Beruflich Dokumente

Kultur Dokumente

259 Seriesc Helicalworm

Hochgeladen von

HEMANTKHERAOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

259 Seriesc Helicalworm

Hochgeladen von

HEMANTKHERACopyright:

Verfügbare Formate

7

GEARED DRIVES (EUROPEAN MOUNTING)

(a) Absorbed Power

EXAMPLE

Calculate absorbed power (kW) to drive

designated machine P.

A Series C motorised shaft mounted gear

unit is required for a uniformly loaded

conveyor which absorbs 5.7 kW at 46 rev/

min when running for up to 16 hours/day

during which it stops and starts 8 times.

(b) Absorbed Torque

Determine the absorbed torque and speed

required by the driven machine. If the

required output torque is not known it can be

calculated using the following formula:

T = P x 9550

N2

T = required output torque (Nm)

P = absorbed power (kW)

N2 = machine speed (rev/min)

Section

Fenner Series C Motorised Selection

(d) Closest motor power above 5.7kW is

7.5kW and the nearest available speed is

46 rev/min.

(e) First unit with output torque in excess

of 1183 Nm is capable of 1424 Nm and has

a maximum service factor of 1.37.

(a) Absorbed power is 5.7kW

(b) Torque = 5.7 x 9550 = 1183 Nm

Service factor exceeds 1.25 from step (c)

therefore read across to unit selection

column for product code, 875A1156.

46

(c) From table 1 service factor is 1.25.

(f) From column 5 the overhung load

capacity is 37565 N. If an indirect drive is

tted calculate the load using the formula

on page 188 and compare it with this value.

The machine stops and starts only 8 times

a day therefore an additional stop/start

factor is not required.

(g) Shaft diameter needs to be 70 mm.

(c) Service Factor

From Table 1 select the Mechanical Service

Factor (Fm) applicable to the drive.

Refer to the selection tables and choose

motor power closest above the required

absorbed power then nd the nearest

available output speed to that required.

Ensure it has sufcient output torque, if not,

move to next motor size.

(e) Unit Selection

At the selected output speed read

downwards to the rst unit with an output

torque in excess of the absorbed torque from

step (b).

Read across to column 3 and check if the

maximum service factor exceeds the value

from step (c).

If maximum service factor equals or

exceeds the value from step (c) read across

to unit selection column, this gives the

relevant product code.

If the value from step (c) exceeds the

maximum service factor read down to the

rst service factor to equal or exceed the

value from step (c) and read across to the

unit selection column.

(f) Overhung Loads

If the unit is to be tted with an output shaft

and an indirect drive attached to the shaft,

calculate the overhung load value using the

formula on page 188 and compare this value

with the maximum allowable value given in

column 5 of the selection tables. If the value

exceeds the maximum allowed, then either

re-design the indirect drive or select a larger

unit capable of supporting the overhung load.

(g) Shaft Mounted

Types of Driven Machine

under 3

3 to 10

over 10

0.80

1.00

1.25

1.00

1.25

1.50

1.50

1.75

2.00

Uniform Loads

Agitators and Mixers liquid or semi-liquid

Blowers centrifugal

Bottling Machines

Conveyors and Elevators uniformly loaded

Cookers

Laundry Washing Machines non-reversing

Line Shafts

Pumps centrifugal and gear

Wire Drawing Machines

Moderate Shock Loads

Agitators and Mixers variable density

Conveyors not uniformly loaded

Cranes, travel motion and hoisting

Drawbench

Feeders pulsating load

Hoists

Kilns

Laundry Tumblers

Lifts

Pumps reciprocating with 3 or more cylinders

Pulp and Paper Making Machinery

Rubber Mixers and Calenders

Screens rotary

Textile Machinery

Heavy Shock Loads

Brick Presses

Briquetting Machines

Conveyors reciprocating and shaker

Crushers

Feeders reciprocating

Hammer Mills

Pumps reciprocating, 1 or 2 cylinders

Rubber Masticators

Screens vibrating

For High Inertia Applications, consult your authorised distributor for verication of selection

* See page 252 for notes on reducing service factors

TABLE 2 - STARTING SERVICE FACTOR FS

From the relevant dimension pages determine

the required machine shaft diameter.

NOTE:

Operational hours per day

Start/stops per hour

Factor Fs

Up to 1

10

40

60

>200

1.00

1.03

1.06

1.10

1.15

1.20

(i) The output speeds in the selection table

assume nominal motor speeds. In order to

determine the exact output speeds of the

unit refer to the motor details on page 251.

