Beruflich Dokumente

Kultur Dokumente

Chapter 5 Generator Transformer

Hochgeladen von

Anonymous nwByj9LCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chapter 5 Generator Transformer

Hochgeladen von

Anonymous nwByj9LCopyright:

Verfügbare Formate

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer CHAPTER 5

GENERATOR TRANSFORMER

1.00.00

CODES AND STANDARDS All equipments provided under the specification shall in general, conform to the latest issue of the following standards: Indian Standards (1) IS: 2026 IS: 3639 (2) Power transformers Fittings & accessories for power transformers IS: 335 Insulating for alternating voltages switchgear IS: 2099 Bushing for alternating voltages above 1000 V IS: 2705 IS: 325 IS: 375 Current transformers Three phase induction motors Marking & arrangement for switchgear bus bars, main connections & auxiliary wiring. IS: 3637 IS: 10028 Gas operated relays Code of practice for selection installation& maintenance of transformers IS : 5 IS: 1866 Colours for ready mix paints Code of practice for maintenance & Supervision of mineral insulating oil in equipment IS: 6272 IS: 6600 Industrial cooling fans Guide for Loading of oil immersed transformers IS: 3347 Specification for dimensions of porcelain bushing IS:2071 High voltage test technique IEC: 60060 IEC: 60354 IEC: 60185 IEC: 60034-1 IEC: 60137, BS: 223 IEC: 60296, BS:148 (3) IEC: 60076 Title International standards

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:112

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer IS:2165 Insulation co-ordination NEMA standard publication for Power transformers IS: 10597 Code of practice for selection, Installation operation & maintenance of pumps for industrial applications IS: 9434 Guide for sampling & analysis of free & dissolved gas & oil from oil filled electrical equipment IS: 12676 Dimensions for OIP insulated condenser bushings IEEE: 32 IEEE standard requirement terminology& test procedure for neutral grounding device The electrical installation shall meet the requirements of Indian Electricity Rules 1956 & IS: 10028 Code of practicefor selection, installation & maintenance of transformers as named up to date. IEC:60567 IEC: 60071 NEMA-TR-1

2.00.00 2.01.00

DESIGN CRITERIA Sizing Criteria

GT will be sized to evacuate maximum power output of generator under turbine VWO condition.

2.01.01

The GT shall be designed for an ambient temperature of 50C. The GT shall comprise of a bank of three nos. single phase oil immersed outdoor type transformers with class A insulation and OFAF cooled rating of 275 MVA each. The GT shall also have ONAF/ONAN ratings of 80 % and 60% respectively of the OFAF rating. The GT shall have voltage ratio of generator voltage/ 420/3 kV. No reduction in capacity shall be made for the auxiliary load tapped before the GT.

2.01.02

Total cooling system of transformer with oil forced & air forced (OFAF) cooling shall be so designed that during total failure of power supply to cooling fans & oil pumps, the transformer shall be able to operate at full load for at least ten (10) minutes without the calculated winding hot spot temperature exceeding 140 deg. C. Also stopping of one of the cooling fan should not have any effect on the cooling system of transformers.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:113

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer The maximum flux density in any part of the core & yoke at the rated MVA, voltage & frequency shall be such that under 110% continuous voltage condition it does not exceed 1.9 tesla.

2.01.03

2.01.04

The transformer & all its accessories including CTs etc shall be designed to withstand without injury the thermal & mechanical effects of any external short circuit to earth & of short circuits at the terminal of any winding for a period of 3 seconds. Contractor shall submit the short circuit withstand calculations.

2.01.05

Transformers shall withstand, without injurious heating, combined voltage & frequency fluctuations, which produce the following over fluxing condition: 110 % 125% 140% - continuous - for one minute - for five seconds

2.01.06

The transformers shall be capable of being operated continuously with out danger on any tapping at the rated MVA with voltage variation of 10% corresponding to the voltage of tapping. Transformer shall be rated to deliver rated MVA continuously even at the lowest tap without exceeding the temperature rise at site condition. Tap position shall be indicated in DDC MIS.

2.02.00

General Technical Particulars

S.No. a) Rating & Quantity b) c) d) Cooling Type Voltage ratio e) f) g) h) i) Frequency Phase Impedance Service Duty

Rating 165/220/275 MVA 7 nos. (3 nos. for each unit and 1 common spare) ONAN/ONAF/OFAF Two (2) Winding, Bidirectional rated generator voltage/420/3 50 Hz Single Phase less than15% (Indicative) Outdoor Continuous

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:114

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer j) Applicable Standard k)

IS: 2026

Temperature rise at full load with 100% coolers. i) ii) Oil Winding. 50 C 55C

l)

Max. Design Ambient temp.

50C

HV: Star (neutral solidly earthed) m) Winding Connections LV: Delta

n)

Vector Group

YNd 1 (for 3 phase bank)

(*) Rated Generator Voltage o) Tap Changer i) ii) p) Creepage distance of insulators 31 mm/kV per unit of system phase to phase voltage Tap range Tap control (+) 5 % to (-) 5 % in equal steps of 2.5% on HV side. OFF Circuit

q) r)

Noise level Short circuit capability

As per NEMA TR-1 Refer cl.2.01.04. HV: Graded insulation LV: Uniform

s)

Type of insulation

t)

Winding insulation level Rated 1050 kVp

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:115

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer switching impulse withstand voltage Rated Lightning impulse withstand voltage u) Bushing insulation level Rated power frequency withstand voltage Rated switching impulse withstand voltage Rated Lightning impulse withstand voltage v) Overload Capacity w) HV Neutral earthing x) Terminal arrangement xi) Efficiency As per IS 6600 Solidly earthed with copper bar with CT mounted on bushing Refer cl. 3.05.00 99.7% 1425 kVp 1050 kVp 630 kVrms 1300 kVp

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:116

DESEIN

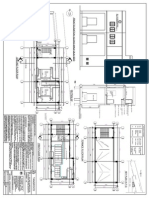

Tender Specification Vol-IV : Electrical Works Generator Transformer Layout Criteria for power transformers

2.03.00

Refer cl. 4.00.00 chapter 1.

3.00.00

CONSTRUCTION The features & construction details of each transformer shall be in accordance with the requirement stated hereunder:

3.01.00

Tank And Tank Accessories (a.) Tank shall be of welded construction & fabricated from tested quality low carbon steel of adequate thickness. The welding procedure specified (WPS), procedure qualification record (PQR), shop welding schedule, welders qualification shall be subject to Owners approval. After completion of welding, all joints shall be subjected to dye penetration testing. Weld joints at all loads bearing member shall be left unpainted till carrying out of jacking test followed by Degree of Protection test during final inspection of transformer. Details of acceptance norms of welding shall be submitted for Owners approval which shall include permissible undercut, overlap, surface crack, porosity, out of alignment of plate surface in butt joints, maximum gap due to incorrect fit up of fillet joint etc. (b.) Transformers shall be with bell type tank with the joint at about 500-mm above the bottom of the tank. (c.) Each tank shall be provided with : 1) 2) Lifting lug suitable for lifting the equipment complete with oil. A minimum of four jacking pads in accessible position to enable the transformer complete with oil to be raised or lowered using hydraulic or mechanical screw jacks. 3) Suitable haulage holes shall be provided for transformer wheeling in all four directions. (d.) The transformers are to be provided with flanged bi-directional wheels & axles & shall be mounted on wheels on foundation. Suitable locking arrangement shall be provided for the wheels to prevent accidental movement of transformer. The rail track gauge shall be 1676 mm along longer axis as well as along shorter axis.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:117

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer (e.) At least two adequately sized inspection openings one at each end of the tank shall be provided for easy access to bushing & earth connections. The inspection covers shall not weight more than 25 Kg. Handles shall be provided on the inspection cover to facilitate lifting. (f.) Turrets & other parts surrounding the conductor of individual phase shall be non-magnetic. (g.) All bolted connections shall be fitted with weather proof, hot oil resistant, rubberized cork gasket in between for complete oil tightness. If gasket is compressible, metallic stops shall be provided to prevent over compression. (h.) Vibration level at rated voltage and frequency shall not be more than 200 microns peak to peak. Average vibration shall not exceed 60 microns peak to peak. Tank stress shall not exceed 2.0 kg/mm at any point on the tank.

