Beruflich Dokumente

Kultur Dokumente

Van'S Aircraft, Inc.: Figure 4: Switch

Hochgeladen von

Mark Evan SalutinOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Van'S Aircraft, Inc.: Figure 4: Switch

Hochgeladen von

Mark Evan SalutinCopyright:

Verfügbare Formate

VAN'S AIRCRAFT, INC.

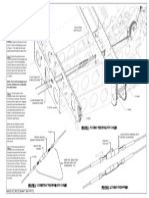

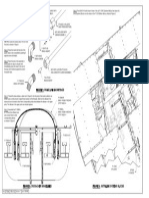

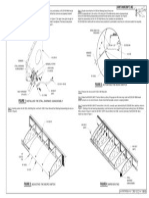

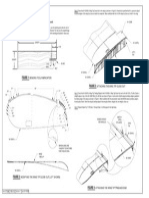

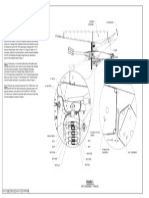

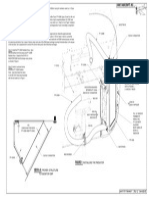

Step 1: Install snap bushings in the F-1204C-L & -R Fwd Bulkhead Sides and F-1204B-L & -R Aft Bulkhead Sides as shown in Figure 2 and Figure 3. Step 2: Choose one of the two ES RS 49-496 Reed Switches. Trim one of the two wires back to 4 1/2 inches in length. Strip the ends of both wires coming from each switch. To the 4 1/2 inch long wire crimp on a ring terminal as called out in Figure 3. Step 3: Using the hardware called out in Figure 2 and Figure 3 attach the ES RS 49-496 Reed Switches to the F-1248-L & -R Arm Rests (attach the ring terminal from Step 2 at the same time). Align the inboard end of the switch with the inboard face of the armrest. See Figure 4. Route the remaining wire on the right side of the aircraft and both wires on the left side of the aircraft through the snap bushings installed in Step 1. Crimp on butt splices to the switch wires as shown in Figure 1. Step 4: To test the ES RS 49-496 Reed Switches, temporarily connect a multimeter as shown in Figure 5 by connecting one wire coming from the left reed switch to the positive multimeter lead and the remaining reed switch wire and negative multimeter lead to the fuselage frame (ground). Turn the multimeter to the continuity check mode (most multimeters will generate an audible tone when continuity is made. Another method is to measure resistance. Infinite resistance indicates no continuity and zero resistance indicates continuity). Snap the left WD-1217C Fuselage Pin Stopper into the F-1248B Fuselage Pin Latch. The multimeter should indicate continuity. Repeat this step for the right reed switch. SB187-2 When the stoppers are not latched there should be no continuity through the reed switch. If the stoppers are engaged and there is continuity, try moving the reed switches in or out. Be sure to check that if the stopper is F-1204B-R not in the pin latch hole but under the pin latch there still should be no continuity. The only position that should create continuity is when the stopper is fully engaged in the pin latch hole! It may be necessary to trim the WD-1217 tube. When installed, the top of the tube should be approximately centered on the reed switch as shown in Figure 4. Remove the stopper from the fuselage pin and trim 1/32 of an inch from the top of the tube. Reassemble the fuselage pin with the stopper and test. Repeat as required. Up to, but not exceeding, 1/8 of an inch may be removed. Step 5: Make WH-B167 (WHT) Spar Pin Interconnect Wire by cutting a 42 inch long piece of 22 gauge wire and striping both ends. Crimp one end to the butt splice installed in Step 3 on the right ES RS 49-496 Reed Switch, route through the F-1204Y Wire Run Conduit and crimp the other end to one of the butt splices installed in Step 3 on the left reed switch. Crimp the remaining butt splice on the left switch to the WH-F50 (BRN/BLU) Spar Pin Wire. Step 6: Double check that hardware installed in Step 3 is tight if altered when troubleshooting in Step 4.