(ii) For exact ratios of series C units refer to

page 186.

Drive Design & Maintenance Manual - 2006

175

(EURO MOUNT)

(d) Motor Power

TABLE 1 - MECHANICAL SERVICE FACTOR FM

GEARED DRIVES

If the unit is to be subjected to frequent

stop/starts in excess of 10 times per day then

multiply factor Fm by Factor Fs from table 2.

GEARED DRIVES (EUROPEAN MOUNTING)

Fenner Series C Motorised Selection

Bold print denotes triple reduction gearbox. Higher ratios availableconsult your local Authorised Distributor

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

Unit

Selection

Overhung

Load

N

870A0102

870A0202

870A0302

870A0402

870A0502

870A0602

870A0702

870A0802

870A0902

870A1002

870A1102

870A1202

870A1302

870A1402

870A1502

870A1602

870A1702

870A1802

871A1802

870A1902

871A1902

870A2002

871A2002

870A2102

871A2102

870A2202

871A2202

872A2202

870A2302

871A2302

872A2302

870A2402

871A2402

870A2502

871A2502

872A2502

871A4502

870A4602

871A4602

872A2602

870A2602

871A2602

871A4702

872A2702

873A2702

871A2702

873A4802

872A4902

871A5002

873A4902

872A5002

873A5002

874A5102

871A5102

872A5102

873A5102

874A5202

872A5202

873A5202

875A5302

872A5302

873A5302

872A5402

873A5402

874A5402

872A5502

873A5502

874A5502

873A5602

874A5602

873A5702

874A5702

2858

2857

2857

2857

2856

2856

2856

2856

2855

2855

2844

2844

2844

2841

2831

2841

2830

2825

5284

2818

5284

2825

5287

2816

5285

2801

5280

7438

2796

5278

7438

2801

5278

2796

5280

7436

5278

2780

5271

7433

2770

5271

5271

7437

11852

5261

11830

7430

5250

11728

7432

11828

28143

5240

7428

11828

27930

7421

11704

29161

7416

11661

7421

11707

29152

7420

11707

29152

11600

29130

11500

29116

0.18KW MOTOR

158

117

103

91

83

71

66

62

54

48

40

37

35

30

26

24

21

18

18

17

17

16

16

13

13

12

12

12

11

11

11

10

10

8.7

8.7

8.6

7.2

6.8

6.8

6.5

6.3

6.3

6.0

5.7

5.7

5.5

5.2

4.7

4.5

4.5

4.4

4.2

4.0

3.8

3.7

3.7

3.7

3.4

3.4

3.3

3.0

3.0

2.7

2.7

2.7

2.4

2.4

2.4

1.8

1.8

1.6

1.6

176

8

12

13

15

14

19

20

19

22

25

33

31

34

44

52

47

54

71

72

79

80

71

73

82

84

108

108

107

122

123

121

113

116

124

127

133

176

153

157

174

168

172

178

196

206

194

265

273

237

297

246

275

330

275

286

297

384

374

390

429

425

440

394

419

479

435

469

522

610

701

688

784

9.03

7.30

6.67

6.09

5.83

5.11

4.84

4.77

4.36

4.02

3.38

3.39

3.22

2.72

2.44

2.51

2.29

2.00

2.84

1.85

2.39

1.94

3.11

1.73

2.77

1.20

1.20

3.23

1.03

1.03

3.19

1.32

1.32

1.20

2.02

3.61

1.13

0.97

1.75

2.76

0.88

1.20

1.55

2.45

3.71

1.03

2.89

1.42

1.17

2.57

1.95

2.78

3.84

1.00

1.67

2.57

3.49

1.02

1.96

3.12

0.90

1.74

1.21

1.83

2.65

1.10

1.63

2.43

1.25

1.80

1.11

1.61

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

Unit

Selection

Overhung

Load

N

870A0106

870A0206

870A0306

870A0406

870A0506

870A0606

870A0706

870A0806

870A0906

870A1006

870A1106

870A1206

871A1206

870A1306

871A1306

870A1406

871A1406

870A1506

871A1506

870A1606

871A1606

