Beruflich Dokumente

Kultur Dokumente

Gayathri Bio Fuels

Hochgeladen von

Kiran KumarCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Gayathri Bio Fuels

Hochgeladen von

Kiran KumarCopyright:

Verfügbare Formate

Gayathri Bio Fuels

CONTENTS

Sl.No 1. 2. 3. 4. 5. 6.

PARTICULARS Industry Profile Company Profile Organizational Structure SWOT Analysis Findings, Suggestions and Conclusion Bibilography

PAGE NO 2 - 10 11 14 15 27 28 32 33 - 36 65- 66

Challakere

Page 1

Gayathri Bio Fuels

INDUSTRY PROFILE

A briquette (or briquette) is a block of flammable matter used as fuel to start and maintain fire. Common types of briquettes are charcoal briquettes and biomass briquettes.

Constituents of charcoal briquettes Wood charcoal (fuel)

Mineral char (fuel) Mineral carbon (fuel) Limestone (ash colorant) Starch (binder) Borax (release agent) Sodium nitrate (accelerant) Sawdust Wax (some brands: binder, accelerant, ignition facilitator). Chaff (Rice chaff and peanut chaff)

Some briquettes are compressed and dried brown coal extruded into hard blocks. This is a common technique for low rank coals. They are typically dried to 12-18% moisture, and are primarily used in household and industry.

Peat briquettes In Ireland, peat briquettes are a common type of solid fuel, largely replacing sods of raw peat as a domestic fuel. These briquettes consist of shredded peat, compressed to form a virtually smokeless, slow-burning, easily stored and transported fuel. Although often used as the sole fuel for a fire, they are also used to quickly and easily light a coal fire.

Challakere

Page 2

Gayathri Bio Fuels

Biomass briquettes Biomass briquettes are made from agricultural waste and are a replacement for fossil fuels such as oil or coal, and can be used to heat boilers in manufacturing plants, and also have applications in developing countries. Biomass briquettes are a renewable source of energy and avoid adding fossil carbon to the atmosphere. A number of companies in India have switched from furnace oil to biomass briquettes to save costs on boiler fuels. The use of biomass briquettes is predominant in the southern parts of India, where coal and furnace oil are being replaced by biomass briquettes. A number of units in Maharashtra (India) are also using biomass briquettes as boiler fuel. Use of biomass briquettes can earn Carbon Credits for reducing emissions in the atmosphere. Lanxess India and a few other large companies are supposedly using biomass briquettes for earning Carbon Credits by switching their boiler fuel. Biomass briquettes also provide more calorific value/kg and save around 30-40 percent of boiler fuel costs. A popular biomass briquette emerging in developed countries takes a waste produce such as sawdust, compresses it and then extrudes it to make a reconsistuted log that can replace firewood. It is a similar process to forming a wood pellet but on a larger scale. There are no binders involved in this process. The natural lignin in the wood binds the particles of wood together to form a solid. Burning a wood briquette is far more efficient than burning firewood. Moisture content of a briquette can be as low as 4%, whereas green firewood may be as high as 65%. The extrusion production technology of briquettes is the process of extrusion screw wastes (straw, sunflower husks, buckwheat, etc.) or finely shredded wood waste (sawdust) under high pressure when heated from 160 to 350 C . Sawdust briquettes have developed over time with two distinct types: those with holes through the centre, and those that are solid. Both types are classified as briquettes but are formed using different techniques. A solid briquette is manufactured using a piston press that compresses sandwiched layers of sawdust together. Briquettes with a hole are produced with a screw press. The hole is from the screw thread passing through the centre, but it also increases the surface area of the log and aids efficient combustion. Since 2009 in North India biomass briquette consumption has seen new dimensions. Many companies like Nishant Bio energy and Ekta Bio energy in Rajasthan are leading in the briquette supply and manufacturing.

Challakere

Page 3

Gayathri Bio Fuels

Biomass briquettes

Biomass briquettes are a bio fuel substitute to coal and charcoal. They are used to heat industrial boilers in order to produce electricity from steam. The most common use of briquettes are in the developing world, where energy sources are not as widely available. There has been a move to the use of briquettes in the developed world through the use of cofiring, when the briquettes are combined with coal in order to create the heat supplied to the boiler. This reduces carbon dioxide emissions by partially replacing coal used in power plants with materials that are already contained in the carbon cycle. Manufacturers mainly use three methods to create the briquettes, each depending on the way the biomass is dried out. Although biomass briquettes are usually manufactured, biomass has been used throughout history all over the world from simply starting campfires to the mass generation of electricity.

