Beruflich Dokumente

Kultur Dokumente

Semi Conduct o 1

Hochgeladen von

Chaitu ChaitanyaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Semi Conduct o 1

Hochgeladen von

Chaitu ChaitanyaCopyright:

Verfügbare Formate

Semiconductor: All about it, all inside it, and what all can it do... to change our lifes.

What is a Semiconductor? Semiconductors are materials which have a conductivity between conductors (general metals) and nonconductors or insulators (such as ceramics). Semiconductors are made from pure elements, typically silicon or geranium, or compounds such as gallium arsenide. In a process called doping, small amounts of impurities are added to pure semiconductors causing large changes in the conductivity of the material.

Due to their role in the fabrication of electronic devices, semiconductors are an important part of our lives. Imagine life without electronic devices. There would be no radios, not TV's, no computers, no video games, and poor medical diagnostic equipment. Although many electronic devices could be made using vacuum tube technology, the developments in semiconductor technology during the past 50 years have made electronic devices smaller, faster, and more reliable. Think for a minute of all the encounters you have with electronic devices. How many have you seen or used in the last twenty-four hours? Each has important components that have been manufactured with electronic materials.

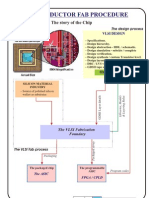

How is a Semiconductor Chip Made? Wafer Fab Manufacturing The process of manufacturing semiconductors or integrated circuits (commonly called ICs or chips) typically consists of hundreds of steps, during which hundreds of copies of an integrated circuit are formed on a single wafer.

The processing of Silicon wafers to produce integrated circuits involves a good deal of chemistry and physics. In order to alter the surface conditions and properties, it is necessary to use both inert and toxic chemicals, specific and unusual conditions, and to manipulate those conditions with both plasma-state elements and with RF (Radio Frequency) energies. Starting with thin, round wafers of silicon crystal, in diameters of 150, 200, and 300mm, the processes described here build up a succession of layers of materials and geometries to produce thousands of electronic devices at tiny sizes, which together function as integrated circuits (ICs). The devices which now occupy the surface of a one-inch square IC would have occupied the better part of a medium-sized room 20 years ago, when all these devices (transistors, resistors, capacitors, and so on) were only available as discreet units.

The conditions under which these processes can work to successfully transform the silicon into ICs require an absolute absence of contaminants. Thus, the process chambers normally operate under vacuum, with elemental, molecular, and other particulate contaminants rigorously controlled. In order to understand these processes, then, we will begin the study of semiconductor processing with an overview of vacuum systems and theory, of gas systems and theory, as applied specifically to these tools, and of clean room processes and procedures.

Generally, the process involves the creation of 8 to 20, and frequently more, patterned layers on (and into) the wafer, ultimately forming the complete integrated circuit. This layering process creates (interconnected) electrically active regions on the semiconductor wafer surface.

Silicon Wafer Manufacturing

Silicon Wafer Manufacturing Semiconductor manufacturing begins with production of the wafer, i.e., a thin, round slice of a semiconductor material varying in size 6 inches to 12 inches in diameter. The finished wafer is approximately 15 mil thick. The materials are primarily silicon; however, gallium arsenide, silicon carbide, germanium and others undergo similar processes. Purified polycrystalline silicon is created from sand, one of the most abundant materials available on our planet, is heated to a molten liquid. In a process similar to repeatedly dipping a wick in wax to make a candle, a small piece of solid silicon (seed) is dipped in molten liquid. As the seed is slowly withdrawn (by mechanical means) from the melt, the liquid quickly cools to form a single crystal ingot.

This cylindrical crystal ingot is then ground to a uniform diameter. A diamond saw blade slices the ingot into thin wafers. The cut wafers are then processed through a series of machines where they are ground (optically) smooth and chemically polished. The wafers are now ready to be sent to the wafer fabrication area fab,where they are used as the foundation for manufacturing integrated circuits (ICs).

The heart of any semiconductor manufacturing business is the fab,where the integrated circuit is formed on the wafer. The fabrication process, which takes place in an environmentally controlled clean room, involves a series of principle repetitive steps described below. Typically, it takes from 10-30 days, and frequently much longer, to complete the fabrication process.

