Beruflich Dokumente

Kultur Dokumente

666G

Hochgeladen von

leroniusOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

666G

Hochgeladen von

leroniusCopyright:

Verfügbare Formate

CHOCKFAST Black

High Temperature Chocking Compound

Technical Bulletin # 666G

Product Description

CHOCKFAST Black is a specifically formulated 100% solids, inert filled casting compound developed for use as a chocking material. It is a cost-effective method of maintaining permanent precise alignment of critical equipment. It will withstand severe environments involving high physical and thermal shock.

Use & Benefits

This unique product is used under gas and diesel engines, compressors, generators, turbines, motors, pumps and various other types of equipment. CHOCKFAST Black is ideal for use under these hot running reciprocating and rotating machines because of its excellent resistance to creep and fatigue at high operating temperatures. It is non-shrinking and has a very high impact and compressive strength. Resin chocks made with CHOCKFAST Black reduce possible bearing or crankshaft damage because they (1) minimize heat build-up on foundations, (2) assure precise and unsurpassed contact with bedplates, and (3) provide a high coefficient of friction to help hold engines down tight. The excellent flowability of CHOCKFAST Black allows it to fill voids in the chock area and conform to all surface irregularities

Design Considerations

CHOCKFAST Black was designed to be a thick pour liquid chocking material. A chock depth of 2" (50mm) is standard; however, thinner or thicker pours can be made satisfactorily. The 2" (50mm) chock elevates equipment above the underlying foundation, which allows a free flow of air thereby reducing possible foundation humping problems. Contact ITW Polymer Technologies for information regarding pours less than 1-1/4" (32mm) in thickness or greater than 2-1/2" (62mm) in thickness.

Installation Instructions

Construct a chock mold around one or more anchor bolts using open cell foam damming material on three sides. Wrap the shank of the anchor bolt with tape, cover with foam pipe insulation or coat with non-melt grease to prevent the CHOCKFAST from sticking to it and to seal the bolt hole. Place a metal dam 1/2 to (12mm to 18mm) from the mounting pad and seal with caulk. Spray the inside of the mold and front metal dam with Release Agent. Mix and pour the epoxy as directed.

Side and back dams should be made from open-cell foam.

Wrap all bolt threads with tape or Armaflex tubing insulation

inch to inch (12 mm to 18 mm) Maximum

inch (12 mm) Minimum 2 inches (50 mm)

ITW POLYMER TECHNOLOGIES

130 Commerce Drive Montgomeryville, PA 18936 215-855-8450 Fax 215-855-4688 www.chockfastgrout.com

CHOCKFAST Black Bulletin No. 666G, Page 2

Physical Properties

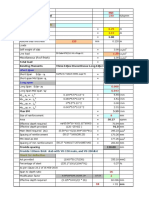

COMPRESSIVE STRENGTH COMPRESSIVE MODULUS OF ELASTICITY LINEAR SHRINKAGE COEFFICIENT OF LINEAR THERMAL EXPANSION FLEXURAL STRENGTH FLEXURAL MODULUS OF ELASTICITY TENSILE STRENGTH SHEAR STRENGTH IZOD IMPACT STRENGTH FIRE RESISTANCE SPECIFIC GRAVITY BARCOL HARDNESS MAXIMUM OPERATING TEMPERATURE 17,300 psi 2 (1,216 kg/cm ) 800,000 psi 2 (56,000 kg/cm ) 0.00018 in/in (0.00018 mm/mm) -6 32F to 140F @ 15.0 X 10 /F (0.000027/C @ 0C to 60C) 6,200 psi (435 kg/cm2) 2 1,400,000 psi (101,300 kg/cm ) 2 2,900 psi (204 kg/cm ) 2 5,000 psi (350 kg/cm ) 5.1 in.lbs./in (0.23 N.m/cm) Self Extinguishing 1.94 55 Full Cure o o 200 F (94 C) ASTM C-695 (Modified) ASTM C-695 (Modified) ASTM D-2566 ASTM D-696 ASTM C-580 ASTM C-580 ASTM D-638 FED-STD-406 (Method 1041) ASTM D-256 ASTM D-635 ASTM D-2583

