Beruflich Dokumente

Kultur Dokumente

Pawan Report

Hochgeladen von

Pawan KumarCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pawan Report

Hochgeladen von

Pawan KumarCopyright:

Verfügbare Formate

About company Infra Support is a professionally managed multi disciplinary organization providing engineering consultancy services in the field

of Infrastructure, Transportation and Development projects. There can be many rationales for the existence of an organization, but for Infra support there is only one rationale to provide excellence oriented services to build world-class infrastructure.

Infra support has a dynamic team who has vast and rich experience in diversified fields of infrastructure development. Be it Highways, Expressways, Municipal Roads, Transport Planning, Pavement Management, infrastructure development, Area Development, Housing Development the list goes on.

Infra support has provided services for many projects in India and abroad. We have long list of satisfied clients ranging from Pvt. Companies to Govt. organizations.

Effective project management and construction supervision is a key aspect in completing the project successfully. Transferring designs and drawings to reality, finding solutions to field problems, construction planning, executing with high precession and completing within the stipulated time is the essence of construction supervision and project management. Infra support PMC team enables clients to focus on their core business, with the assurance that their project goals will be successfully achieved. We ensure that a qualified and dedicated team of professionals is assembled to suit the specific project needs. We then provide a focal point for the client, ensuring clear communication, overall quality control and simplified project administration.

About Project It is a facility for the Karnataka police department for training recruits, the project comprises of building various buildings required for the same purpose. It has a spread of 32 acres, it is divided

into many phases out of which dining block, admin block, hostel block and parade ground are being constructed at first phase.

Internship Activities 1.Quality control monitoring 2.Quantity Estimation of dining block 3.Planning of dining block using msp

Quality control monitoring Quality control during construction consists largely of ensuring conformance to the original design and specifications, which were agreed on during planning of the facility. QC monitoring was done for following 1. Concreting 2. Plastering 3. Tile laying 4. Masonry 5. Windows Concreting The following components were checked before concreting 1. Shuttering Inspection 2. Steel placement 3. Concrete placement 4. Curing of concrete

1. Shuttering Inspection Shuttering is a temporary support provided for placing Steel reinforcement and to provide a platform for laying green concrete and supporting the same till concrete hardens and gains design strength. The quality of surface finish of hardened concrete depends on the surface of shuttering, as green concrete takes the shape of shuttering, so it is necessary to have a smooth surface of shuttering without any deformities, any leakages of slurry will result in honey combing of concrete resulting in loss of strength. Shuttering was made out of MS steel plates supported on steel jacks and acrospans as compression and flexure members respectively. Visual inspection was carried to check the following a. Deformities of the plates b. Beam dimensions c. Possible slurry leakages

Corrective measures adopted a. Deformed plates are replaced or hammered to correct deformity b. Beam dimensions are checked for breadth and with of the beam according to structural drawings. c. Possible Slurry leakage points were covered using masking tape and fillers.

2. Steel Reinforcement checking R.C.C is a composite material of steel and cement concrete. Steel takes the tension concrete takes compression, there by maintaining equilibrium. There for inspection of steel is very important to check if the placement of steel is according to the drawings & conforming to IS codes. Steel was checked for following a. Diameter and length of steel as per drawings b. Rusting of steel c. Cover blocks d. Presence of dirt or debris e. Provision of chairs or spacers f. Lapping length

Corrective measures adopted a. Checked for diameter and length if they are provided as per drawing or if there are any deviations. b. Rust is removed by brushing using wire brushes c. Cement cover blocks of M40 strength was used to provide clear cover at the rate of 8 per square meter. d. Dirt and debris were removed using brush and manually

e. Chairs were provided in roof steel to maintain the spacing between top and bottom reinforcement 3. Concrete Placement Placing of concrete is a very important operation, concrete starts setting as soon as it comes into contact with water, so the concrete has to be placed at the required place as soon as it is mixed with water. At site RMC Ready mix concrete was used which was delivered to site using transit mixers and placed using boom placer or concrete pump. Concrete is densified using a needle vibrator of 60mm size and by using a finishing trowel surface is leveled A small rod is bent to the required thickness and checked for thickness of concrete. The following were checked during concreting. a. Slump of concrete b. Batching sheet of concrete

