Beruflich Dokumente

Kultur Dokumente

DESIGN

Hochgeladen von

jaythakar8887Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DESIGN

Hochgeladen von

jaythakar8887Copyright:

Verfügbare Formate

DESIGN

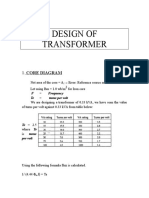

>> DESIGN OF SINGLE PHASE 1KVA, 50HZ, 230/110V TRANSFORMER:

I) CORE SECTION:

Volt ampere rating of Transformer = 1000 VA Turns per volt, Te = 1.6 Flux, m = 1/(4.44*f* Te) = 1/(4.44*50*1.6) m = 2.81*103 Wb Taking Flux density as 1.3 Wb/m2 So, Net iron area of core, Ai = m/Bm = 2.81*103/1.3 Ai = 2.16*103 mm2 Gross core area, Agi = 2.16*103/0.9 Agi = 2.406*103 mm2 Taking a Square section for central limb. Width of central limb, A = Sq. rt. (Agi) = Sq. rt. (2.406*103) A = 49.05 mm

PAGE: 1

II) PRIMARY WINDING:

Taking efficiency of transformer, = 85% So, Primary winding current, Ip = VA/(*Vp) = 1000/(0.85*230) Ip =5.11 A Taking current density as p = 2.5 A/mm2 Area of primary winding conductor, ap = Ip/p = 5.11/2.5 ap = 2.046 mm2 Diameter of bare conductor = Sq. rt. (4*ap/) = Sq. rt. (4*2.046/3.14) = 1.614 mm Using enamelled conductors. The nearest standard conductor has bare diameter, d = 1.7 mm. The diameter of insulated conductor, d 1= 1.81 mm with medium covering of insulation. Space factor for primary winding, Sf = 0.8*(d/d1) 2 = 0.8*(1.7/1.81) 2 = 0.703 Area of primary conductor used, ap = /4*(d) 2 = /4*(1.7) 2 ap = 2.269 mm2 Number of primary winding turns, Tp =Vp*Te = 230*1.6 Tp = 368 turns PAGE: 2

Window space required by primary winding, Wp = Tp*ap/Sf = 368*2.269/0.703 Wp = 1184.38 mm2

III) SECONDARY WINDING:

Secondary winding current, Is = VA/Vs = 1000/110 = 9.09 A Area of secondary winding conductor, as = Is/s = 9.09/2.5 as = 3.639 mm2 Diameter of bare conductor = Sq. rt. (4*as/) = Sq. rt. (4*3.639/3.14) = 2.151 mm Using enamelled conductor for secondary winding. The nearest standard conductor has bare diameter, d = 2.240 mm The diameter of insulated conductor, d1 = 2.365 mm Space factor for secondary winding, Sf = 0.8*(d/d1) 2 = 0.8*(2.240/2.365) 2 Sf = 0.717 Area of secondary conductor used, as = /4*(d) 2 = /4*(2.240) 2 as = 3.940 mm2

PAGE: 3

When calculating the number of secondary winding turns an allowance of 5 percent extra turns are made to compensate for the voltage drop in the winding. Number of secondary winding turns, Ts = 1.05*Vs*Te = 1.05*110*1.6 Ts = 185 turns Window space required by secondary winding, Ws = Ts*as/Sf = 185*3.940/0.717 Ws = 1015.5 mm2

IV) STAMPING SIZE:

Total window space required, Aw = 1.2*(space required for primary and secondary winding) = 1.2*(Wp+Ws) = 1.2*(1184.38+1015.5) = 2639.83 mm2 Aw = 10.39 Sq. inch Now, we have to select a stamping which gives: a) Width of central limb, A = 49.05 mm A = 1.93 b) Area of window, Aw = 2639.83 mm2 Aw = 10.39 Sq. inch Using a combination of E and I stampings.

PAGE: 4

From figure:

Diagram of lamination for small transformers (E-I type):

i)

ii) iii) iv) v) Now,

A = 2 B = 7.25 C = 6.75 D = 1 E = 1 Width of window, Ww = (B-A-2*D)/2 = (7.25-2-(2*1))/2 Ww = 1.625 inch Height of window, Hw = C-2*E = 6.75-(2*1) Hw = 4.75 inch

PAGE: 5

Area of window provided, Aw = Ww*Hw = 1.625*4.75 Aw = 7.718 Sq. inch Width of central limb, A = 2 = 50.08 mm >> Thus, it satisfies the above conditions, which are required.

