft ground with precision tolerances Demountable vibrator head assembly Self-contained oil bath lubrication Adjustable frequency at speeds of 820 RPM to 3200 RPM Dry and humid classication Solid HUCK bolted construction with CORTEN side plates Cut sizes from 34 inches to 100 mesh Allows for various classication deck congurations of up to 2 decks Installed at angles of 5 to 30 degrees depending on application Width of up to 5 ft (1500mm) Length of up to 12 ft (3500mm) Optional full or partial closure for dust collection Optional ball tray for classication of ne and sticky material

10

Fine Screening Systems

The H-CLASS / The FINELINE

TYCAN has two systems for ne screening, the TYCAN H-Class and the TYCAN Fineline. The designs were conceived in order to obtain high efciency, versatility and simplicity of operation and maintenance. The operation principle utilizes high frequency vibrating motors, which directly

excite the screening media without transmitting vibration into the screen body. The range of products that may be classied with this equipment is very wide. The excellent results achieved during operation at industrial level for the classication of products speak for themselves.

FINELINE System H-CLASS V85 4x15 (1200mm x 4500mm) PRINCIPAL CHARACTERISTICS: Simple and modular design Higher screening capacity (t/m2/h) when compared with traditional screens Higher classication efciencies Dry classication Drive by means of vibrating motors Adjustable frequency, amplitude and inclination Static screen box, avoiding the transmission of vibration into the structure Allows for quick and easy change of the screening media Low energy consumption Reduced maintenance Enclosed for dust collection Cuts between 0.1 and 5 mm Allows for congurations of 1 or 2 classication decks Modules up to 6 ft wide x 5 ft long Screening Media

Feeding

Adjustable Inclination

Overow

Vibrating Motor

Underow

11

Engineered Media

TYCAN strives to be an application oriented solutions provider by offering a wide media product line, ranging from the standard wire cloth decks to performance engineered screening systems such polyurethane panels, self-cleaning wire screens with urethane strips and perforated plate. The ISO 9002 laboratory equipment and sieves, with which Washington S. Tyler revolutionized the analyzing process of bulk materials since the turn of the 20th century, remain a very important part of the product family. The new generation of product analysis has been introduced with Tylers photo analytical technology. Diversifying into new markets, the media division also supplies numerous woven wire products into the chemical, pharmaceutical and even architectural industries.

Cobra Vibe self-cleaning screens

Engineered media solutions

Polyurethane media solutions

Computerized Particle Analysis

Woven Wire Cloth Screens

Full Screening Media product line

Finger Deck solutions

12

Vibrating Feeding Systems: V-Feeders

Tubular vibrating feeder TYCAN vibrating feeders are used in many and various applications, one of which is the withdrawal of product from silos Model UF and feeding and distribution of materials to the vibrating screens.

Typical installation of a vibrating feeder The drive is designed to use two vibrating motors with opposite rotation directions. Depending on the necessity, the feeders may be congured openly or enclosed to ensure dust collection.

Model UF R

Model UF with support frame Model UF A

Product withdrawal from the silo feeding of the screen

Inclinated gate

Circular gate

Flat Gate

Bars Gate

13

Hydro - Clean

Before

Afterwards

Often customers not only require screened product but cleanly screened products, TYCAN has developed a technology capable of cleaning material mixtures with particle sizes ranging from 0-150 mm, with the use of high pressured water: The TYCAN Hydro Clean. The result of this technological quantum leap is a high pressure cleaning system for production rates from 50 to 400 tons of output material per hour. Designed similar to a household washing machine the contaminated material is fed into an actual washing chamber by a hopper. Inside the machine the material builds a column standing on a conveyor belt, the speed of which controls the throughput of the material and the washing cycle. To protect the chamber, its inside is lined with standard polyurethane screening panels allowing dirty water to escape and be returned to a settling pond. The constantly recycled water is fed to jet valves, which rotate at the top of the washing chamber. As a result the water is injected at rates from 800 to 2000 PSI and intensely interacts with the contaminated product by blowing onto the particles and penetrating porous areas, which friction based washing technology could never reach. This means the Hydro Clean is capable of offering never before seen cleaning degrees. Products thought to be impossible to clean can now be sold at premium prices. ADVANTAGES: Highest cleaning results possible Lowest water consumption available No tool wearing water jet The water jet reaches directly the material to be washed The drum is coated with PUR-standard screens Optimum material adaptation

Typical installation of a Hydro-Clean

1- Input material; 2- Washing rotor; 3- High pressure nozzle;

4- Washing chamber; 5- Material output conveyor; 6- Contaminated water.

