Beruflich Dokumente

Kultur Dokumente

4f27e 2006 Workshop Manual

Hochgeladen von

Transmisiones Automáticas ChepeOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

4f27e 2006 Workshop Manual

Hochgeladen von

Transmisiones Automáticas ChepeCopyright:

Verfügbare Formate

2005 Focus Workshop Manual

Page 1 of 23

SECTION 307-01: Automatic Transaxle/Transmission DESCRIPTION AND OPERATION

2005 Focus Workshop Manual

Procedure revision date: 05/19/2006

Transaxle Description

PrintableView(2533KB)

The automatic transmission used in the vehicle is a new development. It is a fully automatic, electronically controlled four-speed transmission designed for front-wheel drive vehicles. Its abbreviated designation 4F27E means:

4 four-speed transmission F front-wheel drive 27 originally designed for maximum input torque after torque converter: 365 Nm (270 lb-ft) E fully electronic control

The individual ratios are achieved through two planetary gear sets, connected one behind the other. The individual components of the planetary gear sets are driven or held by means of three multiplate clutches, a multiplate brake, a brake band and a roller one-way clutch. The torque is transmitted to the final drive assembly through an intermediate gear stage. MERCON V is the fluid specified for the 4F27E transmission. The fluid is changed as directed by the Scheduled Maintenance Guide that is supplied with the vehicle. The manual selector lever gives the driver a choice of P, R, N, 1, 2 and D. In drive range "D" it is also possible to operate an O/D switch on the manual selector lever to prevent the transmission from shifting into fourth gear. The default gear for this transmission is third gear. To minimize fuel consumption, the torque converter lock-up clutch is closed by the PCM in 3rd and 4th gears depending on the throttle position and vehicle speed. The transmission has electronic synchronous shift control (ESSC), which guarantees extremely smooth gear shifting over the entire life of the transmission. A hydraulic emergency operating program maintains limited operation in the event of failure of important electrical components. The transmission can be tested using FDS2000, NGS or WDS through the data link connector (DLC) in the passenger compartment.

Gear Ratio (Typical shown, ratios are model dependent) 1st 2nd 3rd 4th Reverse Identification tags When servicing the automatic transaxle, refer to the identification tag located on the case. 2.816:1 1.498:1 1.000:1 0.726:1 2.649:1

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 2 of 23

Item 1 2 3 4

Part Number Sample build date code (DDMMYY)

Description Transmission assembly part number

Sample Julian build date and build number (YDDDXXX) Service model code

Range selection The transaxle range selector has six positions: P, R, N, D, 2, 1.

Manual selector lever position "P" In manual selector lever position "P" no gear is selected. The parking pawl is engaged manually by the manual selector lever cable and the shift shaft. For safety reasons, always apply the parking brake whenever the vehicle is parked. Manual selector lever position "R" In manual selector lever position "R" reverse gear is selected. REVERSE allows the vehicle to be operated in a rearward direction, at a reduced gear ratio. Manual selector lever position "N" In manual selector lever position "N" no gear is selected. The driveline is not locked, so the wheels are free to rotate. The vehicle may be started in NEUTRAL. Manual selector lever position "D" In manual selector lever position "D" and when the O/D switch is not pressed, the transmission control allows all the gears to be selected. When the O/D switch is pressed, shifting into fourth gear is prevented or the transmission shifts down to third gear. Manual selector lever position "1" In manual selector lever position "1" only first gear is selected. In addition to the first gear one-way clutch, the transmission control closes the reverse gear brake to produce engine braking effect in overrun. If the manual selector lever is moved to position "1" at an excessive vehicle speed for first gear, the transmission control only allows the downshift to take place when the corresponding vehicle speed has been reached. Manual selector lever position "2" In manual selector lever position "2" only second gear is selected. The transmission control does not allow shifting into first gear. If the manual selector lever is moved to position "2" at an excessive vehicle speed for second gear, the transmission control only allows the downshift to take place when the corresponding vehicle speed has been reached. Converter Housing with Converter Assembly and Fluid Pump Assembly

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 3 of 23

Item 1 2 3 4 5 6 7 8 9 10 11 12 13 14 7902 1177 7H103

Part Number Converter assembly Seal assembly differential

Description

Output shaft speed sensor bolt Output shaft speed (OSS) sensor O-ringOSS sensor Boltconverter housing Retainerfluid tube Converter housing Seal fluid pump Seal assembly fluid pump Boltfluid pump Fluid pump assembly Seal forward clutch cylinder Washer fluid pump support thrust

W706315-S300 7005 7A248 7A248 7A103 7D019 7H042

Forward Clutch

Item 1 2 3 4 5 6 7

Part Number 7F207 7A262 7F235 7H360 7H365 7B442 7B164 Shaft assembly turbine Piston assembly forward clutch

Description

Spring assembly forward piston return Piston forward clutch balance Snap ring forward clutch balance piston Steel plate forward clutch separator (4) Friction plate assembly forward clutch (forward 4)

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 4 of 23

8 9 10

7B066 7D483 7B067

Plate forward/direct clutch pressure (1 each) Retaining ring (selective) Hub forward clutch cylinder

Differential Assembly and Final Drive Input

Item 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 4067 4222 4221 4221

Part Number Shim differential bearing Cup differential bearing Cone and roller assembly Bearing assembly