PAGE: 6

SIGN:

PAGE: 7

Das könnte Ihnen auch gefallen

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsVon EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNoch keine Bewertungen

- Design of TransformersDokument26 SeitenDesign of TransformersSagun KatuwalNoch keine Bewertungen

- Core DesignDokument3 SeitenCore DesignJAMES WARURUNoch keine Bewertungen

- Transformer Design Module 2 NewDokument17 SeitenTransformer Design Module 2 NewRajath SuryaNoch keine Bewertungen

- Transformer Solved Examples of Basic Electrical Eng by Nagrath and KothariDokument4 SeitenTransformer Solved Examples of Basic Electrical Eng by Nagrath and KothariAnurag ZwNoch keine Bewertungen

- unit-II TransformersDokument19 Seitenunit-II Transformersc.naresh9727100% (1)

- E. WORKSHOP II by SemereDokument93 SeitenE. WORKSHOP II by SemereSami Ye KiyaNoch keine Bewertungen

- Final Report Transformer Design Section A PDFDokument68 SeitenFinal Report Transformer Design Section A PDFThabiso Kyle100% (1)

- Objective:: Voltage Per Turn: EDokument19 SeitenObjective:: Voltage Per Turn: EMohammed Rubayet Sharif100% (1)

- Transformer Design ParametersDokument6 SeitenTransformer Design ParametersPravat SatpathyNoch keine Bewertungen

- Autotransformer ModifiedDokument32 SeitenAutotransformer ModifiedFahad MemonNoch keine Bewertungen

- S1S2122 KE37503 Chapter 4Dokument100 SeitenS1S2122 KE37503 Chapter 4PenziiNoch keine Bewertungen

- Transformer CalculationDokument6 SeitenTransformer CalculationsathiyaseelanNoch keine Bewertungen

- Zener Diode and Diode ApplicationDokument62 SeitenZener Diode and Diode Applicationnibar dyllanNoch keine Bewertungen

- Harmonics Transformer de RatingDokument6 SeitenHarmonics Transformer de RatingFabricio Dias CoimbraNoch keine Bewertungen

- 192 - EE8301, EE6401 Electrical Machines I - Question Bank 3Dokument15 Seiten192 - EE8301, EE6401 Electrical Machines I - Question Bank 3Kaleeswari SaraswathiNoch keine Bewertungen

- Vector GroupDokument8 SeitenVector GroupSuraj Kumar GuptaNoch keine Bewertungen

- IEEMA-Basics of Dual Ratio TransformersDokument3 SeitenIEEMA-Basics of Dual Ratio TransformersHari Krishna.MNoch keine Bewertungen

- New Bharat: A Applied PH Hysics 2Dokument2 SeitenNew Bharat: A Applied PH Hysics 2Ashish VermaNoch keine Bewertungen

- What Is The Use of Choke in Florescent TubesDokument7 SeitenWhat Is The Use of Choke in Florescent Tubessumanta1981100% (2)

- HW 3 SolDokument3 SeitenHW 3 SolJonathan Bathistoel100% (1)

- Boost DesignDokument4 SeitenBoost DesignmuthukumartharaniNoch keine Bewertungen

- Ee6604 Quesition Bank PDFDokument64 SeitenEe6604 Quesition Bank PDFisctomaslopezNoch keine Bewertungen

- Lattice DiagramDokument19 SeitenLattice DiagramDDragos GeorgeNoch keine Bewertungen

- 1.to Find Voltage Regulation of Single Phase TransformerDokument7 Seiten1.to Find Voltage Regulation of Single Phase Transformershahabrandhawa50% (2)

- EEE 465 - PPT - 3Dokument12 SeitenEEE 465 - PPT - 3Md IbtidaNoch keine Bewertungen

- Lecture 11 Electrification of Commercial InstallationDokument7 SeitenLecture 11 Electrification of Commercial InstallationBUKENYA BEEE-2026Noch keine Bewertungen

- Testing of Transformers-OC&SC-Sumpners TestDokument15 SeitenTesting of Transformers-OC&SC-Sumpners Testshree100% (1)

- ICL8038 Linear Sweep Function Generator CCTDokument2 SeitenICL8038 Linear Sweep Function Generator CCTian_new100% (1)

- Section - 1 (Power Transformer) A. Purpose: The Purpose of This Document Is To Design (Sizing Calculation) MainDokument2 SeitenSection - 1 (Power Transformer) A. Purpose: The Purpose of This Document Is To Design (Sizing Calculation) Mainsrikanta100% (1)