Thermal Oxidation--Wafers are pre-cleaned using high-purity deionized water and various low-particulate chemicals, a must for high-yield production. The silicon wafers are heated to approximately 1000 C and exposed to ultra-pure oxygen in the oxidation furnace. Under carefully controlled conditions, a silicon dioxide insulator film of uniform thickness is formed on the surface of the wafer. Patterning--Masking is used to protect one area of the wafer while working on another. This process is referred to as photolithography. A photo resist, light-sensitive film is spin coated onto the wafer, giving it characteristics similar to a photographic film. A (micro) aligner aligns the wafer to a glass mask and then projects an intense ultraviolet light through the mask, exposing the photo resist with the mask pattern, thereby transferring the image from the mask into the lightsensitive film. Etching--The wafer image is then developed (like a photo negative). The exposed photo resist is chemically removed and baked to harden the remaining photo resist pattern, which now is no longer light sensitive. It is then exposed to a chemical wet solution or plasma (gas discharge) so that areas not covered by the hardened photo resist are etched away. The remaining photo resist is now removed using either wet or plasma chemistry. The wafer is optically inspected to assure that the image transfer from the mask to the top silicon layer is correct, and then goes on to the next step.

Doping/Diffusion--Atoms with one less electron than silicon (such as boron) or one more electron than silicon (such as phosphorus) are introduced into the area exposed by the etch process, to alter the electrical character (conductivity) of the silicon. These areas are called P type or N type, respectively, which reflects their conducting characteristics. Repeating the Above Steps--The thermal oxidation, masking, etching and doping steps are repeated many times until the last "front end" layer is completed (all active devices have been formed). Dielectric Deposition and Metallization--Following completion of the "front end," the individual devices are interconnected "backend" (like on a PC board) using a series of alternating metal depositions, dielectric films, with their respective patterning. Current semiconductor fabrication includes as many as 5 to 7 metal layers for logic, and fewer for memory, separated by dielectric layers (insulators). Passivation--After the last metal is patterned, a final insulating layer (passivation) is deposited to protect the circuit from damage and contamination. Openings are etched in this film to allow access to the top metal later by electrical probes and subsequent wire bonds. Electrical Test--An automatic, computer-driven test system checks for functionality of each chip on the wafer. Chips that do not pass the test are marked for automatic rejection. For simpler devices a mechanical probe is used. Assembly--A diamond saw slices the wafer into single chips. Sizes can vary from 1 x 1 mm to 10 x 10 mm. The rejected chips are discarded and the remaining chips are visually inspected under a high-power microscope before packaging. Each chip is then assembled into an appropriate package that provides the contact leads for the chip. In one type of interconnect a wire bonding machine attaches wires, a fraction of the width of a human hair, to the leads of the package. The packaged chip is tested again prior to delivery to the customer. Alternative, the chip can be assembled in a ceramic package for certain high performance applications.

The Video Below show a complete step by step procedure of wafer Fab Manufacturing.

Detailed steps of Preparation of the Silicon Wafer Media

Wafer products are measured at various stages of the process to identify defects inducted by the manufacturing process. This is done to eliminate unsatisfactory wafer materials from the process stream and to sort the wafers into batches of uniform thickness and at a final inspection stage. These wafers will become the basic raw material for new integrated circuits.

The following is a summary of the steps in a typical wafer manufacturing process.

Crystal Growth and Wafer Slicing Process The first step in the wafer manufacturing process is the formation of a large, perfect silicon crystal. The crystal is grown from a seed crystal that is a perfect crystal. The silicon is supplied in granular powder form, then melted in a crucible. The seed is immersed carefully into the crucible of molten silicon, then slowly withdrawn.

The Czochralski method

Step 1: Obtaining the Sand The sand used to grow the wafers has to be a very clean and good form of silicon. For this reason not just any sand scraped off the beach will do. Most of the sand used for these processes is shipped from the beaches of Australia.

Step 2: Preparing the Molten Silicon Bath The sand (SiO2)is taken and put into a crucible and is heated to about 1600 degrees C just above its melting point. The molten sand will become the source of the silicon that will be the wafer.

Step 3: Making the Ingot A pure silicon seed crystal is now placed into the molten sand bath. This crystal will be pulled out slowly as it is rotated. The dominant technique is known as the Czochralski (cz) method. The result is a pure silicon cylinder that is called an ingot.

