Beruflich Dokumente

Kultur Dokumente

Epl 2

Hochgeladen von

Luis Alberto OrtegaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Epl 2

Hochgeladen von

Luis Alberto OrtegaCopyright:

Verfügbare Formate

SUSPENSION

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT. . . . . . . . . . . . . . . . . . . . . . . . 1

FRONT SUSPENSION . . . . . . . . . . . . . . . . . . . . . . . 9

REAR SUSPENSION . . . . . . . . . . . . . . . . . . . . . . . 35

WHEEL ALIGNMENT

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

WHEEL ALIGNMENT . . . . . . . . . . . . . . . . . . . . . . . 1

DIAGNOSIS AND TESTING

SUSPENSION AND STEERING DIAGNOSIS . . . . . 3

SERVICE PROCEDURES

CURB HEIGHT MEASUREMENT . . . . . . . . . . . . . . 5

WHEEL ALIGNMENT . . . . . . . . . . . . . . . . . . . . . . . 5

SPECIFICATIONS

WHEEL ALIGNMENT SPECIFICATIONS. . . . . . . . . 8

DESCRIPTION AND OPERATION

WHEEL ALIGNMENT

Proper vehi cl e wheel al i gnment i s the proper

adjustment of al l i nterrel ated front and rear suspen-

si on angl es. These angl es are what affects the han-

dl i ng and steeri ng of the vehi cl e when i t i s i n moti on.

The method of checki ng a vehi cl es front and rear

wheel al i gnment wi l l vary dependi ng on the type and

manufacturer of the equi pment bei ng used. I nstruc-

ti ons furni shed by the manufacturer of the equi p-

ment bei ng used shoul d al ways be fol l owed to ensure

accuracy of the al i gnment, except when al i gnment

speci fi cati ons recommended by thi s corporati on di ffer.

Typi cal wheel al i gnment angl es and measurements

are camber, caster, toe, and thrust angl e.

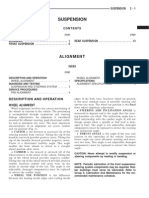

Camber i s the number of degrees the top of the

ti re and wheel are ti l ted ei ther i nward or outward

(Fi g. 1). Camber i s a ti re weari ng angl e. Excessi ve

negati ve camber wi l l cause tread wear at the i nsi de

of the ti re, whi l e excessi ve posi ti ve camber wi l l cause

outsi de ti re wear.

Caster i s the number of degrees of forward or

rearward ti l t of the steeri ng knuckl e. Forward ti l t

provi des a negati ve caster angl e, whi l e rearward ti l t

provi des a posi ti ve caster angl e. Caster i s not adjust-

abl e on thi s vehi cl e.

Cross Camber i s the di fference between l eft and

ri ght camber. The ri ght si de camber i s to be sub-

tracted from the l eft, resul ti ng i n the cross camber

readi ng. For exampl e, i f the l eft camber i s +0.3 and

the ri ght camber i s 0.0, the cross camber woul d be

+0.3.

Toe i s measured i n degrees or i nches and i s the

di fference i n wi dth between the centered l eadi ng and

trai l i ng edges of the ti res on the same axl e (Fi g. 1).

Toe-i n means that the front wi dth i s more narrow

than the rear. Toe-out means that the front wi dth i s

wi der than the rear.

Thrust Angl e i s defi ned as the average of the toe

setti ngs on each rear wheel . I f thi s measurement i s

out of speci fi cati on, readjust the rear wheel toe so

that each wheel has 1/2 of the total toe measure-

ment. When readjusti ng, do not exceed the total toe

speci fi cati on.

PL SUSPENSION 2 - 1

Fig. 1 Alignment Camber And Toe

1 LOOSEN NUT TO ADJUST TOE

2 TOE ADJUSTMENT

3 POSITIVE

4 NEGATIVE

5 CAMBER

6 TOE-OUT

7 TOE-IN

2 - 2 SUSPENSION PL

DESCRIPTION AND OPERATION (Continued)

DIAGNOSIS AND TESTING

SUSPENSION AND STEERING DIAGNOSIS

CONDITION POSSIBLE CAUSES POTENTIAL CORRECTIONS

Front End Whine On

Turns

1. Defective Wheel Bearing 1. Replace Wheel Bearing

2. Incorrect Wheel Alignment 2. Check And Reset Wheel Alignment

3. Worn Tires 3. Replace Tires

Front End Growl Or

Grinding On Turns

1. Defective Wheel Bearing 1. Replace Wheel Bearing

2. Engine Mount Grounding

Against Frame Or Body Of Vehicle.

2. Check For Motor Mount Hitting Frame

Rail And Reposition Engine As Required

3. Worn Or Broken C/V Joint 3. Replace C/V Joint

4. Loose Wheel Lug Nuts 4. Verify Wheel Lug Nut Torque

5. Incorrect Wheel Alignment 5. Check And Reset Wheel Alignment

6. Worn Tires 6. Replace Tires

Front End Clunk Or

Snap On Turns

1. Loose Wheel Lug Nuts 1. Verify Wheel Lug Nut Torque

2. Worn Or Broken C/V Joint 2. Replace C/V Joint

3. Worn Or Loose Tie Rod Or Ball Joint 3. Tighten Or Replace Tie Rod End Or Ball

Joint

4. Worn Control Arm Bushing 4. Replace Control Arm Bushing

5. Loose Sway Bar Or Upper Strut

Attachment

5. Tighten Sway Bar Or Upper Strut

Attachment To Specified Torque

Front End Whine

With Vehicle Going

Straight At A

Constant Speed

1. Defective Wheel Bearing 1. Replace Wheel Bearing

2. Incorrect Wheel Alignment 2. Check And Reset Wheel Alignment

3. Worn Tires 3. Replace Tires

Front End Growl Or

Grinding With

Vehicle Going

Straight At A

Constant Speed

1. Engine Mount Grounding 1. Reposition Engine As Required

2. Worn Or Broken C/V Joint 2. Replace C/V Joint

Front End Whine

When Accelerating

Or Decelerating

1. Worn Or Defective Transaxle Gears Or

Bearings

1. Replace Transaxle Gears Or Bearings

Front End Clunk

When Accelerating

Or Decelerating

1. Worn Or Broken Engine Mount 1. Replace Engine Mount

2. Worn Or Defective Transaxle Gears Or

Bearings

2. Replace Transaxle Gears Or Bearings

PL SUSPENSION 2 - 3

CONDITION POSSIBLE CAUSES POTENTIAL CORRECTIONS

3. Loose Wheel Lug Nuts 3. Verify Wheel Lug Nut Torque

4. Worn Or Broken C/V Joint 4. Replace C/V Joint

5. Worn Or Loose Ball Joint 5. Tighten Or Replace Ball Joint

6. Worn Or Loose Control Arm Bushing 6. Tighten To Specified Torque Or Replace

Control Arm Bushing

7. Loose Crossmember Bolts 7. Tighten Crossmember Bolts To Specified

Torque

Road Wander 1. Incorrect Tire Pressure 1. Inflate Tires To Rcommended Pressure

2. Incorrect Front Or Rear Wheel Toe 2. Check And Reset Front Wheel Toe

3. Worn Wheel Bearings 3. Replace Wheel Bearing

4. Worn Control Arm Bushings 4. Replace Control Arm Bushing

5. Excessive Friction In Steering Gear 5. Replace Steering Gear

6. Excessive Friction In Steering Shaft

Coupling

6. Replace Steering Coupler

7. Excessive Friction In Strut Upper

Bearing

7. Replace Strut Bearing

Lateral Pull 1. Unequal Tire Pressure 1. Inflate All Tires To Recommended

Pressure

2. Radial Tire Lead 2. Perform Lead Correction Procedure

3. Incorrect Front Wheel Camber 3. Check And Reset Front Wheel Camber

4. Power Steering Gear Imbalance 4. Replace Power Steering Gear

5. Wheel Braking 5. Correct Braking Condition Causing

Lateral Pull

Excessive Steering

Free Play

1. Incorrect Steering Gear Adjustment 1. Adjust Or Replace Steering Gear

2. Worn Or Loose Tie Rod Ends 2. Replace Or Tighten Tie Rod Ends

3. Loose Steering Gear Mounting Bolts 3. Tighten Steering Gear Bolts To The

Specified Torque

4. Loose Or Worn Steering Shaft Coupler 5. Replace Steering Shaft Coupler

Excessive Steering

Effort

1. Low Tire Pressure 1. Inflate All Tires To Recommended

Pressure

2. Lack Of Lubricant In Steering Gear 2. Replace Steering Gear

3. Low Power Steering Fluid Level 3. Fill Power Steering Fluid Reservoir To

Correct Level

4. Loose Power Steering Pump Belt 4. Check and replace automatic belt

tensioner as necessary. If drive belt is worn

or glazed, replace belt.

5. Lack Of Lubricant In Steering Ball Joints 5. Lubricate Or Replace Steering Ball Joints

6. Steering Gear Malfunction 6. Replace Steering Gear

7. Lack Of Lubricant In Steering Coupler 7. Replace Steering Coupler

2 - 4 SUSPENSION PL

DIAGNOSIS AND TESTING (Continued)

SERVICE PROCEDURES

CURB HEIGHT MEASUREMENT

The wheel al i gnment i s to be checked and al l al i gn-

ment adjustments made wi th the vehi cl e at i ts

requi red curb hei ght speci fi cati on.

Vehi cl e hei ght i s to be checked wi th the vehi cl e on

a fl at, l evel surface, preferabl y a vehi cl e al i gnment

rack. The ti res are to be i nfl ated to the recommended

pressure. Al l ti res are to be the same si ze as stan-

dard equi pment. Vehi cl e hei ght i s checked wi th the

fuel tank ful l of fuel , and no passenger or l uggage

compartment l oad.

Vehi cl e hei ght i s not adjustabl e. I f the measure-

ment i s not wi thi n speci fi cati ons, i nspect the vehi cl e

for bent or weak suspensi on components. Compare

the parts tag on the suspect coi l spri ng(s) to the

parts book and the vehi cl e sal es code, checki ng for a

match. Once removed from the vehi cl e, compare the

coi l spri ng hei ght to a correct new or known good coi l

spri ng. The hei ghts shoul d vary i f the suspect spri ng

i s weak.

