Beruflich Dokumente

Kultur Dokumente

Rice Mill Project

Hochgeladen von

Vishal Rajaram JoshiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Rice Mill Project

Hochgeladen von

Vishal Rajaram JoshiCopyright:

Verfügbare Formate

G V Agrotech Pvt Ltd

1

st

Generation in Rice & Flour Mill Page 1

RICE MILL

Introduction:

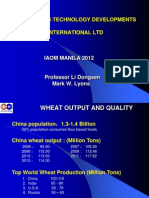

Rice is the staple food for 65%of the population in India. India is the second largest producer of rice in

the world next to China. In India paddy occupies the first place both in area and production. The India's

rice production reached to a record high of 104.32 million tonnes in 2011-2012 crop year. It is

fundamentally a kharif crop in India. It demands temperature of around 25 degree Celsius and above

and rainfall of more than 100 cm. Rice grows on a variety of soils like silts, loams and gravels. It can also

tolerate alkaline as well as acid soils. However, clayey loam is well suited to the raising of this crop. In

some of the states like West Bengal, Assam, Orissa and Bihar, two crops of rice are raised in a year. This

provides us with ample opportunity for development of rice based value-added products for earning

more foreign exchange. Apart from rice milling, processing of rice bran for oil extraction is also an

important agro processing activity for value addition, income and employment generation. Many of the

rice processing units are of the traditional huller type and are inefficient. Modern rice mills are having

high capacity and are capital intensive, although efficient. Small modern rice mills have been developed

and are available in the market but the lack of information is a bottleneck in its adoption by the

prospective entrepreneur. The present model will go a long way in bridging the information gap.

Status of Rice Milling Units in India

Rice milling is the oldest and the largest agro processing industry of the country. At present it has a turn

over of more than 25,500/- crore per annum. It processes about 85 million tonnes of paddy per year and

provides staple food grain and other valuable products required by over 60%of the population.

Print to PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

G V Agrotech Pvt Ltd

1

st

Generation in Rice & Flour Mill Page 2

The basic rice milling processes consist of:

1. Pre Cleaning : Removing all impurities and unfilled grains from paddy

2. De-stoning : Separating small stones from paddy

3. Parboiling (Optional) : Helps in improving the nutritional quality by gelatinization of starch

inside the rice grain. It improves the milling recovery percent during deshelling and polishing /

whitening operation 4. Husking : Removing husk from paddy

5. Husk Aspiration : Separating the husk from brown rice/ unhusked paddy

6. Paddy Separation : Separating the unhusked paddy from brown rice

7. Whitening : Removing all or part of the bran layer and germ from brown rice

8. Polishing : Improving the appearance of milled rice by removing the remaining bran particles

and by polishing the exterior of the milled kernel

9. Length Grading : Separating small and large brokens from head rice

10. Blending : Mixing head rice with predetermined amount of brokens, as required by the

customer

11. Weighing and bagging : Preparing the milled rice for transport to the customer

Investment components of an improved rice mill:

The land requirement for establishing an improved rice milling unit will depend upon

1. Whether the unit will be using a parboiling unit for pre-treatment of paddy before

commencement of milling operation or it will be directly milling raw paddy.

2. Whether a single pass or a multipass milling unit is to be installed.

Generally 2.00 to 2.50 acre of land is required for establishing an improved rice milling unit having an

installed processing capacity of 2 MT/ hr; operating for single shift / day of 8 hr duration; 300 days per

annum; i.e. 4800 MT /annum. The tentative cost of land and land development charges for the model

project has been considered at Rs. 5.00 Lakh.

Print to PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

G V Agrotech Pvt Ltd

1

st

Generation in Rice & Flour Mill Page 3

Civil construction:

The various construction requirement of an improved rice milling unit are as follows:

1. Raw paddy godown

2. Cleaning unit

3. Drier and necessary supporting structures such as, boiler /blower system etc.

4. Milling section

5. Finished product stores

6. Machine rooms

7. Auxiliary structures such as office, watch and ward etc.

Project Cost

S.No. Description

Cost

(Rs in Crores)