14

Pelletizing Systems

Installation of a Pelletizing Disk line Model GR7500 for iron ore TYCAN also offers pelletizing disks, which are frequently used in the pelleting of materials such as iron ore. The operation principle of the equipment consists in the continual feeding of powdered material, processing it into granules of uniform size. This process is obtained by means of regular rotation of the inclined plate, together with the repeated rolling movement of the product and the simultaneous addition of liquid. PRINCIPAL CHARACTERISTICS: Heavy duty design Vibration free design Dimensions up to 7,5 m of diameter Allows for precise rotation Device for cleaning of the machine bottom and borders Regulated Inclination Centralized Lubrication

15

Extraordinary Solutions King-Sized Screens

For customers that demand the answer to extraordinary problems, TYCAN has the solution. Those projects are designed on the highest technical criterias and the most modern technology. The new tools used to design and calculate such mammoth-sized machines, range from 3D-design over Finite Element Analysis (FEA) to specially designed test measurements of vibration modes. Driven by multiple exciters and decades of experience in manufacturing vibrating screens, TYCAN can provide these type of large-sized machines with width of up to 13 ft and length of up to 36 ft.

HBL Latinoamericana team

BASIC DATA: XL-Class Vibrating Screen 4,000 x 11,000 mm Width: 13 ft (4,000 mm)

Length: 36 ft (11,000 mm) Screen total weight: 110 tons Capacity: 10,000 t/h Total number of coil springs: 196

16

Extraordinary Solutions Engineered to Application

L-CLASS X2-400 8 x 24 (2400mm x 7500mm) 3D

In addition to decades of experience in researching and developing vibrating screens, TYCAN counts on: 3D Design; Structural calculation based on Finite Element Analysis (FEA); Calculation testing through tension measurement with strain gages; Measurement of vibrating modes; Drive by high performance exciters.

To engineer solutions to customer requirements and specication. T-CLASS CD1102 Grizzly

UM L-CLASS 3 x 14 (1000mm x 4000mm)

T-CLASS model 990 - ICS - Integrated cooling system for the refrigeration of bearings in hot applications

UM L-CLASS 4 x 10 (1200mm x 3000mm)

17

Services

ESS Engineered Screening Study calculations, and most importantly the recommendations and proposals for the plant layout. These recommendations are backed by our experience and are evaluated and proven where applicable in collaboration with the customers structural engineers. All recommendations to design changes on existing plant structural work show the best accommodation of new or moved equipment and enable the best ow of material under existing circumstances.

Fitting of a new machine into an existing structure

Our aim is not only to satisfy our customers with our machinery, but to provide complete solutions. Therefore, the services of TYCANs engineering department are not limited to machines but allow the following services:

Engineered Screening Studies

Running different R&D projects and design studies on TYCAN machines our engineers provide a complete process analysis in the form of an Engineered Screening Study (ESS). Utilizing our own programmed software and digitized tools, TYCAN Engineering can provide complete screening and crushing studies for existing or future projects ranging from a one-deck system to high-capacity processing plants. The basic data for such Engineered Screening Studies (ESS) are provided by the customer on-site during the visit of our TYCAN engineer. The data is used to build a computerized

model of the customers existing or new plant and operation. Depending on the customers improvement targets, the impact of changes to plant settings can be tested by the model in a fast and efcient manner, revealing the correct and necessary adjustments in terms of process optimization and process design. To visualize the different scenarios, computerized ow sheets are developed which demonstrate the related efciencies and/or usage of the crushing and screening equipment under the different settings. Finally, the customer receives a precise and accurate report documenting the ndings, the results, the

18

Services

Vibration Analysis

Self developed and Custom programmed for vibrating screens, TYCANs Vibration Analysis Service (VA) allows for easy hook-up of a lap-top computer to your vibrating screen on site by TYCANs trained technicians. Based on the data the performance of vibrating screens can be evaluated in terms of proper speed and stroke. Machine and screening media are synchronized by automatic improvement recommendations. The determination of critical and developing faults such as bearing failures, spring problems, loose machine components or other are also possible. The measuring system features up to 8 accelerometer channels allowing a full scale screen performance analysis. The information allows for on-screen display of orbit plots, peak-to-peak and average accelerations and displacements as well as RPM computing and FFT analysis. The results of the tests are put into a valuable and easy to understand customer report. This document not only outlines the analyzed data, but also makes recommendations on how to improve screen performance based on different settings or new parts.

