Beruflich Dokumente

Kultur Dokumente

11 Ok Comparison Leakage Rates API 598 & API 6d

Hochgeladen von

ZoebairOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

11 Ok Comparison Leakage Rates API 598 & API 6d

Hochgeladen von

ZoebairCopyright:

Verfügbare Formate

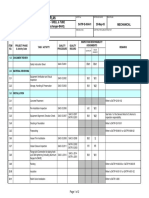

Comparison of Leakage Rates Between API Standard 598 and API Specification 6D / ISO 14313

API Spec. 6D / ISO 14313

API Standard 598

Ob

Obtuator

Ti

Tightness

h

T

Test L

Leakage

k

R

Rate 1) 2)

Rate B

Valve Size

Rate

A

(SoftSeated

Valves)

Leakage Rate

(LR) when

Testing with

Liquid

LR X DN

cc

/min.

M i

Maximum

Allowable

All

bl Leak

L k Rates

R t for

f Closure

Cl

Tests

T t

Rate C

Leakage Rate

(LR) when

Testing with

Gas

LR X DN

cc

/min.

Leakage Rate

(LR) when

Testing with

Liquid

LR X DN

cc

/min.

Leakage Rate

(LR) when

Testing with Gas

LR X DN

cc

/min.

Leakage Rate (LR)

when Testing with

Liquid

Leakage Rate (LR)

when Testing with

Gas

NPS

(in)

DN

1/2

15

0.01

0.27

0.03

2.7

0.09

27

3/4

20

0.01

0.36

0.04

3.6

0.12

36

25

0.02

0.45

0.05

4.5

0.15

45

LR

LR

LR

LR

LR

cc

LR X DN

/min.

Metal-Seated

Check Valves

All Metal-Seated Valves

Rate D

LR

cc

Valve

Size

(NPS)

All

ResilientSeated

Valves

Except Check

Liquid Test

Gas Test

Liquid Test

Gas Test

(drops/min)

cc/min

(bubbles/min)

cc/min

cub.meter of

gas/hour

cub.meter of

gas/min.

1/2

1.50

0.021

0.0004

3/4

2.25

0.032

0.0005

3.00

0.042

0.0007

LR X DN

/min.

1 1/4

3.75

0.053

0.0009

72

1 1/2

4.50

0.063

0.0011

50

0.03

0.90

0.09

9.0

0.30

90

6.00

0.084

0.0014

2 1/2

65

0.04

1.17

0.12

11.7

0.39

117

2 1/2

12

0.75

24

7.50

0.105

0.0018

80

0.05

1.44

0.14

14.4

0.48

144

12

0.75

24

9.00

0.126

0.0021

100

0.06

1.80

0.18

18.0

0.60

180

12

0.75

24

12.00

0.168

0.0028

150

0.09

2.70

0.27

27.0

0.90

270

12

0.75

24

18.00

0.252

0.0042

200

0 12

0.12

3 60

3.60

0 36

0.36

36 0

36.0

1 20

1.20

360

20

1

25

1.25

40

24 00

24.00

0 336

0.336

0 0056

0.0056

10

250

4.50

0.45

45.0

1.50

450

10

20

1.25

40

30.00

0.420

0.0070

12

300

540

12

20

1.25

40

36.00

0.504

0.0084

14

350

630

14

28

1.75

56

42.00

0.588

0.0098

16

400

720

16

28

1.75

56

42.00

0.672

0.0112

18

450

810

18

28

1.75

56

42.00

0.756

0.0126

8.10

0.81

72.0

81.0

1.80

2.10

2.40

2.70

3)

0.72

63.0

0.63

3)

7.20

54.0

30 N

0.27

6.30

0.54

3N

0.24

3)

0.21

5.40

0.18

0.3 N

0.15

0 (No visible leakage

e)

