Beruflich Dokumente

Kultur Dokumente

FRP Pipe Catalogos

Hochgeladen von

jloblitasnOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

FRP Pipe Catalogos

Hochgeladen von

jloblitasnCopyright:

Verfügbare Formate

CNBM

Lianzhong

FRP PIPE

Sea Water Pipe Series

o

d

n

ca

e

W

r.

e

t

t

e

b

t

i

Lianyungang Zhongfu Lianzhong Composites Group Co., Ltd

CNBM

Lianyungang Zhongfu Lianzhong Composites Group Co., Ltd

Lianyungang China

Contents

1. Company Profile ........................................................ 1

2. Product Advantages ................................................... 3

3. Performance Standards .............................................. 4

4. Qualification Testing ................................................... 5

Application fields

5. Control Testing ........................................................... 6

Power Plant

6. Pipe Performance and Dimensions ............................ 7

7. Pipe Joints ................................................................10

8. Fittings and Accessories ...........................................11

LNG receiving station

9.UnloadingHandlingTransportation and Storage ..........20

10. Installation ..............................................................21

11. Successful case .....................................................22

Sea water

desalination plant

Lianzhong

CNBM

1. Company Profile

Zhongfu Lianzhong is a modern joint-venture company which is holding by China Composites Group Corporation Ltd.which

is branch company of CNBM,sharing by Goldman Sachs,Hony Capital and Govtor Capital.The headquarter of Zhongfu

Lianzhong locate in Lianyungang city,Jiangsu Province.The production base locate in Lianyungang,Shenyang,Baotou and

Qiuqu.The research and development department locate in Thueringen state of Germany. Zhongfu Lianzhong was founded

in 1989 with more than 2800 employees,of which engineering staff is more than 600.Now the company has developed to a

national key new technology company,which gathers composites product design,manufacture and service together,with

rotor blade,FRP pipe,FRP tank and high pressure pipe as main products.

The ISO9001-2000, ISO14001 and OHSAS18001 quality system of company have gone well now.The technical center is

recognized as state-level enterprise technical centers by five departments of China.The company has the first indoor rotor

blade inspection center. FRP pipe of Lianzhong brand have been awarded the title of ChinaTop brand and the certificate

of API and WRAS,which are applied in electric power, nuclear power, sea water desalination, LNG Terminal and water

supply projects around Middle East,Africa and Centeral Asia.The company is the largest composites manufacture company

in China.They have 20 production lines of FRP pipe and tank and manufacture 80000 tons of FRP pipe,rotor blade and tank

every year. Zhongfu Lianzhong have manufactured the largest diameter FRP tank in China,25meters and is also the largest

rotor blade manufacture company.

Making Best Use of Resources to Serve Construction is our unalterable industry belief,Unite the efforts to strive for the

best is our remorseless spirit!The struggling aim of Zhongfu Lianzhong is to become:Asia top-tanking rotor blade

manufacture base,domestic leading composites products research and manufacture company,excellent supplier with

customers satisfaction,and modern company with highly responsibility of social civilization.

Workshops

Lianyungang Zhongfu Lianzhong Composites Group Co.; Ltd

AddressNo.195, Hailian East Road, Lianyungang City, Jiangsu Province, Peoples Republic of China

ZhongfuLianzhong Jiuquan Co.; Ltd

AddressHigh-tech development area in Jiuquan City, Gansu Province, Peoples Republic of China

ZhongfuLianzhong Baotou Co.; Ltd

Main Products

GRV PIPE

GRP PIPE

GRE PIPE

ROTAR BLADE

FRP TANK

AddressEquipment Fabrication area in Baotou City, Inner Mongolia, Peoples Republic of China

ZhongfuLianzhong Shenyang Co.; Ltd

AddressHigh-tech development area in Tiexi District , Shenyang City,Liaoning Province, Peoples Republic of China

SINOI GmbH

AddressKohnsteinbrcke 10

99734 Nordhausen, Germany

LARGE DIAMETER TANK FABRICATE AT SITE

CNG CYLINDER

PAGE

PAGE

Lianzhong

CNBM

2.Product Advantages

Features & Benefits

3.Performance Standards

Standards developed by ASTM and AWWA are applied to a variety of fiberglass pipe applications including conveyance

of sanitary sewage, water and industrial waste. A thread common to all of the product standards is that they are all

performance based documents. This means that the required performance and testing of the pipe is specified.

ASTM

Currently there are several ASTM Product Standards in

use which apply to a variety of fiberglass pipe

applications.

All product standards apply to pipe with diameter ranges

of 25 mm to 4000 mm and require the flexible joints to

withstand hydrostatic testing in configurations (per ASTM

D4161) that simulate exaggerated in-use conditions.

These standards include many tough qualification and

quality control tests. Lianzhong pipe is designed to meet

all of these ASTM standards.

Corrosion-resistant

Long, effective service-life materials

No need for linings, coatings, cathodic protection, wraps or other forms of corrosion protection

Low maintenance costs

Hydraulic characteristics essentially constant over time

Light weight

(1/4 weight of ductile iron; 1/10 weight of concrete)

Low transport costs (nestable)

Eliminates need for expensive pipe handling equipment

Long standard lengths

(6, 12 metres)

Fewer joints reduce installation time

More pipe per transport vehicle means lower delivery costs

Extremely smooth bore

Low friction loss means less pumping energy needed and lower operating costs

Minimum slime build-up can help lower cleaning costs

Precision sealability

ASTM

D3262

Gravity Sewer

ASTM

D3517

Pressure Pipe

ASTM

D3754

Pressure Sewer

AWWA

AWWA C950 is one of the most comprehensive product standards in existence for fiberglass pipe. This standard for

pressure water applications has extensive requirements for pipe and joints, concentrating on quality control and

prototype qualification testing. Like ASTM standards, this is a product performance standard.Lianzhong pipe is designed

to meet the performance requirements of this standard. AWWA has recently issued a new standards manual, M-45, which

includes several chapters on the design and fabricate of GRP pipe for buried and aboveground installations.

AWWA

C950

Fiberglass Pressure Pipe

AWWA

M-45

Fiberglass Pipe Design Manual

CHINA STANDARD

Currently there are several China Standards in use for GRP pipe, such as GB21238JC552CECS190CECS129,

which basically equivalent foreign standard. The performance and design and burying of GRP pipe are specified by these

standard. Lianzhong participated in the formulating of these standards.

With elastomeric rubber rings

Tight, efficient joints designed for bell & spigot to eliminate infiltration and ex-filtration

Ease of joining, reducing installation time

Accommodates small changes in line direction without fittings or differential settlement

GB21238

Fiberglass pipe with sand filler

JC552

Fiberglass pressure pipe

CECS190

Fiberglass pipe Design Manual

Flexible manufacturing

CECS129

Fiberglass pipe Installation & Inspection Manual

Custom diameters can be process manufactured to provide maximum flow volumes with ease of installation for rehabilitation

lining projects

High technology pipe design

Lower wave celerity than other piping materials can mean less cost when designing for surge and water hammer pressures

High technology pipe manufacturing system producing pipe that complies

to stringent performance standards (AWWA, ASTM, DIN, EN, etc.)

High and consistent product quality worldwide which ensures reliable product performance

Others

Other standardization organizations such as BS and DIN have also published performance specifications for GRP pipes.

Lianzhong pipe conforms to these standards performance requirements too.

DIN

16868

Glass Fiber-Reinforced Polyester Resin Pipes

BS

5480

Pipes and Fittings for Water and Sewage

PAGE

PAGE

Lianzhong

CNBM

4.Qualification Testing

A common element shared by all standards is the need for a pipe manufacturer to demonstrate compliance with the standards

minimum performance requirements. In the case of GRP pipe, these minimum performance requirements fall into both short-term

and long-term requirements. The most important of these and generally specified at the same level of performance in all the

previously defined standards is joint, initial ring deflection, long-term ring bending, long-term pressure and strain corrosion

capability. Lianzhong pipe has been rigorously tested to verify conformance to the ASTM D3262, ASTM D3517, AWWA C950 and

DIN 16868 requirements.

