Beruflich Dokumente

Kultur Dokumente

IR For Dummies 1999

Hochgeladen von

Zvonko DamnjanovicOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

IR For Dummies 1999

Hochgeladen von

Zvonko DamnjanovicCopyright:

Verfügbare Formate

IR For Dummies: a brief non-technical introduction to what you can't see

Infrared (IR) Radiation

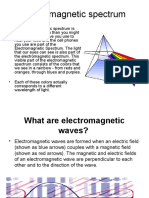

In everyday life we encounter electromagnetic radiation in many different forms. Visible light, ultraviolet light, radio waves, and X-rays are all examples of electromagnetic radiation, differing only in wavelength. Infrared radiation occupies that region of the electromagnetic spectrum between visible light and microwaves. The figure below shows the major divisions of the electromagnetic spectrum, along with some specific features within the spectrum.

Violet light Peak emission from the sun Red light Peak emission from an object at 70oF Television Medical X-Rays Gamma rays X-Rays UV Visible light Infrared Radar Microwaves AM Radio Power & Telephone

Radio waves

10-10 10-9 10-8 10-7 10-6 10-5 10-4 10-3 .01 .1 1 10 Wavelength, centimeters

100

103

104

105

106

107

108 cm

Figure 1. The Electromagnetic Spectrum All objects constantly emit IR radiation as a function of their temperature. As an object gets hotter, it gives off more intense infrared radiation, and it radiates at shorter wavelengths. At moderate temperatures (above 200F), the intensity of the radiation gets high enough so that the human body can detect that radiation as heat. At high enough temperatures (above 1200F), the intensity gets high enough and the wavelength gets short enough so that the radiation crosses over the threshold to the red end of the visible light spectrum. This is why hot steel glows red. As an object gets even hotter (for example, the tungsten filament of a light bulb at 5000F), the intensity gets even higher (that is, it glows brighter) and the wavelength gets even shorter (more white). But even at low temperatures, below the threshold of visible light emission, everything glows with this longer wavelength infrared light, and objects at different temperatures glow with different wavelengths and intensities. The radiation from these objects creates an infrared scene, similar in nature to a visible light scene.

IR Imaging Systems

The human eye cannot detect infrared light. But infrared energy can be detected electronically. Sophisticated electronic instruments exist which can scan a scene and convert the infrared light to an electrical signal which can be displayed on a video

monitor, analyzed by a computer, or recorded on film. Electrically, the output of these instruments is very similar to the output of a conventional video camera. Unlike the human eye or a conventional video camera, which rely on reflected visible light to illuminate the objects in a scene, these infrared cameras are detecting IR energy which is being emitted by the objects in the scene. So an infrared camera works as well in total darkness as it does in normal daylight. IR imaging systems are designed to satisfy different performance parameters, depending on their intended use. Military applications, such as missile guidance, require the highest level of accuracy and reliability. Many commercial applications require low cost, ease of use, and ease of maintenance. IR imaging applications are virtually limitless. They allow you to see at night or through haze and smoke. They allow you to measure the temperature profiles of objects at great distances with high accuracy. Military applications include target acquisition, missile and weapon guidance, navigation, reconnaissance, surveillance, and terrain analysis. Commercial applications exist in many fields: industrial (plant maintenance, quality control, non-destructive testing), environmental and scientific (earth and solar sciences, pollution control, energy conservation, resource development), medical (mammography, detection of arterial constriction, evaluation of soft tissue injury), and civil (law enforcement, fire fighting, surveillance, border patrol), to name just a few. Figure 2 shows the breadth of applications for infrared technology. This table was compiled by Richard Hudson in his 1969 text, Infrared System Engineering, a universally respected infrared handbook. In the time since this publication first appeared, the majority of activity has been in military applications; the high cost of infrared imaging systems has limited its use in commercial applications. However, the last few years have yielded significant breakthroughs in detector technology and associated support electronics, resulting in major reductions in the cost of imaging infrared systems. The price of these new systems now makes practical the whole array of applications listed in Hudson, opening up vast new markets for IR equipment.

