Beruflich Dokumente

Kultur Dokumente

470 - Actifloc Package Plant

Hochgeladen von

LTE002Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

470 - Actifloc Package Plant

Hochgeladen von

LTE002Copyright:

Verfügbare Formate

Actifloc

TM

Package Plant

Pre-engineered Water Plant for High-quality Drinking Water

MODEL

One line Two lines

AFP-1

AFP-2

AFP-3

AFP-4

Typical Design Flow m3/h

40

80

160

320

80

160

320

640

The pre-engineered ActiflocTM system combines clarification and filtration in one prefabricated, fully automatic unit. The plant consistently delivers high-quality drinking water and is designed to treat surface water with high colour, high TOC or high turbidity - up to 1,000 NTU, with spikes up to 3,000 NTU. Engineered for flexibility and robustness, the system offers quick chemical optimization and instantaneous startup and shut-down. Especially suited for the following applications: Highly turbidity water High colour and/or high TOC High algae levels Cold water Flashy waters with rapidly fluctuating raw water sources Facilities with space restrictions that demand a small footprint Plants that frequently start up and shut down, requiring quick optimization to reach steady-state

Length Dimensions (Each Tank) Width (m) Height

6.3

8.2

11.2

16.1

1.8

2.4

2.7

3.6

3.2

3.2

3.2

3.2

Being modular allows multiple tank designs and easy future expansion.

The Actif locTM Package Plant is available in expoxy steel or stainless steel quality.

The

Technology

ded solids. The ballasted floc settle out very fast in the settling tank and are removed from the treated water. The sludge drawn from the settler is pumped through a set of hydrocyclones, where the microsand is separated from the sludge and returned to the Actiflo system for reuse. Water then passes through lamellar settling tubes and onto the filtration stage. The high content of microsand in the system stabilizes the process when the flow rate, turbidity or temperature fluctuates rapidly. Dentention time is very short making the response to changes in chemical dosage very rapid (10-15 minutes), allowing the process to reach a steady operational state in less than 20 minutes. From the ActifloTM treatment process, flow passes through the Mixed MeKrger A/S, Gladsaxevej 363, DK-2860 Sborg Tel: +45 3969 0222 - Fax: +45 3969 0806 E-mail: kruger@kruger.dk - Web: www.kruger.dk The MultiblockTM underdrain

The ActiflocTM treatment process combines the ActifloTM clarification process and the Microfloc Mixed Media filter, which is supported by the new MultiblockTM underdrain. ActifloTM: A proven clarification technology, the Actiflo process uses a microsand ballast that functions as a seed, enhancing floc formation and settling. Raw water enters the coagulation tank, where chemical coagulant and efficient mixing are used to destabilize suspended solids and colloidal matter. Polymer and microsand are added in the injection tank. The treatment continues as the water flows to the maturation tank, where conditions are ideal for the formation of polymer bridges between the microsand floc and destabilized suspen-

dia filtration chamber. The Mixed Media filtration technology uses progressively finer media from top to bottom and as such creates superior quality finished water. After the filtration, the flow is collected by the MultiblockTM underdrain, which allows filters to run at up to 30% higher flow rates, providing increased plant capacity. Even under extreme spike loading, the combination of the ActifloTM clarification and Mixed Media filtration contributes to resist breakthrough by Cryptosporidum and Giardia and provides a consistent high quality effluent.

Das könnte Ihnen auch gefallen

- ACTIFLO® ProcessDokument6 SeitenACTIFLO® ProcesscartagliNoch keine Bewertungen

- HGP4 Power Point ExDokument34 SeitenHGP4 Power Point ExRobert LemboNoch keine Bewertungen

- Clarification: Filtration Types of FiltrationDokument4 SeitenClarification: Filtration Types of Filtrationmaypeee100% (1)

- Sydney Football Stadium Lifting Drawing (0008) - Lifting Drawing PDFDokument1 SeiteSydney Football Stadium Lifting Drawing (0008) - Lifting Drawing PDFEmon RayNoch keine Bewertungen

- Haber Gold Proc Des CPDFDokument2 SeitenHaber Gold Proc Des CPDFHemanth Kumar RamachandranNoch keine Bewertungen