Strain Corrosion Testing

A unique and important performance requirement for GRP gravity pipe used in sewer applications is the chemical testing of the

pipe in a deflected or strained condition. This strain corrosion testing is carried out in accordance with ASTM D3681, and requires

a minimum of 18 ring samples of the pipe to be deflected to various levels and held constant. These strained rings are then exposed

at the invert of the interior surface to 1.0N (5% by weight) sulphuric acid (see Figure 1). This is intended to simulate a buried septic

sewer condition. This has been shown to be representative of the worst sewer conditions including those found in the Middle East,

where many Lianzhong pipes have been successfully installed.

The time to failure (leakage) for each test sample is measured. The minimum extrapolated failure strain at 50 years, using a least

squares regression analysis of the failure data, must equal the values shown for each stiffness class. The value achieved is then

relatable to the pipe design to enable prediction of safe installation limitations for GRP pipe used for this type of service. Typically

this is 5% in-ground long-term deflection.

Figure 1

Strain Corrosion Test Apparatus

Stiffness Class

Scv. Strain, %

SN2500

.49 (t/d)

SN5000

.41 (t/d)

SN10000

.34 (t/d)

Initial Ring Deflection

All pipes must meet the initial ring deflection levels of no visual evidence of cracking or crazing (Level A) and no structural

damage to the pipe wall (Level B) when vertically deflected between two parallel flat plates or rods.

Deflection

Level*

Stiffness Class SN

2500

5000

10000

15%

12%

9%

25%

20%

15%

*Laboratory Test

Long-Term Ring Bending

AWWA C950 requires the test to be carried out, with the resulting

50-year predicted value used in the pipes design. Lianzhong pipe is

tested using the guidelines of ASTM D5365 Long-Term Ring Bending

Strain of Fiberglass Pipe and meets both requirements.

Potable Water Approvals

Lianzhong pipe has been tested and approved for the conveyance of

potable water meeting many of the worldss leading authorities and

testing institutes criteria, including:

WRASWater Regulations Advisory Scheme

The license of drinking water safety products

5.Control Testing

Raw Materials

Raw materials are delivered with vendor certification demonstrating their compliance with Zhongfu Lianzhong quality

requirements. In addition, all raw materials are sample tested prior to their use. These tests ensure that the pipe materials

comply with the specifications as stated.

Hydrostatic Design Basis - HDB

Physical Properties

Another important qualification test is the establishment of the Hydrostatic

Design Basis - HDB. This test is carried out in accordance with ASTM D2992

Procedure B and requires hydrostatic pressure testing to failure (leakage) of

many pipe samples at a variety of very high constant pressure levels. As in the

previously described strain corrosion test, the resulting data is evaluated on a

log-log basis for pressure (or hoop tensile strain) vs. time to failure and then

extrapolated to 50 years. The extrapolated failure pressure (strain) at 50 years,

referred to as the hydrostatic design basis (strain) or HDB, must be at least 1.8

times the rated pressure class (strain at the rated pressure).

The manufactured pipes hoop and axial load capacities are verified on a routine basis. In addition,

pipe construction and composition are confirmed.

In other words, the design criteria requires that the average pipe be capable of

withstanding a constant pressure of 1.8 times the maximum operating condition

for 50 years. Due to combined loading considerations, that is the interaction of

internal pressure and external soil loads; the actual long-term factor of safety

against pressure failure alone is higher than 1.8. This qualification test helps

assure the long-term performance of the pipe in pressure service.

Finished Pipe

All pipes are subjected to the following control checks:

Visual inspection

Barcol hardness

Wall thickness

Section length

Diameter

Hydrostatic leak tightness test to 1.5 rated pressure (only PN6 and above)

On a sampling basis, the following control checks are performed:

Pipe stiffness

Deflection without damage or structural failure

Axial and circumferential tensile load capacity

Joint Testing

This important qualification test is conducted on joint prototypes for elastomeric gasket sealed bell and spigot joint. This is a severe

test carried out in accordance with ASTM D4161. It incorporates some of the most stringent joint performance requirements in the

piping industry for pipe of any material within the pressure and size ranges of Lianzhong pipe. ASTM D4161 requires these flexible

joints to withstand hydrostatic testing in configurations that simulate very severe in-use conditions. Pressures used are twice those

rated and 200 kPa (2 bar) is used for gravity flow pipe. Joint configurations include straight alignment, maximum angular rotation

and differential shear loading. A partial vacuum test and some cyclical pressure tests are also included.

PAGE

PAGE

Lianzhong

CNBM

6.Pipe Performance and Dimensions

6.1 Mechanical Performance

Parameter Table

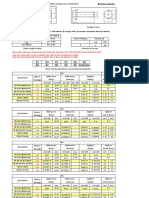

6.7 Thickness and Weight of Standard Pipes based on Internal Pressure

1. Internal liner (thickness 1.0 2.0 mm)

In tables bellow thickness include 1.5mm of liner and minimum pipe Stiffness 1250 Pa

2. Mechanical resistant layer in glass filament winding (based on internal pressure)

3. Top coat (0.2 0.3mm) . In tables bellow thickness include 0.2mm of top coat

Mechanical Property Parameters of GRP

1. Pipes

Hoop tensile strength

250MPa

Axial compressive modulus

11GPa

Axial tensile strength

120MPa

Vertical shear strength

60MPa

Axial flexural strength

100MPa

Elongation at break

0.8%

Interlaminar shear strength

13MPa

Maxmum allowable short time composite strain 0.3%

Hoop tensile modulus

22GPa

Maxmum allowable composite strain

Axial tensile modulus

12.5GPa

*The above table refer to laminated obtained by the filament

winding process having a winding angle of 55 degrees.

Hoop bending modulus

22GPa

Axial bending modulus

12.5GPa

Hoop bending strength

220MPa

0.17%

2. Fittings

Tensile strength

160MPa

Bending Strength

160MPa

Compressive strength

140MPa

0.6MPa

1.0MPa

DN

t(mm)

t(mm)

25

4.5

0.8

4.5

0.8

32

4.5

1.0

4.5

1.0

40

4.5

1.2

4.5

50

4.5

1.4

65

4.5

1.6MPa

t(mm)

2.5MPa

L(m)

t(mm)

