Beruflich Dokumente

Kultur Dokumente

Canalta Meter Run Info Sheet

Hochgeladen von

autrolCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Canalta Meter Run Info Sheet

Hochgeladen von

autrolCopyright:

Verfügbare Formate

The Canalta Meter Run

Custom Designed using the Latest Technology, meeting the Latest Standards, providing the Highest Accuracy

Phone: 403.342.4494 Email: sales@canaltaflow.com www.canaltaflow.com

An ISO 9001:2008 registered company

For more information or to order, contact us at

An ISO 9001:2008 Registered Company

Phone: 403.342.4494 | Fax: 403.346.7110 | Email: sales@canaltaflow.com | Web: www.canaltaflow.com

Canalta fabricates custom meter runs for all of our orifice fitting models and a variety of other metering applications. Whether the size is 2 or 30, high or low pressure, wet, dry or corrosive service, we can put together a custom meter run package that meets your specification or performance needs and perfectly matches your Canalta Orifice Fitting or other specialized metering device.

Let the experts design and fabricate your Meter Runs and Flow Conditioning Solutions to meet your exact performance needs or specification requirements.

You trust Canalta at the orifice plate. When accuracy counts, trust Canalta up and downstream, too.

Weve been working with AGA-3 / API 14.3 and ISO 5167-1 specifications for over fifteen years. Skilled technicians, engineers and inspectors work together to design and manufacture first-rate meter tubes out of pipe carefully selected and prepared with the appropriate surface requirements, roundness and I.D. tolerances. Hydrostatic test results are included as a standard. PWHT stress relief, x-ray, ultra-sonic and liquid dye penetration test results are available on request. Our rigorous inspection regime and comprehensive documentation mean you can be sure your meter run is reliable, exceptionally accurate and ready for service.

4 5

FLOW CONDITIONING ACCESSORIES

The goal of meter run design is to account for swirl and turbulence. From traditional 19-tube bundle straightening vanes in carbon or stainless steel, to the compact Zanker or 50E Flow Conditioners and Flow Conditioner Housings, we will help you develop the flow profile you need to achieve maximum performance and accuracy in the field.

BRANCH CONNECTION OPTIONS

Industry standard offerings provide one 1 and one 3/4 branch connection on the downstream spool. Our custom meter tube design capability allows us to fabricate nearly any combination of weldolets, sockolets, flanged outlets, threadolets and latrolets in any size and orientation.

270 (Left) 90 (Right)

180 A-A T.O.L. ORIENTATION

END CONNECTION OPTIONS

Canalta Meter Runs can be fabricated with a variety of standard tube ends. All inner surface welds are precision ground and inspected to meet exacting I.D. surface and roundness tolerances. Per your requirements, two and three-piece meter runs can have dissimilar end types up and downstream of the orifice fitting.

5

Welding Neck Threaded

METER RUN SPECIFICATION PLATE

All Canalta Meter Runs include a specification plate mounted immediately upstream of the orifice fitting. These spec plates detail pipe schedule, pressure rating, maximum beta, maximum orifice and other information essential to proper operation.

Flanged (Raised Face / RTJ)

90 Elbow

WELDING STANDARDS

Each Canalta Meter Run is professionally fabricated by our team of certified B Pressure Welders and experienced pipe finishers to meet and exceed the stringent specifications of AGA /API/ISO. Our welding procedures are registered with the Alberta Boiler and Safety Association (ABSA) and are in accordance with the applicable ASME Boiler and Pressure Vessel Codes. Canalta will ensure that all of your NDT and stress relieving requirements are met with full documentation.

_ Th

_ Tb

tc

With literally endless configurations possible, Canalta will custom design and fabricate your meter run for any application.

ACCURACY, RELIABILITY, PERFORMANCE.

ACCURACY, RELIABILITY, PERFORMANCE.

Whether you are replacing existing equipment in an established metering line, or designing a project from the ground up, our experienced sales and technical teams will work closely with you to produce a meter run package that meets your specifications and addresses your budgetary and delivery needs.