NOTE: Prior to reading the curb height measure-

ment, the front an rear of the vehicle should be

jounced. Induce jounce by grasping the center of

the rear, then front bumper (or fascia) and jouncing

the vehicle an equal number of times. Release the

bumper at the bottom of the jounce cycle.

(1) Measure from the i nboard edge of the wheel

openi ng fender l i p di rectl y above the wheel center

(spi ndl e), to the fl oor or al i gnment rack surface.

(2) When measuri ng, maxi mum l eft-to-ri ght di ffer-

enti al i s not to exceed 10 mm (0.39 i n.).

(3) Compare the measurements to speci fi cati ons

l i sted i n the fol l owi ng CURB HEI GHT SPECI FI CA-

TI ONS chart.

CURB HEIGHT SPECIFICATIONS

VEHICLE FRONT REAR

ALL NEON

672 mm 8 mm 679 mm 8 mm

26.46 in. 0.32 in. 26.73 in. 0.32 in.

WHEEL ALIGNMENT

PRE-WHEEL ALIGNMENT VEHICLE INSPECTION

CAUTION: If during the inspection the front sus-

pension crossmember shows any sign of impact

damage, the steering column lower coupling must

be inspected. Refer to DIAGNOSIS AND TESTING in

the STEERING group in this service manual.

Before any attempt i s made to change or correct

the wheel al i gnment, the fol l owi ng i nspecti on and

necessary correcti ons must be made to the vehi cl e to

ensure proper al i gnment.

(1) Be sure the fuel tank i s ful l of fuel . I f the fuel

tank i s not ful l , the reducti on i n wei ght wi l l affect

the curb hei ght of the vehi cl e and the al i gnment

speci fi cati ons.

(2) The passenger and l uggage compartments of

the vehi cl e shoul d be free of any l oad that i s not fac-

tory equi pment.

(3) Check the ti res on the vehi cl e. The ti res are to

be i nfl ated to the recommended ai r pressure. Al l ti res

must be the same si ze and i n good condi ti on wi th

approxi matel y the same tread wear.

(4) Check the front ti re and wheel assembl i es for

excessi ve radi al runout.

(5) I nspect al l suspensi on component fasteners for

l ooseness and torque.

(6) I nspect the l ower front bal l joi nts and al l steer-

i ng l i nkage for l ooseness and any si gn of wear or

damage.

(7) I nspect the rubber bushi ngs on al l the suspen-

si on components for si gns of wear or deteri orati on. I f

any bushi ngs show si gns of wear or deteri orati on,

they shoul d be repl aced pri or to al i gni ng the vehi cl e.

WHEEL ALIGNMENT SETUP

(1) Posi ti on the vehi cl e on an al i gnment rack.

(2) I nstal l al l requi red al i gnment equi pment on

the vehi cl e, per the al i gnment equi pment manufac-

turers i nstructi ons. On thi s vehi cl e, a four-wheel

al i gnment i s recommended.

NOTE: Prior to reading the vehicles alignment

readouts, the front and rear of vehicle should be

jounced. Induce jounce (rear first, then front) by

grasping the center of the bumper and jouncing

each end of vehicle an equal number of times. The

bumper should always be released when vehicle is

at the bottom of the jounce cycle.

(3) Read the vehi cl es current front and rear al i gn-

ment setti ngs. Compare the vehi cl es current al i gn-

ment setti ngs to the vehi cl e speci fi cati ons for camber,

caster and toe-i n. Refer to WHEEL ALI GNMENT

PL SUSPENSION 2 - 5

SPECI FI CATI ONS i n thi s secti on of thi s servi ce

manual group.

(4) I f the rear al i gnment i s out of speci fi cati on,

adjust i t fi rst before proceedi ng to the front.

CAMBER AND CASTER

Front and rear camber and caster setti ngs on thi s

vehi cl e are determi ned at the ti me the vehi cl e i s

desi gned, by the l ocati on of the vehi cl es suspensi on

components. Thi s i s referred to as Net Bui l d. The

resul t i s no requi red adjustment of camber and

caster after the vehi cl e i s bui l t or when servi ci ng the

suspensi on components. Thus, when performi ng a

wheel al i gnment, caster and camber are not normal l y

consi dered adjustabl e angl es. Camber and caster

shoul d be checked to ensure they meet vehi cl e speci -

fi cati ons.

I f ei ther front or rear camber i s found not to meet

al i gnment speci fi cati ons, i t can be adjusted usi ng an

avai l abl e camber adjustment bol t package. Before

i nstal l i ng a camber adjustment bol t package on a

vehi cl e found to be outsi de the speci fi cati ons, i nspect

the suspensi on components for any si gns of damage

or bendi ng.

No adjustment can be made to the caster setti ng

on thi s vehi cl e. I f the vehi cl es caster i s not wi thi n

al i gnment speci fi cati ons, check for damaged suspen-

si on components or body parts.

CAUTION: Do not attempt to adjust the vehicles

wheel alignment by heating or bending any of the

suspension components.

CAMBER ADJUSTMENT BOLT PACKAGE INSTALLATION

NOTE: The following procedure should only be

used on vehicles without the ACR competition

package.

The camber adjustment bol t package contai ns new

bol ts and nuts for attachi ng the strut cl evi s bracket

to the steeri ng knuckl e. The bol ts contai ned i n the

package are sl i ghtl y undersi ze al l owi ng for move-

ment between the strut cl evi s bracket and the steer-

i ng knuckl e. The movement al l owed by the undersi ze

bol ts provi de approxi matel y two degrees of camber

adjustment per si de of the vehi cl e. To i nstal l and

adjust the camber adjustment bol t package, fol l ow

the procedure bel ow.

CAUTION: There are separate camber adjustment

bolt packages for the front and rear of the vehicle.

Be sure to use the correct package.

(1) Rai se the vehi cl e unti l i ts ti res are not support-

i ng the wei ght of the vehi cl e.

CAUTION: The knuckle to strut assembly attaching

bolt shanks are serrated and must not be turned

during removal. Remove the nuts while holding the

bolts stationary.

(2) Remove the ori gi nal upper bol t attachi ng the

strut cl evi s bracket to the knuckl e (Fi g. 2) (Fi g. 3).

(3) I nstal l a bol t from the adjustment package i nto

the hol e where the ori gi nal bol t was removed. I nstal l

the bol t from the rear.

Fig. 2 Front Strut Clevis Bracket Attaching Bolts

1 STRUT CLEVIS BRACKET

2 STRUT CLEVIS BRACKET TO STEERING KNUCKLE

ATTACHING BOLTS

3 STEERING KNUCKLE

4 LOOSEN THIS BOLT

5 REMOVE AND REPLACE THIS BOLT

Fig. 3 Rear Strut Clevis Bracket Attaching Bolts

1 KNUCKLE

2 STRUT ASSEMBLY CLEVIS BRACKET

3 CLEVIS BRACKET TO KNUCKLE ATTACHING BOLTS

2 - 6 SUSPENSION PL

SERVICE PROCEDURES (Continued)

(4) I nstal l a nut provi ded i n adjustment package

on the repl acement bol t. Ti ghten the nut unti l i ts

snug, but sti l l al l owi ng the knuckl e to sl i de i n the

cl evi s bracket.

(5) Remove the ori gi nal l ower bol t.

(6) I nstal l a bol t from the adjustment package i nto

the bottom hol e of the strut cl evi s bracket. I nstal l the

bol t from the rear.

(7) I nstal l a nut provi ded i n adjustment package

on the repl acement bol t. Ti ghten the nut unti l i ts

snug.

(8) Rei nstal l the ti re and wheel assembl y.

(9) Perform the above procedure to any of the

remai ni ng struts as requi red.

(10) Lower the vehi cl e and jounce the front and

rear of the vehi cl e.

(11) Adjust the front or rear camber to the pre-

ferred setti ng by pushi ng or pul l i ng on the top of the

ti re. When camber i s set to speci fi cati ons, ti ghten the

upper and l ower strut cl evi s bracket bol ts. Agai n

jounce the front and rear of the vehi cl e, then veri fy

the camber setti ngs.

(12) Torque front strut cl evi s bracket-to-steeri ng

knuckl e attachi ng bol ts to 53 Nm (40 ft. l bs.), pl us

an addi ti onal 1/4 turn after the torque i s met. Torque

the rear strut cl evi s bracket-to-rear knuckl e attach-

i ng bol ts to 95 Nm (70 ft. l bs.).

(13) Once camber i s wi thi n speci fi cati ons, adjust

toe to meet the preferred speci fi cati on setti ng. Refer

to TOE wi thi n thi s wheel al i gnment servi ce proce-

dure.

TOE

(1) Center the steeri ng wheel and l ock i t i n pl ace

usi ng a steeri ng wheel cl amp.

NOTE: When performing the toe setting procedure,

make sure the rear toe is set to the preferred spec-

ification before setting the front toe to the preferred

specification.

REAR TOE

(1) Loosen the nuts on the l eft and ri ght rear l at-

eral l i nk attachi ng bol ts at the rear crossmember as

necessary to al l ow rotati on of the rear toe adjustment

cams (Fi g. 4).

CAUTION: When adjusting rear toe, the notches on

the toe adjustment cams are not to be facing down.

The notches in the adjustment cams are only to be

facing up or toward one side.

(2) Rotate each toe adjustment cam unti l the pre-

ferred rear toe speci fi cati on i s obtai ned (Fi g. 4). Refer

to WHEEL ALI GNMENT SPECI FI CATI ONS i n thi s

secti on of thi s servi ce manual group.

(3) Whi l e hol di ng the toe adjustment cams from

turni ng, ti ghten the attachi ng bol t nuts. Thi s wi l l

securel y hol d the adjustment cams i n posi ti on.

Ti ghten the attachi ng bol t nuts to a torque of 88 Nm

(65 ft. l bs.).

(4) Proceed to FRONT TOE to set the front toe.

FRONT TOE

CAUTION: Do not twist the inner tie rod-to-steering

gear rubber boots while turning the inner tie rod

during the front toe adjustment.

(1) Loosen the ti e rod adjusti ng jam nuts (Fi g. 5).