870A1706

871A1706

871A1806

872A1806

870A1806

870A1906

871A1906

872A1906

870A2006

871A2006

870A2106

871A2106

872A4006

870A2206

870A4106

871A2206

871A4106

872A2206

872A4106

870A4206

871A4206

872A2306

872A4206

873A2306

870A2406

870A4306

871A2406

872A2406

870A2506

871A2506

872A2506

873A4406

873A4506

872A4506

872A4606

873A2606

871A2606

872A2606

872A2706

873A2706

874A4806

872A4806

873A4806

874A4906

872A4906

873A4906

872A5006

873A5006

874A5006

874A5106

872A5106

873A5106

2856

2855

2854

2854

2853

2852

2852

2852

2849

2849

2837

2837

5286

2837

5286

2831

5285

2821

5281

2831

5283

2818

5281

5277

7437

2808

2804

5277

7436

2808

5284

2800

5279

7433

2780

2780

5269

5268

7435

7430

2790

5271

7436

7427

11838

2780

2780

5269

7436

2770

5264

7431

11817

11796

7427

7430

11817

5250

7425

7434

11796

29152

7424

11748

29143

7419

11644

7424

11744

28013

26909

7214

11744

0.25KW MOTOR

159

118

104

92

84

72

66

62

54

48

41

38

38

35

35

30

30

26

26

24

24

21

21

19

19

18

17

17

17

16

16

13

13

13

12

12

12

12

12

12

11

11

11

11

11

10

10

10

10

8.9

8.7

8.7

8.2

7.6

7.5

7.0

6.5

6.3

6.3

5.7

5.7

5.6

5.2

5.2

5.1

4.7

4.7

4.4

4.4

4.4

4.1

3.8

3.8

Drive Design & Maintenance Manual - 2006

12

16

18

21

20

27

28

27

31

34

46

43

44

47

47

62

61

72

71

66

66

75

74

98

99

99

110

109

111

99

99

115

114

137

149

151

147

154

145

156

138

142

164

151

173

151

148

156

162

169

172

181

234

253

243

222

252

233

235

265

280

354

335

360

386

372

404

335

374

422

449

390

404

6.64

5.37

4.90

4.48

4.29

3.76

3.56

3.51

3.21

2.95

2.49

2.49

3.98

2.37

3.78

2.00

3.35

1.79

2.92

1.85

2.96

1.69

2.70

2.09

3.83

1.47

1.36

1.76

3.45

1.43

2.29

1.27

2.04

2.91

0.88

0.98

0.88

1.31

2.70

2.55

1.07

1.68

2.34

3.25

3.05

0.97

1.00

1.61

2.97

0.88

1.46

2.65

3.27

3.02

1.61

2.16

3.03

0.88

2.04

1.82

2.73

3.78

1.16

2.12

3.46

1.04

1.89

1.44

2.05

3.01

2.82

1.24

1.89

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

3.7

522

2.56

3.5

530

1.44

3.3

584

2.29

3.0

599

1.28

2.8

535

0.90

2.8

651

1.95

2.7

569

1.34

2.6

710

1.79

2.4

637

1.20

1.9

953

1.32

1.7

1066

1.18

Unit

Selection

874A5206

873A5206

874A5306

873A5306

872A5406

874A5406

873A5406

874A5506

873A5506

874A5606

874A5706

Overhung

Load

N

26449

11592

29117

11500

7400

29096

11600

29096

11600

29048

29018

870A0108

870A0208

870A0308

870A0408

870A0508

870A0608

870A0708

870A0808

871A0808

870A0908

871A0908

870A1008

871A1008

870A1108

871A1108

870A1208

871A1208

870A1308

871A1308

870A1408

871A1408

870A1508

871A1508

870A1608

871A1608

870A1708

871A1708

870A1808

871A1808

872A1808

870A1908

871A1908

872A1908

873A1908

870A2008

871A2008

872A2008

871A2108

872A2108

871A4008

872A2208

872A4008

873A2208

871A4108

872A4108

871A4208

872A2308

872A4208

873A2308

871A2408

871A4308

872A2408

872A4308

873A2408

873A2508

872A2508

874A4408

871A2508

872A4408

873A4408

874A4508

2852