4.5

0.8

4.5

0.8

4.5

1.0

4.5

1.0

1.2

4.5

1.2

4.5

1.2

4.5

1.4

4.5

1.4

4.5

1.4

1.8

4.5

1.8

4.5

1.8

5.5

1.8

Hoop compressive strength

160MPa

Axial compressive strength

100MPa

Tensile modulus

13GPa

80

4.5

2.2

4.5

2.2

4.5

2.2

5.5

2.2

Hoop compressive modulus

20GPa

Bending modulus

13GPa

100

4.5

2.8

4.5

2.8

4.5

2.8

5.0

3.2

125

4.5

3.5

4.5

3.5

4.5

3.6

6.0

4.8

150

4.5

4.2

5.0

4.7

5.0

4.7

6.5

6.2

200

5.0

6.3

5.0

6.3

6.0

7.7

8.0

10.4

12

250

5.0

7.9

6.0

9.3

7.0

11.2

9.5

15.4

12

300

6.0

11.4

6.0

11.4

8.0

15.4

11.0

21.4

12

6.0

13.2

6.5

14.3

9.0

20.2

12.5

28.3

12

400

6.5

16.4

7.0

17.6

10.0

25.6

14.0

36.2

12

450

6.5

18.4

7.5

21.2

11.0

31.7

15.5

45.1

12

500

7.0

22.0

8.5

26.8

12.0

38.4

17.0

54.9

12

0.26

600

7.5

28.2

9.5

35.8

14.0

53.7

20.0

77.5

12

700

8.5

37.3

11.0

48.4

15.5

69.3

23.0

104.0

12

800

9.0

45.1

12.0

60.3

16.0

81.6

26.0

134.3

12

900

10.0

56.3

13.0

73.5

17.5

100.4

29.0

168.4

12

1000

11.0

68.8

14.0

87.9

19.5

124.3

32.0

206.5

12

1200

13.0

97.6

15.0

120.4

23.0

175.9

12

1400

15.0

131.4

18.5

162.4

26.5

236.3

12

1500

15.5

145.4

20.0

188.1

28.0

267.5

12

1600

16.5

165.1

21.0

210.7

30.0

305.7

12

1800

18.5

208.2

23.0

259.5

33.5

384.0

12

2000

20.0

250.0

26.0

326.0

37.0

471.2

12

2200

22.0

302.5

28.0

386.1

12

2500

24.5

382.8

31.0

485.6

12

2800

28.5

498.9

35.0

614.1

12

3000

29.0

543.6

37.0

695.4

12

3200

31.0

619.9

12

3600

35.0

787.4

12

4000

38.0

949.7

12

6.2 Physical properties

Property

Density

g/cm

Pipes

Fittings

1.85-2.1

1.55-1.75

Glass content(by weight)

65-75

35-50

Specific Gravity

kg/m3

1.850

1.650

Coefficient of Linear Thermal Expansion

1/

1.8*10-5-2.2*10-5

1.8*10-5-2.2*10-5

Thermal Conductivity

W/m*K

0.26

Electical Resistivity(standard pipe)

Ohm/m

109

109

Electical Resistivity(conductive pipe)

Ohm/m

<105

<105

6.3 Flow Velocity

Maximum recommended flow velocity is 3.0m/sec. Velocities of up to 4.0m/sec can be used if the water is clean and contains

no abrasive material.

6.4 UV Resistance

There is no evidence to suggest that ultraviolet degradation is a factor that affects the long-term service life of Lianzhong

pipes. The outermost surface will be affected with discoloring of the surface observed. If so desired, the installing contractor

may paint the exterior surface of Lianzhong pipe with a two-part urethane paint compatible with GRP. However, this will then

become an item requiring future maintenance.

6.5 Flow Coefficients

Based on tests carried out over a 3-year period on Lianzhong pipe, the Colebrook-White coefficient may be taken as 0.029

mm. This corresponds to a Hazen-Williams flow coefficient of approximately C=150.

Contact your pipe supplier for more detailed information if needed.

6.6 Abrasion Resistance

Abrasion resistance can be related to the effects that sand or other similar material may have on the interior surface of the

pipe. While there is no widely standardized testing procedure or ranking method, GRP pipe has been evaluated by using the

Darmstadt Rocker method. Results will be highly influenced by the type of abrasive material used in the test. Using gravel

which was obtained from the same source as that used at Darmstadt University, the average abrasion loss of GRP pipe is

0.34 mm at 100.000 cycles.

350

All values presented in tables above are only for information and they are vary from the project to project.

ZhongfuLianzhong do not produce their pipe on stock, products are designed for each specific project separately.

PAGE

PAGE

Lmax for ND<50 is 1mm and for 50 ND<200 is 5900mm and for ND200 is 11700mm.

Lianzhong

CNBM

6.8 Thickness and Weight of Standard Pipes based on Stiffness

7.Pipe joints

1. Internal liner (thickness 1.0 2.0mm)

In tables bellow thickness include 1.0mm of liner

2. Mechanical resistant layer in glass filament winding (based on stiffness class)

3. Top coat (0.2 0.3mm)

In tables bellow thickness include 0.2mm of top coat

7.1 Double O ring Bell & Spigot joint

Joint Angular Deflection

The joint is extensively tested and qualified in accordance with ASTM D4161

and ISO DIS8639.

Maximum angular deflection (turn) at each joint, considering both combined

vertical and horizontal, measured as the change in adjacent pipe center lines,

must not exceed the amounts given in Table below.

Lmax for ND<50 is 1mm and for 50 ND<200 is 5900mm and for ND200 is 11700mm.

SN1250 [Pa]

SN 2500 [Pa]

SN 5000 [Pa]

Nominal sizes(ND mm)

SN 10000 [Pa]

ND

[mm]

t

[mm]

W

[kg/m]

ND

[mm]

t

[mm]

W

[kg/m]

ND

[mm]

t

[mm]

W

[kg/m]

ND

[mm]

t

[mm]

W

[kg/m]

25

40

50

65

80

100

125

150

200

250

300

350

400

450

500

550

600

700

750

800

900

1000

1100

1200

1300

1400

1500

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.2

4.6

5.0

5.4

5.8

6.6

7.0

7.4

8.2

9.0

9.8

10.6

11.4

12.2

13.0

0.7

1.0

1.3

1.6

2.0

2.5

3.0

3.6

4.8

6.0

7.2

8.4

10.0

12.3

14.9

17.7

20.7

27.5

31.3

35.3

44.0

53.6

64.2

75.7

88.2

101.7

116.1

25

40

50

65

80

100

125

150

200

250

300

350

400

450

500

550

600

700

750

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

2000

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.5

5.0

5.5

6.0

6.5

7.0

8.1

8.6

9.1

10.1

11.1

12.1

13.1

14.1

15.1

16.1

17.1

18.1

19.1

21.1

0.7

1.0

1.3

1.6

2.0

2.5

3.0

3.6

4.8

6.0

7.2

9.5

12.0

14.9

18.0

21.5

25.3

33.7

38.3

43.3

54.1

66.1

79.3

93.8

109.4

126.2

144.3

163.5

183.9

205.6

252.4

25

40

50

65

80

100

125

150

200

250

300

350

400

450

500

550

600

700

750

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

2000

2250

2300

2500

3000

3400

4000

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.2

4.8

5.4

6.1

6.7

7.3

8.0

8.6

9.9

10.5

11.2

12.4

13.7

15.0

16.2

17.5

18.8

20.0

21.3

22.6

23.8

26.4

29.6

30.2

32.7

39.1

44.2

51.8

0.7

1.0

1.3

1.6

2.0

2.5

3.0

3.6

4.8

6.3

8.7

11.4

14.6

18.1

22.0

26.3

31.0

41.4

47.2

53.4

66.9

82.0

98.5

116.6

136.2

157.3

179.9

204.0

229.7

256.9

315.8

397.9

415.5

489.6

701.4

898.1

1238.8

25

40

50

65

80

100

125

150

200

250

300

350

400

450

500

550

600

700

750

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

2000

2250

2300

2500

3000

3400

4000

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.2

5.0

5.8

6.6

7.4

8.2

9.0

9.8

10.6

12.2

13.0

13.8

15.4

17.0

18.6

20.2

21.8

23.4

25.0

26.6

28.2

29.8

33.0

37.0

37.8

41.0

49.0

55.4

65.0

0.7

1.0

1.3

1.6

2.0

2.5

3.0

3.6

5.1

7.5

10.5

13.9

17.8

22.2

27.0

32.4

38.2

51.3

58.6

66.3

83.2

102.1

122.8

145.5

170.1

196.6

225.0

255.4

287.7

321.9

396.0

499.5

521.6

614.9

881.9

1129.9

1559.6

All values presented in tables above are only for information and they are vary from the project to project.

ZhongfuLianzhong do not produce their pipe on stock, products are designed for each specific project separately.

degrees)

Angular deflection(

3

5

1

0.5

<500

500 to <900

900 to <1800

>1800

7.2 Double O ring

Bell & spigot with

locking key

7.4 Taper/socket joint

7.3 Butt & Strap joint

(Hand Lay-up Joint)

This joint is made from glass fiber

reinforcements and polyester

resin. It is typically used in

situations where the pipe joint is

required to transmit axial forces

from internal pressure, or as a

repair method. The length and

thickness of the lay-up depends

on diameter and pressure. This

type of joint requires clean,

controlled conditions and skilled,

trained

personnel.