Growth of Epitaxial Silicon This step is done to provide a good clean surface for later processing. If a layer of Silicon is grown onto the top of the wafer using chemical methods then that layer is of a much better quality then the slightly

An epitaxial reactor

This step is done to provide a good clean surface for later processing. If a layer of Silicon is grown onto the top of the wafer using chemical methods then that layer is of a much better quality then the slightly damaged or unclean layer of silicon in the wafer. The epitaxial layer is where the actual processing will be done. The diameter of the silicon ingot is determined by the temperature variables as well as the rate at which the ingot is withdrawn. When the ingot is the correct length, it is removed, then ground to a uniform external surface and diameter. Each of the wafers is given either a notch or a flat edge that will be used later in orienting the wafer into the exact position for later procedures. In these two figures you can see a notch (above) and flats. Flats in this image are exaggerated for clarity.

Step 4: Preparing the Wafers After the ingot is ground into the correct diameter for the wafers, the silicon ingot is sliced into very thin wafers. This is usually done with a diamond saw. A diamond saw for cutting wafers Each of these wafers will then go through polishing until they are very smooth and just the right thickness.

Thickness Sorting Following slicing, silicon wafers are often sorted on an automated basis into batches of uniform thickness to increase productivity in the next process step, lapping. During thickness sorting, the wafer manufacturer can also identify defect trends resulting from the slicing process.

Lapping & Etching Processes Lapping removes the surface silicon which has been cracked or otherwise damaged by the slicing process, and assures a flat surface. Wafers are then etched in a chemically active reagent to remove any crystal damage remaining from the previous process step.

Thickness Sorting and Flatness Checking Following lapping or etching, silicon wafers are measured for flatness to identify and control defect trends resulting from the lapping and etching processes. Wafers are also often sorted on an automated basis according to thickness in order to increase productivity in the next process step, polishing.

Polishing Process Polishing is a chemical/mechanical process that smoothes the uneven surface left by the lapping and etching processes and makes the wafer flat and smooth enough to support optical photo lithography

Final Dimensional and Electrical Properties Qualification The wafers undergo a final test, performed in order to demonstrate conformance with customer specification for flatness, thickness, resistivity and type. Process induced defect and defect trend information is used by the wafer manufacturer for yield and process management of the immediately preceding steps. Information regarding surface defects, such as scratches and particles, and defect trend information are used by the wafer manufacturer for yield and process improvement.

Silicon Wafer Processing Steps...Continue in next blog..

Das könnte Ihnen auch gefallen

- 1 Fabrication 20130218 PDFDokument108 Seiten1 Fabrication 20130218 PDFAjay kr PradhanNoch keine Bewertungen

- BioGT Lactase Enzyme Activity Virtual LabDokument5 SeitenBioGT Lactase Enzyme Activity Virtual Labanna rothNoch keine Bewertungen

- 002.0 Surface Sampling TrainingDokument17 Seiten002.0 Surface Sampling TrainingNguyễnTrường100% (1)

- How Semiconductors Are MadeDokument7 SeitenHow Semiconductors Are MadeAshner NovillaNoch keine Bewertungen

- DeviceDokument6 SeitenDeviceChad BahjinNoch keine Bewertungen

- Three CMOS Fabrication VideosDokument5 SeitenThree CMOS Fabrication VideosPhola PatulinNoch keine Bewertungen

- Integrated CircuitsDokument4 SeitenIntegrated CircuitsGurjeet ChahalNoch keine Bewertungen

- Semiconductor Fabrication Lecture NotesDokument11 SeitenSemiconductor Fabrication Lecture NotesJoanna Fabricante100% (1)

- Wafer Production StepsDokument15 SeitenWafer Production StepsmehmetelmaliNoch keine Bewertungen

- Vlsi FabDokument8 SeitenVlsi FabhaheNoch keine Bewertungen

- Fabrication of SemiconductorDokument12 SeitenFabrication of Semiconductorkrish2322100% (1)

- Unit 1Dokument66 SeitenUnit 1srgperumalNoch keine Bewertungen

- Ic FabricationDokument7 SeitenIc FabricationphooolNoch keine Bewertungen

- Steps For IC FabricationDokument4 SeitenSteps For IC FabricationEarnest arujNoch keine Bewertungen

