Beruflich Dokumente

Kultur Dokumente

Codes and Standards 1.1: Preface To The Second Edition Xxi

Hochgeladen von

Noushad P HamsaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Codes and Standards 1.1: Preface To The Second Edition Xxi

Hochgeladen von

Noushad P HamsaCopyright:

Verfügbare Formate

CONTENTS

Preface to the Second Edition

xxi

Chapter 1

Codes and Standards

1.1

General / 1.1 American Gas Association (AGA) / 1.2 American National Standards Institute (ANSI) / 1.2 American Petroleum Institute (API) / 1.2 American Society of Heating, Refrigerating, and Air Conditioning Engineers (ASHRAE) / 1.2 American Society of Plumbing Engineers (ASPE) / 1.3 American Society of Testing and Materials (ASTM) / 1.3 American Society of Mechanical Engineers (ASME) / 1.3 American Society of Sanitary Engineers (ASSE) / 1.3 American Water Works Association (AWWA) / 1.4 American Welding Society (AWS) / 1.4 Compressed Gas Association (CGA) / 1.4 Current Good Manufacturing Practice (cGMP) / 1.4 Code of Federal Regulations (CFR) / 1.5 Environmental Protection Agency (EPA) / 1.5 Food and Drug Administration (FDA) / 1.5 ISO 9000 / 1.5 Occupational Safety and Health Administration (OSHA) / 1.6 Model Regional Building Codes / 1.6 Manufacturers Standardization of the Valve and Fittings Industry (MSS) / 1.7 National Electrical Manufacturers Association (NEMA) / 1.7 National Fire Protection Association (NFPA) / 1.7 National Institutes of Health (NIH) / 1.7 National Oceanic and Atmospheric Administration (NOAA) / 1.8 Nuclear Regulatory Commission (NRC) / 1.8 National Sanitation Foundation, International (NSF) / 1.8 Underwriters Laboratories (UL) / 1.8 3-A Standards / 1.9

Chapter 2

Piping

2.1

Code Acceptance / 2.2 Pressure and Temperature Ratings / 2.2 Cost / 2.3 Corrosion Resistance / 2.3 Physical Strength / 2.5 Fire Resistance / 2.5 Availability / 2.5 Aluminum (Al) / 2.6

vii

viii

CONTENTS

Brass (BR) / 2.6 Cast Iron Soil Pipe (CI) / 2.7 Acid-Resistant Cast Iron (AR) / 2.7 Carbon Steel (ST) / 2.7 Copper / 2.8 Ductile Iron Pipe (DI) / 2.9 Lead (LD) / 2.9 Stainless Steel (SS) / 2.10 Corrugated Steel Pipe / 2.12 Other Metallic Piping Materials / 2.13 Key Properties of Plastic Pipe / 2.15 Description and Classication / 2.16 Plastic Pipe Standards and Nomenclature / 2.17 Elements for Selection / 2.19 Plastic Pipe Materials / 2.24 Asbestos Cement Pipe (ACP) / 2.28 Glass (GL) / 2.28 Vitried Clay (VC) / 2.28 Concrete Pipe / 2.29 Code Considerations / 2.30 Fitting Types / 2.30 Fitting Materials / 2.30 Metallic Pipe Joints / 2.34 Welding / 2.40 Flanged / 2.43 Hinged Clamp / 2.44 Adapters / 2.47 Joints for Plastic Piping / 2.47 Joints for FRP Piping / 2.49 General / 2.54 Codes and Standards / 2.54 Valve Components / 2.54 Valve Body Materials / 2.55 Valve Actuators / 2.56 Operating and Torque Considerations / 2.60 Firesafe Valves / 2.61 Valve Ratings / 2.62 Pressure Loss through Valves / 2.62 Valve Selection Considerations / 2.63 Gate Valves / 2.64 Globe Valves / 2.67 Plug Valves / 2.69 Ball Valves / 2.72 Buttery Valves / 2.73 Diaphragm Valves / 2.73 Pinch Valves / 2.74 Check Valves / 2.74 Miscellaneous Valve Types / 2.75 General / 2.81 Codes and Standards / 2.81 System Components / 2.81 References / 2.93

Chapter 3

Solid-Liquid Separation and Interceptors

3.1

General / 3.2 Filter Categories and Denitions / 3.3

CONTENTS

ix

Filter Ratings / 3.3 Membrane Filter Testing / 3.5 General / 3.7 Types of Strainers / 3.8 Materials of Construction / 3.8 Design Considerations and Selection Criteria / 3.11 Filter Classications / 3.14 Types of Filters / 3.14 Deep Bed Granular (Sand) Filtration / 3.14 Activated Carbon Filters / 3.18 Cartridge Depth Filters / 3.19 General / 3.23 Code Considerations / 3.23 Design Considerations / 3.23 Structural Considerations / 3.23 Location / 3.24 Specic Substances / 3.24 References / 3.34