Testing and Evaluation of IR Imaging Systems

Due to their complexity, IR imaging systems are expensive, sensitive, high-maintenance devices. To assure proper operation of these systems and to achieve their full performance requires frequent test and calibration. Engineers, who design IR imaging systems, test them during the design and development stage to evaluate performance parameters and to refine designs to optimize performance. Manufacturers of IR imaging systems need to compare actual performance to specifications, and need to calibrate the systems prior to delivery. End users must test their systems regularly to verify proper operation, and must recalibrate them periodically while they are in the working environment.

Search, track, and range

Radiometry

Military Intrusion detection Bomber defense Missile guidance Navigation and flight control Proximity fuses Ship, aircraft, ICBM, and mine detection Fire control Aircraft collision warning Target signatures

Industrial Forest fire detection Guidance for fire-fighting missiles Fuel ignition monitor Locating hidden law violators Monitoring parking meters Detect fires in aircraft fuel tanks Detection of hot boxes on railroad cars Noncontact dimensional determination Process control Measurement of the temperatures of brake linings, power lines, cutting tools, welding and soldering operations, and ingots Detection of clear-air turbulence Analysis of organic chemicals Gas analysis Determination of alcohol in the breath Discovery of leaks in pipelines Detection of oil in water Control of oxygen content in germanium and silicon Nondestructive testing Inspection Locating piping hidden in walls and floors Inspection of infrared optical materials Detect and display microwave field patterns Study efficiency of thermal insulators Industrial surveillance and crime prevention Examination of photographic film during manufacture Detection of diseased trees and crops Traveling matte photography Automatic focusing of projectors Intrusion detection Automobile collision prevention Traffic counting Radiant heating and drying Data link Intervehicle speed sensing Aircraft landing aid Cable bonding

Medical Obstacle detection for the blind

Scientific Satellite detection Space vehicle navigation and flight control Horizon sensors Sun followers for instrument orientation Studies of the optical structure of the horizon

Measurement of skin temperature Early detection of cancer Monitor healing of wounds and onset of infection, without removing bandages Remote biosensors Studies of skin heating and temperature sensation Detection and monitoring of air pollution Determination of carbon dioxide in the blood and in expelled air

Measurement of lunar, planetary and stellar temperatures Remote sensing of weather conditions Study of heat transfer in plants Measurements of the earth's heat balance Determination of the constituents of earth and planetary atmospheres Detection of vegetation or life on other planets Terrain analysis Monitor spacecraft atmospheres Zero-G liquid level gauge Measurement of magnetic fields Earth resources surveys Locate and map the gulf stream Detect forest fires from satellites Study volcanoes Detect and study water pollution Locate crevasses Sea-ice reconnaissance Petroleum exploration Detection of forgeries Determine thickness of epitaxial films Determination of the surface constituents of the moon and the planets Gem identification Analysis of water quality Detection of diseased crops

Spectroradiometry

Terrain analysis Poison gas detection Target and background signatures Fuel vapor detection Detection of contaminants in liquid oxygen piping

Thermal imaging

Reconnaissance and surveillance Thermal mapping Submarine detection Detection of underground missile silos, personnel, vehicles, weapons, cooking fires, and encampments Damage assessment

Reflected flux

Night driving Carbine firing Intrusion detection Area surveillance Camouflage detection Station keeping Docking and landing

Early detection and identification of cancer Determination of the optimum site for an amputation Localization of the placental site Studies of the efficiency of Arctic clothing Early diagnosis of incipient stroke Measurement of pupillary diameter Location of blockage in a vein Monitoring eye movements Study the nocturnal habits of animals Examination of the eye through corneal opacities Monitor healing processes Ranging and obstacle detection for the blind Heat therapy

Cooperative source

Terrestrial communications Command guidance for weapons Countermeasures for infrared systems Range finding Drone command link Intrusion detection

Space communications Understand the mechanism of animal communication Peripheral input for computers Study the nocturnal habits of animals Terrain illumination for night photography

Figure 2. INFRARED APPLICATIONS MATRIX (from Infrared System Engineering, by Richard D. Hudson Jr., John Wiley & Sons, 1969)

Some of the important performance characteristics of an IR imaging system are spatial resolution (ability to resolve fine detail), thermal resolution (ability to resolve small temperature differences), speed (ability to respond to a rapidly changing scene without blurring), and dynamic range (how large a temperature span it can view without saturating). Standard tests have been developed to quantify these characteristics. In addition, innumerable specialized tests exist to evaluate specific requirements. For more detail on IR testing, see the article "Automated Testing Improves Infrared Imaging Systems", by Peter L. Chua and Stephen W. McHugh of Santa Barbara Infrared, included in the appendix. This article details some of the complex tests necessary to characterize the various subsystems of an imaging system, and discusses the difficulties involved in achieving accurate and consistent results.