An ISO 9001:2008 Registered Company

Canalta Flow Measurement

An ISO 9001:2008 Registered Company

" ' ) , 5

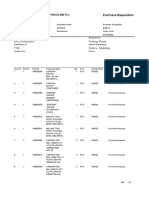

CANALTA FLOW MEASUREMENT DUAL CHAMBER ORIFICE FITTING 2 - 16 150 - 900 ANSI FLANGED FLOW CONDITIONER

DWG # :

Tb Th Tb Tb

Lesser of 1/8" or 0.5 Tb

Tc=Lesser of 1/4" or 0.7 Tb

Lesser of 1/8" or 0.5 Tb

*REFER TO DATA SHEET FOR SPECIFICATIONS*

BRANCH CONNECTION WELD DETAIL

OAL UL2 DL

Our engineering drawings, technical data sheets and an emphasis on open communication help to translate your design requirements into the right finished product. Our experience and ability to design to the appropriate AGA-3 / API 14.3 or ISO 5167-1 requirements and mean your Canalta Meter Run will be reliable, accurate and ready for the field.

UL1 SPEC. PLATE BRACKET

N1

CRN: 0F2015.213 / 0H6217.213 0

LEFT

270 90

!4

180

BY DWN APPD

DATE

A-A T.O.L. ORIENTATION

RIGHT

REV 0-JUN 3 , 2011

Contact us today to find out how Canalta Flow Measurement can provide exceptional value, adding to your bottom line without sacrificing quality, service or performance.

An ISO 9001:2008 registered company

Phone: 403.342.4494 Email: sales@canaltaflow.com www.canaltaflow.com

2011 Canalta Controls Ltd. All rights reserved. Unauthorized reproduction in whole or in part is prohibited.

Das könnte Ihnen auch gefallen

- Canalta DBB Product Manual - LOW RESDokument12 SeitenCanalta DBB Product Manual - LOW RESFer VFNoch keine Bewertungen

- Model"Dc": Dual Chamber Orifice FittingDokument13 SeitenModel"Dc": Dual Chamber Orifice FittingFrankNoch keine Bewertungen

- Canalta SCOF Product ManualDokument11 SeitenCanalta SCOF Product ManualBowo Edhi WibowoNoch keine Bewertungen

- International Fluid Flow Conference (CEESI Colorado) 2012 Philip A LawrenceDokument19 SeitenInternational Fluid Flow Conference (CEESI Colorado) 2012 Philip A LawrencePhilip A Lawrence C.Eng. F. Inst M.C.Noch keine Bewertungen

- FN400 H# Series Long Radius Flow Nozzles - Holding Ring TypeDokument1 SeiteFN400 H# Series Long Radius Flow Nozzles - Holding Ring TypeAjay ChodankarNoch keine Bewertungen

- G61 - 877 - 2 - C4-Ga Drawing PDFDokument16 SeitenG61 - 877 - 2 - C4-Ga Drawing PDFSoumiyaNoch keine Bewertungen

- Manual On Ambient Water Quality MonitoringDokument231 SeitenManual On Ambient Water Quality MonitoringberiNoch keine Bewertungen

- Handbook em Final EngDokument56 SeitenHandbook em Final Engigor_239934024Noch keine Bewertungen

- 3827-E10-067 - High Performance Butterfly Valve - BDokument2 Seiten3827-E10-067 - High Performance Butterfly Valve - BMohamed Elsaid El ShallNoch keine Bewertungen

- Coalescer Vessel CharacteristicsDokument1 SeiteCoalescer Vessel CharacteristicsMEHDINoch keine Bewertungen

- Pub000 054 00 - 0712 PDFDokument12 SeitenPub000 054 00 - 0712 PDFsanchay2503Noch keine Bewertungen

- National Oil Corporation: Rev Date Description Checked ApprovedDokument37 SeitenNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNoch keine Bewertungen

- 2063 72040 Tipicos InstrumentacionDokument42 Seiten2063 72040 Tipicos InstrumentacionZillur RahmanNoch keine Bewertungen