Composition and production

Bio coal briquettes have been introduced to meet the growing demand coal used in burning and heating purposes. These briquettes are perfect to use in boilers and are completely safe to environment. Biomass briquettes, mostly made of green waste and other organic materials, are commonly used for electricity generation, heat, and cooking fuel. These compressed compounds contain various organic materials, including rice husk, bagasse, ground nut shells, municipal solid waste, agricultural waste, or anything that contains high nitrogen content. The composition of the briquettes varies by area due to the availability of raw materials. The raw materials are gathered and compressed into briquette in order to burn longer and make transportation of the goods easier. These briquettes are very different from

Challakere Page 4

Gayathri Bio Fuels

charcoal because they do not have large concentrations of carbonaceous substances and added materials. Compared to fossil fuels, the briquettes produce low net total greenhouse gas emissions because the materials used are already a part of the carbon cycle. One of the most common variables of the biomass briquette production process is the way the biomass is dried out. Manufacturers can use torrefaction, carbonization, or varying degrees of pyrolysis. Researchers concluded that torrefaction and carbonization are the most efficient forms of drying out biomass, but the use of the briquette determines which method should be used. Compaction is another factor affecting production. Some materials burn more efficiently if compacted at low pressures, such as corn Stover grind. Other materials such as wheat and barley-straw require high amounts of pressure to produce heat. There are also different press technologies that can be used. A piston press is used to create solid briquettes for a wide array of purposes. Screw extrusion is used to compact biomass into loose, homogeneous briquettes that are substituted for coal in co-firing. This technology creates a toroidal, or doughnutlike, briquette. The hole in the centre of the briquette allows for a larger surface area, creating a higher combustion rate.

History

People have been using biomass briquettes in Nepal since before recorded history. Though inefficient, the burning of loose biomass created enough heat for cooking purposes and keeping warm. The first commercial production plant was created in 1982 and produced almost 900 metric tons of biomass. In 1984, factories were constructed that incorporated vast improvements on efficiency and

Challakere Page 5

Gayathri Bio Fuels

the quality of briquettes. They used a combination of rice husks and molasses. The King Mahendra Trust for Nature Conservation (KMTNC) along with the Institute for Himalayan Conservation (IHC) created a mixture of coal and biomass in 2000 using a unique rolling machine.

Co-firing

Co-firing relates to the combustion of two different types of materials. The process is primarily used to decrease CO2 emissions despite the resulting lower energy efficiency and higher variable cost. The combination of materials usually contains a high carbon emitting substance such as coal and a lesser CO2 emitting material such as biomass. Even though CO2 will still be emitted through the combustion of biomass, the net carbon emitted is nearly negligible. This is due to the fact that the material gathered for the composition of the briquettes are still contained in the carbon cycle whereas fossil fuel combustion releases CO2 that has been sequestered for millennia. Boilers in power plants are traditionally heated by the combustion of coal, but if co-firing were to be implemented, then the CO2 emissions would decrease while still maintaining the heat inputted to the boiler. Implementing co-firing would require few modifications to the current characteristics to power plants, as only the fuel for the boiler would be altered. A moderate investment would be required for implementing biomass briquettes into the combustion process. Co-firing is considered the most cost-efficient means of biomass. A higher combustion rate will occur when co-firing is implemented in a boiler when compared to burning only biomass. The compressed biomass is also much easier to transport since it is more dense, therefore allowing more biomass to be transported per shipment when compared to loose biomass. Some sources agree that a near-term solution for the greenhouse gas emission problem may lie in co-firing.

Challakere Page 6

Gayathri Bio Fuels

Compared to coal

The use of biomass briquettes has been steadily increasing as industries realize the benefits of decreasing pollution through the use of biomass briquettes. Briquettes provide higher calorific value per dollar than coal when used for firing industrial boilers. Along with higher calorific value, biomass briquettes on average saved 3040% of boiler fuel cost. But other sources suggest that cofiring is more expensive due to the widespread availability of coal and its low cost. However, in the long run, briquettes can only limit the use of coal to a small extent, but it is increasingly being pursued by industries and factories all over the world. Both raw materials can be produced or mined domestically in the United States, creating a fuel source that is free from foreign dependence and less polluting than raw fossil fuel incineration. Environmentally, the use of biomass briquettes produces much fewer greenhouse gases, specifically, 13.8% to 41.7% CO2 and NOX. There was also a reduction from 11.1% to 38.5% in SO2 emissions when compared to coal from three different leading producers, EKCC Coal, Decanter Coal, and Alden Coal. Biomass briquettes are also fairly resistant to water degradation, an improvement over the difficulties encountered with the burning of wet coal. However, the briquettes are best used only as a supplement to coal. The use of cofiring creates an energy that is not as high as pure coal, but emits fewer pollutants and cuts down on the release of previously sequestered carbon. The continuous release of carbon and other greenhouse gasses into the atmosphere leads to an increase in global temperatures. The use of co-firing does not stop this process but decreases the relative emissions of coal power plants.

Challakere

Page 7

Gayathri Bio Fuels

Use in developing world

The Legacy Foundation has developed a set of techniques to produce biomass briquettes through artisanal production in rural villages that can be used for heating and cooking. These techniques were recently pioneered by Virunga National Park in eastern Democratic Republic of Congo, following the massive destruction of the Mountain Gorilla habitat for charcoal.

