Beruflich Dokumente

Kultur Dokumente

Ma Zblt25 Uk 10

Hochgeladen von

Moises Guilherme Abreu BarbosaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ma Zblt25 Uk 10

Hochgeladen von

Moises Guilherme Abreu BarbosaCopyright:

Verfügbare Formate

SECTION INSULATOR ZBLT 25

INSTALLATION INSTRUCTION

Edition 2011/10

Installation with: FluryAdjusting JIG Article number 655.400.035

Accessories for Installation of the FLURY section insulator 1 Spring balance (Article number 655.181.000) 1 Ring and open end spanner 17 mm 1 Torque wrench 17 mm (50 Nm) 1 FluryAdjusting JIG 1 Level gauge (Article number 655.141.000) 1 Bolt cutter (+ maybe 1 metal saw) 1 Hammer

1 Flat or universal file 1 Straightening wood Additionally for: Cutin the messenger wire insulator Replacement of a used section insulator 1 Pulley block with 2 cable sockets

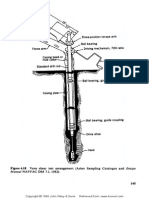

Preparation of contact and messenger wire

Straighten the contact wire at the installation location and make sure it is not twisted! Each section insulator should be well centred and aligned parallel to the track.

parallel

Hogging Instruction

contact wire

Average value = A+B 2 Hogging = average value + X

Align the contact wire and the messenger wire in the middle of the track (+/ 50 mm). Contact wire and the messenger wire must be positioned vertically above each other.

Measure the height of the contact wire at the guide arm clamps before (A) and after (B) the installation location. Calculate the average value. Use a spring balance and pull the contact wire with 120 N 150 N to measure the possible excess height (value x).

Installation Location

a) In autotensioned systems, install the section insulator mid span b) If the messenger wire is fix terminated install the section insulator near to a cantilever. Mounting angle max. 5

Axis of track

a)

b)

Arthur Flury AG

! RISK OF DEATH ! Do not begin to work on the overhead line before you have ensured that it is switched off and correctly grounded!

1. Alignment of the JIG

Direction

5. Cut contact wire

6. Bend contact wire

Place the JIG in a userdefined installation position. Adjust the level gauge. adjust

7. Repair buckling

ends up

2. Install Messenger Wire Insulator 8. Installation of the JIG, fix the rope

First install the messenger wire insulator with 2 cable hangers and messenger wire clamps on each side.

Forked collar socket installation

Direction

3. Preparation for installation

Remove runners, all counternuts and turnbuckles locking wires. Loosen contact wire clamps and open turnbuckles completely.

9. Hogging

Section insulator onto contact wire 4. Mount without runners

Put the insulator body onto the contact wire

Warning!

The teeth of the contact wire clamps must grip over the full length.

Use the rope on the JIG for the adjustment of the hogging. Adjust the section insulator height according to Hogging Instruction on page 1 (if not known value = 70mm).

10a. Adjust the prestress

Tighten the bolts of the contact wire clamp with 50 Nm by using a tourque wrench and retighten 3 times.

Arthur Flury AG | CH4543 Deitingen/Switzerland | T: +41 (0)32 613 33 66 | F: +41 (0)32 613 33 68 | www.aflury.ch | info@aflury.ch

10b. Control and level the prestress

Not enough prestress If the section insulator is leaning on one side, level the prestress with a light strike of a hammer.

12. Mount the runners

Runner contact Contact wires must not touch red blocks.

Counter the screw of the prestress.

Prestress OK

11. Mount and adjust the suspension

Runner contact

Add suspensions and control the section insulator height according to Hogging Instruction on page 1.

13. Tighten the runner fixation

Fine adjustment Set the insulatorbody parallel to the track by using the spirit level on the JIG.

50 Nm

Tighten hanger clamp after hogging.

14. Tighten the nuts with 50 Nm and counter

with the second

same tension

Arthur Flury AG | CH4543 Deitingen/Switzerland | T: +41 (0)32 613 33 66 | F: +41 (0)32 613 33 68 | www.aflury.ch | info@aflury.ch

15.Check gliding

16.Block turnbuckles

17.Secure turnbuckles

18.Secure hanger clamp

Check with spirit level or pantoghraph for optimal gliding.

Check all counternuts once more. Block turnbuckles with counternuts.

Fix the locking device. Lock turnbuckles with a locking wire.

