Beruflich Dokumente

Kultur Dokumente

67 9268

Hochgeladen von

Salvador Reyes0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

199 Ansichten34 SeitenINSTRUCTION 67-9268 Technician Series Model 7. And 10 HP Fuel Injection Pump Calibrating Stands Installation / Operation / Maintenance Rev. 4 - April 1999 Bacharach, inc. 625 Alpha drive, Pittsburgh, PA 15238-2878.

Originalbeschreibung:

Originaltitel

67-9268

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenINSTRUCTION 67-9268 Technician Series Model 7. And 10 HP Fuel Injection Pump Calibrating Stands Installation / Operation / Maintenance Rev. 4 - April 1999 Bacharach, inc. 625 Alpha drive, Pittsburgh, PA 15238-2878.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

199 Ansichten34 Seiten67 9268

Hochgeladen von

Salvador ReyesINSTRUCTION 67-9268 Technician Series Model 7. And 10 HP Fuel Injection Pump Calibrating Stands Installation / Operation / Maintenance Rev. 4 - April 1999 Bacharach, inc. 625 Alpha drive, Pittsburgh, PA 15238-2878.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 34

Bacharach, Inc.

625 Alpha Drive, Pittsburgh, PA 15238-2878

Phone: (412) 963-2000 FAX (412) 963-2091 Web: www.bacharach-inc.com

Registered Trademark

of Bacharach, Inc.

Printed in U.S.A.

INSTRUCTION 67-9268

Technician Series Model

7.5 & 10 HP Fuel Injection Pump

Calibrating Stands

Installation/Operation/Maintenance

Rev. 4 April 1999

Technician 7.5 & 10 Contents

Instruction 67-9268 Bacharach, Inc. Page i

TABI OI CONTNTS

Puge

1.0 INTRO\CTION............................................................................................................................ 1-1

1.1 Specifications ........................................................................................................................... 1-1

1.1.1 General ...................................................................................................................... 1-1

1.1.2 Main Drive ................................................................................................................1-1

1.1.3 Calibration Fluid Supply System ............................................................................ 1-1

1.1.4 Instrumentation ....................................................................................................... 1-2

1.2 Optional Accessories ................................................................................................................ 1-2

2.0 INSTAIIATION ............................................................................................................................. 2-1

2.1 Stand Preparation and Hook-up ............................................................................................. 2-1

2.1.1 Leveling..................................................................................................................... 2-1

2.1.2 Electrical Hook-Up (Wiring) .................................................................................... 2-1

2.3 Filling Reservoir ...................................................................................................................... 2-2

2.4 Basic Accessories...................................................................................................................... 2-2

3.0 OPRATION ................................................................................................................................... 3-1

3.1 Control & Light Functions ...................................................................................................... 3-1

3.1.1 Console Panel (Figure 3-1) ....................................................................................... 3-1

3.1.2 Front Panel (Figure 3-2) .......................................................................................... 3-3

3.1.3 Side Panels (Figure 3-3) ........................................................................................... 3-3

3.2 Tachometer / Counter Assembly ............................................................................................. 3-3

3.3 Calibration Fluid System ........................................................................................................ 3-3

3.3.1 Calibration Fluid Temperature Control (TEMP. ADJ.) .......................................... 3-4

3.3.2 Front Panel Connections (Figure 3-2) ..................................................................... 3-4

3.3.3 Waste Tank ............................................................................................................... 3-5

3.4 Water Cooling System ............................................................................................................. 3-5

3.5 Graduates ................................................................................................................................. 3-5

3.5.1 Reading the Graduates (Figure 3-5) ........................................................................ 3-5

3.5.2 Draining the Graduates (Figure 3-6) ...................................................................... 3-6

3.6 Accumulator Arm Assembly .................................................................................................... 3-6

3.7 Flexible Anti-Backlash Coupling ............................................................................................ 3-6

3.8 Correct Use of Alignment Gauge ............................................................................................ 3-6

3.9 Typical Operating Sequence.................................................................................................... 3-7

3.10 Shutdown Procedure ............................................................................................................... 3-8

3.11 Mounting Injection Pumps and Test Injectors ....................................................................... 3-8

Page ii Bacharach, Inc. Instruction 67-9268

Contents Technician 7.5 & 10

4.0 MAINTNANC & TRO\BISHOOTING ............................................................................... 4-1

4.1 Maintenance............................................................................................................................. 4-1

4.1.1 Belt Tensioning ......................................................................................................... 4-1

4.1.2 Lubrication (Figure 4-1) ........................................................................................... 4-1

4.1.3 Calibration Fluid ...................................................................................................... 4-1

4.1.4 Graduates (Care/Cleaning) ...................................................................................... 4-2

4.1.5 Adjustment of Magnetic Pickup .............................................................................. 4-2

4.1.6 Tach/Counter Replacement ...................................................................................... 4-3

4.1.7 Removal of Flexible Coupling .................................................................................. 4-3

4.1.8 Flexible Coupling Installation ................................................................................. 4-4

4.1.9 Motor Starter Overload Relay Adjustment ............................................................. 4-6

4.2 Troubleshooting ....................................................................................................................... 4-7

4.2.1 Electrical ................................................................................................................... 4-7

4.2.2 Mechanical ................................................................................................................ 4-8

5.0 PARTS IISTS.................................................................................................................................. 5-1

5.1 Belts, Filters, Etc. .................................................................................................................... 5-1

5.2 Electrical Components............................................................................................................. 5-1

5.3 Instruments ............................................................................................................................. 5-2

5.4 Miscellaneous Parts ................................................................................................................. 5-2

5.5 Optional Accessories ................................................................................................................ 5-2

APPNIX A P\MP MO\NTING IAGRAMS ............................................................................... A-1

APPNIX B - INJCTOR ACC\M\IATOR ACCSSORIS ....................................................... B-1

Technician 7.5 & 10 Contents

Instruction 67-9268 Bacharach, Inc. Page iii

WARNINGS AND CAUTIONS

WARNINGS

DO NOT attempt to make any adjustments or repairs to the electrical compo-

nents of the Technician Stand without first disconnecting the main power line

at the wall. Many connections within the Stand carry lethal voltages. Any

work done to the electrical system should be performed by qualified personnel.

DO NOT operate the Technician Stand with the flexible coupling mounted

and no injection pump attached, this is extremely hazardous and will perma-

nently damage the coupling.

Use the flexible coupling guard at all times.

DO NOT depress the run button without being aware of the speed control

selection and setting.

Use of any adapters and/or couplings, not approved by Bacharach, Inc., to

mount injection pumps to the Technician Stand may be dangerous and could

void the warranty. Bacharach approved couplings and mounting adapters are

designed specifically to work with both the Technician 7.5 and 10.

CA\TIONS

DO NOT apply electrical power or attempt to operate the Technician Stand

until all steps in Section 2 are completed.

To maintain a free flow of cooling water, do not install a valve or any restric-

tion in the water drain hose.

To prevent calibration fluid heater burn-out, make certain that the Calibra-

tion Fluid HEAT switch is OFF when power is applied to the Technician

Stand with the fuel reservoir empty.

Make certain that there is 1" clearance between the degree wheel and the

coupling guard. Failure to have sufficient clearance could damage the degree

wheel (Figure 4-11).

The flexible coupling rear flange lock nuts must be checked for tightness

periodically (at least once per month).

Periodically check all hoses and connections to insure safe operation of the

Technician Stand.

DO NOT leave the Technician Stand unattended while the drive system is

rotating.

Page iv Bacharach, Inc. Instruction 67-9268

Contents Technician 7.5 & 10

NOTS

Technician 7.5 & 10 Introduction

Instruction 67-9268 Bacharach, Inc. Page 1-1

1.0 INTRODUCTION

The Bacharach Technician Series Model 7.5 and

10HP Fuel Injection Pump Calibrating Stands are

designed for testing and calibrating light to me-

dium duty diesel fuel injection pumps used on

engines employed in the construction, automotive,

power generation, and farm equipment fields. Its

low cost, compact design and simple operation

make the Technician Stand an ideal choice for a

new or expanding diesel fuel injection shop.

