Beruflich Dokumente

Kultur Dokumente

En Ps Turnkey Solution Cs

Hochgeladen von

california96Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

En Ps Turnkey Solution Cs

Hochgeladen von

california96Copyright:

Verfügbare Formate

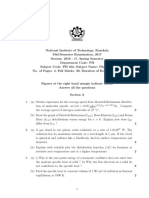

Case Study

Medium Voltage Turnkey Solution for Edmonton Substation

Scope: Design, manufacture, delivery, installation, testing and commissioning of a 22kV substation. End Customer: Ergon Energy Location: Cairns, Queensland

Ergon Energy required a green-field substation in the southern suburbs of Cairns in response to sharp increase in power demand caused by large-scale domestic and commercial development in the greater Cairns area. Initially, the Ergon Energy specified a 22kV switching station with provision for a subsequent upgrade to a 132/22kV zone substation. Siemens won the contract to provide a complete turnkey solution. The exception was the two storey masonry control building built to a standard local design for the tropical, maritime and cyclonic environment. Siemens was responsible for the design, manufacture, supply, installation and commissioning the indoor 22kV switchgear, protection and control, power, control and communications cabling, auxiliary systems and 22kV 8.6MVAr Capacitor Bank housed in an outdoor marine-grade aluminium panel. The inherently safe and reliable design of the Siemens 8BK20 switchboard (complete with vacuum circuit breakers) was chosen to meet the clients expectations. The circuit breakers are free from major maintenance, extending the asset life and lowering life cycle costs. The 8BK20 allows all operations to be conducted behind closed high voltage doors, ensuring maximum operator safety. The switchgear is based on a fully-type-tested design and is rated to withstand internal arcing. The board with ratings of 22/50/125kV, 2000A, 16kA/ 3 seconds was manufactured in the Siemens Jakarta factory. The 16 panels were divided into three bus sections to allow the client additional flexibility with future operational isolations. The secondary fit-out of the LV compartment of the 22kV switchboard was implemented in a subcontractors workshop in Melbourne. The project management team implemented our highest standards of project delivery, according to ISO9001 and our own PM@PTD processes and training. Our project management team produced quality plans, occupational health and safety and environmental plans tailored for the project, site conditions and client requirements. The engineering and design was prepared by Siemens in Melbourne, compliant with client standards but customised for Siemens switchgear and protection and control equipment.

Energy

Power Solutions

Siemens Ltd 2008. All rights reserved.

The electrical package of drawings for the complete substation achieved Approved for Construction by using a co-operative approach with the clients asset, power systems and communications people. The latest generation of Siemens Siprotec 7SJ6 protection relays and bay controllers ensured Ergon Energy innovative protection, control and communications solutions. For the first time, Ergon Energy was prepared to relinquish the mandatory requirement for physical lights, pushbutton and selector switches for 22kV CB control and alarming. The clients operators were given on-site training in the remote and local control of the substation via passwords for authorisation, keypads for scrolling annunciation pages on a screen, calling up a measured value page, selecting dynamic icons on a graphical display to initiate switching, etc. Even though the new way of operating the substation was initially met some with resistance from the Ergon field operators, they soon became accustomed via the hands-on training and the intuitive assistance given by the equipment. To ensure a quality solution, very prescriptive, extensive Factory Acceptance Testing (FAT) protocols were prepared in advance. The Siemens methodology required that an integrated FAT be conducted. Our interpretation of an integrated FAT is that, if physically possible, all product packages including the 22kV switchgear, protection and control equipment and auxiliary systems are connected by inter-panel wiring in a workshop environment and under the watchful eye of the client. In this manner protection trips, alarms, signalling, measured values, control commands were accurately processed and communicated to the various constituents as per the design requirements and duly recorded and witnessed in the FAT protocol documentation. As the consequence the site testing and commissioning (after connection of cables) was relatively straight forward. Signals to the master station in Cairns were extensively tested to the satisfaction of the Engineer. Subsequently, energisation of the switchboard and the substation feeder cut-overs process was undertaken by the client. The client commended Siemens for delivering a quality, innovative substation with all key parameters being delivered including delivery within the project time frame and providing easy to read drawings and documentation.