Product Information

UNIT COVERAGE 265 in (4,343 cm ) o o o o APPLICATION TEMPERATURE 55 F (13 C) to 95 F (35 C) UNIT PACKAGING Resin (NH) 18.2 lbs. (8.3 kg), 1.2 gal (4.5 L) in a 2gal pail Hardener (H) 0.74 lbs. (0.34 kg), 11.5 oz (3.4 L) in an 16 oz plastic bottle SHIPPING WEIGHT 21 lbs. (9.5 kg) CURE TIME (approximate) 48 hours @ 60F (15C) 36 hours @ 65F (18C) 24 hours @ 70F (21C) 18 hours @ 80F (26C) POT LIFE 45 min. @ 70F (21C) SHELF LIFE Exceed 18 months CLEAN UP IMPAX IXT-59 or similar epoxy cleaner For design considerations and application details please request Bulletin No. 642 or contact ITW Polymer Technologies' Engineering Services Department. 06/2006

General: Every reasonable effort is made to insure the technical information and recommendations on these data pages are true and accurate to the best of our knowledge at the date of issuance. However, this information is subject to change without notice. Prior versions of this publication are invalid with the release of this version. Products and information are intended for use by qualified applicators that have the required background, technical knowledge, and equipment to perform said tasks in a satisfactory manner. Consult your local distributor for product availability, additional product information, and technical support. Warranty: ITW Polymer Technologies, a division of Illinois Tool Works Inc., warrants that its products meet their printed specifications. This is the sole warranty. This warranty expires one year after product shipment. Warranty Claims: If any product fails to meet the above, ITW Polymer Technologies will, at its option, either replace the product or refund the purchase price. ITW Polymer Technologies will have no other liability for breach of warranty, negligence, or otherwise. All warranty claims must be made in writing within one year of the date of shipment. No other claims will be considered. Disclaimer: ITW Polymer Technologies makes no other warranty, expressed or implied, and specifically disclaims any warranty of merchantability or fitness for a particular purpose. Suggestions concerning the use of products are not warranties. The purchaser assumes the responsibility for determining suitability of products and appropriate use. ITW Polymer Technologies sole liability, for breach of warranty, negligence or otherwise, shall be the replacement of product or refund of the purchase price, at ITW Polymer Technologies election. Under no circumstances shall ITW Polymer Technologies be liable for any indirect, incidental or consequential damages. Modification of Warranty: No distributor or sales representative has the authority to change the above provisions. No change in the above provisions will be valid unless in writing and signed by an officer or the Technical Director of ITW Polymer Technologies. No term of any purchase order shall serve to modify any provision of this document. Mediation and Arbitration: If any dispute arises relating to products or product warranties, either the purchaser or ITW Polymer Technologies may a) initiate mediation under the then current Center for Public Resources (CPR) Model Procedure for Mediation of Business Disputes, or b) initiate a non-binding arbitration under the rules of the American Arbitration Association for the resolution of commercial disputes.

3 3

Reference Date

Das könnte Ihnen auch gefallen

- Codes Standards RegulationsDokument6 SeitenCodes Standards RegulationsKoshala Balasuriya100% (3)

- Din 931Dokument1 SeiteDin 931Showkath Ali100% (2)

- Diccionario NauticoDokument108 SeitenDiccionario NauticoAngel GomezNoch keine Bewertungen

- DIN 934 NutsDokument1 SeiteDIN 934 NutsleroniusNoch keine Bewertungen

- Using The Curves of The Lines Plan To Ship Conditions 1959Dokument46 SeitenUsing The Curves of The Lines Plan To Ship Conditions 1959leroniusNoch keine Bewertungen

- Finite Element Analysis of A Cracked Cantilever Beam: Research PaperDokument5 SeitenFinite Element Analysis of A Cracked Cantilever Beam: Research PaperSanketNoch keine Bewertungen

