Beruflich Dokumente

Kultur Dokumente

993 - Targa Roof Operation Outline

Hochgeladen von

John PolstraCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

993 - Targa Roof Operation Outline

Hochgeladen von

John PolstraCopyright:

Verfügbare Formate

993 - Targa Roof Operation Outline - pcarworkshop

http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation...

993 - Targa Roof Operation Outline

From pcarworkshop

Contents

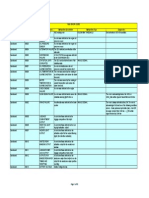

1 Introduction 2 The Main Tracks 3 The Drive Cables 4 The Drive Motors & Cables 5 Two Types of Rear Gate Guides 6 The Cables and the letting go Mechanism 7 The Visor and Front of the Glass Roof 8 The Sunblind 9 Basic Roof Height Adjustment 10 Setting the Roof Timing Stop Points

Introduction

The 993 Targa top is one of the most unnecessarily complicated systems I have ever seen. A company called Webasto manufactures it for Porsche. They make OEM sunroof mechanisms for various auto manufacturers. It is a design that seems to have been created by engineer geeks with access to a shop full of machines and machinists to create whatever they come up with that day. This mentality is further noticeable in how everything seems to have been designed with no forethought for repair. One begins to believe that this may have been done to require service to be done by factory personnel only. When I was looking for my Targa I had heard about there being problems with the roofs. My mechanic said, "buy a coupe or cabriolet, the tops break and sometimes we cant even fix 'em." But after living most of my adult life with a Targa in one form or another (a 1973 914, a 1968 911L and a 1984 Carrera) I decided to get one anyway.

I found one in the color combo that I wanted and the owner said he just spent 1200 dollars at the dealer repairing the top and replacing parts. So I figured it was probably one of the safest bets I could find in a Targa purchase. After driving it about 2000 miles there was a loud clonk and the top jammed and started clickinga sort of ratcheting noisewhen I pressed the button. I messed with it, lubed it up and it would open all the way but at the last push to bring the rear of the glass up, it would jam and make the ratchet noise. Because the top wouldnt close all the way, the wind deflector wouldnt come down. I removed the drive motors in the back under the rear deck and discovered that the cables were stripped a bit and figured that was the problem. I ordered what is called a repair kit which is essentially the two glass top drive cables and a bunch of little plastic bits. The list price on the top repair kit, which is the only way to buy the drive cables, is about $1100. Sunset Porsche [1] (http://www.sunsetimports.com/) got it to me for just over $800 In buying the car, the previous owner said the dealer had done a repair, which gave me confidence. I found out later that virtually no one, at least who I talked toother Targa owners, various dealer parts guys, independent mechanics and dealer service peoplehas a concept of how this mechanism works. Compound this issue with the fact

1 of 16

7/17/2012 5:03 PM

993 - Targa Roof Operation Outline - pcarworkshop

http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation...

that Webasto has updated parts over the years and some newer ones dont work with other older ones. No one I spoke with knew about some of the updates. I was originally going to do a step by step DIY on how to remove and replace the mechanism for operating the Glass Roof and Sunblind, but it is a lot, as you will see, so I decided to do this overview instead. Procedures are covered in the service notes which are available here on MikeJ's Pcarworkshop.com In the TSBs, Parts Guides section for the 993. Here are direct links: Targa Service Technical Notes Part 1 and Targa Service Technical Notes Part 2 Note: Mikej asks that you limit your downloads. By combining the information herein with the Targa service guides you can pretty much figure it out. If you have any problems, or other questions, PM me on Rennlist, username: "Amfab" One problem with the Service Guide is that the glass roof drive mechanism is not designed to be replaced with the top on the car, and so the Service Guide describes the procedure with the top off the car. And by top I mean the whole top. The Targa is based on the cabriolet body with some modifications here and there. The top is a single unit that comes from Webasto and is bolted and bonded with adhesive to the body. Mike, who created this site is the only one I know who has attempted (successfully) a complete top replacement, and I will leave explanations of that to him. The glass roof drive mechanism is designed to be replaced with the top off the car. However it can be done with the top on the car, but it is far from easy. If you are going to attempt this, or if anyone has specific questions, again, you can contact me through Rennlist, username: Amfab. I encourage anyone with a Porsche to become a member, the assistance and information you will receive there is invaluable. In this document I left out a full explanation of how the Wind Deflector works as it is self evident to a Targa owneronce the function of the cables and Gate Guides is understoodhow the Wind Deflector pivots up and down. I also want to thank Mike and Robin for their contributions to the 993 community, and with a special note to Mike who was the only person on the planet whom I felt fully understood, and empathized with my frustrations with the top as I undertook this project. -Andrew MacKenzie

The Main Tracks

Running inside the two sides of the roof, above the side windows, are two large extruded aluminum channels that are bent to follow the inside of the roofline. On this page are two pictures. One, a drawing I did of a section of the track, and an actual photo of the track removed from my car

In these two pictures the right, or passengers side track is shown.