- Dual Ratio Transformer MonographDokument7 SeitenDual Ratio Transformer MonographGhanshyam Lalwani0% (1)

- PUT Experiment EditedDokument9 SeitenPUT Experiment EditedReineirDuranNoch keine Bewertungen

- Lecture 4 Symmetrical ComponentsDokument15 SeitenLecture 4 Symmetrical ComponentsJomel CristobalNoch keine Bewertungen

- Swing and Deflection CalculationsDokument28 SeitenSwing and Deflection CalculationsanandpurushothamanNoch keine Bewertungen

- Push-Pull Converter Design and CircuitDokument4 SeitenPush-Pull Converter Design and Circuitchinnathambij0% (1)

- 2015 Distance Relay ExampleDokument2 Seiten2015 Distance Relay ExampleAmanNoch keine Bewertungen

- Electromagnetic Relay Static Relay Numerical Relay: Single Input Comparator Dual Input Comparator Multi Input ComparatorDokument34 SeitenElectromagnetic Relay Static Relay Numerical Relay: Single Input Comparator Dual Input Comparator Multi Input ComparatorSathiyarajNoch keine Bewertungen

- Lecture Objectives: Working Principle of Alternator OR Synchronous Generator StatorDokument5 SeitenLecture Objectives: Working Principle of Alternator OR Synchronous Generator StatorZ_JahangeerNoch keine Bewertungen

- Economic Load Dispatch (Optimal Power Flow) : by Adisu TeshaleDokument26 SeitenEconomic Load Dispatch (Optimal Power Flow) : by Adisu TeshaleAdisuNoch keine Bewertungen

- Transformer Design CodeDokument10 SeitenTransformer Design CodemaheshggargNoch keine Bewertungen

- ! - 1979 - Drouet, M., & Nadeau, F. - Pressure Waves Due To Arcing Faults in A SubstationDokument4 Seiten! - 1979 - Drouet, M., & Nadeau, F. - Pressure Waves Due To Arcing Faults in A SubstationMikeNoch keine Bewertungen

- TransformerDokument20 SeitenTransformerKarthikeyanKarunNoch keine Bewertungen

- Motor Pump Protection RelaysDokument6 SeitenMotor Pump Protection RelaysSufyan HashmiNoch keine Bewertungen

- Understanding Vector Group of Transformer 1 PDFDokument9 SeitenUnderstanding Vector Group of Transformer 1 PDFkishansaiNoch keine Bewertungen

- Electronic Devices and Circuits Lab - Full Wave Rectifier With and Without Filters - Notes - SboDokument6 SeitenElectronic Devices and Circuits Lab - Full Wave Rectifier With and Without Filters - Notes - SboECEOCETNoch keine Bewertungen

- Transmission Lines: OlutionDokument15 SeitenTransmission Lines: Olutionbansalr100% (1)

- 360 Topic 6 DC MachineDokument33 Seiten360 Topic 6 DC MachineAchsan ArfandiNoch keine Bewertungen

- Time-Current Coordination ExampleDokument6 SeitenTime-Current Coordination ExamplekishansaiNoch keine Bewertungen

- What Is R.M.S (Root Mean Square) ?Dokument5 SeitenWhat Is R.M.S (Root Mean Square) ?Muhammad UmairNoch keine Bewertungen

- Experiment# 10: Measure The Power and Power Factor by Three Ammeter MethodDokument10 SeitenExperiment# 10: Measure The Power and Power Factor by Three Ammeter MethodFarwa MunirNoch keine Bewertungen

- Over Reach of Distance RelayDokument2 SeitenOver Reach of Distance Relayimcoolmailme2Noch keine Bewertungen

- Transformer DesignDokument8 SeitenTransformer DesignAzminAg100% (1)

- LLG FaultDokument8 SeitenLLG Faultranjish_007Noch keine Bewertungen

- Study of Over Current Earth Fault RelayDokument1 SeiteStudy of Over Current Earth Fault RelayVirender RanaNoch keine Bewertungen

- Phasor Representation of ACDokument21 SeitenPhasor Representation of ACKavitha NaikNoch keine Bewertungen

- Design of Induction Motor v3Dokument17 SeitenDesign of Induction Motor v3hamzaNoch keine Bewertungen

- Three Phase Transformer TrainerDokument20 SeitenThree Phase Transformer TrainerHaroon AsadNoch keine Bewertungen