- Weld JointDokument44 SeitenWeld JointPratiek RaulNoch keine Bewertungen

- Iiar OrgDokument99 SeitenIiar OrgPongtorn ChaisamranNoch keine Bewertungen

- Structural Fiberglass Design ManualDokument82 SeitenStructural Fiberglass Design ManualJoemarie MartinezNoch keine Bewertungen

- Drum Filter PDFDokument8 SeitenDrum Filter PDFleroniusNoch keine Bewertungen

- ST52 3Dokument1 SeiteST52 3henrychtNoch keine Bewertungen

- Desguace 3Dokument5 SeitenDesguace 3leroniusNoch keine Bewertungen

- ST52 3Dokument1 SeiteST52 3henrychtNoch keine Bewertungen

- ABS Shipbuilding and Repair Standards - Pub87 - SRQS - GuideDokument44 SeitenABS Shipbuilding and Repair Standards - Pub87 - SRQS - Guidesamnortan100% (1)

- REC 34 Standard Wave Data 2000Dokument4 SeitenREC 34 Standard Wave Data 2000leroniusNoch keine Bewertungen

- Ver 4.3Dokument59 SeitenVer 4.3leroniusNoch keine Bewertungen

- APPEA Guidelines For Liting Equipment Combined)Dokument101 SeitenAPPEA Guidelines For Liting Equipment Combined)kunbasukiadi100% (1)

- ST52 3Dokument1 SeiteST52 3henrychtNoch keine Bewertungen

- Finite Element Analysis of A Cracked Cantilever Beam: Research PaperDokument5 SeitenFinite Element Analysis of A Cracked Cantilever Beam: Research PaperSanketNoch keine Bewertungen

- UI PASSUB Passenger Submersible Craft 2001Dokument3 SeitenUI PASSUB Passenger Submersible Craft 2001leroniusNoch keine Bewertungen

- Finite Element Analysis of A Cracked Cantilever Beam: Research PaperDokument5 SeitenFinite Element Analysis of A Cracked Cantilever Beam: Research PaperSanketNoch keine Bewertungen

- REC 42 Guidelines For Use of Remote Survey Techniques 2004Dokument1 SeiteREC 42 Guidelines For Use of Remote Survey Techniques 2004leroniusNoch keine Bewertungen

- Asshto LRFDDokument108 SeitenAsshto LRFDJose Belito Belito ManchaNoch keine Bewertungen

- Frases Verbales Ingles 2Dokument3 SeitenFrases Verbales Ingles 2leroniusNoch keine Bewertungen

- Steel Watertight DoorDokument1 SeiteSteel Watertight DoorleroniusNoch keine Bewertungen

- Rockwool 3Dokument16 SeitenRockwool 3leroniusNoch keine Bewertungen

- 3222Dokument1 Seite3222leroniusNoch keine Bewertungen

- Ventilation Guide 05-08Dokument78 SeitenVentilation Guide 05-08leroniusNoch keine Bewertungen

- ST52 3Dokument1 SeiteST52 3henrychtNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- House Construction - Structural Building - Wikibooks, Open Books For An Open WorldDokument8 SeitenHouse Construction - Structural Building - Wikibooks, Open Books For An Open WorldJojo JojoNoch keine Bewertungen

- Facility Condition Assessment: GuidebookDokument54 SeitenFacility Condition Assessment: GuidebookMaxmore KarumamupiyoNoch keine Bewertungen

- Zenbes Catalogue (2018)Dokument6 SeitenZenbes Catalogue (2018)Haris FarhanNoch keine Bewertungen

- Catalogo - Sispro S.A.Dokument21 SeitenCatalogo - Sispro S.A.JUAN CNoch keine Bewertungen

- Balanced Concession For The Airport Industry PDFDokument80 SeitenBalanced Concession For The Airport Industry PDFPricop CosminNoch keine Bewertungen

- SPAN Part H - Particular Construction...Dokument8 SeitenSPAN Part H - Particular Construction...ang.xicongNoch keine Bewertungen