Corrective measures adopted if non-conformance 1. Slump required for placement of concrete is 80-100 mm, if there is a marginal higher slump than specified, transit mixer was rotated vigorously to reduce the slump, if there was a very high slump then the truck was rejected, similarly if the slump is lower than specified range truck was rejected and sent back to the batching plant. 2. Batching sheet was checked for the contents as per specified concrete mix design, and time of mixing was checked if it is not too late before it is placed, i.e 1 hour after mixing if without admixture and 3 hours with addition of admixtures.

4. Curing of concrete Concrete takes 28 days to gain its full strength after mixing. Curing is carried out to ensure the cement hydrates fully and gains its design strength. Curing for columns was done by tying a jute cloth around columns and wetting them periodically to control temperature. Slabs were cured by ponding method, water was being filled up in the temporary bunds periodically. Shuttering were removed after 3 days after concrete placement and for slabs shuttering were removed after 14 days after concrete placement.

Das könnte Ihnen auch gefallen

- Concrete Structures: Repair, Rehabilitation and StrengtheningVon EverandConcrete Structures: Repair, Rehabilitation and StrengtheningNoch keine Bewertungen

- Construction EstimateDokument42 SeitenConstruction EstimateAngelica GicomNoch keine Bewertungen

- The Views Tangent Pile-Method StatementDokument5 SeitenThe Views Tangent Pile-Method Statementaliengineer953Noch keine Bewertungen

- Method Statement For Concrete WorkDokument6 SeitenMethod Statement For Concrete WorktotA ahmedNoch keine Bewertungen

- 175 Civil Engineering Interview Questions For Civil EngineerDokument25 Seiten175 Civil Engineering Interview Questions For Civil EngineerApon khan0% (1)

- G. ACI 360R-06 Brings Slabs On Ground Into The 21st Century - Art McKinney PDFDokument2 SeitenG. ACI 360R-06 Brings Slabs On Ground Into The 21st Century - Art McKinney PDFinitbashNoch keine Bewertungen

- W5b-IBS - TILT UP CONSTRUCTIONDokument16 SeitenW5b-IBS - TILT UP CONSTRUCTIONIkhwan HasiffNoch keine Bewertungen

- PRECAST FLAT PANEL SYSTEM CONSTRUCTIONDokument12 SeitenPRECAST FLAT PANEL SYSTEM CONSTRUCTIONShreenidhi Joshi100% (2)

- OJT2 Vertical (Orchard Residences)Dokument89 SeitenOJT2 Vertical (Orchard Residences)Jansen Paul Sanidad Arista100% (1)

- Physics ExamDokument30 SeitenPhysics Examjomar bolasocNoch keine Bewertungen

- Site Visit ReportDokument15 SeitenSite Visit ReportKaushal PatelNoch keine Bewertungen

- Suspended Manual-English-Volume 3-Part 3 - Construction ManualDokument106 SeitenSuspended Manual-English-Volume 3-Part 3 - Construction ManualkoklenderNoch keine Bewertungen

- Proposed Method Statement For Yangon CCRDokument31 SeitenProposed Method Statement For Yangon CCRMyo Lwin100% (1)

- Method Statement for Footing Concrete PourDokument4 SeitenMethod Statement for Footing Concrete PourRizky V 'dHee'Noch keine Bewertungen

- Common Mistake by Engineers During RCC WorksDokument4 SeitenCommon Mistake by Engineers During RCC WorksAnonymous P7VckOJZUgNoch keine Bewertungen

- Method Statement Footing Concrete PourDokument6 SeitenMethod Statement Footing Concrete PourNino Celso AstilleroNoch keine Bewertungen

- TMC 421 PDFDokument82 SeitenTMC 421 PDFJamie MooreNoch keine Bewertungen

- Concrete BasicsDokument56 SeitenConcrete Basicsengcecbepc100% (6)