- Design Flow Line & H/Up for ES-PCP Well Mukhaizna-02/10Dokument6 SeitenDesign Flow Line & H/Up for ES-PCP Well Mukhaizna-02/10Salman FaisalNoch keine Bewertungen

- Piping Class Planta de Tratamiendo de AguaDokument13 SeitenPiping Class Planta de Tratamiendo de AguaAntonio Anatoly Viamont PintoNoch keine Bewertungen

- Steam Quality AnalyzerDokument7 SeitenSteam Quality Analyzerdaniel adamNoch keine Bewertungen

- A554 252 Khe 325 1093 008 - AwcDokument30 SeitenA554 252 Khe 325 1093 008 - AwcrubenvarelafunNoch keine Bewertungen

- Servo Gauge TI00452G08EN06.14Dokument41 SeitenServo Gauge TI00452G08EN06.14jeduardo2325Noch keine Bewertungen

- RFI Brida Size Request for Central Termica Electrodunas Luren ProjectDokument1 SeiteRFI Brida Size Request for Central Termica Electrodunas Luren ProjectVictor Ismael Salazar SoteroNoch keine Bewertungen

- Compatibility (Power Source) : EngineeredDokument3 SeitenCompatibility (Power Source) : Engineeredsiddiquiee74Noch keine Bewertungen

- BOP - DCS IO List Rev 2.4 (27.01.2014)Dokument566 SeitenBOP - DCS IO List Rev 2.4 (27.01.2014)vinospaceshuttleNoch keine Bewertungen

- Parker Instrument Tube Fitting Installation ManualDokument4 SeitenParker Instrument Tube Fitting Installation ManualBooster HidroNoch keine Bewertungen

- KA143FA6Dokument76 SeitenKA143FA6TreeNoch keine Bewertungen

- Kaiser Optograf™ Analyzer DatasheetDokument2 SeitenKaiser Optograf™ Analyzer Datasheetcraigorio616100% (1)

- Well data analysisDokument20 SeitenWell data analysisAhmedNoch keine Bewertungen

- PHR-ICM-DTL-105253 Piping and Instrument Diagrams, Process Flow Diagrams, and Material Flow DiagramsDokument54 SeitenPHR-ICM-DTL-105253 Piping and Instrument Diagrams, Process Flow Diagrams, and Material Flow Diagramsmashari budiNoch keine Bewertungen

- NOC Pressure Instrument SpecificationDokument26 SeitenNOC Pressure Instrument SpecificationRochdi SahliNoch keine Bewertungen

- Cad Wor X Error NumbersDokument71 SeitenCad Wor X Error Numbersberrima bilelNoch keine Bewertungen

- BP GS162-1 Valves PDFDokument24 SeitenBP GS162-1 Valves PDFMohd Khairul100% (1)

- Jun97 PDFDokument20 SeitenJun97 PDFAnonymous fj9ypF83Noch keine Bewertungen

- r2b p3 206 02 P HD 00200 - Datasheets For Control Valve, Globe, U 21000 - Rev.1Dokument377 Seitenr2b p3 206 02 P HD 00200 - Datasheets For Control Valve, Globe, U 21000 - Rev.1Diana Paula Echartea MolinaNoch keine Bewertungen

- Isogen Isometrics Creation and Setup WebinarDokument5 SeitenIsogen Isometrics Creation and Setup WebinarCarlos LopezNoch keine Bewertungen

- Trip and Alarm Schedule-Rev-0Dokument8 SeitenTrip and Alarm Schedule-Rev-0anbesivam87_49857255Noch keine Bewertungen

- Mechanical Engineering Software Newsletter Focuses on Power and Petrochemical IndustriesDokument24 SeitenMechanical Engineering Software Newsletter Focuses on Power and Petrochemical IndustriesHoGSPNoch keine Bewertungen

- File 1428726206Dokument8 SeitenFile 1428726206Rizwanahmad Khan Rizwanahmad KhanNoch keine Bewertungen

- Grab SamplesDokument5 SeitenGrab SamplesKrishnaNoch keine Bewertungen

- 21010-BAE-70000-In-SP-0028 Tech Spec For Inst. and Control CablesDokument43 Seiten21010-BAE-70000-In-SP-0028 Tech Spec For Inst. and Control CablesJignesh BanavaNoch keine Bewertungen