Description

7H150 7F465 4230 4215 4236 4228 4241 4211 7H367 7H344 7170 7H338 7H348 7L267 7F342 7M102

Wheel output shaft speed sensor Differential and gear assembly transaxle Pinion thrust washer (2) Differential pinion gear (2) Differential side gear (2) Side gear thrust washer (2) Pin Differential pinion shaft Shim transfer shaft roller bearing Cup-transfer shaft roller Cone and roller assembly Bearing assembly transfer shaft (2) Transfer shaft gear assembly Funnel transfer shaft Gear final drive input Cone and roller assembly

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 5 of 23

21 22 23 24 25

7C236 7F403 7H369 7H106 7B364

Bearing cup Bearing assembly (2) Spacer Retainer ring Nut

Clutches and Planet Gears

Item 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Part Number 7A262 7B070 7D171 7D483 7B070 7B442 7B164 7B066 7D483 7H199 7A089 7D483 7D392 7A398 7H375 7H362 7A399 7H337 Piston low/reverse clutch Spring low/reverse clutch return

Description

Race low one-way clutch (OWC) inner Retaining ring low OWC Spring low/reverse clutch wave Steel plate low/reverse clutch separator (5) Friction plate assembly low/reverse clutch (5) Pressure plate low/reverse clutch Retaining ring low/reverse clutch plate (selective) Retainer low gear OWC OWC assembly low Retaining ring Front ring gear Gear assembly front planet Bearing assembly front planet carrier thrust Snap ring Front planet sun gear assembly Bearing assembly front sun gear thrust

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 6 of 23

19 20

7D006 7H361

Gear assembly rear planet Snap ring

Clutches and Band

Item 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Part Number 7D483 7A019 7C041 7H351 7D483 7B066 7B164 7B442 7H363 7H359 7F235 7A262 7H335 7F283 7D483 7B066 7B442 7B164 7H075 7D406 7B070 7D402 7D044 7D034 Retaining ring reverse clutch Rear sun gear assembly

Description

Thrust bearing assembly rear sun gear Direct clutch hub assembly Retaining ring Pressure plate forward/direct clutch (1 each) Friction plate assembly forward/direct clutch (forward 4, direct 3) Steel plate direct clutch (DC)(3) Snap ring DC balanced piston Direct clutch balanced piston Piston return spring assembly forward/direct clutch Piston assembly direct clutch Thrust bearing assembly direct clutch Cylinder assembly direct clutch Retaining ring reverse clutch (selective) Pressure plate reverse clutch Steel plate reverse clutch (2) Friction plate assembly reverse clutch (2) Spring retainer ring reverse clutch Spring retainer reverse clutch Piston return spring reverse clutch Piston assembly reverse clutch Drum assembly intermediate and overdrive Band assembly intermediate and overdrive

Main Control Assembly

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 7 of 23

Item 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

Part Number 7D142 7F194 7H140 7G179 7K720 7G408 W500100 W705271 7N266 W705271 7A092 7C155 7A008 7A101 7R294 7F445 7A270 7C338 7G411 7H392 7D400 7D398 7G408 7G316 7M040 7Z490 Valve assembly manual control Plate spring retainer (7) Spring bypass clutch control (4) Valve bypass clutch control Spring modulation valve Valve line pressure modulator Bolt M6 x 30 (3) Bolt M6 x 63 (5) Seal valve body Bolt M6 x 60 (5) Body control valve upper Gasket control valve body Gasket control body separator Body control valve lower Stop main regulator valve Clipthrottle valve plunger sleeve

Description

Spring main fluid pressure regulator valve Valve main fluid pressure regulator Spring solenoid regulator valve Valve shift solenoid Spring intermediate servo accumulator Piston intermediate servo accumulator Valveconverter pressure relief Spring converter regulator valve Valve lock-up control Gasket solenoid body

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 8 of 23

27 28 29 30 31 32 33 34 35 36 37 38

7G179 7M040 7G383 7H148 7H148 7G484 7G484 7G484 7H185 W500211 W500012 7G391

Valvelow/reverse shift Valve3-4 shift Main regulator valve variable force solenoid (VFS) (PCA) Shift solenoid (on/off) valve (SSA) Shift solenoid (on/off) valve (SSB) Pulse width modulation (PWM) solenoid valve (SSC) PWM solenoid valve (SSE) PWM solenoid valve (SSD) Bracket shift control solenoid hold down Screw M6 x 12 (7) Screw M6 x 14 (2) Body solenoid shift throttle pressure

Case Assembly

Item 1 2 3 4 5 6 7 8 9 10 11

Part Number 7D071 7A441 7D070 W706892-S300 7005 7H389 7B148 7M101 W500214-S300 W706316-S300 W703961-S309 Parking pawl shaft Parking brake pawl Pawl return spring Case dowel Case Case orifice plug Service identification tag Turbine shaft speed (TSS) sensor Bolt M6-1 x 20 O-ring Case stud

Description

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 9 of 23

12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

7L282 7A246 7F206 1177 7B362 7D028 7D021 W500214-S300 7D027 7D024 7F251 7G300 7G395 7F251 7G267 7G326 W701515-S309 7N148 7G101 7D419

Rubber vent cap Breather tube Overdrive band anchor stud Differential seal 1/8-27 Hex socket Connector 1/4 x 5/8 x 22.9 Case dowel pin Servo piston return spring Intermediate and overdrive servo piston and seal assembly Screw M6-1 x 20 Intermediate overdrive band servo cover Intermediate overdrive servo cover seal Neutral/drive accumulator piston Neutral/drive shift accumulator outer spring Neutral/drive shift accumulator inner spring 1-2 shift accumulator piston 1-2 shift accumulator outer spring 1-2 shift accumulator inner spring Line tap plug Oil transfer tube Park pawl actuating abutment Park pawl actuating plate

