Beruflich Dokumente

Kultur Dokumente

Hmma - 820 TN03 07

Hochgeladen von

Mohamed Elkharbotly0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

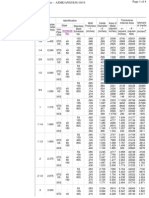

54 Ansichten0 SeitenTechnical notes

Originaltitel

HMMA_820-TN03-07

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenTechnical notes

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

54 Ansichten0 SeitenHmma - 820 TN03 07

Hochgeladen von

Mohamed ElkharbotlyTechnical notes

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 0

National Association of

Architectural Metal Manufacturers

otes TechNotes

HMMA-820 TN03-07

Guidelines for Glazing of Hollow Metal Transoms,

Sidelights and Windows

1. Hollow metal transoms, sidelights and windows are an

excellent choice at exterior locations. Proper applica-

tion of sealing methods commonly used with other

window systems will result in excellent performance. In

addition, hollow metal is a superior solution for securi-

ty, durability, thermal transfer, wind load, and seismic

performance.

2. Hollow metal shall be manufactured in compliance with

HMMA Guide Specifications and TechNotes HMMA-820

TN02-03, Continuously Welded Frames. It should be

noted that a continuously welded assembly alone does

not ensure a watertight condition. Whenever possible, it

is strongly recommended that glazing material be

installed on the exterior rabbet of the frame assembly,

which will help act as a deterrent to water penetration.

3. The Hollow Metal manufacturer does not control the

installation of their product or application of perimeter

caulking, joint sealants, or glazing materials. This work

should be specified in the Installation / Glass / Glazing

/ Caulking section of the specifications.

4. These are recommended guidelines for the prevention

of air and water infiltration for exterior hollow metal. A

primary source of leakage is the interface of the wall

and the hollow metal frame. The contractor must

ensure proper flashing and sealant procedures are fol-

lowed as specified in the contract documents. The

glazing installer must also follow proper caulking meth-

ods during installation of glazing, panels, and/or opera-

ble window units. To ensure that glazing, panels,

and/or operable window units are sealed properly,

these are to be installed in the field.

5. The attached figures and accompanying text show

methods successfully tested to the following stan-

dards: ASTM E283, Air Infiltration, ASTM E331, Static

Water Penetration, and AAMA 501.1, Dynamic Water

Penetration.

6. The sealant tested was Corning 795 silicone. It is the

responsibility of the general contractor to ensure that this

or an equivalent sealant is used. Silicone sealant cannot

be painted. Colored silicone sealants are available.

1. Space between edge of glass and steel frame shall

receive a continuous heel bead of sealant. Care shall

be taken to ensure adhesion of sealant to glass edge

and steel frame as shown in Figure 1A.

2. At the same time as the heel bead is applied, the rab-

bet area at all joints shall be caulked. Caulking shall be

a continuous homogeneous bead from the heel bead

to the face of the frame as shown in Figure 1B.

Removable Glass Stop on Exterior Side (Preferred Method)

18783_TN03-07.qxp 8/17/07 12:41 PM Page 1

3. Care shall be taken to ensure that each piece of

removable glass stop channel is reinstalled at the

same location and direction. This will ensure that glass

stop screws go back into the original holes.

4. Prior to reinstalling glass stop screws, caulk threads as

shown in Figure 1A.

5. It is recommended that horizontal mullions and sills be

sloped to shed water or formed with a smaller rabbet

dimension at the exterior side to minimize exposed

surface areas as shown in Figure 1C, 1D.

Removable Stop on Interior Side:

1. Whenever possible, it is strongly recommended that

the glazing material be installed on the exterior rabbet

of the frame assembly, which will act as a deterrent to

water penetration. However when glazing on the interi-

or side is required we recommend the following steps

be taken.

2. Continuous cap bead around perimeter of glass on

exterior side as shown in Figure 2A.

3. At the same time as the cap bead is applied, the soffit,

stop and rabbet area at all joints shall be caulked.

Caulking shall be a continuous homogeneous bead

from the cap bead to the face of the frame as shown

in Figure 2B.

18783_TN03-07.qxp 8/17/07 12:41 PM Page 2

4. It is recommended that horizontal mullions and sills be

sloped to shed water as shown in Figure 2C, 2D.

Sill Condition at Floor:

1. Sill channel shall be continuously sealed as shown in

Figure 3A and 3B.

2. All vertical frame members shall be continuously sealed

around profile at floor as shown in Figure 3C.

18783_TN03-07.qxp 8/17/07 12:41 PM Page 3

Operable Window Inserts

1. All exposed seams shall be continuously sealed as

shown in Figure 4.

2. Water shall not be permitted to weep onto the hollow

metal frame members at an area that has not been

sealed.

18783_TN03-07.qxp 8/17/07 12:42 PM Page 4

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Baseline Schedule Narrative ReportDokument6 SeitenBaseline Schedule Narrative ReportMuhammad63% (8)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 1.1 General Overview of Surface StructuresDokument23 Seiten1.1 General Overview of Surface StructuresCivilEngClub100% (6)

- Pcin SoftwareDokument27 SeitenPcin SoftwareManish TiwariNoch keine Bewertungen

- RAL - Color CardDokument1 SeiteRAL - Color CardMohamed ElkharbotlyNoch keine Bewertungen

- Evolution EVC-H Conventional Heat Detector: Base: UB-4 UB-4-EV UB-4SD UB-6 Stb-4Se-Ev Stb-4Se-Sw-EvDokument1 SeiteEvolution EVC-H Conventional Heat Detector: Base: UB-4 UB-4-EV UB-4SD UB-6 Stb-4Se-Ev Stb-4Se-Sw-EvMohamed ElkharbotlyNoch keine Bewertungen