Pangani, Tanzania, is an area covered in coconut groves. After harvesting the meat of the coconut, the indigenous people would litter the ground with the husks, believing them to be useless. The husks later became a profit center after it was discovered that coconut husks are well suited to be the main ingredient in bio briquettes. This alternative fuel mixture burns incredibly efficiently and leaves little residue, making it a reliable source for cooking in the undeveloped country. The developing world has always relied on the burning biomass due it its low cost and availability anywhere there is organic material. The briquette production only improves upon the ancient practice by increasing the efficiency of pyrolysis. Two major components of the developing world are China and India. The economies are rapidly increasing due to cheap ways of harnessing electricity and emitting large amounts of carbon dioxide. The Kyoto Protocol attempted to regulate the emissions of the three different worlds, but there were disagreements as to which country should be penalized for emissions based on its previous and future emissions. The United States has been the largest emitter but China has recently become the largest per capita. The United States had emitted a rigorous amount of carbon dioxide during its development and the developing nations argue that they should not be forced to meet the requirements. At the lower end, the undeveloped nations believe that they have little responsibility for what has

Challakere Page 8

Gayathri Bio Fuels

been done to the carbon dioxide levels. The major use of biomass briquettes in India, is in industrial applications usually to produce steam. A lot of conversions of boilers from FO to biomass briquettes have happened over the past decade. A vast majority of those projects are registered under CDM (Kyoto Protocol), which allows for users to get carbon credits.

The use of biomass briquettes is strongly encouraged by issuing carbon credits. One carbon credit is equal to one free ton of carbon dioxide to be emitted into the atmosphere. India has started to replace charcoal with biomass briquettes in regards to boiler fuel, especially in the southern parts of the country because the biomass briquettes can be created domestically, depending on the availability of land. Therefore, constantly rising fuel prices will be less influential in an economy if sources of fuel can be easily produced domestically. Lehra Fuel Tech Pvt. Ltd. is approved by Indian Renewable Energy Development Agency (IREDA), is one of the largest briquetting machine manufacturers from Ludhiana, India.

In the African Great Lakes region, work on biomass briquette production has been spearheaded by a number of NGOs with GVEP (Global Village Energy Partnership) taking a lead in promoting briquette products and briquette entrepreneurs in the three Great Lakes countries; namely, Kenya, Uganda and Tanzania. This has been achieved by a five year EU and Dutch government sponsored project called DEEP EA (Developing Energy Enterprises Project East Africa) . The main feed stock for briquettes in the East African region has mainly been charcoal dust although alternative like sawdust, bagasse, coffee husks and rice husks have also been used.

Challakere

Page 9

Gayathri Bio Fuels

Use in developed world

Coal is the largest carbon dioxide emitter per unit area when it comes to electricity generation. It is also the most common ingredient in charcoal there has been a recent push to replace the burning of fossil fuels with biomass. The replacement of this non-renewable resource with biological waste would lower the carbon footprint of grill owners and lower the overall pollution of the world. Citizens are also starting to manufacture briquettes at home. The first machines would create briquettes for homeowners out of compressed sawdust, however, current machines allow for briquette production out of any sort of dried biomass.

Arizona has also taken initiative to turn waste biomass into a source of energy. Waste cotton and pecan material used to provide a nesting ground for bugs that would destroy the new crops in the spring. To stop this problem, farmers buried the biomass, which quickly led to soil degradation. These materials were discovered to be a very efficient source of energy and took care of issues that had plagued farms.

The United States Department of Energy has financed several projects to test the viability of biomass briquettes on a national scale. The scope of the projects is to increase the efficiency of gasifiers as well as produce plans for production facilities

Challakere

Page 10

Gayathri Bio Fuels

COMPANY PROFILE

COMPANY NAME : Gayathri Agro Tech (P) Ltd. Bangalore Road Challakere, 577535.

NATURE OF BUSINESS : Mfg / selling based Industry.

OWNERS

Sudhakar

TYPE OF OWNERSHIP : Sole Entrepreneurship.

TEL-NO E-mail RAW MATERIAL

: : :

098452 83086, 08195 223736. gayathribiofuels@yahoo.co.in Saw Dust, Rice Husk Groundnut shells.

TURN OVER

7-8 lacs/month

FINISHED PRODUCTS OWNERS INVESTMENT AT STARTING

Challakere

Biomass Briquettes

25 Lacs

Page 11

Gayathri Bio Fuels

GAYATHRI AGRO TECH

Gayathri Bio-Fuels established in the year 1991 near Hiriyur road, Challakere, Chitradurga District, Karnataka as a manufacturer of Solid biomass briquette fuels. Gayathri Bio-Fuels manufacture briquettes using the best grade of raw materials procured from reputed vendors. Their product is widely appreciated by their clients for its reliable performance and high efficiency.

Gayathri Bio Fuels has built its reputation by offering unparalleled quality briquettes and service. They robust infrastructural facility equipped with the advanced machinery and technologies enabling them to meet large scale orders of their clients. Their manufacturing facilities are spread at different places.

Challakere

Page 12

Gayathri Bio Fuels

GAYATHRI AGRO TECH

Challakere

Page 13

Gayathri Bio Fuels

Introduction

Gayathri Agro Tech Ltd is the only industry that got success by manufacturing a different product in Challakere. i.e. Briquettes made of the agro wastes such as coffee extracts, groundnut shells, saw dust, Rice husk, Turmeric waste and chilli powder(waste). First of all they starting their own manufacturing industry with the capital of 25lacs by purchasing the machinery by Radhe Industrial Corporation at Challakere. Now it is the leading industry in Challakere and they also own another two briquette manufacturing plants in Challakere and one plant in Tumkur Industrial area. A huge demand is there for the product that manufactured in the Gayathri agro tech. They supplies there product to various states also such as Goa, Tamilnadu, Kerala and Maharashtra also.