Seals, Rings and Gaskets

Item 1 2 3 4 5 6 7 8

Part Number 7D402 7A262 7H359 7A262 W706316-S300 7H360 7A262 7D019 Piston assembly reverse clutch Piston assembly direct clutch Piston direct clutch balance Piston low/reverse clutch O-ring turbine shaft speed (TSS) Piston forward clutch balance Piston assembly forward clutch

Description

Seal forward and direct clutch cylinder (4)

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 10 of 23

9 10 11 12 13 14 15 16 17 18 19 20 21

7A248 7A248 1177 W706315-S300 7N266 7B498 7Z302 7D024 7D021 7Z490 7C155 7R284 7D020

Seal assembly fluid pump Seal fluid pump Seal assembly differential O-ring output shaft speed (OSS) sensor Seal valve body (2) Seal manual shaft fluid (2) Seal fluid filter Seal overdrive servo cover Piston and seal assembly intermediate and overdrive servo Gasket solenoid body Gasket control valve body (1) Seal case cover (2) Seal reverse clutch cylinder (2)

Snap Rings

Item 1 2 3 4 5 6 7 8 9 10

Part Number 7D483 7D483 7H106 7H365 7D483 7D483 7D483 7D483 7H363 7D483 Ring reverse clutch retaining

Description Ring low/reverse clutch plate retaining (select fit) Ring final drive retainer Ring forward clutch balance piston Ring forward/direct clutch plate retaining (select fit) Snap ring front sun gear Ring low one-way clutch (OWC) retaining Ring reverse clutch retaining (select fit) Snap ring Direct clutch (DC) balance piston Ring forward/direct clutch planet retaining

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 11 of 23

11 12 13

7H075 7D483 7H361

Ring reverse clutch spring retaining Ring forward/direct clutch plate retaining (select fit) Snap ring rear planet assembly

Bearings, Bushings and Thrust Washers

Item 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Part Number 7C041 7H337 7H375 7M102 7C236 7H042 4221 4222 4228 4230 7H344 7170 7H335 7D234

Description Bearing assembly rear sun gear thrust No. 3 Bearing assembly front sun gear thrust No. 5 Bearing assembly front planet carrier thrust No. 6 Cone and roller assembly input shaft bearing (2) Cup input shaft bearing (2) Washer fluid pump support thrust Cone and roller assembly differential bearing (2) Cup differential bearing (2) Washer front axle differential side (2) Washer front axle differential bearing thrust (2) Cup transfer shaft roller bearing (2) Cone and roller assembly transfer shaft (2) Bearing assembly rear planet carrier thrust No. 4 Bearing assembly rear sun gear thrust No. 2 Bearing assembly direct clutch cylinder thrust No. 1

Overview of Construction and Function

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 12 of 23

Item 1 2 3 4 5 6 7 8 9 10 11 12 13

Part Number Intermediate/overdrive band

Description

Front ring gear planetary gear sets Low/reverse clutch Forward clutch Fluid pump and stator support Torque converter Transmission input shaft Differential Transfer shaft assembly Final drive input gear Low one-way clutch Reverse clutch Direct clutch

Torque Converter and Torque Converter Lock-up Clutch

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 13 of 23

Item 1 2 3 4 5

Part Number

Description Converter housing and impeller Turbine Stator Torque converter lock-up clutch Transmission input shaft

The torque converter transmits engine torque hydraulically to the transmission input shaft. The stator boosts the torque to the input shaft (approximately 85% difference in speed between the impeller and the turbine). The stator is made of synthetic resin to reduce weight. To increase the efficiency of the automatic transmission, the torque converter has an apply clutch. When the torque converter lock-up clutch is closed, the torque is transmitted directly from the crankshaft through the torque converter housing to the transmission input shaft. The torque converter clutch is applied hydraulically by the PCM by means of the solenoid valves in the valve body in third and fourth gears. Apply is dependent on the throttle position, vehicle speed and manual selector lever position. Fluid Pump and Stator Support

Item 1 2 3 4

Part Number Stator support Fluid pump Converter impeller hub Stator

Description

The fluid pump is a crescent gear pump and is driven directly from the crankshaft by means of drivers on the converter impeller hub. The fluid pump is bolted to the transmission housing. The stator support is part of the fluid pump. Splines on the support locate and hold the converter stator. Planetary gear sets

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 14 of 23

The individual gears are shifted by means of two planetary gear sets, connected one behind the other. Clutches and bands The individual ratios are selected by means of four multiplate clutches, a brake band and a roller one-way clutch. The components are controlled by the PCM through pulse width modulation (PWM) solenoid valves. Valve Body

Item 1 2 3 4 5 6

Part Number 7G484 7G484 7G484 7H148 7H148 7G383

Description Pulse width modulation (PWM) solenoid valve (SSC) PWM solenoid valve (SSE) PWM solenoid valve (SSD) Shift solenoid (on/off) valve (SSB) Shift solenoid (on/off) valve (SSA) Main regulator valve variable force solenoid (VFS) (PCA)

The valve body contains six solenoid valves:

three PWM solenoid valves (pulse width modulation solenoid valves, two shift solenoid (on/off) valves, one main regulating valve (variable force solenoid).