2

3.02.00

Core (a.) The core shall be constructed from high-grade non-aging, cold rolled, super grain oriented, silicon steel laminations, known as HI-B steel trade name. The core shall be boltless. (b.) The insulation of boltless cores to clamp plates shall be able to withstand a voltage of 2 kV (rms.) for 1 minute in air. (c.) In order to ensure prevention of multiple cores earthing, core isolation test at 2 kV for 1 minute shall be done during pre commissioning stage. To facilitate above, the core earthing has to tank with suitable bushing. (d.) (e.) Adequate lifting lugs will be provided to enable the core & windings to be lifted. The air core reactance of HV winding of transformers shall not be less than 20%.

3.03.00

Windings (a.) The contractor shall ensure that windings are made in dust proof & conditioned atmosphere. The contractor shall furnish details of the facilities available at his works along with the bid. (b.) The conductors shall be of electrolytic grade copper free from scales & burrs.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:118

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer (c.) All windings of the transformers having voltage less than 66 kV shall have uniform insulation. Higher voltage rated windings may be provided with graded insulation.

3.04.00

Insulating Oil The oil supplied with transformers shall conform to all parameters as per IS: 335 while tested at suppliers premises. No inhibitors shall be used in oil. Subsequently oil samples shall be drawn at: 1) Prior to filling in main tank at site & tested for

i) ii) iii) iv) v) 2)

BDV Moisture content Tan delta at 90 deg. C Resistivity at 90 deg. C Interfacial tension

60 kV (min) 50 ppm (max.) 0.002 (max.)

12

35 x 10

ohm-cm

0.04 N/m(min)

Prior to energization at site for following properties & acceptance norms: i) ii) iii) iv) v) BDV Moisture content Tan delta at 90 deg. C Resistivity at 90 deg. C Interfacial tension 60 kV (MIN) 15 ppm (max.) 0.05 (max.) 1 x 1012 ohm-cm 0.03 N/m (min)

3.05.00 3.05.01

Terminal Arrangements Bushings (a.) The electrical & mechanical characteristics of bushings shall be in accordance with IS: 2099, IS: 3347 & IS: 12676. (b.) Bushings for 52 kV & above shall be of the oil filled condenser type & shall be of draw lead type to facilitate removal. Bushings of rating below 52 kV shall be solid porcelain or oil communicating type. (c.) Condenser type bushings shall be provided with : 1) 2) 3) (d.) Oil level gauge Oil filling plug & drain valve ( if not hermetically sealed) Tap for capacitance & tan delta test.

Clamps & fittings shall be of hot dip galvanized steel.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:119

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer (e.) Bushing & fittings shall be provided with vent pipes that shall be connected to route any gas collection through the Buchholz relay. (f.) (g.) No arcing horns shall be provided on the bushings. Outdoor type porcelain bushing with all accessories shall be provided for HV neutral terminal. (h.) Phase arrangement on HV side: R, Y, B sequence (from left while viewing from switchyard & towards the Power House).

3.05.02

Bus Duct Terminations (a.) For termination of busduct a flanged throat or equivalent connection shall be provided for termination of busduct enclosure. The LV winding termination shall be on outdoor type of bushings. The material of the busduct termination shall be non-magnetic. A drain with stopcock arrangement shall be provided at flange to drain leakage of oil/water at termination. As bus duct will be pressurized stopcocks shall be airtight. (b.) Tolerance permissible for the height of the terminal connected to busduct over rail top level is 5 mm. Contractor has to ensure that radiator & conservator does not obstruct the path of the bus ducts in position & during movement of transformer. The contractor shall co-ordinate final design of terminal arrangement to suit bus duct arrangement during detailed engineering. (c.) The transformer bushing enclosed in bus duct enclosure shall be designed for satisfactory operation in the high ambient temperature existing inside the bus duct enclosure. The temperature inside the bus duct enclosure may be of the order of 90 100 deg. C. The bus duct conductor temperature may be as high as 105 deg. C & temperature in the bus duct enclosure will be of the order of 80 deg. C.

3.05.03

Terminal Connector (a.) Bushing terminal shall be provided with terminal connectors of approved type & size for connection to external part. Terminal connectors must have been successfully type tested as per IS: 5561. (b.) (c.) These shall be suitable for either horizontal or vertical take off. Aluminum alloy if used shall conform to designation 4600 M of IS: 617 or of better quality. (d.) (e.) No part of a clamp shall be less than 10 mm thick. All ferrous parts shall be hot dip galvanized conforming to IS: 2633.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:120

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer (f.) For bi-metallic clamp, copper alloy liner of minimum 2-mm thickness shall be cast integral with aluminum body. Alternatively Contractor may offer bimetallic connector with loose bimetallic sleeve. (g.) (h.) Flexible connectors shall be made from tinned copper sheets. Size of terminal/conductor for which the clamp is suitable & rated current under the conditions shall be embossed/ punched on each component of the clamp, except hardware. (i.) Rated continuous & short time current of the terminal connectors shall be same as that of corresponding bushing.

3.06.00

Bushing Current Transformer (a.) Current transformer shall comply with IS: 2705/IEC 60185. CTs shall be mounted in the turret of bushing. Provision of the same inside the tank is not permitted. (b.) It shall be possible to remove turret mounted current transformers from the transformer tank without removing the tank cover. Necessary precautions shall be taken to minimize eddy currents & local heat generated in the turret. (c.) All secondary leads shall be brought to a weatherproof terminal box near each bushing. These terminals shall be wired out to cooler control cabinet using separate cables for each core.

3.07.00

Terminal Marking The terminal marking & their physical position shall be as per IS: 2026 unless specified otherwise.

3.08.00

Neutral Earthing Arrangement The neutral of transformers shall be brought to the ground level at a convenient point, for connection to ground network through two (2) galvanized steel flats of minimum size 75 x 12 mm or by suitable copper flats. The connection shall be made by using two (2) bolted neutral grounding terminals with necessary accessories.