- Anodes For Cu-EWDokument28 SeitenAnodes For Cu-EWvictor perez villegasNoch keine Bewertungen

- Andritz Sidebar and Overhead Filter Presses DataDokument20 SeitenAndritz Sidebar and Overhead Filter Presses DataTiago J C MachadoNoch keine Bewertungen

- Combination of Ion Exchange and Solvent Extraction Versus Solvent Extraction, A Technical-Economical ComparisonDokument14 SeitenCombination of Ion Exchange and Solvent Extraction Versus Solvent Extraction, A Technical-Economical ComparisonJordan GonzalezNoch keine Bewertungen

- 28586, Actiflo Industrial2014 LR-1 PDFDokument8 Seiten28586, Actiflo Industrial2014 LR-1 PDFAkulSenapatiNoch keine Bewertungen

- Review of Heap Leach Pad and Waste Rock Dump Design Draft Feb2006Dokument13 SeitenReview of Heap Leach Pad and Waste Rock Dump Design Draft Feb2006babakfun2000Noch keine Bewertungen

- Ahmad, 2008 PDFDokument6 SeitenAhmad, 2008 PDFfitriNoch keine Bewertungen

- GOLD RECOVERY FROM COPPER-RICH ORES EMPLOYING THE PUROLITE S992 GOLD-SELECTIVE ION EXCHANGE RESIN by J. Van Deventer Et Al PDFDokument8 SeitenGOLD RECOVERY FROM COPPER-RICH ORES EMPLOYING THE PUROLITE S992 GOLD-SELECTIVE ION EXCHANGE RESIN by J. Van Deventer Et Al PDFFerudun AkyolNoch keine Bewertungen

- Polymers For Coagulation, Flocculation and Dewatering of Solids and SludgeDokument15 SeitenPolymers For Coagulation, Flocculation and Dewatering of Solids and SludgebradburywillsNoch keine Bewertungen

- PLS Viscosity PaperDokument5 SeitenPLS Viscosity PaperYessirkegenov MeirbekNoch keine Bewertungen

- Actiflo PPT Presentation For Øvre SirdalDokument51 SeitenActiflo PPT Presentation For Øvre SirdalMadalina Luca ZambreaNoch keine Bewertungen

- Efficient Tailings Dewatering - BrochureDokument8 SeitenEfficient Tailings Dewatering - BrochureCentrifugal SeparatorNoch keine Bewertungen

- Water and Energy Use in Mineral ProcessingDokument5 SeitenWater and Energy Use in Mineral ProcessingEnoque MatheNoch keine Bewertungen

- Electrowinning ReportDokument31 SeitenElectrowinning ReportScribdTranslationsNoch keine Bewertungen

- DMR-2505 DMR-2505Dokument44 SeitenDMR-2505 DMR-2505vijaymwaghNoch keine Bewertungen

- The History of BioleachingDokument10 SeitenThe History of BioleachingDanilo BorjaNoch keine Bewertungen

- Densadeg GBDokument4 SeitenDensadeg GBadalcayde2514Noch keine Bewertungen

- 14impc Program PDFDokument25 Seiten14impc Program PDFGabo Fuentealba CastilloNoch keine Bewertungen

- Morrell SAGDokument13 SeitenMorrell SAGEigen Galvez100% (1)

- Adding Value To Lix SX Ew Operations by Recovering Copper From Bleed, Raffinate and Other Plant StreamsDokument21 SeitenAdding Value To Lix SX Ew Operations by Recovering Copper From Bleed, Raffinate and Other Plant StreamsHamed PiriNoch keine Bewertungen

- Copper Extraction From Chloride Solution by Solvating and Chelating ExtractantsDokument17 SeitenCopper Extraction From Chloride Solution by Solvating and Chelating ExtractantsPasha TanNoch keine Bewertungen

- Characterizing Frothers Through Critical Coalescence ConcentrationDokument8 SeitenCharacterizing Frothers Through Critical Coalescence ConcentrationjvchiqueNoch keine Bewertungen

- 2005 07 28 MTB Ballasted FlocculationDokument8 Seiten2005 07 28 MTB Ballasted FlocculationSong Nguyen NguyenNoch keine Bewertungen