Challakere

Page 14

Gayathri Bio Fuels

MANUFACTURING PROCESS

RAW MATERIALS

Challakere

Page 15

Gayathri Bio Fuels

Challakere

Page 16

Gayathri Bio Fuels

Calorific Value Of Raw Materials

Raw Materials Approx Bark (wood) Bagasse (sugar Cane) Bamboo Dust Cotton Stalk Coir Pitch Maize Stalks Pine Niddles Rice Husk Rice Straw Sar Khanda Grass Coffee Husk Ground Nut Shell Castor Seed Shell Jute Waste Mustarad Husk Sugar Mill Waste Sugar Cane Trash Wheat Straw Arhar Stalik Saw Dust Heavy Furnace Oil Kerosene Diesel Lpg Coal Grade 'b' Coal Grade 'c' Fire Wood Char Coal Calorific Value Of Briquette "white Coal" K Cal / Kg 3900 4200 3700 3800 4000 3800 4000 3500 3500 3700 4200 4000 4000 4500 4500 3300 3500 3700 4000 4000 9900 8900 9400 9400 5000 4000 3300 6000 4000

Challakere

Page 17

Gayathri Bio Fuels

MANUFACTURING PROCESS

1. Material Like Saw Dust, Ground Nut Shells, Castor Seed Shells And All Another Raw Material Up To 25mm Size Are Supplied To The Screw Conveyor. 2. When More Then One Material Is Used, Make Sure That They Are Mixed In Suitable Proportion. 3. Materials With Higher Moisture Content I.e. More Then 10-12% Needs To Be Dried In Sunlight. 4. Material From Conveyor Is Discharged With The Help Of Conveyor, Veram And Gear. 5. Material In The Feeder Box Is Compressed By The Press, Forcing It Through Tapper Die (ram Punch) Fitted In The Die Holder. 6. The Compression Raises The Temperature Of Material Which Results In Softening Of The Lignin, Inherent In Every Biomass. This Lignin Comes To The Surface And Binds The Materials Together. 7. Briquettes Formed Are In The Shape Of Logs Which Are Pushed Through Cooling Tracks Under Slight Pressure For Cooling And Transport Storage Point. 8. Cooled Briquettes Are Broken & Packed In Bags Or Stored In Bulk For Dispatch.

Challakere

Page 18

Gayathri Bio Fuels

BRIQUETTE PROCESSING MACHINE

Challakere

Page 19

Gayathri Bio Fuels

Quality Gayathri Bio-Fuels manufacture and supply the finest quality Briquettes for Industrial use, which are processed using an amalgamation of groundnut shells, saw dust and coffee husk. Infrastructure Gayathri Bio Fuels have two manufacturing units at Challakere and one at Tumkur. Gayathri Bio fuels are also the largest manufacturer of industrial Biomass Briquettes in the country with the production capacity of 5000 Mt/Month.

Gayathri Bio Fuels Concerns The sister concerns of Gayathri Bio-Fuels are as follows

Gayathri Agro-Tech (P) Ltd. Challakere 577 522

Surabhi Bio Fuels Somaguddu road, Challakere

Gayathri Bio-Fuels Plot no 140, 2nd phase, Antharasanahalli Industrial Area Tumkur, Karnataka

Challakere

Page 20

Gayathri Bio Fuels

Why Industries prefer Gayathri Bio Fuels

Eco-friendly Bio-Mass Briquettes Timely Delivery Economical Price Customers Satisfaction

A number of companies in India have switched from furnace oil to biomass briquettes to save costs on boiler fuels. Use of biomass briquettes can earn Carbon Credits for reducing emissions in the atmosphere. Biomass briquettes also provide more calorific value and save around 40 percent of boiler fuel costs.

Bio-mass briquette is one which takes agriculture residues such as saw dust, groundnut shells and coffee husk and compresses it to make solid Briquettes. There are no binders involved in this process. The natural lignin in the wood binds the particles of wood together to form a solid briquette. Burning a wood briquette is far more efficient than burning firewood. Moisture content of a briquette can be as low as 4%, where as green firewood may be as high as 65%.

Challakere

Page 21

Gayathri Bio Fuels

Specification.

Size: 90mm Dia. with variable length of 4" to 6" Ash Content: About less than 10% Moisture Content: less than 10% Calorific Value: between 3800 to 4200 Kcal / Kg Chemical contents: Sulphur Nil Phosphorus Nil

Advantages of Briquettes

Briquettes are cheaper than coal. High sulfur content of oil and coal, when burnt, pollutes the environment.There is no sulfur content in briquetted fuels.

Briquettes have consistent quality, high burning efficiency, and are ideally sized for complete combustion.

Combustion is more uniform as compared to coal and boiler response for change in steam requirements is faster due to higher quantity of volatile matter in Briquettes

A Briquette is an Ideal Fuel due to

Eco friendly and Renewable Energy Fuel. Economical and Cheaper than other solid fuels ie. Coal and Wood. Higher Thermal calorific value around 4000 Kcal/Kg. Pollution free because there is no sulphur or any hazardous materials. Lower ash content 4 to 8 %. Consistent high burning efficiency due to the low moisture. Contain High Density and Higher Fix Carbon Value. Easy for Transportation, feeding & combustion due to unique shape.