Special

instructions can be provided

when this type of joint is required.

7.5 Flange joint

The selection of Lianzhong pipe is based on stiffness and pressure class requirements.

PAGE

PAGE

10

Lianzhong

CNBM

DN

8.Fittings and Accessories

t1

Flange

Flange adaptors

t2

DN

0.6MPa

1.0MPa

1.6MPa

t1

t2

t1

t2

t1

t2

7.5

40

12

4.5

7.5

40

14

4.5

7.5

50

14

15

120

4.5

20

120

4.5

7.5

40

14

4.5

7.5

40

14

4.5

7.5

50

16

25

120

4.5

7.5

40

14

4.5

7.5

40

14

4.5

7.5

50

16

32

120

4.5

7.5

45

16

4.5

8.0

45

18

4.5

8.0

50

18

40

120

4.5

7.5

45

16

4.5

8.0

45

18

4.5

8.0

50

18

50

150

4.5

7.5

50

16

4.5

8.0

50

18

4.5

8.0

60

20

65

150

4.5

7.5

50

16

4.5

8.0

50

20

4.5

8.0

75

20

80

150

4.5

8.0

65

18

4.5

8.0

65

20

4.5

8.5

80

100

DN

L1

L2

0.6MPa

1.0MPa

1.6MPa

t1

t1

t1

200

500

25

5.0

30

5.0

40

6.0

250

500

30

5.0

35

6.0

45

7.0

25

300

550

30

6.0

40

6.0

50

8.0

150

4.5

8.0

75

18

4.5

8.5

75

25

4.5

8.5

90

25

350

550

35

6.0

45

6.5

60

9.0

125

150

4.5

8.0

75

20

4.5

8.5

90

25

4.5

10.0

90

30

8.0

90

20

5.0

8.5

90

25

5.0

10.5

100

35

550

35

6.5

50

7.0

65

10.0

200

4.5

400

150

200

200

5.0

8.5

100 25

5.0

10.0

125

30

5.0

11.0

125

40

450

650

35

6.5

50

7.5

70

11.0

250

250

5.0

10.0

125 30

6.0

10.5

150

35

6.0

11.5

150

45

500

650

40

7.0

55

8.5

80

12.0

300

250

6.0

10.0

125 30

6.0

11.0

150

40

6.0

13.0

200

50

600

700

40

7.5

65

9.5

90

14.0

350

300

6.0

10.5

150 35

6.0

11.5

175

45

6.0

14.0

225

60

700

700

45

8.5

75

11

90

15.5

400

300

6.5

10.5

150 35

6.5

13.0

200

50

6.5

14.5

250

65

450

6.5

10.5

165 35

6.5

13.0

225

50

6.5

15.0

300

70

800

750

50

9.0

80

12

100

16.0

350

500

400

7.0

11.0

175 40

7.0

13.5

250

55

7.0

16.0

350

80

900

900

55

10.0

85

13

110

17.5

600

450

7.5

11.0

200 40

7.5

14.5

300

65

7.5

17.0

400

90

1000

1000

60

11.0

90

14

120

19.5

700

500

8.5

11.5

225 45

8.5

15.5

350

75

8.5

17.0

450

90

1200

1000

70

13.0

110

16

140

23.0

800

550

9.0

13.0

250 50

9.0

16.0

400

80

9.0

18.0

500

100

1400

1200

80

15.0

120

18.5

160

26.5

900

600

10.0

13.5

275 55

10.0

16.5

400

85

10.0

19.0

500

110

1000

650

11.0

14.0

300 60

11.0

17.0

400

90

11.0

20.0

500

120

1500

1200

85

15.5

130

20

170

28.0

1200

700

13.0

15.0

400 70

13.0

19.0

400

110

13.0

22.0

600

140

1600

1200

90

16.5

140

21

180

30.0

1400

800

15.0

16.0

450 80

15.0

20.0

450

120

15.0

24.0

650

160

1800

1400

100

18.5

150

23

190

33.5

1500

850

15.5

16.5

450 85

15.5

21.0

500

130

15.5

25.0

700

170

2000

1600

110

20.0

160

26

200

37.0

1600

900

16.5

17.0

450 90

16.5

22.0

500

140

16.5

26.0

750

180

2200

18.0

500 100 18.5

23.0

600

150

18.5

27.0

800

190

120

22.0

170

28

1000

18.5

1600

1800

2000

1100

20.0

19.0

550 110 20.0

24.0

650

160

20.0

28.0

900

200

2400

1800

130

24.0

180

30

2200

1100

20.0

20.0

550 120 20.0

25.0

700

170

2600

1800

140

25.5

190

32

2400

1100

20.0

21.0

550 130 20.0

26.0

700

180

2800

2000

150

28.5

210

35

2600

1200

20.0

22.0

600 140 20.0

27.0

800

190

3000

2000

160

29.0

220

37

2800

1200

20.0

23.0

600 150 20.0

29.0

800

210

24.0

650 160 20.0

30.0

900

220

2000

180

31.0

1200

20.0

3200

3000

3200

1200

20.0

26.0

650 180

3600

2000

200

35.0

3600

1200

20.0

28.0

700 200

PAGE

PAGE

11

12

Lianzhong

CNBM

Elbow with Bell & Spigot joint

90Elbow with Plain End

DN

DN

mm

mm

200

L1

L2

0.6MPa

1.0MPa

1.6MPa

mm

t

mm

t1

mm

t

mm

t1

mm

t

mm

t1

mm

300

500

5.0

5.0

10

6.0

250

375

500

5.0

6.0

12

7.0

300

450

550

6.0

10

6.0

14

8.0

350

525

550

6.0

11

6.5

16

9.0

400

400

550

6.5

12

7.0

17

10.0

450

450

600

10

6.5

13

7.5

18.5

11.0

500

500

600

10.5

7.0

14.5

8.5

19

600

600

650

12

7.5

17

9.5

700

700

700

13

8.5

18.5

800

800

700

14

9.0

900

900

750

16

10.0

1000

1000

750

17

1200

1200

850

20

1400

1400

850

23

15.0

32.5

18.5

1500

1500

900

24

15.5

35

20.0

1600

1600

950

26

16.5

37

21.0

1800

1800

1000

28

18.5

41.5

2000

2000

32

20.0

1000

DN

mm

mm

mm

15

22.5

0.6MPa

1.0MPa

1.6MPa

22.5

t

mm

5.0

t

mm

5.0

t

mm

6.0

20

30

30

5.0

5.0

6.0

25

37.5

37.5

5.0

5.0

6.0

32

48

48

5.0

5.0

6.0

40

60

60

5.0

5.0

6.0

50

75

75

6.0

7.0

8.0

65

97.5

97.5

6.0

7.0

8.0

80

120

120

6.0

7.0

8.0

100

150

150

6.0

7.0

8.0

125

187.5

187.5

7.0

8.0

9.0

150

225

225

7.0

8.0

9.0

200

300

300

7.0

8.0

10.0

250

375

375

8.0

9.0

12.0

300

450

450

8.0

10.0

14.0

350

525

525

9.0

11.0

16.0

12.0

400

400

400

9.0

12.0

17.0

20.5

14.0

450

450

450

10.0

13.0

18.5

11.0

23

15.5

500

500

500

10.5

14.5

19.0

19

12.0

26

16.0

600

600

600

12.0

17.0

20.5

21

13.0

29

17.5

700

700

700

13.0

18.5

23.0

11.0

22.5

14.0

32

19.5

800

800

800

14.0

19.0

26.0

13.0

28

16.0

38

23.0

900

900

900

16.0

21.0

29.0

44

26.5

1000

1000

1000

17.0

22.5

32.0

47

28.0

1200

1200

1200

20.0

28.0

38.0

50

30.0

1400

1400

1400

23.0

32.5

44.0

23.0

56

33.5

1500

1500

1500

24.0

35.0

47.0

46.5

26.0

62

37.0

1600

1600

1600

26.0

37.0

50.0

1800

1800

1800

28.0

41.5

56.0

2000

2000

2000

32.0

46.5

62.0

2200

2200

2200

34.0

51.0

2400

2400

2400

36.0

55.5

2600

2600

2600

39.0

60.0

2800

2800

2800

42.0

65.0

3000

3000

3000

45.0

69.5

3200

3200

3200

48.0

3600

3600

3600

54.0

2200

2200

1100

34

22.0

51

28.0

2400

2400

1150

36

24.0

55.5

30.0

2600

2600

1200

39

25.5

60

32.0

2800

2800

1300

42

28.5

65

35.0

3000

3000

1300

45

29.0

69.5

37.0

3200

3200

1400

48

31.0

3400

3400

1400

50

33.0

3600

3600

1500

54

35.0

PAGE

PAGE

13

14

Lianzhong

CNBM

1.0MPa

t(mm)