3.09.00

Common Marshalling Box (CMB), Cooler Control Cabinet (CCC) Unit (a.) Each transformer shall be provided with one cooler control cabinet housing all the cooler control, OTI, WTI for each winding etc. for one unit. Alternatively the contractor may provide two different boxes; one for housing cooler controls

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:121

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer named as cooler control cabinet & separate box for housing OTI, WTI etc. named as Marshalling box. (b.) The sheet steel used for all the cabinet boxes shall be at least 2.5 mm thick. The gasket used shall be of neoprene rubber. A space heater & cubicle lighting with on off switch shall be provided in each cabinet. A circuit breaker/contactor with thermal overload device for controlling the AC auxiliary supply shall be provided. (c.) Terminal Blocks 1) The terminal blocks to be provided shall be fully enclosed with removable covers & made of molded, non-inflammable plastic material with blocks & barriers molded integrally. The terminal blocks shall be1100V grade & have 10 A continuous rating. Terminal blocks for current transformer secondary leads shall be provided with test links & isolating facilities. Also current transformer secondary leads shall be provided with short circuiting & earthing facilities .At least 20% spare terminals shall be provided on each panel & these spare terminals shall be uniformly distributed on all terminal blocks.

2)

Terminal blocks shall be suitable for connecting the following conductors on each side : i) Current transformer circuits minimum of two No. of 2.5 sq. mm copper wires each side ii) Other circuits -- minimum of one No. of 2.5 sq. mm copper wire each side

(d.)

The temperature indicators shall be so mounted that the dials are not more than 1200 mm from ground level. Glazed door of suitable size shall be provided for convenience of reading.

(e.)

One cooler control cabinet / marshalling box of each type for each rating of transformer shall be tested for IP 55 protection in accordance with IS: 2147

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:122

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer

3.10.00 3.10.01

Auxiliary Power Supply For Coolers Two Auxiliary Power Supplies at 415 V three phase four wire at cooler control cabinets shall be provided. All loads shall be fed by one of the two feeders through an electrically interlocked automatic transfer switch. Design features of the transfer switch shall include the following: (a.) Provision for the selection of one of the feeder as normal source & other as standby (b.) Upon failure of the normal source, the loads shall automatically transfer, after an adjustable time delay, to standby source. (c.) Indication to be provided for failure of normal source & for transfer to standby source & also for failure to transfer. (d.) Automatic retransfer to normal source without any intentional time delay following re-energization of the normal source. (e.) Both the transfer & the re- transfer shall be dead transfers & AC feeders shall not be paralleled at any time.

3.10.02

The contractor shall derive AC feeders for cooler control cabinets after suitable selection at CMB/CCC for which description is given above. The contractor shall derive AC supply for control circuitry from the AC feeder as mentioned above by using appropriately rated dry type transformer. If the control circuit is operated by DC supply, then suitable main & standby converters shall be provided by the supplier to be operated from AC feeder.

3.11.00

Control Wiring & Cabling Supply, laying & termination of all cables & accessories required of proper termination from the CCC so as to make equipment complete & functional shall be in scope of supplier. The cable between the CCC & transformer shall be laid by the contractor through GI conduits/ pipes. Cable box / sealing end shall be suitable for following types of cables: i) 415 V power : 1100 V grade PVC insulated FRLS PVC outer sheathed aluminum conductor cable with armour. ii) Control : 1100 V grade PVC insulated 2.5 sq. mm stranded copper conductor with armour Contractor shall co-ordinate the total auxiliary power requirement for each rating.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:123

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer Painting The paint inside the tank shall be of white colour. The internal & external surface including oil filled chambers & structural steel work to be painted shall be shot or sand blasted to remove all rust & scale or foreign adhering matter. All steel surfaces in contact with insulating oil shall be painted with two coats of heat resistant, oil insoluble, insulating varnish. No grinding is permitted afterwards. All steel surfaces exposed to weather shall be given a primary coat of Zinc chromate, second coat of oil & weather resistant varnish of a colour distinct from primary & final two coats of glossy oil & weather resisting non fading paint of colour corresponding to shade No. RAL 5012 Primary paint shall be as per IS: 104 & intermediate & final coats of paint shall be as per IS: 2932. All paints shall be carefully selected to withstand heat & extremes of weather. The paint shall not scale off or wrinkle or be removed by abrasion due to normal handling. The desired coating thickness & drying time are mentioned below: Thickness & Drying Time Primary coat of Zinc Chromate Secondary coat of Varnish Under coat (First coat) Paint Final Paint - 70 micron 4 hours. - 70 micron 4 hours. - 70 micron 8 hours. - 70 micron 6 hours.

3.12.00

3.13.00 3.13.01

Cooling Equipment Cooling equipment for Generator Transformer Generator Transformer cooling shall be OFAF. In addition cooling equipment shall conform to the requirement stipulated below:

a)

Transformer cooling shall be affected by use of separately mounted, detachable type cooler banks. Capacity of each cooler bank shall be minimum 60% of the total cooling requirements. The orientation of coolers shall be subject to Owners approval during detailed engineering.

b)

Each cooler bank shall have 2 x 50% cooling radiator bank, adequate number of cooling fans (1 standby fan), 2 x 100 % oil pumps, oil flow indicator, shut off valves at the top and bottom (80mm size) lifting lugs, top and bottom oil filling valves, air release plug at the top, a drain and sampling

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:124

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer valve and thermometer pocket fitted with captive screw cap on the inlet and outlet.

c)

Total capacity of coolers furnished for each transformer shall be minimum 120% of actual requirements.

d)

Cooler fans & oil pumps of all coolers (except standby fans/pumps) shall operate continuously. Coolers start shall be interlocked with generator breaker contract. Provision shall be kept to start the coolers by WTI contact.

e)

Suitable manual control facility for cooler fans & oil pumps shall be provided.

f)

Centrifugal or axial in line oil pumps shall be so designed that upon failure of power supply to the pump motor, the pump impeller shall not limit the natural circulation of oil.

g)

Max oil velocity shall be such that it does not lead to static discharges inside the transformer. The same shall be verified during design review.

h)

An oil flow indicator shall be provided for the confirmation of normal pump operation. An indicator shall be provided in the flow indicator to indicate reverse flow through the pump.

i)

Cooling fan & oil pump motor shall be suitable for operation on 415 V + 10%, three phase, 50 Hz -3%/+ 5% power supply. & shall conform to IS: 325. Each cooling fan & oil pump motors shall be provided with starter with thermal overload & short circuit protection. Motor shall have enclosure with degree of protection equivalent to IP 55 as per IS: 4691. The temperature rise of the motor shall be limited to 70 deg. C above ambient of 50 deg. By winding resistance method & shall comply with IS: 325.

j)

Fault indicating device- For each transformer, an alarm contact shall be furnished to indicate the unintended stoppage of a fan, pump or oil flow. The contractor shall also indicate if any additional lamp is required to be provided in Owners control room.

k)

Following lamp indications shall be provided in MB/CMB/CCC:

1)

Cooler supply failure (main)

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:125

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer 2) 3) 4) 5) 6) 7) Cooler supply changeover Cooler supply failure (standby) Control supply failure Cooling unit failure for each unit cooler for GTs No oil/reverse oil flow for pumps Common thermal overload trip