2850

2849

2849

2847

2844

2844

2844

5286

2840

5284

2840

5284

2826

5280

2826

5282

2826

5282

2815

5282

2805

5274

2815

5278

2799

5274

2780

5266

7434

2780

5266

7432

11909

2780

5280

74342

5270

7429

5255

7432

7427

11797

5249

7422

5255

7434

7424

11780

5250

5250

7434

7422

11780

11780

7424

29139

5240

7416

11741

29145

0.37KW MOTOR

161

119

105

92

84

72

67

63

63

56

56

49

49

41

41

38

38

35

35

30

30

26

26

25

25

21

21

19

19

19

17

17

17

17

16

16

16

14

14

13

13

13

13

12

12

11

11

11

11

10

10

10

10

10

8.9

8.8

8.8

8.7

8.7

8.2

8.2

18

24

27

30

30

39

41

39

41

45

46

50

52

67

68

63

65

68

70

90

91

104

105

96

98

108

110

143

145

147

159

161

165

171

143

146

159

169

171

200

215

204

230

228

232

210

243

219

257

232

225

240

235

257

279

268

340

255

309

346

361

4.49

3.63

3.31

3.03

2.90

2.54

2.41

2.37

3.78

2.17

3.47

2.00

3.21

1.68

2.82

1.68

2.69

1.60

2.55

1.35

2.26

1.21

1.97

1.25

2.00

1.14

1.82

0.99

1.41

2.59

0.92

1.19

2.33

3.55

0.97

1.54

3.00

1.38

2.82

1.02

1.82

1.96

2.74

0.89

1.72

1.14

1.58

2.19

2.06

1.09

1.09

2.00

2.05

2.97

2.74

1.79

3.94

1.00

1.28

2.21

3.71

GEARED DRIVES (EUROPEAN MOUNTING)

872A4508

873A4508

874A4608

871A4608

872A4608

872A2608

873A2608

874A4708

872A4708

872A2708

873A2708

874A4808

873A4808

874A4908

873A4908

872A5008

874A5008

873A5008

874A5108

872A5108

873A5108

874A5208

873A5208

874A5308

874A5408

874A5508

874A5808

Overhung

Load

N

7416

11701

29145

5230

7422

7412

11741

29127

7416

7430

11701

29109

11609

29091

11500

7410

26917

11600

24796

7390

11600

23910

11400

29041

29001

29001

28909

870A0116

870A0216

870A0316

871A0316

870A0416

871A0416

870A0516

871A0516

870A0616

871A0616

870A0716

871A0716

870A0816

871A0816

870A0916

871A0916

870A1016

871A1016

872A1116

870A1116

871A1116

872A1216

870A1216

871A1216

870A1316

871A1316

872A1316

870A1416

871A1416

872A1416

870A1516

871A1516

872A1516

870A1616

871A1616

872A1616

871A1716

872A1716

873A1716

871A1816

872A1816

873A1816

874A1916

871A1916

872A1916

2847

2844

2841

5283

2841

5285

2838

5283

2833

5283

2833

5283

2833

5283

2825

5280

2825

5280

7440

2809

5274

7440

2809

5276

2809

5276

7440

2890

5276

7440

2880

5262

7440

2890

5269

7440

5262

7440

11896

5250

7431

11844

29200

5250

7426

0.55KW MOTOR

164

121

107

107

94

94

86

86

74

74

68

68

64

64

56

56

50

50

42

42

42

40

39

39

36

36

36

31

31

31

27

27

27

25

25

25

21

21

21

19

19

19

19

17

17

26

35

39

40

45

46

44

45

57

58

61

62

58

60

66

67

74

76

99

98

99

98

93

95

100

102

110

132

133

141

153

155

152

140

143

147

162

165

180

213

215

230

243

236

241

3.06

2.47

2.26

3.76

2.07

3.45

1.98

3.17

1.73

2.88

1.64

2.74

1.62

2.58

1.48

2.37

1.36

2.19

3.44

1.15

1.92

3.85

1.15

1.83

1.09

1.74

3.51

0.92

1.54

2.71

0.83

1.35

2.56

0.85

1.36

2.81

1.24

2.58

3.99

0.97

1.76

3.31

3.85

0.81

1.59

Nom.