2 of 16

7/17/2012 5:03 PM

993 - Targa Roof Operation Outline - pcarworkshop

http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation...

The large upright part on the outer side (left in the pictures) has eight holes where the hex bolts are. These bolt the track into the frame of the top. The two round tubular shaped portions of the track carry the drive cables. The cables are actually long springs that act as flexible rack gears that gets driven by motors under the rear deck.

The Drive Cables

The top cable in the above picture is a healthy new cable. It essentially is along spring with a pipe cleaner running down the middle. The little hairs help to keep the track clean. You do not want to lube these cables. It will not help them to move more freely and will only gum them up while causing potential slippage against the drive gears of the motors. The second cable down is one that has been stripped against the drive gear of a motor. The third one down shows a mild kink. This kink is enough to cause binding, which can lead to stripping. Any work done on the mechanism that involves removing of the tracks or cables requires a lot of care to avoid any kinking. The cables are the same type for the Sunblind mechanismthis is the cable that runs in the inside tube of trackand for the top mechanism, which runs in the inside tube of the track.

The Drive Motors & Cables

The three drive motors sit under the upholstered rear deck. Two of the motors drive both sides of the top and one motor drives both sides of the Sunblind. It is the gear at the head of the motor that drives the cables. Here is a photo of the three motors; they mount on a metal plate on the back deck. The motors have a red plastic cap (seen on the top motor in the picture below) that can be removed to allow the top or blind to be moved manually with allen wrenches. These caps interlock the motor to the drive mechanism. If these red caps are damaged to the point of being unusable, the motors will not be able to engage the drive gears. Porsche only sells the motor with the caps as a complete unit (list price is in the $600 range). User "Targagr" from Rennlist discovered that Audi sells these same plastic caps separately (part number: 895 877 899) for a couple bucks each. 'Italic text' The photo shows the single Sunblind motor mounted and the two glass roof drive motors removed from their mounts. Visible are the three threaded mounting holes for each motor where the bolts go to hold the motors that are removed. Care must be taken not to over torque these as they strip very easily. The mounting plate is soft steel and it isnt thick enough to have sufficient threads. I stripped two of them, even being very careful. The motors gear fits in the gaps between the two lower cable tubes. In the picture below one cable is removed. The gears on the end of the motors drive the cables directly. The cable is held against the gear by the metal channels on the motor head right next to the gear. Note the motor with the blue plastic gear on it. That mechanism is what counts the revolutions and trips a switch to stop the motor in the proper spot as the roof closes. The mechanism will pause and wait for another touch of the button to close the wind deflector, and trip the second switch. The Motor control unit reverses this process.

3 of 16

7/17/2012 5:03 PM

993 - Targa Roof Operation Outline - pcarworkshop

http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation...

The motors drive the roof and blind as illustrated below. The blind is light and needs only one motor while the heavier glass top requires two

4 of 16

7/17/2012 5:03 PM

993 - Targa Roof Operation Outline - pcarworkshop

http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation...

The mounting plate has several tubes running off of it, they are steel guide tubes that route the cables to the back of the tracks. On the opposite side of each tube that feeds the back of the track, there are other steel tubes that extend a bit then have plastic extension tubes that run behind the rear interior panels to hold the loose end of the cables when the top is retracted The pictures below shows the two steel pipes: one for the blind and one for the roof going to the back of the track and the two plastic pipes that route the loose end of the cables from the other track behind the rear side trim panels.

5 of 16

7/17/2012 5:03 PM

993 - Targa Roof Operation Outline - pcarworkshop

http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation...

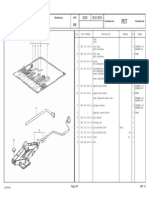

The drive cables for the blind and the glass top have plastic pieces bonded to them that carry the blind and top forward and aft. These are called Gate Guides. The picture below shows the largest of these Guides, the rear guide, which grabs and carries the rear mount of the glass roof

6 of 16

7/17/2012 5:03 PM

993 - Targa Roof Operation Outline - pcarworkshop

http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation...

Two Types of Rear Gate Guides

There are two types of Rear Gate Guides. A metal type and a plastic type. My car is a 1996 (a late 1995 build). When I went to replace the cables and Gate Guides I found that my car had metal ones, I don't think they were replaced by the previous owner, but I cannot confirm this so they may not be original. Rennlist Member Strost (Stefan) has an early Targa too (9/95 build) and it has the metal guide also. The parts I bought to replace them in 2007 are plastic, so I assume that the plastic is the updated part. No dealer parts person or service manager had any information on this update. The only part number that shows up in the PET is the plastic one, and there is no information that I could find regarding any superceding part. Even though I am still not 100% sure of which type was first I will refer to the metal Gate Guides from here on as the "earlier version" The plastic guides have a raised hook that grabs the and engages the axle plate.