58

0.24

- mm /s X DN

0.19

0.1 mm /s X DN

5.8

7.2

- mm /s X DN

0.06

0.07

0.03 mm /s X DN

0.58

0.72

- mm /s X DN

0.02

0.02

0.01 mm /s X DN

32

40

No visible leakage for the duratiion of the test

1 1/4

1 1/2

0.30

9.00

0.90

90.0

3.00

900

20

28

1.75

56

42.00

0.840

0.0140

0.33

9.90

0.99

99.0

3.30

990

22

28

1.75

56

42.00

0.924

0.0154

0.36

10.80

1.08

108.0

3.60

1080

24

28

1.75

56

42.00

1.008

0.0168

0.39

11.70

1.17

117.0

3.90

1170

26

28

1.75

56

42.00

1.092

0.0182

0.42

12.60

1.26

126.0

4.20

1260

28

28

1.75

56

42.00

1.176

0.0196

0.45

13.50

1.35

135.0

4.50

1350

30

28

1.75

56

42.00

1.260

0.0210

900

0.54

16.20

1.62

162.0

5.40

1620

36

28

1.75

56

42.00

1.512

0.0252

42

1100

0 66

0.66

19 80

19.80

1 98

1.98

198 0

198.0

6 60

6.60

1980

42

28

1 75

1.75

56

42 00

42.00

1 764

1.764

0 0294

0.0294

48

1200

0.72

21.60

2.16

216.0

7.20

2160

48

28

1.75

56

42.00

2.016

0.0336

54

1400

0.84

25.20

2.52

252.0

8.40

2520

54

28

1.75

56

42.00

2.268

0.0378

60

1500

0.90

27.00

2.70

270.0

9.00

2700

60

28

1.75

56

42.00

2.520

0.0420

20

500

22

550

24

600

26

650

28

700

30

750

36

a For liquid test, 1 milliliter (1 cc) is considered equivalent to 16 drops.

1)

The obtuator tightness test leakage rate to be used for each valve type shall

be used as specified in the valve product standard.

The minimum duration for obturator tightness tests shall be in

accordance with API Spec. 6D / ISO 14313.

2)

These leakage rate only apply when discharging to the atmosphere.

Liquid : Water which may contain a corrosion inhibitor,

kerosene, or other suitable liquid having a viscosity not greater

than that of water.

d The maximum permisible leakage rate shall be 1.5 standard cubic feet (0.042 cubic meter) of gas per hour per inch of nominal pipe size.

3)

N = standard test conditions.

Gas : air or other suitable gas.

e For check valves larger than NPS 24, the allowable leak rate shall be per agreement between purchaser and manufacturer.

b There shall be no leakage for the minimum specified test duration (see Table 4.). For liquid test, 0 drops means no visible leakage per minimum specified test duration.

For gas test, 0 bubble means less than 1 bubble per minimum specified test duration.

Notes

c The maximum permisible leakage rate shall be 0.18 cubic inch (3 cubic centimeters) per minute per inch of nominal pipe size.

Das könnte Ihnen auch gefallen

- Pt. Pertamina Ep Asset 3 Field Jatibarang: Calculation SheetDokument2 SeitenPt. Pertamina Ep Asset 3 Field Jatibarang: Calculation Sheetrobiansah100% (1)

- Inspection & Test Plan For Nozzle Replacement On VS ShellDokument1 SeiteInspection & Test Plan For Nozzle Replacement On VS ShellQC Taner 453100% (2)

- NBIC Part 2 PDFDokument12 SeitenNBIC Part 2 PDFjhonjimenez87Noch keine Bewertungen

- PFI ES 2 2000 Method of Dimensioning Piping AssembliesDokument4 SeitenPFI ES 2 2000 Method of Dimensioning Piping AssembliesedwinNoch keine Bewertungen

- 1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Dokument2 Seiten1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Anonymous S9qBDVkyNoch keine Bewertungen

- Torque Tables For Spiral Wound Gaskets, ASME B16.5: Class 150Dokument2 SeitenTorque Tables For Spiral Wound Gaskets, ASME B16.5: Class 150akalp1005Noch keine Bewertungen

- AnsiDokument4 SeitenAnsiHendrie NMcNoch keine Bewertungen

- ADG001Dokument80 SeitenADG001faisalqrNoch keine Bewertungen

- Saudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Dokument1 SeiteSaudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Mohammed Hamed BaganNoch keine Bewertungen