One potential free initiating contact for all the above conditions shall be wired independently to the terminal blocks of CMB/CCC exclusively for Owners use. 3.14.00 Valves (a.) All valves up to and including 100mm shall be of gun metal or of cast steel. Larger valves may be of gun metal or may have cast iron bodies with gun metal fittings. They shall be of full way type with internal screw and shall open when turned counter clockwise when facing the hand wheel. (b.) Suitable means shall be provided for locking the valves in the open and close positions. Provision is not required for locking individual radiator valves. (c.) Each valve shall be provided with the indicator to show clearly the position of the valve. (d.) Gland packing/gasket material shall be of Teflon rope/nitrile rubber. In case of gate/globe valves, gland packing preferably of Teflon rope shall be used to prevent oil seepage through the gland. (e.) Oil sampling shall have provision to fix rubber hose of 100mm size to facilitate oil sampling. (f.) After testing, inside surface of all cast iron valves coming in contact with oil shall be applied with one coat of oil resisting paint/varnish with two coats of red oxide zinc chromate primer followed by two coats of fully glossy finishing paint conforming to IS: 2932 and of a shade (Preferably red or yellow) distinct and different from that of main tank surface. Outside surface except gasket setting surface of butterfly valves shall be painted with two coats of red oxide zinc chromate conforming to IS: 2074 followed by two coats of fully glossy finishing paint. (g.) All hardware used shall be cadmium plated/electro galvanized.

(h)

Drain pipes of GT & ST in the transformer yard shall be extended upto burnt oil pit & shall be provided with additional isolation valve, in

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:126

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer

addition to the drain valve provided at transformer end. Drain valve at the transformer end shall normally be open & isolation valve at burnt oil pit shall remain closed. In case of any major fault in the transformer oil can be drained to the pit by opening valve at burnt oil pit.

3.15.00

Fittings

3.15.01

The following fittings shall be provided with each transformer covered in this specification: 1) Conservator for main tank with oil filling hole and cap, isolating valves, drain valve, magnetic oil level gauge with low level alarm contacts and dehydrating silica gel breather. Separate breather for conservator shall be mounted not more than 1400 mm above rail top. 2) 3) Oil preservation system: - Air cell type. Minimum two Nos. of spring operated pressure relief devices with alarm/trip contacts. Discharge of PRD shall be properly taken through pipes & directed away from the transformer /other equipment. 4) Buchholz relay double float type with isolating valves on both sides, bleeding pipe with Gas collecting device at the end to collect gases and alarm and trip contacts. 5) 6) 7) Air release plug. Inspection openings and covers. Bushing with metal parts and gaskets to suit the termination arrangement. 8) Cover lifting eyes, transformer lifting lugs, jacking pads, towing holes and core and winding lifting lugs. 9) 10) Protected type Mercury or alcohol in glass thermometer. Bottom and top filter valves with threaded male adapters, bottom Sampling valve & drain valve. 11) 12) 13) 14) 15) 16) Rating and diagram plates on transformers and auxiliary apparatus. Fans, Pumps and Coolers as specified. Magnetic Oil level gauge with low level alarm contacts. Dehydrating filter breather. Prismatic/toughened glass oil gauge for transformers 150 mm dial type oil temp indicator with alarm and trip contacts, maximum reading pointer & resetting device. Accuracy class shall be

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:127

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer 1.5 % or better. 17) 150-mm dial type Winding temp indicator for each winding with alarm and trip contacts, maximum reading pointer & resetting device. Accuracy class shall be 1.5 % or better. 18) Remote WTI. It should not be repeater dial of local WTI. Duplex or equipment platinum RTD to be provided for remote winding temp. indication. In addition 4-20 mA signals shall be provided for DDCMIS. Any special cable required for shielding purpose for connection between CCC & remote WTI. 19) 20) 21) 22) 23) 24) Flanged bi-directional wheels /Trolley for movement. Cooler control cabinet. Cooling equipment. Bushing current transformers. Insulating oil. Drain valves/plugs shall be provided in order that each section of pipe work can be drained independently. 25) 26) 27) 28) Terminal marking plates. Oil flow indicator Valves schedule plates. Two (2) earthing terminals on all the equipments mounted separately suitable for connection to 75 x 12 mm GI flat along with 2 Nos. tapped holes. M10 bolts etc. 29) Online continuous oil condition monitor to monitor the content of dissolved gases & moisture in oil. With alarm contacts and communication links with DDCMIS.

3.15.02

The fittings listed above are only indicative and other fittings, which are generally required for satisfactory operation of the transformer, are deemed to be included.

4.00.00

PROTECTION OF GENERATOR TRANSFORMER

The minimum required protections for generator transformer are covered in chapter no. 2A, cl.2.00.04.

5.00.00

ONLINE MONITORING FOR GENERATOR TRANSFORMER

A dedicated online condition monitoring system shall be provided for Generator Transformer. For specifications & requirements of the equipments, Chapter 23 (Electrical Laboratory Equipments) shall be referred.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:128

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer INSPECTION AND TESTING

6.00.00

a)

The contractor shall carry out a comprehensive inspection and testing program during manufacture of the transformer. It is Contractors responsibility to draw up and carry out such a program in the form of detailed quality plan duly approved for necessary implementation.

b)

The Contractor shall arrange to carry out all type tests and routine tests on the transformers. The tests are listed under clause 7.00.00. Special tests other than type and routine tests, as listed in clause 7.03.00, shall also be carried out as per IS: 2026.

c)

The equipment checks to be carried out by the Contractor are to be specified.

d) 7.00.00

The requirements of site tests are also to be specified.

LIST OF TESTS TO BE CONDUCTED

7.01.00

Routine tests on assembled transformers: (a.) All routine test in accordance with IS 2026/IEC 60076 shall be carried out on all transformer. Measurement of no load losses & current shall be done at 90%, 100% & 110% of rated voltage. Dielectric tests shall be carried out as per IEC 60076-3. Lightning impulse test shall be carried out as per clause no. 14 of IEC 60076-3. (b.) Following additional routine tests shall also be carried out on each transformer. (1.) Repeat no load current/loss measurement after completion of all electrical tests. (2.) (3.) Dye-penetration test Oil leakage test: This test shall be done on completely assembled transformer for the unit on which type test shall be done. On the other units this may be conducted without conservator & coolers. (4.) Temperature rise test: This test shall be a routine test. Temperature rise test shall be performed at a tap corresponding to maximum losses. The test shall be carried out at minimum 110 % of rated current. Oil samples as per IEC 60567 shall be taken before & immediately after temperature

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:129

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer rise test. DGA shall be conducted on this oil sample & the values shall be recorded in the report. For evaluation of gas analysis in temperature rise test the procedure shall be as per IS: 9434 (based on IEC: 60567) & results will be interpreted as per IS: 10593 (based on IEC: 60599). (5.) (6.) (7.) (8.) (9.) 5 kV isolation test for core. Measurement of no load current with 415 V, 50 Hz AC supply. IR measurement. Frequency response analysis test Capacitance and tan delta measurement between winding & earth.