Caution! Danger of accident if these points are not observed:

The contact wire and messenger wire must lay vertically on each other at the installation location. Otherwise the hangers are not under continuous tension and optimal functioning is impossible. In extreme cases it may even occur that the current collector hooks into the runners at the spark gap which leads to damage. The screws at the contact wire clamps must be retightened three times. Otherwise the teeth do not grip the contact wire material completely. The contact wire could therefore slide out later and falling parts could cause damage of material or even injure people. The screws must be restrained with a ring wrench when tightening the counternuts at the contact wire clamps. The screws could otherwise get loosened when tightening the counternuts and this could cause the contact wire to slide out, damage material and injure people. The runners of the section insulator must be correctly adjusted as described. Otherwise shocks might damage the section insulator or the carbon sliders. Turnbuckles must be locked with counternuts and secured with locking wires. These could otherwise open and the resulting incorrect position of the section insulator could cause malfunction of the overhead line. All screws and nuts must be tightened correctly according to the description. They could otherwise become loosened by vibration and cause malfunction of the overhead line. Should the protective plastic finish of EVA of one of our insulators be so severely damaged, either that the glass fiber inside is visible or that humidity and dirt can obviously penetrate, the insulator must be replaced immediately. Otherwise a highvoltage flashover could damage the insulator and the overhead line. Arthur Flury AG rejects responsibility for any damage caused by not observing this installation

After complete hogging and fine adjustment cut the unnecessary hanger rope.

19.Check alignment

bad alignment

perfect alignment Adjust the next 3 hangers in both directions.

instruction.

Maintenance and Service

A well adjusted section insulator of Arthur Flury AG does not require any maintenance for a long period of time. Isolator The cover of the insulating rod is cleaned well enough by rain water under normal circumstances. In case of exceptionally strong dirt accumulation (for instance from frequent diesel traffic, installation in a tunnel and so on) we suggest cleaning the insulator once a year with slightly soaped water. The insulator must be replaced if the GRP rod becomes visible through damage of the cover. Kufen Well adjusted runners need to be checked first after approximately 200'000 to 300'000 passages of current collectors. Should the wear have reached the maximum value (bulb only 12 mm thick) the runners must be replaced.

Recommendations and Trouble shooting of AF Insulators

a) Notice: A well adjusted section insulator can be raised by a spring balance at any extreme point of the runners (tips of runners at the arcing horns) applying 120 N without releasing the hanger load. If hangers get loose, the insulator must be hung higher step by step (each 10 mm) until it remains straight. b) Performance: The AF section insulator must provide a constant performance for passing current collectors and remain stable. Observe the suspension while passing current collectors. If it swings strongly or gets loose, the pantograph presses the section insulator too much and tries to lift it. In this case the section insulator must be positioned higher so that the suspension remains stable when being passed. c) Excessive wear of runners: It is a sign of inaccurate adjustment if the runners show excessive wear at the intake point. They must be readjusted according to the detailed installation instructions. Well adjusted runners show a constant wear from the beginning till the end of the section insulator.

Arthur Flury AG | CH4543 Deitingen/Switzerland | T: +41 (0)32 613 33 66 | F: +41 (0)32 613 33 68 | www.aflury.ch | info@aflury.ch

worn out

new

Das könnte Ihnen auch gefallen

- Green School BaliDokument83 SeitenGreen School BaliWayanParwitaNoch keine Bewertungen

- Bosch Aftertreatment DEF Controller ConnectorDokument4 SeitenBosch Aftertreatment DEF Controller ConnectorO mecanicoNoch keine Bewertungen

- Carver Cascade2 RapideDokument8 SeitenCarver Cascade2 Rapidepetrica laurentiuNoch keine Bewertungen

- Kobalt - Lawn Mower GuideDokument21 SeitenKobalt - Lawn Mower Guidessss23r5Noch keine Bewertungen

- Methodology For Stressing of PSC GirdersDokument8 SeitenMethodology For Stressing of PSC GirdersHegdeVenugopal100% (1)

- MW0JZE G3TXQ Broadband Hexagonal Beam Assembly Manual-18Dokument10 SeitenMW0JZE G3TXQ Broadband Hexagonal Beam Assembly Manual-18Marcos MillerNoch keine Bewertungen

- 177: 1 Cross Brook Cottages, Trefil, Blaenau Gwent. Building RecordingDokument42 Seiten177: 1 Cross Brook Cottages, Trefil, Blaenau Gwent. Building RecordingAPAC LtdNoch keine Bewertungen

- CF Moto MT650 Engine ManualDokument44 SeitenCF Moto MT650 Engine Manual1320 ENFIERRADOSNoch keine Bewertungen