Rebuild Programs

Equipment for Vibrating Analysis Our Preventative Maintenance Program (PMP) is designed to considerably cut the operation and maintenance costs for our customers vibrating screens and media. Even though emergency situations can never be fully avoided they can be minimized with proper, manufacturer-supported maintenance. But in addition continuous costs for spare parts and service can be reduced signicantly with the proper program. The benets of the general services covered by a preventative TYCAN maintenance program include the combination of our ESS, Vibration Analysis and our Rebuild Program. As a result our customers receive the following advantages: 1. 2. 3. 4. Reduced Service Rates Inspection and Vibration Analysis Sizing Assistance Regular Maintenance & Media Seminars 5. Rebuild Program Management 6. Spare Parts Inventory Management 7. Reduced Spare Part Prices

Preventive maintenance and rebuild programs You can expect prompt on-site evaluations, a detailed itemized report and quotation, scheduling of the rebuilding process and delivery to customer site. A TYCAN Service Representative will be on-site to supervise start-up.

Preventative Maintenance

Not only does TYCAN build screening machines to last, but we can rebuild them to last even longer. Over time and years of constant use even a TYCAN screen can show its age. Now with the TYCAN Rebuild Program you can reduce maintenance costs and even increase your productivity by avoiding costly replacements. Our Rebuild Program can be accomplished on-site to minimize the time your machine is down.

Todays market demands for economical products and high production efciencies make it necessary for our customers to reduce machine downtimes to a minimum. Whether for regular scheduled maintenance routines or in emergency cases the equipment must be ready to produce again as fast as possible. As a screening solutions provider TYCAN has recognized the necessity for a new service.

19

The Screening Circle

225 Ontario Street P.O. Box 3006 ST. CATHARINES, Ontario L2R 7B6 Canada Tel: +1-905-688-2644 +1-800-325-5993 Fax: +1-905-688-4733 wstsales@wstyler.on.ca www.wstyler.com

HBL-TYCAN 020 E - Revised 07/05

The machines and plants shown in this leaflet as well as the stated technical parameters are examples of customer-specific technical solutions. Therefor they are subject to modifications.

Das könnte Ihnen auch gefallen

- International 7400 Parts Manual 2006Dokument1.886 SeitenInternational 7400 Parts Manual 2006Gustavo92% (26)

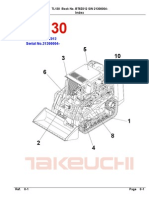

- Takeuchi Parts Manual Tl130 Bt8z012 (21300004 )Dokument495 SeitenTakeuchi Parts Manual Tl130 Bt8z012 (21300004 )Gustavo100% (1)

- Raptor XL900 Cone CrushersDokument8 SeitenRaptor XL900 Cone CrushersLmf DanielNoch keine Bewertungen

- C1 1 PDFDokument114 SeitenC1 1 PDFVidaurri100% (1)

- Hazemag Hpi-H EngDokument16 SeitenHazemag Hpi-H Engekrem0867100% (1)

- MANUAL CONO 11-MAR-15 CRSH-OM-0002ENG - OCT2011 - All APP and APS Models HSI TRIO PDFDokument52 SeitenMANUAL CONO 11-MAR-15 CRSH-OM-0002ENG - OCT2011 - All APP and APS Models HSI TRIO PDFCuello Marin Nayely100% (1)

- Screens ENGDokument14 SeitenScreens ENGSurendar Perumal100% (2)

- Av Vibrating Screens PDFDokument2 SeitenAv Vibrating Screens PDFArnaldo BenitezNoch keine Bewertungen

- 6199026M2 Pre Powershift and Synchro Shuttle TX750 TX760 TX860Dokument394 Seiten6199026M2 Pre Powershift and Synchro Shuttle TX750 TX760 TX860Gustavo100% (8)