Grasp each i nner ti e rod at i ts hex and rotate i t one

way or the other unti l the front wheel toe i s set to

the preferred speci fi cati on. Refer to WHEEL ALI GN-

MENT SPECI FI CATI ONS i n thi s secti on of thi s ser-

vi ce manual group.

Fig. 4 Adjustment Cams

1 BOLTS

2 ADJUSTMENT CAMS

3 NUTS

PL SUSPENSION 2 - 7

SERVICE PROCEDURES (Continued)

(2) Ti ghten ti e rod adjusti ng jam nuts to a torque

of 75 Nm (55 ft. l bs.).

(3) Make sure the i nner ti e rod-to-steeri ng gear

rubber boots are not twi sted. I f twi sted, l oosen the

boot cl amp at the i nner ti e rod and move the boot as

necessary.

(4) Remove steeri ng wheel cl amp.

(5) Remove the al i gnment equi pment.

(6) Road test the vehi cl e to veri fy the steeri ng

wheel i s strai ght and the vehi cl e does not pul l or

wander.

SPECIFICATIONS

WHEEL ALIGNMENT SPECIFICATIONS

NOTE: All specifications are given in degrees.

NOTE: All wheel alignments are to be set with the

vehicle at curb height. Refer to CURB HEIGHT MEA-

SUREMENT in SERVICE PROCEDURES.

FRONT WHEEL ALIGNMENT PREFERRED SETTING ACCEPTABLE RANGE

CAMBER 0.00 -0.40to +0.40

Cross Camber (Maximum

Side-To-Side Difference)

0.00 0.50

CASTER +2.60 +1.60to +3.60

Cross Caster (Maximum Side-To-

Side Difference)

0.00 1.00

TOTAL TOE* +0.10 0.10to +0.30

REAR WHEEL ALIGNMENT PREFERRED SETTING ACCEPTABLE RANGE

CAMBER -0.25 -0.65to +0.15

TOTAL TOE* +0.30 +0.10to +0.50

THRUST ANGLE 0.00 -0.10to +0.10

Note:

* TOTAL TOE is the sum of both the left and right wheel toe settings. TOTAL TOE must be equally split between

each front wheel to ensure the steering wheel is centered after setting toe. Positive toe (+) is toe-in and negative

toe () is Toe-out.

Fig. 5 Jam Nuts

1 OUTER TIE ROD

2 INNER TIE ROD HEX

3 JAM NUT

2 - 8 SUSPENSION PL

SERVICE PROCEDURES (Continued)

FRONT SUSPENSION

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

FRONT SUSPENSION SYSTEM. . . . . . . . . . . . . . . 9

STRUT ASSEMBLY (FRONT) . . . . . . . . . . . . . . . . 11

STEERING KNUCKLE . . . . . . . . . . . . . . . . . . . . . 11

LOWER CONTROL ARM . . . . . . . . . . . . . . . . . . . 11

STABILIZER BAR (FRONT) . . . . . . . . . . . . . . . . . 12

DIAGNOSIS AND TESTING

STRUT ASSEMBLY (FRONT) . . . . . . . . . . . . . . . . 12

STEERING KNUCKLE . . . . . . . . . . . . . . . . . . . . . 13

WHEEL BEARING AND HUB . . . . . . . . . . . . . . . . 13

LOWER CONTROL ARM . . . . . . . . . . . . . . . . . . . 13

BALL JOINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

STABILIZER BAR (FRONT) . . . . . . . . . . . . . . . . . 14

SERVICE PROCEDURES

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS . . . . . . . . 14

STRUT ASSEMBLY (FRONT) . . . . . . . . . . . . . . . . 14

STEERING KNUCKLE . . . . . . . . . . . . . . . . . . . . . 15

LOWER CONTROL ARM . . . . . . . . . . . . . . . . . . . 18

STABILIZER BAR (FRONT) . . . . . . . . . . . . . . . . . 20

WHEEL MOUNTING STUD (FRONT) . . . . . . . . . . 21

DISASSEMBLY AND ASSEMBLY

STRUT ASSEMBLY (FRONT) . . . . . . . . . . . . . . . . 22

STEERING KNUCKLE (WHEEL BEARING AND

HUB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

LOWER CONTROL ARM (BALL JOINT) . . . . . . . . 29

LOWER CONTROL ARM (REAR ISOLATOR

BUSHING). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

SPECIFICATIONS

FRONT SUSPENSION FASTENER TORQUE

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . 33

SPECIAL TOOLS

FRONT SUSPENSION . . . . . . . . . . . . . . . . . . . . . 33

DESCRIPTION AND OPERATION

FRONT SUSPENSION SYSTEM

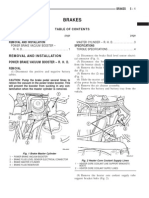

The front suspensi on al l ows each front wheel on a

vehi cl e to adapt to di fferent road surfaces and condi -

ti ons wi thout greatl y affecti ng the opposi te wheel

and the abi l i ty to control the vehi cl e. Each si de of the

front suspensi on i s al l owed to pi vot so the vehi cl e can

be steered i n the di recti on preferred.

Thi s vehi cl e has a gas pressuri zed MacPherson

strut type front suspensi on desi gn (Fi g. 1).

A strut assembl y i s used i n pl ace of the front sus-

pensi on upper control arm and upper bal l joi nt.

When a vehi cl e stri kes a bump, the force i s trans-

ferred through the hub, beari ng, and knuckl e, i nto

the strut assembl y to absorb the force and dampen i t.

The top of the strut i s mounted di rectl y to the strut

tower of the vehi cl e. Duri ng steeri ng maneuvers, the

strut assembl y (through a pi vot beari ng i n the upper

strut mount) and steeri ng knuckl e (through the l ower

bal l joi nt mounted on the l ower control arm) turn as

an assembl y.

PL SUSPENSION 2 - 9

Fig. 1 Front Suspension System

2 - 10 SUSPENSION PL

DESCRIPTION AND OPERATION (Continued)

For more i nformati on on the descri pti on and oper-

ati on of an i ndi vi dual component, refer to the appl i -

cabl e component headi ng i n thi s secti on.

STRUT ASSEMBLY (FRONT)

A Macpherson type desi gn strut assembl y i s used

i n pl ace of the front suspensi on upper control arm

and upper bal l joi nt (Fi g. 1). The bottom of the strut

mounts di rectl y to the steeri ng knuckl e usi ng 2

attachi ng bol ts and nuts goi ng through the strut cl e-

vi s bracket and steeri ng knuckl e. The top of the strut

mounts di rectl y to the strut tower of the vehi cl e

usi ng the three threaded studs on the strut assem-

bl i es upper mount. Duri ng steeri ng maneuvers, the

strut assembl y (through a pi vot beari ng i n the upper

strut mount) and steeri ng knuckl e (through the l ower

bal l joi nt) turn as an assembl y. The strut assembl y i s

used to dampen the front suspensi on and smooth the

ri de of the vehi cl e.

The strut assembl y i ncl udes the fol l owi ng compo-

nents: A rubber i sol ated upper mount, an upper

spri ng seat and beari ng, a dust shi el d, a jounce

bumper, a coi l spri ng, a l ower spri ng i sol ator and a

strut (Fi g. 1). Each component i s servi ced by remov-

i ng the strut assembl y from the vehi cl e and di sas-

sembl i ng i t.

COIL SPRING

The strut and front suspensi on of the vehi cl e i s

supported by coi l spri ngs posi ti oned around the

upper hal f of each strut. The spri ngs are contai ned

between the upper and the l ower seats of the strut

assembl y.

Coi l spri ngs are rated separatel y for each corner or

si de of the vehi cl e dependi ng on opti onal equi pment

and type of vehi cl e servi ce. Duri ng servi ce procedures

of the strut assembl y, i f both spri ngs are removed,

mark the spri ngs to ensure i nstal l ati on i n i ts ori gi nal

posi ti on.

NOTE: If a coil spring requires replacement, be

sure that it is replaced with a spring meeting the

correct load rating for the vehicle and its specific

options.

STEERING KNUCKLE

The steeri ng knuckl e i s a si ngl e casti ng wi th l egs

machi ned for attachment to the front strut assembl y

on the top and the l ower control arm bal l joi nt on the

bottom (Fi g. 1). The steeri ng knuckl e al so has

machi ned abutments on the casti ng to support and

al i gn the front brake cal i per assembl y.

WHEEL BEARING AND HUB

The knuckl e al so supports the wheel beari ng and

hub (Fi g. 1). The wheel hub i s pressed i nto a seal ed

for l i fe wheel beari ng that i s pressed i nto the steer-

i ng knuckl e. A retai ner pl ate al so hol ds i t i n pl ace.

The hub supports the dri veshaft outer constant vel oc-

i ty (C/V) joi nt. Each i s spl i ned and meshes i n the

center of the hub. The outer C/V joi nt i s retai ned to

the hub usi ng a nut. The nut i s hel d on the outer C/V

stub shaft usi ng a nut retai ner and cotter pi n.

The wheel beari ng i s a Uni t 1 type cartri dge bear-

i ng that requi res no mai ntenance. The wheel beari ng

i s servi ced separatel y from the hub.

LOWER CONTROL ARM

There i s one l ower control arm on each si de of the

vehi cl e. Each l ower control arm i s a stamped steel

uni t usi ng rubber i sol ated pi vot bushi ngs to i sol ate i t

from the front suspensi on crossmember and frame of

the vehi cl e (Fi g. 1). The rear bushi ng can be servi ced

separatel y.

The front of the l ower control arm i s bol ted to the

front crossmember usi ng a bol t through the center of

the rubber pi vot bushi ng. The rear of the l ower con-

trol arm i s mounted to both the front crossmember

and the frame rai l of the vehi cl e usi ng a thru-bol t.

The thru-bol t goes through both the crossmember

and rear l ower control arm bushi ng, threadi ng

di rectl y i nto the frame rai l of the vehi cl e.

The l eft and ri ght l ower control arms are i ntercon-

nected through a l i nked rubber i sol ated stabi l i zer

bar.

The outboard end of each l ower control arm con-

nects to the steeri ng knuckl e usi ng a bal l joi nt.