F-1248B WD-1217C TOP EDGE OF WD-1217

ES RS 49-496 INBOARD END INBOARD FACE OF F-1248-R

ES RS 49-496

TOP EDGE OF WD-1217 SHOULD ALIGN WITH CENTER LINE HERE WD-1217 F-1248-R

ES 36154 AN525-10R7 MS21919DG4 AN365-1032 F-1204C-R

FIGURE 4: SWITCH ADJUSTMENT

ES 320559 WH-B167 (WHT)

AN525-10R7 MS21919DG4 AN365-1032 ES RS 49-496 F-1248-L SB187-2 F-1204B-L F-1204Y ES 320559 F-1204C-L

FIGURE 3: RIGHT SWITCH BOTTOM VIEW

FIGURE 1: INSTALLING THE SPAR PIN SWITCHES

NEGATIVE LEAD MULTIMETER FUSELAGE FRAME (GROUND) ES RS 49-496 POSITIVE LEAD

WIRES FROM ES RS 49-496 WH-F50 (BRN/BLU)

FIGURE 2: LEFT SWITCH BOTTOM VIEW

PAGE

FIGURE 5: SWITCH TEST

31-06

RV-12

REVISION:

DATE:

12/31/09

Das könnte Ihnen auch gefallen

- FIGURE 2: VA-188B: Van'S Aircraft, IncDokument1 SeiteFIGURE 2: VA-188B: Van'S Aircraft, IncMark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: Together Into The Same Side of A Butt Splice The Red Wire Coming From TheDokument1 SeiteVan'S Aircraft, Inc.: Together Into The Same Side of A Butt Splice The Red Wire Coming From TheMark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: Figure 1: OptionalDokument1 SeiteVan'S Aircraft, Inc.: Figure 1: OptionalMark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: Figure 1: Fan Install andDokument1 SeiteVan'S Aircraft, Inc.: Figure 1: Fan Install andMark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: Figure 1: Routing Line Through Ribs Figure 3: Terminal Bracket InstallationDokument1 SeiteVan'S Aircraft, Inc.: Figure 1: Routing Line Through Ribs Figure 3: Terminal Bracket InstallationMark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: Lighting Bracket Cockpit Light Wires Connections 40-11 RV-12Dokument1 SeiteVan'S Aircraft, Inc.: Lighting Bracket Cockpit Light Wires Connections 40-11 RV-12Mark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: Figure 1: Tunnel Wire Figure 2: Stall Warn HookupDokument1 SeiteVan'S Aircraft, Inc.: Figure 1: Tunnel Wire Figure 2: Stall Warn HookupMark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: Figure 2: Attaching The Control Sticks Figure 1: PTT InstallDokument1 SeiteVan'S Aircraft, Inc.: Figure 2: Attaching The Control Sticks Figure 1: PTT InstallMark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: Figure 2: Installing Wires in Figure 1: Hooking Up The FuelDokument1 SeiteVan'S Aircraft, Inc.: Figure 2: Installing Wires in Figure 1: Hooking Up The FuelMark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: Must Be Installed Prior To Adjusting The Cable TensionDokument1 SeiteVan'S Aircraft, Inc.: Must Be Installed Prior To Adjusting The Cable TensionMark Evan SalutinNoch keine Bewertungen

- Figure 2: Wiring Diagram: Van'S Aircraft, IncDokument1 SeiteFigure 2: Wiring Diagram: Van'S Aircraft, IncMark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: Figure 2: Installing Pins in TheDokument1 SeiteVan'S Aircraft, Inc.: Figure 2: Installing Pins in TheMark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: Figure 3: Drilling The Terminal BlockDokument1 SeiteVan'S Aircraft, Inc.: Figure 3: Drilling The Terminal BlockMark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: Revision: DateDokument1 SeiteVan'S Aircraft, Inc.: Revision: DateMark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: Figure 1: Installing The Side SkinsDokument1 SeiteVan'S Aircraft, Inc.: Figure 1: Installing The Side SkinsMark Evan SalutinNoch keine Bewertungen

- Figure 3: Activating The Micro Switch: Van'S Aircraft, IncDokument1 SeiteFigure 3: Activating The Micro Switch: Van'S Aircraft, IncMark Evan SalutinNoch keine Bewertungen

- FAULT CODE E0152-11 - Separator - Unidentified Failure CodeDokument4 SeitenFAULT CODE E0152-11 - Separator - Unidentified Failure CodeLeonardo Barbosa MartinsNoch keine Bewertungen

