Beruflich Dokumente

Kultur Dokumente

Ultrasonic Utility Gas Meter Low Flow

Hochgeladen von

autrolOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ultrasonic Utility Gas Meter Low Flow

Hochgeladen von

autrolCopyright:

Verfügbare Formate

SB 6530.

Ultrasonic-Flow Meter (USM)

For Measuring Non-Combustible Industrial Gases

Using Signal-Propagation Time Measurements

American Meter Ultrasonic-Flow Meter (USM)

Operating Principle

Ultrasound is the term for those acoustic oscillations which cannot be heard by humans because the frequencies are higher than 20 kHz and, thus, beyond the audible range of the human ear. The principle of measurement of Elster/AMCOs Ultrasonic-Flow Meters (USM) is based on the measurement of the signal propagation times. An ultrasound measurement path consists of two ultrasonic transducers, A and B, mounted on opposite sides of the meter tube (see diagram). The transducers A can be operated both as senders L and receivers vm and therefore allow to reverse B the direction of irradiation.

AB BA

Overview

Elster/AMCOs Ultrasonic-Flow Meters (USM) are suitable for the measurement of nitrogen, compressed air, or other non-combustible industrial gases. Due to a specific two-channel arrangement of the measuring paths, the meter is insensitive to a preflow. The measuring unit allows to record the operating volume Vb (ft3 or m3) as well as the operating flow Qb (ft3/h or m3/h). Pressing a key on the display can indicate both parameters alternately. The 4-20 mA interface supplies a signal that is proportional to the flow and can be transmitted to a connected control and regulation unit. A pulse output connector is also available, sending 1 pulse/10 ft3 to auxiliary equipment in remote locations. Both the 4-20 mA signal and pulse output connection are standard equipment on the USM. Since there are no moving or other parts of the USM in the measuring pipe which would hinder the flow, the pressure drop is extremely low. In addition, the USM has a long service life and no maintenance requirements.

The time required by the ultrasound for passing the distance L between the two transducers is known as the propagation time of sound. In the event that this time is measured in the direction of the gas flow (tAB) or in the opposite direction (tBA), the result will be shorter or longer because of the drag effect caused by the gas flow. By subtracting the reciprocal values of the propagation time and taking into account the angle of irradiation and the length L, it is possible to calculate the average speed Vm of the gas flow. Hence, the propagation time is an indicator of the flow rate. This procedure is called the direct-transit, time-difference method.

Installation

Due to the compact intermediate-flange installation design, the Ultrasonic-Flow Meter is easy to install in the pipe and saves space. To ensure optimal flow conditions, we recommend an upstream and downstream run of 1-1/2 pipe diameters. In the case of dry gases, the meter can be installed in any position. An UltrasonicFlow Meter, which is to be used for the measurement of polluted gases or those tending to condense at the point of measurement, must be installed vertically. Any additional measures are not required. An installation kit consisting of threaded spindles, centering sleeves, nuts and connection pieces is provided with each USM.

Major Features

T1 T3

2", 3", 4" and 6" ANSI 150 sizes available MAOP = 175 psig Flow ranges up to 56,000 scfh High rangeability Flow-volume meter for compressed air, nitrogen and other non-combustible industrial gases Quick response time to changing loads 4-20 mA interface for connection of control and regulation units Pulse-output connection (1 pulse/10 ft3) No maintenance required Virtually zero-pressure drop Two-channel measurement

T2

T4

American Meter Ultrasonic-Flow Meter (USM)

Technical Specifications

Model 2" CA 3" CA 4" CA 6" CA ANSI Class 150 150 150 150 Operating Pressure 7" w.c. 175 psig 7" w.c. 175 psig 7" w.c. 175 psig 7" w.c. 175 psig Qmax (scfh) 5,650 12,500 23,000 56,000 Qmax (scfm)* 94 208 383 933 Rangeability (2%) 1:63 1:139 1:131 1:112

* Capacities indicated are at 7" w.c. (0.25 psig) metering pressure.