The individual clutches and bands are supplied pressure from the PWM solenoid valves and the shift solenoid (on/off) valves and thus the gears are shifted. The PWM solenoid valves allow direct actuation of the clutches and bands to ensure extremely smooth gear shifting through precise pressure regulation. The shift solenoid (on/off) valves switch the hydraulic path to the clutches and bands, reducing the number of required modulating valves. The main regulating valve (variable force solenoid) ensures that sufficient hydraulic pressure is available in all operating conditions. PWM solenoid valves 1-3 PWM solenoid valves 1, 2 and 3 control the pressure to the bands and clutches. Shift solenoid (on/off) valves 1 and 2 The shift solenoid (on/off) valves switch the different oil passages in the valve body to direct the pressure to the individual clutches and bands. The use of the shift solenoid valves are needed for direct actuation of the individual clutches and bands. Main regulating valve The main regulating valve (variable force solenoid) controls the required main line pressure for the individual transmission ranges. The main line pressure is controlled dependent on the current engine load. Internal Shift Mechanism

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 15 of 23

Item 1 2 3 4 5

Part Number 7A256 7C493 7E160 Lever on manual shaft Manual shaft Parking pawl engaging lever

Description

Lever and bracket control assembly Manual valve (in valve body which is not shown)

The shift lever is secured on a square on the manual shaft. Axial movement of the selector lever cable is changed into rotation of the manual shaft. In the transmission, the manual shaft operates the parking pawl engaging lever and the actuating lever of the manual valve. The manual valve, a valve operated entirely manually, is moved by means of the manual valve actuating lever in the valve body. The manual valve guarantees the functions during hydraulic emergency operation. External Shift Mechanism

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 16 of 23

Item 1 2 3 4 5 6

Part Number Selector lever assembly Selector lever Selector lever cable Lead-through Clip Lever on shift shaft

Description

The transmission end of the manual selector lever cable is attached to a ball on the lever on the manual shaft. The cable abutments are secured to the transmission housing, and then to the bracket of the manual selector lever. The adjuster for the manual selector lever cable is located at the transmission side of the sheath. At the manual selector lever end the cable is clipped onto a ball. Intermediate Gear Stage and Final Drive Assembly

Item 1

Part Number Final drive input gear

Description

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 17 of 23

2 3 4

Transfer shaft input gear Transfer shaft output gear Differential

The final drive input gear is splined to the planet carrier of the front planetary gear set and drives the transfer shaft input gear of the intermediate gear stage. The transfer shaft output gear of the intermediate gear stage drives the final drive assembly. The torque is transmitted to the halfshafts through the final drive assembly. The differential offsets differences in speed of rotation of the halfshafts. The intermediate gear stage is designed so that the final drive ratio can be adapted to requirements when the automatic transmission is used in conjunction with different engines. Overview Transmission Control

Item 1 2 3 4 5 6 7 8 9 10 11 12 13

Part Number EEC-V PCM Data link connector (DLC) Throttle position (TP) sensor

Description

Mass airflow (MAF) and intake air temperature (IAT) sensors Crankshaft position (CKP) sensor Output shaft speed (OSS) sensor Turbine shaft speed (TSS) sensor Transmission range (TR) sensor Transmission fluid temperature (TFT) sensor Overdrive (O/D) switch Stoplamp switch Selector lever shift lock solenoid Ignition key lock solenoid

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 18 of 23

14 15 16 17

Air conditioning relay Solenoid valves in the valve body Powertrain warning indicator in instrument cluster O/D indicator in instrument cluster

Powertrain Control Module (PCM)

Item 1 2

Part Number EEC-V PCM Inertia fuel shutoff (IFS)

Description

The PCM is located under the trim panel on the right-hand A-pillar. On vehicles with automatic transmissions, the EEC-V PCM controls the transmission in addition to the engine management system. In this case, a module with 104 pins is used. The PCM evaluates the incoming signals from the individual sensors and actuates the solenoid valves in the valve body of the transmission directly according to the operating state. Diagnostic checks can be carried out on the transmission through the data link connector (DLC) above the central junction box (CJB). Emergency operating program If correct gear shifting can no longer be guaranteed due to failure of certain signals, the PCM changes to an emergency operating program. The driver is informed of the operation of the emergency operating program by the illumination of the powertrain warning indicator in the instrument cluster. Continued motoring is guaranteed in the following limited conditions:

maximum main line pressure. 3rd gear in manual selector lever positions "D", "2" and "1" without the torque converter lock-up clutch. reverse gear in manual selector lever position "R".

Electronic Synchronous Shift Control (ESSC) Control of Shift Operations During a shift operation certain elements are released while others are actuated. Ideally, this process takes place simultaneously (synchronously) to avoid jerky gear shifting. The time for the shift operation should remain within the time limits provided. When the shift operation is controlled conventionally, the pressure buildup and reduction at the shift elements are set and defined for ideal conditions (synchronous shifting). As there is no way of influencing the control in the event of different levels of wear in the shift elements, when the transmission has been used for a fairly high mileage it is possible that the pressure buildup and reduction may no longer be synchronous. The result or premature pressure reduction at the element to be switched off is an unwanted rise in the turbine shaft speed as the element to be switched on cannot transmit the input torque. The result of delayed pressure reduction at the element to be switched off is an unwanted decrease in the turbine shaft speed as both shift elements transmit the input torque. In the process the torque is transmitted to the transmission housing through internal locking.