- Figure 1: Cutting The In-Line Fuse Holder: Van'S Aircraft, IncDokument1 SeiteFigure 1: Cutting The In-Line Fuse Holder: Van'S Aircraft, IncMark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: Figure 1: Bending Tool Fabrication Figure 3: Attaching The Wing Tip Close-OutDokument1 SeiteVan'S Aircraft, Inc.: Figure 1: Bending Tool Fabrication Figure 3: Attaching The Wing Tip Close-OutMark Evan SalutinNoch keine Bewertungen

- AOR AR3030 VHF Converter InstallationDokument4 SeitenAOR AR3030 VHF Converter InstallationDavid RossNoch keine Bewertungen

- PEAKE Package A-CDokument14 SeitenPEAKE Package A-CEduardo PierluissiNoch keine Bewertungen

- Van'S Aircraft, Inc.: Figure 4: Adding The Terminal BlockDokument1 SeiteVan'S Aircraft, Inc.: Figure 4: Adding The Terminal BlockMark Evan SalutinNoch keine Bewertungen

- Cable Spacer: Van'S Aircraft, IncDokument1 SeiteCable Spacer: Van'S Aircraft, IncMark Evan SalutinNoch keine Bewertungen

- 206 Asb 19 138Dokument8 Seiten206 Asb 19 138Kraven YagamyNoch keine Bewertungen

- 3TW42 DOL StarterDokument26 Seiten3TW42 DOL StarterluvlijNoch keine Bewertungen

- TH 3jrs ManualDokument11 SeitenTH 3jrs ManualOscar NavaNoch keine Bewertungen

- Van'S Aircraft, Inc.: Jack Is Grounded - Remove Paint or Primer As NeccesaryDokument1 SeiteVan'S Aircraft, Inc.: Jack Is Grounded - Remove Paint or Primer As NeccesaryMark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: Cable PositionsDokument1 SeiteVan'S Aircraft, Inc.: Cable PositionsMark Evan SalutinNoch keine Bewertungen

- Henry 2K-3 RF Linear AmplifierDokument27 SeitenHenry 2K-3 RF Linear Amplifierw9fe100% (1)

- Van'S Aircraft, Inc.: F-1211D PreparationDokument1 SeiteVan'S Aircraft, Inc.: F-1211D PreparationMark Evan SalutinNoch keine Bewertungen

- VDO Gauge InstallationDokument4 SeitenVDO Gauge Installationurule2kNoch keine Bewertungen

- Model Lp3: Installation and Service Instructions For Streamline™ Lp3 Strobe LightsDokument20 SeitenModel Lp3: Installation and Service Instructions For Streamline™ Lp3 Strobe LightsRogers Hermann Olivares CuevaNoch keine Bewertungen

- 00811izv Antena ButternutDokument9 Seiten00811izv Antena Butternutcarlitos48Noch keine Bewertungen

- Sony KDL 42W800A42W801A42W807A47W800A47W801A47W807A55W800A55W801A55W807A L3Dokument34 SeitenSony KDL 42W800A42W801A42W807A47W800A47W801A47W807A55W800A55W801A55W807A L3pasantito100% (1)

- Firefly PCB Guide 8Dokument16 SeitenFirefly PCB Guide 8Renier Orlando BlancoNoch keine Bewertungen

- Van'S Aircraft, Inc.: Figure 2: Trimming The Support FramesDokument1 SeiteVan'S Aircraft, Inc.: Figure 2: Trimming The Support FramesMark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: 11-08 RV-12 Ast Assembly TravelDokument1 SeiteVan'S Aircraft, Inc.: 11-08 RV-12 Ast Assembly TravelMark Evan SalutinNoch keine Bewertungen

- Mody Leo Toro en r4Dokument28 SeitenMody Leo Toro en r4SinaNoch keine Bewertungen

- Yaesu FT 736r Ps RepairDokument9 SeitenYaesu FT 736r Ps RepairBravo KiloNoch keine Bewertungen

- Ball Valve TechDokument54 SeitenBall Valve TechcontorrresjulianNoch keine Bewertungen

- Channel Master 2-4m ManualDokument9 SeitenChannel Master 2-4m ManualWilfredo AriasNoch keine Bewertungen