- ASME Pressure and Leak TestingDokument4 SeitenASME Pressure and Leak TestingBohdan100% (1)

- BPVC - VIII-1 - U-2A FormDokument2 SeitenBPVC - VIII-1 - U-2A FormPranesh BhatNoch keine Bewertungen

- Agenda Item: 650-2024: Coating Prior To Hydrostatic TestingDokument4 SeitenAgenda Item: 650-2024: Coating Prior To Hydrostatic Testinggigiphi1Noch keine Bewertungen

- Guide FOR Asme Review Teams FOR Review of Applicants FOR Asme Certificates of Authorization (A, M, PP, S, E, H, HLW, U, UM, U2, U3, PRT and T)Dokument16 SeitenGuide FOR Asme Review Teams FOR Review of Applicants FOR Asme Certificates of Authorization (A, M, PP, S, E, H, HLW, U, UM, U2, U3, PRT and T)Adam GrajewskiNoch keine Bewertungen

- PY SEW Do P T: Pipe Wall Thickness Calculation SheetDokument1 SeitePY SEW Do P T: Pipe Wall Thickness Calculation Sheetanon_714194540Noch keine Bewertungen

- Radiographic Requirements On Api 650tanksDokument1 SeiteRadiographic Requirements On Api 650tankssbmmlaNoch keine Bewertungen

- Calculation Sheet API - 510: Pressure VesselDokument5 SeitenCalculation Sheet API - 510: Pressure Vesselah1525Noch keine Bewertungen

- Asme Sec V-2013 3Dokument1 SeiteAsme Sec V-2013 3dhasdj100% (1)

- ASTM E 1066 - 95 Standard Practice For Ammonia Colorimetric Leak Testing PDFDokument5 SeitenASTM E 1066 - 95 Standard Practice For Ammonia Colorimetric Leak Testing PDFАртем ТитовNoch keine Bewertungen

- Form U-1ADokument2 SeitenForm U-1ADanDeMarcoNoch keine Bewertungen

- Open Book Testing - API 653Dokument9 SeitenOpen Book Testing - API 653EdisonCorderoNoch keine Bewertungen

- Cement-Mortar Lined & Coated Steel PipeDokument5 SeitenCement-Mortar Lined & Coated Steel Pipenay denNoch keine Bewertungen

- API 576 - Pressure GaugeDokument1 SeiteAPI 576 - Pressure GaugearianaseriNoch keine Bewertungen

- 01-B. - API STD 510 10th Ed (May 2014) + (Addendum 2 March 2018)Dokument3 Seiten01-B. - API STD 510 10th Ed (May 2014) + (Addendum 2 March 2018)PelifullHDNoch keine Bewertungen

- Satr W 2012Dokument1 SeiteSatr W 2012Mohammed Hamed BaganNoch keine Bewertungen

- Procedure Manual: Cast Valve ProductionDokument10 SeitenProcedure Manual: Cast Valve ProductionParveen Kohli0% (1)

- How To Select ElectrodeDokument2 SeitenHow To Select Electrodesbmmla100% (1)

- API 6D QuestionnaireDokument5 SeitenAPI 6D Questionnaireshridhar0% (1)

- When Should Category M Fluid Service Be Selected For ASME B31Dokument2 SeitenWhen Should Category M Fluid Service Be Selected For ASME B31gpskumar22Noch keine Bewertungen

- API 598 Testing Procedure-20130720-032647Dokument2 SeitenAPI 598 Testing Procedure-20130720-032647JOMAGUES100% (1)

- ASME B31.4 Pipeline Transportation Systems For Liquid HydrocarbonsDokument1 SeiteASME B31.4 Pipeline Transportation Systems For Liquid HydrocarbonsAmrit Sarkar100% (1)

- Tank Selection COde - API 650Dokument2 SeitenTank Selection COde - API 650Suresh Yadav0% (1)

- Rstreng PDFDokument5 SeitenRstreng PDFwellyNoch keine Bewertungen

- Useful Information For The Valve IndustryDokument9 SeitenUseful Information For The Valve Industryhummingbird4uNoch keine Bewertungen