- Hollow Metal DoorDokument42 SeitenHollow Metal DoorMohamed ElkharbotlyNoch keine Bewertungen

- PowerWizard GB 2012Dokument4 SeitenPowerWizard GB 2012Mohamed ElkharbotlyNoch keine Bewertungen

- 2011 CatalogeDokument28 Seiten2011 CatalogeMohamed ElkharbotlyNoch keine Bewertungen

- Schedule No.: - T - D - A - ADokument4 SeitenSchedule No.: - T - D - A - AMohamed ElkharbotlyNoch keine Bewertungen

- Schematic For DriveDokument1 SeiteSchematic For DriveMohamed ElkharbotlyNoch keine Bewertungen

- Ffid Re: ' (Ffis##Dokument1 SeiteFfid Re: ' (Ffis##Mohamed ElkharbotlyNoch keine Bewertungen

- ST Paul-Cathedral PDFDokument15 SeitenST Paul-Cathedral PDFMD ModeloNoch keine Bewertungen

- Yacht Design - Interior Design - Naval ArchitectureDokument15 SeitenYacht Design - Interior Design - Naval ArchitectureVirginia MarkovicNoch keine Bewertungen

- Ghana Building Code - Part 9.5 PDFDokument51 SeitenGhana Building Code - Part 9.5 PDFvasvukNoch keine Bewertungen

- Dwln251 Wireless Lans: School of EngineeringDokument5 SeitenDwln251 Wireless Lans: School of EngineeringAndy BlackmurNoch keine Bewertungen

- Ep 3 51Dokument1.218 SeitenEp 3 51Reece WheatleyNoch keine Bewertungen

- Osmaster M - Learning Application Integrated With Cloud Computing For Principles of Operating System CSC520 - 3 PDFDokument118 SeitenOsmaster M - Learning Application Integrated With Cloud Computing For Principles of Operating System CSC520 - 3 PDFJimmy GolbergNoch keine Bewertungen

- Smartcare Joint Tape (Roof Tape) - Code 5402 5403 5404 PDFDokument2 SeitenSmartcare Joint Tape (Roof Tape) - Code 5402 5403 5404 PDFGopal KrishnanNoch keine Bewertungen

- Design of Concrete Structures 15edDokument4 SeitenDesign of Concrete Structures 15ederjuniorsanjipNoch keine Bewertungen

- Scheme Development: Conceptual Design of Truss and Column SolutionsDokument9 SeitenScheme Development: Conceptual Design of Truss and Column SolutionsRam BabuNoch keine Bewertungen

- Report of Office ManagementDokument48 SeitenReport of Office ManagementayabadakalNoch keine Bewertungen

- Tempcon Sandwich Panel BrochureDokument10 SeitenTempcon Sandwich Panel BrochureskmeshramNoch keine Bewertungen

- Boysen EstimatesDokument36 SeitenBoysen Estimatesdasmin anne depacaquiboNoch keine Bewertungen

- Plagiarism ReportDokument27 SeitenPlagiarism ReportKuldeep MunjaniNoch keine Bewertungen

- GSM Call FlowDokument2 SeitenGSM Call Flownagendra_badamNoch keine Bewertungen

- KPI Library - Definitions, FormulaDokument36 SeitenKPI Library - Definitions, Formulaমোহাম্মাদ নাবিল নূর0% (1)

- Intro. 2 Command Line Interfaces: Data Link University CollegeDokument23 SeitenIntro. 2 Command Line Interfaces: Data Link University CollegeSefakor AwuramaNoch keine Bewertungen

- Bob Smeets Network Virtualisation and Cloud OrchestrationDokument11 SeitenBob Smeets Network Virtualisation and Cloud OrchestrationAndrea StefanelliNoch keine Bewertungen

- Wagner Nick - Moving To Oracle 10g How To Eliminate DowntimeDokument28 SeitenWagner Nick - Moving To Oracle 10g How To Eliminate DowntimeTamil100% (1)

- How To Install A MUI Language CAB File in Windows 10Dokument7 SeitenHow To Install A MUI Language CAB File in Windows 10myke0505Noch keine Bewertungen

- TSSM's Bhivarabai Sawant College of Engineering and Research, Narhe, Pune-41 Department of Civil EngineeringDokument2 SeitenTSSM's Bhivarabai Sawant College of Engineering and Research, Narhe, Pune-41 Department of Civil EngineeringGiridhari ChandrabansiNoch keine Bewertungen

- Netvertex Use CasesDokument66 SeitenNetvertex Use CasesAniket UmekarNoch keine Bewertungen

- Standard Calculation For Outdoor Lighting PDFDokument7 SeitenStandard Calculation For Outdoor Lighting PDFankit50% (2)

- Rafiq Seminar ReportDokument24 SeitenRafiq Seminar Reportrafiq mirNoch keine Bewertungen

- Hot Work ProgramDokument14 SeitenHot Work ProgramImtiyaz AkhtarNoch keine Bewertungen

- Advantages of Powder Coating vs. Wet PaintDokument6 SeitenAdvantages of Powder Coating vs. Wet PaintAlekxNoch keine Bewertungen

- Paris MouDokument24 SeitenParis MouPrince DhakaNoch keine Bewertungen

- TextDokument15 SeitenTextNathan PellingNoch keine Bewertungen

- Tutorial C30Dokument7 SeitenTutorial C30Fabio Ferreira AngaritaNoch keine Bewertungen