Energy

Power Solutions

Siemens Ltd 2008. All rights reserved.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Organic Light Emitting Transistor (OLET)Dokument7 SeitenOrganic Light Emitting Transistor (OLET)Alvin FarizNoch keine Bewertungen

- Megasan-Catalog CompressedDokument16 SeitenMegasan-Catalog CompressedCasamed ServiceNoch keine Bewertungen

- Lesson 12a - Et332bDokument23 SeitenLesson 12a - Et332bLawiii KkkNoch keine Bewertungen

- PH102Dokument2 SeitenPH102Shobhit ParkiNoch keine Bewertungen

- b2 Symmetry and RelativityDokument70 Seitenb2 Symmetry and RelativityAndrew OrrNoch keine Bewertungen

- Traction Drive HES880 - Flyer - 3AUA0000161471 - RevF - EN PDFDokument2 SeitenTraction Drive HES880 - Flyer - 3AUA0000161471 - RevF - EN PDFjalilemadiNoch keine Bewertungen

- 2005 June Physics 2h PDFDokument24 Seiten2005 June Physics 2h PDFTatenda ChimwandaNoch keine Bewertungen

- France en Dec. 2022 v3Dokument37 SeitenFrance en Dec. 2022 v3Tarek OsmanNoch keine Bewertungen

- Design - Guide Elastomers and ThermoplasticsDokument117 SeitenDesign - Guide Elastomers and ThermoplasticsJuan Miguel CalzadaNoch keine Bewertungen

- Environmental and Social Impacts of Solar Energy: A View Point With Reference To India Abhishek Gawande & Pradeep ChaudhryDokument11 SeitenEnvironmental and Social Impacts of Solar Energy: A View Point With Reference To India Abhishek Gawande & Pradeep ChaudhrySafikul HossainNoch keine Bewertungen

- Maruti Esteem Mpi Engine PDFDokument18 SeitenMaruti Esteem Mpi Engine PDFVaandu PiplupNoch keine Bewertungen

- Four Bar Linkage Knee Analysis: by Michael P. Greene, B.S., M.E., C.P.ODokument10 SeitenFour Bar Linkage Knee Analysis: by Michael P. Greene, B.S., M.E., C.P.ObaksoNoch keine Bewertungen

- Essentials of Economics, 10th Edition (2016)Dokument468 SeitenEssentials of Economics, 10th Edition (2016)Luis EstradaNoch keine Bewertungen

- Capacitors: Publishing As Pearson (Imprint) BoylestadDokument71 SeitenCapacitors: Publishing As Pearson (Imprint) BoylestadFaisal UddinNoch keine Bewertungen

- API Standards ListDokument9 SeitenAPI Standards ListSohail Aziz Ahmad MalikNoch keine Bewertungen

- Climate Change: Frequently Asked QuestionsDokument8 SeitenClimate Change: Frequently Asked QuestionsAdriano Racho MelendresNoch keine Bewertungen

- Ii 2G Ex D Iic T6 GB Cesi 03 Atex 323 X: Sonde A Transmetteur 4÷20ma Pour Gaz InflammablesDokument10 SeitenIi 2G Ex D Iic T6 GB Cesi 03 Atex 323 X: Sonde A Transmetteur 4÷20ma Pour Gaz Inflammablesdewidewi76Noch keine Bewertungen

- MRV 5 T3 Service Manual 202203Dokument253 SeitenMRV 5 T3 Service Manual 202203asadadNoch keine Bewertungen

- Installation and Operation Manual: 2301A Speed Control With Ma Speed Setting InputDokument40 SeitenInstallation and Operation Manual: 2301A Speed Control With Ma Speed Setting Inputsorangel_123Noch keine Bewertungen

- Boardworks - Magnetic FieldsDokument43 SeitenBoardworks - Magnetic Fieldsdiane hoyles100% (6)

- Aermec PXA E INSTALLATION MANUAL EngDokument8 SeitenAermec PXA E INSTALLATION MANUAL EngMauricio Andres Vidal ColomaNoch keine Bewertungen

- Stem - Physics 1 CGDokument13 SeitenStem - Physics 1 CGVictoria MabiniNoch keine Bewertungen

- Plant Design For The Production of Sodium CarbonateDokument29 SeitenPlant Design For The Production of Sodium CarbonateMuhammad Adeel KhalidNoch keine Bewertungen

- Lesson 1 Bajo BalanceDokument42 SeitenLesson 1 Bajo BalanceJesus Antonio Mazo GarciaNoch keine Bewertungen

- Chapter 1Dokument7 SeitenChapter 1Ram Darcy PeñalosaNoch keine Bewertungen

- Management Analysis of MayfairDokument42 SeitenManagement Analysis of MayfairIrfan KhalidNoch keine Bewertungen

- Releu SpecialDokument18 SeitenReleu SpecialEug ManuelNoch keine Bewertungen

- Fallsem2016-17 1286 RM001 27-Jul-2016 Mee1003 THDokument74 SeitenFallsem2016-17 1286 RM001 27-Jul-2016 Mee1003 THaman agarwalNoch keine Bewertungen

- Quick Exhaust Solenoid Valves: NC NODokument4 SeitenQuick Exhaust Solenoid Valves: NC NOMuhammad AsadNoch keine Bewertungen

- Green Building PBLDokument11 SeitenGreen Building PBLsofea1121Noch keine Bewertungen