- Minimum Distance Between Two Circumferential PipeDokument7 SeitenMinimum Distance Between Two Circumferential PipeAbdulrahmanNoch keine Bewertungen

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptDokument13 SeitenJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNoch keine Bewertungen

- Manual Weldoffice PDFDokument51 SeitenManual Weldoffice PDFAnonymous wKvJXBJ2iNoch keine Bewertungen

- Asme b16 48 2005 Juntas Ciegas PDFDokument50 SeitenAsme b16 48 2005 Juntas Ciegas PDFNguyen HaiNoch keine Bewertungen

- Piping Material Service IndexDokument3 SeitenPiping Material Service IndexOghenekevwe OrumahNoch keine Bewertungen

- Asme PCC-2 - 2022 HighlightedDokument112 SeitenAsme PCC-2 - 2022 HighlightedAhmed Shakir67% (3)

- Process Industry Practices PipingDokument5 SeitenProcess Industry Practices Pipingabdo samadNoch keine Bewertungen

- Low Pressure Gas Piping Pressure Loss CalculationDokument1 SeiteLow Pressure Gas Piping Pressure Loss CalculationJohn ANoch keine Bewertungen

- Inspection of Storage TankDokument19 SeitenInspection of Storage TanknovazhaiNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument6 SeitenSaudi Aramco Inspection ChecklistAnonymous 4e7GNjzGWNoch keine Bewertungen

- Electrode Consumption On Pipe WeldingDokument2 SeitenElectrode Consumption On Pipe Weldinganjangandak2932100% (1)

- Integrity Testing Above Ground Storage TanksDokument39 SeitenIntegrity Testing Above Ground Storage TanksOlivier RioNoch keine Bewertungen

- API Repair ProcedureDokument1 SeiteAPI Repair ProcedurejacquesmayolNoch keine Bewertungen

- ASME B 31.3 2016 Process PipingDokument30 SeitenASME B 31.3 2016 Process Pipingr.devendran25% (4)

- Pressure Vessel Dimension InspectionDokument3 SeitenPressure Vessel Dimension InspectionAnas Sarkiah0% (1)

- FittingsDokument50 SeitenFittingsashokNoch keine Bewertungen

- API 660 Vs TEMADokument2 SeitenAPI 660 Vs TEMAloqNoch keine Bewertungen

- Progress Tracking Sheet-Piping Fabrication: Enter % Complete For Each Work StepDokument1 SeiteProgress Tracking Sheet-Piping Fabrication: Enter % Complete For Each Work StepMohamed AtefNoch keine Bewertungen

- 23 Tecnimont ChiaruttiniDokument16 Seiten23 Tecnimont ChiaruttiniRsn786Noch keine Bewertungen

- Flange Inspection Procedure - Applus (NXPowerLite)Dokument6 SeitenFlange Inspection Procedure - Applus (NXPowerLite)ndt_inspectorNoch keine Bewertungen

- Manhole. API 650-2021Dokument3 SeitenManhole. API 650-2021jose luisNoch keine Bewertungen

- 10 Ok Leakage Rates API 6d and Iso 14313Dokument0 Seiten10 Ok Leakage Rates API 6d and Iso 14313ZoebairNoch keine Bewertungen

- Api-598-En-12266-1 Seat LeakDokument2 SeitenApi-598-En-12266-1 Seat Leakelumalai24100% (10)

- Valve Testing StandardsDokument2 SeitenValve Testing StandardsPrashant Puri0% (1)

- Seat Leakage Article Valve WorldDokument2 SeitenSeat Leakage Article Valve WorldjshadwanNoch keine Bewertungen

- Sec-9-Line Size & Thickness-NewDokument22 SeitenSec-9-Line Size & Thickness-NewkusdiyantaNoch keine Bewertungen

- 2-TWO Phase Separator Design Guide by Manish ShahDokument62 Seiten2-TWO Phase Separator Design Guide by Manish Shahdennis_ugarteNoch keine Bewertungen

- Structures and Mechanisms ClassificationsDokument1 SeiteStructures and Mechanisms ClassificationsminakirolosNoch keine Bewertungen