Chapter 4

Water Treatment and Purication

4.1

Codes and Standards / 4.1 Suspended Matter (Particulates) / 4.5 Dissolved Minerals and Organic Substances / 4.6 Dissolved Gases / 4.7 General / 4.9 Deposits / 4.14 Corrosion / 4.15 General / 4.16 pH / 4.16 Langelier Saturation Index (LSI) / 4.16 Ryznar Stability Index (RI) / 4.18 Aggressiveness Index (AI) / 4.18 Aeration / 4.20 Clarication / 4.21 Deaeration / 4.22 Decarbonation / 4.22 Dealkalizing / 4.22 Distillation / 4.23 Filtration / 4.27 Ion Exchange and Removal / 4.27 Membrane Filtration and Separation / 4.36 Microbial Control / 4.40 Utility Water Treatment / 4.44 Boiler Feedwater Conditioning / 4.45 Cooling Water Conditioning / 4.46 Potable Water Treatment / 4.47 Codes and Standards / 4.51 Laboratory Systems / 4.51 Pharmaceutical Water / 4.53 Puried Water Types / 4.53 Pharmaceutical Water Treatment Process / 4.55 Feedwater / 4.57 Purication System Design / 4.57 Central Purication Equipment / 4.59 References / 4.62

CONTENTS

Chapter 5

Heat Transfer, Insulation, and Freeze Protection

5.1

Codes and Standards / 5.1 Basics / 5.2 Types of Insulation / 5.7 Jackets / 5.9 Coatings, Adhesives, and Sealants / 5.13 Insulation Material and Thickness Selection / 5.14 Calculation of Insulation Thickness / 5.19 Freezing of Water / 5.24 The Mechanics of the Freezing Process / 5.24 Pipe Damage Due to Freezing / 5.25 The Freezing of Water in Atmospheric Vessels / 5.27 Sewer and Water Supply Piping Design / 5.30 Frost Closure of Vents / 5.35 Derivation of the Basic Formula for Frost Depth / 5.36 Electric Heat Tracing / 5.50 Steam Tracing / 5.56 Acknowledgments / 5.69 References / 5.69

Chapter 6

Site Utility Systems

6.1

Hydrologic Cycle / 6.2 Aquifers / 6.4 Inow into Excavations / 6.5 Preliminary Investigations / 6.10 Storm Water Inlet Selection / 6.11 System Design Criteria / 6.21 System Design Procedure / 6.29 System Design Considerations / 6.33 Roof Retention / 6.35 Site Retention Methods / 6.35 General / 6.53 Codes and Standards / 6.53 Pipe and Installation Classications / 6.53 Loads Acting on a Pipe / 6.54 Superimposed Loads / 6.57 Bedding / 6.67 Strength of Pipe Materials / 6.69 Total Load on Buried Pipe / 6.74 Cleaning Methods / 6.78 Repair of Cracks and Joint Separations in Piping / 6.79 Repair of Manholes / 6.80 Preventive Maintenance / 6.80 Sewer Components / 6.81 Manholes / 6.81 Sizing the Sanitary Sewer / 6.84 Sanitary Sewer Design Considerations / 6.96 Codes and Standards / 6.100 System Components / 6.100 Component Design and Selection / 6.102 System Design Considerations / 6.104 Storm Water Disposal / 6.106 Water Supplied from a Public Utility / 6.112

CONTENTS

xi

Water Supplied from Wells / 6.131 Water Supplied from Surface Water Sources / 6.142 Domestic Water Service / 6.143 Fire Protection Water Service / 6.150 Codes and Standards / 6.153 Drilling Methods / 6.153 Casing / 6.153 Grout / 6.153 Intakes / 6.154 Well Development / 6.154 Finishing the Monitor Well / 6.155 References / 6.155

Chapter 7

Turf Irrigation Systems

7.1

General / 7.1 System Components / 7.1 Codes and Standards / 7.2 General Design Considerations / 7.2 The Soil / 7.2 System Design / 7.5 Acknowledgments / 7.12

Chapter 8

Cryogenic Storage Systems

8.1

System Components / 8.1 Codes and Standards / 8.1 Bulk Storage / 8.2 Sizing the Large Bulk Tank / 8.4 Sizing the Vaporizer / 8.8 Pressure from Liquid Gases / 8.9 Pressure Relief Valves / 8.10 Pipe Materials and Insulation / 8.11 Pipe Sizing Methods / 8.12 System Design Considerations / 8.13 References / 8.13

Chapter 9

Plumbing Systems

9.1

General / 9.1 Codes and Standards / 9.2 Fixture Units / 9.3 Plumbing Fixtures / 9.3 Equivalent Length of Piping / 9.3 Velocity of Water / 9.6 System Description / 9.7 Major System Components / 9.7 Sanitary System Design / 9.11 Suds Pressure Areas / 9.14 Sump Pumps and Sewage Ejectors / 9.15 House Sewer Design / 9.20 Introduction / 9.21