IR Test Equipment

Setup, test, and calibration of IR imaging systems requires the use of specialized test equipment. This test equipment is designed to create an infrared scene of precisely known characteristics, to project this scene to the input of the IR imaging system being tested, and to evaluate the quality of the output of the IR imaging system. The nature of the testing needed depends on the application of the IR imaging system. Obviously, proper function of a camera used for parking lot surveillance is a less critical than proper function of an IR navigation and targeting system used by a supersonic jet fighter in low-altitude night battle. So different test equipment is needed for different IR imaging systems, and for different applications. For some applications, standard off-theshelf equipment exists that can be used to properly test an imaging system. For other applications, elaborate custom equipment must be developed to meet the testing requirements. Some of the standard IR test instruments are described below. Pictures of these instruments can be seen in the Product Information section of the Appendix. Blackbodies. A blackbody is a precisely characterized source of infrared radiation. When used to test an IR imaging system, a blackbody is used to generate an accurate temperature difference between two surfaces, which yields a precise radiance contrast for an input to the IR imaging system being tested. A blackbody with suitable performance for testing state-of-the-art imaging systems is a very sophisticated instrument, controlling the temperature of the blackbody surface with resolution and stability on the order of .001C. Targets. A typical target used for IR testing consists of a flat copper plate with a testspecific pattern etched or machined through it. The target is placed in front of the blackbody, and the blackbody controls the temperature difference between the target and the blackbody's surface. When an IR imaging system views the blackbody surface through the target features, it sees an infrared image in the shape of the target pattern with a contrast determined by the temperature difference between the blackbody and the target. One common example of a target pattern is a set of rectangular bars etched through the copper plate. It is used in a test similar to the way an eye chart is used by an

optometrist: this target, along with a blackbody, would generate patterns used to test the spatial resolution of an IR imaging system. Target Wheels. To minimize handling of different targets, to automate target selection, and to speed up test time, several targets of different sizes and different features can be mounted into a motorized target wheel. Collimators. A collimator is a optical assembly which projects the IR image generated by a blackbody and target onto the IR imaging system being tested. Typically, a collimator is used to create the illusion of the IR image existing at a great distance from the unit under test. This is needed, because an IR imaging system is normally used to view objects at distances greater than those achievable in a laboratory. Target Projectors. A blackbody, targets, target wheel, and collimator, properly integrated together, form a system called a target projector. Frequently, the blackbody and target wheel in a target projector are designed to be controlled by a computer, to allow automation of the testing. Other special features such as range simulation or boresight alignment tooling are sometimes added as accessories to target projectors. These integrated components are sold as turnkey test equipment for IR imaging systems. A target projector is analogous to a slide projector, with its components (blackbody, target, target wheel, and collimator) analogous to the slide projector's components (bulb, slide, slide carousel, and lens). A significant difference between the two is that a slide projector projects a visible light scene, typically onto a white screen; a target projector projects an infrared light scene, typically into the input optics of an IR imaging system. Another important difference is that unlike a slide projector's bulb with its constant light output, the target projector's blackbody provides a precisely variable illumination behind the slide (target).

SBIR's Role in IR Testing

Santa Barbara Infrared designs and manufactures both standard and custom test equipment used to measure performance of IR imaging systems. Products are sold as individual components or as integrated turnkey IR test stations. The company has a robust catalog of standard products which can be delivered in multiple configurations. The company's products are used to test IR imaging systems, in the lab or for field use, in a commercial or military environment. The company also manufactures test equipment for other electro-optical systems such as lasers and visible light cameras, to provide complete test solutions for sophisticated multi-sensor military systems. The company has developed three distinct business areas related to IR test equipment: standard products, design-to-spec engineering, and build-to-print production. Standard products consist of instruments conceived and designed at SBIR and sold as catalog items, sometimes reconfigured to customer requirements. SBIR's design-to-spec engineering and build-to-print production both support the company's involvement in

program-specific products (in contrast to standard products). For the design-to-spec engineering, a customer's specification document is the basis for a custom design by SBIR's engineering staff, which the company will then build, test, and deliver to the customer. Build-to-print production utilizes the customer's engineering design, with SBIR supplying purchasing, fabrication, and test services along with engineering support during the project.