- 90 Series (ET1590) InstructionsDokument24 Seiten90 Series (ET1590) InstructionsZoebairNoch keine Bewertungen

- TurbinesDokument19 SeitenTurbinesSamarakoon BandaNoch keine Bewertungen

- Appendix B - 20100903 - 145453Dokument25 SeitenAppendix B - 20100903 - 145453AkoKhalediNoch keine Bewertungen

- Spring-Supported Thrust BearingsDokument4 SeitenSpring-Supported Thrust BearingsZoebairNoch keine Bewertungen

- International Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsDokument9 SeitenInternational Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsZoebairNoch keine Bewertungen

- Installation and Operating Procedures: Manual Grease InterceptorsDokument8 SeitenInstallation and Operating Procedures: Manual Grease InterceptorsZoebairNoch keine Bewertungen

- Quality Conference TTL KUDokument6 SeitenQuality Conference TTL KUZoebairNoch keine Bewertungen

- Type of ThreadDokument13 SeitenType of ThreadVils ArabadzhievaNoch keine Bewertungen

- ENZX TechDokument30 SeitenENZX TechZoebairNoch keine Bewertungen

- Ratle Enm Reply Tecnical Prebid Points 080212Dokument42 SeitenRatle Enm Reply Tecnical Prebid Points 080212ZoebairNoch keine Bewertungen

- Construction Specification 71-Water Control Gates: Instructions For UseDokument2 SeitenConstruction Specification 71-Water Control Gates: Instructions For UseZoebairNoch keine Bewertungen

- 1 12 (End)Dokument17 Seiten1 12 (End)ZoebairNoch keine Bewertungen

- 1 Technical Data Sheets TurbineDokument7 Seiten1 Technical Data Sheets TurbineZoebairNoch keine Bewertungen

- 1 - Layout of H-FrancisDokument1 Seite1 - Layout of H-FrancisZoebairNoch keine Bewertungen

- Calculate The Number of Extinguishers Needed in A BuildingDokument3 SeitenCalculate The Number of Extinguishers Needed in A BuildingZoebairNoch keine Bewertungen

- CA6NMDokument2 SeitenCA6NMjoene3Noch keine Bewertungen

- Indigenous ManufacturersDokument6 SeitenIndigenous ManufacturersZoebairNoch keine Bewertungen

- Solutions EngDokument6 SeitenSolutions EngZoebairNoch keine Bewertungen

- 8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0Dokument1 Seite8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0ZoebairNoch keine Bewertungen

- Load AcceptanceDokument2 SeitenLoad AcceptanceZoebairNoch keine Bewertungen

- PJPR0 V 200 Ucturing 0 Data 0 SheetDokument3 SeitenPJPR0 V 200 Ucturing 0 Data 0 SheetZoebairNoch keine Bewertungen

- Scada SystemDokument1 SeiteScada SystemZoebairNoch keine Bewertungen

- Datasheet TurbineDokument2 SeitenDatasheet TurbineZoebairNoch keine Bewertungen

- PJPR0 V 200 Ucturing 0 Data 0 SheetDokument3 SeitenPJPR0 V 200 Ucturing 0 Data 0 SheetZoebairNoch keine Bewertungen

- Hy 25 ValvesDokument3 SeitenHy 25 ValvesZoebairNoch keine Bewertungen

- Hy 25 ValvesDokument3 SeitenHy 25 ValvesZoebairNoch keine Bewertungen

- CEE 331: Fluid Mechanics, Homework Set 2, SolutionsDokument7 SeitenCEE 331: Fluid Mechanics, Homework Set 2, SolutionsZoebairNoch keine Bewertungen

- 3DS Net OrthoGen For Intergraph CADWorx Plant ProfessionalDokument2 Seiten3DS Net OrthoGen For Intergraph CADWorx Plant ProfessionalThanadkitBunkaewNoch keine Bewertungen

- 3 Tables Friction Loss AquacultureDokument10 Seiten3 Tables Friction Loss AquacultureZoebairNoch keine Bewertungen

- User Manual SteadyControlDokument57 SeitenUser Manual SteadyControlrobiny100% (2)