On the earlier version (metal) the rear axle plates in the car had a metal sleeve with a locking pin that allowed them to engage the metal gate guides. These pins would not allow the axles to work with the plastic Guides and had to be removed. Upon removing the sleeves with the pin, the axle plates seem to be the same. I thought it odd that the old version had an extra part that had to be removed to work with a new version part, which caused me to not be totally sure of the plastic gate guides being the updated version, but it seems so, as the replacement updated axles currently being sold fit the plastic Gate Guides. See Basic Roof Height Adjustment section below for more information, and to see what the axle plate with the sleeve looks like see the photo of the broken axle plates below

7 of 16

7/17/2012 5:03 PM

993 - Targa Roof Operation Outline - pcarworkshop

http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation...

The glass roof has metal pieces bolted to it (colored blue in the photo on the right below). Bolted to these metal pieces are metal axel/roof supports (Colored red In the photo), that are grabbed by the Gate Guides and are carried forward and backward. Below left is the entire mechanism that carries the rear of the glass roof, shown mounted in the track.

As the plastic Gate Guide moves forward (right in this picture) it grabs the rear roof support, which is connected to the lever mechanism. As the roof comes to the final inch of closing, the upper round finger (A) of the lever mechanism rides along the upper part of the track. This kicks up the little shaft part of the lever (B) that rides in the lower part of the track. This lower shaft then pivots on the hinge (C) and rides up into the curved 90-degree upward slot that is riveted to the track. This is what causes the glass top to rise to the level of the rear window glass, making it flush. At this point the plastic Gate Guide lets go of the glass top as the cable mechanism continues moving forward a few inches. At the front end of the cable is another smaller Gate Guide that then triggers the wind deflector to drop.

The Cables and the letting go Mechanism

Because the glass top is driven by a single cable on each side, this cable has to perform two functions, 1) moving the glass roof and 2) raising the wind deflector. These operations have to occur at two separate times. To close the roof, the cable must pull the roof forward and into its final raised position. The cable must then release the glass roof and continue forward in order to flip up the deflector. This is accomplished by a complicated, delicate mechanism. Somehow it all actually works.

8 of 16

7/17/2012 5:03 PM

993 - Targa Roof Operation Outline - pcarworkshop

http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation...

The drawing is oversimplified, in reality the Gate Guide and Lever Mount have a groove and a rib to keep them aligned, the photos below show what they really look like. The top part shows the Guide and Lever Mount separated. The bottom shows the mechanism assembled how it would be in the track. Its position in the bottom part of the picture is where it would be as the glass top is about to close (or when the top is beginning to retract - depending on which direction it is moving). When moving rearward, the angled ramp allows the raised portion to snap under the lever, so when later it moves forward the other side of the ramp can help grab and raise the lever. The Angled ramp can then slip back under the lever when it is moving backwards.

9 of 16

7/17/2012 5:03 PM

993 - Targa Roof Operation Outline - pcarworkshop

http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation...

These pictures illustrate why it is so important not to lubricate the mechanism with any type of grease or even WD-40. Anything that could potentially goop up the delicate lock and release mechanism by hindering the locking block could cause the top to jam. If the top jams the motors can very quickly strip the drive cables. Even if the drive cables arent stripped beyond working, if the cable jumps a few gear teeth on one side the top can bind, as it isnt being pulled forward evenly. If the cable skips only a couple of teeth, the top will still slide and operate, but when it gets to the end of the cycle the wind deflector will not tightly close on the side that arrives latest, creating excessive wind noise, and it will leak.

The Visor and Front of the Glass Roof

Bonded to the front end of the same cable is another Gate Guide. When it reaches the Wind Deflector, it kicks it up. The front Gate Guide does two things, it holds a slotted plastic piece called a Gate that lifts the front of the glass roof into place and then it goes on to lift the Wind Deflector.

The front Gate Guide has a Locking Block like the rear Gate Guide to engage the Wind Deflector. This one works in reverse of the rear. It grabs the Wind Deflector mechanism by the same, but reversed, Locking Block scheme as it moves forward. This pushes the Wind Deflector up. When the cable moves backwards it pulls the Deflector down, then the locking block falls, and frees the Gate Guide of the Deflector mechanism allowing the cable to move all the way back to open the glass roof.

10 of 16

7/17/2012 5:03 PM

993 - Targa Roof Operation Outline - pcarworkshop

http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation...