- ESAB Welding HandbookDokument31 SeitenESAB Welding Handbookhooky1100% (4)

- Civil Engineering Industrial Training Report (Piling and Road)Dokument30 SeitenCivil Engineering Industrial Training Report (Piling and Road)Bshfirnaudz80% (20)

- Construction Method of StatementDokument11 SeitenConstruction Method of Statementperunding thd100% (2)

- Methods of Reinforced Concrete ConstructionDokument25 SeitenMethods of Reinforced Concrete ConstructionIra MejiaNoch keine Bewertungen

- Modernize Customer Service with a Cloud-Based Contact CenterDokument11 SeitenModernize Customer Service with a Cloud-Based Contact CenterMishNoch keine Bewertungen

- PDVSA Engineering Design Manual Volume 9–I Process AnalyzersDokument25 SeitenPDVSA Engineering Design Manual Volume 9–I Process AnalyzersAlberto Enrique De Santa Anna CampderáNoch keine Bewertungen

- NO.06BMethod Statement For Gravity Retaining Walls Using C20 Contrete Rev.aDokument10 SeitenNO.06BMethod Statement For Gravity Retaining Walls Using C20 Contrete Rev.aisurupushNoch keine Bewertungen

- Highway Project ManagementDokument15 SeitenHighway Project Managementsuhas vermaNoch keine Bewertungen

- Building Construction ReportDokument15 SeitenBuilding Construction ReportDevendra SharmaNoch keine Bewertungen

- Method Statement For Casting, Prestressing & Grounting of PSC GirdersDokument15 SeitenMethod Statement For Casting, Prestressing & Grounting of PSC Girdersrohit singhNoch keine Bewertungen

- Work MethodDokument4 SeitenWork MethodYahyaNoch keine Bewertungen

- PileDokument5 SeitenPileSuman NakarmiNoch keine Bewertungen

- Concrete ReportDokument11 SeitenConcrete ReportSANTOSH GAIKWADNoch keine Bewertungen

- G - 1 Observation Report InternshpDokument13 SeitenG - 1 Observation Report Internshpgerearegawi721Noch keine Bewertungen

- Wood FlooringDokument5 SeitenWood FlooringYunitaNoch keine Bewertungen

- RajatDokument23 SeitenRajatShah PriyamNoch keine Bewertungen

- 303ENG20006 - S. WijesiriDokument9 Seiten303ENG20006 - S. WijesirishalukaNoch keine Bewertungen

- BALJOT IndustrialDokument44 SeitenBALJOT IndustrialHarmeet Singh100% (1)

- High-performance concrete used in Millau Viaduct constructionDokument10 SeitenHigh-performance concrete used in Millau Viaduct constructionRohit RahulNoch keine Bewertungen

- Sequatchie Concrete Service: Precast Prestressed Hollow Core Concrete Floor and Roof Systems Design ManualDokument31 SeitenSequatchie Concrete Service: Precast Prestressed Hollow Core Concrete Floor and Roof Systems Design ManualNirmal KishorNoch keine Bewertungen

- Marriot Grand Ballroom Concrete Works: Project Title: Contract Package No. Document TitleDokument10 SeitenMarriot Grand Ballroom Concrete Works: Project Title: Contract Package No. Document TitleImho TepNoch keine Bewertungen

- Government Polytechnic Civil Engineering Building Cracks Investigation and Repair ReportDokument10 SeitenGovernment Polytechnic Civil Engineering Building Cracks Investigation and Repair ReportJoshi MayurNoch keine Bewertungen

- A RC Filler Slab With Non-Autoclaved Cellular Concrete Blocks For Sustainable ConstructionDokument8 SeitenA RC Filler Slab With Non-Autoclaved Cellular Concrete Blocks For Sustainable ConstructionShailendra Mark EkkaNoch keine Bewertungen

- 150 IndDokument13 Seiten150 Ind2022486166Noch keine Bewertungen

- What Is Distress of Concrete and Its Remedial MeasuresDokument5 SeitenWhat Is Distress of Concrete and Its Remedial MeasuresTejas DoshiNoch keine Bewertungen