- Design of Low Voltage Step Down Transformer (220/30V, 200VA)Dokument5 SeitenDesign of Low Voltage Step Down Transformer (220/30V, 200VA)Usman RasheedNoch keine Bewertungen

- GETCO Power Map 01.10.2020Dokument1 SeiteGETCO Power Map 01.10.2020jaythakar8887Noch keine Bewertungen

- 0 - Resume - Shrivastav Akash S - Format2Dokument2 Seiten0 - Resume - Shrivastav Akash S - Format2jaythakar8887Noch keine Bewertungen

- Arjun Suresh Kumar: Work Experience EducationDokument1 SeiteArjun Suresh Kumar: Work Experience Educationjaythakar8887Noch keine Bewertungen

- Smart Farming: A Farmer Is An Economist, Botanist, MeteorologistDokument2 SeitenSmart Farming: A Farmer Is An Economist, Botanist, Meteorologistjaythakar8887Noch keine Bewertungen

- ૫૧ શક્તિપીઠ ના દર્શન નામ સાથેDokument52 Seiten૫૧ શક્તિપીઠ ના દર્શન નામ સાથેjaythakar8887Noch keine Bewertungen

- Presentation by Evren EKMEKÇİDokument35 SeitenPresentation by Evren EKMEKÇİbluffmaster8995888Noch keine Bewertungen

- Presentation ON Intra - State Abt: BY General Manager (SLDC) DelhiDokument45 SeitenPresentation ON Intra - State Abt: BY General Manager (SLDC) Delhijaythakar8887Noch keine Bewertungen

- CH-1 - DC Generator Q.bank PDFDokument2 SeitenCH-1 - DC Generator Q.bank PDFjaythakar8887Noch keine Bewertungen

- Chapter 56 Highway LightingDokument56 SeitenChapter 56 Highway Lightingjaythakar8887Noch keine Bewertungen

- Transformer StudiesDokument52 SeitenTransformer StudiesSyed JaveedNoch keine Bewertungen

- Failure Reports of Equipment - 66 KV ITC Make CT at 220 KV Khanpur Sub StationDokument2 SeitenFailure Reports of Equipment - 66 KV ITC Make CT at 220 KV Khanpur Sub Stationjaythakar8887Noch keine Bewertungen

- Cub Pveff Lesson01 Fundamentalsarticle v2 Tedl DWCDokument4 SeitenCub Pveff Lesson01 Fundamentalsarticle v2 Tedl DWCjaythakar8887Noch keine Bewertungen

- 3 Phase Power GenerationDokument9 Seiten3 Phase Power Generationjaythakar8887Noch keine Bewertungen

- Student Profile FinalDokument4 SeitenStudent Profile Finaljaythakar8887Noch keine Bewertungen

- Secrets of SuccessDokument4 SeitenSecrets of Successjaythakar8887Noch keine Bewertungen

- List of Endangered Species in IndiaDokument5 SeitenList of Endangered Species in Indiajaythakar8887Noch keine Bewertungen

- Climate Change Global WarmingDokument1 SeiteClimate Change Global Warmingjaythakar8887Noch keine Bewertungen

- Current AffairsDokument4 SeitenCurrent Affairsjaythakar8887Noch keine Bewertungen

- Digital Wattmeter: Aaron Fogle & Pat GilesDokument29 SeitenDigital Wattmeter: Aaron Fogle & Pat Gilesjaythakar8887Noch keine Bewertungen

- Hockey: India Face A Must-Win Vs SpainDokument5 SeitenHockey: India Face A Must-Win Vs Spainjaythakar8887Noch keine Bewertungen

- Electrical Workshop First YearDokument25 SeitenElectrical Workshop First Yearjaythakar888775% (4)

- 14ahmedabad City Pg16 0Dokument1 Seite14ahmedabad City Pg16 0jaythakar8887Noch keine Bewertungen

- BE Semester-3 (Electrical Engineering) Question Bank Electric Power Generation All Questions Carry Equal Marks (10 Marks)Dokument2 SeitenBE Semester-3 (Electrical Engineering) Question Bank Electric Power Generation All Questions Carry Equal Marks (10 Marks)jaythakar8887Noch keine Bewertungen

- Gas TurbinesDokument74 SeitenGas TurbinesEnas Al-khawaldehNoch keine Bewertungen

- Drop Test of ContainerDokument10 SeitenDrop Test of ContainerFABIAN FIENGONoch keine Bewertungen

- Cyclotron Bunker ShieldDokument6 SeitenCyclotron Bunker ShieldDomenico Barillari100% (2)