The anti-backlash, flexible, pump coupling is

driven by an AC motor coupled to a flywheel.

Controls for pump rotation selection, speed set-

tings, run, and stop are located on the console

panel. The speed setting control (potentiometer)

can vary the drive speed between 70 and

3500RPM (nominal).

The components located on the Technician Stands

front panel are: the digital tachometer/stroke

counter, Calibration Fluid Supply Temperature,

and the Calibration Fluid Vacuum/Pressure

gauges. The gauges have English and metric

scales. The calibration fluid collection and measur-

ing system consists of a swiveling single block

accumulator, attached to either side of the Stand,

feeding into 8 graduates of 160cc capacity. The

calibration fluid reservoir has a spout with a built

in dipstick for measuring fluid level.

1.1 Specifications

1.1.1 General

(a) Dimensions Width - 28" (.71 m)

Height - 68" (1.73 m)

Depth - 40" (1.02 m)

Weight Dry - 1200 lbs (545 kg)

(b) Electrical requirements:

Refer to Table 2-2.

(c) Water Consumption: Cold tap at approxi-

mately 1.2 gpm (4.5 liters/min.), gravity

drain.

1.1.2 Main Drive

(a) AC adjustable frequency electric motor.

(b) Rotary dial speed control adjustable from

703500 RPM.

(c) Flywheel moment of inertia: WR

2

= 1145 lb

in

2

(0.336 kgm

2

).

(d) Backlash free flexible coupling, laminated

disc design (Light Duty).

1.1.3 Calibration Fluid Supply System

(a) Fluid is either supplied under pressure to

the injection pump or drawn from the

reservoir under suction by the supply pump

that is mounted on the injection pump

under test.

(b) Thermostatically controlled calibration

fluid reservoir [capacity: 13 gallons (50li-

ters)] complete with four 500 watt heaters,

cooling coil, temperature sensor, overheat

safety switch with solid-state temperature

controller. Calibration Fluid temperature

controlled to 2 F under normal operating

conditions.

(c) Large 10 micron submersed reservoir filter.

(d) Automatic temperature control of calibra-

tion fluid to 2 F, heated by electric

submersible heaters, and cooled by cold tap

water that flows through copper-finned

tubing in the reservoir.

(e) Transfer pump driven by a

1

/3 horsepower

motor at a rate of 150 GPH (9.5 liter/min)

at zero pressure, valves for controlling fuel

supply pressure and for suction testing of

injection pumps with integral transfer

pumps.

Page 1-2 Bacharach, Inc. Instruction 67-9268

Introduction Technician 7.5 & 10

1.2 Optional Accessories

(Not Supplied, see Section 5.5)

(a) Final Stage Filter and Gauge Kit: (Cus-

tomer installed) contains a 2 micron

spin-on type filter, hoses, 0100 psi (07 kg/

cm

2

) gauge and hardware.

(b) Pressure Lubrication System: Self con-

tained with motor driven lube oil supply

pump, reservoir, filter, hoses, and hard-

ware. This unit conveniently attaches to

the side of the Stand. Recommended for

pumps requiring pressurized lube oil

supply (AMBAC Model 100 and some

others).

(c) Portable High Pressure Timing Unit: Self

contained with motor driven high pressure

pump, reservoir, filter, hoses and hard-

ware. Required for timing and phasing

many in-line fuel injection pumps. For

more information, ask for Leaflet 1035.

1.1.4 Instrumentation

(a) Dual mode digital tachometer and stroke

counter: Automatic shift from tachometer

to stroke count; accuracy 1 RPM, 1 count.

(b) Compound pressure/vacuum gauge: Range

of 030" Hg (0-76 cm Hg) vacuum and

0100 psi (0-6.9 bar) pressure, both mea-

sured in the fuel supply line.

(c) Fuel inlet temperature gauge: Range of

40140 F (560 C).

(d) Eight collection graduates: 160 cc clear

acrylic pyramidal design with 0.5 cc subdi-

visions from 035 cc and 1 cc subdivisions

from 35160 cc.

Technician 7.5 & 10 Installation

Instruction 67-9268 Bacharach, Inc. Page 2-1

2.0 INSTALLATION

CA\TION

DO NOT apply electrical power or attempt

to operate the Technician Stand until all

steps in this section are completed.

2.1 Stand Preparation and Hook-up

The Technician Stand is shipped bolted to a pallet.

Remove these bolts; then use a lift truck to remove

the Stand from the pallet.

CA\TION

Take care that the forks of the lift truck do

not damage the four heavy-duty leveling

pads that protrude from beneath the Stand.

The Stand should be installed with sufficient

surrounding space on the sides and in the rear

(approximately 18 inches) to permit removal of its

access panels for periodic lubrication, maintenance

and/or inspection of the Stand.

2.1.1 Leveling

The Stand must be leveled to permit accurate

reading of the graduates. Four heavy-duty leveling

pads are provided, one in each corner of the frame.

Use a carpenters level, across and in parallel with

the pump mounting rails, and adjust the level jack

nuts to position the Stand level.

2.1.2 Electrical Hook-Up (Wiring)

Fuse the Stands circuit breaker wall panel to NEC

or local code. Table 2-1 will assist in selecting the

correct fuse size.

Tub!e 2-1. AC Pune! Iuse SIze

Stand Model / AC Input Amps (Time Delay Fuse)

Technican 7.5:

230 VAC, 3 ph., 60 Hz 35

460 VAC, 3 ph., 60 Hz 20

Technicain 10:

230 VAC, 3 ph., 60 Hz 45

Before attempting to wire the Technician Stand,

refer to Figure 2-2. Make certain to follow that

portion which refers to the exact voltage, phase

and frequency noted on the electrical nameplate

located at the rear of the Stand.

NOT: At this point, it is suggested to

remove the lower front and rear panels.

Referring to Table 2-2 and Figure 2-1, connect the

AC mains to terminal block TB1. Connect a ground

wire to the ground terminal. Note that wire size

(AWG) will vary with types of insulation, length of

conductors, etc. Consult NEC codes.

CA\TION

To prevent the possibility of burning out

the calibration fluid heaters with the fuel

reservoir empty, make certain that the

Calibration Fluid HEAT switch is off when

power is applied to the Stand.

Tub!e 2-2. AC MuIns Cuvvent und WIve SIze

Stund Vo!ts/Hz Motov 3 WIve SIze

No. HP Amps AWG

67-7683 460/60 7.5 18 10

67-7682 230/60 7.5 32 8

67-7696 230/60 10 40 8

2.2 Cold Water Hook-up

Two connecting points for water are provided at

the lower left rear of the Stand. Cold tap water

input should be connected to the upper bulkhead

adapter after installing a -NPT fitting to accom-

modate the cold water supply. A manual shutoff

valve is suggested for connection upstream of the

inlet fitting.

The cold water return connection (drain) is located

directly below the inlet bulkhead adapter and

requires a -NPT fitting for a drain hose connection.

CA\TION

Do not install any valves on the water

return drain line.

A hose (or pipe) " inside diameter (minimum)

should be provided for the unrestricted return of

cooling water to the drain. After the water inlet

Installation Technician 7.5 & 10

Page 2-2 Bacharach, Inc. Instruction 67-9268

and drain have been connected to the Stand (and

the water turned on), inspect all connections for

leaks. For operating details of the cooling system

refer to Section 3.4.

2.3 Filling Reservoir

Fill the calibration fluid reservoir (filling tube located in

the lower front panel) with approximately 13 U.S. gallons

(50 liters) of calibration fluid that meets SAE J967 (ISO

4113), see Section 5.1 for ordering a 15 gal. drum..

NOT: Use calibration fluid approved by

the fuel injection pump manufacturer only.

Most recommend SAE J967 (ISO 4113).

IIguve 2-1. !ectvIcu! CLussIs

2.4 Basic Accessories

The individual accessories supplied with each

Stand are listed in the Accessories Drawing

67-6323 enclosed with this Instruction.