(10.) ACLD test as per cl. 12.4 of IEC 60076-3 with U 1 =1.8Um/3 and U 2 =1.6Um/3. Max allowed change in PD after voltage enhancement shall be 100pC. 7.02.00 Type Tests Following type tests shall be conducted on one transformer of each rating: (a.) (b.) (c.) Tank vacuum test as specified elsewhere in this specification. Tank pressure test as specified elsewhere in this specification. Short circuit test: The test procedure shall be same as per IEC 60076-5 All type tests other than tank tests shall be conducted only after S.C. test to ensure delivery of healthy & proven transformer. The time duration for each shot during S.C. test shall be as per IEC 60076-5. The allowed variation in inductance shall be as per IEC 60076-5. All dielectric routine tests shall be conducted before & after S.C. test at full value including following also: (1.) (2.) (d.) (e.) Dissolved gas analysis Frequency response analysis

Recurrence surge oscillograph Measurement. Reports for Degree of Protection test (IP 55) on CCC/CMB of each rating of transformer shall be submitted.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:130

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer Special Test Following special test shall be conducted on the transformer of each rating (a.) (b.) (c.) Power taken by cooling equipment No load harmonic measurement Noise level measurement as per NEMA TR-1

7.03.00

7.04.00

Tank Test (a.) Routine test Oil leakage test on assembled transformer All tank & oil filled compartment shall be tested for oil tightness by being completely filled with oil of viscosity not greater than that of insulating oil conforming to IS: 335 at the ambient temperature & applying pressure equal to the normal pressure plus 35 KN/sq. m measured at the base of the tank. The pressure shall be maintained for a period of not less than 24 hours during which time no sweating shall occur. This test shall be repeated as a pre commissioning test at site. The gaskets & flanges used shall be capable of meeting the above requirement. The gaskets shall not deteriorate during the life of transformer if not opened for maintenance at site. Contractor shall also recommend quality & make of gaskets to be used for replacement during maintenance if required. All joints flanged or welded associated with oil shall be such that no oil leakage or sweating occurs during the life of transformer. The quality of these joints is considered established, only if the joints do not exhibit any oil leakage or sweating for a continuous period of at least 3 months during the guarantee period. In case any sweating / leakage are observed, contractor shall rectify the same & establish for a further period of 3 months of the same. If it is not established during the guaranteed period, the guaranteed period shall be extended until the performance is established. (b.) Type Tests (1.) VACUUM TEST

Each transformer tank shall be subjected to the specified vacuum. the tank designed for full vacuum shall be tested at an internal pressure of 3.33 KN/sq.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:131

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer m absolute (25 torr) for one hour. The permanent deflection of the plate after the vacuum has been released shall not exceed the values specified below:

Horizontal Length of Flat Plate (in mm) Upton and including 750 751 to 1250 1251 to 1750 1751 to 2000 2001 to 2250 2251 to 2500 2501 to 3000 Above 3000 (2.) Pressure Test

Permanent deflection(in mm) 5.0 6.5 8.0 9.5 11.0 12.0 16.0 19.0

Transformer tank of each size shall be subjected to a pressure corresponding to twice the normal head of oil or to the normal pressure plus 35 KN / sq. m whichever is lower, measured at the base of the tank & maintained for one hour. The permanent deflection of the plates after the excess pressure has been released shall not exceed the figure specified above for vacuum test. 8.00.00 INSPECTION AND TESTING AT SITE The Contractor shall arrange to carry out a detailed inspection and testing program for field activities covering areas right from the receipt of material stage up to commissioning stage. An indicative program of inspection as envisaged is given below. This is however not intended to form comprehensive program, as it is contractors responsibility to draw up and carry out such a duly approved program. Testing of oil sample at site shall be carried out as per specification. 8.01.00 Receipt and Storage Checks (a.) Check and record condition of each package, visible parts of the transformer etc. for any damage. (b.) Check and record the gas pressure in the transformer tank as well as in the gas cylinder.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:132

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer (c.) Visual check for wedging of core and coils before filling up with oil and also check conditions of core and winding in general. (d.) Check and Record reading of impact recorder at receipt and verify the allowable limits as per manufacturers recommendation.

8.02.00

Installation Checks (a.) Inspection and performance testing of accessories like tap changers, cooling fans, oil pumps etc. (b.) Check the direction of rotation of fans and pumps. Check the bearing lubrication. (c.) (d.) (e.) (f.) (g.) Check whole assembly for tightness, general appearance etc. Oil leakage test. Check oil sample prior to filling Leakage test on bushing before erection. Capacitance & tan delta measurement of bushing before fixing / connecting to the winding, contractor shall furnish these values for site reference.

8.03.00

Commissioning Checks (a.) (b.) Check the colour of silica gel in silica gel breather. Check the oil level in the breather housing, conservator tanks, cooling system, condenser-bushing etc. (c.) Check the bushing for conformity of connection to the lines etc. and tan delta test for bushing at 10 kV (min.) (d.) Check for correct operation of protection devices and alarms: (1.) (2.) (3.) Buchhloz relay. Excessive winding temperature Excessive oil temperature

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:133

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer (4.) (5.) (6.) (7.) (8.) (9.) Low oil flow Low oil level indication Fan and pump failure protection Oil flow failure Pressure relief valve Differential relay

(10.) Overload relay (11.) Earth fault relay (12.) Restricted earth fault relay (13.) Inter trip (14.) Trip free check (15.) Over fluxing relay (e.) Check for the adequate protection on the electric circuit supplying the accessories. (f.) Check resistance of all windings on all steps of the tap changer. Insulation resistance measurement for the following 1) 2) 3) 4) 5) 6) Control wiring. Cooling system motor and control Main windings Tap changer motor and control Tank & turret mounted CTs Core and clamp - Core to earth

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:134

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer - Core clamp to earth - Core to core clamp (g.) (h.) Check for cleanliness of the transformer and the surroundings. Check the following 1) 2) Direction and overload setting of cooling Accessories Buchholz, oil level indicator, pressure gauges, temp indicators etc. for fitting 3) & operation.

Earthing of main tank, marshaling Box, tap changer driving gear, pump and fan motor etc.

4) 5) 6) 7) 8) 9) (i.) (j.) (k.) (l.)

Neutral earthing Calibration of WTI and OTI Earthing of bushing test tap Connection of WTI CT with its heater Tightness of CT secondary connection and shorting of unused CTs All valves for their correct opening and close sequence

Phase out and vector group test. Ratio test on all taps. Magnetizing current test (HV winding & LV winding). Capacitance and Tan delta measurement of winding

(m.) Measurement of noise level. (n.) Oil Dielectric strength test-the various tests on oil shall be conducted prior to filling in main tank at site & prior to energization at site. Oil samples are to be drawn from top & bottom of main tank, cooling system. (o.) DGA of oil before commissioning

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:135

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer (p.) (q.) (r.) Core isolation test Short circuit impedance measurement Test on tank/turret mounted CTs 1) 2) 3) 4) 5) (s.) IR value between secondary winding & earth and between windings Secondary resistance Polarity Ratio test Magnetization current

Test on cooler fan & pump 1) 2) 3) IR Value Starting current Running current

(t.) WTI and OTI setting for alarm/trip, fan start/stop and pump start/stop (u.) Final IR Value 1) HV/E+LV 2) LV/E+HV 3) HV/LV (v.) Continuously observe the transformer operation at no load for 24 hrs. W.r.t. Voltage, no load current, temperature rise and noise. (w.) Gradually put the transformer on load, check and measure increase in temperature in relation to the load and check the operation with respect to temperature rise and noise level etc.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:136

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer FIRE PROTECTION SYSTEM Necessary Fire protection and fighting system shall be provided for transformers. The requirements lay down in section 5 of Tariff Advisory Committees Regulations for the Electrical Equipment of Building and section 7.9 of IS: 10028 (part II) shall be followed. Following fire fighting system shall be considered: Drain and Stir method in which on detecting fire, oil is partially drained from the transformer and nitrogen gas is bubbled into the transformer tank to quench the fire. Cables, busduct, or cable tray penetrating an exposed wall should be sealed with a fire stop.