Output

Rev/Min

17

17

15

15

15

14

14

14

13

13

11

11

11

10

10

10

9

9

9

8.3

7.3

6.7

6.7

6.7

6.3

6

6

6

5.5

5.5

5

4.3

4

3.7

3.3

2.8

2.6

Output

Torque

Nm

251

271

233

250

303

250

265

330

316

338

357

376

366

352

377

413

394

409

454

529

571

511

548

612

658

609

678

699

782

767

838

915

975

1133

1266

1412

1540

Max

Service

Factor

2.42

3.79

2.05

3.06

3.45

1.92

2.88

2.94

1.24

1.87

1.08

1.41

2.64

1.37

2.03

2.71

1.22

1.87

2.51

2.53

2.08

0.94

1.40

1.96

1.85

1.26

1.80

3.61

0.98

1.74

1.60

1.39

1.30

1.18

1.06

0.90

0.82

Unit

Selection

873A1916

874A2016

872A2016

873A2016

874A2116

872A2116

873A2116

874A2216

872A2216

873A2216

872A2316

873A2316

874A2316

872A2416

873A2416

874A2416

872A2516

873A2516

874A2516

874A4516

874A4616

872A2616

873A2616

874A2616

874A4716

873A2716

874A2716

875A2716

873A4816

874A4816

874A4916

874A5016

874A5116

874A5216

874A5316

874A5416

874A5516

Overhung

Load

N

11844

29200

7426

11844

29200

7422

11844

29200

7426

11724

7430

11695

29200

7430

11695

29200

7412

11695

29200

29106

29106

7392

11626

29200

29075

11558

29200

41900

11400

29044

29013

25273

21625

20101

28926

28858

28858

870A0118

871A0118

870A0218

871A0218

870A0318

871A0318

870A0418

871A0418

870A0518

871A0518

870A0618

871A0618

872A0618

870A0718

871A0718

872A0718

870A0818

871A0818

872A0818

870A0918

871A0918

872A0918

870A1018

871A1018

872A1018

870A1118

871A1118

872A1118

870A1218

871A1218

872A1218

871A1318

872A1318

871A1418

872A1418

2841

5287

2837

5283

2832

5283

2832

5280

2827

5280

2821

5280

7440

2821

5280

7439

2821

5280

7439

2810

5276

7439

2810

5276

7438

2790

5267

7437

2790

5270

7437

5270

7437

5270

7437

0.75KW MOTOR

165

165

119

119

105

105

93

93

85

85

72

72

72

67

67

67

63

63

63

55

55

55

49

49

49

42

42

42

39

39

39

35

35

30

30

36

37

48

49

54

56

62

62

60

62

78

79

79

84

85

89

80

82

87

90

93

95

101

104

107

134

136

135

127

131

134

140

151

182

193

2.24

3.70

1.81

3.01

1.65

2.75

1.51

2.52

1.44

2.32

1.27

2.11

3.57

1.20

2.00

3.30

1.18

1.89

3.94

1.08

1.73

3.68

1.00

1.60

3.37

0.84

1.41

2.51

0.84

1.34

2.81

1.27

2.56

1.13

1.98

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

30

205

3.38

26

212

0.98

26

208

1.87

26

218

3.24

26

222

3.96

25

196

1.00

25

201

2.06

25

215

3.24

22

222

0.91

22

226

1.89

22

247

2.91

22

262

3.70

19

295

1.29

19

314

2.42

19

304

3.04

19

333

2.81

17

330

1.16

17

344

1.77

15

319

1.50

15

342

2.24

15

371

2.77

14

343

1.41

14

363

2.11

14

415

2.52

13

432

0.91

13

409

0.98

13

462

1.37

13

452

2.15

12

465

0.86

11

440

1.09

11

515

1.03

11

516

1.64

11

502

1.93

10

472

1.02

10

516

1.48

10

566

1.98

10

578

3.99

9

539

0.89

9

560

1.37

9

621

1.83

9

633

3.71

8

710

1.10

8

725

1.85

7

749

1.02

7

700

1.09

7

838

1.43

7

836

2.95

6

833

0.92

6

928

1.31

6

957

2.64

5

1050

1.28

4

1252

1.01

3.5

1550

0.86

Unit

Selection

873A1418

871A1518

872A1518

873A1518

874A1518

871A1618

872A1618

873A1618

871A1718

872A1718

873A1718

874A1718

872A1818

873A1818

874A1818

874A1918

872A1918

873A1918

872A2018

873A2018

874A2018

872A2118

873A2118

874A2118

872A2218

872A4018

873A2218

874A2218

872A4118

872A4218

873A2318

873A4218

874A2318

872A4318

873A2418

874A2418

875A2418

872A2518

873A2518

874A2518

875A2518

873A4418

874A4518

873A2618

873A4618

874A2618

875A2618

873A2718

874A2718

875A2718

874A4818

874A5018

874A5218

Drive Design & Maintenance Manual - 2006

Overhung

Load

N

11868

5250

7435

11848

29187

5260

7435

11878

5250

7433

11848

29182

7427

11771

29182

29176

7420

11771

7420

11771

29175

7414

11771

29175

7420

7407

11642

29175

7395

7401

11600

11690

29163

7395

11600

29157

41882

7400

11600

29157

41883

11500

29603

11500

11500

29127

41867

11500

29090

41875

28971

23447

15869

177

(EURO MOUNT)