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 19 of 23

In both cases a jerk will be felt during the shift operation. In addition, wear in the shift elements leads to a lengthening of the shift operation. Therefore, shifting takes longer when the transmission has accumulated a higher mileage. Control of Shift Operations With ESSC In the automatic transmission, electronic synchronous shift control (ESSC) is used. ESSC monitors the shift operations and is able to adapt to the wear in the shift elements over the life of the transmission. This is possible since the shift elements are actuated by modulating valves. The system monitors the shift time whether the shift operation is synchronous. If the PCM detects a deviation from the stored values for the shift time and synchronization of the shift operation, the pressure buildup or reduction is adapted accordingly. Throttle position (TP) sensor The TP sensor is located on the throttle body. It supplies the PCM with information about the position of the throttle plate. It also detects the speed of actuation of the throttle plate. The PCM uses the signals for the following functions among other things:

to determine the shift timing, to control the main line pressure, to control the torque converter lock-up clutch, for kickdown.

In case of absence of the TP signal the engine control uses the signals of the MAF and IAT sensors as a substitute signal. The main line pressure is increased and hard shifts may occur. Mass air flow (MAF) and intake air temperature (IAT) sensor The MAF sensor is located between the air cleaner housing and the air intake hose leading to the throttle housing. The IAT sensor is incorporated in the housing of the MAF sensor. The MAF sensor in conjunction with the IAT sensor provides the PCM with the primary load signal. The PCM uses the signals for the following functions among other things:

to control the shift operations, to control the main line pressure.

If the MAF sensor fails, the signal of the TP sensor is used as a substitute. Crankshaft position (CKP) sensor The CKP sensor is located on the engine/transmission flange. The CKP sensor is an inductive sensor which provides the PCM with information about the engine speed and position of the crankshaft. The signal is used for the following functions among other things:

to control the torque converter lock-up clutch, to check the torque converter slip, to control the main line pressure.

No substitute signal is available for the CKP sensor. If the signal is not present, the engine stops. Turbine shaft speed (TSS) sensor The TSS sensor is located in the transmission housing over the transmission input shaft. The TSS sensor is an inductive sensor which senses the speed of rotation of the transmission input shaft. The signal is used for the following functions:

to control the shift operations, to control the torque converter clutch, to check the torque converter slip.

If the TSS sensor fails, the signal of the output shaft speed (OSS) sensor is used as a substitute signal. Output Shaft Speed (OSS) Sensor

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 20 of 23

The OSS sensor is located in the transmission housing above the rotor in the differential. The OSS sensor is an inductive sensor which detects the vehicle speed by means of a rotor on the differential. The signal is used for the following functions among other things:

to determine the shift timing, to supply the vehicle speed input signal for the PCM.

If the OSS sensor fails, the signal of the TSS sensor is used as a substitute signal. Transmission Range (TR) Sensor

The TR sensor is located on the manual shaft on the transmission housing. When the manual shaft is moved by means of the manual selector lever cable, an engagement pin in the inner ring of the TR sensor moves through the different positions. The signals are transmitted to the PCM, the reversing lamps and the starter inhibitor relay. NOTE: Correct operation of the TR sensor is only guaranteed when the manual selector lever cable is adjusted correctly. The signals of the TR sensor are used for the following functions:

to recognize the manual selector lever position, to actuate the starter inhibitor relay, to actuate the reversing lamps,

No substitute signal is available for the TR sensor. If the connection is cut, the vehicle cannot be started. Stoplamp switch The brake pedal position (BPP) switch is mounted on the brake pedal bracket.

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 21 of 23

It switches the stoplights on and tells the EEC-V PCM when the brakes are applied. The signal of the stoplamp switch is used by the PCM for the following functions:

to release the torque converter lock-up clutch when the brake pedal is depressed, to switch off the manual selector lever shift lock when the brake pedal is depressed in "P".

No substitute signal is available for the BPP switch. If the connection to the BPP switch is cut, the manual selector lever cannot be moved out of "P". Transmission fluid temperature (TFT) sensor The TFT sensor is located on the internal wiring harness to the solenoid valves in the fluid pan. It is a resistor and measures the transmission fluid temperature. The transmission fluid temperature is used by the PCM for the following functions:

Applying the torque converter clutch is not permitted until the transmission fluid reaches a certain temperature, engagement of fourth gear is prevented in extreme sub-zero temperatures until the normal operating temperature is reached, if the transmission fluid temperature is excessive, a pre-set fixed shift curve is selected and the torque converter lock-up clutch is closed in "2", "3" and "4"; of the transmission warning indicator is activated. No substitute signal is available for the TFT sensor.

Overdrive (O/D) Switch

The O/D switch transmits a signal to the PCM to select or suppress fourth gear in manual selector lever position "D". The signal of the O/D switch is used for the following functions:

as an input signal to convey the driver's intent to the PCM. to display the driver's intent with the O/D indicator in the instrument cluster.

No substitute signal is available for the O/D switch. If it should fail, it is always possible to shift into fourth gear in manual selector lever position "D". Manual Selector Lever Shift Lock Solenoid

Item 1 2 3

Part Number Solenoid Locking pin

Description

Manual release mechanism

When the ignition is switched on, the manual selector lever shift lock solenoid is actuated by depressing the brake (signal from the stoplamp switch). This retracts the locking pin so that he manual selector lever can be moved out of position "P".