Applications

Suitable for non-intrusive measurement of (non-combustible) industrial gases such as nitrogen, air, argon, etc. Please consult your American Meter representative for other gases. -4 to +158 F (ambient temperature) +14 to +140 F (flowing temperature) ASME Pressure Vessel (Sect. VII, Div. 1 and 2) ANSI B16.6 flanges AGA 9 definition of terms and test procedures Body extruded aluminum Electronics Cover die-cast aluminum Endplates stamped tin Connectors steel LED display of totalized volume (ft3 or m3) and flow rate (ft3/h or m3/h) Badge: MAOP, size, Qmin, Qmax, and serial number 20/sec 24 VDC Current = 4-20 mA; Load = 0-750 Pulse output = 1 pulse/10 ft3 (open collector)

Temperature Rating Codes and Standards Materials

Display/Badge Sampling Rate Auxiliary Power Output Signals

Dimensions

Model 2" CA 3" CA 4" CA 6" CA A 6.06 6.06 6.16 8.19 B 8.90 8.90 10.16 12.21 C 19.92 4.72 5.91 8.86

A B

DN

A Complete Family of Gas Measurement, Pressure Regulation, and Testing Systems

Turbine Gas Meters High-performance meters provide accurate measurement of high-volume gas flow. Turbines are available from 3" to 12" line sizes and line pressures up to 1440 psig. See bulletin SB 4510 for more information.

Rotary Gas Meters RPM Series Rotary Meters are designed for commercial and industrial loads to provide accurate flow measurement and outstanding performance in the most adverse conditions. See bulletin SB 5500 for more information.

Pressure Regulators Inlet- and outlet-pressure regulators with a wide range of capacities. These regulators have optional overpressure and underpressure shutoff and full-capacity internal relief. See bulletin SB 8540 for more information.

Pilot-Loaded Regulators 1800 PFM industrial regulators are designed for applications requiring medium to high capacity, extremely precise outlet-pressure control, and fast response to changing loads. See bulletin SB 8551 for more information.

American Meter Company is committed to a program of continuous quality enhancement. All equipment designed and manufactured by American Meter Company benefits from the companys quality assurance standards, which are approved to ISO 9001 or ISO 9002. American Meter Company has a program of continuous product development and improvement; and, therefore, the information in this bulletin is subject to change or modification without notice.

AMERICAN METER 300 Welsh Road Building One Horsham, PA 19044-2234 U.S.A. Phone: 215/830-1800 Fax: 215/830-1890 Website: americanmeter.com

Printed in U.S.A.

CANADIAN METER 275 Industrial Road Cambridge, Ontario, N3H 4R7 Canada Phone: 877/461-2626 (toll free) Phone: 519/650-1900 Fax: 519/650-1917 Website: canadianmeter.com

Core 1500 5/02

Das könnte Ihnen auch gefallen

- 1702 Tekbar-3150Dokument5 Seiten1702 Tekbar-3150autrolNoch keine Bewertungen

- Natural Gas Dry Vs Wet - 050913Dokument1 SeiteNatural Gas Dry Vs Wet - 050913autrolNoch keine Bewertungen

- 970804C Calculation of Natural Gas Net Volume and EnergyDokument9 Seiten970804C Calculation of Natural Gas Net Volume and EnergyautrolNoch keine Bewertungen

- Canalta Meter Run Info SheetDokument3 SeitenCanalta Meter Run Info Sheetautrol100% (1)

- TechSpec Summit8800 EN Final09b PDFDokument4 SeitenTechSpec Summit8800 EN Final09b PDFautrolNoch keine Bewertungen

- Quick Install GuideDokument165 SeitenQuick Install GuideautrolNoch keine Bewertungen

- Quick Install GuideDokument165 SeitenQuick Install GuideautrolNoch keine Bewertungen

- 3100 DS01Dokument11 Seiten3100 DS01autrolNoch keine Bewertungen

- Smart Temperature Transmitter: Application AreasDokument8 SeitenSmart Temperature Transmitter: Application AreasautrolNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Dilg-Mbcrpp Isf Q2 2023Dokument2 SeitenDilg-Mbcrpp Isf Q2 2023Mallari GabrielNoch keine Bewertungen

- Solution of Tutorial Sheet-3 (Three Phase Networks) : Ans. Given, - Vab - 45kV, ZL (0.5 + j3), Z (4.5 + j9)Dokument10 SeitenSolution of Tutorial Sheet-3 (Three Phase Networks) : Ans. Given, - Vab - 45kV, ZL (0.5 + j3), Z (4.5 + j9)Shroyon100% (2)

- FE Yeet GUIDokument3 SeitenFE Yeet GUINobodyNoch keine Bewertungen

- Cs9152 DBT Unit IV NotesDokument61 SeitenCs9152 DBT Unit IV NotesNivithaNoch keine Bewertungen