1 Land & Site Development 1.42

2 Buildings & Civil works 2.02

3 Plant & Machinery Indigenous 1.19

4 Plant & Machinery Imported 1.60

5 Electrical Infrastructure 0.15

6 Electricity Deposits 0.06

7 Furniture & Fixtures 0.05

8 Preliminary Expenses 0.08

9 Pre-operative Expenses 0.55

10 Contingency @5% 0.24

11 Margin Money for Working capital 1.32

Total Project Cost 8.69

Print to PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

G V Agrotech Pvt Ltd

1

st

Generation in Rice & Flour Mill Page 4

Means of Finance

S.No. Sources of Funds

Cost

(Rs in Crores)

1 Share Capital - Equity 4.69

2 Term Loan from Bank 4.00

Total 8.69

Key Financial indicators

The returns are adequate enough to repay the term loan in 7 years. The key financial

indicators are tabulated below.

S No Particulars Year 1 Year 2 Year 3 Year 4 Year 5 Year 6 Year 7

1 Sales 14.98 18.38 19.25 19.29 19.29 19.29 19.29

2 Total Expenditure 13.06 15.71 16.69 17.02 17.05 17.06 17.09

3 PBIDT 1.93 2.66 2.56 2.27 2.24 2.23 2.20

4 PBT 1.30 1.39 1.32 1.11 1.16 1.25 1.32

5 PAT 1.05 1.04 0.96 0.80 0.82 0.86 0.89

6 Cash Accruals 1.16 1.27 1.20 1.03 1.05 1.09 1.13

7 BEP @ Installed capacity 24.11% 30.57% 35.83% 37.07% 34.67% 31.32% 28.14%

8 BEP @ Operating capacity 34.44% 38.21% 42.15% 43.61% 40.79% 36.85% 33.11%

9 Debt Equity Ratio 0.68 0.57 0.44 0.30 0.14 0.00 0.00

10 DSCR (Gross) 2.33 1.93 1.75 1.48 1.42 1.36 1.71

11 Average DSCR 1.68

12 DSCR (Net) 3.28 2.92 2.33 1.75 1.57 1.43 1.76

13 Average DSCR 2.28

14 IRR (%) 15.48%

Print to PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

G V Agrotech Pvt Ltd

1

st

Generation in Rice & Flour Mill Page 5

Reference

1. NABARD.

2. G V Agrotech Pvt Ltd, Research & Marketing Wing,

3. Small & Medium Industries of India.

4. Commercial Industries of India

Print to PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

G V Agrotech Pvt Ltd

1

st

Generation in Rice & Flour Mill Page 6

Project Report on Rice Mills

Prepared by

G V Agrotech,

Research & Marketing Wing

Print to PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

G V Agrotech Pvt Ltd

1

st

Generation in Rice & Flour Mill Page 7

Print to PDF without this message by purchasing novaPDF (http://www.novapdf.com/)

Das könnte Ihnen auch gefallen

- Organic Production of Some Agronomic Crops: Basmati Rice, Cotton, Red Gram and SugarcaneVon EverandOrganic Production of Some Agronomic Crops: Basmati Rice, Cotton, Red Gram and SugarcaneNoch keine Bewertungen

- Amit Project ReportDokument21 SeitenAmit Project ReportPankaj UpadhyayNoch keine Bewertungen

- Nabard Rice Mill ProjectDokument13 SeitenNabard Rice Mill ProjectJayant Aggarwal80% (10)

- Rice MillDokument15 SeitenRice Millkannan606100% (4)

- Rice Mill WriteupDokument17 SeitenRice Mill Writeupsaquib786100% (1)

- Modern Rice Mill - KSIDCDokument5 SeitenModern Rice Mill - KSIDCHemant SharmaNoch keine Bewertungen

- Rice Mill: Description of Rice Milling OperationDokument6 SeitenRice Mill: Description of Rice Milling OperationsarveshnemaNoch keine Bewertungen

- Model Project On Improved Rice MillDokument50 SeitenModel Project On Improved Rice Millpramit04Noch keine Bewertungen

- Project Report On Rice MillDokument26 SeitenProject Report On Rice MillRaghu Kurada72% (29)

- Rice Mill Project ReportDokument31 SeitenRice Mill Project ReportNikitaTibrewal67% (27)

- Model Project ProfilesDokument13 SeitenModel Project Profilesabhisek guptaNoch keine Bewertungen