- KampasDokument1 SeiteKampasSamer aneNoch keine Bewertungen

- Mba Cet 2018Dokument2 SeitenMba Cet 2018Aarav AroraNoch keine Bewertungen

- Resume Executive Summary ExampleDokument5 SeitenResume Executive Summary ExampleSathish GunasekarNoch keine Bewertungen

- SB658Dokument3 SeitenSB658ricardo novoa saraviaNoch keine Bewertungen

- Fastcap 22 630v PDFDokument1 SeiteFastcap 22 630v PDFDarrenNoch keine Bewertungen

- Ar10 Jig Instructions PDFDokument5 SeitenAr10 Jig Instructions PDFterrencebelles100% (2)

- CFD Analysis of Free Cooling of Modular Data CentersDokument4 SeitenCFD Analysis of Free Cooling of Modular Data CentersEmad AbdelsamadNoch keine Bewertungen

- Dometic RM4185 6405 PDFDokument20 SeitenDometic RM4185 6405 PDFcarlosrei2Noch keine Bewertungen

- Web Content Management SystemsDokument30 SeitenWeb Content Management SystemsTharmi KNoch keine Bewertungen

- Est-Pergola Octogonal 21-03-2022Dokument1 SeiteEst-Pergola Octogonal 21-03-2022Victor MuñozNoch keine Bewertungen

- 1-Introduction To Process ControlDokument30 Seiten1-Introduction To Process ControlRazif Metta100% (4)

- Document 1Dokument14 SeitenDocument 1bismarckandresNoch keine Bewertungen

- AS9104 2A Form-CDokument3 SeitenAS9104 2A Form-C44abcNoch keine Bewertungen

- SAP Lot Sizing ParameterDokument1 SeiteSAP Lot Sizing ParameterWilliam HolidiNoch keine Bewertungen

- Task 3.a-WordDokument22 SeitenTask 3.a-WordVenkata jahnavi PunatiNoch keine Bewertungen

- Giving Constructive Feedback Training Course OutlineDokument3 SeitenGiving Constructive Feedback Training Course OutlineJeeNoch keine Bewertungen

- Blender 04Dokument38 SeitenBlender 04Ana Maria100% (1)

- Plasma TV SMPS TroubleshoutingDokument5 SeitenPlasma TV SMPS TroubleshoutingmindjokerNoch keine Bewertungen

- ABB REL5xx RIOConverterDokument10 SeitenABB REL5xx RIOConverterzinab90100% (1)

- Pawan Kumar Dubey: ProfileDokument4 SeitenPawan Kumar Dubey: Profilepawandubey9Noch keine Bewertungen

- Sony Blitz h36 - ManualDokument212 SeitenSony Blitz h36 - ManualBohorc Ivica JerryNoch keine Bewertungen

- Factors Affecting Beam StrengthDokument2 SeitenFactors Affecting Beam StrengthkalpanaadhiNoch keine Bewertungen

- MagnetostictiveDokument17 SeitenMagnetostictivekanikasharma22Noch keine Bewertungen

- Software Project Engineer in Richland Kennewick Pasco WA Resume Robert VeklotzDokument2 SeitenSoftware Project Engineer in Richland Kennewick Pasco WA Resume Robert VeklotzRobertVeklotzNoch keine Bewertungen

- A Transactive Energy Future PDFDokument6 SeitenA Transactive Energy Future PDFGilberto CastrejeNoch keine Bewertungen

- BSBPMG531 - Assessment Task 3 v2Dokument19 SeitenBSBPMG531 - Assessment Task 3 v2Felipe ParadaNoch keine Bewertungen

- Manual ArchicadDokument67 SeitenManual ArchicadkhajaimadNoch keine Bewertungen

- Iare WCN Tutorial Question BankDokument7 SeitenIare WCN Tutorial Question BankVigneshNoch keine Bewertungen

- Software: Measurlink Is An Easy-To-Use, Windows-Based Family of Quality Data Management Software ApplicationsDokument8 SeitenSoftware: Measurlink Is An Easy-To-Use, Windows-Based Family of Quality Data Management Software ApplicationsBrandi DaleNoch keine Bewertungen