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 22 of 23

Substitute Function

If the brake signal should fail due to a malfunction, manual unlocking is possible. For this, the cover of the release mechanism must be removed and a suitable object (ignition key) pressed into the opening until the manual selector lever can be moved out of position "P". NOTE: If "P" is selected again, the manual selector lever is locked again. Air conditioning If the PCM registers a kickdown signal (WOT, throttle plate opened 95%), the air conditioning is switched off for a maximum of 15 seconds. Starter inhibitor relay The relay prevents the engine starting in manual selector lever positions "R", "D", "2" and "1". The relay obtains the information about the position of the selector lever directly from the TR sensor. Ignition key lock solenoid The solenoid is incorporated in the ignition lock. In manual selector lever position "P" the ground connection to the solenoid is cut. The locking pin does not engage in the ignition lock. In all the other manual selector lever positions, the ground connection to the solenoid is closed and the locking pin engages in the ignition lock. When the manual selector lever is not in position "P", removal of the ignition key is prevented. O/D indicator The O/D indicator is located in the instrument cluster and is colored green.

It tells the driver that shifting into 4th gear is prevented by the transmission control. Powertrain warning indicator The powertrain warning indicator is located in the instrument cluster and is colored orange.

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

2005 Focus Workshop Manual

Page 23 of 23

It lights to tell the driver that the transmission control has switched to the emergency operating program or that the transmission fluid temperature is too high.

http://www.fordtechservice.dealerconnection.com/pubs/content/~WS5Y/~MUS~LEN/19/S... 9/27/2009

Das könnte Ihnen auch gefallen

- Shop Manual U-341FDokument115 SeitenShop Manual U-341FDavid100% (3)

- U140eand U241Dokument25 SeitenU140eand U241yosergey80% (5)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideVon EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideBewertung: 4.5 von 5 Sternen4.5/5 (8)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyVon EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyBewertung: 5 von 5 Sternen5/5 (1)

- U151E ComponentsDokument203 SeitenU151E ComponentsAndres Chavez Barrios100% (3)

- 4f27e 1Dokument75 Seiten4f27e 1Andres Daniel Garcia Farquet89% (9)

- Toyota A40a41 A43da43de Aw70 Aw71 Atsg Automatic Transmission Service GroupDokument112 SeitenToyota A40a41 A43da43de Aw70 Aw71 Atsg Automatic Transmission Service Groupanon_575426223100% (2)

- U 250eDokument132 SeitenU 250eRoman Filatov83% (6)

- A541e Automatic TransaxleDokument132 SeitenA541e Automatic TransaxleHuey_7480% (10)

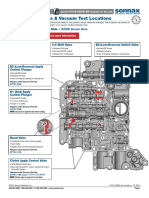

- A750-A761E VacTestLocationsDokument5 SeitenA750-A761E VacTestLocationsPedroMecanico100% (5)

- Nissan RE4F04AV Overhaul PDFDokument91 SeitenNissan RE4F04AV Overhaul PDFpedro melendez100% (2)

- Workshop Manual 3L30Dokument87 SeitenWorkshop Manual 3L30Михаил Пантелеев100% (8)

- AISIN Introducing The AW 6 SpeedDokument5 SeitenAISIN Introducing The AW 6 SpeedhaddadiNoch keine Bewertungen

- Baya - Bgha - Bvga - Byba - B7wa - Maya - Mfya - MGDokument4 SeitenBaya - Bgha - Bvga - Byba - B7wa - Maya - Mfya - MGAlex Maceira GraterolNoch keine Bewertungen

- CUERPO de Válvulas Ford 4F27EDokument5 SeitenCUERPO de Válvulas Ford 4F27Egtran50% (2)

- A 340 e 343Dokument8 SeitenA 340 e 343Mauricio Exequiel Chavez100% (1)

- U440e PDFDokument2 SeitenU440e PDFMaxisys Autel75% (4)

- JF016E-JF017E Vacuum Manual Valve BodyDokument4 SeitenJF016E-JF017E Vacuum Manual Valve Bodyak_adamNoch keine Bewertungen

- 4N71B PDFDokument94 Seiten4N71B PDFUlloaEliasNoch keine Bewertungen

- Abbreviations Used in This ManualDokument126 SeitenAbbreviations Used in This ManualSteve Fisher100% (6)

- Location Valve Body U151EDokument5 SeitenLocation Valve Body U151EgabotoyoNoch keine Bewertungen

- 5L40 eDokument1 Seite5L40 ePedroMecanicoNoch keine Bewertungen

- A442F Automatic Transmission Service and Repair ManualDokument142 SeitenA442F Automatic Transmission Service and Repair Manualstephany castroNoch keine Bewertungen

- 6L45 6L90 Zip in PDFDokument12 Seiten6L45 6L90 Zip in PDFAnonymous WzR5h9g8V100% (4)

- Import Checkball Vol III 82-92 PDFDokument11 SeitenImport Checkball Vol III 82-92 PDFJulio Chalbaud100% (1)

- 4f27e PDFDokument8 Seiten4f27e PDFUrszula WalczewskaNoch keine Bewertungen

- Transmisión AUT 03 - 72L Service ManualDokument134 SeitenTransmisión AUT 03 - 72L Service ManualJose nicolas Perez VasquezNoch keine Bewertungen

- JR405EDokument8 SeitenJR405ELalo Barajas Garcia100% (2)

- At PDFDokument200 SeitenAt PDFchory_1100% (1)

- CRV Matic MCVA BZKA PDFDokument8 SeitenCRV Matic MCVA BZKA PDFAlli Yanti50% (2)

- A 4 CF 2Dokument4 SeitenA 4 CF 2Diêgo MarcosNoch keine Bewertungen

- F4ael PDFDokument120 SeitenF4ael PDFPablo Cansas100% (2)

- F4A4x at ManualDokument135 SeitenF4A4x at Manualcavp271% (7)