- Solution Manual For Laboratory Manual in Physical Geology 11th by American Geological InstituteDokument9 SeitenSolution Manual For Laboratory Manual in Physical Geology 11th by American Geological InstituteKarenAcevedotkoi100% (40)

- Posttraumatic Stress Disorder (PTSD) and War-Related StressDokument56 SeitenPosttraumatic Stress Disorder (PTSD) and War-Related Stresshiggjp3Noch keine Bewertungen

- b0700sv F PDFDokument188 Seitenb0700sv F PDFabdel taibNoch keine Bewertungen

- Designpro V3 - Gas Lift Design Tutorial: Return To Main - NextDokument81 SeitenDesignpro V3 - Gas Lift Design Tutorial: Return To Main - NextAli AliNoch keine Bewertungen

- Hewitt, Vibrex Manual PDFDokument98 SeitenHewitt, Vibrex Manual PDFCarlos anderson Sossa ChaverraNoch keine Bewertungen

- Hewitt (Nordberg), Low Profile Elip Vib For Screens FeedersDokument36 SeitenHewitt (Nordberg), Low Profile Elip Vib For Screens FeedersCarlos anderson Sossa ChaverraNoch keine Bewertungen

- Washing Equipment Product Handbook - WEB - 06 2016Dokument52 SeitenWashing Equipment Product Handbook - WEB - 06 2016Lmf DanielNoch keine Bewertungen

- Hewitt (Nordberg), Floatex ShakeoutDokument34 SeitenHewitt (Nordberg), Floatex ShakeoutCarlos anderson Sossa ChaverraNoch keine Bewertungen

- Washing and Classifying Brochure EnglishDokument24 SeitenWashing and Classifying Brochure EnglishMohammed Alshami GeologistNoch keine Bewertungen

- Canica 80 Vsi ManualDokument112 SeitenCanica 80 Vsi ManualLuis Vallecillo100% (1)

- F-Class: Four Bearing Vibrating ScreenDokument23 SeitenF-Class: Four Bearing Vibrating ScreenkosmcNoch keine Bewertungen

- Hewitt (Nordberg) Gyrex ScreenDokument36 SeitenHewitt (Nordberg) Gyrex ScreenCarlos anderson Sossa ChaverraNoch keine Bewertungen

- Aggregate ScreeningDokument38 SeitenAggregate Screeningssmith2007Noch keine Bewertungen

- Flip Flow ScreenDokument6 SeitenFlip Flow Screenani1985Noch keine Bewertungen

- JW Series Jaw Crushers: Terex Minerals Processing SystemsDokument16 SeitenJW Series Jaw Crushers: Terex Minerals Processing SystemsKarin Anderson100% (1)

- Hewiit, Eliptex ShakeoutDokument43 SeitenHewiit, Eliptex ShakeoutCarlos anderson Sossa ChaverraNoch keine Bewertungen

- LT3387 Loctite Nordback Backing MaterialsDokument4 SeitenLT3387 Loctite Nordback Backing MaterialsestramilsolutionNoch keine Bewertungen

- Purchased Part Specification: Extended DescriptionDokument1 SeitePurchased Part Specification: Extended DescriptionWilliam VillamizarNoch keine Bewertungen

- Cedarapids Overview BrochureDokument28 SeitenCedarapids Overview BrochureJuan Marcos RodriguezNoch keine Bewertungen

- Jaw Crusher Broch 2Dokument12 SeitenJaw Crusher Broch 2Nanjappa K NuchumaniandaNoch keine Bewertungen

- Brochure Nordberg HP Series 4236-10-22 en AggDokument20 SeitenBrochure Nordberg HP Series 4236-10-22 en Aggkev YNoch keine Bewertungen

- Flowsheet 130TPH II Stage Wheel Mounted Plant-0-22mm&GSBDokument1 SeiteFlowsheet 130TPH II Stage Wheel Mounted Plant-0-22mm&GSBMukesh BharatNoch keine Bewertungen

- MANUAL DE CONO SYMONS DESDE EMCC - Archivo PDFDokument27 SeitenMANUAL DE CONO SYMONS DESDE EMCC - Archivo PDFGuillermo BalarinniNoch keine Bewertungen