- Wall-Mounted Split Air Conditioner Service ManualDokument42 SeitenWall-Mounted Split Air Conditioner Service ManualManuel Azabache GrandezNoch keine Bewertungen

- Extended Range Contactor ModificationDokument7 SeitenExtended Range Contactor ModificationJose A. Basanta H.Noch keine Bewertungen

- sealey SMS2008Dokument3 Seitensealey SMS2008cabuloNoch keine Bewertungen

- Terminales Termocontractiles PDFDokument18 SeitenTerminales Termocontractiles PDFcbeltranochoaNoch keine Bewertungen

- Cl20702 705 Manual Mup HiDokument33 SeitenCl20702 705 Manual Mup HiRamadan RashadNoch keine Bewertungen

- Tri-band HF Beam Antenna ManualDokument11 SeitenTri-band HF Beam Antenna ManualOscar NavaNoch keine Bewertungen

- Heater Replacement Instructions For Point Gate and Thru Hole TipsDokument2 SeitenHeater Replacement Instructions For Point Gate and Thru Hole TipsEsteban Vanegas AlvarezNoch keine Bewertungen

- S - Hose Binding and Binding Device - MDokument5 SeitenS - Hose Binding and Binding Device - Mcata1108Noch keine Bewertungen

- TV Circuit Diagram GuideDokument14 SeitenTV Circuit Diagram Guideeduscribd18Noch keine Bewertungen

- Installation Instructions for 755/775LR Elbow ConnectorsDokument5 SeitenInstallation Instructions for 755/775LR Elbow Connectorsvladimir_71Noch keine Bewertungen

- Elastimold Compact I JointDokument6 SeitenElastimold Compact I Jointwerawatb819Noch keine Bewertungen

- EU3512-3X Environmental Enclosure and Light Duty Wall Mount: InstallationDokument12 SeitenEU3512-3X Environmental Enclosure and Light Duty Wall Mount: InstallationByron RieraNoch keine Bewertungen

- Installation Manual PTFE SNSDokument4 SeitenInstallation Manual PTFE SNSDANDE VENKATA RAJESH100% (1)

- BA_F1_F1 170_F1 200_enDokument16 SeitenBA_F1_F1 170_F1 200_enChristian LamertzNoch keine Bewertungen

- Manual Del AerogeneradorDokument39 SeitenManual Del AerogeneradorJORDY ALVARADONoch keine Bewertungen

- GARD G6000: Installation Instructions For Swift Road BarriersDokument24 SeitenGARD G6000: Installation Instructions For Swift Road BarriersShah JeeNoch keine Bewertungen

- 15kV Front connector_KSU_500sq.mmDokument7 Seiten15kV Front connector_KSU_500sq.mmabd elmohsen saedNoch keine Bewertungen

- JC2013 JAW CRUSHER 200 X 130 All Voltages (Rev3)Dokument15 SeitenJC2013 JAW CRUSHER 200 X 130 All Voltages (Rev3)sharedfilepcNoch keine Bewertungen

- Instruction C02 78.3Dokument4 SeitenInstruction C02 78.3ВиталийКрутиковNoch keine Bewertungen

- Methodology For Stressing of PSC Girders (C)Dokument2 SeitenMethodology For Stressing of PSC Girders (C)VB665Noch keine Bewertungen

- Methodology For Stressing of PSC Girders (C)Dokument2 SeitenMethodology For Stressing of PSC Girders (C)HegdeVenugopalNoch keine Bewertungen

- Tost Winch Manual UltralightDokument9 SeitenTost Winch Manual Ultralightcaf28035Noch keine Bewertungen

- Ceiling Fan Lucci WhitehavenDokument13 SeitenCeiling Fan Lucci Whitehaven2201Noch keine Bewertungen

- Troubleshooting Manual, TS2712EN 04Dokument82 SeitenTroubleshooting Manual, TS2712EN 04thibierozNoch keine Bewertungen

- Split Type Air Conditioner Installation ManualDokument10 SeitenSplit Type Air Conditioner Installation ManualChalitha Nayana Hewawasam100% (1)

- Methodology For PSC GirdersDokument5 SeitenMethodology For PSC GirdersvnilNoch keine Bewertungen

- Dräger Polytron 7000 Measuring Unit, Installation InstructionsDokument15 SeitenDräger Polytron 7000 Measuring Unit, Installation InstructionsTài NguyễnNoch keine Bewertungen