xii

CONTENTS

Codes and Standards / 9.21 Septic System / 9.21 Collection and Treatment Alternatives / 9.33 Solvent Plumbing System / 9.34 System Description / 9.35 Nomenclature / 9.35 System Design / 9.35 Circuit and Loop Vents / 9.38 Wet Vents / 9.39 Suds Relief Vents / 9.39 Sump and Ejector Vents / 9.39 Vent Headers / 9.40 System Description / 9.42 General System Criteria / 9.42 Roof Drainage Systems / 9.42 System Description / 9.55 Water Treatment / 9.55 Water Meters / 9.55 Contamination Prevention / 9.56 Water Velocity / 9.59 Water Distribution Systems / 9.60 Estimating Water Demand / 9.60 Design of the Water Supply Distribution System / 9.62 Adjusting Water Pressure / 9.64 Pipe Size Selection / 9.75 System Description / 9.76 Codes and Standards / 9.76 Water Heating Methods and Equipment / 9.76 Acceptable Hot Water Temperatures / 9.78 Water Heater Sizing / 9.79 Safety and Protective Devices / 9.88 System Design Considerations / 9.89 Hot Water Temperature Maintenance / 9.90 Circulating Water System / 9.94 Electric Heating Cable / 9.102

Chapter 10

Special Waste Drainage Systems

10.1

Codes and Standards / 10.1 System Approval Requirements / 10.2 Pipe Material and Joint Selection Considerations / 10.3 Pipe Sizing Considerations / 10.3 pH Denition / 10.4 General System Design Considerations / 10.4 General / 10.7 Selection of Laboratory Waste Piping and Joint Material / 10.10 System Design Considerations / 10.10 Acid Waste Treatment / 10.10 General / 10.12 The Nature of Radiation / 10.12 Radiation Measurement / 10.13 Units of Radiation Dose / 10.14 Allowable Radiation Levels / 10.14 Shielding / 10.15 Radioactive Materials / 10.16 System Design Criteria / 10.16

CONTENTS

xiii

General Design Criteria / 10.17 Pipe Material Selection / 10.17 General Design Considerations / 10.18 Decontamination / 10.19 Codes and Standards / 10.21 Biological Safety Levels / 10.22 Liquid Waste Decontamination System / 10.23 System Design Considerations / 10.24 General / 10.25 Codes and Standards / 10.25 Pipe Material and Joint Selection / 10.25 System Design Considerations / 10.25 System Description / 10.27 References / 10.27 Oil in Water / 10.28 Methods of Separation and Treatment / 10.28 Gravity Separators / 10.29 Flotation Devices / 10.29 Centrifugal Separators / 10.29 Filtration / 10.29 Smaller Systems / 10.30 Additional References / 10.30

Chapter 11

Facility Steam and Condensate Systems

11.1

Systems Description / 11.1 Codes and Standards / 11.1 Steam / 11.2 Boiler Feedwater / 11.2 Steam Temperature / 11.2 Steam Quality / 11.2 Heat / 11.3 Specic Volume / 11.7 System Classications / 11.7 Steam System Venting / 11.8 Steam Supply Systems / 11.9 Condensate Return Systems / 11.11 General / 11.13 Component Description / 11.13 Steam System Component Sizing / 11.28 Boiler Feed Pumps / 11.31 Condensate Recovery System Description / 11.33 Component Description / 11.34 Component Selection and Sizing Criteria / 11.36 Steam Trap Selection and Sizing / 11.39 Project Design Examples / 11.44 System Design Considerations / 11.49 Acknowledgments / 11.53 References / 11.53

Chapter 12

Liquid Fuel Storage and Dispensing Systems

12.1

Denitions and Liquid Fuel Classications / 12.1 Codes and Standards / 12.2 System Description / 12.5

xiv

CONTENTS

System Components / 12.6 Storage Tanks / 12.7 Leak Detection and System Monitoring / 12.17 Vapor Recovery Systems / 12.23 Product Dispensing Systems / 12.25 Storage Tanks / 12.29 Atmospheric Tank Venting / 12.32 Leak Detection and System Monitoring / 12.32 System Monitoring / 12.33 Vapor Recovery / 12.33 Product Dispensing Systems / 12.33 Tank Protection / 12.34 Fire Pump Fuel Storage / 12.37 Emergency Generator Fuel Storage / 12.38 Piping Materials / 12.41 Pipe Sizing / 12.42 Submersible Pump Sizing / 12.44 General Design Considerations / 12.46 Tests / 12.46 Evaluation of AST or UST Installation / 12.47 AST / 12.48 UST / 12.48 System Design Considerations / 12.49 References / 12.51

Chapter 13

Fuel Gas Systems

13.1

Fuel Gas Description / 13.1 Codes and Standards / 13.1 System Operating Pressures / 13.3 General / 13.5 Major Natural Gas System Components / 13.6 Site Distribution / 13.9 Site Service Sizing Procedure / 13.11 NG Site Service Pipe Sizing Methods / 13.14 Pipe and System Materials for Site Installation / 13.14 Interior Pipe Sizing Procedure / 13.18 Storage Tanks / 13.28 Maximum Content of Liquid in Tanks / 13.31 Location of Equipment on the Site / 13.31 Tank Foundations and Support / 13.31 Regulators / 13.33 Pressure Relief Devices / 13.33 Excess Flow Valve / 13.35 Service Line Valves / 13.35 Filler Valves / 13.36 Vapor Equalizing Valves / 13.36 Liquid Level Gauges / 13.36 Miscellaneous Equipment / 13.36 Vaporizer / 13.37 Propane Mixers / 13.37 LPG System Design / 13.39 Piping Materials / 13.47 System Description / 13.48 Codes and Standards / 13.48 System Components / 13.48