- Part I ADokument206 SeitenPart I AsenthilkumaranvNoch keine Bewertungen

- Electronics-And-Semi-Conductor Manufacturing ProcessDokument55 SeitenElectronics-And-Semi-Conductor Manufacturing ProcessDovah KiinNoch keine Bewertungen

- Steps For IC Manufacturing - VLSI Tutorials - MepitsDokument6 SeitenSteps For IC Manufacturing - VLSI Tutorials - MepitsAbhiNoch keine Bewertungen

- Main Reference Seminar ReportDokument26 SeitenMain Reference Seminar ReportAbid YusufNoch keine Bewertungen

- How Microprocessors Are Manufactured PDFDokument2 SeitenHow Microprocessors Are Manufactured PDFdanielconstantin4Noch keine Bewertungen

- Chapter 5 Fabrication of Microelectronic DevicesDokument35 SeitenChapter 5 Fabrication of Microelectronic Devicesmuhamadsaidi60% (5)

- IC Manufacturing Process: SudhaDokument13 SeitenIC Manufacturing Process: SudhaSudha KNoch keine Bewertungen

- In Order For Silicon To Turn Into A Semiconductor ChipDokument5 SeitenIn Order For Silicon To Turn Into A Semiconductor ChipultrasonicdochNoch keine Bewertungen

- Chapter 5 Fabrication of Microelectronic DevicesDokument26 SeitenChapter 5 Fabrication of Microelectronic Devicesmuhamadsaidi100% (2)

- Fabrication of Ic'sDokument14 SeitenFabrication of Ic'sBhaskar Rao OndruNoch keine Bewertungen

- SedraSmith6e Appendix ADokument17 SeitenSedraSmith6e Appendix Anehalem650Noch keine Bewertungen

- Week 4 - EMIDokument10 SeitenWeek 4 - EMIMuhammad ShahzaibNoch keine Bewertungen

- Aezy Joy T. Lascano Engr. May C. Layson Bsece-5ADokument5 SeitenAezy Joy T. Lascano Engr. May C. Layson Bsece-5AAljon Ticsay LascanoNoch keine Bewertungen

- Introduction To IC Fabrication Techniques-1Dokument5 SeitenIntroduction To IC Fabrication Techniques-1gezaegebre1Noch keine Bewertungen

- Tech Sem Doc ShinyDokument19 SeitenTech Sem Doc Shinyvenu madugulaNoch keine Bewertungen

- Semiconductor Device FabricationDokument33 SeitenSemiconductor Device FabricationMuddaserNoch keine Bewertungen

- CHAPTER 5 - Fundamentals of Solar PV - BMEDokument8 SeitenCHAPTER 5 - Fundamentals of Solar PV - BMEBIJETA KUNWARNoch keine Bewertungen

- Semiconductor Device FabricationDokument35 SeitenSemiconductor Device FabricationAnonymous gUjimJK100% (1)

- Fiber Fabrication: Presented By: Ali Ahmed Usama Presented To: Ma'Am Faiza IftikharDokument20 SeitenFiber Fabrication: Presented By: Ali Ahmed Usama Presented To: Ma'Am Faiza Iftikharkashafnasir9977Noch keine Bewertungen

- Introduction To Integrated Circuit TechnologyDokument45 SeitenIntroduction To Integrated Circuit TechnologyShrikant JagtapNoch keine Bewertungen

- Making Microchips - ComputerworldDokument4 SeitenMaking Microchips - ComputerworldAbhiNoch keine Bewertungen

- Q1) "There Is Aplenty of Room at The Bottom",by Feynman: Method 1Dokument7 SeitenQ1) "There Is Aplenty of Room at The Bottom",by Feynman: Method 1Gopinath ChakrabortyNoch keine Bewertungen

- Types of Solar CellsDokument7 SeitenTypes of Solar CellsDouglas OngomNoch keine Bewertungen

- Introduction To IC FabricationDokument7 SeitenIntroduction To IC FabricationAbhishek DasNoch keine Bewertungen

- 001 Device FabricationDokument60 Seiten001 Device FabricationSerwan BamerniNoch keine Bewertungen

- Video Viewing and Question AnsweringDokument1 SeiteVideo Viewing and Question AnsweringBeverly Ann GonzalesNoch keine Bewertungen