- Technical Bulletin: Tion 129.00, and Aft and Down To The Fuel Vent Line Hole at Station 131.00Dokument17 SeitenTechnical Bulletin: Tion 129.00, and Aft and Down To The Fuel Vent Line Hole at Station 131.00sebastian cruzNoch keine Bewertungen

- Rcrit 11V338 2736Dokument13 SeitenRcrit 11V338 2736bpcdivNoch keine Bewertungen

- Seeburg StereoConsolette SC1Dokument17 SeitenSeeburg StereoConsolette SC1asegal0000100% (1)

- Displacer Type Level SwitchDokument10 SeitenDisplacer Type Level SwitchKarthik Chockkalingam100% (1)

- Continental Aileron Cable Rigging Event Criteria: Page 1Dokument11 SeitenContinental Aileron Cable Rigging Event Criteria: Page 1Jose Miguel Atehortua ArenasNoch keine Bewertungen

- Clinical Pelvimetry - HZ Undergraduate Obstetrics & GynaecologyDokument24 SeitenClinical Pelvimetry - HZ Undergraduate Obstetrics & GynaecologyErica AlabanNoch keine Bewertungen

- TM 11-5805-239-35 - Power - Supply - PP-1209 - 1966 PDFDokument27 SeitenTM 11-5805-239-35 - Power - Supply - PP-1209 - 1966 PDFWurzel1946Noch keine Bewertungen

- Van'S Aircraft, Inc.: Figure 1: Installing The Radiator View A-A: Proper StructureDokument1 SeiteVan'S Aircraft, Inc.: Figure 1: Installing The Radiator View A-A: Proper StructureMark Evan SalutinNoch keine Bewertungen

- Stereo Coder PDFDokument3 SeitenStereo Coder PDFDragonestaNoch keine Bewertungen

- Foster WF-100k FAQDokument2 SeitenFoster WF-100k FAQivoloviNoch keine Bewertungen

- Van'S Aircraft, Inc.: J-Stiffener Forward of The F-1208 Frame For Additions LaterDokument1 SeiteVan'S Aircraft, Inc.: J-Stiffener Forward of The F-1208 Frame For Additions LaterMark Evan SalutinNoch keine Bewertungen

- Van'S Aircraft, Inc.: Figure 1: InstallingDokument1 SeiteVan'S Aircraft, Inc.: Figure 1: InstallingMark Evan SalutinNoch keine Bewertungen

- KV 21RS20Dokument40 SeitenKV 21RS20Luis Emilio QuiñonesNoch keine Bewertungen

- LPB040 Installation Guide (B - 2040139 - 1 - 5) - 1Dokument14 SeitenLPB040 Installation Guide (B - 2040139 - 1 - 5) - 1Fabian CruzNoch keine Bewertungen

- Universal: Flow Monitor Installation and Maintenance Instructions For Vane and Piston Style Variable Area Flow MonitorsDokument40 SeitenUniversal: Flow Monitor Installation and Maintenance Instructions For Vane and Piston Style Variable Area Flow Monitors4lk0nNoch keine Bewertungen

- PM 300 v2.2Dokument4 SeitenPM 300 v2.2GabNoch keine Bewertungen

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142Von EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142Noch keine Bewertungen

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationVon EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNoch keine Bewertungen

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsVon EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsBewertung: 3 von 5 Sternen3/5 (2)

- Ignition Cables and Igniter Installation PDFDokument6 SeitenIgnition Cables and Igniter Installation PDFMark Evan SalutinNoch keine Bewertungen

- Ignition Cables and Igniter Installation PDFDokument6 SeitenIgnition Cables and Igniter Installation PDFMark Evan SalutinNoch keine Bewertungen

- Ignition Cables and Igniter Installation PDFDokument6 SeitenIgnition Cables and Igniter Installation PDFMark Evan SalutinNoch keine Bewertungen

- High Low Tension Ignition Comparison PDFDokument4 SeitenHigh Low Tension Ignition Comparison PDFMark Evan SalutinNoch keine Bewertungen

- Ignition System - Inspection Check PDFDokument4 SeitenIgnition System - Inspection Check PDFMark Evan SalutinNoch keine Bewertungen