1 VEHICLE STRUT TOWER

2 OUTER TIE ROD

3 STEERING GEAR

4 STRUT ASSEMBLY

5 JAM NUT

6 LOWER CONTROL ARM

7 CROSSMEMBER

8 BALL JOINT

9 STABILIZER BAR

10 STABILIZER BAR CUSHION AND RETAINER

11 STABILIZER BAR LINK

12 HUB

13 KNUCKLE

14 STRUT

15 LOWER SPRING ISOLATOR

16 COIL SPRING

17 JOUNCE BUMPER

18 DUST SHIELD

19 SPRING SEAT AND BEARING

20 UPPER MOUNT

PL SUSPENSION 2 - 11

DESCRIPTION AND OPERATION (Continued)

BALL JOINT

The l ower control arm connects to the steeri ng

knuckl e through a bal l joi nt mounted at the outboard

end of the arm (Fi g. 1). The bal l joi nt i s pressed i nto

the l ower control arm and has a non-tapered stud

wi th a notch for steeri ng knuckl e pi nch bol t cl ear-

ance. The bal l joi nt stud i s cl amped and l ocked to the

steeri ng knuckl e l ower l eg usi ng a pi nch bol t.

The bal l joi nt i s l ubri cated for l i fe duri ng the man-

ufacturi ng process. Once l ubri cated for l i fe, the

grease fi tti ng head i s snapped off by the manufac-

turer. Thi s i s done to el i mi nate the possi bi l i ty of

l ubri cati on l ater i n the bal l joi nts l i fe thus damagi ng

the non-vented bal l joi nt seal boot.

The bal l joi nt used on thi s vehi cl e i s repl aceabl e

and, i f found defecti ve, can be servi ced as a separate

component of the l ower control arm.

STABILIZER BAR (FRONT)

The stabi l i zer bar hel ps control vehi cl e body rol l .

Jounce and rebound movements affecti ng one wheel

are parti al l y transmi tted to the opposi te wheel of the

vehi cl e to stabi l i ze body rol l .

The stabi l i zer bar i nterconnects both front l ower

control arms of the vehi cl e and i s attached to the

front suspensi on crossmember (Fi g. 1).

Attachment of the stabi l i zer bar to the front sus-

pensi on crossmember i s through 2 rubber-i sol ator

cushi on and retai ners (Fi g. 1). The stabi l i zer bar

attachment to the l ower control arm i s done by uti -

l i zi ng an i sol ated stabi l i zer bar l i nk at each arm. Al l

components of the stabi l i zer bar are servi ceabl e.

DIAGNOSIS AND TESTING

STRUT ASSEMBLY (FRONT)

I nspect the strut assembl y for the fol l owi ng condi -

ti ons (Fi g. 3):

I nspect for a damaged or broken coi l spri ng.

I nspect for a torn or damaged strut assembl y

dust shi el d.

Li ft the dust shi el d and i nspect the strut assem-

bl y for evi dence of fl ui d runni ng from the upper end

of the strut fl ui d reservoi r. (Actual l eakage wi l l be a

stream of fl ui d runni ng down the si de and dri ppi ng

off l ower end of uni t.) A sl i ght amount of seepage

between the strut shaft and strut shaft seal i s not

unusual and does not affect performance of the strut

assembl y.

Li ft the dust shi el d and i nspect the jounce

bumper for si gns of damage or deteri orati on.

I nspect the cl earance between the shock tower

and the coi l spri ng. Make sure no fasteners are pro-

trudi ng through the shock tower possi bl y contacti ng

the coi l spri ng and strut. Because of the mi ni mum

cl earance i n thi s area (Fi g. 2), i nstal l ati on of metal

fasteners coul d damage the coi l spri ng coati ng and

l ead to a corrosi on fai l ure of the spri ng.

CAUTION: At no time when servicing a vehicle can

a sheet metal screw, bolt or other metal fastener be

installed into the shock tower to take the place of

an original plastic clip. Also, do not drill holes into

the front shock tower for the installation of any

metal fasteners into the shock tower area indicated

(Fig. 2).

Fig. 2 Shock Tower Area (Typical)

1 SHOCK TOWER

2 COIL SPRING

3 NO SHEET METAL SCREWS, BOLTS, OR ANY OTHER

METAL FASTENERS ARE TO BE INSTALLED INTO SHOCK

TOWER IN THIS AREA. ALSO, NO HOLES ARE TO BE

DRILLED INTO SHOCK TOWER IN THIS SAME AREA.

2 - 12 SUSPENSION PL

DESCRIPTION AND OPERATION (Continued)

STEERING KNUCKLE

The front suspensi on steeri ng knuckl e i s not a

repai rabl e component of the front suspensi on. I t

must be repl aced i f found to be damaged i n any way.

I f i t i s determi ned that the steeri ng knuckl e i s bent

when servi ci ng the vehi cl e, no attempt i s to be made

to strai ghten the steeri ng knuckl e.

WHEEL BEARING AND HUB

The wheel beari ng i s desi gned for the l i fe of the

vehi cl e and requi res no type of peri odi c mai ntenance.

The fol l owi ng procedure may be used for di agnosi ng

the condi ti on of the wheel beari ng and hub.

Wi th the wheel , di sc brake cal i per, and brake rotor

removed, rotate the wheel hub. Any roughness or

resi stance to rotati on may i ndi cate di rt i ntrusi on or a

fai l ed hub beari ng. I f the beari ng exhi bi ts any of

these condi ti ons duri ng di agnosi s, the hub beari ng

wi l l requi re repl acement. The beari ng i s not servi ce-

abl e.

Damaged beari ng seal s and the resul ti ng excessi ve

grease l oss may al so requi re beari ng repl acement.

Moderate grease weapage from the beari ng i s consi d-

ered normal and shoul d not requi re repl acement of

the wheel beari ng.

To di agnose a bent hub, refer to BRAKE ROTOR i n

the DI AGNOSI S AND TESTI NG secti on i n the

BRAKES servi ce manual group for the procedure on

measuri ng hub runout.

LOWER CONTROL ARM

I nspect the l ower control arm for si gns of damage

from contact wi th the ground or road debri s. I f the

l ower control arm shows any si gn of damage, l ook for

di storti on. Do not attempt to repai r or strai ghten a

broken or bent l ower control arm. I f damaged, the

l ower control arm stampi ng i s servi ced onl y as a

compl ete component.

The servi ceabl e components of the l ower control

arm are: the bal l joi nt, the bal l joi nt grease seal and

the l ower control arm rear i sol ator bushi ng.

I nspect both l ower control arm i sol ator bushi ngs

for severe deteri orati on and repl ace as requi red.

I nspect the bal l joi nt per the i nspecti on procedure i n

thi s secti on of the servi ce manual and repl ace as

requi red. Refer to BALL JOI NT i n thi s secti on of thi s

servi ce manual group.

BALL JOINT

Wi th the wei ght of the vehi cl e resti ng on the road

wheel s, grasp the headl ess grease fi tti ng as shown

(Fi g. 4). Wi th no mechani cal assi stance or added

force, attempt to move the grease fi tti ng. I f the bal l

joi nt i s worn, the grease fi tti ng wi l l move. I f move-

ment i s noted, repl ace the bal l joi nt.

Fig. 3 Strut Assembly

1 NUT

2 STRUT ASSEMBLY

3 STRUT

4 LOWER SPRING ISOLATOR

5 COIL SPRING

6 JOUNCE BUMPER

7 DUST SHIELD

8 SPRING SEAT AND BEARING (WITH SPRING ISOLATOR)

9 UPPER MOUNT

Fig. 4 Checking Ball Joint Wear

1 BALL JOINT

2 HEADLESS GREASE FITTING

PL SUSPENSION 2 - 13

DIAGNOSIS AND TESTING (Continued)

CAUTION: No attempt should be made to service

the headless grease fitting on the ball joint. It has

been purposely snapped off by the manufacturer to

avoid over-greasing.

STABILIZER BAR (FRONT)

I nspect for broken, cracked or di storted stabi l i zer

bar cushi ons and retai ners. I nspect for worn or dam-

aged stabi l i zer bar l i nks (Fi g. 1).

SERVICE PROCEDURES

LUBRICATION

There are no servi ceabl e l ubri cati on poi nts on the

front suspensi on. The front l ower bal l joi nts have

grease fi tti ngs whi ch have had the head snapped off

by the manufacturer after they have been fi l l ed. Thi s

has been done to el i mi nate the possi bi l i ty of damag-

i ng the non-vented seal s. Grease wi l l not l eak from

the broken grease fi tti ngs. The bal l joi nts are seal ed

for l i fe and requi re no mai ntenance.

CAUTION: No attempt should be made to replace

the ball joint grease fitting with a new fitting, then

filling the ball joint with grease. Damage to the

grease seal can result.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: DO NOT REMOVE THE STRUT SHAFT

NUT WHILE STRUT ASSEMBLY IS INSTALLED IN

VEHICLE, OR BEFORE THE COIL SPRING IS COM-

PRESSED WITH A COMPRESSION TOOL. THE

SPRING IS HELD UNDER HIGH PRESSURE.

CAUTION: Only frame contact hoisting equipment

can be used on this vehicle. All vehicles have a

fully independent rear suspension. The vehicles

cannot be hoisted using equipment designed to lift

a vehicle by the rear axle. If this type of hoisting

equipment is used, damage to rear suspension

components will occur.

CAUTION: At no time when servicing a vehicle can

a sheet metal screw, bolt, or other metal fastener be

installed in the shock tower to take the place of an

original plastic clip. It may come into contact with

the strut or coil spring.

CAUTION: Wheel bearing damage will result if after

loosening the hub nut, the vehicle is rolled on the

ground or the weight of the vehicle is allowed to be

supported by the tires for a length of time.

STRUT ASSEMBLY (FRONT)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Rai se the vehi cl e. Refer to HOI STI NG i n the

LUBRI CATI ON AND MAI NTENANCE group for the

proper l i fti ng procedure.

(2) Remove ti re and wheel assembl y from l ocati on

on front of vehi cl e requi ri ng strut removal .

(3) I f both strut assembl i es are to be removed,

mark the strut assembl i es ri ght or l eft accordi ng to

whi ch si de of the vehi cl e they were removed from.

(4) Remove the screw securi ng the ground strap to

the rear of the strut (Fi g. 5).