9.00.00

10.00.00

ON LINE PARTIAL DISCHARGE MONITORING SYSTEM For continuous monitoring of the condition of insulation of the transformer it shall include the on line PD monitoring system. The method used for PD testing shall be in accordance with IEC-60076-3 and IEC-60270.The system shall be interfaced with plant DDCMIS.

11.00.00

TRANSPORTATION Nitrogen/dry air filled with sufficient number of impact recorders with necessary arrangement for maintaining the gas pressure during transit and storage. The temperature and pressure at the time of gas filling shall be marked on a tag. A graph showing pressure vs. temperature shall be attached for reading pressures at different temperatures. Necessary valves, two-stage pressure regulators, filled up Nitrogen cylinder (in case of nitrogen gas is used) etc. along with other accessories required shall be provided with the tank for intermittent replenishment during transportation. The impact recorders will be taken back only after obtaining written permission from Purchasers Site Incharge.

12.00.00

TRANSFORMER OIL FILTRATION PLANT One no. mobile transformer oil filtration plant shall be provided. The capacity of transformer oil filtration plant shall not be less then 10KLPH with vacuum in three stage degassing plant. First stage will be evacuated by a two stage rotary oil sealed pump. Second stage of degassing column will be evacuated by a mechanical booster pump.

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:137

DESEIN

Tender Specification Vol-IV : Electrical Works Generator Transformer Third stage of the degassing column will be evacuated by a roots pump. The plant shall be rated for continuous operation. The plant shall be mobile with four (4) wheel pneumatic tyres and suitable for being towed on motorable road. The plant shall also be supplied along with transformer evacuation system consisting of roots pump backed by a two stage rotary pump. Provision at suitable place in the path of oil being processed shall also be made for connecting an ionic reaction column to be used for removal of acidity and product of oxidation and ageing in used transformer oil. The ionic reaction column shall be supplied with the plant. The plant shall be complete with on-line testing instruments and annunciating panel. Shed/ Canopy at suitable location shall be provided for the transformer oil filtration plant. Technical Particulars a) Dielectric strength : Suitable for 70kV or better with spark gap of 2.5mm for 1 minute b) Water content in purified oil c) Suspended particles d) Gas content : Better then 20ppm in single pass. : 1 Micron : 0.1% by volume

e) Dissipation factor of oil at 90C after : 0.05 filling into the equipment

2x660 MW Ennore SEZ Supercritical Thermal Power Project at Ash Dyke of NCTPS Spec. No. CE/C/P&E/EE/E/OT. No. 03/2013-14 Vol. IV: Electrical Works:138

Das könnte Ihnen auch gefallen

- Knowledge is "Real Power": Introduction to Power QualityVon EverandKnowledge is "Real Power": Introduction to Power QualityNoch keine Bewertungen

- Report On Study of Electrical Equipments in Power SystemDokument92 SeitenReport On Study of Electrical Equipments in Power Systemvanya gupta100% (2)

- Check ListDokument6 SeitenCheck ListdevcharuNoch keine Bewertungen

- Earthing Calculation - Open ElectricalDokument11 SeitenEarthing Calculation - Open ElectricalChihiya Fitria NurhayatiNoch keine Bewertungen

- Selecting Transformers For Hydro Power PlantsDokument16 SeitenSelecting Transformers For Hydro Power PlantsDIPAK VINAYAK SHIRBHATE100% (1)

- Major ProjectDokument30 SeitenMajor ProjectRakesh YadavNoch keine Bewertungen

- Electrical Online CalculationsDokument5 SeitenElectrical Online Calculationsdarsh2001patelNoch keine Bewertungen

- 7SJ61 As High Impedance RelayDokument36 Seiten7SJ61 As High Impedance Relayzarun1Noch keine Bewertungen

- Electrical Design GuideDokument222 SeitenElectrical Design GuideMeCebu Philippinetonan100% (1)

- An Example How To Calculate Voltage Drop and Size of Electrical Cable - EEP PDFDokument8 SeitenAn Example How To Calculate Voltage Drop and Size of Electrical Cable - EEP PDFtatianaNoch keine Bewertungen

- Bhel Lem ReportDokument33 SeitenBhel Lem ReportHarshita GautamNoch keine Bewertungen

- Switchyard EquipmentDokument73 SeitenSwitchyard EquipmentAbhishek Kumar Jha100% (1)

- Tutorial: Starting ETAPDokument20 SeitenTutorial: Starting ETAPelenildo6509Noch keine Bewertungen

- Experienced Electrical Engineer CVDokument3 SeitenExperienced Electrical Engineer CVfradeepNoch keine Bewertungen

- Type 2 Co Ordination in LV SwitchgearDokument46 SeitenType 2 Co Ordination in LV Switchgearkapil100% (4)

- 33 KV GIS - 09 Panel Board 19-12-19Dokument29 Seiten33 KV GIS - 09 Panel Board 19-12-19Abhinav Tewari100% (1)

- 500kV Single-Phase Oil-Immersed Convert TransformerDokument2 Seiten500kV Single-Phase Oil-Immersed Convert TransformerDante FilhoNoch keine Bewertungen

- 04.datasheet ElectricalDokument36 Seiten04.datasheet ElectricalVikas Dwivedi0% (1)

- CV - Electrical Engineer-Design-VigneshDokument2 SeitenCV - Electrical Engineer-Design-VigneshvigneshNoch keine Bewertungen

- Auto Bus Transfer Scheme in Power PlantsDokument58 SeitenAuto Bus Transfer Scheme in Power Plantsashu_pandaNoch keine Bewertungen

- Interview QuestionsDokument5 SeitenInterview QuestionsShahed HussainNoch keine Bewertungen

- Per Unit System PPDokument15 SeitenPer Unit System PPfatank04100% (1)

- Sub-Station SpecificationDokument6 SeitenSub-Station SpecificationsbpathiNoch keine Bewertungen

- REC Spec.Dokument128 SeitenREC Spec.Sanjay RoutNoch keine Bewertungen

- Technical Data 33kV GIS GV3Dokument5 SeitenTechnical Data 33kV GIS GV3muthusamyeeeNoch keine Bewertungen

- Datasheet of Grounding TransformerDokument4 SeitenDatasheet of Grounding TransformerpctinformationNoch keine Bewertungen

- Electrical Thumb Rules-Illumination - (Part-16) - Electrical Notes & ArticlesDokument14 SeitenElectrical Thumb Rules-Illumination - (Part-16) - Electrical Notes & ArticlesElectrical Radical100% (1)

- GridMgmtOverview Nov2007 ElectricalIndiaDokument7 SeitenGridMgmtOverview Nov2007 ElectricalIndiaSiva RamanNoch keine Bewertungen