CONTENTS

xv

System Design Considerations / 13.50 References / 13.51

Chapter 14

Compressed Gas Systems

14.1

General / 14.2 Denitions and Pressure Measurements / 14.2 Physical Properties of Air / 14.4 Water Vapor in Air / 14.5 Impurities and Contamination / 14.8 System Components / 14.12 System Design / 14.33 Project Design Example / 14.56 General / 14.62 Codes and Standards / 14.62 Air Quality Standards / 14.62 Air Pressure Requirements / 14.63 Generation of Instrument Air / 14.63 Pipe and Fittings / 14.63 General / 14.64 Codes and Standards / 14.64 Classication of Specialty Gases / 14.65 Grades of Specialty Gases / 14.65 Storage and Generation of Gases / 14.68 Distribution System Components / 14.71 Distribution Network / 14.80 General / 14.98 Codes and Standards / 14.98 Description and General Uses for the Common Gases / 14.99 Storage and Generation of Gases / 14.100 The Surgical-Medical Air Compressor Assembly / 14.106 Dental Air Compressor Assembly / 14.109 The Distribution Network / 14.110 Pipe Materials, Joints, and Installation / 14.110 Valves / 14.111 System and Equipment Sizing / 14.116 General / 14.133 Codes and Standards / 14.133 System Components / 14.133 Required Pressure and Flow Rate / 14.133 System Design Considerations / 14.134 General / 14.135 Acknowledgments / 14.137 References / 14.137

Chapter 15

Vacuum Air Systems

15.1

Denitions and Pressure Measurement / 15.2 System Components / 15.11 General / 15.19 Codes and Standards / 15.19 Medical-Surgical Vacuum Air Systems Description / 15.20 System Components / 15.20 Vacuum Source / 15.20 Distribution Network Sizing and Arrangement / 15.24

xvi

CONTENTS

System Sizing / 15.26 Purge and Tests / 15.31 General / 15.32 Methods of Anesthesia Gas Removal / 15.33 System Sizing / 15.34 System Operating Characteristics / 15.35 General / 15.36 Codes and Standards / 15.36 System Components / 15.36 Design Criteria / 15.37 Vacuum Generation / 15.38 Vacuum Source Design Considerations / 15.42 Distribution Network / 15.42 General Design Considerations / 15.43 Codes and Standards / 15.44 Vacuum Source / 15.44 Redundancy / 15.45 Distribution Network / 15.45 Sizing Criteria / 15.47 Types of Systems and Equipment / 15.49 Codes and Standards / 15.49 System Components / 15.49 Detailed System Design / 15.54 Acknowledgments / 15.63 References / 15.63

Chapter 16

Animal Facility Piping Systems

16.1

General / 16.1 Codes and Standards / 16.1 Animal Drinking Water System / 16.2 Drinking Water Treatment / 16.3 Drinking Water System Components and Selection / 16.5 Animal Rack Manifold Congurations / 16.6 System Sizing Methods / 16.8 Cleaning and Drainage Practices / 16.12 Equipment Washing / 16.18 Equipment Sanitizing / 16.18 Monitoring Systems / 16.18 General Systems Design Considerations / 16.19 Swine Cooling Systems / 16.19 Acknowledgment / 16.21 References / 16.21

Chapter 17

Life Safety Systems

17.1

General / 17.1 General / 17.2 System Components / 17.2 System Classications / 17.2 Codes and Standards / 17.2 Types of Drench Equipment / 17.3 Installation Requirements for Drench Equipment / 17.8 Drench Equipment Components / 17.12

CONTENTS

xvii

Flushing Water Disposal / 17.16 Visibility of Devices / 17.17 System Design / 17.17 General / 17.20 Codes and Standards / 17.20 System Components / 17.20 Types of Systems / 17.20 Types of Personal Respirators / 17.21 Breathing Air Purity / 17.24 System Components / 17.26 Component Selection and Sizing / 17.30 References / 17.34

Chapter 18

Water Display Fountains and Pools

18.1

General / 18.1 Types of Installations / 18.1 System Components / 18.2 Equipment / 18.2 System Congurations / 18.7

Chapter 19

Nonpotable Water Systems

19.1

Denitions / 19.2 General / 19.2 Common Uses / 19.2 Codes and Standards / 19.3 System Description / 19.3 System Components / 19.3 Design Flow / 19.4 Treatment Systems / 19.4 Precautions / 19.4 Public Acceptance / 19.6 Typical Installations and Details / 19.7 General / 19.12 Codes and Standards / 19.12 Methods of Preventing Attachment of Organisms / 19.12 Pipeline Cleaning / 19.13 Filters / 19.13 Seawater Intake / 19.14 Piping Materials / 19.15 Equipment Selection and Mechanical Room Design Considerations / 19.16 References / 19.16