Ground

Terminals

Main Power

Input Terminals

Fuses (F1 & F2)

460 VAC Only

Main Power

Cable Inlet

3 O I NPUT

FRONT VI EW

DANGER

HI GH VOLTAGE

\

TOP VI EW

(MC)

Motor

Control l er

(MC)

Motor

Control l er

(M1 )

Motor

Starter

(M1 )

(TC)

Temperature

Control er

(K1 )

Control

Rel ay

(GND)

Ground

Termi nal

Bl ock

(TB1 )

I nput

Termi nal

Bl ock

(TB2)

Termi nal

Bl ock

(BR1 & BR2)

(BR1 & BR2)

Braki ng

Resi stors

(TC)

Fuses

(F1 & F2)

Technician 7.5 & 10 Installation

Instruction 67-9268 Bacharach, Inc. Page 2-3

IIguve 2-2. !ectvIcu! ScLemutIc

W

H

T

/

B

R

N

W

H

T

W

H

T

/

Y

E

L

B

R

N

P

L

-

W

P

L

-

X

P L - Y

2

W

H

T

/

B

L

K

/

R

E

D

C

O

N

T

R

O

L

L

E

R

M

O

T

O

R

B

1

S

H

I

E

L

D

T

1

T

2

L

T

B

L

U

1

2

1 1

T

3

B

2

B

1

S

2

B

R

2

2

B

R

1

2

G R A Y

L

T

B

L

U

3

T

A

C

H

4

V

I

O

7 8 O

R

N

L

T

B

L

U

2

3

H

4

O

V

E

R

H

E

A

T

H

3

H

2

H

1

T

S

1

T

2

L

2

T

B

1

L

2

L

1

G

R

N

3 1

2

0

K

R

1

C

L

E

A

R

2

R

E

D

B

L

K

F

S

F

V

M

C

F

C

G

L

1

L

2

L

1

G R N

T

1

G

R

N

G

N

D

L

3

T

B

2

3

S

W

4

S

W

6

-

2

W

H

T

/

G

R

N

S

1

S

C

M

B

R

E

D

M

C

L

3

S

T

O

P

W

H

T

/

R

E

D

6

K

1

9

4

S

L

A

T

E

1

2

S

W

5

R

U

N

L

3

T

3

M

1

R

E

D

R

E

D

C

B

W

H

T

W

H

T

L

T

B

L

U

2

L

T

B

L

U

3

A

L

T

3

1

O

R

N

W

H

T

/

B

L

U

8

5

K

1

R

E

D

K

1

L

T

B

L

U

L

T

B

L

U

L

T

B

L

U

7

4

L

T

B

L

U

L

T

B

L

U

M

1

W

H

T

/

B

L

K

W

H

T

/

R

E

D

4

3

4

4

M

1

1

3

3

2

M

1

3

1

1

4

W

H

T

/

V

I

O

S

W

6

-

1

3

4

W

H

T

W

H

T

G

R

A

D

U

A

T

E

F

I

L

L

S

O

L

O

N

O

I

D

W

H

T

W

H

T

B

L

K

M

A

G

P

I

C

K

U

P

2

1

S

O

L

1

C

A

L

.

S

U

P

P

L

Y

M

O

T

O

R

O

R

N

B

2

A

L

T

4

B

L

K

B

L

K

S

W

3

R

E

D

B

L

K

1

4

G

R

N

8

2

1

W

A

T

E

R

4

1

B

L

K

S

O

L

2

t

S

1

1 2

W

H

T

W

H

T

W

H

T

W

H

T

W

H

T

S

W

2

C

O

N

T

R

O

L

L

E

R

5 2

T

C

T

E

M

P

R

U

N

L

I

G

H

T

L

T

2

1

2

A

C

O

I

L

K

1

R

2

13

B

L

K

7 9

2

R

E

D

6 3

Y

E

L

4

1

9

5

C

O

I

L

S

T

O

P

L

I

G

H

T

R

R

/

C

2

1

2

L

T

1

M

1

R

/

C

1

M

1

9

6

T

E

M

P

E

R

A

T

U

R

E

A

D

J

U

S

T

H

E

A

T

L

I

G

H

T

T

E

R

M

I

N

A

L

B

L

O

C

K

C

I

R

C

U

I

T

B

R

E

A

K

E

R

M

O

T

O

R

S

T

A

R

T

E

R

I

N

P

U

T

T

E

R

M

I

N

A

L

B

L

O

C

K

S

P

E

E

D

A

D

J

U

S

T

R

O

T

A

T

I

O

N

M

A

I

N

D

R

I

V

E

M

O

T

O

R

R

U

N

B

R

E

A

K

I

N

G

R

E

S

I

S

T

O

R

S

R

E

L

A

Y

H

E

A

TC

A

L

.

S

U

P

P

L

Y

C

A

L

.

S

U

P

P

L

Y

L

I

G

H

T

R

/

C

3

R

/

C

4

C

A

L

.

F

L

U

I

D

H

E

A

T

E

R

S

R

/

C

5

R

/

C

6

A

B

W

H

T

/

Y

E

L

Y E L

W

H

T

G R A Y

G R A Y

G R A Y

G R A Y

G R A Y

G R A Y

T

B

1

L

2

L

1

G R A Y

G R A Y

L

3

G R A Y

3 1

4

C

B

2

W

H

T

W

H

T

R

E

D

R

E

D

W

H

T

W

H

T

1

2

F

1

1

F

2

2

Y

E

L

Y

E

L

T

1

4 6 0 V O L T

H2 H4

X1 X3

H1 H3

X4 X2

2 3 0 V O L T

T

O

(

M

1

)

T

O

(

T

B

2

)

4

6

0

V

A

C

S

T

A

N

D

S

2

3

0

V

A

C

S

T

A

N

D

S

Installation Technician 7.5 & 10

Page 2-4 Bacharach, Inc. Instruction 67-9268

IIguve 2-3. Cu!IbvutIon I!uId System

2 Optional Final Stage Filter and Gauge Kit (see Section 5.5) shown in enclosed area.

Technician 7.5 &10 Operation

Instruction 67-9268 Bacharach, Inc. Page 3-1

3.0 OPERATION

3.1 Control & Light Functions

The following is a description of the control and

light functions for the Technician Stand.

NOT: The numbers in the text refer to the

numbers on the corresponding figures.

3.1.1 Console Panel (Figure 3-1)

1. SUPPLY Switch (Calibration Fluid): Activates

the calibration fluid supply pump.

2. Calibration Fluid Indicator: Lit when the

SUPPLY switch is ON.

3. HEAT Switch (Calibration Fluid Heater):

Activates the calibration fluid automatic

temperature control system.

4. Calibration Fluid Heater Indicator: Lit when

the calibration fluid is being heated.

NOT: The Calibration Fluid Heater

indicator will cycle on and off during

normal operation.

5. TEMP. ADJ. Control (Temperature Adjust-

ment): Sets calibration fluid temperature in

the calibration fluid reservoir.

6. PUMP ROTATION Switch: Controls the

pumps direction of rotation.

7. STOP Button: Shuts down the main drive and

disconnects power to the controller. Once

activated, the button is locked, and must be

turned counterclockwise before it will unlock.

8. Stop Indicator: Lit while the main drive system

is in the STOP or unpowered state.

9. RUN Button: Starts the drive shaft rotating.

10. Run Indicator: Indicates that power is con-

nected to the main drive motor, and the drive

shaft is rotating.

11. SPEED Control: Sets speed (RPM) of the drive

shaft.

IIguve 3-1. Conso!e

2 4 8 10

1 3 5 6 7 9 11

DRIVE SYSTEM

SUPPLY

OFF OFF

HEAT

ON ON

TEMP ADJ.

CCW

PUMP ROTATION

CW

STOP

CALIBRATION FLUID

RUN SPEED

Operation Technician 7.5 & 10

Page 3-2 Bacharach, Inc. Instruction 67-9268

IIguve 3-3. By Puss & SLut OII Vu!ves

12 13

14 16

15

17

18 20

19 19

22

21

IIguve 3-4. TucL / Countev

IIguve 3-2. Ivont Pune!