Unit

Selection

GEARED DRIVES

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

7.5

360

1.09

7.5

375

2.04

7.2

389

3.05

7.0

316

0.87

7.0

329

1.46

6.5

349

1.38

6.5

373

2.05

6.2

449

2.71

6.1

375

1.29

5.8

392

1.23

5.8

415

1.84

5.6

523

2.56

5.2

533

1.44

5.1

572

2.34

4.7

599

1.28

4.5

496

0.97

4.4

624

2.03

4.3

553

1.38

4.1

665

1.91

3.9

577

0.84

3.9

599

1.28

3.7

773

1.73

3.5

784

0.98

3.3

864

1.55

2.8

963

1.32

2.6

1051

1.21

1.9

1411

0.89

Section

Fenner Series C Motorised Selection

Bold print denotes triple reduction gearbox. Higher ratios availableconsult your local Authorised Distributor

GEARED DRIVES (EUROPEAN MOUNTING)

Fenner Series C Motorised Selection

Bold print denotes triple reduction gearbox. Higher ratios availableconsult your local Authorised Distributor

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

Unit

Selection

1.1KW MOTOR

165

165

165

120

120

120

105

105

105

93

93

93

85

85

85

72

72

72

68

68

68

68

64

64

64

55

55

55

48

48

48

41

41

41

38

38

38

34

34

34

30

30

30

27

27

27

25

25

25

22

22

22

19

19

19

17

17

15

15

15

15

14

14

14

14

14

12

12

12

12

11

11

11

178

53

54

53

71

72

74

80

82

81

91

92

92

88

91

93

115

117

116

123

125

131

137

117

121

128

136

140

149

153

158

167

201

199

216

193

197

208

206

222

235

284

302

290

307

322

327

297

317

338

333

364

386

434

463

448

506

490

470

503

547

546

504

534

612

621

612

680

665

718

756

687

739

749

1.52

2.51

3.88

1.23

2.04

3.20

1.12

1.87

3.02

1.03

1.71

2.80

0.98

1.57

3.41

0.86

1.43

2.42

0.82

1.36

2.25

3.86

0.80

1.28

2.68

1.18

2.50

3.97

1.09

2.29

3.65

0.95

1.71

2.88

0.91

1.91

3.05

0.87

1.74

2.77

1.34

2.30

3.00

1.27

2.20

2.69

1.40

2.20

2.79

1.28

1.98

2.51

0.88

1.64

2.07

1.20

1.91

1.02

1.52

1.88

3.88

0.95

1.43

1.71

2.16

3.53

0.93

1.46

1.87

3.77

1.11

1.31

1.47

870A0124

871A0124

872A0124

870A0224

871A0224

872A0224

870A0324

871A0324

872A0324

870A0424

871A0424

872A0424

870A0524

871A0524

872A0524

870A0624

871A0624

872A0624

870A0724

871A0724

872A0724

873A0724

870A0824

871A0824

872A0824

871A0924

872A0924

873A0924

871A1024

872A1024

873A1024

871A1124

872A1124

873A1124

871A1224

872A1224

873A1224

871A1324

872A1324

873A1324

872A1424

873A1424

874A1424

872A1524

873A1524

874A1524

872A1624

873A1624

874A1624

872A1724

873A1724

874A1724

872A1824

873A1824

874A1824

873A1924

874A1924

872A2024

873A2024

874A2024

875A2024

872A2124

873A2124

874A2124

874A4024

875A2124

873A2224

874A2224

874A4124

875A2324

873A4224

874A2324

874A4224

Overhung

Load

N

2831

5286

7440

2824

5279

7440

2817

5280

7440

2817

5275

7438

2810

5275

7440

2800

5275

7440

2800

5275

7437

11944

2800

5275

7437

5268

7437

11944

5268

7435

11936

5254

7433

11820

5260

7433

11836

5260

7433

11832

7434

11795

29166

7428

11764

29166

7428

11811

29168

7422

11764

29152

7420

11644

29152

11644

29136

7410

11644

29133

41877

7400

11644

29133

29097

41884

11500

29133

29029

41868

11500

29100

29087

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

10

773

0.99

10

833

1.34

10

851

2.71

9

914

1.25

9

932

2.52

7

1234

0.97

7

1230

2.01

6

1366

0.89

6

1409

1.79

6

1485

3.76

Unit

Selection

873A4324

874A2424

875A2424

874A2524

875A2524

874A2624

875A2624