- Victor Horta-2Dokument18 SeitenVictor Horta-2PREETHI M ANoch keine Bewertungen

- ONE Lake Club IIDokument15 SeitenONE Lake Club IIErvin92Noch keine Bewertungen

- Study To Measure Market Potential For L&TDokument32 SeitenStudy To Measure Market Potential For L&TPreeti BajajNoch keine Bewertungen

- ASTM STP 1104 Field Vane Shear TestDokument370 SeitenASTM STP 1104 Field Vane Shear TestAndrew GarfieldNoch keine Bewertungen

- Gen Slab and Wall Tutorial 1492723667 PDFDokument49 SeitenGen Slab and Wall Tutorial 1492723667 PDFVijayNoch keine Bewertungen

- Selection and Application of Piping System Materials: Standard Practice ForDokument23 SeitenSelection and Application of Piping System Materials: Standard Practice ForRoberto Omar Morante VillarrealNoch keine Bewertungen

- California Plumbing CodeDokument7 SeitenCalifornia Plumbing CodeMOHAMMAD ASIFNoch keine Bewertungen

- Fuel Tank Ring Beam Design CalculationDokument11 SeitenFuel Tank Ring Beam Design CalculationDawson Preethi EA94% (16)

- Installation & Servicing Instructions: For Use Only With Specially Designed FirefrontsDokument32 SeitenInstallation & Servicing Instructions: For Use Only With Specially Designed FirefrontsCristea GabrielNoch keine Bewertungen

- Aamir CV Updated 12 July 2023Dokument7 SeitenAamir CV Updated 12 July 2023Ahmad fayyazNoch keine Bewertungen

- Rheomac® 707Dokument4 SeitenRheomac® 707M HAFEEZ RAJANoch keine Bewertungen

- Slab Code: Grade of Concrete Permissble Stress in SteelDokument1 SeiteSlab Code: Grade of Concrete Permissble Stress in Steeljuliyet strucNoch keine Bewertungen

- Nova ABS Plastic Formwork by Sandeep NaikwadeDokument11 SeitenNova ABS Plastic Formwork by Sandeep NaikwadeNovaFormworkNoch keine Bewertungen

- Micra Kv4 Kv6Dokument4 SeitenMicra Kv4 Kv6Mohamed Anouar BidaNoch keine Bewertungen

- Item 200 - Aggregate Sub Base Course Sieve DesignationDokument20 SeitenItem 200 - Aggregate Sub Base Course Sieve DesignationAeron Paul AntonioNoch keine Bewertungen

- Epolam2500 GB PDFDokument2 SeitenEpolam2500 GB PDFMcFlyNoch keine Bewertungen

- Pykrete Dome Case StudyDokument7 SeitenPykrete Dome Case StudyMahaManthraNoch keine Bewertungen

- Pt. Setia Pratama Lestari: Hdpe St7 BK HDPE Black Jacketing CompoundDokument1 SeitePt. Setia Pratama Lestari: Hdpe St7 BK HDPE Black Jacketing CompoundMOKHAMAD NURDINNoch keine Bewertungen

- Piling: Information Provided Rules Definition Coverage Rules Supp MentDokument1 SeitePiling: Information Provided Rules Definition Coverage Rules Supp MentVimalNoch keine Bewertungen

- Analyis of Hollow Slab CoreDokument13 SeitenAnalyis of Hollow Slab CoreHendra GintingNoch keine Bewertungen

- A Study On Creep and Drying Shrinkage of High Performance ConcreteDokument4 SeitenA Study On Creep and Drying Shrinkage of High Performance Concreteit does not exist for the [mpossibleNoch keine Bewertungen

- Structural Standard Details: Construction NotesDokument4 SeitenStructural Standard Details: Construction Notesjohn rey toledo100% (1)

- Developing A Housing Microfinance Product - The First Microfinance Banks Experience in AfghanistanDokument32 SeitenDeveloping A Housing Microfinance Product - The First Microfinance Banks Experience in AfghanistanBhagyanath MenonNoch keine Bewertungen