(5) I f the vehi cl e i s equi pped wi th Anti l ock brakes

(ABS), remove the screw securi ng the ABS wheel

speed sensor to the rear of the strut (Fi g. 5).

CAUTION: The strut assembly-to-steering knuckle

attaching bolts are serrated and must not be turned

during removal. Hold the bolts stationary in the

steering knuckle while removing the nuts, then tap

the bolts out using a pin punch.

Fig. 5 Ground Strap And ABS Sensor Bracket

1 ABS WHEEL SPEED SENSOR ROUTING BRACKET (IF

EQUIPPED)

2 GROUND STRAP

3 GROUND STRAP SCREW

4 ABS SENSOR BRACKET SCREW (IF EQUIPPED)

2 - 14 SUSPENSION PL

DIAGNOSIS AND TESTING (Continued)

(6) Remove the two bol ts attachi ng the strut to the

steeri ng knuckl e (Fi g. 1).

(7) Lower the vehi cl e just enough to open the

hood, but wi thout l etti ng the ti res touch the fl oor.

(8) Remove the three nuts attachi ng the upper

mount of the strut assembl y to the vehi cl es strut

tower (Fi g. 6).

(9) Remove the strut assembl y from the vehi cl e.

(10) For di sassembl y and assembl y procedures,

refer to STRUT ASSEMBLY i n the DI SASSEMBLY

AND ASSEMBLY secti on i n thi s secti on of thi s ser-

vi ce manual group.

INSTALLATION

(1) I nstal l the strut assembl y i nto the strut tower,

al i gni ng the three studs on the strut upper mount

wi th the hol es i n strut tower. I nstal l the three

mounti ng nuts on the studs (Fi g. 6). Ti ghten the

three nuts to a torque of 34 Nm (300 i n. l bs.).

(2) Cl ose the hood of the vehi cl e.

CAUTION: The strut assembly-to-steering knuckle

attaching bolts are serrated and must not be turned

during installation. Install the nuts while holding the

bolts stationary in the steering knuckle.

(3) Posi ti on the l ower end of the strut assembl y i n

l i ne wi th the upper end of the steeri ng knuckl e and

al i gn the mounti ng hol es (Fi g. 1). I nstal l the two

attachi ng bol ts. The bol ts shoul d be i nstal l ed wi th so

that the nuts face towards the front of the vehi cl e

once i nstal l ed. I nstal l the nuts. Hol di ng the bol ts i n

pl ace ti ghten the nuts to a torque of 53 Nm (40 ft.

l bs.) pl us an addi ti onal 90 turn after the speci fi ed

torque i s met.

(4) I f the vehi cl e i s equi pped wi th Anti l ock brakes

(ABS), attach the ABS wheel speed sensor to the rear

of the strut (rearward ear) usi ng i ts mounti ng screw

(Fi g. 5). Ti ghten the mounti ng screw to a torque of

13 Nm (120 i n. l bs.).

(5) Attach the ground strap to the rear of the strut

(forward ear) usi ng i ts mounti ng screw (Fi g. 5).

Ti ghten the mounti ng screw to a torque of 13 Nm

(120 i n. l bs.).

(6) I nstal l the ti re and wheel assembl y. I nstal l and

ti ghten the wheel mounti ng nuts i n proper sequence

unti l al l nuts are torqued to hal f speci fi cati on. Next,

repeat the ti ghteni ng sequence to the ful l speci fi ed

torque of 135 Nm (100 ft. l bs.).

(7) Lower the vehi cl e.

STEERING KNUCKLE

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Appl y the brakes and hol d i n pl ace.

(2) Rai se the vehi cl e. Refer to HOI STI NG i n the

LUBRI CATI ON AND MAI NTENANCE group for the

proper l i fti ng procedure.

(3) Remove the front ti re and wheel assembl y.

(4) Whi l e the brakes are appl i ed, l oosen and

remove the hub nut on the end of the dri veshaft (Fi g.

7).

(5) Rel ease the brakes.

Fig. 6 Upper Mounting Nuts

1 STRUT TOWER

2 MOUNTING NUTS

Fig. 7 Hub Nut

1 DRIVESHAFT

2 HUB

3 HUB NUT

PL SUSPENSION 2 - 15

REMOVAL AND INSTALLATION (Continued)

(6) Remove the two gui de pi n bol ts securi ng the

front di sc brake cal i per to the steeri ng knuckl e (Fi g.

8).

(7) Remove the di sc brake cal i per from the steer-

i ng knuckl e. The cal i per i s removed by fi rst ti ppi ng

ei ther the top (ri ght si de) or bottom (l eft si de) of the

cal i per away from the brake rotor, then pul l i ng the

cal i per off the opposi te ends cal i per sl i de (on the

knuckl e) and rotor.

(8) Hang the cal i per out of the way usi ng a wi re

hanger or cord. Do not support the cal i per by l etti ng

i t hang by the hydraul i c hose.

(9) Remove any retai ner cl i ps from the wheel

mounti ng studs. Remove the brake rotor from the

front hub (Fi g. 8).

(10) Remove the nut attachi ng the outer ti e rod to

the steeri ng knuckl e. To do thi s, hol d the ti e rod end

stud wi th a wrench whi l e l ooseni ng and removi ng the

nut wi th a standard wrench or crowfoot wrench (Fi g.

9).

(11) Remove the ti e rod end from the steeri ng

knuckl e usi ng Remover, Speci al Tool MB991113 (Fi g.

10).

Fig. 8 Brake Caliper And Rotor

1 RETAINER CLIP

2 BRAKE ROTOR

3 HUB

4 GUIDE PIN BOLTS

5 DISC BRAKE CALIPER

Fig. 9 Tie Rod Nut Removal/Installation

1 OUTER TIE ROD

2 STUD

3 NUT

Fig. 10 Tie Rod Removal

1 OUTER TIE ROD

2 STEERING KNUCKLE

2 - 16 SUSPENSION PL

REMOVAL AND INSTALLATION (Continued)

(12) Remove the ti e rod heat shi el d.

(13) Remove the nut and pi nch bol t cl ampi ng the

bal l joi nt stud to the steeri ng knuckl e (Fi g. 11).

CAUTION: The strut assembly-to-steering knuckle

attaching bolts are serrated and must not be turned

during removal. Hold the bolts stationary in the

steering knuckles while removing the nuts, then tap

the bolts out using a pin punch.

(14) Remove the two bol ts attachi ng the strut to

the steeri ng knuckl e (Fi g. 1).

NOTE: Use caution when separating the ball joint

stud from the steering knuckle, so the ball joint seal

does not get cut.

(15) Separate the bal l joi nt stud from the steeri ng

knuckl e by pryi ng down on l ower control arm and up

agai nst the bal l joi nt boss on the steeri ng knuckl e

(Fi g. 12).

NOTE: Do not allow the driveshaft to hang by the

inner C/V joint; it must be supported to keep the

joint from separating during this operation.

(16) Pul l the steeri ng knuckl e off the dri veshaft

outer C/V joi nt spl i nes and remove the steeri ng

knuckl e.

NOTE: The cartridge type front wheel bearing used

on this vehicle is not transferable to the replace-

ment steering knuckle. If the replacement steering

knuckle does not come with a wheel bearing, a new

bearing must be installed in the steering knuckle.

Installation of the new wheel bearing and hub must

be done before installing the steering knuckle on

the vehicle.

(17) I f the steeri ng knuckl e i s to be repl aced, refer

to STEERI NG KNUCKLE i n the DI SASSEMBLY

AND ASSEMBLY secti on i n thi s secti on of thi s ser-

vi ce manual group for the wheel beari ng and hub

removal and i nstal l ati on procedure. Do not reuse the

wheel beari ng

INSTALLATION

(1) I f the steeri ng knuckl e has been repl aced, refer

to STEERI NG KNUCKLE i n DI SASSEMBLY AND

ASSEMBLY found i n thi s secti on of thi s servi ce man-

ual group for the wheel beari ng and hub i nstal l ati on

procedure. Do not reuse the ol d wheel beari ng.

(2) Sl i de the hub of the steeri ng knuckl e onto the

spl i nes on the dri veshaft C/V joi nt.

(3) I nstal l the steeri ng knuckl e onto the bal l joi nt

stud al i gni ng the bol t hol e i n the knuckl e boss wi th

the notch formed i n the si de of the bal l joi nt stud.

(4) I nstal l a new bal l joi nt stud pi nch bol t and nut

(Fi g. 11). Ti ghten the nut to a torque of 95 Nm (70

ft. l bs.).

CAUTION: The strut assembly-to-steering knuckle

attaching bolts are serrated and must not be turned

during installation. Install the nuts while holding the

bolts stationary in the steering knuckle.

(5) Posi ti on the l ower end of the strut assembl y i n

l i ne wi th the upper end of the steeri ng knuckl e and

al i gn the mounti ng hol es (Fi g. 1). I nstal l the two

attachi ng bol ts. The bol ts shoul d be i nstal l ed wi th so

that the nuts face towards the front of the vehi cl e

Fig. 11 Ball Joint Bolt And Nut

1 NUT

2 BOLT

3 BALL JOINT

Fig. 12 Separate Ball Joint from Knuckle

1 STEERING KNUCKLE

2 PRY BAR

3 LOWER CONTROL ARM

4 BALL JOINT STUD

PL SUSPENSION 2 - 17

REMOVAL AND INSTALLATION (Continued)

once i nstal l ed. I nstal l the nuts. Hol di ng the bol ts i n

pl ace ti ghten the nuts to a torque of 53 Nm (40 ft.

l bs.) pl us an addi ti onal 90 turn after the speci fi ed

torque i s met.

(6) Pl ace the ti e rod heat shi el d on the steeri ng

knuckl e arm so that the shi el d i s posi ti oned strai ght

away from the steeri ng gear and ti e rod end once

i nstal l ed. Al gn the hol e i n the shi el d wi th the hol e i n

the steeri ng knucl e arm.