- High Low Tension Ignition Comparison PDFDokument4 SeitenHigh Low Tension Ignition Comparison PDFMark Evan SalutinNoch keine Bewertungen

- Ignition System - Inspection Check PDFDokument4 SeitenIgnition System - Inspection Check PDFMark Evan SalutinNoch keine Bewertungen

- High Low Tension Ignition Comparison PDFDokument4 SeitenHigh Low Tension Ignition Comparison PDFMark Evan SalutinNoch keine Bewertungen

- Aluminum in AircraftDokument117 SeitenAluminum in AircraftMark Evan Salutin91% (11)

- Poly FIber BR-8600 Blush RetarderDokument2 SeitenPoly FIber BR-8600 Blush RetarderMark Evan SalutinNoch keine Bewertungen

- Wing in Ground Effect Craft Review ADA361836Dokument88 SeitenWing in Ground Effect Craft Review ADA361836Mark Evan SalutinNoch keine Bewertungen

- Petroleum JellyDokument6 SeitenPetroleum JellyMark Evan SalutinNoch keine Bewertungen

- Agard 406351 Ground Effect MachinesDokument169 SeitenAgard 406351 Ground Effect MachinesMark Evan SalutinNoch keine Bewertungen

- Material Safety Data Sheet For Odorized Propane: 1. Chemical Product and Company IdentificationDokument5 SeitenMaterial Safety Data Sheet For Odorized Propane: 1. Chemical Product and Company IdentificationShemi KannurNoch keine Bewertungen

- Poly Fiber Poly-TakDokument2 SeitenPoly Fiber Poly-TakMark Evan SalutinNoch keine Bewertungen

- Poly Fiber Reducer R65-75Dokument2 SeitenPoly Fiber Reducer R65-75Mark Evan SalutinNoch keine Bewertungen

- Safety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingDokument10 SeitenSafety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingMark Evan SalutinNoch keine Bewertungen

- PolyFLex Evercoat.Dokument7 SeitenPolyFLex Evercoat.Mark Evan SalutinNoch keine Bewertungen

- Sting-X II, Aerosol Certified LabsDokument4 SeitenSting-X II, Aerosol Certified LabsMark Evan SalutinNoch keine Bewertungen

- Permatex Form A GasketDokument3 SeitenPermatex Form A GasketMark Evan SalutinNoch keine Bewertungen

- Poly Fiber Poly-SprayDokument2 SeitenPoly Fiber Poly-SprayMark Evan SalutinNoch keine Bewertungen

- Power CleanDokument2 SeitenPower CleanMark Evan SalutinNoch keine Bewertungen

- Poly Fiber Poly-SprayDokument2 SeitenPoly Fiber Poly-SprayMark Evan SalutinNoch keine Bewertungen

- Rundolph Spray VarnishDokument7 SeitenRundolph Spray VarnishMark Evan SalutinNoch keine Bewertungen

- Sulfuric Acid Electrolyte 5-05Dokument5 SeitenSulfuric Acid Electrolyte 5-05Mark Evan SalutinNoch keine Bewertungen

- Spotcheck Reg Cleaner Remover SKC-HFDokument3 SeitenSpotcheck Reg Cleaner Remover SKC-HFMark Evan SalutinNoch keine Bewertungen

- Simple GreenDokument4 SeitenSimple GreenMark Evan SalutinNoch keine Bewertungen

- Sonnen Honing OilDokument5 SeitenSonnen Honing OilMark Evan SalutinNoch keine Bewertungen

- Superior Graphite Tube o LubeDokument3 SeitenSuperior Graphite Tube o LubeMark Evan SalutinNoch keine Bewertungen

- Soldering Flux PasteDokument9 SeitenSoldering Flux PasteMark Evan SalutinNoch keine Bewertungen

- Postal CodesDokument5 SeitenPostal CodesasimNoch keine Bewertungen

- Cpar ReviewerDokument7 SeitenCpar ReviewerAngela Marie CenaNoch keine Bewertungen

- Tour Guiding-2d&1n 1Dokument4 SeitenTour Guiding-2d&1n 1Lorielyn Arnaiz CaringalNoch keine Bewertungen