The front of the roof has an axle that rides in a deep angled groove (above). When the top is pulled back the axle sits in the front of the groove. As the glass roof comes to the point where it is about to close, the top stops and the gate slides forward causing the angled groove to lift the front of the roof about 3/8ths of an inch to its closed position

This is a photo of the cable, gate, and the mechanism that raises the Wind Deflector. This photo shows clearly how the plastic guides are bonded to the drive cables. The Gate Guide is attached to the Gate via a slot that a metal tab on the gate is inserted into. (See area denoted by dotted line. The tab and slot is also visible in the previous photo above). All of this stuff is held together, and slides in the channels of the main track with the little plastic white tabs on either side. These are not visible when the assembly is in the track. The locking block is what grabs and releases the mount for the Lifting lever.

The Sunblind

The Sunblind is spring loaded and pre-tensioned when inserted in its mount, like an old window blind. This keeps it taught as it rolls back up. Unlike a regular window blind it must be supported, as it is overhead. There are three rods that are sewn into slots across the blind to support it when deployed. The ends of these rods ride in the plastic tracks on each side of the car; these tracks are clipped to the main aluminum tracks described above. The ends of the rods have little plastic football shaped guides on them. The shape enables them to enter the track smoothly as the blind unwinds.

11 of 16

7/17/2012 5:03 PM

993 - Targa Roof Operation Outline - pcarworkshop

http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation...

There are plastic Bow Guides that are bonded to the Sunblind cables that grab the blind and pull it back. To complicate the mechanism, there isnt simply one track for each side of the blind mechanism, there are two. If the blind is pulled that along the curve of the aluminum extrusion shown above in the glass roof mechanism section, the Sunblind would follow the curve of the main aluminum channel. While this would be simpler, this would reduce the headroom so Webasto decided to make two tracks, one for the blind, which sits up higher, above the aluminum track and a lower one for what they call the "Pullbow".

The Pullbow is pulled by the Bow Guide and follows the Aluminum track while the blind itself rides higher in the plastic track. The other end of the Pullbow pulls the blind and the Pullbow pivots slightly as the blind rises for headroom. In operation the plastic blind track actually rises and falls slightly as the blind rolls out. Because the track moves up and down and is very flexible, the cable also has a piece of plastic bonded to ita Track Alignment Jaw behind the Bow Guide to grab the track and keep it aligned horizontally.

The Pullbow is attached to the blind via a metal sliding piece that has a pultrusion (A) that inserts into a rectangular aluminum tube which is the support for the rear edge of the blind. The other part that sticks out (B) connects it to the Pullbow to allow the blind to be operated. (Note Targa top in photo from a simpler time when men were men and one had to get out of the car to open the top.)

12 of 16

7/17/2012 5:03 PM

993 - Targa Roof Operation Outline - pcarworkshop

http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation...

When the button is pressed, the control unit behind the rear seats looks to see if it is OK to deploy the blind (it will not if the glass roof is open). If the roof is closed, the motor reels the cables back. The Bow Guide grabs the Pullbow, which in turn grabs the end of the blind. The Pullbow swivels up as the blind rides up in the higher track. This way the drive mechanism for the blind can ride in the same extrusion as the top mechanism for rigidity, while the lightweight blind can ride in the higher track to give more headroom. There is a problem however. The plastic track is higher than the glass roof when the roof is open. To prevent the track from getting hit by the roof as it opens and closes there is a bent steel spring inserted into the back of the plastic blind track. As the roof opens and closes it pushes on the spring and the plastic track gets moved out of the way.

Basic Roof Height Adjustment

Height adjustment of the roof is done with bolts that hold what Porsche/Webasto call "axles" or "axle plates". These bolt to metal blocks that are bolted to the underside of the frame of the glass roof. In the photos below, the axles (shown in red) have plates with holes to mount them (hence the term "axle plates"). The plates are ribbed on the back and mate with ribs on the blocks bolted to the frame (colored blue in the photographs). The front axle plates have single hex bolts and the rear each have two Torx bolts holding them. Front Axles (from in cabin, and with roof removed):

Rear axle (from in cabin):

13 of 16

7/17/2012 5:03 PM

993 - Targa Roof Operation Outline - pcarworkshop

http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation...

Height adjustment is done by loosening the bolts and raising or lowering the roof in relation to the axle plates. Do not over-torque these. The ribs in the axle plates and the ribs on the blocks they attach to will hold the top from slipping, it is not necessary to tighten the bolts down as if it is simply friction between two smooth surfaces holding the roof up. If the bolts are over-torqued the low quality pot-metal the plates are made of can be compressed a bit by the hard steel bolts and weakened, especially on the rear axle plates at the rear bolt hole. Cracks can develop here and the axle can break from the plate and jam the top. Webasto has updated the part to be a little wider to give more metal where the crack occurs, and they are the slightest bit thicker overall, maybe 1/1000th of an inch, so obviously this has been an issue. Tthe newer plates don't look that much stronger than the older style, so again, be careful not to over-torque. Unfortunately the new ones (part # 993.562.579.01) list close to $300 each, ($208 at Sunset Imports as of Spring 2008). Also problems can occur from vibration loosening the bolts - Use Locktite and torque to proper specs (see TSB below). The picture below shows the differences between the old style and updated rear axle plates:

Note: In the PET there seem to be two types of rear axle plates. One type works for both left and right, one type has separate part numbers for each side. Noone can explain this to me. My car uses the type that works on both sides. There is no TSB that refers to the updated rear axle plates, but there is one for the updated front axle plates: Checking the Tightness of the Targa Roof Axle Plate refers to the updated front ones and advises on adjustment of both the front and rear. The sketch of the rear plate in the TSB looks like an updated one. The rear axle plates are easy to access; the front ones are more difficult to get to, the TSB says they are most easily accessed with the sunblind deployed a bit over halfway. I find opening the roof about 14 inches or so, and unclipping the front part of the sunblind track allows me better access. Once the axle plates are replaced, then I do final adjustment with the roof closed. There is good information in the TSB along with the information about the updated front axle plates.

14 of 16

7/17/2012 5:03 PM

993 - Targa Roof Operation Outline - pcarworkshop

http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation...

Setting the Roof Timing Stop Points

These are the three motors. The rear motor is for the sunblind. The slightly more forward rear passenger side motor and the rear drivers side motor both drive the sliding glass roof.

The motors in the picture of the rear deck on the right side have metal gears to drive the cables but the right side motor also has a big blue gear. This gear is connected to the motor drive also, and it counts revolutions. When the glass roof control button on the console is depressed the two motors are actuated, and the roof slides forward. Once the blue gear has counted a certain amount of revolutions it triggers one of the blue stop switches (see photo). This stops the motors, and therefore the roof, from moving forward. At this point the roof should be in its full forward, raised and closed position. When the console switch is pressed a second time the motors start turning until the blue gear triggers the second stop switch and stops the motor again (wind deflector in full down position.) If for some reason the blue timing gear is off buy a tooth or two the roof may stop before it is actually fully closed and raised. In other to correct this the roof position and the stop position of the motor/blue timing gear must be synchronized to the proper top position. Here are the steps to synchronize the glass roof and the stop timings: 1) The rear deck cover must be removed: a) Fold down the rear seats, taking care the seat belt receptacles are folded neatly down otherwise they can poke and do damage to the rear seat upholstery. b) Remove the four black screws and washers that retain the rear cover. c) Carefully pull out the rear cover. The felt piece where the rear deck cover meets the window cracks easily where it meets the rear deck, take care as the cover is pulled forward and out not to snag the rear felt piece. d) Disconnect the rear deck speakers once the rear cover is pulled out far enough to get under there. e) Fold the rear cover down so the speaker grills are facing the back of the front seats. This will cause the rear felt piece to be facing down, so no pressure or weight can be put on the inverted cover. This repair operation can be done with the rear deck laying in the back of the car, but is easier to avoid damage like cracking the felt piece with the cover out of the car. This adds a lot of time to this part of the procedure though, because the seat belt bolts must be removed so the belts can be fed through the slots in the rear deck.

15 of 16

7/17/2012 5:03 PM

993 - Targa Roof Operation Outline - pcarworkshop

http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation...

2) Open the glass roof, then the close the roof until it stops the first time (what should be in the roof's fully closed and raised position.) Turn the ignition key off so the switch won't work if it is accidentally touched. Note:The top mechanism takes quite a bit of power to operate, so occasionally start the car to recharge the battery, or put on a trickle charger. Operating the top 20 or 30 times can drain a battery that is not in the greatest of shape. 3) Remove the three bolts holding down the drivers side roof motor. Be careful not to rock it back and forth too much as it is lifted off. It is not that easy to move the gear as the motor is lifted off, but care should still be taken so the gear positions are not disturbed. Note: Do NOT remove both roof motors at the same time as this can cause the left and right cables to get out of synchronization. 4) Remove the red cap from the motor on the passenger's side, this will allow an allen wrench to be inserted into the motor gear assembly and the roof can be manually moved forward to the fully closed position. 5) With the allen wrench turn the gear and move the roof forward. Watch the rear axel plate (shown in red in the photo below) on one side of the car as the roof is moved

forward The roof will get to a point where it is as far forward as it will go. As the allen wrench is turned more the roof axle plate will start to rise, lifting the back of the roof. Once the roof is lifted all the way the pivot continues to move slightly forward. The motor must be turned until the axle is fully up and then must be turned a bit more. This point is critical. To find this point the motor can be turned a little more until the wind deflector is seen to start to move down. Then the motor can be backed up slightly. 6) Once it is determined that the roof is in the correct position, the motor with the blue gear can be reinstalled. Note: the bolts holding in the motors are screwed into the mounting plate which is very easy to strip, take care not to over torque. If they become strippedI stripped two of minethe holes can be tapped to the next size thread and new larger bolts can be used as the holes in the motor casings through which they feed are large enough. 7) Replace the red caps (these engage the motor to the drive gear) and test the roofs operation by hitting the roof button in short bursts. Observe if the roof is closing and stopping at the correct position. If it is not, redo steps 2 through 6 until the proper position is obtained. Note: Do not try close the wind deflector until the stop point for the roof is correct, because if the timing for the second stop is too late, the cables will be in the full far forward position and the drive motors will continue to turn, and because the cables have no where to go, this could strip the cables.