- Project Profile of Edible OilDokument47 SeitenProject Profile of Edible OilManish Bhoyar100% (2)

- Iubat - International University of Business Agriculture and TechnologyDokument35 SeitenIubat - International University of Business Agriculture and TechnologyMohammad Jubayer Ahmed100% (3)

- Project Report ON Dal MillDokument24 SeitenProject Report ON Dal MillGOLLAVILLI GANESH50% (2)

- 15-Project Profile-Modern Rice MillDokument6 Seiten15-Project Profile-Modern Rice MillRajender SinghNoch keine Bewertungen

- Rice Mill ProjectDokument24 SeitenRice Mill Projectbull88% (8)

- Srisairice Mill ProjectDokument59 SeitenSrisairice Mill Projectnational courses100% (1)

- Project Report On MillDokument13 SeitenProject Report On MillAashish KuNoch keine Bewertungen

- Rice Mill - Detailed Project Report - 9t Per Hour - For Finance, Subsidy & Project Related Support Contact - 9861458008Dokument50 SeitenRice Mill - Detailed Project Report - 9t Per Hour - For Finance, Subsidy & Project Related Support Contact - 9861458008Radha Krishna Sahoo100% (2)

- Project Report of Food Grains ProcessingDokument21 SeitenProject Report of Food Grains ProcessingSTRAIGHT TALK BY SURYA PRAKASH100% (3)

- Mini Flour Mill KarnalDokument9 SeitenMini Flour Mill KarnalAnand Kishore100% (2)

- Priya Rice MillDokument33 SeitenPriya Rice MillKonark PoddarNoch keine Bewertungen

- Shri Ganesh Dal Mill Is A Prominent Name in The Dal IndustryDokument9 SeitenShri Ganesh Dal Mill Is A Prominent Name in The Dal IndustryNeerajSinghNoch keine Bewertungen

- Rice Mill InformationDokument17 SeitenRice Mill InformationRadha Krishna Sahoo100% (2)

- Dal Mill Report IndiaDokument12 SeitenDal Mill Report Indiarituverma587Noch keine Bewertungen

- Rice Mill Project ReportDokument31 SeitenRice Mill Project ReportNajeeb Mirza Khan50% (2)

- Rice Mill COSTDokument8 SeitenRice Mill COSTzohaibssNoch keine Bewertungen

- Maize Processing Unit 1Dokument4 SeitenMaize Processing Unit 1Nikita Arora50% (2)

- Edible Oil ReportDokument19 SeitenEdible Oil Reportsreeramchellappa100% (1)

- Bankable Project Report & Quotation For GreenhouseDokument40 SeitenBankable Project Report & Quotation For Greenhousetiyasee25Noch keine Bewertungen

- Rice Husking Mill - 26 Tons Rs. 71.46 Million Apr 2020Dokument22 SeitenRice Husking Mill - 26 Tons Rs. 71.46 Million Apr 2020Junaid AhmedNoch keine Bewertungen

- Project Report On Processing of AttaDokument16 SeitenProject Report On Processing of AttaRaghu Kurada100% (3)

- Business Case (2) - RICE BRAN OIL PRODUCTIONDokument23 SeitenBusiness Case (2) - RICE BRAN OIL PRODUCTIONAhamed Naxeeb100% (3)

- Feasibility of Rice Bran Oil PDFDokument248 SeitenFeasibility of Rice Bran Oil PDFSajidur Rehman Syed100% (1)

- FPO-BUSINESS PLAN - BhadohiDokument60 SeitenFPO-BUSINESS PLAN - Bhadohifpo docs100% (6)

- Atta FlourDokument4 SeitenAtta FloursubhamNoch keine Bewertungen

- Mustard Oil KanpurDokument10 SeitenMustard Oil KanpurVinay YadavNoch keine Bewertungen

- Project Report On King Chilli Processing UnitDokument39 SeitenProject Report On King Chilli Processing UnitPrakash Pokhrel0% (1)

- Dpr-Meghana Roofing Industries-From Page5Dokument20 SeitenDpr-Meghana Roofing Industries-From Page5technopreneurvizagNoch keine Bewertungen

- Madina Mini Flour MillDokument11 SeitenMadina Mini Flour MillHusnainShahidNoch keine Bewertungen