- Mesda Crukings Product ManualDokument26 SeitenMesda Crukings Product ManualJake HuangNoch keine Bewertungen

- Wmd0976 Trio Tc66 Series Cone Crusher Spec SheetDokument2 SeitenWmd0976 Trio Tc66 Series Cone Crusher Spec SheetYang Wan100% (1)

- HEWITT, Dual 2e13 FeederDokument64 SeitenHEWITT, Dual 2e13 FeederCarlos anderson Sossa ChaverraNoch keine Bewertungen

- Current Revision Approved: Base Unit Hydraulics, 68H/SbsDokument2 SeitenCurrent Revision Approved: Base Unit Hydraulics, 68H/Sbscapslive_001Noch keine Bewertungen

- Trio Materials Washers.Dokument3 SeitenTrio Materials Washers.SinaiNoch keine Bewertungen

- Terex Simplicity Vibrating Feeders: Terex Minerals Processing SystemsDokument6 SeitenTerex Simplicity Vibrating Feeders: Terex Minerals Processing SystemsestramilsolutionNoch keine Bewertungen

- TRIO CT Series 20x36 Jaw Crusher 1 PDFDokument33 SeitenTRIO CT Series 20x36 Jaw Crusher 1 PDFYeco MachineryNoch keine Bewertungen

- MARCY 8 X 6 Ball Mill, Shell, Gear and Liners, Parts UnitDokument2 SeitenMARCY 8 X 6 Ball Mill, Shell, Gear and Liners, Parts UnitRicardo Rodriguez100% (1)

- 2 1 PDFDokument8 Seiten2 1 PDFSergio MondacaNoch keine Bewertungen

- XL2000 Technical SpecificationDokument3 SeitenXL2000 Technical SpecificationLeonardo SilvaNoch keine Bewertungen

- Trio Grizzly Feeders - TF Series: Product CollectionDokument2 SeitenTrio Grizzly Feeders - TF Series: Product CollectionEnso E Rosales FNoch keine Bewertungen

- Socket Assembly: MP1250 Cone CrusherDokument1 SeiteSocket Assembly: MP1250 Cone Crusherrlexl6darvNoch keine Bewertungen

- Lj-Ts Series Horizontal ScreensDokument8 SeitenLj-Ts Series Horizontal ScreensLuis Vallecillo100% (1)

- TrioTIH5162C Screen Manual (SN 045 046) PDFDokument39 SeitenTrioTIH5162C Screen Manual (SN 045 046) PDFkenoyNoch keine Bewertungen

- Kreiselbrecher enDokument7 SeitenKreiselbrecher enDiegoAlvarezHuguezNoch keine Bewertungen

- Replacement PartsDokument19 SeitenReplacement PartsVladimirNoch keine Bewertungen

- 39 ConeCrushersDokument8 Seiten39 ConeCrushersestramilsolutionNoch keine Bewertungen

- Size Control: - Screening Using A Geometrical Pattern For Size ControlDokument5 SeitenSize Control: - Screening Using A Geometrical Pattern For Size ControlSergei DumrovaNoch keine Bewertungen

- Dokumen - Tips - Powerscreen Premiertrak 400 r400 Jaw Crusher Jaw Crusher Crusher TypeDokument14 SeitenDokumen - Tips - Powerscreen Premiertrak 400 r400 Jaw Crusher Jaw Crusher Crusher TypeManuel dlHNoch keine Bewertungen

- HP Liners (Compatibility Mode)Dokument18 SeitenHP Liners (Compatibility Mode)Jeir leao Valencia100% (1)

- HP - CONICA General-Introduction PDFDokument25 SeitenHP - CONICA General-Introduction PDFluisantonio2Noch keine Bewertungen

- TrioTIO6203 Screen Manual (207) Banana Doble DeckDokument39 SeitenTrioTIO6203 Screen Manual (207) Banana Doble DeckPatricio Contreras100% (2)

- Apron FeederDokument4 SeitenApron FeederMineria28Noch keine Bewertungen

- Excel Components For Cone and Gyratory Crushers PDFDokument2 SeitenExcel Components For Cone and Gyratory Crushers PDFDanny Joel Espinoza CastañedaNoch keine Bewertungen