TEMPERATURE

CAL. FLUID

SUPPLY RETURN

CAL. FLUID

VACUUM/PRESSURE

CAL. FLUID TO

FLOWMETER

TO FINAL

STAGE FILTER

CAL. FLUID FROM FINAL

STAGE FILTER RETURN

CALIBRATION FLUID SUPPLY

VACUUM/PRESSURE

TECHNICIAN 7.5

TEMPERATURE

CALIBRATION FLUID SUPPLY

Technician 7.5 &10 Operation

Instruction 67-9268 Bacharach, Inc. Page 3-3

3.1.2 Front Panel (Figure 3-2)

12. CALIBRATION FLUID SUPPLY VACUUM/

PRESSURE Indicator: A compound gauge that

indicates either positive or negative pressure

(vacuum) of the calibration fluid in the fuel

supply line (just behind the front panel).

13. CALIBRATION FLUID TEMPERATURE

Indicator: Displays the temperature of the

calibration fluid (just behind the front panel).

14. CAL. FLUID TO FLOWMETER: Measures the

calibration fluid return flow rate of rotary

distributor type pumps.

15. Graduates: Measures the fuel delivery of each

pump cylinder/outlet, which is routed from the

accumulator block.

16. TACH/COUNTER: A dual purpose unit consist-

ing of a digital tachometer and a preselectable

stroke counter. The stroke-cycle controls are

mounted on its front panel.

17. Flowmeter Input: Routes fluid to the

flowmeter.

18. CAL. FLUID SUPPLY Fitting: Provides

calibration fluid to the pump.

19. CAL. FLUID RETURN Fitting: Routes calibra-

tion fluid back to the calibration fluid reser-

voir.

20. TO/FROM FINAL STAGE FILTER Fittings:

Routes calibration fluid to and from the final

stage filter (Optional Accessory).

3.1.3 Side Panels (Figure 3-3)

21. Bypass Valve (Left hand side of Stand): Allows

operator to adjust Cal. Fluid Pressure.

22. Shut Off Valve (Left hand side of Stand):

Restricts or stops Cal. fluid flow to the pump.

23. DRAIN Valve (Right hand side of Stand,

Figure 3-6): Operating this lever drains the

graduates.

3.2 Tachometer / Counter Assembly

(Figure 3-4)

The TACH/COUNTER assembly in conjunction

with a magnetic pick-up and 120-tool gear provide

speed indication and revolution (stroke) counting.

The pick-up and gear are located in the rear of the

Stand. The gap between pick-up and gear is factory

set to .006 inches .001.

The TACH/COUNTER assembly is built into the

upper right-hand-front panel of the Stand. This

assembly processes the signals that it receives

from the magnetic pick-up assembly and indicates

the results on its 4-digit LED display. This unit

incorporates a 4-digit thumbwheel SELECT

STROKE switch for preselecting strokes. Indicator

lights show the assemblys mode of operation

either TACH MODE (tachometer) or COUNT

MODE (counter).

COUNT MODE is started by preselecting any

number of strokes in the SELECT STROKE

counter from 5 to 9999 and depressing the START

COUNT (draw) switch. If necessary, the count can

be stopped by the INTERRUPT (cancel) switch

after the draw cycle has begun.

The TACH/COUNTER assembly in its TACH

MODE continuously indicates drive shaft revolu-

tions per minute that is updated every 1 second.

3.3 Calibration Fluid System

(Figures 2-3 and 3-2)

This system consists of a fluid reservoir, waste

collector, motor-driven gear pump, SHUT OFF

VALVE, BY PASS VALVE, check valve, primary

filter, necessary plumbing and instrumentation.

Calibration fluid is drawn from a submerged filter

in the reservoir. Fluid is either supplied under

pressure to the injection pump, or drawn from the

reservoir under suction by the supply pump that is

mounted on the injection pump under test. If fluid

is to be supplied by the Stands supply pump to the

injection pump under test, then the one-way check

valve is closed. Manual adjustment of the calibra-

tion fluid pressure is done using the BY PASS

VALVE (Figure 3-3). Maximum available pressure

is approximately 75 psi.

Operation Technician 7.5 & 10

Page 3-4 Bacharach, Inc. Instruction 67-9268

If the calibration fluid is drawn out of the reservoir

with the Stands supply pump switched off, the

fluid passes through the check valve and out the

SHUT OFF VALVE to the injection pump under

test. In this mode, the BY PASS VALVE must be

closed (fully clockwise). Closing the SHUT OFF

VALVE completely or partially (Figure 3-3) will

stop or restrict the flow to the pump under test and

create vacuum upstream of the shut off valve. This

vacuum is indicated by the CALIBRATION FLUID

SUPPLY VACUUM/PRESSURE gauge. If re-

quired, calibration fluid can be circulated through

the final stage filter (an optional final stage filter

kit available for customer installation).

There are two CAL. FLUID RETURNs available

on the front panel. They are both routed directly to

the reservoir. The calibration fluid delivered by the

injection pump and injected into the accumulator

chambers is discharged into the graduate rack

housing and returns by gravity to the reservoir by

a separate line.

The reservoir is divided into three compartments

by baffles. This permits maximum mixing of hot

and cold calibration fluid and provides for stabi-

lized fuel temperature under all operating condi-

tions. The cooling compartment contains a coil of

finned tubing through which cold tap water flows

for cooling purposes when required. All fluid

returns from the pump and the test injectors are

diverted into this compartment.

The temperature of the fluid entering the reservoir

is generally higher than that in the reservoir. The

heating compartment contains four immersed

electrical heaters that provide heat to the calibra-

tion fluid when necessary. The thermostat is

mounted above the heaters. The main compart-

ment contains the submersible primary filter. The

three compartments are interconnected to permit

fluid flow from the cooling compartment past the

cooling coil into the heating compartment past the

heaters and thermostat into the main compart-

ment and out through the filter into the system.

A overheat thermostat is wall mounted on the

reservoir to detect possible overheating of the

calibration fluid. This could occur if the automatic

temperature controller malfunctions.

The temperature of the calibration fluid is mea-

sured in the supply piping (manifold) behind the

front panel and is indicated by the CALIBRATION

FLUID SUPPLY TEMPERATURE gauge mounted

in the upper right side of the front panel.

3.3.1 Calibration Fluid Temperature Control

(TEMP. ADJ.)

Heating of the calibration fluid is accomplished by

four 500 watt immersed electric heaters. Cooling is

provided by cold water flowing through finned

tubing immersed in the fuel reservoir. The thermo-

stat either switches on the heaters or admits cold

water for cooling. The thermostat is set at the

factory for a calibration fuel inlet temperature

range of 102106 F. Readjustment may be neces-

sary for specific pumps and particular test condi-

tions.

When adjusting the thermostat on the front

console, the injection pump should already be

warmed up and the whole system at operating

temperature. To maintain close control of the

calibration fluid temperature, it is recommended

that the supply pump operate during all tests,

whenever this is possible (open BY PASS VALVE

fully counterclockwise). Increased fuel flow

through the reservoir will increase the frequency

of the heating/cooling cycle and thereby supply

calibration fluid at a uniform temperature under

most operating conditions.

To readjust temperature setting after complete

warm-up, observe CALIBRATION FLUID SUP-

PLY TEMPERATURE gauge, then turn Calibra-

tion Fluid TEMP. ADJ. thermostat adjustment on

the front console CW to increase or CCW to de-

crease. Adjust by small increments only.

CA\TION

Allow 1015 minutes for calibration fluid

system to stabilize.

3.3.2 Front Panel Connections (Figure 3-2)

CAL. FLUID SUPPLY accepts

5

/8" ID hose (#10)

that is required for testing Cummins PT pumps.

For other applications, suitable reducers are

supplied for use with

1

/2" ID (#8) or

3

/8" ID (#6)

rubber or PVC hoses.