- Transmission-Line FiltersDokument6 SeitenTransmission-Line FiltersgongsengNoch keine Bewertungen

- Physics 72 SyllabusDokument7 SeitenPhysics 72 Syllabuscontinentalfloss100% (1)

- Thermal Analysis of The Heat Exchanger Tubes Using Ansys PDFDokument4 SeitenThermal Analysis of The Heat Exchanger Tubes Using Ansys PDFMuhammadBarrylAnggriawanNoch keine Bewertungen

- SENIOR TWO PhysicsDokument7 SeitenSENIOR TWO PhysicsNdawula Isaac100% (1)

- Dielectric MetamaterialsDokument6 SeitenDielectric MetamaterialspanchopanzaNoch keine Bewertungen

- Electromacnetic WavesDokument13 SeitenElectromacnetic WavesChaztan RajNoch keine Bewertungen

- Soal PTS Ii B.inggris Kelas 5 2022-2023Dokument4 SeitenSoal PTS Ii B.inggris Kelas 5 2022-2023Aizen nyatirNoch keine Bewertungen

- Light 10th1Dokument30 SeitenLight 10th1Aryan Rajeev GowdaNoch keine Bewertungen

- Set BDokument12 SeitenSet BDan CasuraoNoch keine Bewertungen

- SCI 10 Module 2 Assignment 1 Perform Activity 1.1 A Critique of Hubble S Classic Paper A Century ADokument3 SeitenSCI 10 Module 2 Assignment 1 Perform Activity 1.1 A Critique of Hubble S Classic Paper A Century AMay GloriaNoch keine Bewertungen

- 03 Stars and The UniverseDokument71 Seiten03 Stars and The UniverseNaz KhaliliNoch keine Bewertungen

- MM326 SYSTEM DYNAMICS - hw1 - Sol PDFDokument9 SeitenMM326 SYSTEM DYNAMICS - hw1 - Sol PDFdragons123x100% (1)

- Raman, Infrared and X-Ray Diffraction Study of Phase Stability in La 1 X Ba X Mno 3 Doped ManganitesDokument9 SeitenRaman, Infrared and X-Ray Diffraction Study of Phase Stability in La 1 X Ba X Mno 3 Doped ManganitesAde MulyawanNoch keine Bewertungen

- Vertical Curve DesignDokument6 SeitenVertical Curve DesignMidhun JosephNoch keine Bewertungen

- PVA Grades and SpecificationsDokument2 SeitenPVA Grades and Specificationspasalacqua85Noch keine Bewertungen

- ADDC Construction QuestionairesDokument19 SeitenADDC Construction QuestionairesUsman Arif100% (1)

- Mechanical Properties of Fluids - Mind Map - NEET 2024Dokument3 SeitenMechanical Properties of Fluids - Mind Map - NEET 2024rkamini995Noch keine Bewertungen

- Math 121A: Homework 8 (Due April 10)Dokument2 SeitenMath 121A: Homework 8 (Due April 10)cfisicasterNoch keine Bewertungen

- Earthquakes and FaultsDokument3 SeitenEarthquakes and Faultsayeen miguelNoch keine Bewertungen

- Senior Presentation Old FormatDokument14 SeitenSenior Presentation Old FormatkosNoch keine Bewertungen

- Ingles Tecnico Ii ELI-300: Star-Delta StarterDokument2 SeitenIngles Tecnico Ii ELI-300: Star-Delta StarterEnrique Valdez JordanNoch keine Bewertungen

- Design of Mechanical ComponentsDokument40 SeitenDesign of Mechanical Componentsharish1989Noch keine Bewertungen

- Tugas 1 Advanced CrystallographyDokument7 SeitenTugas 1 Advanced CrystallographyMuhammad Hisyam FMIPANoch keine Bewertungen

- Skema Kertas 2 KimiaDokument9 SeitenSkema Kertas 2 KimiaariesNoch keine Bewertungen

- All Questions SLDokument50 SeitenAll Questions SLRoberto Javier Vázquez MenchacaNoch keine Bewertungen

- Pa V VB RT GL GL (G L G L: Reason: Magnitude of The Centripetal ForceDokument13 SeitenPa V VB RT GL GL (G L G L: Reason: Magnitude of The Centripetal ForcedemoNoch keine Bewertungen

- Chapter 11. A Sling Psychrometer and Relative Humidity: A Structured-Inquiry ActivityDokument4 SeitenChapter 11. A Sling Psychrometer and Relative Humidity: A Structured-Inquiry Activityks aksNoch keine Bewertungen