- TranX 2000 Operator Manual 7-09Dokument188 SeitenTranX 2000 Operator Manual 7-09Robert Holt83% (6)

- A4CF2Dokument65 SeitenA4CF2Alex Maceira Graterol100% (2)

- A 960eDokument28 SeitenA 960elucasgratao100% (3)

- G4a ElDokument6 SeitenG4a ElEvan Valentine CalderwoodNoch keine Bewertungen

- Auto Trans Repair 6l45Dokument88 SeitenAuto Trans Repair 6l45Manos Stavrou88% (8)

- Toyota U660 Transmission Exploded ViewDokument5 SeitenToyota U660 Transmission Exploded ViewMarkus of Tau86% (7)

- 4f27e Book PDFDokument75 Seiten4f27e Book PDFcorie132100% (1)

- Aw60 41sn Zip BookDokument8 SeitenAw60 41sn Zip BookRiki Nurzaman100% (3)

- Critical Wear Areas & Vacuum Test Locations: Valve & Pump BodiesDokument2 SeitenCritical Wear Areas & Vacuum Test Locations: Valve & Pump BodiesAndersonNoch keine Bewertungen

- F4a51 PDFDokument82 SeitenF4a51 PDFJoão Ezer0% (1)

- 4R44E 5R55E Vac LocationsDokument2 Seiten4R44E 5R55E Vac LocationsPedroMecanico100% (1)

- U151E/U151F: Technical Bulletin #1575Dokument3 SeitenU151E/U151F: Technical Bulletin #1575oscarNoch keine Bewertungen

- Aw60 40le Zip inDokument10 SeitenAw60 40le Zip inMarko PavlovicNoch keine Bewertungen

- Rl4f02a PDFDokument98 SeitenRl4f02a PDFdanny tuning100% (2)

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WVon EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildVon EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildBewertung: 5 von 5 Sternen5/5 (1)

- GM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyVon EverandGM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyBewertung: 5 von 5 Sternen5/5 (1)

- 2005 FocusDokument8 Seiten2005 FocusRudi DCNoch keine Bewertungen

- Auto 4HP16 (0 30)Dokument31 SeitenAuto 4HP16 (0 30)Jose David Huanca Taype67% (3)

- 4 F 27 e SolenoidsDokument5 Seiten4 F 27 e Solenoidsseminar1212Noch keine Bewertungen

- Hyundai Santa Fe 2006 Auto TransaxleDokument194 SeitenHyundai Santa Fe 2006 Auto Transaxlebravo6d78% (9)

- C100 Service Training Manual:: All Wheel Drive (AWD)Dokument18 SeitenC100 Service Training Manual:: All Wheel Drive (AWD)sertex_jo100% (5)

- Ishift and Powertronioc TrainingDokument265 SeitenIshift and Powertronioc TrainingSherzad Chem100% (26)

- 950f Wheel Loaders Power Shift Transmission - Prueba y AjusteDokument15 Seiten950f Wheel Loaders Power Shift Transmission - Prueba y AjusteJosé de BritoNoch keine Bewertungen

- Azera Automatic Transaxle SystemDokument170 SeitenAzera Automatic Transaxle SystemPaulo Correa100% (1)

- Tranny 722 RepairDokument159 SeitenTranny 722 Repairpaschov100% (3)

- Torque Converter Catalogue For Web PDFDokument345 SeitenTorque Converter Catalogue For Web PDFTransmisiones Automáticas Chepe100% (7)

- 700 R4 Transmission EvolutionDokument14 Seiten700 R4 Transmission EvolutionTransmisiones Automáticas Chepe100% (2)

- Código P0171Dokument4 SeitenCódigo P0171Transmisiones Automáticas ChepeNoch keine Bewertungen

- Cuerpos de Válvulas Catálogo PDFDokument68 SeitenCuerpos de Válvulas Catálogo PDFTransmisiones Automáticas Chepe83% (6)

- Revista de TransmisionesDokument68 SeitenRevista de TransmisionesTransmisiones Automáticas Chepe100% (4)

- AX4N Vs AX4S OPERACIÓN DE SOLENOIDESDokument7 SeitenAX4N Vs AX4S OPERACIÓN DE SOLENOIDESTransmisiones Automáticas Chepe100% (2)

- 4L60E Common ProblemsDokument4 Seiten4L60E Common ProblemsTransmisiones Automáticas Chepe100% (2)

- 4L60 eDokument112 Seiten4L60 eFelipe Jaramillo RoblesNoch keine Bewertungen

- Mercedes 722.0 To 722.6 5 Speed Chassis Ending 177-123 - 4 Bolt Pan Chassis Ending 123-126 - 6 Bolt Pan 3-4 SPEEDDokument6 SeitenMercedes 722.0 To 722.6 5 Speed Chassis Ending 177-123 - 4 Bolt Pan Chassis Ending 123-126 - 6 Bolt Pan 3-4 SPEEDTransmisiones Automáticas Chepe0% (1)

- Previous MenuDokument95 SeitenPrevious MenuTransmisiones Automáticas Chepe100% (2)

- Previous MenuDokument88 SeitenPrevious MenuTransmisiones Automáticas ChepeNoch keine Bewertungen

- Previous MenuDokument88 SeitenPrevious MenuTransmisiones Automáticas Chepe100% (2)

- A4ld HBDokument110 SeitenA4ld HBTransmisiones Automáticas ChepeNoch keine Bewertungen

- No 3-4 Ax4n Forward Control ValveDokument2 SeitenNo 3-4 Ax4n Forward Control ValveTransmisiones Automáticas ChepeNoch keine Bewertungen