- 4 ConversationDokument12 Seiten4 Conversationehajer186Noch keine Bewertungen

- HSV HC35WBxR2 01 US (0622) DS Y FINALDokument3 SeitenHSV HC35WBxR2 01 US (0622) DS Y FINALHéctor RodríguezNoch keine Bewertungen

- Alchemy Gold Slot Demo RTP 96.78 Free PlayDokument1 SeiteAlchemy Gold Slot Demo RTP 96.78 Free Playbc287724Noch keine Bewertungen

- Tourism Board DETAILS MUMBAIDokument2 SeitenTourism Board DETAILS MUMBAIManoj SatheNoch keine Bewertungen

- Prepositions of MovementDokument4 SeitenPrepositions of MovementLucia MeloNoch keine Bewertungen

- Ielts Writing Task 1 Maps Introductory SentencesDokument2 SeitenIelts Writing Task 1 Maps Introductory SentencesPhùng ThúyNoch keine Bewertungen

- Varalakshmi VrathamDokument3 SeitenVaralakshmi VrathamSundar SyamNoch keine Bewertungen

- Sno. Area Yamuna Sports Complex, Delhi Talkatora Stadium, Delhi InferencesDokument1 SeiteSno. Area Yamuna Sports Complex, Delhi Talkatora Stadium, Delhi InferencesSAKET TYAGINoch keine Bewertungen

- Week 2 Welcome To The Lord's TableDokument10 SeitenWeek 2 Welcome To The Lord's TableShower of RosesNoch keine Bewertungen

- Explanation, Apology, and RantDokument8 SeitenExplanation, Apology, and RantAnonymous xV9mg4vPG0Noch keine Bewertungen

- Altec 436C PDFDokument6 SeitenAltec 436C PDFjoeeNoch keine Bewertungen

- Manual Hmi Pws6300sDokument10 SeitenManual Hmi Pws6300skiedinhoNoch keine Bewertungen

- 011 DYLAN THE DRAGON Free Childrens Book by Monkey PenDokument24 Seiten011 DYLAN THE DRAGON Free Childrens Book by Monkey PenAmanda HuiNoch keine Bewertungen

- Kid's Box 3 - Revision - Unit 1 - EuDokument4 SeitenKid's Box 3 - Revision - Unit 1 - EuBernadete100% (1)

- Zayne's Plate Preorder GiftDokument15 SeitenZayne's Plate Preorder GiftSin YinNoch keine Bewertungen

- 1993 - Pat Metheny Group - The Road To YouDokument3 Seiten1993 - Pat Metheny Group - The Road To YouМихаил КондратьевNoch keine Bewertungen

- American English File 1-Writing and Speaking Questions: The Questions Are The Same As Speaking PartDokument6 SeitenAmerican English File 1-Writing and Speaking Questions: The Questions Are The Same As Speaking PartIsmael Shahamat100% (1)

- Footwear IndustryDokument50 SeitenFootwear IndustrySahilNoch keine Bewertungen

- Series: "FLUGEL Does Care About PATIENT "Dokument2 SeitenSeries: "FLUGEL Does Care About PATIENT "Mohamed Abd ElrahmanNoch keine Bewertungen

- Art Gallery Owners in SingaporeDokument5 SeitenArt Gallery Owners in SingaporeMavis AngNoch keine Bewertungen

- KDLV32XBR1Dokument174 SeitenKDLV32XBR1videosonNoch keine Bewertungen

- Catch Us If You CanDokument11 SeitenCatch Us If You Cano'Zill DZullNoch keine Bewertungen

- Billie JeanDokument5 SeitenBillie JeanAnonymous SYErujsNoch keine Bewertungen

- PS 1 Suit Techpack FinalDokument22 SeitenPS 1 Suit Techpack FinalyeraNoch keine Bewertungen

- Editing WX - Sample - Bin (Random Option) IN GLOGICSERVER - RCCDokument3 SeitenEditing WX - Sample - Bin (Random Option) IN GLOGICSERVER - RCCDaniel ManivoughNoch keine Bewertungen

- Email MarketingDokument1 SeiteEmail MarketingRoss BeadmanNoch keine Bewertungen

- Bibliografia InventariDokument39 SeitenBibliografia InventariDani100% (1)