1.6MPa

t(mm)

9.0

13.0

15.0

625

10.0

13.0

16.0

500

10.0

13.0

16.0

350

375

10.0

13.0

16.0

400

250

10.0

13.0

16.0

450

125

10.0

13.0

16.0

600

300

750

11.0

14.0

18.0

600

350

625

11.0

14.0

18.0

Specification

Reducer

Reducer length h=(D-d)x2.5

h

mm

450

400

125

500

250

500

300

500

500

500

0.6MPa

t(mm)

1.0MPa

t(mm)

1.6MPa

t(mm)

400

500

11.0

14.0

18.0

0.6MPa

t(mm)

h

mm

600

600

450

375

11.0

14.0

18.0

65

50

37.5

5.0

5.0

6.5

600

500

250

11.0

14.0

18.0

80

50

75

5.0

5.5

7.0

700

350

875

12.0

15.0

20.0

Specification

80

65

37.5

5.0

5.5

7.0

700

400

750

12.0

15.0

20.0

100

50

125

5.0

5.5

8.0

700

450

625

12.0

15.0

20.0

100

65

87.5

5.0

5.5

8.0

700

500

500

12.0

15.0

20.0

100

80

50

5.0

5.5

8.0

700

600

250

12.0

15.0

20.0

125

65

150

5.0

5.5

8.0

800

400

1000

13.0

16.5

23.0

125

80

112.5

5.0

5.5

8.0

800

450

875

13.0

16.5

23.0

125

100

62.5

5.0

5.5

8.0

800

500

750

13.0

16.5

23.0

150

80

175

5.0

6.0

9.0

800

600

500

13.0

16.5

23.0

150

100

125

5.0

6.0

9.0

800

700

250

13.0

16.5

23.0

150

125

62.5

5.0

6.0

9.0

900

450

1125

14.0

18.0

25.0

200

100

250

6.0

7.0

10.0

900

500

1000

14.0

18.0

25.0

200

125

187.5

6.0

7.0

10.0

900

600

750

14.0

18.0

25.0

200

150

125

6.0

7.0

10.0

900

700

500

14.0

18.0

25.0

250

125

312.5

7.0

9.0

12.0

900

800

250

14.0

18.0

25.0

250

150

250

7.0

9.0

12.0

1000

500

1250

15.0

20.0

28.0

250

200

125

7.0

9.0

12.0

1000

600

1000

15.0

20.0

28.0

300

150

375

8.0

10.0

13.0

1000

700

750

15.0

20.0

28.0

300

200

250

8.0

10.0

13.0

1000

800

500

15.0

20.0

28.0

300

250

125

8.0

10.0

13.0

1000

900

250

15.0

20.0

28.0

350

150

500

8.0

11.0

14.0

1200

800

1000

18.0

25.0

34.0

350

200

375

8.0

11.0

14.0

1200

900

750

18.0

25.0

34.0

350

250

250

8.0

11.0

14.0

1200

1000

500

18.0

25.0

34.0

350

300

125

8.0

11.0

14.0

1400

1000

1000

21.0

30.0

40.0

400

200

500

9.0

12.0

14.0

1400

1200

500

21.0

30.0

40.0

400

250

375

9.0

12.0

14.0

1500

1200

750

22.0

32.0

43.0

400

300

250

9.0

12.0

14.0

1500

1400

250

22.0

32.0

43.0

400

350

125

9.0

12.0

14.0

1600

1200

1000

24.0

34.0

46.0

450

200

625

9.0

13.0

15.0

1600

1400

500

24.0

34.0

46.0

450

250

500

9.0

13.0

15.0

1800

1400

1000

26.0

39.0

52.0

450

300

375

9.0

13.0

15.0

1800

1600

500

26.0

39.0

52.0

450

350

250

9.0

13.0

15.0

2000

1800

500

30.0

44.0

58.0

PAGE

PAGE

15

16

Lianzhong

CNBM

Equal Tee

Cap

DN

0.6MPa

Specification

DN(mm)

DN

0.6MPa

1.0MPa

15

1.6MPa

t(mm)

1.0MPa

H(mm) L(mm)

t(mm)

1.6MPa

H(mm)

L(mm)

t(mm)

H(mm)

L(mm)