874A2724

875A2724

876A2724

Overhung

Load

N

11500

29084

41852

29084

41855

29000

41810

28900

41833

53800

870A0128

871A0128

872A0128

870A0228

871A0228

872A0228

870A0328

871A0328

872A0328

873A0328

871A0428

872A0428

873A0428

871A0528

872A0528

873A0528

871A0628

872A0628

873A0628

871A0728

872A0728

873A0728

871A0828

872A0828

873A0828

871A0928

872A0928

873A0928

871A1028

872A1028

873A1028

872A1128

873A1128

874A1128

872A1228

873A1228

872A1328

873A1328

872A1428

873A1428

874A1428

872A1528

873A1528

874A1528

872A1628

873A1628

874A1628

872A1728

873A1728

874A1728

873A1828

874A1828

873A1928

874A1928

875A1928

873A2028

874A2028

875A2028

873A2128

874A2128

874A4028

875A2128

2820

5285

7440

2810

5275

7440

2800

5276

7440

11945

5270

7437

11923

5270

7440

11942

5270

7440

11904

5270

7436

11904

5270

7436

11904

5260

7436

11904

5260

7432

11889

7428

11762

28940

7428

11789

7428

11783

7430

11712

29142

7420

11668

29142

7420

11734

29144

7410

11668

29117

11500

29117

11500

29089

41845

11500

29084

41861

11500

29084

29056

41872

1.5KW MOTOR

162

162

162

120

120

120

105

105

105

105

93

93

93

86

86

86

74

74

74

67

67

67

63

63

63

56

56

56

49

49

49

43

43

43

39

39

34

34

30

30

30

28

28

28

25

25

25

22

22

22

20

20

18

18

18

16

16

16

14

14

14

14

Drive Design & Maintenance Manual - 2006

72

73

72

96

98

100

109

111

110

116

125

125

130

123

126

131

158

157

164

170

177

186

164

174

182

185

190

202

207

214

226

270

292

278

268

282

301

318

384

409

393

415

436

443

402

429

458

451

493

523

627

606

685

663

677

682

740

739

724

829

841

829

1.12

1.85

2.87

0.91

1.51

2.36

0.83

1.38

2.23

3.82

1.27

2.07

3.56

1.16

2.52

3.94

1.06

1.79

3.08

1.01

1.66

2.85

0.95

1.98

3.18

0.87

1.85

2.93

0.80

1.69

2.70

1.26

2.13

2.85

1.41

2.25

1.29

2.04

0.99

1.70

2.21

0.94

1.63

1.98

1.03

1.63

2.06

0.95

1.46

1.85

1.21

1.53

0.89

1.41

3.78

1.12

1.39

2.87

1.06

1.27

1.59

2.60

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

13

901

1.08

13

897

3.08

12

1000

0.97

12

972

1.38

12

1024

2.78

11

1014

1.08

10

1128

0.99

10

1152

2.00

9

1238

0.92

9

1262

1.86

8

1445

0.93

6.5

1666

1.48

6.5

1803

3.09

5.6

1908

1.33

5.6

2011

2.77

Unit

Selection

874A2228

875A2228

874A2328

874A4128

875A2328

874A4228

874A2428

875A2428

874A2528

875A2528

874A4528

875A2628

876A2628

875A2728

876A2728

Overhung

Load

N

29084

41872

29027

28960

41844

29006

29000

41817

29000

41822

28900

41744

53736

41784

53727

871A0136

872A0136

873A0136

871A0236

872A0236

873A0236

871A0336

872A0336

873A0336

871A0436

872A0436

873A0436

872A0536

873A0536

874A0536

872A0636

873A0636

874A0636

872A0736

873A0736

874A0736

872A0836

873A0836

874A0836

872A0936

873A0936

874A0936

872A1036

873A1036

874A1036

872A1136

873A1136

874A1136

872A1236

873A1236

874A1236

875A1236

872A1336

873A1336

874A1336

875A1336

873A1436

874A1436

875A1436

873A1536

874A1536

875A1536

873A1636

874A1636

875A1636

873A1736

874A1736

875A1736

874A1836

875A1836

874A1936

875A1936

5282

7440

11928

5268

7440

11905

5270

7440

11905

5260

7435

11866

7440

11900

27500

7440

11833

28200

7433

11833

29200

7433

11833

29200

7433

11833

29200

7426

11808

29200

7420

11660

28748

7420

11708

29200

41900

7420

11697