Das könnte Ihnen auch gefallen

- Accretion Power in Astrophysics PDFDokument400 SeitenAccretion Power in Astrophysics PDFAnonymous Di2yBGsNoch keine Bewertungen

- EMC Pocket Guide PDFDokument66 SeitenEMC Pocket Guide PDFRAVI RANJAN100% (1)

- Lab Report Fundamentals of MicrosDokument15 SeitenLab Report Fundamentals of MicrosKyle DunnNoch keine Bewertungen

- Acrylite Sheet Sales HandbookDokument100 SeitenAcrylite Sheet Sales HandbookJnanam ShahNoch keine Bewertungen

- Infrared System Specifications - What Does It All Mean?: AbstractDokument8 SeitenInfrared System Specifications - What Does It All Mean?: Abstractkov709324Noch keine Bewertungen

- 4 ParulDokument30 Seiten4 Parulanon_931964125Noch keine Bewertungen

- Concealed Weapon DetectionDokument10 SeitenConcealed Weapon DetectionPoreddy Rajesh ReddyNoch keine Bewertungen

- Govt. SKSJT Institute.: K.R Circle BangaloreDokument13 SeitenGovt. SKSJT Institute.: K.R Circle BangaloreVicky VigneshNoch keine Bewertungen

- Infrared Background and Missiles Signature SurveyDokument5 SeitenInfrared Background and Missiles Signature Surveyamiry1373Noch keine Bewertungen

- IRresearchreport PDFDokument9 SeitenIRresearchreport PDFPawan Kumar YadavNoch keine Bewertungen

- Presentation 5Dokument30 SeitenPresentation 5shannpalao06Noch keine Bewertungen

- "Remote Sensing and Its Application": Other Converging FieldsDokument11 Seiten"Remote Sensing and Its Application": Other Converging FieldsChinmai HemaniNoch keine Bewertungen

- A Research Paper On Infrared ThermographyDokument7 SeitenA Research Paper On Infrared ThermographyAdit GuptaNoch keine Bewertungen

- What Is Sensor and What Are Different Types of SensorsDokument11 SeitenWhat Is Sensor and What Are Different Types of SensorschdiNoch keine Bewertungen

- Elements of Infrared Detection SystemDokument6 SeitenElements of Infrared Detection SystemMonikaPuniaNoch keine Bewertungen

- Infrared Sensors & Its Applications: Kamalrajsinh K. SodhaDokument11 SeitenInfrared Sensors & Its Applications: Kamalrajsinh K. Sodhanirav68127245Noch keine Bewertungen

- The Working Principle and Key Applications of Infrared SensorsDokument6 SeitenThe Working Principle and Key Applications of Infrared SensorsrajeshNoch keine Bewertungen

- Infrared Radiation ReportingDokument6 SeitenInfrared Radiation ReportingJoy Mary100% (1)

- InfraredDokument18 SeitenInfraredabcd3511Noch keine Bewertungen

- List of SensorsDokument4 SeitenList of SensorsBarun SarkarNoch keine Bewertungen

- Ultrasonic Detection and Ranging: ECE Department, NNRGDokument36 SeitenUltrasonic Detection and Ranging: ECE Department, NNRGlakshmi prasannaNoch keine Bewertungen

- ThermographyDokument27 SeitenThermographyAmir Mahmoud Mahdavi Abhari0% (1)

- (461513) 1.4 BGE 1 - Electromagnetic Spectrum Summary NotesDokument7 Seiten(461513) 1.4 BGE 1 - Electromagnetic Spectrum Summary NotesAarti PrajapatiNoch keine Bewertungen

- Theory of Operation: Infrared Radiation Camera Visible Light WavelengthsDokument13 SeitenTheory of Operation: Infrared Radiation Camera Visible Light WavelengthsgabrieltinNoch keine Bewertungen

- Designof Ultrasonic RadarDokument6 SeitenDesignof Ultrasonic RadarDelaya Ningsi LohoNoch keine Bewertungen