Chapter 20

Drinking Water Systems

20.1

Codes and Standards / 20.1 System Components / 20.2 Drinking Fountain Installation / 20.3 System Design / 20.4 Pipe and Insulation Sizing and Selection / 20.5 System and Component Sizing / 20.5

xviii

CONTENTS

References / 20.10 Acknowledgments / 20.10

Chapter 21

Heat Exchangers

21.1

Introduction / 21.1 Codes and Standards / 21.1 ASTM B-31.9, Code for Pressure Piping, ASHRAE B-90.1, Conservation of Energy Denitions / 21.2 General Heat Exchanger Types / 21.3 Choosing Off-the-Shelf Shell and Tube Exchangers / 21.9 Plate Type Heat Exchangers / 21.10 Plate and Frame Heat Exchangers / 21.10 Immersion Heat Exchangers / 21.14 Air-Cooled Exchangers / 21.14 Heat Exchanger Selection / 21.15 Shell and Tube Heat Exchangers / 21.17 Sizing Pressure and Temperature Relief Valve / 21.19 References / 21.20

Chapter 22

Measurement Instrumentation and Methods

22.1

Introduction / 22.1 General / 22.1 Codes and Standards / 22.2 Denitions / 22.2 Newtonian Fluids / 22.3 Sensors / 22.3 Hydraulic Radius / 22.3 Flowmeter Classication / 22.4 Principles of Flowmeter Operation / 22.5 Electronic (Electromagnetic) Flowmeters / 22.18 Flowmeter Selection / 22.21 General / 22.23 Level Technologies / 22.23 Level Measurement Selection / 22.33 Liquid Expansion Thermometers / 22.35 Bimetallic Devices / 22.25 Change of State Sensors / 22.35 Silicon Diode / 22.36 Infrared Sensors / 22.36 Thermocouples / 22.36 Resistive Temperature Devices / 22.37 Manometer / 22.38 Bourdon Gauge / 22.38 Diaphragm Gauges / 22.39 Capacitance Meters / 22.39 Strain Gauges / 22.39 Introduction / 22.43 Metering Pump Description / 22.43 Metering Pump Considerations / 22.47 Calculating the Hydraulic Radius of an Open Channel / 22.50 Calculating the Flow of an Open Channel / 22.50 Meters for Measuring Flowrate in Open Channels / 22.51 Miscellaneous Devices and Measurement Methods / 22.58 References / 22.60

CONTENTS

xix

Appendix A

Pipe Distribution Systems

A.1

Appendix B

Trade Associations

B.1

Appendix C

Glossary and Abbreviations

C.1

Appendix D

Metric Unit Conventions and Conversions

D.1

Index

I.1

Das könnte Ihnen auch gefallen

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionVon EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionBewertung: 4.5 von 5 Sternen4.5/5 (16)

- Swimming Pool DesignDokument49 SeitenSwimming Pool Designcashlover100% (1)

- Essentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsVon EverandEssentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsBewertung: 4.5 von 5 Sternen4.5/5 (4)

- Method StatementDokument206 SeitenMethod StatementHassan Naqvi25% (8)

- Piping - Mapress Installation GuidelinesDokument144 SeitenPiping - Mapress Installation GuidelinesPetru VladeanuNoch keine Bewertungen

- Natural Gas Processing: Technology and Engineering DesignVon EverandNatural Gas Processing: Technology and Engineering DesignBewertung: 5 von 5 Sternen5/5 (8)

- Condensor EPRIDokument6 SeitenCondensor EPRIlacoste11111Noch keine Bewertungen

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesVon EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesBewertung: 4.5 von 5 Sternen4.5/5 (2)

- WSA 06 Version 1 - 2 - Code Contents ExtractDokument32 SeitenWSA 06 Version 1 - 2 - Code Contents ExtractHuzayfa PandorNoch keine Bewertungen

- Corrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesVon EverandCorrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesNoch keine Bewertungen

- Marine Piping SystemDokument233 SeitenMarine Piping SystemKagira Drawing Soltuion67% (6)

- Marine Piping System PDFDokument233 SeitenMarine Piping System PDFNaresh100% (4)

- Chemical Process Equipment - Selection and Design (Revised 2nd Edition)Von EverandChemical Process Equipment - Selection and Design (Revised 2nd Edition)Bewertung: 5 von 5 Sternen5/5 (3)

- HVAC Course ContentsDokument4 SeitenHVAC Course ContentsMohammedNoch keine Bewertungen

- Pipingchevronoffshore 2Dokument56 SeitenPipingchevronoffshore 2Velpandian ManiNoch keine Bewertungen

- Oil and Gas Pipelines: Integrity and Safety HandbookVon EverandOil and Gas Pipelines: Integrity and Safety HandbookNoch keine Bewertungen

- (Msia) Guide To Sewer Selection and Installation (Dec2006) - VC Pipe pg17Dokument168 Seiten(Msia) Guide To Sewer Selection and Installation (Dec2006) - VC Pipe pg17Rachael Hoo100% (7)

- Biological Sampling in the Deep SeaVon EverandBiological Sampling in the Deep SeaMalcolm R. ClarkNoch keine Bewertungen

- TR Diss 1672 PDFDokument302 SeitenTR Diss 1672 PDFsalamrefighNoch keine Bewertungen

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationVon EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNoch keine Bewertungen