7.5

5.0

3.8

7.5

5.0

3.8

7.5

6.0

3.8

5.0

5.0

10

5.0

5.0

10

6.0

5.0

10

25

5.0

6.3

12.5

5.0

6.3

12.5

6.0

6.3

12.5

32

5.0

8.0

16

5.0

8.0

16

6.0

DN

20

50

300

150

400

200

400

200

8.0

16

65

400

200

400

200

500

250

40

5.0

10.0

20

5.0

10.0

20

6.0

10.0

20

50

6.0

12.5

25

7.0

12.5

25

8.0

12.5

25

65

6.0

16.3

32.5

7.0

16.3

32.5

8.0

16.3

32.5

40

80

400

200

500

250

500

250

100

600

300

600

300

600

300

80

6.0

20.0

40

7.0

20.0

40

8.0

20.0

125

600

300

600

300

600

300

100

6.0

25.0

50

7.0

25.0

50

8.0

25.0

50

125

7.0

31.3

62.5

8.0

31.3

62.5

9.0

31.3

62.5

150

7.0

37.5

75

8.0

37.5

75

9.0

37.5

75

200

7.0

50.0

100

8.0

50.0

100

10.0

50.0

100

250

8.0

62.5

125

9.0

62.5

125

12.0

62.5

125

150

700

350

700

350

700

350

200

800

400

800

400

900

450

250

800

400

1000

500

1000

500

300

1000

500

1100

550

1300

650

300

8.0

75.0

150

10.0

75.0

150

14.0

75.0

150

350

9.0

87.5

175

11.0

87.5

175

16.0

87.5

175

400

9.0

100.0

200

12.0

100.0

200

17.0

100.0

200

350

1100

550

1200

600

1400

700

400

1200

600

1400

700

1600

800

450

10.0

112.5

225

13.0

112.5

225

18.5

112.5

225

450

1300

650

1500

750

1800

900

500

10.5

125.0

250

14.5

125.0

250

19.0

125.0

250

600

12.0

150.0

300

17.0

150.0

300

20.5

150.0

300

700

13.0

175.0

350

18.5

175.0

350

23.0

175.0

350

800

14.0

200.0

400

19.0

200.0

400

26.0

200.0

400

900

16.0

225.0

450

21.0

225.0

450

29.0

225.0

450

17.0

250.0

500

22.5

250.0

500

500

1400

700

1700

850

2100

1050

600

1600

800

2000

1000

2400

1200

700

1800

900

2300

1150

2700

1350

800

2000

1000

2600

1300

3000

1500

1000

32.0

250.0

500

1200

20.0

300.0

600

28.0

300.0

600

38.0

300.0

600

1400

23.0

350.0

700

32.5

350.0

700

44.0

350.0

700

1500

24.0

375.0

750

35.0

375.0

750

47.0

375.0

750

800

900

2200

1100

2700

1350

3300

1650

1000

2400

1200

2800

1400

3600

1800

1200

3000

1500

3200

1600

4000

2000

1600

26.0

400.0

800

37.0

400.0

800

50.0

400.0

2300

1800

28.0

450.0

900

41.5

450.0

900

56.0

450.0

900

2000

32.0

500.0

1000

46.5

500.0

1000

62.0

500.0

1000

2200

34.0

550.0

1100

51.0

550.0

1100

2400

36.0

600.0

1200

55.5

600.0

1200

1700

4100

2050

4600

1400

3400

1500

3700

1850

4100

2050

4900

2450

1600

4200

2100

4200

2100

5200

2600

1800

4600

2300

4600

2300

2600

39.0

650.0

1300

60.0

650.0

1300

2000

5000

2500

5200

2600

2800

42.0

700.0

1400

65.0

700.0

1400

2200

5400

2700

5600

2800

3000

45.0

750.0

1500

69.5

750.0

1500

3200

48.0

800.0

1600

2400

5800

2900

6200

3100

3400

51.0

850.0

1700

3600

54.0

900.0

1800

PAGE

PAGE

17

18

Lianzhong

CNBM

9.UnloadingHandling

Transportation and Storage

Blind Flange

GB9112-2000

9.1 Unloading and Handling Pipes

0.6MPa

Specification

DN(mm)

1.0MPa

t(mm)

D(mm)

15

12

80

55

20

14

90

65

25

14

100

32

16

40

t(mm)

1.6MPa

D(mm)

t(mm)

14

95

65

14

105

75

75

14

115

120

90

18

16

130

100

50

16

140

65

16

D(mm)

14

95

65

16

105

75

85

16

115

85

140

100

18

140

100

18

150

110

18

150

110

110

18

165

125

20

165

125

160

130

20

185

145

20

185

145

80

18

190

150

20

200

160

25

200

160

100

18

210

170

25

220

180

25

220

180

125

20

240

200

25

250

210

30

250

210

150

20

265

225

30

285

240

35

285

240

200

25

320

280

35

340

295

40

340

295

250

30

375

335

40

395

350

50

405

355

300

35

440

395

45

445

400

60

460

410

350

40

490

445

50

505

460

65

520

470

400

45

540

495

55

565

515

75

580

525

450

50

595

550

65

615

565

80

640

585

500

50

645

600

70

670

620

90

715

650

600

60

755

705

80

780

725

110

840

770

700

70

860

810

90

895

840

120

910

840

800

80

975

920

110

1015

950

130

1025

950

900

90

1075

1020

120

1115

1050

150

1125

1050

1000

100

1175

1120

130

1230

1160

160

1255

1170

1200

120

1405

1340

150

1455

1380

190

1485

1390

1400

140

1630

1560

180

1675

1590

220

1685

1590

1500

145

1730

1660

190

1785

1700

240

1820

1710

1600

150

1830

1760

200

1915

1820

250

1930

1820

1800

170

2045

1970

220

2115

2020

280

2130

2020

2000

190

2265

2180

245

2325

2230

310

2345

2230

2200

205

2475

2390

270

2550

2440

340

2555

2440

2400

220

2685

2600

290

2760

2650

365

2765

2650

2600

240

2905

2810

310

2960

2850

390

2965

2850

2800

260

3115

3020

335

3180

3070

3000

275

3315

3220

360

3405

3290

3200

290

3525

3430

3400

310

3735

3640

3600

330

3970

3860

Unloading the pipe is the responsibility of the customer. Be sure

to maintain control of the pipe during unloading. Guide ropes

attached to pipes or packages will enable easy manual control

when lifting and handling. Do not drop, impact, or bump the pipe,

particularly at pipe ends.

If at any time during handling or installation of the pipe, any

damage such as a gouge, crack or facture occurs, the pipe

should be repaired before the section is installed.

Lifting pipe at one support point

Lifting unitized package

Lifting nested pipes

9.2 Transporting Pipes

Strap pipe to the vehicle over the support points using pliable straps or rope. Never use steel cables or chains

without adequate padding to protect the pipe from abrasion. Bulges, flat areas or other abrupt changes of

curvature are not permitted. Transport of pipes outside of these limitations may result in damage to the pipes.

Transportation

of FRP pipes

Emplacing

of FRP pipes

9.3 Site Pipe Storage

It is generally advantageous to store pipe on flat timber to facilitate placement and removal of lifting slings

around the pipe.

When storing pipe directly on the ground, be sure that the area is relatively flat and free of rocks and other

potentially damaging debris. Placing the pipe on mounds of backfill material has been found to be an effective

way of site storing the pipe. All pipes should be chocked to prevent rolling in high winds.

PAGE

PAGE

19

20

Lianzhong

CNBM

10. Installation

11. Successful Case

Lianzhong pipes will meet the users different requirements: on the ground, underground and underwater installation, as long

as using the reasonable installation method.

11.1 Power Plant

10.1 Above ground pipe

The support of GRP piping system is completely different from that of

any other pipes and requires considerable attention.

The modulus of elasticity of GRP pipe is low, in order to minimize the

deflection, the proper spacing between racks must be selected. In

order to minimize localized stress, the wide-band support should be

used. In order to avoid the localized stress near the joint, the

supporting point should be near the connection, all valves should be

supported independently. Make sure the pipe standing support is firm

to ensure the position of pipe standing from moving and to minimize

the vibration of the vibrant part of pipe standing. The function of pipe

standing or lift-standing should not be clip but conductivity to the

pipes. For long pipeline, proper disposition of support spots is crucial

to watch out for twisting moment in FRP pipe caused by the

deformation of pipes which might result the break of pipes. Generally,

for FRP pipeline, expansion joints may be unnecessary.

Zhongfu Lianzhong manufactured and installed

seawater circulating cooling pipe, DN2400 for Indonesia

Labu Bay Power Station in 2006.

10.2 Underground pipe

Ditching and excavation, pipe beddings compaction and backfill of the backfill material should meet the technique requirement

of the installation of FRP pipe.

To minimize the work volume of pipe connections on the spot and to lay out pipes rapidly, all the difficult connections should be

put on by the factory.

When the installation is finished, pipeline should be tested with water pressure in accordance with the guide of specifications for

installation of underground FRP filament winding pipe issued by Zhongfu Lianzhong.

10.3 Under water pipe

Details please refer to theGRP pipe installation instructionsissued by Zhongfu Lianzhong.

Crane

Sea

Bottom

PAGE

PAGE

21

22

Lianzhong

CNBM

Zhongfu Lianzhong supplied DN3000 GRP pipe for

CSPC Nanhai project.

Zhongfu Lianzhong manufactured seawater circulating cooling pipe, DN1800 for Pakistan

Feuerbach combined cycle power station in 1991.

Zhongfu Lianzhong supplied and installed

seawater circulating cooling pipes, DN2800 for

Qinshan Nuclear power station in 1997.

Zhongfu Lianzhong supplied DN2400

seawater circulating cooling pipes for

Indonesia Labu Bay Power Station in 2006.

Zhongfu Lianzhong supplied DN2400 seawater circulating cooling pipes and installed for Indonesia PLTU1

INDRAMAYU 3*330MW coal-fired power station in 2006.

PAGE

PAGE

23

24

Lianzhong

CNBM

11.2 LNG receiving station

Zhongfu Lianzhong supplied and installed seawater pipes, DN1600 for

Fujian LNG project in 2007

Zhongfu Lianzhong supplied and installed GRP pipes for Sudan Khartoum North Power Station

(2100MW) in 2007.

PAGE

PAGE

25

26

Lianzhong

CNBM

Nantong LNG Project: In 2009,Zhongfu Lianzhong

supplied GRV pipe of DN1800,PN 1.0MPA.and also

supplied installation service in 2010. The most important

Zhongfu Lianzhong supplied and installed

thing is that in this project Zhongfu Lianzhong make the

seawater pipe, DN1500 for Guangdong Dapeng

stress analysis with Caesar,make the water hammer

LNG project, in 2008

analysis with Impulse,which is from American AFT

company. Until finishing the hydraulic test, we turn over

this project to client. The end user of this project is China

National Petroleum Corporation(CNPC).