Challakere

Page 22

Gayathri Bio Fuels

Combustion is more uniform compared to other fuels. Good Market due to rise in price of Fossil Fuels

Agro Residue briquettes have benefits over coal like

Easy handling, packing and transportation of briquettes can be made in any conventional length and diameter.

Low ash content below 10% in comparison to coal 25 to 40% resulting in less boiler ash disposal problems.

There will be no corrosion effect on boiler equipments resulting in negligible maintenance cost. Coal on the other hand produces sulphur dioxide, which on mixing with moisture produces sulphuric acid,a corrosive acid.

It has low ignition point, when compared to coal. It gives sustained combustion and more efficient combustion than loose agro wastes. It is a clean fuel. No gas and effluents like coal. So no health hazards. Easy Handling compared to loose husk and fire wood. Can be mixed with coal and fire wood of inferior quality which improves burning.

Briquettes are Cheaper than coal. High Sulphur content of oil and coal, when burnt, pollutes the environment. There is no sulfur in briquettes. Biomass briquettes have a higher practical thermal value and much lower ash content 4-8 % compared to 20-40% in coal.

Briquettes have a consistent quality, have high burning efficiency are ideally sized for complete combustion. Combustion is more uniform compared to coal and boiler response to change in steam requirements is faster due to higher quantity of volatile matter in briquettes.

Briquettes are usually produced near the consumption centers and supplies don't depend on erratic transport from long distance.

Challakere

Page 23

Gayathri Bio Fuels

Uses of Finished Briquettes in various Industries (Thermal Application)

Gasifier System applications Refractory Industries Chemical Industires Vegetable Plants Leather Industries Milk Plant Rubber Industries Textile Units Dyeing Units Brick making units Ceramic Industries Solvent Extraction Plant Steam generation for various industrial applications Distilleries Food Processing Industries Lamination Industries Any Industrial Thermal Applications Bio coal is a forth coming fuel of the world. It's a high quality asset towards economical, ecological and advanced environmental company policy.

Challakere

Page 24

Gayathri Bio Fuels

HUMAN RESOURCE

Human resource in this industry means workers that are working in this industry. Gayathri agro tech provided more employment opportunities to the surrounded villages people. There are 100 - 120 workers working in this industry in different section of manufacturing process. Incentives and Bonuses have been given for motivating them to undertake more and more production work. Direct Labour Indirect Labour Wages per day : : : 40 80 100 120 Rs.

Challakere

Page 25

Gayathri Bio Fuels

FINANCE

As seen in the Gayathri Bio Fuels Industry, there is a huge capital that the industry have. That is they invested approximately 25 lacs at the time of establishment, But now the total capital may approximately 6 7 crores.This industry have well financial system that meets all working capital requirements.

Investment

approx. 25 lacs

Total Capital

approx. 6-7 crores

Turn over

approx. 15-20 lacs

Challakere

Page 26

Gayathri Bio Fuels

MARKETING

Marketing is the last process that all the industries have. In Gayathri Bio Fuels industry their marketing is well because they supplies their product to various states also like Goa, Kerala, Tamilnadu and Maharashtra. And they supply in karnataka viz. Bangalore, Hassan, Bellary also.

Mode Of Transportation

lorries

Selling Price/ton

4800 Rs.

Challakere

Page 27

Gayathri Bio Fuels

SWOT ANALYSIS

Challakere

Page 28

Gayathri Bio Fuels

Strengths

They have good brand and image in all over south India. They provide fair wages to the labours. They manufacture good briquettes. They facilitate the farmers to sell their agro wastes to the industry. They are using Modern technology. They have well equipped machineries.

Challakere

Page 29

Gayathri Bio Fuels

WEAKNESS

They Doesnt have their own transportation facility. There is scarcity of Raw materials hence the production will be lower in the time of scarcity. There is a scarcity of workers also.

Challakere

Page 30

Gayathri Bio Fuels

OPPORTUNITIES

They can use latest technology of manufacturing the Briquettes i.e. Radhe industrial corporation invented another fast making machine called JUMBO for making the production faster that leads to meeting the demand.

There is no other manufacturer in surrounding hence this as an strength as well as opportunity.

Challakere

Page 31

Gayathri Bio Fuels

THREATS

The Raw materials suppliers are not supplying the raw materials sufficiently hence this causes the problem.

If Raw material is not stored in the godown means it will case the dryness of moisture content.

Challakere

Page 32

Gayathri Bio Fuels

FINDINGS SUGGESTIONS CONCLUSION

Challakere

Page 33

Gayathri Bio Fuels

FINDINGS

As all know that Gayathri Bio Fuels industry having a good brand and image They provide good wages to the workers They established the industry with well furnished resources They have their own vast land They have a good financial system They have good production system

Challakere

Page 34

Gayathri Bio Fuels

SUGGESTIONS

They can make their production even faster by using the modern technology.

They can use other natural raw materials to produce briquettes hence this will cover the uncertainity of raw material supply.