(7) I nstal l the outer ti e rod bal l stud i nto the hol e

i n the steeri ng knuckl e arm. Start the ti e rod attach-

i ng nut onto the stud. Hol d the ti e rod end stud wi th

a wrench whi l e ti ghteni ng the nut wi th a standard

wrench or crowfoot wrench (Fi g. 9). To ful l y ti ghten

the nut to speci fi cati ons, use a crowfoot wrench on a

torque wrench to turn the nut, and a wrench on the

stud. Ti ghten the nut to a torque of 55 Nm (40 ft.

l bs.).

(8) I nstal l the brake rotor on the hub (Fi g. 8).

(9) I nstal l the di sc brake cal i per (wi th pads) on the

brake rotor and steeri ng knuckl e. The l eft si de cal i -

per i s i nstal l ed by fi rst sl i di ng the top of the cal i per

past the top abutment on the steeri ng knuckl e to

hook the top edge of the cal i per, then pushi ng the

l ower end of the cal i per i nto pl ace agai nst the

knuckl e (Fi g. 13). The ri ght si de cal i per i s i nstal l ed

by fi rst sl i di ng the bottom edge of the cal i per past

the l ower abutment on the steeri ng knuckl e to hook

the l ower edge of the cal i per, then pushi ng the top of

the cal i per i nto pl ace agai nst the steeri ng knuckl e.

(10) I nstal l the two gui de pi n bol ts securi ng the

front di sc brake cal i per to the steeri ng knuckl e (Fi g.

8). Ti ghten the gui de pi n bol ts to a torque of 22 Nm

(192 i n. l bs.).

(11) Cl ean al l forei gn matter from the threads of

the dri veshaft outer C/V joi nt (Fi g. 7).

(12) I nstal l the hub nut i n the end of the dri ve-

shaft and snug i t.

(13) Have a hel per appl y the brakes. Wi th vehi cl e

brakes appl i ed to keep brake rotor and hub from

turni ng, ti ghten the hub nut to a torque of 244 Nm

(180 ft. l bs.)

(14) I nstal l the ti re and wheel assembl y. I nstal l

the wheel mounti ng nuts and ti ghten them to a

torque of 135 Nm (100 ft. l bs.).

(15) Lower the vehi cl e.

(16) Set the front toe on the vehi cl e to requi red

speci fi cati on. Refer to WHEEL ALI GNMENT i n thi s

servi ce manual group.

LOWER CONTROL ARM

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Rai se the vehi cl e. Refer to HOI STI NG i n the

LUBRI CATI ON AND MAI NTENANCE group for the

proper l i fti ng procedure.

(2) Remove the front ti re and wheel assembl y.

(3) Remove both stabi l i zer bar l i nks from the vehi -

cl e (Fi g. 14). Remove each l i nk by hol di ng the upper

retai ner/nut wi th a wrench and turni ng the l i nk bol t.

(4) Rotate the forward ends of the stabi l i zer bar

downward. I t may be necessary to l oosen the stabi -

Fig. 13 Brake Caliper Installation

1 SLIDE TOP OF BRAKE CALIPER UNDER TOP ABUTMENT

OF STEERING KNUCKLE AS SHOWN

2 BRAKING DISC

3 DISC BRAKE CALIPER

4 STEERING KNUCKLE BRAKE ABUTMENT

Fig. 14 Stabilizer Bar Links

1 STABILIZER BAR CUSHION RETAINERS

2 CUSHIONS

3 FRONT STABILIZER BAR

4 STABILIZER BAR LINKS

2 - 18 SUSPENSION PL

REMOVAL AND INSTALLATION (Continued)

l i zer bar cushi on retai ner bol ts a l i ttl e to ease any

turni ng resi stance.

(5) Remove the nut and pi nch bol t cl ampi ng the

bal l joi nt stud to the steeri ng knuckl e (Fi g. 15).

CAUTION: After removing the steering knuckle

from the ball joint stud, do not pull outward on the

knuckle. Pulling the steering knuckle outward at

this point can separate the inner C/V joint on the

driveshaft. Refer to FRONT DRIVESHAFTS in the

DIFFERENTIAL AND DRIVELINE group for further

information.

NOTE: Use caution when separating the ball joint

stud from the steering knuckle, so the ball joint seal

does not get cut.

(6) Separate the bal l joi nt stud from the steeri ng

knuckl e by pryi ng down on l ower control arm and up

agai nst the bal l joi nt boss on the steeri ng knuckl e

(Fi g. 12).

(7) I f the ri ght l ower control arm i s bei ng servi ced,

remove the bol ts mounti ng the engi ne torque strut i n

pl ace (Fi g. 16), then remove the engi ne torque strut

from the vehi cl e.

(8) Remove the front pi vot bol t attachi ng the l ower

control arm to the front suspensi on crossmember

(Fi g. 17). Remove the rear pi vot bol t attachi ng the

l ower control arm to the front suspensi on crossmem-

ber and frame rai l . Remove the l ower control arm

from the crossmember.

INSTALLATION

(1) Posi ti on the l ower control arm i nto the cross-

member (Fi g. 17). I nstal l , but do not ful l y ti ghten,

the rear pi vot bol t attachi ng the l ower control arm to

the front suspensi on crossmember and frame rai l .

I nstal l the front pi vot bol t attachi ng the l ower con-

trol arm to the front suspensi on crossmember.

(2) Ti ghten the l ower control arm rear pi vot (and

suspensi on crossmember) bol t to a torque of 203 Nm

(150 ft. l bs.), then ti ghten the l ower control arm front

pi vot bol t to a torque of 163 Nm (120 ft. l bs.).

(3) I nstal l the bal l joi nt stud i nto the steeri ng

knuckl e al i gni ng the bol t hol e i n the knuckl e boss

Fig. 15 Ball Joint Bolt And Nut

1 NUT

2 BOLT

3 BALL JOINT

Fig. 16 Engine Torque Strut

1 MOUNTING BOLTS

2 ENGINE TORQUE ISOLATOR STRUT

3 FRONT SUSPENSION CROSSMEMBER

Fig. 17 Lower Control Arm Attaching Bolts

1 LOWER CONTROL ARM

2 FRONT BOLT

3 CROSSMEMBER

4 REAR BOLT

PL SUSPENSION 2 - 19

REMOVAL AND INSTALLATION (Continued)

wi th the notch formed i n the si de of the bal l joi nt

stud.

(4) I f the ri ght l ower control arm has been ser-

vi ced, i nstal l the engi ne torque strut (Fi g. 16). Fol l ow

the procedure descri bed i n the ENGI NE servi ce man-

ual group to properl y al i gn and ti ghten the torque

strut.

(5) I nstal l a new bal l joi nt stud pi nch bol t and nut

(Fi g. 15). Ti ghten the nut to a torque of 95 Nm (70

ft. l bs.).

(6) Rotate the forward ends of the stabi l i zer bar

i nto mounti ng posi ti on.

(7) I nstal l both stabi l i zer bar l i nks back on vehi cl e

(Fi g. 14). Start each stabi l i zer bar l i nk bol t wi th

bushi ng from the bottom, through the stabi l i zer bar,

i nner l i nk bushi ngs, l ower control arm, and i nto the

upper retai ner/nut and bushi ng (Fi g. 1). Do not ful l y

ti ghten the l i nk assembl i es at thi s ti me.

(8) Lower the vehi cl e to ground l evel .

NOTE: It may be necessary to put the vehicle on a

platform hoist or alignment rack to gain access to

the stabilizer bar mounting bolts with the vehicle at

curb height.

(9) Ti ghten each stabi l i zer bar l i nk by hol di ng the

upper retai ner/nut wi th a wrench and turni ng the

l i nk bol t. Ti ghten each l i nk bol t to a torque of 23

Nm (200 i n. l bs.).

(10) I f previ ousl y l oosened, ti ghten the stabi l i zer

bar cushi on retai ner bol ts to a torque of 28 Nm (250

i n. l bs.).

STABILIZER BAR (FRONT)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Rai se the vehi cl e. Refer to HOI STI NG i n the

LUBRI CATI ON AND MAI NTENANCE group for the

proper l i fti ng procedure.

(2) Remove both stabi l i zer bar l i nks from the vehi -

cl e (Fi g. 18). Remove each l i nk by hol di ng the upper

retai ner/nut wi th a wrench and turni ng the l i nk bol t.

(3) Remove the stabi l i zer bar cushi on retai ner

bol ts and retai ners (Fi g. 18), and remove the stabi -

l i zer bar wi th cushi ons attached from the vehi cl e.

(4) To remove the cushi ons from the stabi l i zer bar,

peel back each cushi on at the sl i t and rol l i t off the

bar.

INSTALLATION

NOTE: Before stabilizer bar installation, inspect the

cushions and links for excessive wear, cracks, dam-

age and distortion. Replace any pieces failing

inspection.

(1) I f removed, i nstal l the stabi l i zer bar cushi ons

on the stabi l i zer bar uti l i zi ng the sl i t i n each cush-

i on. Posi ti on the cushi ons at each end of the bars

strai ght beam, just before i t begi ns to curve.

NOTE: Before installing the stabilizer bar, make

sure the bar is not upside-down. The stabilizer bar

must be installed with the curve on the outboard

ends of the bar facing downward to clear the con-

trol arms once fully installed (Fig. 19).

(2) Fi rst, pl ace the stabi l i zer bar i n posi ti on on the

front suspensi on crossmember. The sl i ts i n each

cushi on must poi nt toward the front of the vehi cl e

and si t di rectl y on top of the rai sed beads formed

i nto the stampi ng on the crossmember. Next, i nstal l

the cushi on retai ners, matchi ng the rai sed beads

formed i nto the cushi on retai ners to the grooves

formed i nto the cushi ons. I nstal l the cushi on retai ner

bol ts, but do not compl etel y ti ghten them at thi s

ti me.

(3) I nstal l both stabi l i zer bar l i nks back on vehi cl e

(Fi g. 18). Start each stabi l i zer bar l i nk bol t wi th

bushi ng from the bottom, through the stabi l i zer bar,

i nner l i nk bushi ngs, l ower control arm, and i nto the

upper retai ner/nut and bushi ng (Fi g. 1). Do not ful l y

ti ghten the l i nk assembl i es at thi s ti me.

Fig. 18 Stabilizer Bar

1 STABLILIZER BAR CUSION RETAINERS

2 CUSHIONS

3 FRONT STABLIZER BAR

4 STABILIZER BAR LINKS

2 - 20 SUSPENSION PL

REMOVAL AND INSTALLATION (Continued)

(4) Lower the vehi cl e.