- DS For Chlorine Analyzer-Rev-0Dokument26 SeitenDS For Chlorine Analyzer-Rev-0anbesivam87_49857255Noch keine Bewertungen

- 800 Col Line: Bill of Material Sketch ListDokument1 Seite800 Col Line: Bill of Material Sketch ListAcfMacNoch keine Bewertungen

- Flow Overview Brochure PDFDokument64 SeitenFlow Overview Brochure PDFRenzoNoch keine Bewertungen

- Tag No. Process Variable Instrument Type Service State Location Sr. NoDokument6 SeitenTag No. Process Variable Instrument Type Service State Location Sr. NoAjay TiwariNoch keine Bewertungen

- Hook Ups PDFDokument8 SeitenHook Ups PDFAnonymous d7Jde8Noch keine Bewertungen

- SMP PH AnalyserDokument4 SeitenSMP PH AnalyserSreekanthMylavarapuNoch keine Bewertungen

- Daniel OrificeDokument60 SeitenDaniel Orificedocrafi75% (4)

- AVK Pneumatic Gate Valves BrochureDokument2 SeitenAVK Pneumatic Gate Valves BrochureCuong Nguyen ChiNoch keine Bewertungen

- Diaphragm ValveDokument10 SeitenDiaphragm Valveshganesh81Noch keine Bewertungen

- 50B10 Standard Assembly LibraryDokument78 Seiten50B10 Standard Assembly Libraryishu vohraNoch keine Bewertungen

- Analyser Sample SystemsDokument19 SeitenAnalyser Sample Systemsaslam.amb100% (1)

- CERT TRANSMISOR DIFERENCIAL MODELO EJA-E - EJX-A - TUV - SIL - Certificate - Us PDFDokument1 SeiteCERT TRANSMISOR DIFERENCIAL MODELO EJA-E - EJX-A - TUV - SIL - Certificate - Us PDFJohn Armely Arias GuerreroNoch keine Bewertungen

- SY Y StranerDokument2 SeitenSY Y StranerPhú Song LongNoch keine Bewertungen

- Al-Khobar Seawater Reverse Osmosis 2 Desalination PlantDokument4 SeitenAl-Khobar Seawater Reverse Osmosis 2 Desalination PlantABAID ULLAHNoch keine Bewertungen

- National Oil Corporation: Rev Date Description Checked ApprovedDokument22 SeitenNational Oil Corporation: Rev Date Description Checked ApprovedRochdi Sahli100% (1)

- Bahregan Crude Oil Storage Tanks DCS SpecificationDokument29 SeitenBahregan Crude Oil Storage Tanks DCS SpecificationFatholla SalehiNoch keine Bewertungen

- Level Switches VAutomatDokument6 SeitenLevel Switches VAutomatJagankumarNoch keine Bewertungen

- Iso-Propanol Production Report: Student Name: Course Name: Submission DateDokument18 SeitenIso-Propanol Production Report: Student Name: Course Name: Submission DateAmir Javed official100% (1)

- CADWorxPlantUsersGuide PDFDokument568 SeitenCADWorxPlantUsersGuide PDFselvarajvijayakumarNoch keine Bewertungen

- PFDDokument19 SeitenPFDCyril JohnsonNoch keine Bewertungen

- Canalta Parts Info SheetDokument3 SeitenCanalta Parts Info SheetmrbiznussNoch keine Bewertungen

- Pastite For Pipe Connection System Bul 4300 PTPDokument6 SeitenPastite For Pipe Connection System Bul 4300 PTPanoop9079Noch keine Bewertungen

- HOBUT Selection GuideDokument4 SeitenHOBUT Selection Guidebahramhoo100% (1)

- 1702 Tekbar-3150Dokument5 Seiten1702 Tekbar-3150autrolNoch keine Bewertungen

- Density Measurement DP PressureDokument5 SeitenDensity Measurement DP PressureIrfanNoch keine Bewertungen