- Chapter 13: Worksheet Mark SchemeDokument2 SeitenChapter 13: Worksheet Mark SchemeAdam DanialNoch keine Bewertungen

- Design of BaseplateDokument9 SeitenDesign of BaseplatejohnNoch keine Bewertungen

- Product Presentation PPT NeerajDokument8 SeitenProduct Presentation PPT NeerajNeeraj UdiniyaNoch keine Bewertungen

- NB! This Price List Applies To Service Agreements, That Are Concluded With Nordea Bank AB Latvia BranchDokument34 SeitenNB! This Price List Applies To Service Agreements, That Are Concluded With Nordea Bank AB Latvia Branchwaraxe23Noch keine Bewertungen

- Waste Management in Selected Hotels in GoaDokument11 SeitenWaste Management in Selected Hotels in GoaSyna SoaresNoch keine Bewertungen

- Solar Storage System Comp GUIDEGTM 2 1Dokument10 SeitenSolar Storage System Comp GUIDEGTM 2 1harosalesvNoch keine Bewertungen

- Patrick C Hall@yahoo - com-TruthfinderReportDokument13 SeitenPatrick C Hall@yahoo - com-TruthfinderReportsmithsmithsmithsmithsmithNoch keine Bewertungen

- CS2305 PP Lecture Notes PDFDokument367 SeitenCS2305 PP Lecture Notes PDFVijai KirubaNoch keine Bewertungen

- List of International and National Professional Bodies - PECDokument4 SeitenList of International and National Professional Bodies - PECerumerNoch keine Bewertungen

- Illumination: "The Established Leader Ee Review"Dokument6 SeitenIllumination: "The Established Leader Ee Review"IVex Brykz Jay Ro60% (5)

- Instalación Sensor RPM TurboDokument13 SeitenInstalación Sensor RPM TurboLuis Herrera MarinNoch keine Bewertungen

- BUT11F/11AF: NPN Silicon TransistorDokument4 SeitenBUT11F/11AF: NPN Silicon TransistorfabioboogNoch keine Bewertungen

- Blue Solar Charge Controller MPPT: NOT AcceptedDokument12 SeitenBlue Solar Charge Controller MPPT: NOT Accepted1382aceNoch keine Bewertungen

- WEdu Abroad - Study Abroad E-GuidebookDokument111 SeitenWEdu Abroad - Study Abroad E-GuidebookRithyKhouyNoch keine Bewertungen

- 888 Gallant Security Services Corp NewDokument12 Seiten888 Gallant Security Services Corp Newnareyes11Noch keine Bewertungen

- Banumathy.D Updated Profile 1Dokument7 SeitenBanumathy.D Updated Profile 1engineeringwatchNoch keine Bewertungen

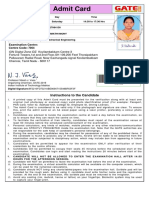

- Admit Card: Examination Centre: Centre CodeDokument1 SeiteAdmit Card: Examination Centre: Centre CodekrishnaNoch keine Bewertungen

- En 10268Dokument4 SeitenEn 10268Alex LacerdaNoch keine Bewertungen

- MN5200 Issue1.1 APR2009Dokument2 SeitenMN5200 Issue1.1 APR2009Roger ReisNoch keine Bewertungen

- Color Code - Canadian Standard - ABES - PROD.PW - MC.B017.E24806.ATTA003Dokument14 SeitenColor Code - Canadian Standard - ABES - PROD.PW - MC.B017.E24806.ATTA003Adam Michael GreenNoch keine Bewertungen

- GH13 Heavy Duty Body Installation Manual PDFDokument132 SeitenGH13 Heavy Duty Body Installation Manual PDFPrashant Sharma100% (14)

- Project Report JamiaDokument76 SeitenProject Report JamiaShoaibNoch keine Bewertungen

- Diesel GateDokument41 SeitenDiesel Gateanon_934477879100% (1)

- STN6200 Product Description - V6.4.22-ENDokument118 SeitenSTN6200 Product Description - V6.4.22-ENmohamed elkassehNoch keine Bewertungen

- New Approach For The Measurement of Damping Properties of Materials Using The Oberst BeamDokument6 SeitenNew Approach For The Measurement of Damping Properties of Materials Using The Oberst BeamMatnSambuNoch keine Bewertungen