- Sensors 13 05054Dokument45 SeitenSensors 13 05054Mojo ZNoch keine Bewertungen

- 996-Article Text-5770-1-10-20200926Dokument13 Seiten996-Article Text-5770-1-10-20200926Murali KrishnaNoch keine Bewertungen

- New Microsoft Office Word DocumentDokument17 SeitenNew Microsoft Office Word DocumentAmit KaushikNoch keine Bewertungen

- InfraredDokument8 SeitenInfraredAlex BrenesNoch keine Bewertungen

- Proceedings of Spie: Laser Warning System As An Element of Optoelectronic Battlefield SurveillanceDokument8 SeitenProceedings of Spie: Laser Warning System As An Element of Optoelectronic Battlefield Surveillancemuhammad haziqNoch keine Bewertungen

- MSA Guide To Flame DetectionDokument9 SeitenMSA Guide To Flame DetectionGianfranco GirardiNoch keine Bewertungen

- Thermograph yDokument26 SeitenThermograph yVivekanand KhavatkoppaNoch keine Bewertungen

- Design of Ultrasonic Radar: January 2015Dokument6 SeitenDesign of Ultrasonic Radar: January 2015Firas KachroudiNoch keine Bewertungen

- Thermal ImagingDokument21 SeitenThermal ImagingKaustubh Rajwade100% (5)

- 2nd Q ReviewerDokument7 Seiten2nd Q ReviewerFeiNoch keine Bewertungen

- NDT ThermographyDokument30 SeitenNDT ThermographyAshwini SinghNoch keine Bewertungen

- Submiteed By: Muhammad Farhan Malik ROLL # BEE-09-165 Class: 4-B Department of Electric Engineering University of Lahore Islamabad CampusDokument18 SeitenSubmiteed By: Muhammad Farhan Malik ROLL # BEE-09-165 Class: 4-B Department of Electric Engineering University of Lahore Islamabad Campussalman28100Noch keine Bewertungen

- Sesión Nro. 7: TermografíaDokument38 SeitenSesión Nro. 7: TermografíaRodrigo Javier Quinto AcunaNoch keine Bewertungen

- Influence of IR Sensor Technology On The Military and Civil DefenseDokument15 SeitenInfluence of IR Sensor Technology On The Military and Civil DefenseXannixNoch keine Bewertungen

- InfraredDokument2 SeitenInfraredAjmal MpNoch keine Bewertungen

- Early Warning Chemical Sensing: Juliette A. Seeley and Jonathan M. RichardsonDokument15 SeitenEarly Warning Chemical Sensing: Juliette A. Seeley and Jonathan M. RichardsonNguyễn QuốcNoch keine Bewertungen

- "Infrared Thermography: Presented By: Kumar Kartikey 12EJAME048Dokument36 Seiten"Infrared Thermography: Presented By: Kumar Kartikey 12EJAME048surbhi pareekNoch keine Bewertungen

- Remote Sensing and Gis Module 1Dokument12 SeitenRemote Sensing and Gis Module 1Shaik SulemanNoch keine Bewertungen

- Secondary Radar Concepts (New) 2019Dokument209 SeitenSecondary Radar Concepts (New) 2019Pradeep Seemala100% (1)

- Article Minimising False Alarms Rosemount en 72138Dokument1 SeiteArticle Minimising False Alarms Rosemount en 72138Abdelhakim ChaouchNoch keine Bewertungen

- Infrared Spectroscopy: Dr. W. Richard Thilagaraj SRM UniversityDokument11 SeitenInfrared Spectroscopy: Dr. W. Richard Thilagaraj SRM UniversityKaran DhingraNoch keine Bewertungen

- Infrared Thermography of Electrical System & Case StudiesDokument31 SeitenInfrared Thermography of Electrical System & Case StudiesSujith MenonNoch keine Bewertungen

- Infrared WavesDokument52 SeitenInfrared WavesJuliever EncarnacionNoch keine Bewertungen

- Electromagnetic SpectrumDokument22 SeitenElectromagnetic SpectrumArenz Rubi Tolentino IglesiasNoch keine Bewertungen

- Physics Investigatory On Infrared SensorsDokument18 SeitenPhysics Investigatory On Infrared SensorsshahazeerNoch keine Bewertungen

- Laser: Light Detection and RangingDokument26 SeitenLaser: Light Detection and RangingUllasSanthuNoch keine Bewertungen