- Profile On The Setup of Poultry FeedDokument26 SeitenProfile On The Setup of Poultry FeedMOHIT KHATWANINoch keine Bewertungen

- Dairy Farm Project Report Ten Cows ,Dairy Farming,Dairy Farming Ptofit,Dairy Project, Dairy Farm Business Plan, Loan for Dairy Farm, Deshi Cow Dairy Farm Project, Dairy Farm Subsidy, Cow Buffalo Farm Subsidy, Deds, PdeDokument8 SeitenDairy Farm Project Report Ten Cows ,Dairy Farming,Dairy Farming Ptofit,Dairy Project, Dairy Farm Business Plan, Loan for Dairy Farm, Deshi Cow Dairy Farm Project, Dairy Farm Subsidy, Cow Buffalo Farm Subsidy, Deds, PdeRahul N Shripati100% (1)

- Mini Wheat Flour MillDokument5 SeitenMini Wheat Flour Millstalinkbc2847Noch keine Bewertungen

- Annd Rice MillDokument54 SeitenAnnd Rice MillGreatAkx100% (1)

- Project Report - Dairy FarmingDokument10 SeitenProject Report - Dairy FarmingVivek AggarwalNoch keine Bewertungen

- Mustard Oil Project ReportDokument8 SeitenMustard Oil Project ReportAkhilesh KumarNoch keine Bewertungen

- Mini Rice MillDokument14 SeitenMini Rice Mill124swadeshiNoch keine Bewertungen

- Maize Assignment FinalDokument20 SeitenMaize Assignment FinalDeep Pandya100% (1)

- Gajanan Rice Mill ReportDokument68 SeitenGajanan Rice Mill ReportChannu Arjun100% (1)

- Cotton Seed OilDokument29 SeitenCotton Seed OilYem Ane100% (2)

- Basmati Rice Manufacturing ProcessDokument4 SeitenBasmati Rice Manufacturing ProcessShamli Karumannil100% (1)

- Chaff CutterDokument23 SeitenChaff Cutterabel_kayel100% (2)

- Bhushan Flour Mill A9-B9 Live ProjectDokument39 SeitenBhushan Flour Mill A9-B9 Live ProjectABHIRUP ANANDNoch keine Bewertungen

- Project Report On Poultry Farming BHOG PURDokument29 SeitenProject Report On Poultry Farming BHOG PURpj singhNoch keine Bewertungen

- Dal Mill Project ReportDokument8 SeitenDal Mill Project ReportMohan Rao Paturi80% (5)

- Wheat FlourDokument16 SeitenWheat FlourRajesh Chowhan100% (4)

- Rice MillDokument7 SeitenRice MillgoalbreakerNoch keine Bewertungen

- Detail Project Report of Wheat FDokument27 SeitenDetail Project Report of Wheat FYogesh PatilNoch keine Bewertungen

- Small Scale Cashew Processing PlantDokument19 SeitenSmall Scale Cashew Processing PlantRashid KayumNoch keine Bewertungen

- My Business PlanDokument7 SeitenMy Business PlankrmkochasNoch keine Bewertungen

- Overview of India S Bathroom Kitchen IndustryDokument16 SeitenOverview of India S Bathroom Kitchen IndustryVishal Rajaram JoshiNoch keine Bewertungen

- OPEX Reduction in Telecom Industry: Qarib Raza Kazmi SP-2010/M.M/205 Telecom Business ManagementDokument41 SeitenOPEX Reduction in Telecom Industry: Qarib Raza Kazmi SP-2010/M.M/205 Telecom Business ManagementVishal Rajaram JoshiNoch keine Bewertungen

- Must Knows About THE Ujarat Tate UdgetDokument23 SeitenMust Knows About THE Ujarat Tate UdgetVishal Rajaram JoshiNoch keine Bewertungen

- Flyashbusinessplan 090613040509 Phpapp02Dokument47 SeitenFlyashbusinessplan 090613040509 Phpapp02Vishal Rajaram JoshiNoch keine Bewertungen

- Business Markets and Business Buyer BehaviorDokument39 SeitenBusiness Markets and Business Buyer BehaviorVishal Rajaram JoshiNoch keine Bewertungen

- Main List of StudentsDokument28 SeitenMain List of StudentsVishal Rajaram JoshiNoch keine Bewertungen