- PWD Handbook CH 40 - Placement - of - ConcreteDokument61 SeitenPWD Handbook CH 40 - Placement - of - ConcreteaesirNoch keine Bewertungen

- Building Construction and Techniques: Sam College of Engineering & Technology, BhopalDokument15 SeitenBuilding Construction and Techniques: Sam College of Engineering & Technology, Bhopalashi ashiNoch keine Bewertungen

- Portland Cement PavementDokument36 SeitenPortland Cement PavementMenchebelle Grace Talha TabarnoNoch keine Bewertungen

- Applications of Self Compacting ConcreteDokument9 SeitenApplications of Self Compacting ConcreteRizalPurnamaNoch keine Bewertungen

- Industrial Internship Presentation 1Dokument30 SeitenIndustrial Internship Presentation 1ATHARVA BAIS100% (1)

- Civil InternshipDokument44 SeitenCivil InternshipShah PriyamNoch keine Bewertungen

- L.D College of Engineering: A Report On Construction Site VisitDokument15 SeitenL.D College of Engineering: A Report On Construction Site VisitNeel TurkhiyaNoch keine Bewertungen

- Industrial Training Report on Construction ProjectDokument24 SeitenIndustrial Training Report on Construction Projectjasekan.dc100% (1)

- Brick Work SpecificationsDokument9 SeitenBrick Work SpecificationsPrasidh Choudhary100% (3)

- Concrete Technologypart 1Dokument8 SeitenConcrete Technologypart 1Marmik JavareNoch keine Bewertungen

- Mr. Pioc General SpecificationsDokument11 SeitenMr. Pioc General SpecificationsErick Anopol Del MonteNoch keine Bewertungen

- Tupi NHSDokument6 SeitenTupi NHSRimar LiguanNoch keine Bewertungen

- Construction MethodologyDokument6 SeitenConstruction Methodologyadrianalbacete75Noch keine Bewertungen

- Precast ConcreteDokument5 SeitenPrecast ConcreteSurya TejNoch keine Bewertungen

- Test 3 FinalDokument8 SeitenTest 3 FinaladithyaNoch keine Bewertungen

- D345-MS for Block Work - 05.01.2023Dokument7 SeitenD345-MS for Block Work - 05.01.2023naseerdropboxNoch keine Bewertungen

- Precast Segment Study of Hyderabad Metro Rail ProjectDokument66 SeitenPrecast Segment Study of Hyderabad Metro Rail Projectashwini0393Noch keine Bewertungen

- BY Pravin Kr. GauravDokument27 SeitenBY Pravin Kr. Gaurav2K19/BMBA/13 RITIKANoch keine Bewertungen

- Construction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDokument23 SeitenConstruction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDevendra SharmaNoch keine Bewertungen

- Pre Pour and Post Pour Concrete InspectionDokument6 SeitenPre Pour and Post Pour Concrete InspectionBBGNoch keine Bewertungen

- Ashwani Aaeesha Oct'18 (Site Visit Report)Dokument15 SeitenAshwani Aaeesha Oct'18 (Site Visit Report)Madan GopalNoch keine Bewertungen

- Methodology of WorkDokument9 SeitenMethodology of WorkMekonen YeteshaNoch keine Bewertungen

- 01Dokument9 Seiten01ansal mtechNoch keine Bewertungen

- Expert Witness ReportDokument21 SeitenExpert Witness Reportguanfanggei64Noch keine Bewertungen

- Experimental Study On Geo-Polymer Concrete Incorporating GGBSDokument5 SeitenExperimental Study On Geo-Polymer Concrete Incorporating GGBSPawan KumarNoch keine Bewertungen

- Plastic Waste Insulation Re-Use PETDokument29 SeitenPlastic Waste Insulation Re-Use PETPawan KumarNoch keine Bewertungen