- Excel Tramp Release System Upgrade For HP700 and HP800 Cone CrushersDokument2 SeitenExcel Tramp Release System Upgrade For HP700 and HP800 Cone CrushersCarlos Andres Maldonado ArdilesNoch keine Bewertungen

- PF1214 Impact CrusherDokument1 SeitePF1214 Impact Crushermartinez gerardoNoch keine Bewertungen

- Mobile Jaw Crusher PDFDokument7 SeitenMobile Jaw Crusher PDFNguyễn LinhNoch keine Bewertungen

- Cone Crusher vs. VSI Crusher For Iron Application - A ThoughtDokument2 SeitenCone Crusher vs. VSI Crusher For Iron Application - A Thoughtrajeevup2004Noch keine Bewertungen

- Pinion Rebuild 42-65Dokument19 SeitenPinion Rebuild 42-65Oscar Aragon TejadaNoch keine Bewertungen

- Trio - Group Washers LogDokument4 SeitenTrio - Group Washers LogCemYurtseverNoch keine Bewertungen

- Basics RELEASE DATE: 3-12-03Dokument15 SeitenBasics RELEASE DATE: 3-12-03Victor Ivan BarriosNoch keine Bewertungen

- MVP Chancadora PDFDokument8 SeitenMVP Chancadora PDFTeofilo Paredes Cosme0% (1)

- Vsi 2Dokument9 SeitenVsi 2Vivek AgrawalNoch keine Bewertungen

- Metso Minerals Cone CrushersDokument12 SeitenMetso Minerals Cone CrushersJavier Hobak50% (2)

- PT Dusenbery Advantage Series 13Dokument4 SeitenPT Dusenbery Advantage Series 13mahajoonNoch keine Bewertungen

- Tapis TeknikDokument13 SeitenTapis Teknikrizki arfiNoch keine Bewertungen

- Introduction of High Output Engine SAA12V140 For Generator: Key WordsDokument5 SeitenIntroduction of High Output Engine SAA12V140 For Generator: Key WordsGustavoNoch keine Bewertungen

- Group 2 Electrical Circuit: Earth 1Dokument18 SeitenGroup 2 Electrical Circuit: Earth 1GustavoNoch keine Bewertungen

- Hy Gard Sales BrochureDokument1 SeiteHy Gard Sales BrochureGustavoNoch keine Bewertungen

- Rammax 1515-1510 enDokument12 SeitenRammax 1515-1510 enGustavoNoch keine Bewertungen

- Full Line Brochure ENdoosanDokument2 SeitenFull Line Brochure ENdoosanGustavoNoch keine Bewertungen

- Butacas CTPDokument8 SeitenButacas CTPGustavoNoch keine Bewertungen

- Engine Serial # Guide-: PH: 713.675.6100 FX: 713.675.6600 8123 Hillsboro Avenue Houston, TX 77029 USADokument1 SeiteEngine Serial # Guide-: PH: 713.675.6100 FX: 713.675.6600 8123 Hillsboro Avenue Houston, TX 77029 USAGustavoNoch keine Bewertungen

- 07A, 18C, 33D, 72D, 87D, 99D, 07E, 22E: CuchillasDokument14 Seiten07A, 18C, 33D, 72D, 87D, 99D, 07E, 22E: CuchillasGustavoNoch keine Bewertungen

- Pegp5027 06Dokument16 SeitenPegp5027 06SQ Yosbd100% (1)

- Dientes VOLVO 1Dokument20 SeitenDientes VOLVO 1Gustavo0% (1)

- Catalogo ZapatasDokument15 SeitenCatalogo ZapatasGustavo100% (1)

- 13 Cat Tec K AtornillableDokument5 Seiten13 Cat Tec K AtornillableGustavoNoch keine Bewertungen

- 03 Cat Tec MototraillaDokument6 Seiten03 Cat Tec MototraillaGustavoNoch keine Bewertungen

- Baby Checklist: Room Furniture Baby Wear Baby BeddingDokument2 SeitenBaby Checklist: Room Furniture Baby Wear Baby BeddingLawrence ConananNoch keine Bewertungen

- 4200 Magnetometer Interface Manual 0014079 - Rev - ADokument34 Seiten4200 Magnetometer Interface Manual 0014079 - Rev - AJose Alberto R PNoch keine Bewertungen