- Gas-Freeing and Cleaning of Oil Storage Tank: ManualDokument86 SeitenGas-Freeing and Cleaning of Oil Storage Tank: ManualBalaji ArumugamNoch keine Bewertungen

- Engineering UtilitiesDokument2 SeitenEngineering Utilitiesbatiola.elleona018Noch keine Bewertungen

- Ped GuidelinesDokument225 SeitenPed Guidelinesbabis1980Noch keine Bewertungen

- M and e Induction CourseDokument10 SeitenM and e Induction CourseTiffany CombsNoch keine Bewertungen

- Aeration Manual DRAFT P PDFDokument251 SeitenAeration Manual DRAFT P PDFgarisa1963100% (1)

- Lesson Plan: Veer Surendra Sai University of Technology, BurlaDokument1 SeiteLesson Plan: Veer Surendra Sai University of Technology, Burlasanthi saranyaNoch keine Bewertungen

- General Specification: 2017 EDITIONDokument174 SeitenGeneral Specification: 2017 EDITIONmohammudaphNoch keine Bewertungen

- Mse Purchase 86725389Dokument5 SeitenMse Purchase 86725389shubhendrasahaNoch keine Bewertungen

- Hec22 (2) DrainageDokument545 SeitenHec22 (2) DrainagejhallcsNoch keine Bewertungen

- Ped GuidelinesDokument225 SeitenPed GuidelinesMatteo PeddisNoch keine Bewertungen

- SW-G.S. - Swimming Pool Water Treatment InstallationDokument174 SeitenSW-G.S. - Swimming Pool Water Treatment InstallationjackchiangdhkNoch keine Bewertungen

- Sewerage Manual Part 1 - With EurocodesDokument107 SeitenSewerage Manual Part 1 - With Eurocodesgiu_pradoNoch keine Bewertungen

- Sewerage Manual Part 1 - With EurocodesDokument107 SeitenSewerage Manual Part 1 - With Eurocodeselsayedamr100% (1)

- Eadips Manual Engl PDFDokument390 SeitenEadips Manual Engl PDFbkarabasevicNoch keine Bewertungen

- Curso Ventilacion IndustrialDokument207 SeitenCurso Ventilacion IndustrialEberthson100% (1)

- Estas Son Las Normas de Importancia Que Indico El Ingeniero MayorgaDokument9 SeitenEstas Son Las Normas de Importancia Que Indico El Ingeniero MayorgaROSA BASURTO LOPEZNoch keine Bewertungen

- Plant Design Engineering SyllabusDokument1 SeitePlant Design Engineering SyllabusDavidNoch keine Bewertungen

- Usace / Navfac / Afcec / Nasa UFGS-23 64 26 (August 2009) Change 6 - 11/22 - Preparing Activity: NAVFAC Superseding UFGS-23 64 26 (April 2008)Dokument54 SeitenUsace / Navfac / Afcec / Nasa UFGS-23 64 26 (August 2009) Change 6 - 11/22 - Preparing Activity: NAVFAC Superseding UFGS-23 64 26 (April 2008)Ramon De los ReyesNoch keine Bewertungen

- Sabaar h2s Removal WorkDokument3 SeitenSabaar h2s Removal WorkMuhammad SaadullahNoch keine Bewertungen

- Bhave R.R., (Ed.) Inorganic Membranes. Synthesis, Characteristics and Applications (Only 1,2,3,6 and 7 Chapters) (1991) (T) (155s) PDFDokument155 SeitenBhave R.R., (Ed.) Inorganic Membranes. Synthesis, Characteristics and Applications (Only 1,2,3,6 and 7 Chapters) (1991) (T) (155s) PDFiko1402Noch keine Bewertungen

- Fire Safety Guidelines For Open Plant Structures in Oil Chemical and Process IndustriesDokument50 SeitenFire Safety Guidelines For Open Plant Structures in Oil Chemical and Process IndustriesMosaddekNoch keine Bewertungen

- Recommended Standards Water 5Dokument159 SeitenRecommended Standards Water 5nmulyonoNoch keine Bewertungen

- Chilled, Chilled-Hot and Condenser Water Piping SystemsDokument51 SeitenChilled, Chilled-Hot and Condenser Water Piping SystemsgabrielNoch keine Bewertungen

- PID Check ListDokument6 SeitenPID Check ListArunachalam KaliyaperumalNoch keine Bewertungen

- PID Check ListDokument6 SeitenPID Check ListArunachalam KaliyaperumalNoch keine Bewertungen

- Ufgs 33 52 43.13Dokument40 SeitenUfgs 33 52 43.13Tendai Felex MadukeNoch keine Bewertungen

- Table of Contents PDFDokument4 SeitenTable of Contents PDFDevendra BangarNoch keine Bewertungen

- Fuel Cell FundamentalsDokument11 SeitenFuel Cell FundamentalsSanket Shah50% (4)

- Technical Manual: Punjab Rural Water Supply & Sanitation Programme (World Bank Assisted)Dokument294 SeitenTechnical Manual: Punjab Rural Water Supply & Sanitation Programme (World Bank Assisted)Udomsin WutigulpakdeeNoch keine Bewertungen