- ExcavatorsDokument41 SeitenExcavatorsPawan KumarNoch keine Bewertungen

- Assignment - Iv Examples of Design of Transformer: W 2 M 2 T W WDokument1 SeiteAssignment - Iv Examples of Design of Transformer: W 2 M 2 T W Wiamketul6340Noch keine Bewertungen

- Tabla 1 Engine ControlDokument2 SeitenTabla 1 Engine Controljulio montenegroNoch keine Bewertungen

- Node diagnostics report for RBS6601WDokument9 SeitenNode diagnostics report for RBS6601WWilson DiazNoch keine Bewertungen

- Simucube 2 Quick Release GuideDokument7 SeitenSimucube 2 Quick Release Guideemyrs12Noch keine Bewertungen

- Ea80 Series PDFDokument82 SeitenEa80 Series PDFAnca MunteanuNoch keine Bewertungen

- Lec 958975Dokument19 SeitenLec 958975Rajasekar PichaimuthuNoch keine Bewertungen

- FAA Significant Regulatory DifferencesDokument3 SeitenFAA Significant Regulatory DifferencesOpteron K.Noch keine Bewertungen

- Concrete: Concrete Is A Composite Material Composed of Fine and CoarseDokument36 SeitenConcrete: Concrete Is A Composite Material Composed of Fine and CoarseclubmailusNoch keine Bewertungen

- Cs 180 Notes UCLADokument3 SeitenCs 180 Notes UCLAnattaq12345Noch keine Bewertungen

- SW-TS40T Sub-Miniature Toggle SwitchesDokument4 SeitenSW-TS40T Sub-Miniature Toggle SwitchesVALTERNoch keine Bewertungen

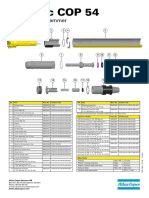

- 9853 1239 01 - COP 54 Service Poster - LOWDokument1 Seite9853 1239 01 - COP 54 Service Poster - LOWValourdos LukasNoch keine Bewertungen

- Wireless Mouse m325 Quick Start GuideDokument2 SeitenWireless Mouse m325 Quick Start GuideFabolos 9Noch keine Bewertungen

- How rock layers are formedDokument3 SeitenHow rock layers are formedAlemar AllecerNoch keine Bewertungen

- Cassette toilet spare parts guide for models C2, C3 and C4Dokument21 SeitenCassette toilet spare parts guide for models C2, C3 and C4georgedragosNoch keine Bewertungen

- Online Institute Reporting Slip of The Application Number - 200310422837 PDFDokument1 SeiteOnline Institute Reporting Slip of The Application Number - 200310422837 PDFRohith RohanNoch keine Bewertungen

- InverterDokument8 SeitenInverterrajinipre-1Noch keine Bewertungen

- NTP35N15 Power MOSFET Features and SpecificationsDokument7 SeitenNTP35N15 Power MOSFET Features and SpecificationsChristine GomezNoch keine Bewertungen

- Strength of Pressure Vessels With Ellipsoidal HeadsDokument8 SeitenStrength of Pressure Vessels With Ellipsoidal Headsنصرالدين ادريسNoch keine Bewertungen

- Cotta Transfer Case Lube PlanDokument3 SeitenCotta Transfer Case Lube PlanMatias Alfredo Contreras KöbrichNoch keine Bewertungen

- Unit-I: Introduction To J2EEDokument29 SeitenUnit-I: Introduction To J2EEsurakshaNoch keine Bewertungen

- Manual Servicio SubaruDokument5.963 SeitenManual Servicio SubaruCristian Mauricio Alarcon RojasNoch keine Bewertungen

- Ultrasonic Testing Level 2 MCQsDokument8 SeitenUltrasonic Testing Level 2 MCQspandab BkNoch keine Bewertungen

- Master Opp GaveDokument84 SeitenMaster Opp GaveRizki Al AyyubiNoch keine Bewertungen

- 49 CFR Ch. I (10-1-11 Edition) 173.318Dokument5 Seiten49 CFR Ch. I (10-1-11 Edition) 173.318MauricioNoch keine Bewertungen