NOT: Use PVC hoses for supply under

very low pressures (below 10 psi) and

return. In all other cases use rubber hoses.

The two CAL. FLUID RETURNs accept

1

/2" ID (#8)

hoses and are provided for return of calibration

fluid to the reservoir. All connecting points, gauges

and controls are well identified by

Technician 7.5 &10 Operation

Instruction 67-9268 Bacharach, Inc. Page 3-5

nameplate and the calibration fluid system is

represented on the front and left-hand panel by

interconnecting lines and symbols.

3.3.3 Waste Tank

The drain pan is connected to a waste tank. By

preventing the spillage in the drain pan from

returning to the calibration fluid reservoir, the

possibility of contamination is greatly reduced.

Check the waste tank level periodically, and

discard the waste fluid as required.

The waste tank is located at the lower left rear of

the Stand and is accessible without removing the

rear panel. Remove drain hose and then slide tank

to rear for removal.

3.4 Water Cooling System

The cooling system will automatically shut off the

flow of cooling water when the power is off. This

system consists of a cooling coil, a solenoid valve,

and necessary plumbing. The cooling coil is in-

stalled in the calibration fluid reservoir.

The solenoid valve is a normally-closed, 2-way

valve. When energized, it permits cooling water to

flow through the calibration fluid reservoir and

then to the drain. This solenoid is energized when

the Calibration Fluid HEAT switch is ON, and

when the temperature control calls for cooling.

With the Calibration Fluid HEAT switch "ON", the

heaters or solenoid valve can be energized. When

the solenoid is energized, cooling water will flow

through the coil in the calibration fluid reservoir

and the heaters are shut-off.

When the temperature drops below the set point,

the thermostat provides a current path through

the normally closed safety thermostat, applying

current to the heaters. This causes the water

solenoid to de-energize and the heater light to

come ON. By this action, cooling water is blocked

from flowing through the reservoirs cooling coil,

thus allowing the calibration fluid temperature to

increase up to the set point previously established

at the TEMP. ADJ. potentiometer located on the

front panel.

3.5 Graduates

The Technician Stand contains a number of unique

features. The graduates are of clear molded plastic,

with 160 cc capacity. Graduations are every 1cc

except in the range from 035 where 0.5 cc gradua-

tions can be read. The pyramidal shape features a

high degree of readability. An aluminum spray

deflector located at the top of each graduate

diverts fluid to its back surface to minimize foam

accumulation.

The black vertical line on the rear wall of the

graduate provides a method of eliminating paral-

lax reading error.

3.5.1 Reading the Graduates (Figure 3-5)

A black vertical stripe painted on the back wall of

the plastic graduate serves to obtain an accurate

reading line for the correct fluid level. To find the

exact fluid level, move your eyes to the level of the

fluid and to a position at which the distance A is

at a minimum. At this position, the image (shown

in Figure 3-5) is formed.

The thin black horizontal line resulting from the

black stripe and fluid meniscus is the reading line.

Follow this line horizontally to the graduations

and read the volume in cubic centimeters (ccs).

IIguve 3-5. ReudIng Gvuduute

Operation Technician 7.5 & 10

Page 3-6 Bacharach, Inc. Instruction 67-9268

3.5.2 Draining the Graduates (Figure 3-6)

The graduate DRAIN lever is located on the upper

right side of the Stand. To drain fuel from the

graduates after a count, push in the graduate

DRAIN lever and move clockwise to the DRAIN

position. Release the lever to allow its notch to

engage the latch plate and hold the control lever in

the DRAIN position.

The graduates will continue to drain until the

control lever is released from the latch plate drain

position. Return the control lever to the FILL

position before starting the next count. The recom-

mended drain time is 30 to 35 seconds.

IIguve 3-6. Gvuduute vuIn Ievev

3.6 Accumulator Arm Assembly

(Figure 3-7)

Eight nozzle clamp post assemblies (and set

screws), used to assemble the accumulator for

operation, are packed in the parts bag.

1. Align flat spot on base of post with the

threaded hole on back of accumulator.

2. Slide each nozzle clamp post into holes pro-

vided for them on top of accumulator.

3. Place each set screw into a threaded hole on

the side of the accumulator block; then tighten

until it secures the nozzle clamp post.

The accumulator arm can be mounted on either

the right or left side of the Stands front panel

depending on the injection pumps application. If

the accumulator arm needs to be moved to the

other side of the front panel, slide the accumulator

arm out of its mounting tube and slide it into the

mounting tube on the opposite side. The accumula-

tor arm can be swung to move the accumulator out

of the way when necessary.

3.7 Flexible Anti-Backlash Coupling

(Refer to Sections 4.1.7 & 4.1.8

for Removal / Installation)

The coupling is secured to the Stand drive shaft by

a tapered-hub. The front (driving) flange is de-

signed for direct attachment to the pump driving

component (hub) without any backlash. The flange

also provides a pilot to ensure concentricity. A

drive Adapter (see Section 5.5) is available as an

optional accessory to make the flexible coupling

semirigid. The drive adapter is used only when it is

necessary to convert the flexible coupling for

driving pumps that require a tanged-type drive.

3.8 Correct Use of Alignment Gauge

For correct engagement of drive hub to the flexible

coupling, use the Alignment Gauge that is supplied

with the coupling.

1. Insert pins of the gauge between lamination

and flanges on each side.

2. When correct engagement exists the gauge will

drag slightly, exhibiting a slide-fit between

the pins on one side and the lamination and

flanges on the other. Note that excessive pull

or push on the lamination will permanently

distort them, requiring their replacement.

3. To avoid distorting or damaging the laminated

disc, the flexible coupling must always be

connected to an injection pump coupling before

the Stand is operated.

CA\TION

The rear flange lock nuts must be periodi-

cally checked for tightness (at least once per

month).

It is recommended that all bolts and nuts of the

coupling be periodically checked for tightness and

proper torque. There are approximately 6 Lamina-

tion (see Section 5.4 for part number) on each side

of the Flexible Coupling.

Technician 7.5 &10 Operation

Instruction 67-9268 Bacharach, Inc. Page 3-7

3.9 Typical Operating Sequence

Before performing the following steps, ensure that

the pump is mounted on the Stand according to

pump mounting diagrams or pump manufacturers

instructions (see Section 3.11), all necessary

connections have been made, and the pump is

ready for testing.

1. Set all switches on the Stand to their OFF or

fully CCW position.

2. Turn on water supply.

3. Turn on power to the Stand at the main

distribution panel.

4. Set main circuit breaker (CB1) on upper left

side to ON

5. Observe that the STOP (red) light is ON and

the RUN (amber) light is OFF.

6. Set the PUMP ROTATION switch to the

desired direction of pump rotation.

7. Turn BYPASS VALVE fully CCW (open).

8. Turn SHUTOFF VALVE to OPEN

9. Set the CALIBRATION FLUID SUPPLY and

HEAT switches to ON before running an

injection pump. Allow enough time for the

calibration fluid to reach operating tempera-

ture.

NOT: When calibration fluid reaches its

preset temperature, the HEAT ON lamp

will turn off. The calibration fluid system

will automatically run the heater elements

(HEAT lamp will be ON) or water will be

routed through the calibration fluid cool-

ing coil (HEAT lamp OFF) to maintain the

temperature preset by the TEMP ADJ.

control. The temperature is factory adjusted

to 104 2 F. In the event the injection

pump manufacturers instructions call for a

different temperature setting, use the

calibration fluid TEMP ADJ. to make

adjustments (reference Section 3.3.1).

10. Adjust the BYPASS VALVE to obtain the

desired calibration fluid supply pressure.

NOT: Negative pressure (vacuum)

generated by an injection pumps supply

pump (feed or transfer) can be read on the

compound gage after closing the SHUTOFF

VALVE.

11. Make sure that the STOP button is in the up

position. This control remains in the down

position once it has been depressed. The button

must be rotated counterclockwise in order for it

to release.