So there are the basics of how the top mechanism works, as I get to it I will add to this page more details on the top and how it comes apart and goes back together. -Andrew

Retrieved from "http://www.pcarworkshop.com/index.php/993_-_Targa_Roof_Operation_Outline" This page was last modified 20:48, 13 August 2009.

16 of 16

7/17/2012 5:03 PM

Das könnte Ihnen auch gefallen

- Porsche 356: The Engine Handbook: An Engine Assembly GuideVon EverandPorsche 356: The Engine Handbook: An Engine Assembly GuideNoch keine Bewertungen

- BMW 3-Series (E36) 1992-1999: How to Build and ModifyVon EverandBMW 3-Series (E36) 1992-1999: How to Build and ModifyBewertung: 5 von 5 Sternen5/5 (5)

- 997 PDK Oil Change ProcedureDokument11 Seiten997 PDK Oil Change ProcedureEd MoralesNoch keine Bewertungen

- F430 Error CodesDokument63 SeitenF430 Error CodesIsrael Negrete Dominguez100% (2)

- AfterSales Training - 911 Turbo GT2 GT3 Engine RepairDokument94 SeitenAfterSales Training - 911 Turbo GT2 GT3 Engine RepairPaul Williams100% (5)

- Carrera Convertible Top Side Flap Microswitch ModificationpdfDokument3 SeitenCarrera Convertible Top Side Flap Microswitch Modificationpdftalyerautoshop5432Noch keine Bewertungen

- TECHNIK491321Dokument76 SeitenTECHNIK491321Elena Guijarro de ArmasNoch keine Bewertungen

- Mercedes SLK R171 Vario Roof OperationDokument15 SeitenMercedes SLK R171 Vario Roof Operationsnshami80% (5)

- Porsche 911alignmentDokument12 SeitenPorsche 911alignmentviking911s100% (1)

- Automatic transmission oil and filter change guideDokument8 SeitenAutomatic transmission oil and filter change guideHitesh Har100% (1)

- 18672622-2PPSRMS-2010 Porsche Panamera Service Repair Manual Software-1 PDFDokument1 Seite18672622-2PPSRMS-2010 Porsche Panamera Service Repair Manual Software-1 PDFTodor NakovNoch keine Bewertungen

- Porsche Handbook Cup2009 V2 1 enDokument75 SeitenPorsche Handbook Cup2009 V2 1 enIvanTrujilloGarciaNoch keine Bewertungen

- Porsche PDFDokument3 SeitenPorsche PDFRegisAraújoAbdallaNoch keine Bewertungen

- Porsche 918 Spyder DrivetrainDokument13 SeitenPorsche 918 Spyder DrivetrainclevercogNoch keine Bewertungen

- Ferrari 250 GTE Owners ManualDokument10 SeitenFerrari 250 GTE Owners ManualWalter Reynaldo Díaz ReáteguiNoch keine Bewertungen

- 722.9 Tranny Oil Line FlushDokument3 Seiten722.9 Tranny Oil Line FlushAntonio da LuzNoch keine Bewertungen

- Catalog E46 M3 RacecarDokument31 SeitenCatalog E46 M3 RacecarblancohccNoch keine Bewertungen

- F355 engine removal procedureDokument8 SeitenF355 engine removal proceduretomNoch keine Bewertungen

- Maintenance Booklet SLK 55 AMG 2006Dokument71 SeitenMaintenance Booklet SLK 55 AMG 2006Stefano Tenzi100% (1)

- Bosch K Jetronic Fuel InjectionDokument10 SeitenBosch K Jetronic Fuel Injectionvictoson100% (5)

- 87 Test Plan EZF and LHDokument53 Seiten87 Test Plan EZF and LHjelliott48278100% (1)

- Intake System Analysis of The Ferrari 550 Maranello Using The Wave CodeDokument10 SeitenIntake System Analysis of The Ferrari 550 Maranello Using The Wave Coderudey18Noch keine Bewertungen

- 575 Maranello Error P CodesDokument906 Seiten575 Maranello Error P CodesDamien Jorgensen100% (1)

- AfterSales Training - Advanced Engine Management SystemsDokument58 SeitenAfterSales Training - Advanced Engine Management SystemsMichele Colombo100% (1)

- 09 Cooling SystemsDokument44 Seiten09 Cooling SystemsHumberto LojanNoch keine Bewertungen