PAGE

PAGE

27

28

Lianzhong

CNBM

11.3 Sea water desalination plant

Dalian LNG Project:In 2009,Zhongfu Lianzhong supplied GRV pipe of DN1800,PN 1.0MPA.and also

supplied installation service in 2010.The end user of this project is China National Petroleum

Corporation(CNPC).

Zhongfu Lianzhong supplied and installed seawater pipes DN100-1800 for Algeria TLEMCEN

desalination plant project in 2009.

PAGE

PAGE

29

30

Lianzhong

CNBM

ProjectJebel alipower and desalination stationM

ProjectTianjin Beijiang power plant

LocationDubai-UAE

LocationTianjin,China

ContractorFISIA

ContractorSEPCOElectric power Construction Corporation

Pipe size25mm to 2100mm

Pipe size600mm to 1300mm

Pressure classPN10,PN16

Pressure classPN10

Installation Year2009

Installation Year2009

PAGE

PAGE

31

32

Das könnte Ihnen auch gefallen

- Flowtite Product Guide 2010Dokument28 SeitenFlowtite Product Guide 2010Anonymous 87xpkIJ6CFNoch keine Bewertungen

- Compipe BrochureDokument48 SeitenCompipe Brochureninju1Noch keine Bewertungen

- HOBAS Pressure Pipes SystemsDokument40 SeitenHOBAS Pressure Pipes Systemsu_florinNoch keine Bewertungen

- FRP PipeDokument4 SeitenFRP PipealvinchuanNoch keine Bewertungen

- Astm F2561-16Dokument4 SeitenAstm F2561-16hugoNoch keine Bewertungen

- GRP and HDPE PipeDokument1 SeiteGRP and HDPE PipeRashid KayumNoch keine Bewertungen

- Technical Catalouge PDFDokument41 SeitenTechnical Catalouge PDFDhanish KumarNoch keine Bewertungen

- Wiik & Hoeglund Pipe FittingsDokument60 SeitenWiik & Hoeglund Pipe Fittingsliang jasonNoch keine Bewertungen

- Sec 05100 - Structural SteelDokument10 SeitenSec 05100 - Structural Steeltiju2005hereNoch keine Bewertungen

- P Li 009 0 PDFDokument66 SeitenP Li 009 0 PDFHumberto Ernesto Di CiccioNoch keine Bewertungen

- Wiik Catalogue 2007Dokument16 SeitenWiik Catalogue 2007suosvannakNoch keine Bewertungen

- UPVC Pipes & Fittings Upload 11.03.2019Dokument20 SeitenUPVC Pipes & Fittings Upload 11.03.2019Rushan LakdimuthuNoch keine Bewertungen

- Manhole Sizing RecommendationsDokument4 SeitenManhole Sizing Recommendationss_omeone4usNoch keine Bewertungen

- Storage Tank Design GuidelinesDokument6 SeitenStorage Tank Design GuidelinespaaryNoch keine Bewertungen

- 72957d3bb1659d7c77dbf6b6c550abeeDokument41 Seiten72957d3bb1659d7c77dbf6b6c550abeerasheedillikkalNoch keine Bewertungen

- Cu-Ni Pipes, Flanges & FittingsDokument67 SeitenCu-Ni Pipes, Flanges & Fittingssdk1978Noch keine Bewertungen

- Eot Crane Datasheet-BDokument5 SeitenEot Crane Datasheet-Bbashok20Noch keine Bewertungen

- SleeveDokument16 SeitenSleeveengsamerhozinNoch keine Bewertungen

- Hanger Support Spacing and Rod Size For Horizontal PipesDokument8 SeitenHanger Support Spacing and Rod Size For Horizontal Pipesyarzar17Noch keine Bewertungen

- Test Report Long-Term Ring Bending Strain (SB)Dokument4 SeitenTest Report Long-Term Ring Bending Strain (SB)Diana QuinteroNoch keine Bewertungen

- HDPE Pipe Specifications and DetailsDokument2 SeitenHDPE Pipe Specifications and DetailsSandeep BhatiaNoch keine Bewertungen

- GRP Stress AnalysisDokument13 SeitenGRP Stress AnalysisCarlos Luis Esquerdo MarcanoNoch keine Bewertungen

- Future Pipe InfoDokument29 SeitenFuture Pipe Infomekag94Noch keine Bewertungen

- Xcpipe PDFDokument6 SeitenXcpipe PDFalberto rodriguezNoch keine Bewertungen

- Book 2: Chapter 4 - Fluid Flow: Application LimitationsDokument20 SeitenBook 2: Chapter 4 - Fluid Flow: Application LimitationsVaniya GoelNoch keine Bewertungen

- Ryowo GRP Sectional Storage Tanks ManufacturerDokument8 SeitenRyowo GRP Sectional Storage Tanks Manufacturershi_salbe_15838Noch keine Bewertungen

- Amipox GRE Cal Manual Ws HiddDokument20 SeitenAmipox GRE Cal Manual Ws HiddrahulNoch keine Bewertungen

- Duplex StrainersDokument1 SeiteDuplex StrainersBossman Instruments TechnologyNoch keine Bewertungen

- Flanges Research Maart 2011Dokument62 SeitenFlanges Research Maart 2011lauro330Noch keine Bewertungen

- Heat Loss in Pipe Support PDFDokument60 SeitenHeat Loss in Pipe Support PDFThaku KishorNoch keine Bewertungen

- 1a Aquaflow HDPE Pipe CatalogueDokument12 Seiten1a Aquaflow HDPE Pipe CatalogueNick BesterNoch keine Bewertungen

- Piping Stress CriteriaDokument11 SeitenPiping Stress CriteriasbrencuNoch keine Bewertungen

- PipingDokument4 SeitenPipingramthecharm_46098467Noch keine Bewertungen

- DNV RP f202 2010-10Dokument46 SeitenDNV RP f202 2010-10b_afrinaldiNoch keine Bewertungen

- CIBSE C4 Instructions V2Dokument2 SeitenCIBSE C4 Instructions V2Abi PascuaNoch keine Bewertungen

- Vertical CompressDokument47 SeitenVertical CompressSivi NallamothuNoch keine Bewertungen

- Fibrelogic Flowtite Engineering Guidelines DES M-004 REFER PDFDokument122 SeitenFibrelogic Flowtite Engineering Guidelines DES M-004 REFER PDFA.Subin DasNoch keine Bewertungen

- Victaulic Carbon Steel Couplings and Grooved FittingsDokument16 SeitenVictaulic Carbon Steel Couplings and Grooved FittingsAnonymous 7I5qQ0eAxgNoch keine Bewertungen

- HDPE Pipe Catalogue PDFDokument12 SeitenHDPE Pipe Catalogue PDFRadicalNoch keine Bewertungen

- Flange Dim EN1092 1 BS4504Dokument13 SeitenFlange Dim EN1092 1 BS4504rcpretoriusNoch keine Bewertungen

- Metallic Expansion Joint GuideDokument55 SeitenMetallic Expansion Joint Guidebigsteve9088Noch keine Bewertungen

- Analysis of Fiber Reinforced Plastic Needle Gate For K.T. WeirsDokument5 SeitenAnalysis of Fiber Reinforced Plastic Needle Gate For K.T. WeirsIJIRAE- International Journal of Innovative Research in Advanced EngineeringNoch keine Bewertungen

- Data Sheets For GRP Pipe PN10Dokument7 SeitenData Sheets For GRP Pipe PN10nilanga123Noch keine Bewertungen

- Pigging - Concept, Installation & Operations: Presenters: Uma Maheswar Gali & S. Chellasamy - Completions DepartmentDokument69 SeitenPigging - Concept, Installation & Operations: Presenters: Uma Maheswar Gali & S. Chellasamy - Completions DepartmentARAVINDRAJ V RNoch keine Bewertungen