12. Depress and hold the RUN button until the

drive begins to turn.

13. Adjust the SPEED control to the desired RPM.

The RPM will be displayed on the TACH/

COUNTER.

14. Dial in the desired stroke count on the

SELECT STROKE thumb wheel switches.

15. Make sure the graduate FILL / DRAIN lever is

in the FILL position.

16. Depress the START COUNT switch to begin

the stroke count cycle. The graduate solenoid

energizes causing the graduates to begin

filling. The TACH/COUNTER will first display

the stroke count during the count cycle, and

then automatically return to its tachometer

mode.

NOT: The stroke count cycle may be

stopped at any time by depressing the

INTERRUPT switch.

17. After reading the graduates, move the gradu-

ate FILL / DRAIN lever to the DRAIN posi-

tion. Recommended drain time is 30 to 35sec-

onds.

Operation Technician 7.5 & 10

Page 3-8 Bacharach, Inc. Instruction 67-9268

3.10 Shutdown Procedure

1. Turn RPM control completely CCW (if not

already CCW).

2. Push the STOP Button.

3. Turn Cal. Fluid SUPPLY switch to OFF.

4. Turn Calibration Fluid HEAT switch to OFF.

5. Set main circuit breaker to OFF.

6. Turn OFF cold water supply.

3.11 Mounting Injection Pumps and

Test Injectors

Appendix A is a list of Pump Connection Dia-

grams available from Bacharach. These drawings

will assist the operator in mounting the fuel pumps

on the Stand. For exact pump test procedure and

specifications, refer to the pump manufacturers

service literature.

Refer to Appendix B for a listing what adapters,

spacers, bleed-off tubing, and clamps are needed to

mount and hold down the test injectors. Some

injectors require no adapters, while others may

require one or two in order to mount them into the

accumulator.

To install a nozzle:

1. Use appropriate nozzle holder adapters and

O Rings, as called for in Appendix B, on the

test injector.

2. Slide the injector into one of the accumulator

holes.

3. Slide the Nozzle Clamp under a set of posts on

the nozzle clamp post assembly so that the

ends rest on top of the injector. The notches on

top of the nozzle clamp should rest under the

posts.

4. Screw down the clamp screw assembly so that

it holds the nozzle tight.

IIguve 3-?. InJectov Instu!!utIon

NOZZLE CLAMP POST ASSY.

NOZZLE CLAMP

CLAMP SCREW ASSY.

NOZZLE HOLDER

ADAPTER

O-RING (05-5202)

15/16 ID x 1-3/16 OD

O-RING (05-5162)

1-3/16 ID x 1-5/8 OD

SET SCREWS

ACCUMULATOR

NOZZLE BLOCK

Technician 7.5 & 10 Maintenance & Troubleshooting

Instruction 67-9268 Bacharach, Inc. Page 4-1

4.0 MAINTENANCE &

TROUBLESHOOTING

4.1 Maintenance

CA\TION

Before performing any maintenance,

disconnect electrical power to the Stand at

the main AC distribution panel.

4.1.1 Belt Tensioning

The electric motor drive belt stretches in the first

few hours of operation. Check for proper tension at

the mid-position. Slack should not exceed

1

/2 inch

when compressed by hand.

To tighten electric motor drive belt:

1. Remove rear access panel

2. Loosen electric motor mounting bolts and

move complete assembly to tighten belt

3. Retighten mounting bolts to 10 lb-ft torque.

4.1.2 Lubrication (Figure 4-1)

Lubrication of the two main drive shaft bearings is

recommended after each 1000 hours of operation

or once a year, whichever occurs first. The follow-

ing lithium-base greases have been found to be

acceptable for this application.

Socony-Mobil Armvac-781

Texas Company Multifak 2 (E-P)-1990

Shell Oil Co. Alvania 2

To grease the main drive shaft bearings mounted

on the brackets, remove the rear access panels.

4.1.3 Calibration Fluid

The fluid should be replaced whenever any one of

the following events occur:

(a) After every 200 hours of operation.

(b) Viscosity increases to 3.2 cst (based on

SAE J967 (ISO 4113)) or more.

(c) Every three months or 200 pumps.

IIguve 4-1. MuIn vIve SLuIt Gveuse IIttIngs

Fill reservoir with 13 U.S. gallons (50 liters) of the

recommended calibration fluid. Most fuel injection

pump manufacturers recommend SAE J967 (ISO

4113) calibration fluid.

Replace primary filter every second fluid replace-

ment. To replace primary filter:

1. Drain calibration fluid reservoir with the

supply (transfer) pump.

2. Connect drain hoses to both drain valves.

3. Open both valves and drain residual calibra-

tion fluid in reservoir from both sides.

4. Remove screws securing the calibration fluid

reservoir to the frame.

5. Lower the calibrating reservoir to the floor.

6. Pull out all return hoses and remove the lid.

7. Loosen and remove the filter retainer and

slide out the filter.

8. Replace the filter with new filter and reas-

semble the reservoir in the reverse order.

Page 4-2 Bacharach, Inc. Instruction 67-9268

Maintenance & Troubleshooting Technician 7.5 & 10

Replace the optional final stage filter every second

fluid replacement. The final stage spin-on filter is

located behind the front panel. To replace filter,

use an automotive-type filter spanner wrench. For

correct part numbers of primary and final stage

filters, see Sections 5.1 and 5.5.

4.1.4 Graduates (Care/Cleaning)

Proper maintenance of the Graduates necessitates

periodic removal. Remove the rear access panel,

then proceed with the following:

1. Loosen the two socket head set screws in the

drain arm assembly.

2. Remove the drain arm from the drain rod.

3. Remove the upper right-hand side panel.

4. Remove two socket head cap screws from drain

arm mounting plate.

5. Remove graduate drain hose.

6. Pull the eight individual accumulator hoses from

front panel and drape them in the rear of Stand.

7. Remove two quick connects from graduate

solenoid.

8. Remove four hex nuts from graduate mounts

and remove complete assembly.

9. Remove the fill tube holder assembly by

removing the set screw and lock nut on the end

opposite the fill solenoid.

10. Remove three hex nuts holding the graduate

retainer bracket in place (located at the top of

graduates).

11. Slide retainer from the welded stud.

12. Graduates may now be serviced.

NOT: When cleaning graduates, a

detergent solution must be used. Do not

use solvents.

Reassemble in the opposite order of disassembly up

to Step 4, then proceed with the following to

properly set (bias) the graduate DRAIN lever.

1. Use vise grips on the drain rod assembly and

turn until the graduate drain valves are

raised to their maximum drain position as

viewed from the front.

2. Keep the drain rod assembly in this position,

then slide the drain lever mechanism onto the

end of the drain rod shaft.

3. Align the detent into the drain position and

secure drain arm to rod by tightening two set

screws.

4. Check results by shifting from DRAIN to

FILL position, then remove the vise grips.

4.1.5 Adjustment of Magnetic Pickup

(Figure 4-2)

The gap between the magnetic pickup and the 120

tooth gear is factory set to .006 inches.

The general indication that the gap setting is out

of tolerance, or that the magnetic pickup is defec-

tive and must either be reset or replaced is exem-

plified by an erratic RPM display on the TACH/

COUNTER. To adjust the magnetic pickup gap

setting, use the following procedure:

1. Turn main circuit breaker to OFF.

2. Remove the rear panel to gain access to the

magnetic pickup.

3. Loosen locknut on magnetic pickup body and

adjust until the gap between the top of the

teeth and the pickup is .006 in. (.001in.).

4. Manually rotate the flywheel one full turn

making certain that all teeth clear the pickup.

Use a dial indicator to check for concentricity

around the gear. If the encoder gear is eccen-

tric, loosen the three hex head cap screws

that secure the gear to the hub. Readjust the

gear and retighten the screws.

5. When proper gap setting is achieved, tighten

locknut, then recheck for concentricity.

6. Check Stand for correct RPM indication with

a hand held tachometer, especially at low

speeds (around 70 RPM). If RPM is incorrect,

refer to Section 4.2 Troubleshooting.