- Fisher 500-T Service ManualDokument12 SeitenFisher 500-T Service ManualMrWasabihead50% (2)

- Shimano Ultegra 6700 Shifters Double Owners ManualDokument2 SeitenShimano Ultegra 6700 Shifters Double Owners ManualTimNoch keine Bewertungen

- Stripper Wire HandHeldDokument5 SeitenStripper Wire HandHeldIvana IviNoch keine Bewertungen

- Aa150 Operation Installation ManualDokument20 SeitenAa150 Operation Installation ManualJose Carlos Vaz CarneiroNoch keine Bewertungen

- Split Air Conditioner Wall Mounted Type Service Manual: AUS-07C (H) 53R010Lx AUS-07C (H) 53R150Lx AUS-09C (H) 53R150LxDokument42 SeitenSplit Air Conditioner Wall Mounted Type Service Manual: AUS-07C (H) 53R010Lx AUS-07C (H) 53R150Lx AUS-09C (H) 53R150Lxanon_226950787Noch keine Bewertungen

- Installation, Operation and Care Guide for Range Hood Models ZVE-E30S, ZVE-E36S, ZVEE42SDokument14 SeitenInstallation, Operation and Care Guide for Range Hood Models ZVE-E30S, ZVE-E36S, ZVEE42Sfandy15Noch keine Bewertungen

- Bop Brace Tool MecanicaDokument9 SeitenBop Brace Tool MecanicaEdwin AbelloNoch keine Bewertungen

- Outdoor Unit Drain Pipe InstallationDokument2 SeitenOutdoor Unit Drain Pipe InstallationJoyee BasuNoch keine Bewertungen

- Matrix FF InstallDokument22 SeitenMatrix FF Installgcu93Noch keine Bewertungen

- CWS-300 Instruction Manual DownloadDokument20 SeitenCWS-300 Instruction Manual DownloadRonnie OoiNoch keine Bewertungen

- MTS E-Beam Evaporator ManualDokument11 SeitenMTS E-Beam Evaporator ManualMarco SalvatoriNoch keine Bewertungen

- RFS 1.8mDokument13 SeitenRFS 1.8mMarius Tresor EdiboussieNoch keine Bewertungen

- PYROTENAX FIRE SURVIVAL CABLE TERMINATION GUIDEDokument12 SeitenPYROTENAX FIRE SURVIVAL CABLE TERMINATION GUIDEShameel PtNoch keine Bewertungen

- (TOPIC 3) Solar Systems AccessoriesDokument9 Seiten(TOPIC 3) Solar Systems AccessoriesIan MutugiNoch keine Bewertungen

- Bow Thruster Installation InstructionsDokument9 SeitenBow Thruster Installation InstructionsRovert AlonzoNoch keine Bewertungen

- Method Statement of Utracon Post TensioningDokument7 SeitenMethod Statement of Utracon Post TensioningIrshad Khan0% (1)

- PEAK Sidewall Cutter Data ManualDokument13 SeitenPEAK Sidewall Cutter Data ManualRizky WahyuNoch keine Bewertungen

- Mp3 Recording Usb TurntableDokument14 SeitenMp3 Recording Usb TurntableleinaduoNoch keine Bewertungen

- Installation of FittingsDokument4 SeitenInstallation of FittingsRobert SantiagoNoch keine Bewertungen

- R1874TY InstallationManualDokument8 SeitenR1874TY InstallationManualPatrice PaulNoch keine Bewertungen

- 5 GHZ, 30 Dbi Slant 45 Antenna For Airfiber: Model: Af-5G30-S45Dokument24 Seiten5 GHZ, 30 Dbi Slant 45 Antenna For Airfiber: Model: Af-5G30-S45komangNoch keine Bewertungen

- 400 Watt Wind Turbine ÉOLIENNE 400 Watts Turbina Eólica de 400 WattsDokument39 Seiten400 Watt Wind Turbine ÉOLIENNE 400 Watts Turbina Eólica de 400 WattsCarlosIvanFerreiraMenesesNoch keine Bewertungen

- Manual Evaporador RotatorioDokument28 SeitenManual Evaporador Rotatorioratt10Noch keine Bewertungen

- Makita UC4020ADokument108 SeitenMakita UC4020AAlexandru ZsoldNoch keine Bewertungen

- 500W Wind Generator ManualDokument18 Seiten500W Wind Generator ManualNicolae ȘoituNoch keine Bewertungen