- Design Criteria Document of Electrical Systems For 2 X 660 MW Thermal Power Plant DCD NPT10111-PE-E-ED-500100-001 - R2Dokument141 SeitenDesign Criteria Document of Electrical Systems For 2 X 660 MW Thermal Power Plant DCD NPT10111-PE-E-ED-500100-001 - R2Suresh ChintaNoch keine Bewertungen

- Earthing System PDFDokument24 SeitenEarthing System PDFasexyguyNoch keine Bewertungen

- Power Transformers DatasheetDokument3 SeitenPower Transformers DatasheetMuhammad Ibad AlamNoch keine Bewertungen

- Power Evacuation 300 MW - ChettikuruchiDokument8 SeitenPower Evacuation 300 MW - ChettikuruchiAbhishek KukrejaNoch keine Bewertungen

- Techint Trainee Manual Hazardous Area ClassificationDokument7 SeitenTechint Trainee Manual Hazardous Area ClassificationYogesh MittalNoch keine Bewertungen

- Switch Yard Training Report (NTPC Barh)Dokument43 SeitenSwitch Yard Training Report (NTPC Barh)Praveen KumarNoch keine Bewertungen

- 220 KV Switchyard EquipmentsDokument3 Seiten220 KV Switchyard EquipmentsRaj Kumar Prajapati100% (1)

- Tender For High Mast Lighting SystemDokument8 SeitenTender For High Mast Lighting SystemArchishman BhattacharyaNoch keine Bewertungen

- 6.6kv MV Switch Board-1 (Single Bus) Part - 02 of 02Dokument46 Seiten6.6kv MV Switch Board-1 (Single Bus) Part - 02 of 02unimarineNoch keine Bewertungen

- Ground Potential Rise & Equipotential BondingDokument24 SeitenGround Potential Rise & Equipotential BondingShrikant KajaleNoch keine Bewertungen

- Soft Starter Vs VFDDokument2 SeitenSoft Starter Vs VFDaqhammamNoch keine Bewertungen

- Trfo Voltage DropDokument74 SeitenTrfo Voltage DropshivvaramNoch keine Bewertungen

- Bus Duct Sizing CalculationDokument5 SeitenBus Duct Sizing CalculationmohammadkassarNoch keine Bewertungen

- Best Practices - Earthing Installations - Myths & FactsDokument43 SeitenBest Practices - Earthing Installations - Myths & FactskapilNoch keine Bewertungen

- Hongdong PDF DRG PDFDokument50 SeitenHongdong PDF DRG PDFhonghoaso1100% (1)

- 1.0 Power System StudiesDokument7 Seiten1.0 Power System StudiesL Rahman AliffiantoNoch keine Bewertungen

- SWITCHYARDDokument30 SeitenSWITCHYARDKaran TripathiNoch keine Bewertungen

- Molded Case Circuit Breakers PDFDokument7 SeitenMolded Case Circuit Breakers PDFMohamedAhmedFawzyNoch keine Bewertungen

- DG Set - Rev 0Dokument30 SeitenDG Set - Rev 0jhakg_169712275Noch keine Bewertungen

- Assemblies of Switchgear and Control Panels 1Dokument6 SeitenAssemblies of Switchgear and Control Panels 1sabeerNoch keine Bewertungen

- Worked Example of Cable CalculationDokument6 SeitenWorked Example of Cable CalculationSasa Hary100% (2)

- Off Load Tap Changer - Part 1Dokument20 SeitenOff Load Tap Changer - Part 1Moncoz Aye100% (3)

- Chapter 2 Generator and AccessoriesDokument43 SeitenChapter 2 Generator and AccessoriesAnonymous nwByj9LNoch keine Bewertungen

- J0263-Ff-El-Dsh-211 Data Sheet For LV Motors (Part Iia)Dokument7 SeitenJ0263-Ff-El-Dsh-211 Data Sheet For LV Motors (Part Iia)jaikolangaraparambilNoch keine Bewertungen

- Electrical SpecificationDokument40 SeitenElectrical SpecificationChandrasekar KaruppasamyNoch keine Bewertungen

- VFDDokument9 SeitenVFDVenkatesh RaoNoch keine Bewertungen

- 51 SDMS 01rev022Dokument20 Seiten51 SDMS 01rev022Shabir Afzal KhanNoch keine Bewertungen

- Ddugjy 3 Phase DTsDokument32 SeitenDdugjy 3 Phase DTspraveenkumarNoch keine Bewertungen

- Technical Description Td-95/3 400 KV, 30 Mvar or 50 Mvar or 60 Mvar Shunt ReactorsDokument25 SeitenTechnical Description Td-95/3 400 KV, 30 Mvar or 50 Mvar or 60 Mvar Shunt ReactorsK Vijay Bhaskar ReddyNoch keine Bewertungen

- Power Energy - Tender SpecsDokument6 SeitenPower Energy - Tender SpecsAbdul-Madid Ciudad GuimbaNoch keine Bewertungen

- Transformers SpecDokument13 SeitenTransformers SpecAkshay PanttNoch keine Bewertungen

- Staad Pro-Open ChannelDokument5 SeitenStaad Pro-Open ChannelAnonymous nwByj9LNoch keine Bewertungen

- Planwin / RCDC Is A Total End To End Solution For RCC Building Design and Drawing. It Offers FollowingDokument4 SeitenPlanwin / RCDC Is A Total End To End Solution For RCC Building Design and Drawing. It Offers FollowingAnonymous nwByj9LNoch keine Bewertungen

- Staad Auto Load CombinationDokument1 SeiteStaad Auto Load CombinationAnonymous 48jYxR1CNoch keine Bewertungen

- Pushover CE&CRDokument9 SeitenPushover CE&CRAnonymous nwByj9LNoch keine Bewertungen

- ETABS Example-1Dokument64 SeitenETABS Example-1Anonymous nwByj9L0% (1)

- Is 808-1989 Steel TableDokument24 SeitenIs 808-1989 Steel TableAtul Kumar Engineer86% (28)

- Continuous Beam 2Dokument6 SeitenContinuous Beam 2Anonymous nwByj9LNoch keine Bewertungen

- Section Viii AnnexuesDokument11 SeitenSection Viii AnnexuesAnonymous nwByj9LNoch keine Bewertungen

- Schematic Layout of Bazaar Road SSDokument1 SeiteSchematic Layout of Bazaar Road SSAnonymous nwByj9LNoch keine Bewertungen

- Staad Pro-Open ChannelDokument5 SeitenStaad Pro-Open ChannelAnonymous nwByj9LNoch keine Bewertungen

- Compound WallDokument3 SeitenCompound WallAnonymous nwByj9L0% (1)

- WindDokument9 SeitenWindAnonymous nwByj9LNoch keine Bewertungen

- Steps To E-Filing For ITDokument4 SeitenSteps To E-Filing For ITAnonymous nwByj9LNoch keine Bewertungen

- Etabs: Extended Three Dimensional Analysis For Building System Example 1Dokument41 SeitenEtabs: Extended Three Dimensional Analysis For Building System Example 1Anonymous nwByj9L100% (2)