- KULIAH 2 MRT 10-PerpetaanDokument85 SeitenKULIAH 2 MRT 10-PerpetaanDeviSulistiaNoch keine Bewertungen

- Catalogo de SensoresDokument64 SeitenCatalogo de SensoresfedtamagusNoch keine Bewertungen

- Sensor Technology Documentation FinalDokument25 SeitenSensor Technology Documentation Final19-494 Manoj ReddyNoch keine Bewertungen

- Emerging Trends in Sensor Application in Industrial ScenarioDokument41 SeitenEmerging Trends in Sensor Application in Industrial ScenarioBikash DasNoch keine Bewertungen

- Remote SensingDokument20 SeitenRemote SensingPotlapalli PraveenkumarNoch keine Bewertungen

- Automobile Prototype SensorsDokument5 SeitenAutomobile Prototype SensorsIJSTENoch keine Bewertungen

- Lec-PH301 17 Optical Sources-2 13.09.2023Dokument28 SeitenLec-PH301 17 Optical Sources-2 13.09.2023Latu BharaliNoch keine Bewertungen

- Flame Detector PDFDokument4 SeitenFlame Detector PDFAhmed Mahmoud ElgayedNoch keine Bewertungen

- Remote SensingDokument42 SeitenRemote SensingAndrea DeleonNoch keine Bewertungen

- Unit - 5 NDTDokument7 SeitenUnit - 5 NDTRAJESH. RNoch keine Bewertungen

- Remote Sensing: Advancements and Applications in Computer Vision for Remote SensingVon EverandRemote Sensing: Advancements and Applications in Computer Vision for Remote SensingNoch keine Bewertungen

- Shining a Light on Cool Standards: Infrared Spectroscopy Theory Explored.Von EverandShining a Light on Cool Standards: Infrared Spectroscopy Theory Explored.Noch keine Bewertungen

- SEPA MK 12 Ib en 02Dokument28 SeitenSEPA MK 12 Ib en 02Zvonko DamnjanovicNoch keine Bewertungen

- Thermoelastic Stress Analysis Based on Infrared Thermography-最新动态进展-MedSciDokument1 SeiteThermoelastic Stress Analysis Based on Infrared Thermography-最新动态进展-MedSciZvonko DamnjanovicNoch keine Bewertungen

- 35-GODINA RGGF-a U TUZLIDokument41 Seiten35-GODINA RGGF-a U TUZLIZvonko DamnjanovicNoch keine Bewertungen

- Emont2011 Zvonko PantaDokument15 SeitenEmont2011 Zvonko PantaZvonko DamnjanovicNoch keine Bewertungen

- Emont2011 ZvonkoDokument15 SeitenEmont2011 ZvonkoZvonko DamnjanovicNoch keine Bewertungen

- Inframet: Quantities and UnitsDokument2 SeitenInframet: Quantities and UnitsZvonko DamnjanovicNoch keine Bewertungen

- RO-Infrared Meaurement of Thermoelastic Stress On Mechanical ComponentsDokument13 SeitenRO-Infrared Meaurement of Thermoelastic Stress On Mechanical ComponentsZvonko DamnjanovicNoch keine Bewertungen

- Metalurgia International Sp8 2013Dokument18 SeitenMetalurgia International Sp8 2013Zvonko DamnjanovicNoch keine Bewertungen

- Configuration SystemsDokument9 SeitenConfiguration SystemsZvonko DamnjanovicNoch keine Bewertungen

- Metalurgia International Sp8 2013Dokument18 SeitenMetalurgia International Sp8 2013Zvonko DamnjanovicNoch keine Bewertungen

- Review IR PDFDokument34 SeitenReview IR PDFZvonko DamnjanovicNoch keine Bewertungen

- Ttem 8 1 Web PDFDokument477 SeitenTtem 8 1 Web PDFZvonko DamnjanovicNoch keine Bewertungen

- Zvonko Damnjanovic - MKSM2012Dokument19 SeitenZvonko Damnjanovic - MKSM2012Zvonko DamnjanovicNoch keine Bewertungen

- Numerical Methods in Termal Zvonko Radmi 2011Dokument7 SeitenNumerical Methods in Termal Zvonko Radmi 2011Zvonko DamnjanovicNoch keine Bewertungen