- Highrate Clarification and FlotationDokument17 SeitenHighrate Clarification and FlotationPatricia CangNoch keine Bewertungen

- Agglomeration in The Heap Leaching of Copper OreDokument8 SeitenAgglomeration in The Heap Leaching of Copper OreDr. Khan MuhammadNoch keine Bewertungen

- HAUS Milk Separator PDFDokument8 SeitenHAUS Milk Separator PDFSupatmono NAINoch keine Bewertungen

- Cyanide Analysers: Information SheetDokument2 SeitenCyanide Analysers: Information SheetDavid Fernández VillanuevaNoch keine Bewertungen

- Soil IcpDokument8 SeitenSoil Icpdemesew ephremNoch keine Bewertungen

- Reverse Osmosis Desalination: Our Global Expertise To Address Water ScarcityDokument9 SeitenReverse Osmosis Desalination: Our Global Expertise To Address Water Scarcityabdelkader benabdallahNoch keine Bewertungen

- CyanideDokument193 SeitenCyanideEutimio ChiNoch keine Bewertungen

- 02-MIPR-421-Mineral Processing MethodologiesDokument39 Seiten02-MIPR-421-Mineral Processing MethodologiesGomeh Damien Mtonga100% (1)

- Design of Large Scale Mixer Settlers in SX Solvent Extraction CircuitsDokument18 SeitenDesign of Large Scale Mixer Settlers in SX Solvent Extraction CircuitsHamed PiriNoch keine Bewertungen

- Extraction of Copper From Bacterial Leach Liquor of A Low Grade Chalcopyrite Test Heap Using LIX 984N-CDokument4 SeitenExtraction of Copper From Bacterial Leach Liquor of A Low Grade Chalcopyrite Test Heap Using LIX 984N-Cpmanquera89Noch keine Bewertungen

- Desalination in Arid LandsDokument48 SeitenDesalination in Arid LandsHassanKMNoch keine Bewertungen

- Purolite Product Summary GuideDokument20 SeitenPurolite Product Summary Guidem.rahimiNoch keine Bewertungen

- Flotation ProcessDokument1 SeiteFlotation ProcessnomanhaimourNoch keine Bewertungen

- Measuring Nacl, Salt, and Soluble Contaminants With Bresle Patches-Part 1Dokument8 SeitenMeasuring Nacl, Salt, and Soluble Contaminants With Bresle Patches-Part 1Hami Keserci100% (1)

- The Link Between Operational Practice and Maximising The Life of Stainless Steel Electrodes in Electrowinning and Electrorefining ApplicationsDokument14 SeitenThe Link Between Operational Practice and Maximising The Life of Stainless Steel Electrodes in Electrowinning and Electrorefining ApplicationskianNoch keine Bewertungen

- Hydrometallurgical Process: Analysis of Free, Total & WAD Cyanide in Gold Leach Slurry & WastewaterDokument1 SeiteHydrometallurgical Process: Analysis of Free, Total & WAD Cyanide in Gold Leach Slurry & WastewaterJUNIORNoch keine Bewertungen

- ASH MINERAL-PROCESSING 4pp Webversion-1Dokument4 SeitenASH MINERAL-PROCESSING 4pp Webversion-1pmarteeneNoch keine Bewertungen

- 22 An Amperometric Instrument For The Determination of Cyanide On Gold PlantsDokument6 Seiten22 An Amperometric Instrument For The Determination of Cyanide On Gold PlantsWillard MusengeyiNoch keine Bewertungen

- Activated Carbon08 - Chapter 2Dokument39 SeitenActivated Carbon08 - Chapter 2Jose Manuel Benites PalomaresNoch keine Bewertungen

- Continuous Gravity Concentration in Gold Grinding CircuitsDokument5 SeitenContinuous Gravity Concentration in Gold Grinding CircuitsTarek AounNoch keine Bewertungen

- Parshall FlumesDokument6 SeitenParshall FlumesMohd Yasir PilusNoch keine Bewertungen

- Flotation ReagentsDokument8 SeitenFlotation Reagents4gen_2Noch keine Bewertungen