Technician 7.5 & 10 Maintenance & Troubleshooting

Instruction 67-9268 Bacharach, Inc. Page 4-3

IIguve 4-2. MugnetIc PIc -\p

4.1.6 Tach/Counter Replacement

No attempt should be made to repair this unit in

the field. If unit becomes inoperative with main

switch ON, check for tight electrical connections.

1. Use a voltmeter set on the appropriate range

and check that 230 VAC (approximate) is

present between Terminals 1 and 2 at rear of

tach/counter.

(a) If input voltage is present, it may indicate

that the unit is defective.

2. Another possible malfunction could be a

defective magnetic pick-up. Check the input

signal between Terminals 7 & 8 for

approximately 2.5 volts peak to peak.

(a) If signal is present, the tach/counter is

defective.

To replace this assembly:

1. RMOV POWR TO STAN.

2. Remove the rear access panel.

3. Use a

3

/16" socket wrench with extension and

remove the four hex nuts from the rear of the

tach/counter housing.

4. Disconnect and tag wiring after noting the

exact position of each connection.

5. Remove complete assembly by pulling for-

ward and out from the front panel.

NOT: Make certain to insulate all wiring

connections.

4.1.7 Removal of Flexible Coupling

(Figures 4-3 & 4-4)

IIguve 4-3. SLou!dev Bo!ts

1. Locate and remove the four shoulder bolts

from the rear flange

2. Remove the front flange and centering ring

assembly.

3. Remove the three hex head cap screws from

the tapered hub.

4. Install these screws into the tapped holes to

jack the hub from the rear flange.

5. Use the barring tool to facilitate hub removal,

while gradually tightening each screw in

sequence. Then slide hub off shaft.

6. If difficulty is encountered during hub

removal, wedge a screwdriver into hub slot to

relieve tension on the shaft. Caution: Excessive

force will split the hub.

Page 4-4 Bacharach, Inc. Instruction 67-9268

Maintenance & Troubleshooting Technician 7.5 & 10

IIguve 4-4. RemovIng Hub Ivom Reuv I!unge

7. Slide the rear flange and degree wheel

assembly off the shaft by pulling forward.

4.1.8 Flexible Coupling Installation

(Figures 4-5 thru 4-11)

1. Insert hub into tapered inside diameter of

rear driven flange.

2. Align the three bolt holes in hub with the

three tapped holes in the driven flange and

assemble loosely with three

1

/4-20 bolts and

lockwashers supplied with hub.

3. Slide the complete hub and rear flange

assembly over the drive shaft.

4. Slide hub and flange assembly along shaft

until 1-

3

/16" remains between endd of drive

shaft and hub.

NOT: Reference dimension of 1-

3

/16" is

designed to provide a final clearance of about

3

/4" between degree wheel and front panel

after hub is torqued to final specification.

5. Alternately tighten the three hex head cap

screws in 50, 25, 25 and 8 lb-in. increments in

rotational order. This will draw the driven

flange to the tapered hub uniformly. All three

cap screws will have a final torque of

108 lb-in. (Figure 4-6).

IIguve 4-5. I!e Ib!e Coup!Ing

IIguve 4-6. TIgLtenIng Hub Cup Scve s

NOT: When properly installed, the

tapered hub will remain stationary on the

Stand drive shaft and the drive flange will

be drawn into correct alignment with it.

The distance between front face of degree

wheel disc and degree wheel vernier should

be within

1

/64 when cap screws are

tightened to final torque.

6. With the rear flange and degree wheel se-

curely installed, check the front face of the

driven flange for perpendicularity using a dial

indicator against the top face of the flange

(Figure 4-7).

7. Install the dial indicator using a bracket

around one of the Stand rails.

Technician 7.5 & 10 Maintenance & Troubleshooting

Instruction 67-9268 Bacharach, Inc. Page 4-5

IIguve 4-?. CLec Ing Reuv I!unge Assemb!y

8. Bar coupling over one full turn and check that

deviation does not exceed 0.002 from the

perpendicular plane (wobble).

NOT: To prevent damage to the dial

indicator, make certain that the stem is

held as it passes over the milled slot in the

flange. The total misalignment must not

exceed 0.002 ". Should it exceed this, loosen

the three hex cap screws and retighten them

in the same manner as detailed in Step 5.

After retightening, check for misalignment.

IIguve 4-. P!ucIng Beve!ed WusLevs

Bet een IumInutIons & Reuv I!unce

9. Install four beveled washers over the shoulder

bolts protruding through laminated discs (Fig-

ure 4-8).

10. Refer to Figure 4-9. Horizontally align the

four shoulder bolts protruding through the

laminated discs with the holes in the rear

flange.

11. Place lock nuts (one at a time) into each of the

slots in the rear flange.

12. Tighten each bolt gradually until a final

torque of 13 lb-ft is achieved (Figure 4-10).

IIguve 4- . P!ucIng Ioc Nuts Into

S!ots on Reuv I!unge

IIguve 4-10. TIgLtenIng SLou!dev Bo!ts

Page 4-6 Bacharach, Inc. Instruction 67-9268

Maintenance & Troubleshooting Technician 7.5 & 10

CA\TION

Use Flexible Coupling Guard at all times

when flexible coupling is in operation.

Never operate Stand without flexible

coupling connected to a pump.

Make certain that there is 1" clearance

between the degree wheel and the coupling

guard. Failure to have sufficient clearance

could damage degree wheel (Figure 4-11).

IIguve 4-11. 1 Bet een WLee! & Guuvd

4.1.9 Motor Starter Overload Relay Adjustment

(Figure 4-12)

1. Find the operating volts located on the

nameplate of the Stand.

2. Locate the FLA (Full Load Amps) for the

corresponding voltage (step 1), which can be

found on the main drive motor controller

name plate.

3. The dial setting on the Motor Starter Over-

load Relay is equal to the FLA value.

IIguve 4-12. TypIcu! Motov Stuvtev ItL

Ovev!oud Re!uy

Technician 7.5 & 10 Maintenance & Troubleshooting

Instruction 67-9268 Bacharach, Inc. Page 4-7

4.2 Troubleshooting

Before attempting to troubleshoot, determine if the

problem is electrical and/or mechanical.

1. Electrical Problems

(a) Blown fuses or heaters, removing

power to one or more circuits.

(b) Relay contacts dirty/sticking or vibration

problems.

(c) Extreme line voltage drops (or transients).

(d) Faulty switches.

2. Mechanical Problems

(a) Broken, worn or loose belt.

(b) Loose parts due to vibration.

(c) Dirt/oil buildup on sensitive parts.

(d) Starved system due to clogged filter.

(e) Fluid leakage due to worn seals or loose

parts.

4.2.1 Electrical

Symptom PossIb!e Cuuse Remedy

1. Graduate fill solenoid does not energize Defective fill solenoid. Defective If 230 VAC absent between

when COUNT button is depressed. relay in tach/counter (SOL1)(TACH). Pins 3 & 4 when COUNT is

depressed, replace FILL

Test Points: solenoid SOL.1.

Terminal strip rear of tach/counter

Pins 3-4. Check for 230 VAC If 230 VAC present between 3

(Tolerance: 197-253 VAC). & 4 when COUNT is depressed,

replace defective tach/counter.

2. Motor Overload Relay trips. Improper Motor Overload Relay Readjust using Section 4.1.9.

setting (M1).

or

Improper line voltage. Verify the incoming line voltage

meets specifications.

or

Loss of a phase voltage. Investigate & correct problem.

or

Motor overload. Troubleshoot & correct problem.

or

Faulty motor (B1). Replace motor.

3. All systems function except Stop Button not reset. Rotate Stop Switch CCW to

main drive motor. allow button to return to the

up position (reset).

or

Stop Switch bad (SW5). Replace.

or

Motor starter bad (M1). Reset or replace.

or

Control Relay Bad (K1). Replace.

or

Motor controller bad (MC). Replace.

or

Run button bad (SW6). Replace.