- LazarevicA TTEM 2011Dokument10 SeitenLazarevicA TTEM 2011Zvonko DamnjanovicNoch keine Bewertungen

- The Analysis of AC/A Ratio in Nonrefractive Accommodative Esotropia Treated With Bifocal GlassesDokument6 SeitenThe Analysis of AC/A Ratio in Nonrefractive Accommodative Esotropia Treated With Bifocal GlassesTimbul SianturiNoch keine Bewertungen

- DS Spec AvaSpec ULS2048CL EVODokument2 SeitenDS Spec AvaSpec ULS2048CL EVOCamilo GutierrezNoch keine Bewertungen

- LABREPORT#3Dokument2 SeitenLABREPORT#3reasonbmor69Noch keine Bewertungen

- Lesson Plan What Is LightDokument3 SeitenLesson Plan What Is LightManjula MprkNoch keine Bewertungen

- Electrical DraiwngDokument64 SeitenElectrical Draiwngplasticos_jfm6580Noch keine Bewertungen

- Phy Assignment NITDokument1 SeitePhy Assignment NITKartik GvrNoch keine Bewertungen

- Binocular MicroscopeDokument5 SeitenBinocular MicroscopeAnggaAl-amin100% (1)

- Newton's Ring - Thin FilmsDokument47 SeitenNewton's Ring - Thin FilmsVardhan MunglaNoch keine Bewertungen

- Vandal VN12Dokument1 SeiteVandal VN12EliasNoch keine Bewertungen

- Light Reflection and Refraction Notes For Class 10 Download PDFDokument4 SeitenLight Reflection and Refraction Notes For Class 10 Download PDFdan djNoch keine Bewertungen

- Analysis of Power Received W.R.T Distance For Different Path Loss ExponentsDokument4 SeitenAnalysis of Power Received W.R.T Distance For Different Path Loss ExponentshiNoch keine Bewertungen

- The Optics of Human Skin Aspects Important For HumDokument13 SeitenThe Optics of Human Skin Aspects Important For HumNiteshNoch keine Bewertungen

- Optical Determination of Velocity of Sound in LiquidsDokument4 SeitenOptical Determination of Velocity of Sound in LiquidsBogdan Cel MicNoch keine Bewertungen

- 12port Rosenberger - BA G7G7W8W8W8W8X65V 21 - DEDokument2 Seiten12port Rosenberger - BA G7G7W8W8W8W8X65V 21 - DESarhento KunehoNoch keine Bewertungen

- SX 303Dokument27 SeitenSX 3031alllan1Noch keine Bewertungen

- MCQ Class 10 LightDokument8 SeitenMCQ Class 10 LightRithika GoruNoch keine Bewertungen

- Climate Toolkit A Resource Manual For Science and Action 1593663303 PDFDokument180 SeitenClimate Toolkit A Resource Manual For Science and Action 1593663303 PDFJhinsher TagleNoch keine Bewertungen

- OPTICS-07 - Subjective UnSolvedDokument4 SeitenOPTICS-07 - Subjective UnSolvedRaju SinghNoch keine Bewertungen

- OpticsDokument6 SeitenOpticsDivyankur KainNoch keine Bewertungen

- Series 9000 Photoelectric Sensors: Technical DataDokument10 SeitenSeries 9000 Photoelectric Sensors: Technical DataRafael IbarraNoch keine Bewertungen

- Parabolic Antenna ReportDokument26 SeitenParabolic Antenna ReportGerbo NotsilNoch keine Bewertungen

- Chapter Four Solar Thermal Energy CollectorsDokument30 SeitenChapter Four Solar Thermal Energy CollectorsJoel LogboNoch keine Bewertungen

- Ocular Instruments - Surgcial Chart BDokument2 SeitenOcular Instruments - Surgcial Chart Bvlademir isidoroNoch keine Bewertungen

- Ambrose 1999Dokument11 SeitenAmbrose 1999Meita PuteriNoch keine Bewertungen

- Meterological Aspects of Air PollutionDokument18 SeitenMeterological Aspects of Air PollutionSubbulakshmiNoch keine Bewertungen

- Phy475 Homework 3Dokument1 SeitePhy475 Homework 3ProfAndré GazotoNoch keine Bewertungen