- Connector: Series 1051 A004-9: I - Tool RequiredDokument3 SeitenConnector: Series 1051 A004-9: I - Tool RequiredRodolfo Victor Barrios CastilloNoch keine Bewertungen

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- STRUCTURAL STEEL PROPERTIES AND ANALYSISDokument9 SeitenSTRUCTURAL STEEL PROPERTIES AND ANALYSIScleverstaadproNoch keine Bewertungen

- Soil Stabilization From CaterpillarDokument24 SeitenSoil Stabilization From CaterpillarMoises Guilherme Abreu Barbosa100% (1)

- Systemasafety Marcelino Catalogue Anchorage Points Lifelines 2014-2015 PDFDokument30 SeitenSystemasafety Marcelino Catalogue Anchorage Points Lifelines 2014-2015 PDFMoises Guilherme Abreu BarbosaNoch keine Bewertungen

- Lecture 4 - Activity IdentificationDokument20 SeitenLecture 4 - Activity IdentificationMoises Guilherme Abreu BarbosaNoch keine Bewertungen

- Soil Stabilization in SubgradeDokument67 SeitenSoil Stabilization in Subgradeengrirfan100% (1)

- Invert Your Screen's Colors with NegativeScreenDokument2 SeitenInvert Your Screen's Colors with NegativeScreenMoises Guilherme Abreu BarbosaNoch keine Bewertungen

- 01Dokument34 Seiten01ltu_12Noch keine Bewertungen

- 55 F00108Dokument6 Seiten55 F00108Moises Guilherme Abreu BarbosaNoch keine Bewertungen

- Pile Load TestDokument43 SeitenPile Load TestShafiq Shahimi80% (5)

- KM 28 KM 28: Greater Cairo Metro Al Thawra Line (Line 3) Phase 3Dokument1 SeiteKM 28 KM 28: Greater Cairo Metro Al Thawra Line (Line 3) Phase 3Moises Guilherme Abreu BarbosaNoch keine Bewertungen

- V 102 N 01 P 061Dokument6 SeitenV 102 N 01 P 061Moises Guilherme Abreu BarbosaNoch keine Bewertungen

- Lime Treated Soil Construction ManualDokument41 SeitenLime Treated Soil Construction ManualLarisa ChindrișNoch keine Bewertungen

- 04bDokument41 Seiten04bMoises Guilherme Abreu BarbosaNoch keine Bewertungen

- Invert Your Screen's Colors with NegativeScreenDokument2 SeitenInvert Your Screen's Colors with NegativeScreenMoises Guilherme Abreu BarbosaNoch keine Bewertungen

- WP1052 Time EstimatingDokument7 SeitenWP1052 Time EstimatingMact Manit Cse AlumniAssociationNoch keine Bewertungen

- Volvo - P7820C-P8820C Paver Product BrochureDokument16 SeitenVolvo - P7820C-P8820C Paver Product BrochureMoises Guilherme Abreu BarbosaNoch keine Bewertungen

- Kuoy 81347Dokument359 SeitenKuoy 81347Moises Guilherme Abreu BarbosaNoch keine Bewertungen

- Mia Formato-F. Vertical A-1.0Dokument1 SeiteMia Formato-F. Vertical A-1.0Moises Guilherme Abreu BarbosaNoch keine Bewertungen

- Ac 040038Dokument10 SeitenAc 040038Moises Guilherme Abreu BarbosaNoch keine Bewertungen

- TV 19 2012 2 427 435Dokument9 SeitenTV 19 2012 2 427 435Moises Guilherme Abreu BarbosaNoch keine Bewertungen

- Grammar in 15 Minutes A DayDokument240 SeitenGrammar in 15 Minutes A Daylalith.shankar7971100% (9)

- Airport Construction SafetyDokument58 SeitenAirport Construction SafetyMoises Guilherme Abreu BarbosaNoch keine Bewertungen

- Formwork Girder VT 20k.Dokument2 SeitenFormwork Girder VT 20k.Moises Guilherme Abreu BarbosaNoch keine Bewertungen

- 527EDokument54 Seiten527EMoises Guilherme Abreu BarbosaNoch keine Bewertungen

- Railway TractionDokument27 SeitenRailway TractionAhmad ElsheemyNoch keine Bewertungen

- 2010 Report Rollingstock Final enDokument45 Seiten2010 Report Rollingstock Final enTetsuo YamashitaNoch keine Bewertungen

- Ac 040038Dokument10 SeitenAc 040038Moises Guilherme Abreu BarbosaNoch keine Bewertungen