- Density MeasurementDokument4 SeitenDensity MeasurementautrolNoch keine Bewertungen

- VGPWAR100Dokument4 SeitenVGPWAR100autrolNoch keine Bewertungen

- Paper 7 - E Graham PDFDokument23 SeitenPaper 7 - E Graham PDFautrolNoch keine Bewertungen

- Ametek Evolution of The Wet Gas Venturi Meter and Wet Gas Correction AlgorithmsDokument8 SeitenAmetek Evolution of The Wet Gas Venturi Meter and Wet Gas Correction AlgorithmsautrolNoch keine Bewertungen

- Vgpwar100 PDFDokument2 SeitenVgpwar100 PDFautrolNoch keine Bewertungen

- Dry vs Wet Natural Gas: Key Differences ExplainedDokument1 SeiteDry vs Wet Natural Gas: Key Differences ExplainedautrolNoch keine Bewertungen

- Dasar Dasar Perhitungan OrificeDokument6 SeitenDasar Dasar Perhitungan OrificePaijo TejoNoch keine Bewertungen

- Common AGA ReportsDokument1 SeiteCommon AGA ReportsautrolNoch keine Bewertungen

- Compressor Tech Article 2011Dokument4 SeitenCompressor Tech Article 2011autrolNoch keine Bewertungen

- ReadMe Uconeer - Units Conversion For EngineersDokument3 SeitenReadMe Uconeer - Units Conversion For EngineersRaja DhanasekaranNoch keine Bewertungen

- Ultrasonic Utility Gas Meter Low FlowDokument4 SeitenUltrasonic Utility Gas Meter Low FlowautrolNoch keine Bewertungen

- 970804C Calculation of Natural Gas Net Volume and EnergyDokument9 Seiten970804C Calculation of Natural Gas Net Volume and EnergyautrolNoch keine Bewertungen

- TechSpec Summit8800 EN Final09b PDFDokument4 SeitenTechSpec Summit8800 EN Final09b PDFautrolNoch keine Bewertungen

- Calendar Final Version 2012 2013-SimiDokument1 SeiteCalendar Final Version 2012 2013-SimiautrolNoch keine Bewertungen

- Presentation 1Dokument2 SeitenPresentation 1autrolNoch keine Bewertungen

- Quick Install GuideDokument165 SeitenQuick Install GuideautrolNoch keine Bewertungen

- 3100 DS01Dokument11 Seiten3100 DS01autrolNoch keine Bewertungen

- Quick Install GuideDokument165 SeitenQuick Install GuideautrolNoch keine Bewertungen

- Quick Install GuideDokument165 SeitenQuick Install GuideautrolNoch keine Bewertungen

- Smart Temperature Transmitter: Application AreasDokument8 SeitenSmart Temperature Transmitter: Application AreasautrolNoch keine Bewertungen

- 3100 DS01Dokument11 Seiten3100 DS01autrolNoch keine Bewertungen

- PIPING SPECIFICATIONSDokument49 SeitenPIPING SPECIFICATIONSkasvikrajNoch keine Bewertungen

- DOC132-Rev F-SterilContainer-System-CatalogDokument84 SeitenDOC132-Rev F-SterilContainer-System-CatalogCristianNoch keine Bewertungen

- Critical Wear Areas & Vacuum Test Locations: Upper Valve Body - 46RE ShownDokument4 SeitenCritical Wear Areas & Vacuum Test Locations: Upper Valve Body - 46RE Shownchoco84Noch keine Bewertungen

- Wood ScrewsDokument178 SeitenWood ScrewsOmar AL-jazairiNoch keine Bewertungen

- Presentation BoilerDokument24 SeitenPresentation BoilerRanjanaWaje100% (1)

- Pump Maintenance PDFDokument9 SeitenPump Maintenance PDFkamelNoch keine Bewertungen

- Built Tough: High HeadDokument3 SeitenBuilt Tough: High HeadDodyNoch keine Bewertungen

- Making Lockpicks From Hacksaw Blades - All - EnglishDokument22 SeitenMaking Lockpicks From Hacksaw Blades - All - EnglishScott CNoch keine Bewertungen