- Practical Aspects On Detailing of RCC Members in Building Construction BY V.M.Rajan Ce/Civil/MtppDokument21 SeitenPractical Aspects On Detailing of RCC Members in Building Construction BY V.M.Rajan Ce/Civil/MtppAnonymous nwByj9L100% (1)

- Section VDokument18 SeitenSection VAnonymous nwByj9LNoch keine Bewertungen

- Section VIIDokument29 SeitenSection VIIAnonymous nwByj9LNoch keine Bewertungen

- Trench 2Dokument1 SeiteTrench 2Anonymous nwByj9LNoch keine Bewertungen

- Section IIDokument105 SeitenSection IIAnonymous nwByj9LNoch keine Bewertungen

- Bazzar Road SS-GFDokument1 SeiteBazzar Road SS-GFAnonymous nwByj9LNoch keine Bewertungen

- Trench 1Dokument1 SeiteTrench 1Anonymous nwByj9LNoch keine Bewertungen

- Section IDokument37 SeitenSection IAnonymous nwByj9LNoch keine Bewertungen

- sch-2 - 06.01.2014Dokument1 Seitesch-2 - 06.01.2014Anonymous nwByj9LNoch keine Bewertungen

- WindDokument139 SeitenWindAnonymous nwByj9LNoch keine Bewertungen

- Staad Pro NotesDokument134 SeitenStaad Pro NotesAnonymous nwByj9L100% (31)

- 8 7 Battery Room: S C A D A RTCCDokument1 Seite8 7 Battery Room: S C A D A RTCCAnonymous nwByj9LNoch keine Bewertungen

- Schematic Layout of Bazaar Road SSDokument1 SeiteSchematic Layout of Bazaar Road SSAnonymous nwByj9LNoch keine Bewertungen

- Fire Barrier Wall: Cable TrenchDokument1 SeiteFire Barrier Wall: Cable TrenchAnonymous nwByj9LNoch keine Bewertungen

- Staad FoundationDokument25 SeitenStaad FoundationAnonymous nwByj9L100% (2)

- Bazzar Road Control Room Building DesignDokument39 SeitenBazzar Road Control Room Building DesignAnonymous nwByj9LNoch keine Bewertungen

- 42 - Extensive Feedwater Quality Control and Monitoring Concept For Preventing Chemistry-Related Failures of Boiler Tubes in A Subcritical Thermal Power PlantDokument12 Seiten42 - Extensive Feedwater Quality Control and Monitoring Concept For Preventing Chemistry-Related Failures of Boiler Tubes in A Subcritical Thermal Power PlantBehnam RamouzehNoch keine Bewertungen

- Vallur-II Feasibility ReportDokument131 SeitenVallur-II Feasibility ReportItilekha DashNoch keine Bewertungen

- Chapter 2 - Solar Energy - Solar Energy SystemsDokument54 SeitenChapter 2 - Solar Energy - Solar Energy Systemsaida nasuha100% (1)

- Moteur VehiculeDokument32 SeitenMoteur VehiculeMouna MorchidNoch keine Bewertungen

- Steam PWRDokument3 SeitenSteam PWRIsuru OvinNoch keine Bewertungen

- Steam Power CycleDokument37 SeitenSteam Power CycleAnamikaSharmaNoch keine Bewertungen

- Turbine MTCDokument9 SeitenTurbine MTCArya Singh Rathod100% (1)

- Plasma Ignition Combustion StabilizingDokument21 SeitenPlasma Ignition Combustion StabilizingK R Kumar RanjanNoch keine Bewertungen

- Difference Between Heat Recovery Steam Generators (HRSG) & Combustion BoilerDokument3 SeitenDifference Between Heat Recovery Steam Generators (HRSG) & Combustion Boilerazeemmet9924Noch keine Bewertungen

- 300 Multiple Choice Question Bank On Power Plant EngineringDokument27 Seiten300 Multiple Choice Question Bank On Power Plant Engineringramkrishna77% (39)

- Captive Power PlantDokument30 SeitenCaptive Power PlantDeepakGawasNoch keine Bewertungen

- Boiler Feed PumpDokument32 SeitenBoiler Feed PumpAli Bari100% (1)

- Workshop Exercise - CogenerationDokument3 SeitenWorkshop Exercise - CogenerationJurij BlaslovNoch keine Bewertungen

- Types of Power Plants - 2018 PDFDokument71 SeitenTypes of Power Plants - 2018 PDFJeff Justine GeragaNoch keine Bewertungen

- Gas Turbines: Associate Professor, Mech. Engg. Deptt. Head, Institute of Alternate Energy Research (IAER), R&D Coes, UpesDokument186 SeitenGas Turbines: Associate Professor, Mech. Engg. Deptt. Head, Institute of Alternate Energy Research (IAER), R&D Coes, UpesPRAVEEN100% (1)

- 351 F248S J0101 2015.07.22 Id R1Dokument77 Seiten351 F248S J0101 2015.07.22 Id R1Md Suzon MahmudNoch keine Bewertungen

- Knowledge Is Power EssaysDokument10 SeitenKnowledge Is Power EssaysZekria Noori AfghanNoch keine Bewertungen

- Internship Report 2019Dokument28 SeitenInternship Report 2019Shivani YadavNoch keine Bewertungen

- Basic Thermodynamics: Module 01: Fundamental Concepts and Definitions 1.1 DefinitionDokument22 SeitenBasic Thermodynamics: Module 01: Fundamental Concepts and Definitions 1.1 DefinitionVinayaka G PNoch keine Bewertungen

- Boe MCQDokument13 SeitenBoe MCQSyam Prasad100% (1)

- Practice Problems Thermodynamic Relations CyclesDokument2 SeitenPractice Problems Thermodynamic Relations CyclesSanu SouravNoch keine Bewertungen

- Upgraded & Prefab Insulation System: Recent Developments in Thermal Insulation System in IndustryDokument141 SeitenUpgraded & Prefab Insulation System: Recent Developments in Thermal Insulation System in IndustryBhavesh PatelNoch keine Bewertungen

- Turbine Performance Paper Great S05 - Performance PDFDokument93 SeitenTurbine Performance Paper Great S05 - Performance PDFMas Zuhad100% (1)

- ME8595-Thermal Engineering-II Valliammai PDFDokument19 SeitenME8595-Thermal Engineering-II Valliammai PDFSiva SubramaniamNoch keine Bewertungen

- ESSE Questions Bank ME Power Plant PDFDokument4 SeitenESSE Questions Bank ME Power Plant PDFAmit VikramNoch keine Bewertungen

- 9A03710 Power Plant EngineeringDokument4 Seiten9A03710 Power Plant EngineeringsivabharathamurthyNoch keine Bewertungen

- ASSIGNMENT Me PDFDokument3 SeitenASSIGNMENT Me PDFmahfuzNoch keine Bewertungen

- Heat Exchangers & Waste Heat RecoveryDokument30 SeitenHeat Exchangers & Waste Heat RecoveryrsahayNoch keine Bewertungen

- JPCL - TaqiDokument22 SeitenJPCL - TaqiAsad UllahNoch keine Bewertungen

- Welcome: R.K. Balu Dgm/FesDokument38 SeitenWelcome: R.K. Balu Dgm/Fesrashm006ranjanNoch keine Bewertungen