- Servicemktg 140716051857 Phpapp02Dokument36 SeitenServicemktg 140716051857 Phpapp02Vishal Rajaram JoshiNoch keine Bewertungen

- List of Top 15 Elevator Companies in IndiaDokument18 SeitenList of Top 15 Elevator Companies in IndiaVishal Rajaram JoshiNoch keine Bewertungen

- MAPICS Cycle Count 6.0-7.8 and 9.0Dokument40 SeitenMAPICS Cycle Count 6.0-7.8 and 9.0Vishal Rajaram JoshiNoch keine Bewertungen

- 11.04.06 PastroumasDokument54 Seiten11.04.06 PastroumasVishal Rajaram JoshiNoch keine Bewertungen

- 524all India Pin Code ListDokument549 Seiten524all India Pin Code ListVishal Rajaram JoshiNoch keine Bewertungen

- Cedar Crest On Er 12 Presentation 1247783438Dokument58 SeitenCedar Crest On Er 12 Presentation 1247783438Vishal Rajaram JoshiNoch keine Bewertungen

- Corporate AgentsDokument1.023 SeitenCorporate AgentsVishal Rajaram Joshi0% (1)

- G V Agrotech Modern Rice MillingDokument17 SeitenG V Agrotech Modern Rice MillingVishal Rajaram JoshiNoch keine Bewertungen

- Vinyl India 2013 Delegates ListDokument19 SeitenVinyl India 2013 Delegates ListVishal Rajaram JoshiNoch keine Bewertungen

- Flyashbusinessplan 090613040509 Phpapp02Dokument47 SeitenFlyashbusinessplan 090613040509 Phpapp02Vishal Rajaram JoshiNoch keine Bewertungen

- ElectricVehicleTechnologyRoadmap eDokument71 SeitenElectricVehicleTechnologyRoadmap eVishal Rajaram JoshiNoch keine Bewertungen

- Indian Port Sector: by Hans Ole Madsen - CEO, South Asia For A.P. Moller-MaerskDokument13 SeitenIndian Port Sector: by Hans Ole Madsen - CEO, South Asia For A.P. Moller-MaerskNishant SinghNoch keine Bewertungen

- Special Economic ZonesDokument103 SeitenSpecial Economic ZonesVishal Rajaram JoshiNoch keine Bewertungen

- 01 Ggi 12Dokument55 Seiten01 Ggi 12Vishal Rajaram JoshiNoch keine Bewertungen

- HR Heads All India 16170Dokument2.026 SeitenHR Heads All India 16170Jeevanigi Jagathrana100% (2)

- CFO SummitDokument1 SeiteCFO SummitVishal Rajaram JoshiNoch keine Bewertungen

- Bajaj Electricals LTD 2011Dokument10 SeitenBajaj Electricals LTD 2011Vishal Rajaram JoshiNoch keine Bewertungen

- Bajaj Annual Report 2012Dokument99 SeitenBajaj Annual Report 2012Vishal Rajaram JoshiNoch keine Bewertungen

- SH 2013 Q1 1 ICRA Auto ComponentsDokument6 SeitenSH 2013 Q1 1 ICRA Auto ComponentsVishal Rajaram JoshiNoch keine Bewertungen

- List of Civil ContractorDokument16 SeitenList of Civil ContractorVegas Fred G. Ssekandi100% (1)

- EbrochureDokument40 SeitenEbrochureVishal Rajaram JoshiNoch keine Bewertungen

- Mira Bhayandar DirectoryDokument442 SeitenMira Bhayandar DirectoryVishal Rajaram Joshi33% (3)

- Lamp Color Temperature GuideDokument2 SeitenLamp Color Temperature GuidesvmrNoch keine Bewertungen

- 100 DialogsDokument38 Seiten100 DialogsTramVu100% (2)

- Anil Kumar Singh Archana Pawar Bharti Gyanchandani Sohit Kadwey Sonam Seth Srashti SuneriyaDokument13 SeitenAnil Kumar Singh Archana Pawar Bharti Gyanchandani Sohit Kadwey Sonam Seth Srashti SuneriyaSrashti SuneriyaNoch keine Bewertungen