Page 4-8 Bacharach, Inc. Instruction 67-9268

Maintenance & Troubleshooting Technician 7.5 & 10

4.2.1 Electrical (Cont.)

Symptom PossIb!e Cuuse Remedy

4. No calibration fluid temperature control. Low fluid level. Add fluid.

or

Temp. Sensor bad (S1). Replace.

or

Plug disconnected (P1). Reconnect.

or

Cooling solenoid open (SOL2). Replace

or

Overheat thermoswitch bad (TS1). Replace.

or

Temp. Controller failed (TC). Replace.

5. Motor and drive function at low and Braking resistor open (BR1 or BR2). Replace.

high speeds but trips out upon or

deceleration with light loads. Braking resistor wire(s) loose. Tighten.

6. Tach does not read RPM or Count. Magnetic pickup defective Replace

or Misadjusted. or Readjust.

7. Calibration fluid heating time slow. Heater(s) defective (HTR1-4). Replace.

or

Water solenoid valve stuck open Repair or replace.

(SOL2).

4.2.2 Mechanical

Symptom PossIb!e Cuuse Remedy

1. Air in Calibration Fluid Supply line. Low fluid level. Check and replace.

or

Loose connection(s) in system. Tighten as required.

or

Shut Off Valve leaky or defective. Repair or replace.

or

Supply pump shaft seal leaking. Repair or replace.

2. Excessive vibration when main drive Stand is not level and/or on rubber Make corrections.

motor is running. pads (under leveling screws).

3. Calibration temperature in reservoir No water supply. Troubleshoot.

not stable. or

Water supply valve stuck closed. Repair or replace.

or

Controls set wrong. Reset.

or

Calibration fluid pump inoperative. Troubleshoot.

Technician 7.5 & 10 Parts Lists & Diagrams

Instruction 67-9268 Bacharach, Inc. Page 5-1

5.0 PARTS LISTS

5.1 Belts, Filters, Etc.

Puvt escvIptIon ty/Stund

07-1614 Calibration Fluid Filter Cartridge - 10 micron Purolator 63104-02 or AC PF347................................... 1

05-2122 Main Drive Belt ......................................................................................................................................... 1

05-5107 Graduate 0-Ring S-7-3 (LT1) ................................................................................................................... 8

67-0094 Hose Assy. (Cal. Fluid Pump Inlet) ........................................................................................................... 1

67-4269 Hose Assy. (Cal. Fluid Pump Outlet) ........................................................................................................ 1

67-4517 Hose Assy. (Cal. Fluid Return to Reservoir) ............................................................................................. 3

67-4521 Hose Assy. (From Cal. Fluid Reservoir Outlet) ........................................................................................ 1

03-2912 Cal. Fluid Supply Pressure Gauge Connection (Plastic Line) ............................................................... 3 ft.

03-2913 Nylon Tubing

3

/8 0.D. ............................................................................................................................ 4 ft.

03-5108 Hose (Cal. Fluid Waste) ........................................................................................................................ 2 ft.

03-5109 Hose (Graduate Drain) ........................................................................................................................... 4 ft.

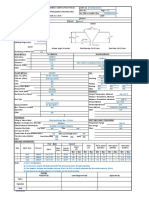

03-6063 Graduate Flexible Vinyl Tubing .............................................................................................................. 13

05-6304 Oil-Seal (For Cal. Fluid reservoir thermoswitch) ...................................................................................... 1

67-5598 Cal. Fluid (15 Gal. Drum) ......................................................................................................................... 1

5.2 Electrical Components

(Reference Pages 2-2 and 2-3 for Component Designations Shown in Parenthesis)

04-3585 Indicating Light (Amber) .......................................................................................................................... 3

04-3584 Indicating Light (Red) (LT2, LT3, LT4) .................................................................................................. 1

67-5426 Heater 240V 500W (Cal. Fluid Reservoir) (HTR1-HTR-4) .................................................................... 4

04-1311 Circuit Breaker (Mounted On Side Panel) (CB) ....................................................................................... 1

04-2719 Fuse (F1 & F2) 460 Volt Stand Only ........................................................................................................ 2

104-0348 Switch (ON/OFF) Cal. Oil Supply/Heat (SW2) ....................................................................................... 1

67-6142 Temperature Controller Assy. (TC) .......................................................................................................... 1

67-6244 Graduate Solenoid Assy. (TC) .................................................................................................................. 1

67-6141 Temperature Sensor (Cal. Fluid Reservoir) (S1) ...................................................................................... 1

67-6887 Supply Pump/Motor Assembly 230V/60 Hz/1 Phase (B2) ....................................................................... 1

03-4222 Solenoid Valve (Water) (SOL2) ............................................................................................................... 2

104-0084 Motor Starter (M1) 7.5 HP, 230 Volt Stand Only ..................................................................................... 1

104-0085 Motor Starter (M1) 7.5 HP, 460 Volt Stand Only ..................................................................................... 1

104-0098 Motor Starter (M1) 10 HP, 230 Volt Stand Only ...................................................................................... 1

04-4062 Main Drive Motor (B1) 7.5 HP, 230 and 460 Volt Stands Only .............................................................. 1

04-4120 Main Drive Motor (B1) 10 HP, 230 Volt Stand Only ............................................................................... 1

77-1122 Motor Controller (MC) 7.5 HP, 230 Volt Stand Only (Consult Factory for Programming Procedure) .. 1

77-1136 Motor Controller (MC) 7.5 HP, 460 Volt Stand Only (Consult Factory for Programming Procedure) ... 1

77-1130 Motor Controller (MC) 10 HP, 230 Volt Stand Only (Consult Factory for Programming Procedure) .... 1

04-5258 Control Relay (K1) .................................................................................................................................... 1

204-9411 Breaking Resistor (BR1 & BR2) 7.5 HP, 230 Volt Stand Only ................................................................ 2

204-9412 Breaking Resistor (BR1 & BR2) 7.5 HP, 460 Volt Stand Only ................................................................ 2

204-9413 Breaking Resistor (BR1 & BR2) 10 HP, 230 Volt Stand Only ................................................................. 2

04-9992 Arc Suppressor (Supply Pump Motor, Heaters, Water Solenoid, Control Relay) (RC2, RC3, RC4, RC5) ... 4

04-9993 Arc Suppressor (Motor Starter, Graduate Fill Solenoid) (RC1, RC6) ...................................................... 2

104-0357 Switch (Cal. Fluid Pump) (SW3) ............................................................................................................... 1

104-0336 Switch (Rotation) (SW4) ........................................................................................................................... 1

Page 5-2 Bacharach, Inc. Instruction 67-9268

Parts Lists & Diagrams Technician 7.5 & 10

104-0554 Contact Block, Normally Closed (Stop Button) (SW5) ............................................................................ 1

104-0555 Contact Block, Normally Open (Run Button) (SW6) ............................................................................... 2

104-0557 Button, Black (Run) *Does Not include Electrical Contact Block ........................................................... 1

104-0558 Button, Red (Stop) *Does Not include Electrical Contact Block.............................................................. 1

04-4872 Potentiometer (Speed Control) (R1) .......................................................................................................... 1

204-4593 Potentiometer 6 ohm, 4 watt W.W. (Temperature Adjust) (R2) .............................................................. 1

67-6170 Thermoswitch (Cal. Fluid Reservoir) (TS1) .............................................................................................. 1

5.3 Instruments

67-6204 Tachometer/Counter Assy. ........................................................................................................................ 1

67-6258 Magnetic Pick-up Assy. ............................................................................................................................ 1

67-6205 Temperature Gauge, 3

1

/2" Dial Size, Range 40-140F (5-60 Celsius) ................................................ 1

67-6206 Compound Gauge, 3

1

/2" Dial Size, Range 0-30" Hg, (0-76 cm Hg VAC), 0-100 psi., (0-7 kg/bar) ...... 1

67-6845 Sho-Rate 150 Flowmeter (Return Flow Meter) ..................................................................................... 1

5.4 Miscellaneous Parts