- TD 201102Dokument68 SeitenTD 201102Transmisiones Automáticas Chepe50% (2)

- 4t65e Epc Sol FallaDokument3 Seiten4t65e Epc Sol FallaTransmisiones Automáticas Chepe100% (1)

- AX4N, Problemas 3-4, Neutralización Por Válvula de Control Del Embrague de AvanceDokument6 SeitenAX4N, Problemas 3-4, Neutralización Por Válvula de Control Del Embrague de AvanceTransmisiones Automáticas ChepeNoch keine Bewertungen

- Operator Manual HL MODELO 90-5000 Ingerson-IntermediaDokument37 SeitenOperator Manual HL MODELO 90-5000 Ingerson-IntermediaRafael Agustin Menchaca MarinNoch keine Bewertungen

- Parsing Pressure and Temperature RatingsDokument6 SeitenParsing Pressure and Temperature RatingsAhmed AbdullaNoch keine Bewertungen

- fn09s PD En0h1116ge23r1009 PDFDokument4 Seitenfn09s PD En0h1116ge23r1009 PDF2267airportNoch keine Bewertungen

- Accurshear Brochure (Web 03 - 18) PDFDokument20 SeitenAccurshear Brochure (Web 03 - 18) PDFFrancisco Javier Sandoval MoralesNoch keine Bewertungen

- Automatic Labeling Machine and MethodDokument14 SeitenAutomatic Labeling Machine and MethodHùng ThanhNoch keine Bewertungen

- Techdoc Print Page-140h-5 PDFDokument8 SeitenTechdoc Print Page-140h-5 PDFFranciscoOliveira100% (1)

- Good Tuning A Pocket Guide Fourth EditionDokument46 SeitenGood Tuning A Pocket Guide Fourth EditionAugusto Cabrera100% (1)

- Grundfosliterature 288192Dokument64 SeitenGrundfosliterature 288192CraftychemistNoch keine Bewertungen

- Splbe - Master Plumber 2015 15.: Page 1 of 4Dokument4 SeitenSplbe - Master Plumber 2015 15.: Page 1 of 4gregNoch keine Bewertungen

- HLR 7965A: Hydraulic Interface ValveDokument2 SeitenHLR 7965A: Hydraulic Interface ValveMalique AdamNoch keine Bewertungen

- Wa250 6 Komatsu Shop ManualDokument1.293 SeitenWa250 6 Komatsu Shop ManualTrung Lê100% (3)

- Crossflow ScrubberDokument8 SeitenCrossflow Scrubbermourinho2Noch keine Bewertungen

- Abu Dhabi Guid To Water Supply RegulationsDokument72 SeitenAbu Dhabi Guid To Water Supply RegulationsAdlan100% (8)

- Aramco Piping QuestionsDokument6 SeitenAramco Piping Questionschandu666creator88% (8)

- BA150E Diesel Driven: Dewatering and Sewage Pump Max. 475 M /hour, Max. 35 MWCDokument6 SeitenBA150E Diesel Driven: Dewatering and Sewage Pump Max. 475 M /hour, Max. 35 MWCGoran MatovicNoch keine Bewertungen

- General Purpose Hydraulic Valves: Bi - Level Float Control ValveDokument2 SeitenGeneral Purpose Hydraulic Valves: Bi - Level Float Control Valvevelikimag87Noch keine Bewertungen

- Manual Spider VarcoDokument45 SeitenManual Spider VarcoJAVIER EDUARDO MANTILLA BUITRAGO100% (1)

- 10 - Ball ValvesDokument12 Seiten10 - Ball ValvesJosh WhiteNoch keine Bewertungen

- Notes About SafetyDokument156 SeitenNotes About SafetycraoNoch keine Bewertungen

- Transmision Automatica CorollaDokument50 SeitenTransmision Automatica Corollajavier guardiaNoch keine Bewertungen

- Hydril MSP 29-500 ManualDokument26 SeitenHydril MSP 29-500 ManualTitanBOP100% (1)

- Docmine: Spare Parts ListDokument98 SeitenDocmine: Spare Parts ListJH Miguel AngelNoch keine Bewertungen

- Seko Spring 2015Dokument12 SeitenSeko Spring 2015unggul baskoroNoch keine Bewertungen

- لقطة شاشة 2023-12-21 في 7.24.27 مDokument45 Seitenلقطة شاشة 2023-12-21 في 7.24.27 مhamza.nasser091Noch keine Bewertungen

- CAT 3408 Testing and AdjustingDokument78 SeitenCAT 3408 Testing and AdjustingCarlos Romero95% (20)

- CEI 90 Series Servo Valves: OEM & Replacement UnitsDokument2 SeitenCEI 90 Series Servo Valves: OEM & Replacement UnitsNabeel MohammedNoch keine Bewertungen

- Imt - 15-113 Instruction ManualDokument26 SeitenImt - 15-113 Instruction ManualJuan Carlos ChaparroNoch keine Bewertungen

- Arjo - Serv GB Rev BDokument54 SeitenArjo - Serv GB Rev Blaszlo123167% (3)

- Industrial Fittings - Couplings: Reloading Couplings - Application in TransportDokument50 SeitenIndustrial Fittings - Couplings: Reloading Couplings - Application in TransportArmando GaviñoNoch keine Bewertungen

- HE - PILBARA - BROCHURE - 17pp A4Dokument17 SeitenHE - PILBARA - BROCHURE - 17pp A4Jorge VillalobosNoch keine Bewertungen