- Competition Coke+PepsiDokument4 SeitenCompetition Coke+PepsiAnurag LekhiNoch keine Bewertungen

- 10-Diary Technology PDFDokument161 Seiten10-Diary Technology PDFAmrithaNoch keine Bewertungen

- A. Name of The CompanyDokument4 SeitenA. Name of The CompanyJodel DagoroNoch keine Bewertungen

- Research SourcesDokument6 SeitenResearch Sourcesapi-318035889Noch keine Bewertungen

- Supply and Demand: Economic Analysis of Maggi NoodlesDokument8 SeitenSupply and Demand: Economic Analysis of Maggi NoodlesMuhammed NiyasNoch keine Bewertungen

- Standards For Cassava Products and Guidelines For Export: June 2005Dokument81 SeitenStandards For Cassava Products and Guidelines For Export: June 2005auliarhhmnnNoch keine Bewertungen

- Spice Grinding and PackagingDokument39 SeitenSpice Grinding and Packagingranbirgautam100% (7)

- West Visayas State University: Graduate SchoolDokument6 SeitenWest Visayas State University: Graduate SchoolBituin LynNoch keine Bewertungen

- Massachusetts CSA DirectoryDokument10 SeitenMassachusetts CSA DirectoryBre-anne BrownNoch keine Bewertungen

- BoxTops Coordinator Kit Other 2011Dokument19 SeitenBoxTops Coordinator Kit Other 2011lccsrrobinsonNoch keine Bewertungen

- Yeast Production Industry: Global Market Is Expected To Grow at CAGR of 8.9% Over The Period 2016-2021Dokument71 SeitenYeast Production Industry: Global Market Is Expected To Grow at CAGR of 8.9% Over The Period 2016-2021Mohammed HammoudehNoch keine Bewertungen

- Answer Scheme: Paper 1 / 013 Section ADokument4 SeitenAnswer Scheme: Paper 1 / 013 Section AAhmadi SaniNoch keine Bewertungen

- CNC Machine Tools W1Dokument28 SeitenCNC Machine Tools W1Islam FouadNoch keine Bewertungen

- E 8 Bai Tap CA Nam KeysDokument139 SeitenE 8 Bai Tap CA Nam KeysTom CatNoch keine Bewertungen

- Ocean Spray Juices Business ReportDokument11 SeitenOcean Spray Juices Business Reportaazra nahasNoch keine Bewertungen

- Agricola Strategy TipsDokument2 SeitenAgricola Strategy Tipsbgmnot5305Noch keine Bewertungen

- Blue Ridge BrochureDokument35 SeitenBlue Ridge BrochureluckieNoch keine Bewertungen

- Bodega Aurrera Express Format Innovation and In-Fill StrategiesDokument8 SeitenBodega Aurrera Express Format Innovation and In-Fill StrategiesAaron ChioNoch keine Bewertungen

- Color Psychology Cheat SheetDokument15 SeitenColor Psychology Cheat SheetRipujoy Bose100% (1)

- Dunkin Brands Corporate Social Responsibility Report (CSR) RedesignDokument22 SeitenDunkin Brands Corporate Social Responsibility Report (CSR) RedesignNatalie Ryder100% (2)

- Alcoholic and Non-Alcoholic BeveragesDokument30 SeitenAlcoholic and Non-Alcoholic BeveragesFrank BookhardtNoch keine Bewertungen

- Caswell Brand GuidelinesDokument18 SeitenCaswell Brand Guidelinesbeucler100% (1)

- Slickables Marketing ResearchDokument23 SeitenSlickables Marketing ResearchJessa Kali ShortNoch keine Bewertungen

- Parking and Loading Space RequirementsDokument2 SeitenParking and Loading Space RequirementsCleo BuendichoNoch keine Bewertungen

- 4 Understanding The Tractor Market PDFDokument7 Seiten4 Understanding The Tractor Market PDFYogesh TripathiNoch keine Bewertungen

- "The Pitch For Pepsi": A Project On Agency ManagementDokument33 Seiten"The Pitch For Pepsi": A Project On Agency ManagementSai PadwalNoch keine Bewertungen

- Unit 6 - Revision Worksheet Without Answers 1Dokument4 SeitenUnit 6 - Revision Worksheet Without Answers 1faisal aljubailiNoch keine Bewertungen