- Ee2254 Lica QBDokument0 SeitenEe2254 Lica QBnjparNoch keine Bewertungen

- Bipolar IC ProcessDokument5 SeitenBipolar IC Processlachuns123Noch keine Bewertungen

- Assignment On Renewable EnergyDokument24 SeitenAssignment On Renewable EnergyHarshil LimbaniNoch keine Bewertungen

- Ic FabricationDokument31 SeitenIc FabricationMukesh Nexus100% (1)

- LIC & ApplicationsDokument92 SeitenLIC & ApplicationsAbhiroop VermaNoch keine Bewertungen

- Voltage Electric Current Light Photoelectric EffectDokument15 SeitenVoltage Electric Current Light Photoelectric EffectKool KingNoch keine Bewertungen

- EE503 Topic 2 HooDokument22 SeitenEE503 Topic 2 HooSasikumar SukumaranNoch keine Bewertungen

- MMICDokument37 SeitenMMICAjay YadavNoch keine Bewertungen

- 104-Article Text-173-1-10-20200206Dokument4 Seiten104-Article Text-173-1-10-20200206Rishav SainiNoch keine Bewertungen

- IC Production Process by PhaniDokument30 SeitenIC Production Process by PhaniPhani HarimanikyamNoch keine Bewertungen

- Manuacturing ProcessDokument7 SeitenManuacturing ProcessMarcelo CardozoNoch keine Bewertungen

- VLSI MID SEM-1 NotesDokument3 SeitenVLSI MID SEM-1 NotesAryanSinghNoch keine Bewertungen

- Thin Film SCDokument6 SeitenThin Film SCalikaya12002Noch keine Bewertungen

- Why Si Better Over Ge SemiconductorDokument3 SeitenWhy Si Better Over Ge Semiconductornishant205kumarNoch keine Bewertungen

- Making of A ProcessorDokument15 SeitenMaking of A ProcessorSprhaa AspirationNoch keine Bewertungen

- Integrated CircuitsDokument43 SeitenIntegrated Circuitsgovardhan50Noch keine Bewertungen

- Microprocessor Manufacturing: Luis E. Garcés PDokument3 SeitenMicroprocessor Manufacturing: Luis E. Garcés Pluis garcésNoch keine Bewertungen

- Tec CmosDokument27 SeitenTec Cmosgovind01Noch keine Bewertungen

- File 1696992905 GUSBAS202131582 L1 SemiconductorWafersDokument5 SeitenFile 1696992905 GUSBAS202131582 L1 SemiconductorWafersÃMĪT KUMAR SINGHNoch keine Bewertungen

- Integrated CircuitDokument51 SeitenIntegrated Circuitparthos100% (1)

- Plasma Etching Processes for Interconnect Realization in VLSIVon EverandPlasma Etching Processes for Interconnect Realization in VLSINicolas PossemeNoch keine Bewertungen

- NCCT - in Plant Training Program Details 2012 - 2013, Ipt Software and Embedded ProgramsDokument2 SeitenNCCT - in Plant Training Program Details 2012 - 2013, Ipt Software and Embedded ProgramsChaitu ChaitanyaNoch keine Bewertungen

- New Microsoft Word DocumentDokument7 SeitenNew Microsoft Word DocumentChaitu ChaitanyaNoch keine Bewertungen

- Letter 3Dokument1 SeiteLetter 3Chaitu ChaitanyaNoch keine Bewertungen

- Rise of PriceDokument27 SeitenRise of PriceHrishikesh.Noch keine Bewertungen

- By T.Radhakrishanan: Elcom DaisDokument1 SeiteBy T.Radhakrishanan: Elcom DaisChaitu ChaitanyaNoch keine Bewertungen

- MatlabDokument11 SeitenMatlabChaitu ChaitanyaNoch keine Bewertungen

- Calander 2012Dokument19 SeitenCalander 2012vharish200Noch keine Bewertungen

- Role of Communications in SmartgridDokument4 SeitenRole of Communications in SmartgridChaitu ChaitanyaNoch keine Bewertungen

- Safety Data Sheet Trans-O-Matic: Product LabelsDokument6 SeitenSafety Data Sheet Trans-O-Matic: Product LabelsizzybjNoch keine Bewertungen

- From Used Cooking Oil To Biodiesel. Full Supply Chain DemonstrationDokument11 SeitenFrom Used Cooking Oil To Biodiesel. Full Supply Chain DemonstrationSteve JenkinsNoch keine Bewertungen