Challakere

Page 35

Gayathri Bio Fuels

CONCLUSION

As we seen that this industry is very well furnished with the finance and machineries and land with all resources. We learnt lot of things by visiting this industry.

Challakere

Page 36

Gayathri Bio Fuels

PHOTO GALLERY

Mr.Sudhakar giving information about their industry

Challakere

Page 37

Gayathri Bio Fuels

Stock of saw dust in the godown

Challakere

Page 38

Gayathri Bio Fuels

Briquette

Challakere

Page 39

Gayathri Bio Fuels

Briquette Manufacturing machine

Challakere

Page 40

Das könnte Ihnen auch gefallen

- Project Report For Biomass BriquettingDokument73 SeitenProject Report For Biomass BriquettingPrakhar SharmaNoch keine Bewertungen

- Toaz - Info Project Report For Biomass Briquetting PRDokument23 SeitenToaz - Info Project Report For Biomass Briquetting PRSarvesh Kumar NayakNoch keine Bewertungen

- Brequetting Plant Project ReportDokument5 SeitenBrequetting Plant Project ReportPathan Sameer Khan67% (3)

- Chapter 2 - Literature ReviewDokument11 SeitenChapter 2 - Literature ReviewAK4780% (5)

- Coconut Shell Charcoal BriquetteDokument15 SeitenCoconut Shell Charcoal BriquetteRoxanne Suyu100% (1)

- Generator MaintenanceDokument24 SeitenGenerator MaintenancePablo Gaspar D'Agostini Amengual100% (9)

- Tak Company Profile PDFDokument32 SeitenTak Company Profile PDFPT. TARUNA AJI KHARISMA Tak100% (2)

- Sydney Tramway - Case Study - EnglishDokument2 SeitenSydney Tramway - Case Study - EnglishLuca Marius CristianNoch keine Bewertungen

- Document On Final Boimass Brquittes 1Dokument18 SeitenDocument On Final Boimass Brquittes 1veera kaur100% (1)

- Project Report FinalDokument24 SeitenProject Report FinalmujeebNoch keine Bewertungen

- Biomass Briquette: Aramco Project ProposalDokument5 SeitenBiomass Briquette: Aramco Project ProposalHeartwell Bernabe Licayan100% (1)

- Biomass BriquettesDokument41 SeitenBiomass BriquettesPamarthi Dhruva100% (3)

- Project Report On Charcoal Barbeque BriquettesDokument8 SeitenProject Report On Charcoal Barbeque BriquettesEIRI Board of Consultants and Publishers0% (1)

- CDM Project On Briquettes ManufacturingDokument2 SeitenCDM Project On Briquettes ManufacturingShanky JainNoch keine Bewertungen

- Kawayan Charcoal Specification: Chichacorn EffluentDokument2 SeitenKawayan Charcoal Specification: Chichacorn EffluentRyan Bacarro BagayanNoch keine Bewertungen

- Bio Mass Briquette PDFDokument17 SeitenBio Mass Briquette PDFJigna PatelNoch keine Bewertungen

- Coir Pith Block Making UnitDokument3 SeitenCoir Pith Block Making UnitMohan RajNoch keine Bewertungen

- BIOMASSDokument22 SeitenBIOMASSPRATIK RUPNAR100% (1)

- Project Report On Biodegradable Plates, Glasses, Food Container, Spoon Etc.Dokument6 SeitenProject Report On Biodegradable Plates, Glasses, Food Container, Spoon Etc.EIRI Board of Consultants and Publishers0% (1)

- Project On National Horticulture BoardDokument9 SeitenProject On National Horticulture Boardrupeshmore145Noch keine Bewertungen

- Project Report On Coal BriquettesDokument10 SeitenProject Report On Coal BriquettesSachin SharmaNoch keine Bewertungen

- Brick fACTORYDokument18 SeitenBrick fACTORYanon_89949176100% (1)

- Manufacturing of ArecaDokument32 SeitenManufacturing of ArecaRocks Kiran67% (3)

- PFR On Biodegradable Plastic BagsDokument35 SeitenPFR On Biodegradable Plastic BagsArsh Adeeb Ghazi0% (1)

- Project Report On Biodegradable Carry BagsDokument9 SeitenProject Report On Biodegradable Carry BagsEIRI Board of Consultants and PublishersNoch keine Bewertungen

- Agro Seed Processing Plant PDFDokument9 SeitenAgro Seed Processing Plant PDFNagendra Patel100% (1)

- Brooms MakingDokument3 SeitenBrooms MakingGohilaRajNoch keine Bewertungen

- Production of Biomass Pallets For Thermal Energy ApplicationDokument10 SeitenProduction of Biomass Pallets For Thermal Energy ApplicationRajesh PantNoch keine Bewertungen

- A Research Proposal OnDokument4 SeitenA Research Proposal OnRukhsan AraNoch keine Bewertungen

- Annex IV KGEPL TEV Report On AV UE TechnologyDokument97 SeitenAnnex IV KGEPL TEV Report On AV UE TechnologyGirish JagtapNoch keine Bewertungen

- A Review of Coconut Husking MachinesDokument11 SeitenA Review of Coconut Husking MachinesjonjonnyNoch keine Bewertungen