NOTE: It may be necessary to put the vehicle on a

platform hoist or alignment rack to gain access to

the stabilizer bar mounting bolts with the vehicle at

curb height.

(5) Ti ghten each stabi l i zer bar l i nk by hol di ng the

upper retai ner/nut wi th a wrench and turni ng the

l i nk bol t. Ti ghten each l i nk bol t to a torque of 23

Nm (200 i n. l bs.).

(6) Ti ghten the stabi l i zer bar cushi on retai ner

bol ts to a torque of 28 Nm (250 i n. l bs.).

WHEEL MOUNTING STUD (FRONT)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

Use the fol l owi ng procedure to remove and i nstal l

one of fi ve studs on one wheel hub.

REMOVAL

(1) Rai se the vehi cl e. Refer to HOI STI NG i n the

LUBRI CATI ON AND MAI NTENANCE group for the

proper l i fti ng procedure.

(2) Remove the front ti re and wheel assembl y.

(3) Remove the two gui de pi n bol ts securi ng the

front di sc brake cal i per to the steeri ng knuckl e (Fi g.

20).

(4) Remove the di sc brake cal i per from the steer-

i ng knuckl e. The cal i per i s removed by fi rst ti ppi ng

ei ther the top (ri ght si de) or bottom (l eft si de) of the

cal i per away from the brake rotor, then pul l i ng the

cal i per off the opposi te ends cal i per sl i de (on the

knuckl e) and rotor.

(5) Hang the cal i per out of the way usi ng a wi re

hanger or cord. Do not support the cal i per by l etti ng

i t hang by the hydraul i c hose.

(6) Remove any retai ner cl i ps from the wheel

mounti ng studs. Remove the brake rotor from the

front hub (Fi g. 20).

CAUTION: Do not hammer wheel mounting studs

out of the hub. Damage to the wheel bearing will

occur, leading to premature bearing failure.

(7) I nstal l a wheel mounti ng nut on the wheel

mounti ng stud bei ng removed from the hub far

enough so the threads on the stud are even wi th end

of l ug nut. Rotate the hub so the stud requi ri ng

removal i s al i gned wi th notch cast i nto front of the

steeri ng knuckl e. I nstal l Remover, Speci al Tool

C-4150, on hub fl ange and wheel stud (Fi g. 21).

(8) Ti ghten the remover, pushi ng the wheel mount-

i ng stud out the rear of the hub fl ange. When the

shoul der of the stud i s past the fl ange, remove the

remover from the hub. Remove the nut from the

stud, then remove the stud from the fl ange.

INSTALLATION

(1) I nstal l the wheel mounti ng stud i n the fl ange

of hub from the rear si de. I nstal l several washers

and a wheel mounti ng nut on the stud (Fi g. 22). The

wheel mounti ng nut must be i nstal l ed wi th the fl at

si de of the wheel mounti ng nut agai nst the washers

to el i mi nate bi ndi ng.

Fig. 19 Downward Curve

1 STABILIZER BAR

2 LINK

3 DOWNWARD CURVE

4 CUSHION RETAINER

Fig. 20 Brake Caliper And Rotor

1 RETAINER CLIP

2 BRAKE ROTOR

3 HUB

4 GUIDE PIN BOLTS

5 DISC BRAKE CALIPER

PL SUSPENSION 2 - 21

REMOVAL AND INSTALLATION (Continued)

(2) Ti ghten the wheel mounti ng nut. Thi s wi l l pul l

the wheel mounti ng stud i nto the fl ange of the hub.

When the head of the stud i s ful l y seated agai nst the

rear of the hub fl ange, remove the wheel mounti ng

nut and washers from the stud.

(3) I nstal l the brake rotor on the hub (Fi g. 20).

(4) I nstal l the di sc brake cal i per (wi th pads) on the

brake rotor and steeri ng knuckl e. The l eft si de cal i -

per i s i nstal l ed by fi rst sl i di ng the top of the cal i per

past the top abutment on the steeri ng knuckl e to

hook the top edge of the cal i per, then pushi ng the

l ower end of the cal i per i nto pl ace agai nst the

knuckl e (Fi g. 23). The ri ght si de cal i per i s i nstal l ed

by fi rst sl i di ng the bottom edge of the cal i per past

the l ower abutment on the steeri ng knuckl e to hook

the l ower edge of the cal i per, then pushi ng the top of

the cal i per i nto pl ace agai nst the steeri ng knuckl e.

(5) I nstal l the two gui de pi n bol ts securi ng the

front di sc brake cal i per to the steeri ng knuckl e (Fi g.

20). Ti ghten the gui de pi n bol ts to a torque of 22 Nm

(192 i n. l bs.).

(6) I nstal l the ti re and wheel assembl y. I nstal l the

wheel mounti ng nuts and ti ghten them to a torque of

135 Nm (100 ft. l bs.).

(7) Lower the vehi cl e.

DISASSEMBLY AND ASSEMBLY

STRUT ASSEMBLY (FRONT)

The Strut assembl y must be removed from the

vehi cl e for i t to be di sassembl ed and assembl ed.

Refer to REMOVAL AND I NSTALLATI ON i n thi s

secti on for the requi red procedure.

For the di sassembl y and assembl y of the strut

assembl y, use strut spri ng compressor, Pentastar Ser-

vi ce Equi pment (PSE) tool W-7200, or the equi val ent,

to compress the coi l spri ng. Fol l ow the manufactur-

ers i nstructi ons cl osel y.

DISASSEMBLY

(1) I f both struts are bei ng servi ced at the same

ti me, mark the coi l spri ng and strut assembl y accord-

i ng to whi ch si de of the vehi cl e the strut was

Fig. 21 Wheel Stud Removal

1 SPECIAL TOOL C-4150A

2 LUG NUT

3 HUB/BEARING

4 STEERING KNUCKLE

5 WHEEL STUD

Fig. 22 Installing Wheel Stud

1 STEERING KNUCKLE

2 WHEEL LUG NUT

3 WASHERS

4 HUB/BEARING

Fig. 23 Brake Caliper Installation

1 SLIDE TOP OF BRAKE CALIPER UNDER TOP ABUTMENT

OF STEERING KNUCKLE AS SHOWN

2 BRAKING DISC

3 DISC BRAKE CALIPER

4 STEERING KNUCKLE BRAKE ABUTMENT

2 - 22 SUSPENSION PL

REMOVAL AND INSTALLATION (Continued)

removed from, and whi ch strut the coi l spri ng was

removed from.

(2) Posi ti on the strut assembl y i n the strut coi l

spri ng compressor fol l owi ng the manufacturers

i nstructi ons. Set the l ower hooks (Fi g. 24), then set

the upper hooks (Fi g. 25). Posi ti on the strut cl evi s

bracket strai ght outward away from the compressor.

Pl ace a cl amp on the l ower end of the coi l spri ng, so

the strut i s hel d i n pl ace once the strut shaft nut i s

removed (Fi g. 24).

WARNING: DO NOT REMOVE THE STRUT SHAFT

NUT BEFORE THE COIL SPRING IS COMPRESSED.

THE COIL SPRING IS HELD UNDER PRESSURE

AND MUST BE COMPRESSED, REMOVING SPRING

TENSION FROM THE UPPER MOUNT AND PIVOT

BEARING, BEFORE THE SHAFT NUT IS REMOVED.

(3) Compress the coi l spri ng unti l al l coi l spri ng

tensi on i s removed from the upper mount.

(4) Once the spri ng i s suffi ci entl y compressed,

i nstal l Strut Nut Socket, Speci al Tool 6864, on the

strut shaft retai ni ng nut (Fi g. 26). Next, i nstal l a

socket on the hex on the end of the strut shaft. Whi l e

hol di ng the strut shaft from turni ng, remove the nut

from the strut shaft.

Fig. 24 Strut Assembly In Compressor (Lower)

1 LOWER HOOKS

2 CLAMP

3 STRUT ASSEMBLY

4 CLEVIS BRACKET

5 SPRING COMPRESSOR

Fig. 25 Strut Assembly In Compressor (Upper)

1 NOTCH IN UPPER SEAT

2 UPPER MOUNT

3 UPPER HOOKS

4 CLEVIS BRACKET

Fig. 26 Shaft Nut Removal/Installation

1 SPRING COMPRESSOR

2 SPECIAL TOOL 6864

3 UPPER MOUNT

PL SUSPENSION 2 - 23

DISASSEMBLY AND ASSEMBLY (Continued)

(5) Remove the upper mount from the strut shaft

(Fi g. 27).

(6) Remove the upper spri ng seat and beari ng,

al ong wi th the upper spri ng i sol ator as an assembl y

from the top of the coi l spri ng by pul l i ng them

strai ght up (Fi g. 27). The upper spri ng i sol ator can

be separated from the spri ng seat and beari ng once

removed from vehi cl e.

(7) Remove the dust shi el d, then the jounce

bumper from the strut shaft by pul l i ng each strai ght

up (Fi g. 27).

(8) Remove the cl amp from the bottom of the coi l

spri ng and remove the strut out through the bottom

of the coi l spri ng.

(9) Remove the l ower spri ng i sol ator from the

l ower spri ng seat on the strut.

NOTE: If the coil spring needs to be serviced, pro-

ceed with the next step, otherwise, proceed with

step 11.

(10) Rel ease the tensi on from the coi l spri ng by

backi ng off the compressor dri ve compl etel y. Push

back the compressor hooks and remove the coi l

spri ng.

(11) I nspect the strut assembl y components for the

fol l owi ng and repl ace as necessary:

I nspect the strut for any condi ti on of shaft bi nd-

i ng over the ful l stroke of the shaft.

I nspect the jounce bumper for cracks and si gns

of deteri orati on.

Check the upper mount for cracks and di storti on

and i ts retai ni ng studs for any si gn of damage.

Check the upper spri ng seat and beari ng for

cracks and di storti on.

Check for bi ndi ng of the upper spri ng seat and

beari ng pi vot beari ng.

I nspect the dust shi el d for ri ps and deteri ora-

ti on.