- ION - CCP - LAB INSTRUCTIONS - Dr. NEUMANN - 2008 - 07 - 10 PDFDokument40 SeitenION - CCP - LAB INSTRUCTIONS - Dr. NEUMANN - 2008 - 07 - 10 PDFRahul Khandelwal100% (2)

- Selective Nickel ElectrowinningDokument36 SeitenSelective Nickel ElectrowinningmehdituranNoch keine Bewertungen

- Astm D 2036-98 CianuroDokument20 SeitenAstm D 2036-98 CianuroGianinaRoncalChávezNoch keine Bewertungen

- CIPCILCIC Adsorption Circuit Process Selection PDFDokument8 SeitenCIPCILCIC Adsorption Circuit Process Selection PDFSheila Mae GardonNoch keine Bewertungen

- Kinetic Leaching CopperDokument15 SeitenKinetic Leaching CopperSteven DziobaNoch keine Bewertungen

- Cyanide Remediation: Current and Past TechnologiesDokument26 SeitenCyanide Remediation: Current and Past TechnologiesCoraKiriNoch keine Bewertungen

- Copper Lead Zinc OresDokument1 SeiteCopper Lead Zinc OresAnnie Black MussaNoch keine Bewertungen

- InmaculadaDokument62 SeitenInmaculadaKevinEqNoch keine Bewertungen

- 150 KLD AhlayaDokument17 Seiten150 KLD Ahlayaalok_rajpoot786100% (1)

- 472 Actiflo WastewaterDokument4 Seiten472 Actiflo WastewaterLTE002Noch keine Bewertungen

- Envitech Company Profile 2013Dokument13 SeitenEnvitech Company Profile 2013Gusryan Zari KhamsyaNoch keine Bewertungen

- ZH - 2005 RCDokument99 SeitenZH - 2005 RCLTE002Noch keine Bewertungen

- Soil WashingDokument19 SeitenSoil WashingLTE002Noch keine Bewertungen

- Cal Methodology - Energy Saving - Electrical - HouseholdDokument15 SeitenCal Methodology - Energy Saving - Electrical - HouseholdLTE002Noch keine Bewertungen

- High PerformanceDokument3 SeitenHigh PerformanceLTE002Noch keine Bewertungen

- Biomass To Ethanol ProcessDokument132 SeitenBiomass To Ethanol ProcessLTE002Noch keine Bewertungen

- Simulation of High-Speed FillingDokument13 SeitenSimulation of High-Speed FillingLTE002Noch keine Bewertungen

- Trigger Sprayer Dynamic Systems ModelDokument5 SeitenTrigger Sprayer Dynamic Systems ModelLTE002Noch keine Bewertungen

- Paper - 84 Magnetic FormingDokument8 SeitenPaper - 84 Magnetic FormingLTE002Noch keine Bewertungen

- 49 Structure Porosity of Flocculated ADDokument8 Seiten49 Structure Porosity of Flocculated ADLTE002Noch keine Bewertungen

- Paper - 5 Noise MinimizationDokument5 SeitenPaper - 5 Noise MinimizationLTE002Noch keine Bewertungen

- HMT Lab ManualDokument55 SeitenHMT Lab ManualHarsha K100% (1)

- Service Report - XXXXXXX River Boat Water Treatment SystemDokument6 SeitenService Report - XXXXXXX River Boat Water Treatment SystemmaterozziNoch keine Bewertungen

- Griffin 1976Dokument21 SeitenGriffin 1976Manu K VasudevanNoch keine Bewertungen

- A-V300!1!6-L-GP General Purpose Potable Water Commercial Industrial Hi-Flo Series JuDokument2 SeitenA-V300!1!6-L-GP General Purpose Potable Water Commercial Industrial Hi-Flo Series JuwillgendemannNoch keine Bewertungen

- PSV Load Calculation For HIPPS Valve Leakage RateDokument5 SeitenPSV Load Calculation For HIPPS Valve Leakage RateAvishek HazraNoch keine Bewertungen

- Cre LabDokument4 SeitenCre LabAtif MehfoozNoch keine Bewertungen

- 9-Mechanical Integrity InspectionsDokument23 Seiten9-Mechanical Integrity InspectionsChegwe Cornelius100% (1)

- Ibo Catalogue 2018Dokument88 SeitenIbo Catalogue 2018bobi gorgievskiNoch keine Bewertungen