- Briquetting MachineDokument46 SeitenBriquetting MachineChandan100% (3)

- Rice Flour Mill PDFDokument12 SeitenRice Flour Mill PDFBabu Viswanath MNoch keine Bewertungen

- Business Study On Plastic Industry New FormatDokument52 SeitenBusiness Study On Plastic Industry New Formatimdeepak1Noch keine Bewertungen

- Project 15 - Water ConservationDokument5 SeitenProject 15 - Water ConservationUjjval NagotaNoch keine Bewertungen

- TahdcoDokument5 SeitenTahdcorajrudrapaaNoch keine Bewertungen

- Briquette PDFDokument7 SeitenBriquette PDFSrinath ReddyNoch keine Bewertungen

- Economics of Bioethanol From Rice StrawDokument8 SeitenEconomics of Bioethanol From Rice StrawJosé Alberto CastilloNoch keine Bewertungen

- Project Report For UNOKEM - Unokem Resins Pvt. Ltd.Dokument31 SeitenProject Report For UNOKEM - Unokem Resins Pvt. Ltd.Rahul PancholiNoch keine Bewertungen

- Analyze Job Satisfaction of Employees at GNFC PDFDokument106 SeitenAnalyze Job Satisfaction of Employees at GNFC PDFShaluRajta0% (1)

- Characterization of Banana Peel Briquettes With The Variation of Binder ConcentrationDokument19 SeitenCharacterization of Banana Peel Briquettes With The Variation of Binder ConcentrationSuriati Eka PutriNoch keine Bewertungen

- Puffed RiceDokument8 SeitenPuffed Riceshubham pratap100% (1)

- K U S E D: Project Proposal OnDokument15 SeitenK U S E D: Project Proposal OnANGUS PRASAINoch keine Bewertungen

- DPR Template For APIIC (Land Allotment)Dokument2 SeitenDPR Template For APIIC (Land Allotment)MallikarjunReddyObbineniNoch keine Bewertungen

- Final Project Anitha 121908Dokument60 SeitenFinal Project Anitha 121908namitha s raj100% (1)

- Report On Plastic Pollution, Waste Management, and Climate Change: Awareness and ChallengesDokument28 SeitenReport On Plastic Pollution, Waste Management, and Climate Change: Awareness and ChallengesMaher Neger AneyNoch keine Bewertungen

- Jharkhand Industrial and Investment Promotion Policy 2016Dokument78 SeitenJharkhand Industrial and Investment Promotion Policy 2016anon_794527129Noch keine Bewertungen

- Complete Project of Biomass Briquetting MachineDokument23 SeitenComplete Project of Biomass Briquetting MachineDeepi17100% (2)

- Biomass Briquette MFG Machine CatalogueDokument6 SeitenBiomass Briquette MFG Machine CatalogueHemanth Kumar RamachandranNoch keine Bewertungen

- Indian Plywood OutlookDokument6 SeitenIndian Plywood OutlookArumugam RamalingamNoch keine Bewertungen

- Biomass ReportDokument94 SeitenBiomass ReportRajat Negi100% (1)

- PROJECT REPORT On Steel Furniture ManufacturingDokument15 SeitenPROJECT REPORT On Steel Furniture ManufacturingPriyam PandaNoch keine Bewertungen

- Detailed Project Report FormatDokument20 SeitenDetailed Project Report FormatMahesh Savaliya100% (1)

- Kirti Dal MillDokument83 SeitenKirti Dal MillRuishabh RunwalNoch keine Bewertungen

- Final Dinesh ProjectDokument16 SeitenFinal Dinesh ProjectAravindhan LNoch keine Bewertungen

- Plant Desin Report For Spice ProductionDokument7 SeitenPlant Desin Report For Spice ProductionUmar Mohammad Mir0% (1)

- Paper Bags and PouchesDokument9 SeitenPaper Bags and Pouchessam krNoch keine Bewertungen

- Basmati Rice Manufacturing ProcessDokument4 SeitenBasmati Rice Manufacturing ProcessShamli Karumannil100% (1)

- FAO Report On GROUNDNUT OIL PDFDokument16 SeitenFAO Report On GROUNDNUT OIL PDFVIRTU 8 HR & IT LLPNoch keine Bewertungen

- Puma SocksDokument8 SeitenPuma Sockswinter_fatimaNoch keine Bewertungen

- Biomass BriquettesDokument9 SeitenBiomass BriquettesMeek ElNoch keine Bewertungen

- Chapter Two Literature ReviewDokument6 SeitenChapter Two Literature ReviewMcLeo AliriNoch keine Bewertungen

- BriquettesDokument17 SeitenBriquettesStephen CrossNoch keine Bewertungen

- Study On Fly Ash BricksDokument66 SeitenStudy On Fly Ash BricksKiran Kumar100% (2)

- Global Depository ReceiptsDokument27 SeitenGlobal Depository ReceiptsKiran KumarNoch keine Bewertungen

- GDRsDokument46 SeitenGDRsmahmoodkamalNoch keine Bewertungen

- Waste Management: Born For Optimum Utilisation.Dokument7 SeitenWaste Management: Born For Optimum Utilisation.Kiran KumarNoch keine Bewertungen