- Case Study 2 Apr 2004Dokument4 SeitenCase Study 2 Apr 2004Moises Guilherme Abreu BarbosaNoch keine Bewertungen

- Back MatterDokument5 SeitenBack MatterMoises Guilherme Abreu BarbosaNoch keine Bewertungen

- Bul 477Dokument2 SeitenBul 477Moises Guilherme Abreu BarbosaNoch keine Bewertungen

- Piping OverviewDokument28 SeitenPiping Overviewعزت عبد المنعمNoch keine Bewertungen

- Elevators and Escalators Design PDFDokument10 SeitenElevators and Escalators Design PDFdanokrayNoch keine Bewertungen

- M 171 Specs for Curing Concrete SheetsDokument1 SeiteM 171 Specs for Curing Concrete SheetsFranz Richard Sardinas MallcoNoch keine Bewertungen

- Product Catalog PDFDokument979 SeitenProduct Catalog PDFa7mos0% (1)

- Reconditioning of ValvesDokument6 SeitenReconditioning of ValvesPaul PhiliphsNoch keine Bewertungen

- Roads Division KasaragodDokument142 SeitenRoads Division KasaragodShameer UppalaNoch keine Bewertungen

- Bim Module EpflDokument105 SeitenBim Module EpflMúÑír PåhôrêNoch keine Bewertungen

- RK Pivot Doors AlbumDokument43 SeitenRK Pivot Doors AlbumJafarNoch keine Bewertungen

- Repair Concrete StructuresDokument3 SeitenRepair Concrete StructuresSindhe SwethaNoch keine Bewertungen

- Rehabilitation of Sindangan-Siayan-Dumingag-Mahayag RoadDokument2 SeitenRehabilitation of Sindangan-Siayan-Dumingag-Mahayag RoadAljie CañeteNoch keine Bewertungen

- Ps-x01 Nls InputdataDokument100 SeitenPs-x01 Nls InputdatapckolNoch keine Bewertungen

- Siemens Wiac - Info PDF Iec 62271 200 Switchgear PRDokument22 SeitenSiemens Wiac - Info PDF Iec 62271 200 Switchgear PRAu Psl FightFor GreatVictoryNoch keine Bewertungen

- DinDokument11 SeitenDinharshadNoch keine Bewertungen

- Material CalculationDokument10 SeitenMaterial CalculationMono BasiranNoch keine Bewertungen

- EQR UttarkashiDokument8 SeitenEQR UttarkashiArjunNoch keine Bewertungen

- LSAW Steel PipeDokument2 SeitenLSAW Steel Pipelisa leeNoch keine Bewertungen

- Steel Fibers For Fiber-Reinforced ConcreteDokument4 SeitenSteel Fibers For Fiber-Reinforced ConcreteIvan TapiaNoch keine Bewertungen

- POWERPACKDokument31 SeitenPOWERPACKcristianNoch keine Bewertungen

- Mod 1Dokument18 SeitenMod 1Zac IriberriNoch keine Bewertungen

- Comparison of Experimental Values With EC 4, ACI-318, AISC-LRFD of Concrete Filled Steel Fluted Columns For Concentric LoadDokument10 SeitenComparison of Experimental Values With EC 4, ACI-318, AISC-LRFD of Concrete Filled Steel Fluted Columns For Concentric Loadmohamed alyozbakiNoch keine Bewertungen

- AnnexureDokument16 SeitenAnnexureAmirNoch keine Bewertungen

- Construction and Building Materials: Chi-Cong Vu, Olivier Plé, Jérôme Weiss, David AmitranoDokument21 SeitenConstruction and Building Materials: Chi-Cong Vu, Olivier Plé, Jérôme Weiss, David Amitranochristian ricaldi100% (1)

- FIDIC Conditions of ContractDokument5 SeitenFIDIC Conditions of ContractlirinasNoch keine Bewertungen

- ABEL SH Solids Handling Pumps GB-web-02 2020Dokument6 SeitenABEL SH Solids Handling Pumps GB-web-02 2020ha liNoch keine Bewertungen

- Presentation - Frame Construction in Concrete SteelDokument23 SeitenPresentation - Frame Construction in Concrete SteelOlay KwongNoch keine Bewertungen

- D7032 1213477 1 PDFDokument11 SeitenD7032 1213477 1 PDFBodhi RudraNoch keine Bewertungen

- BARE COPPER CONDUCTOR SPECIFICATIONSDokument1 SeiteBARE COPPER CONDUCTOR SPECIFICATIONSIan de GaliciaNoch keine Bewertungen