- TechnicalManual Drinking Water SupplyDokument294 SeitenTechnicalManual Drinking Water SupplygovindharajaluNoch keine Bewertungen

- 72C1FDokument5 Seiten72C1FManuel Ayala0% (1)

- UFGS Watertube BoilersDokument94 SeitenUFGS Watertube BoilersDeclanNoch keine Bewertungen

- 03.table of ContentsDokument9 Seiten03.table of ContentsdrpigaNoch keine Bewertungen

- Hydraulic Design Handbook-LarryW - MaysDokument9 SeitenHydraulic Design Handbook-LarryW - Mayscardosso50% (2)

- Metallizing FilmDokument229 SeitenMetallizing Filmdinhtupy16Noch keine Bewertungen

- Rural Ws Technical-Manual - 589475bfb146aDokument269 SeitenRural Ws Technical-Manual - 589475bfb146aN.J. PatelNoch keine Bewertungen

- Alfa Laval Technical Manual 4thedDokument176 SeitenAlfa Laval Technical Manual 4thedrararaf100% (3)

- Total Heat (BTU/hr) 500 X GPM X T (Water) - TONS 24 X GPM X T (Water) - GPM Cooler (24 X TONS) / T (Water)Dokument1 SeiteTotal Heat (BTU/hr) 500 X GPM X T (Water) - TONS 24 X GPM X T (Water) - GPM Cooler (24 X TONS) / T (Water)Nedunuri.Madhav MurthyNoch keine Bewertungen

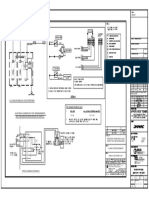

- 003-Ansul R-102 System P & I D-P&IDDokument1 Seite003-Ansul R-102 System P & I D-P&IDNoushad P HamsaNoch keine Bewertungen

- Chilled Water Pipe SizingDokument2 SeitenChilled Water Pipe SizingLarry Bea77% (13)

- Commonly Used Hvac FormulaeDokument5 SeitenCommonly Used Hvac FormulaezakirnagarNoch keine Bewertungen

- CVGF svn02b E4Dokument68 SeitenCVGF svn02b E4Noushad P HamsaNoch keine Bewertungen

- KX SeriesDokument24 SeitenKX SeriesNoushad P HamsaNoch keine Bewertungen

- RWV Balancing Valve TrainingDokument33 SeitenRWV Balancing Valve TrainingNoushad P HamsaNoch keine Bewertungen

- Duct Leakage TestingDokument51 SeitenDuct Leakage Testingducatti996chNoch keine Bewertungen

- Head PressDokument2 SeitenHead PressNoushad P HamsaNoch keine Bewertungen

- Urban Planning & MEP EbookDokument153 SeitenUrban Planning & MEP EbookNoushad P HamsaNoch keine Bewertungen

- Balancing BasicsDokument14 SeitenBalancing BasicspbharrisNoch keine Bewertungen

- CTV Chiller WeightsDokument5 SeitenCTV Chiller WeightsNoushad P HamsaNoch keine Bewertungen

- CompressorsDokument7 SeitenCompressorssyedahmedsabirNoch keine Bewertungen

- CVGF svn02b E4Dokument68 SeitenCVGF svn02b E4Noushad P HamsaNoch keine Bewertungen

- Cvhesvn03den 305Dokument80 SeitenCvhesvn03den 305Noushad P HamsaNoch keine Bewertungen

- A Guide To Air FiltrationDokument50 SeitenA Guide To Air FiltrationNoushad P HamsaNoch keine Bewertungen

- A Guide To Absorption CoolingDokument54 SeitenA Guide To Absorption CoolingNoushad P HamsaNoch keine Bewertungen

- Dynamic Storage in BuildingsDokument114 SeitenDynamic Storage in BuildingsNoushad P HamsaNoch keine Bewertungen

- Buffer Tank Hesabı PDFDokument4 SeitenBuffer Tank Hesabı PDFDevrim GürselNoch keine Bewertungen

- Copper Tube DesignDokument34 SeitenCopper Tube DesignNoushad P HamsaNoch keine Bewertungen

- Urban Planning & MEP EbookDokument153 SeitenUrban Planning & MEP EbookNoushad P HamsaNoch keine Bewertungen

- Energy Planning A Guide To PractitionersDokument75 SeitenEnergy Planning A Guide To PractitionersNoushad P HamsaNoch keine Bewertungen

- A Guide To Air FiltrationDokument50 SeitenA Guide To Air FiltrationNoushad P HamsaNoch keine Bewertungen

- Building Regulation BookDokument135 SeitenBuilding Regulation BookNenad Stjepanovic100% (1)

- Construction Materials E-BookDokument98 SeitenConstruction Materials E-BookNoushad P Hamsa100% (1)

- Plumbing Installations Home Owner Guide PDFDokument19 SeitenPlumbing Installations Home Owner Guide PDFskilmagNoch keine Bewertungen

- Plumbing Installations Home Owner Guide PDFDokument19 SeitenPlumbing Installations Home Owner Guide PDFskilmagNoch keine Bewertungen