- KTC BricksDokument55 SeitenKTC BricksKiran KumarNoch keine Bewertungen

- About RCC Spun PipesDokument42 SeitenAbout RCC Spun PipesKiran Kumar100% (1)

- Gayathri Bio FuelsDokument40 SeitenGayathri Bio FuelsKiran Kumar100% (2)

- Village Brick MakingDokument111 SeitenVillage Brick Makingralph100% (7)

- HRM 370 2011 Spring Additional Materials 12 New Employee Orientation GuideDokument28 SeitenHRM 370 2011 Spring Additional Materials 12 New Employee Orientation GuideH.m. HasanNoch keine Bewertungen

- AuditingDokument9 SeitenAuditingKiran KumarNoch keine Bewertungen

- HRM 370 2011 Spring Additional Materials 12 New Employee Orientation GuideDokument28 SeitenHRM 370 2011 Spring Additional Materials 12 New Employee Orientation GuideH.m. HasanNoch keine Bewertungen

- Icici BankDokument2 SeitenIcici BankKiran KumarNoch keine Bewertungen

- Nikita Green BankingDokument51 SeitenNikita Green BankingAbdul Rasheed100% (1)

- UPQCDokument12 SeitenUPQCG Vignesh GvsNoch keine Bewertungen

- Brochure - City Gas DistributionDokument3 SeitenBrochure - City Gas DistributionIE_kumarNoch keine Bewertungen

- Submersbile PumpDokument8 SeitenSubmersbile PumpIslam FawzyNoch keine Bewertungen

- ATEXDokument42 SeitenATEXBledarNoch keine Bewertungen

- Blue Bbay Bus Prop-191102 PDFDokument29 SeitenBlue Bbay Bus Prop-191102 PDFDominic MichealNoch keine Bewertungen

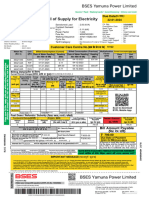

- Bill of Supply For Electricity: BSES Yamuna Power LimitedDokument2 SeitenBill of Supply For Electricity: BSES Yamuna Power LimitedvoiceofindiapressNoch keine Bewertungen

- Sacrificial AnodesDokument4 SeitenSacrificial AnodesCK ZeeKei100% (1)

- Limitamp CatalogDokument120 SeitenLimitamp Catalogpayolin77Noch keine Bewertungen

- Assam PVSyst ReportDokument3 SeitenAssam PVSyst ReportKristen ChangNoch keine Bewertungen

- Electrical VivaDokument5 SeitenElectrical VivaHari KrishnanNoch keine Bewertungen

- QapDokument9 SeitenQaprenjithv_4Noch keine Bewertungen

- Electricity Economics Regulation and Deregulation Geoffrey Rothwell Tomas GomezDokument298 SeitenElectricity Economics Regulation and Deregulation Geoffrey Rothwell Tomas GomezMateo SernaNoch keine Bewertungen

- EnglishDokument215 SeitenEnglishBrian ChenNoch keine Bewertungen

- Green MarketingDokument16 SeitenGreen Marketinghimita desaiNoch keine Bewertungen

- Three-Phase Electric Power - Wikipedia, The Free EncyclopediaDokument13 SeitenThree-Phase Electric Power - Wikipedia, The Free Encyclopediaysk83Noch keine Bewertungen

- Fta and Eta: Faculty of Chemical Engineering Universiti Teknologi MARADokument22 SeitenFta and Eta: Faculty of Chemical Engineering Universiti Teknologi MARACaratsSVTNoch keine Bewertungen

- Press Kit Gestamp Renewables - EnglishDokument8 SeitenPress Kit Gestamp Renewables - EnglishACEK RenewablesNoch keine Bewertungen

- WPC Membership Directory - September 2020Dokument6 SeitenWPC Membership Directory - September 2020杨峻Noch keine Bewertungen

- Circuit BreakerDokument64 SeitenCircuit BreakerAshwani Dogra100% (1)

- Invitation Letter Petrolida 2021Dokument91 SeitenInvitation Letter Petrolida 2021Stephen ZhengNoch keine Bewertungen

- TOC and Sample Page - Global Out-Of-Autoclave (OoA) Prepreg Market - Stratview ResearchDokument37 SeitenTOC and Sample Page - Global Out-Of-Autoclave (OoA) Prepreg Market - Stratview ResearchyigitilgazNoch keine Bewertungen

- Bettis Actuador Neumatico G Series PDFDokument63 SeitenBettis Actuador Neumatico G Series PDFmilecsaNoch keine Bewertungen

- Catalog enDokument13 SeitenCatalog enVEMATELNoch keine Bewertungen

- Vent. DaikinDokument42 SeitenVent. DaikinDaniela BarbuNoch keine Bewertungen

- EVS HD 629 1 S2 2006 en PreviewDokument7 SeitenEVS HD 629 1 S2 2006 en PreviewSandra Milena Arias BetancourthNoch keine Bewertungen

- Smart Grid Maturity Model: Update - October 2010Dokument12 SeitenSmart Grid Maturity Model: Update - October 2010Tan Wei TingNoch keine Bewertungen