- 2004 Carrera GTDokument202 Seiten2004 Carrera GTAllan CancinoNoch keine Bewertungen

- Lamborghini Aventador LP 700 4 EngDokument28 SeitenLamborghini Aventador LP 700 4 EngFelipe MartinezNoch keine Bewertungen

- 176Dokument12 Seiten176[VLVH] Vo Thanh DuyNoch keine Bewertungen

- P30 Drivetrain Repair - Sports CarDokument104 SeitenP30 Drivetrain Repair - Sports CarAllan Cancino100% (1)

- BMW E32 EDC SuspensionDokument7 SeitenBMW E32 EDC SuspensionXaockaNoch keine Bewertungen

- CIS-E Airflow Sensor Potentiometer Replacement GuideDokument2 SeitenCIS-E Airflow Sensor Potentiometer Replacement Guideazizja1100% (2)

- Porsche - Int 718 - 2017 PDFDokument75 SeitenPorsche - Int 718 - 2017 PDFSculatorNoch keine Bewertungen

- AfterSales Training - Air Cooled Engine RepairDokument72 SeitenAfterSales Training - Air Cooled Engine RepairPaul Williams100% (2)

- MED Motronic Case StudyDokument13 SeitenMED Motronic Case StudyÃmit Řajgadkar100% (1)

- 993 Usa KatalogDokument446 Seiten993 Usa KatalogGenocea CfoNoch keine Bewertungen

- 996 Wiring 1999-2000Dokument30 Seiten996 Wiring 1999-2000Van Nguyen100% (3)

- E 964 KatalogDokument578 SeitenE 964 KatalogDoru IacovescuNoch keine Bewertungen

- Brembo CatalogDokument24 SeitenBrembo CatalogMr.JohnNoch keine Bewertungen

- 911 Turbo Main Manual 144Dokument300 Seiten911 Turbo Main Manual 144Laios Alberto NicolaNoch keine Bewertungen

- Porsche Cayenne 2003-2010 fuse box diagramsDokument14 SeitenPorsche Cayenne 2003-2010 fuse box diagramsHicham Meg100% (1)

- Crankcase SuspensionDokument706 SeitenCrankcase SuspensionSteve GaddisNoch keine Bewertungen

- Interject KJetronicDokument7 SeitenInterject KJetronicccumali100% (1)

- 2002 911 GT2Dokument66 Seiten2002 911 GT2Rafa RíoNoch keine Bewertungen

- Service Sheet - Mercedes Benz W211Dokument8 SeitenService Sheet - Mercedes Benz W211Pedro ViegasNoch keine Bewertungen

- 9pa Group 0 GeneralDokument154 Seiten9pa Group 0 GeneralSebastian MunteanNoch keine Bewertungen

- Puma Race Engines - Peugeot 205 8 Valve Engine Tuning Guide: Blocks and CranksDokument11 SeitenPuma Race Engines - Peugeot 205 8 Valve Engine Tuning Guide: Blocks and Cranksspidermaan67% (3)

- SIT Cayenne 08 GB PDFDokument143 SeitenSIT Cayenne 08 GB PDFВадим ТертицаNoch keine Bewertungen

- Porsche Panamera S e Hybrid PDFDokument80 SeitenPorsche Panamera S e Hybrid PDFPancho RiveraNoch keine Bewertungen

- Lamborghini Diablo Engine Parts ManualDokument40 SeitenLamborghini Diablo Engine Parts ManualAndrei Huţanu100% (1)

- Lamborghini Aventador LP 700-4 Technical SpecificationsDokument3 SeitenLamborghini Aventador LP 700-4 Technical Specificationsapi-316832356Noch keine Bewertungen

- 2016 991 Cup Technical Manual V1 PDFDokument326 Seiten2016 991 Cup Technical Manual V1 PDFJaviJi9Noch keine Bewertungen

- Carrera GT 2 Fuel and Ignition System: GeneralDokument26 SeitenCarrera GT 2 Fuel and Ignition System: Generallamia6699Noch keine Bewertungen

- 928 Engine ControlDokument9 Seiten928 Engine Controlbenekski100% (2)

- P2146Dokument30 SeitenP2146Engine Tuning UPNoch keine Bewertungen

- Porsche Academy Training - Vehicle Quick Reference MY2007-08Dokument36 SeitenPorsche Academy Training - Vehicle Quick Reference MY2007-08Michele Colombo100% (4)

- BMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesVon EverandBMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesNoch keine Bewertungen

- 4motion With Haldex Coupling PDFDokument52 Seiten4motion With Haldex Coupling PDFJohn PolstraNoch keine Bewertungen

- Multitronic 01JDokument100 SeitenMultitronic 01JAlex DosofteiNoch keine Bewertungen

- Four Wheel Drive With Haldex Clutch / Coupling PDFDokument44 SeitenFour Wheel Drive With Haldex Clutch / Coupling PDFJohn PolstraNoch keine Bewertungen