- Session1 Kroeger Beth PresDokument83 SeitenSession1 Kroeger Beth PresMahesh GavasaneNoch keine Bewertungen

- Bpharm 5 Sem Industrial Pharmacy 1 bp502t 2020Dokument1 SeiteBpharm 5 Sem Industrial Pharmacy 1 bp502t 2020Amol TupeNoch keine Bewertungen

- AWWA Manual M51 Air-Release, Air - Vacuum, and Combination Air Valves 2016Dokument77 SeitenAWWA Manual M51 Air-Release, Air - Vacuum, and Combination Air Valves 2016maguenhoyos100% (9)

- Quiz 1 With AnswerDokument3 SeitenQuiz 1 With AnswerAltra ZNoch keine Bewertungen

- Bioscrn PDFDokument69 SeitenBioscrn PDFNicolas CancioNoch keine Bewertungen

- SNI 3407-2008 Kekekalan Agregat (Soundness)Dokument9 SeitenSNI 3407-2008 Kekekalan Agregat (Soundness)Richard CobisNoch keine Bewertungen

- Carbohydrates WorksheetDokument4 SeitenCarbohydrates WorksheetNatalie Pemberton86% (7)

- GF-304CR Dossier.Dokument35 SeitenGF-304CR Dossier.suria qaqcNoch keine Bewertungen

- UAV WingDokument5 SeitenUAV WingSUNDARAMAHALINGAM ANoch keine Bewertungen

- Calcium-Magnesium by EDTA TitrationDokument5 SeitenCalcium-Magnesium by EDTA TitrationnisscriNoch keine Bewertungen

- ASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFDokument7 SeitenASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFApolos CastNoch keine Bewertungen

- AlkanolamideDokument5 SeitenAlkanolamidebellesuperNoch keine Bewertungen

- Basf Master BatchDokument6 SeitenBasf Master Batchapi-3842599100% (1)

- Benjamin. Lewin - GENES V.-Oxford (1994)Dokument34 SeitenBenjamin. Lewin - GENES V.-Oxford (1994)AnkitNoch keine Bewertungen

- UC Bracing Gusset - ASDDokument14 SeitenUC Bracing Gusset - ASDFunny & InformativeNoch keine Bewertungen

- ChapterEight1 - 20 of SpectrocopicDokument20 SeitenChapterEight1 - 20 of SpectrocopicHung Le VanNoch keine Bewertungen

- Microbiology With Diseases by Body System 5th Edition Bauman Test BankDokument25 SeitenMicrobiology With Diseases by Body System 5th Edition Bauman Test BankRhondaHogancank100% (50)

- Carboxylic Acid Questions-1Dokument6 SeitenCarboxylic Acid Questions-1Jape GarridoNoch keine Bewertungen

- USP-NF Atorvastatin CalciumDokument8 SeitenUSP-NF Atorvastatin CalciumPhạm Đức LộcNoch keine Bewertungen

- BL-1400ashless Group 2 03Dokument2 SeitenBL-1400ashless Group 2 03M.ASNoch keine Bewertungen

- A Research Project Submitted To The: DR - Naga Rathna SupriyaDokument6 SeitenA Research Project Submitted To The: DR - Naga Rathna Supriyamansi bodaNoch keine Bewertungen

- Journal of Molecular Liquids: Sonu, Sayantan Halder, Sunita Kumari, Rishika Aggrawal, Vinod K. Aswal, Subit K. SahaDokument11 SeitenJournal of Molecular Liquids: Sonu, Sayantan Halder, Sunita Kumari, Rishika Aggrawal, Vinod K. Aswal, Subit K. SahaAbiel Angel GarciaNoch keine Bewertungen

- Fiitjee: Solutions To JEE (Main) - 2020Dokument36 SeitenFiitjee: Solutions To JEE (Main) - 2020srijan jhaNoch keine Bewertungen

- Microbiology of Waste Water TreatmentDokument22 SeitenMicrobiology of Waste Water TreatmentDevendra SharmaNoch keine Bewertungen

- EnggDokument44 SeitenEnggAlex NavalNoch keine Bewertungen

- Chemistry Volumetric LabDokument20 SeitenChemistry Volumetric Labsunil venkataNoch keine Bewertungen

- SG Unit6ProgressCheckMCQ 63fd8804e35951.63fd880808f2a9.47859323Dokument10 SeitenSG Unit6ProgressCheckMCQ 63fd8804e35951.63fd880808f2a9.47859323vDraqNoch keine Bewertungen

- Properties of LightDokument6 SeitenProperties of LightSteffi Bianca U. BelenNoch keine Bewertungen

- Shrimp: In: Use of Sodium Metabisulfite, AlternativesDokument3 SeitenShrimp: In: Use of Sodium Metabisulfite, Alternativesvalerie rosalind angkawidjajaNoch keine Bewertungen

- Effect of Temperature On Sliding Wear of AISI 316 L (N) Stainless Steel  " Analysis of Measured Wear and Surface Roughness of Wear TracksDokument7 SeitenEffect of Temperature On Sliding Wear of AISI 316 L (N) Stainless Steel  " Analysis of Measured Wear and Surface Roughness of Wear TracksSamir BoseNoch keine Bewertungen