- Wireline Retriever: Instruction Manual 8820Dokument5 SeitenWireline Retriever: Instruction Manual 8820john odonnellNoch keine Bewertungen

- Application of Chain Drive and It's Selection MethodDokument21 SeitenApplication of Chain Drive and It's Selection MethodYogesh BNoch keine Bewertungen

- Itt Fluid Technology Asia: Model:3196 Xlti Size:8X10-13 Qty: 3Dokument9 SeitenItt Fluid Technology Asia: Model:3196 Xlti Size:8X10-13 Qty: 3Suriyachai NiamsornNoch keine Bewertungen

- Lathe 150826222523 Lva1 App6892Dokument75 SeitenLathe 150826222523 Lva1 App6892jbcNoch keine Bewertungen

- C Index - Proportioning Equipment Data SheetsDokument2 SeitenC Index - Proportioning Equipment Data SheetsLuis Joel Ramos RamosNoch keine Bewertungen

- Underground Equipment & Rock Drill Machinery Spare Parts Catalogue From STOPARTS LTDDokument41 SeitenUnderground Equipment & Rock Drill Machinery Spare Parts Catalogue From STOPARTS LTDSTOPARTS LTDNoch keine Bewertungen

- MS-02-472 - Válvulas Agulha Série IPT e Sno TrikDokument23 SeitenMS-02-472 - Válvulas Agulha Série IPT e Sno TrikRogério RochaNoch keine Bewertungen

- Hein Warner c10 c10hd c12 SM 9308127 Parts BookDokument6 SeitenHein Warner c10 c10hd c12 SM 9308127 Parts Bookveronica100% (49)

- 05 CE134P-2 Design Principles of Tension Members by ASD and LRFD MethodDokument10 Seiten05 CE134P-2 Design Principles of Tension Members by ASD and LRFD MethodPzynae FlorentinoNoch keine Bewertungen

- Parts Price List Atlas Milli NG Machine: Atlas Press Company - Kalamazoo 13D Michigan - U.S.ADokument16 SeitenParts Price List Atlas Milli NG Machine: Atlas Press Company - Kalamazoo 13D Michigan - U.S.Ataxmac100% (2)

- Solidworks ProjectDokument32 SeitenSolidworks ProjectAbdullah AzizNoch keine Bewertungen

- Experiment No 1Dokument3 SeitenExperiment No 1Apple DocasaoNoch keine Bewertungen

- Electrical Materials List For Construction ProjectsDokument17 SeitenElectrical Materials List For Construction Projectsmuhammad robithNoch keine Bewertungen

- S.No Description Unit QtyDokument3 SeitenS.No Description Unit QtySunilNoch keine Bewertungen

- HACCP Plan for Olam Agro India Private LimitedDokument13 SeitenHACCP Plan for Olam Agro India Private LimitedBalu varaNoch keine Bewertungen

- A Project Report ON: "Air Engine"Dokument3 SeitenA Project Report ON: "Air Engine"Tejas PansareNoch keine Bewertungen

- 4/18/23 43813 Normal DPL - Pradeepg Pradeep Gomis F162 Factory - ModellingDokument2 Seiten4/18/23 43813 Normal DPL - Pradeepg Pradeep Gomis F162 Factory - ModellingJanaka ChathurangaNoch keine Bewertungen

- Mv. Adriani: Bulk CarrierDokument33 SeitenMv. Adriani: Bulk CarrierHazemy putraNoch keine Bewertungen

- PFERD Tool Manual Catalogue 4 Int en PDFDokument160 SeitenPFERD Tool Manual Catalogue 4 Int en PDFBhavish BalkeeNoch keine Bewertungen

- Seepex Plan 01-07-2021Dokument1 SeiteSeepex Plan 01-07-2021Rajaram SawantNoch keine Bewertungen

- Dillinger - S355 J2Dokument22 SeitenDillinger - S355 J2Vinoth MechNoch keine Bewertungen

- Bagging ScaleDokument2 SeitenBagging ScaleAli HusseiniNoch keine Bewertungen