I nspect the upper and l ower spri ng i sol ators for

materi al deteri orati on and di storti on.

I nspect the coi l spri ng for any si gn of damage to

the coati ng.

ASSEMBLY

NOTE: If the coil spring has been removed from the

spring compressor, proceed with the next step, oth-

erwise, proceed with step 3.

(1) Pl ace the coi l spri ng i n the compressor fol l ow-

i ng the manufacturers i nstructi ons. Before compress-

i ng the spri ng, rotate the spri ng so the end of the top

coi l i s di rectl y i n the back as shown (Fi g. 28).

(2) Sl owl y compress the coi l spri ng unti l enough

room i s avai l abl e for strut assembl y reassembl y.

(3) I nstal l the l ower spri ng i sol ator on the l ower

spri ng seat of the strut.

(4) I nstal l the strut through the bottom of the coi l

spri ng unti l the l ower spri ng seat contacts the l ower

end of the coi l spri ng. Rotate the strut as necessary

unti l the cl evi s bracket i s posi ti oned strai ght outward

away from the compressor (Fi g. 24). I nstal l the cl amp

on the l ower end of the coi l spri ng and strut, so the

strut i s hel d i n pl ace.

(5) I nstal l the jounce bumper on the strut shaft.

The jounce bumper i s to be i nstal l ed wi th the smal l er

end poi nti ng downward toward the l ower seat (Fi g.

27).

(6) I nstal l the dust shi el d on the strut shaft (Fi g.

27). The bottom of the dust shi el d wi l l snap past the

retai ner on top of the strut housi ng.

(7) I f di sassembl ed, rei nstal l the upper spri ng i so-

l ator on the upper spri ng seat and beari ng.

(8) I nstal l the upper spri ng seat and beari ng on

top of the coi l spri ng. Posi ti on the notch formed i nto

the edge of the upper seat strai ght out away from the

compressor (Fi g. 25).

Fig. 27 Strut Assembly Components

1 NUT

2 STRUT ASSEMBLY

3 STRUT

4 LOWER SPRING ISOLATOR

5 COIL SPRING

6 JOUNCE BUMPER

7 DUST SHIELD

8 SPRING SEAT AND BEARING (WITH SPRING ISOLATOR)

9 UPPER MOUNT

2 - 24 SUSPENSION PL

DISASSEMBLY AND ASSEMBLY (Continued)

(9) I nstal l the strut upper mount over the strut

shaft and onto the top of the upper spri ng seat and

beari ng.

(10) Loosel y i nstal l the retai ni ng nut on the strut

shaft. I nstal l Strut Nut Socket (on the end of a

torque wrench), Speci al Tool 6864, on the strut shaft

retai ni ng nut (Fi g. 26). Next, i nstal l a socket on the

hex on the end of the strut shaft. Whi l e hol di ng the

strut shaft from turni ng, ti ghten the strut shaft

retai ni ng nut to a torque of 75 Nm (55 ft. l bs.).

(11) Sl owl y rel ease the tensi on from the coi l spri ng

by backi ng off the compressor dri ve compl etel y. As

the tensi on i s rel i eved, make sure the upper mount

and seat and beari ng al i gn properl y. Veri fy the upper

mount does not bi nd.

(12) Remove the cl amp from the l ower end of the

coi l spri ng and strut. Push back the spri ng compres-

sor upper and l ower hooks, then remove the strut

assembl y from the spri ng compressor.

(13) I nstal l the strut assembl y on the vehi cl e.

Refer to REMOVAL AND I NSTALLATI ON i n thi s

secti on for the requi red procedure.

STEERING KNUCKLE (WHEEL BEARING AND

HUB)

NOTE: The removal and installation of the wheel

bearing and hub from the steering knuckle is only

to be done with the steering knuckle removed from

the vehicle. Removal of the wheel bearing from the

steering knuckle must be done using the following

procedure.

DISASSEMBLY

(1) Remove steeri ng knuckl e, hub, and wheel bear-

i ng as an assembl y from the vehi cl e. Refer to

STEERI NG KNUCKLE i n the REMOVAL AND

I NSTALLATI ON secti on i n thi s servi ce manual

group.

(2) Usi ng Remover, Speci al Tool 4150A, (Fi g. 29)

press one wheel mounti ng stud out of hub fl ange.

Rotate the hub to al i gn the removed wheel mounti ng

stud wi th the notch i n beari ng retai ner pl ate (Fi g.

30). Remove the wheel mounti ng stud from the hub.

(3) Rotate the hub so the hol e i n the hub that

wheel mounti ng stud was removed from i s faci ng

away from brake cal i per l ower rai l on steeri ng

knuckl e (Fi g. 31). I nstal l one hal f of the Beari ng

Spl i tter, Speci al Tool 1130, between the hub and the

beari ng retai ner pl ate (Fi g. 31).

NOTE: Align the threaded hole in this first half of

the bearing splitter with the caliper rail on the steer-

ing knuckle (Fig. 31).

Fig. 28 Coil Spring Positioning

1 UPPER END OF COIL

2 COIL SPRING

3 LOWER END OF COIL

4 SPRING COMPRESSOR

Fig. 29 Pressing Out Wheel Mounting Stud

1 SPECIAL TOOL 4150A

2 WHEEL MOUNTING STUD

3 HUB FLANGE

4 STEERING KNUCKLE

PL SUSPENSION 2 - 25

DISASSEMBLY AND ASSEMBLY (Continued)

(4) I nstal l the remai ni ng pi eces of Beari ng Spl i tter,

Speci al Tool 1130, on the steeri ng knuckl e (Fi g. 32).

Hand ti ghten the nuts to hol d beari ng spl i tter i n

pl ace on steeri ng knuckl e.

(5) Once the beari ng spl i tter i n ful l y i nstal l ed, be

sure the three bol ts attachi ng the beari ng retai ner

pl ate to steeri ng knuckl e (Fi g. 33) are contacti ng the

beari ng spl i tter (Fi g. 33). The beari ng retai ner pl ate

shoul d not support the steeri ng knuckl e or contact

the beari ng spl i tter.

Fig. 30 Stud Removal From Hub

1 BEARING RETAINER PLATE

2 HUB

3 STEERING KNUCKLE

4 WHEEL MOUNTING STUD

5 NOTCH

Fig. 31 Bearing Splitter Half Installed

1 CALIPER RAIL

2 THREADED HOLE

3 SPECIAL TOOL 1130

4 STEERING KNUCKLE

5 HOLE FOR WHEEL MOUNTING STUD

6 HUB

Fig. 32 Bearing Splitter Installed

1 STEERING KNUCKLE

2 HUB

3 SPECIAL TOOL 1130

4 NUTS

Fig. 33 Correct Installation Of Bearing Splitter

1 STEERING KNUCKLE

2 SPECIAL TOOL 1130

3 BEARING RETAINER PLATE MOUNTING BOLTS

4 BEARING RETAINER PLATE

2 - 26 SUSPENSION PL

DISASSEMBLY AND ASSEMBLY (Continued)

(6) Pl ace the steeri ng knuckl e i n an arbor press

supported by the beari ng spl i tter as shown (Fi g. 34).

(7) Posi ti on Dri ver, Speci al Tool 6644-2, on the

smal l end of the hub (Fi g. 35). Usi ng the arbor press,

remove the hub from the wheel beari ng. The outer

beari ng race wi l l normal l y come out of the wheel

beari ng when the hub i s pressed out of the beari ng.

(8) Remove the beari ng spl i tter from the steeri ng

knuckl e.

(9) Remove the three bol ts mounti ng the beari ng

retai ner pl ate to the steeri ng knuckl e (Fi g. 36).

Remove the beari ng retai ner pl ate from the steeri ng

knuckl e.

(10) Pl ace the steeri ng knuckl e back i n the arbor

press supported by press bl ocks as shown (Fi g. 37).

The press bl ocks must not obstruct the bore i n the

steeri ng knuckl e so the wheel beari ng can be pressed

out of the steeri ng knuckl e. Pl ace Beari ng Dri ver,

Speci al Tool MB-990799 on the outer race of wheel

beari ng (Fi g. 37). Press the wheel beari ng out of the

steeri ng knuckl e.

(11) I nstal l Beari ng Spl i tter, Speci al Tool 1130, on

the hub. The beari ng spl i tter i s to be i nstal l ed on the

hub so i t i s between the fl ange of the hub and the

outer beari ng race on the hub (Fi g. 38). Pl ace the

hub, beari ng race and beari ng spl i tter i n an arbor

press as shown (Fi g. 38). Pl ace Dri ver, Speci al Tool

6644-2 on end of hub. Press the hub out of the outer

beari ng race.

Fig. 34 Steering Knuckle Supporting For Hub

Removal

1 STEERING KNUCKLE

2 WHEEL BEARING

3 HUB

4 ARBOR PRESS BLOCKS

5 SPECIAL TOOL 1130

Fig. 35 Pressing Hub Out Of Wheel Bearing

1 STEERING KNUCKLE

2 SPECIAL TOOL 66442

3 SPECIAL TOOL 1130

4 ARBOR PRESS BLOCKS

5 HUB

Fig. 36 Wheel Bearing Retainer Plate

1 MOUNTING BOLTS

2 BEARING RETAINER PLATE

3 STEERING KNUCKLE

PL SUSPENSION 2 - 27

DISASSEMBLY AND ASSEMBLY (Continued)

ASSEMBLY

(1) Wi pe the bore of the steeri ng knuckl e cl ean of

any grease or di rt wi th a cl ean, dry shop towel .

(2) Pl ace the new wheel beari ng i nto the bore of

the steeri ng knuckl e. Be sure the wheel beari ng i s

pl aced squarel y i nto the bore. Pl ace the steeri ng

knuckl e i n an arbor press wi th Recei ver, Speci al Tool

C-4698-2, supporti ng the steeri ng knuckl e (Fi g. 39).

Pl ace Dri ver, Speci al Tool 5052, on the outer race of

the wheel beari ng. Press the wheel beari ng i nto the

steeri ng knuckl e unti l i t i s ful l y bottomed i n the bore

of the steeri ng knuckl e. Remove the knuckl e from the

press.

NOTE: Only the original or identical replacement

bolts are to be used to mount the bearing retainer

plate to the steering knuckle.