- Astm A333Dokument9 SeitenAstm A333Andres Fitria FarrelNoch keine Bewertungen

- Hydro 2Dokument91 SeitenHydro 2Deeip DNoch keine Bewertungen

- Chains: Never Exceed The Working Load Limit of Your Chains!Dokument7 SeitenChains: Never Exceed The Working Load Limit of Your Chains!Wade SperryNoch keine Bewertungen

- Clinical Applications of Potentiometry Electrogravimetry and Coulometry 1Dokument15 SeitenClinical Applications of Potentiometry Electrogravimetry and Coulometry 1Migs BernalNoch keine Bewertungen

- Basic Neuroanatomical MethodsDokument11 SeitenBasic Neuroanatomical Methods88jnfNoch keine Bewertungen

- General Chemistry 2 Asynchronous Activity 1Dokument7 SeitenGeneral Chemistry 2 Asynchronous Activity 1casinillojilianNoch keine Bewertungen

- Efka 2526: PropertiesDokument2 SeitenEfka 2526: Propertiessriatul2006Noch keine Bewertungen

- The Six KingdomsDokument4 SeitenThe Six KingdomsBasmanNoch keine Bewertungen

- Chem ProjectDokument28 SeitenChem ProjectUtkarsh ShrivastavaNoch keine Bewertungen

- Phase Diagram 2Dokument6 SeitenPhase Diagram 2Mohd AzhamNoch keine Bewertungen

- Bruice Organic Chemistry 6eDokument26 SeitenBruice Organic Chemistry 6esdfasf asdasdasd100% (1)

- Drinking Water MOHDokument3 SeitenDrinking Water MOHNur Amanina OmarNoch keine Bewertungen

- Water Problems Production PDFDokument47 SeitenWater Problems Production PDFJoseJavier ColinaNoch keine Bewertungen

- Tentative Methods of Test For: Amount of Moisture in Textile Materials'Dokument12 SeitenTentative Methods of Test For: Amount of Moisture in Textile Materials'ArshadNoch keine Bewertungen

- Bacillus Mucilaginosus Can Capture Atmospheric CO 2 by Carbonic AnhydraseDokument8 SeitenBacillus Mucilaginosus Can Capture Atmospheric CO 2 by Carbonic AnhydraseDeborah AwoniranNoch keine Bewertungen

- Example of Petrographic ReportDokument3 SeitenExample of Petrographic Reportbinod2500Noch keine Bewertungen

- Purchase Order No. Sales Document PNDokument6 SeitenPurchase Order No. Sales Document PNisanNoch keine Bewertungen

- Lecture 1Dokument32 SeitenLecture 1Sakib AhmedNoch keine Bewertungen

- Theory of Metal CuttingDokument96 SeitenTheory of Metal Cuttingneelesh singh100% (22)

- Electronic NoseDokument10 SeitenElectronic Noseapi-384576580% (5)

- FMRC 1612 Polyvinyl Chloride (PVC) Pipe and Fittings For Underground Fire Protection Service PDFDokument30 SeitenFMRC 1612 Polyvinyl Chloride (PVC) Pipe and Fittings For Underground Fire Protection Service PDFdyıldırım_4Noch keine Bewertungen

- Astm D5453 - 2004Dokument10 SeitenAstm D5453 - 2004Teymur Regenmaister100% (1)

- Manual BombasDokument56 SeitenManual BombasLuis Cespedes NorambuenaNoch keine Bewertungen

- FGP 50/M - FGP 70/M - FGP 100/M - FGP 120/M - FGP 150/M: Light-Oil Burners Two Stages Progressive or ModulatingDokument6 SeitenFGP 50/M - FGP 70/M - FGP 100/M - FGP 120/M - FGP 150/M: Light-Oil Burners Two Stages Progressive or ModulatingEden BenNoch keine Bewertungen

- Effluent TreatmentDokument21 SeitenEffluent TreatmentRadhika AnandkumarNoch keine Bewertungen

- Modeling of Re Oxidation Inclusion Formation in Steel Sand CastingDokument11 SeitenModeling of Re Oxidation Inclusion Formation in Steel Sand CastingpeymanpeymanNoch keine Bewertungen