- Dimensions of Bolts and Nuts BS3692Dokument6 SeitenDimensions of Bolts and Nuts BS3692azam RazzaqNoch keine Bewertungen

- Simona Pipes, FittingsDokument56 SeitenSimona Pipes, FittingsKristy DavisNoch keine Bewertungen

- Lecture 26-03-2009 Introduction To Fiberglass Pipe SystemsDokument60 SeitenLecture 26-03-2009 Introduction To Fiberglass Pipe SystemsAlexNoch keine Bewertungen

- The in Uence of The Bourdon Effect On Pipe Elbow: September 2016Dokument11 SeitenThe in Uence of The Bourdon Effect On Pipe Elbow: September 2016araz_1985Noch keine Bewertungen

- Carbon Steel Pipe and Fittings GuideDokument10 SeitenCarbon Steel Pipe and Fittings GuideavazcNoch keine Bewertungen

- Storm and Sewerage Pipe Installation Guide, VinidexDokument16 SeitenStorm and Sewerage Pipe Installation Guide, VinidexMiroslav AleksicNoch keine Bewertungen

- PantechSteel CatalogueDokument36 SeitenPantechSteel Cataloguejok1974Noch keine Bewertungen

- GRP Pipes Product ManualDokument17 SeitenGRP Pipes Product Manualrosarr1976Noch keine Bewertungen

- FLOWTITE Pipe Systems: For Subaqueous InstallationsDokument12 SeitenFLOWTITE Pipe Systems: For Subaqueous InstallationsRusu CatalinNoch keine Bewertungen

- GRP Product GuideDokument20 SeitenGRP Product Guidedp75Noch keine Bewertungen

- Upvc Pressure Pipes and FittingsDokument8 SeitenUpvc Pressure Pipes and FittingsjafarkhansfNoch keine Bewertungen

- PDF Version!: Flowtite Pipe SystemsDokument0 SeitenPDF Version!: Flowtite Pipe SystemsDeva RajNoch keine Bewertungen

- Pacific - Pipes IndiaDokument7 SeitenPacific - Pipes IndiaAli Mammadov100% (1)

- 2008 Aug KnowingDokument6 Seiten2008 Aug Knowinggopvij1Noch keine Bewertungen

- Pipe TypesDokument6 SeitenPipe TypesaselabollegalaNoch keine Bewertungen

- Ductile PipesDokument33 SeitenDuctile Pipesanirbanpwd76Noch keine Bewertungen

- Catering Reserving and Ordering System with MongoDB, Express, Node.js (39Dokument5 SeitenCatering Reserving and Ordering System with MongoDB, Express, Node.js (39radha krishnaNoch keine Bewertungen

- AI Berkeley Solution PDFDokument9 SeitenAI Berkeley Solution PDFPrathamGuptaNoch keine Bewertungen

- Training Needs Analysis (Managing Training & Development)Dokument78 SeitenTraining Needs Analysis (Managing Training & Development)Henrico Impola100% (1)

- Aw MD700 Manual G10 150706Dokument73 SeitenAw MD700 Manual G10 150706Heraldo Ulguim Luis OliveiraNoch keine Bewertungen

- Toolbox Meeting Or, TBT (Toolbox TalkDokument10 SeitenToolbox Meeting Or, TBT (Toolbox TalkHarold PonceNoch keine Bewertungen

- As Biology Revision L3 Cells Microscopes and IAM PPQ 2Dokument7 SeitenAs Biology Revision L3 Cells Microscopes and IAM PPQ 2Anonymous fFKqcYNoch keine Bewertungen

- 5 Axis MachinesDokument33 Seiten5 Axis MachinesgsNoch keine Bewertungen

- Instruction Manual Series 854 XTG Level GaugeDokument60 SeitenInstruction Manual Series 854 XTG Level GaugeJandri JacobNoch keine Bewertungen

- CitationCJ4-CB Checklists B v1.2Dokument4 SeitenCitationCJ4-CB Checklists B v1.2Joao Vitor RojasNoch keine Bewertungen

- Detect and Diagnose HVAC Equipment ErrorsDokument1 SeiteDetect and Diagnose HVAC Equipment ErrorsCatalin DragomirNoch keine Bewertungen

- Mental AspectDokument29 SeitenMental AspectBenjii CarlosNoch keine Bewertungen

- Hardware Devices Used in Virtual Reality TechnologiesDokument6 SeitenHardware Devices Used in Virtual Reality TechnologiesTheMoon LightNoch keine Bewertungen

- Kerala University 2013 Admission ProspectusDokument50 SeitenKerala University 2013 Admission ProspectusMuneer SainulabdeenNoch keine Bewertungen

- Efficacy of Platelet-Rich Fibrin On Socket Healing After Mandibular Third Molar ExtractionsDokument10 SeitenEfficacy of Platelet-Rich Fibrin On Socket Healing After Mandibular Third Molar Extractionsxiaoxin zhangNoch keine Bewertungen

- ZXJ 10 SPCDokument7 SeitenZXJ 10 SPCMuhammad Yaseen100% (1)

- Calmark - Birtcher 44 5 10 LF L DatasheetDokument2 SeitenCalmark - Birtcher 44 5 10 LF L DatasheetirinaNoch keine Bewertungen

- Chem 361 Separation Methods IntroDokument8 SeitenChem 361 Separation Methods IntroTwum SomoahNoch keine Bewertungen

- Aspen Plus Tutorial 5 Preparing and Configuring A Distillation Column Using RADFRACDokument13 SeitenAspen Plus Tutorial 5 Preparing and Configuring A Distillation Column Using RADFRACRavi Kant TripathiNoch keine Bewertungen

- EN6VC IIIa 6.2 - 2023 2024Dokument2 SeitenEN6VC IIIa 6.2 - 2023 2024Ma. Feliza SaliganNoch keine Bewertungen

- A. evolve B. protect C. argue D. resist: Thời gian làm bài: 45 phút, không kể thời gian phát đềDokument5 SeitenA. evolve B. protect C. argue D. resist: Thời gian làm bài: 45 phút, không kể thời gian phát đềPham Thuy HuyenNoch keine Bewertungen

- PC 5400 PC 5500Dokument53 SeitenPC 5400 PC 5500ArturHeiseNoch keine Bewertungen

- Statistics Interview QuestionsDokument5 SeitenStatistics Interview QuestionsARCHANA R100% (1)

- Private Void BtnDeleteActionPerformedDokument12 SeitenPrivate Void BtnDeleteActionPerformedDDDNoch keine Bewertungen

- LTE Interview QuestionsDokument10 SeitenLTE Interview QuestionsMahesh Pratap100% (1)

- Tes P 119 10 R0 PDFDokument43 SeitenTes P 119 10 R0 PDFAbin Meetu100% (4)

- Optimization Module For Abaqus/CAE Based On Genetic AlgorithmDokument1 SeiteOptimization Module For Abaqus/CAE Based On Genetic AlgorithmSIMULIACorpNoch keine Bewertungen

- Sample of Application Letter (Updated)Dokument4 SeitenSample of Application Letter (Updated)Mizpah Sarah BautistaNoch keine Bewertungen

- DUPLICATE BILL TITLEDokument8 SeitenDUPLICATE BILL TITLEMohammed AhmedNoch keine Bewertungen

- Samsung GT-I8160 Galaxy Ace 2 08 Level 3 Repair - Block-, PCB Diagrams, Flow Chart of TroubleshootingDokument47 SeitenSamsung GT-I8160 Galaxy Ace 2 08 Level 3 Repair - Block-, PCB Diagrams, Flow Chart of TroubleshootingOuadghiri Badre Ddine50% (2)

- Low rank tensor product smooths for GAMMsDokument24 SeitenLow rank tensor product smooths for GAMMsDiego SotoNoch keine Bewertungen