- Modding For Ysflight - Scenery EditorDokument92 SeitenModding For Ysflight - Scenery Editordecaff_42Noch keine Bewertungen

- Coffee Vibes: Here Is Where Your Presentation BeginsDokument86 SeitenCoffee Vibes: Here Is Where Your Presentation Beginssyeda salmaNoch keine Bewertungen

- Project Risk Management in Hydropower Plant Projects A Case Study From The State-Owned Electricity Company of IndonesiaDokument16 SeitenProject Risk Management in Hydropower Plant Projects A Case Study From The State-Owned Electricity Company of IndonesiaJoli SmithNoch keine Bewertungen

- Unidajump2019,+5 +31-42+JP+9 (1) +April+2018+AminullahDokument12 SeitenUnidajump2019,+5 +31-42+JP+9 (1) +April+2018+AminullahSatria MandalaNoch keine Bewertungen

- TDC Calculation For The Determination of Drill Bit PerformanceDokument3 SeitenTDC Calculation For The Determination of Drill Bit Performancejanuar baharuliNoch keine Bewertungen

- HP Compaq 6531s Inventec Zzi MV Rev A03 (6820s)Dokument54 SeitenHP Compaq 6531s Inventec Zzi MV Rev A03 (6820s)y2k_yah7758Noch keine Bewertungen

- Class 12 Psychology PDFDokument209 SeitenClass 12 Psychology PDFSoumyashis Bhattacharya0% (1)

- Exam Materials ScienceDokument10 SeitenExam Materials ScienceChimzoe CatalanNoch keine Bewertungen

- Crop Prot 2 Final Edited (Checked)Dokument108 SeitenCrop Prot 2 Final Edited (Checked)Cortez ReztyNoch keine Bewertungen

- Transes - Male & Female GenitaliaDokument10 SeitenTranses - Male & Female GenitaliacamatoviancaNoch keine Bewertungen

- Derivation of Gravity Loads PDFDokument4 SeitenDerivation of Gravity Loads PDFHenry TuganoNoch keine Bewertungen

- Chemical Bath DepositionDokument6 SeitenChemical Bath DepositionJune AlapaNoch keine Bewertungen

- Selulitis Orbita Pada Laki-Laki Usia 64 Tahun: Laporan KasusDokument8 SeitenSelulitis Orbita Pada Laki-Laki Usia 64 Tahun: Laporan KasusLuh Dita YuliandinaNoch keine Bewertungen

- Accomplishment Report: Gass/Mfo Success Indicators Actual Accomplishments RemarksDokument1 SeiteAccomplishment Report: Gass/Mfo Success Indicators Actual Accomplishments RemarksGlenn HernandezNoch keine Bewertungen

- 14 Parabola Formula Sheets QuizrrDokument9 Seiten14 Parabola Formula Sheets QuizrrChandanNoch keine Bewertungen

- Raw Material Chemical AnalysisDokument41 SeitenRaw Material Chemical AnalysisVinod Kumar VermaNoch keine Bewertungen

- Discussion 2 Module 2 - Paronda PDFDokument1 SeiteDiscussion 2 Module 2 - Paronda PDFAlvanna ParondaNoch keine Bewertungen

- Nanostructural State of AlloysDokument6 SeitenNanostructural State of AlloysCristina PostolacheNoch keine Bewertungen

- Estericlean Agroalimentaria Registro NSFDokument1 SeiteEstericlean Agroalimentaria Registro NSFwilber jovany monzon uriasNoch keine Bewertungen

- Constructing 30deg AngleDokument4 SeitenConstructing 30deg AngleArthur ChewNoch keine Bewertungen

- Taenia SoliumDokument40 SeitenTaenia SoliumBio SciencesNoch keine Bewertungen

- Design Analysis and Comparison Between The Conventional Materialswith Composite Material of The Leaf Springs Fmoa 1000127Dokument20 SeitenDesign Analysis and Comparison Between The Conventional Materialswith Composite Material of The Leaf Springs Fmoa 1000127Anonymous oTrMzaNoch keine Bewertungen

- Project Sanjay YadavDokument51 SeitenProject Sanjay YadavriyacomputerNoch keine Bewertungen