- User Manual Porsch 996Dokument263 SeitenUser Manual Porsch 996otttiii90% (10)

- Handbrake Encoding NotesDokument1 SeiteHandbrake Encoding NotesJohn PolstraNoch keine Bewertungen

- 1500ZTB107 PDFDokument421 Seiten1500ZTB107 PDFjanosNoch keine Bewertungen

- Manual Tundra 2013Dokument36 SeitenManual Tundra 2013Juan Cristian OgaldeNoch keine Bewertungen

- Starter Delco CaterpillarDokument12 SeitenStarter Delco CaterpillarErick Peña Gonzalez100% (2)

- 81-10-2194 Sherpa MDokument2 Seiten81-10-2194 Sherpa MАлександрNoch keine Bewertungen

- Unit 11, Automotive (Industrial)Dokument2 SeitenUnit 11, Automotive (Industrial)Charly VargasNoch keine Bewertungen

- Fork Diameter Cross RefereceDokument27 SeitenFork Diameter Cross Referecestinger30au100% (1)

- Lista de Precios Unificada Cars Factory Al 29-Ago 22Dokument10 SeitenLista de Precios Unificada Cars Factory Al 29-Ago 22Amaris MedinaNoch keine Bewertungen

- BMWDokument8 SeitenBMWRam KumarNoch keine Bewertungen

- D375a 6Dokument14 SeitenD375a 6zee100% (1)

- 5E Utility Tractors 5075E John Deere USDokument5 Seiten5E Utility Tractors 5075E John Deere USHungagaNoch keine Bewertungen

- Car AssignmentDokument80 SeitenCar AssignmentVineet SharmaNoch keine Bewertungen

- 5-Speed Manual Gearbox 0A4 Jetta Golf 2005 2011 PDFDokument210 Seiten5-Speed Manual Gearbox 0A4 Jetta Golf 2005 2011 PDFrodandoNoch keine Bewertungen

- Retail Selling Price of Petrol Retail Selling Price of DieselDokument15 SeitenRetail Selling Price of Petrol Retail Selling Price of DieselUday KumarNoch keine Bewertungen

- I CDL ParticipantsDokument248 SeitenI CDL ParticipantsYogesh WadhwaNoch keine Bewertungen

- Beurteaux Seating BrochureDokument16 SeitenBeurteaux Seating BrochureArtur ERNoch keine Bewertungen

- 1974 Volkswagen Super BeetleDokument6 Seiten1974 Volkswagen Super BeetleJulz Argüelles VictoreroNoch keine Bewertungen

- W201 SA Code ListDokument106 SeitenW201 SA Code ListFotoniNoch keine Bewertungen

- 2019 Audi A3 19Dokument414 Seiten2019 Audi A3 19zo andriamiarintsoaNoch keine Bewertungen

- DDFSFDokument83 SeitenDDFSFJuan PabloNoch keine Bewertungen

- Red Cat Shockwave ManualDokument1 SeiteRed Cat Shockwave ManualGuillermoNoch keine Bewertungen

- 046 University of Alberta SpecDokument3 Seiten046 University of Alberta SpecMohammad Parvez RazaNoch keine Bewertungen

- Specifications: 2 Speeds Dropbox 2 Speeds DropboxDokument2 SeitenSpecifications: 2 Speeds Dropbox 2 Speeds DropboxTamer Elsebaei EbarhimNoch keine Bewertungen

- Rear Suspension NVH TroubleshootingDokument20 SeitenRear Suspension NVH TroubleshootingRifki AwaludinNoch keine Bewertungen

- SQ8 - TFSI 373 KW TiptronicDokument10 SeitenSQ8 - TFSI 373 KW Tiptronicvzky2016Noch keine Bewertungen

- Ford Endeavour: Take The LeadDokument4 SeitenFord Endeavour: Take The LeadAnonymous UVXO3vLNoch keine Bewertungen

- 6 Marketing Strategies of Hyundai Motors in India Abhishek V 3Dokument11 Seiten6 Marketing Strategies of Hyundai Motors in India Abhishek V 3Nandha S.KNoch keine Bewertungen

- MG DC PDF 0182Dokument250 SeitenMG DC PDF 0182kushNoch keine Bewertungen

- Mitsubishi F1C1, F1C2, W1C1: FWD & Awd CVTDokument2 SeitenMitsubishi F1C1, F1C2, W1C1: FWD & Awd CVTDhanis EganNoch keine Bewertungen

- Hybrid Vehicles Electric Vehicles Fuel Cell Electric Vehicles Traction MotorsDokument13 SeitenHybrid Vehicles Electric Vehicles Fuel Cell Electric Vehicles Traction Motorsddi11Noch keine Bewertungen

- SUPRAJITDokument10 SeitenSUPRAJITmaniamson71% (21)