- Heinen & HopmanDokument39 SeitenHeinen & HopmanSebastian Przybylowicz100% (1)

- Physical - Chemistry - 3th - Castellan 801 860 32 35Dokument4 SeitenPhysical - Chemistry - 3th - Castellan 801 860 32 35Mira YuliartiNoch keine Bewertungen

- RT Acceptance Criteria: API-1104 AWS D1.1Dokument1 SeiteRT Acceptance Criteria: API-1104 AWS D1.1Shabbir ali100% (1)

- Surface Facilities For Waterflooding and Saltwater Disposal.Dokument34 SeitenSurface Facilities For Waterflooding and Saltwater Disposal.Franklyn Frank100% (5)

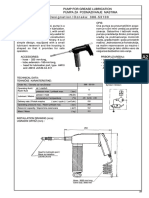

- Pump For Grease Lubrication Pumpa Za Podmazivanje Mastima: Ko Na Tehnika Tehnika PodmazivanjaDokument1 SeitePump For Grease Lubrication Pumpa Za Podmazivanje Mastima: Ko Na Tehnika Tehnika PodmazivanjaAnonymous O0T8aZZNoch keine Bewertungen

- Sectional DrawingsDokument8 SeitenSectional DrawingsjulianNoch keine Bewertungen

- Sauer Lub Oil ListDokument10 SeitenSauer Lub Oil ListjshdlhNoch keine Bewertungen

- PUMP A Spreadsheet Program For The Calculation of Piping Systems andDokument12 SeitenPUMP A Spreadsheet Program For The Calculation of Piping Systems andmsaadullahNoch keine Bewertungen

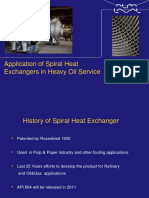

- Application of Spiral Heat Exchangers in Heavy Oil Service External PDFDokument27 SeitenApplication of Spiral Heat Exchangers in Heavy Oil Service External PDFProcess EngineerNoch keine Bewertungen

- P020110831595246434785 PDFDokument259 SeitenP020110831595246434785 PDFvineethNoch keine Bewertungen

- Soil Physics ExerciseDokument14 SeitenSoil Physics ExerciseChanako DaneNoch keine Bewertungen

- (Answer: K 6.36 × 10 CM/S) : Tutorial (Chapter: 2 Permeability)Dokument3 Seiten(Answer: K 6.36 × 10 CM/S) : Tutorial (Chapter: 2 Permeability)Rajesh Prasad Shukla0% (1)

- Falling FIlm Photoreactor With Forced Circulation - Normag (GMM) PDFDokument2 SeitenFalling FIlm Photoreactor With Forced Circulation - Normag (GMM) PDFDnyaneshwar KarwarNoch keine Bewertungen

- Mer - We - db3120 - Domestic Hot Water Produc DiagramDokument6 SeitenMer - We - db3120 - Domestic Hot Water Produc DiagramtienlamNoch keine Bewertungen

- CFS Technology DevelopmentDokument23 SeitenCFS Technology DevelopmentHangga Guna DharmaNoch keine Bewertungen

- Reservoir Inflow Performance: PET-332 E Production Engineering & Surface FacilitiesDokument35 SeitenReservoir Inflow Performance: PET-332 E Production Engineering & Surface Facilities000Noch keine Bewertungen

- Psa Nitrogen GeneratorDokument7 SeitenPsa Nitrogen GeneratorFarjallahNoch keine Bewertungen

- Aeroshell Fluid 31Dokument1 SeiteAeroshell Fluid 31Mohammed BabatinNoch keine Bewertungen

- WILDEN Pump P4 PDFDokument1 SeiteWILDEN Pump P4 PDFsachinmurukateNoch keine Bewertungen

- Condensador de MycomDokument7 SeitenCondensador de MycomsabasthianNoch keine Bewertungen

- HC-EX38: Flow Sharing Compensated ValveDokument44 SeitenHC-EX38: Flow Sharing Compensated ValvemehmetNoch keine Bewertungen

- Thickness Report (New Format)Dokument3 SeitenThickness Report (New Format)Ronel John Rodriguez CustodioNoch keine Bewertungen