29200

41900

11566

29100

41063

11500

29100

41638

11600

29104

41900

11500

29056

41900

29056

41828

29008

41805

2.2KW MOTOR

165

165

165

121

121

121

110

110

110

97

97

97

88

88

88

76

76

76

67

67

67

62

62

62

57

57

57

50

50

50

43

43

43

40

40

40

40

35

35

35

35

30

30

30

28

28

28

25

25

25

22

22

22

20

20

18

18

107

106

109

144

147

152

163

161

170

183

182

191

185

191

205

230

240

237

259

272

269

254

266

282

278

296

315

312

331

347

395

427

406

391

413

448

453

440

465

507

506

598

575

576

637

648

646

627

670

690

720

764

797

886

901

970

989

1.27

1.96

3.40

1.03

1.62

2.80

0.94

1.53

2.61

0.87

1.42

2.44

1.72

2.69

3.49

1.22

2.11

3.70

1.13

1.95

3.42

1.35

2.18

2.77

1.26

2.01

2.54

1.16

1.84

2.37

0.86

1.46

1.95

0.96

1.54

1.94

3.97

0.88

1.40

1.76

3.64

1.16

1.51

3.77

1.11

1.36

3.48

1.11

1.41

2.84

1.00

1.27

2.52

1.05

2.76

0.96

2.59

GEARED DRIVES (EUROPEAN MOUNTING)

874A2036

875A2036

875A2136

874A2136

874A4036

875A2236

876A2136

876A2236

874A4136

875A2336

876A2336

875A2436

876A2436

875A2536

876A2536

875A2636

876A2636

875A2736

876A2736

876A2645

877A2645

Overhung

Load

N

29000

41833

41852

29000

28983

41852

53722

53731

28838

41804

53714

41756

53696

41765

53679

41630

53625

41700

53600

53443

87347

871A0138

872A0138

873A0138

872A0238

873A0238

874A0238

872A0338

873A0338

874A0338

872A0438

873A0438

874A0438

872A0538

873A0538

874A0538

872A0638

873A0638

874A0638

872A0738

873A0738

874A0738

872A0838

873A0838

874A0838

872A0938

873A0938

874A0938

875A0938

872A1038

873A1038

874A1038

875A1038

873A1138

874A1138

875A1138

873A1238

874A1238

875A1238

873A1338

874A1338

875A1338

875A1438

873A1438

874A1438

874A1538

875A1538

874A1638

875A1638

874A1738

875A1738

875A1838

5280

7440

11894

7440

11858

24654

7440

11858

25318

7432

11802

25990

7440

11851

27218

7440

11752

27800

7430

11752

28732

7430

11752

28898

7430

11752

28943

38856

7420

11715

29018

39518

11544

28530

40736

11615

29151

41500

11600

29151

41563

41657

11400

29051

29051

41512

29057

41884

28986

41869

41794

3.0KW MOTOR

171

171

171

123

123

123

116

116

116

100

100

100

90

90

90

80

80

80

70

70

70

62

62

62

58

58

58

58

50

50

50

50

45

45

45

40

40

40

35

35

35

33

31

31

29

29

26

26

22

22

20

147

145

149

200

208

201

220

232

227

249

260

249

253

261

279

314

328

323

354

370

367

347

362

385

379

403

430

434

426

451

473

480

583

554

577

563

611

618

634

691

690

785

815

785

883

881

913

942

1042

1087

1229

0.93

1.44

2.50

1.19

2.05

3.64

1.12

1.92

3.37

1.04

1.79

3.19

1.26

1.98

2.56

0.90

1.55

2.72

0.83

1.43

2.51

0.99

1.60

2.03

0.93

1.47

1.86

3.80

0.85

1.35

1.74

3.54

1.07

1.43

3.37

1.13

1.42

2.91

1.03

1.29

2.67

2.76

0.85

1.11

1.00

2.55

1.04

2.08

0.93

1.85

2.02

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

20

1250

3.41

19

1349

1.89

19

1380

3.12

16

1474

1.43

16

1578

2.98

14

1652

1.30

14

1745

2.78

13

1788

1.54

13

1877

2.37

12

2042

1.21

12

2098

2.14

12

2064

3.87

10

2296

1.00

10

2417

2.19

10

2462

3.15

9

2517

1.00

9

2660

2.04

9

2818

2.82

6.4

3593

1.55

6.4

3757

2.23

5.7

4007

1.39

5.7

4021

2.11

Unit

Selection

876A1838

875A1938

876A1938

875A2038

876A2038

875A2138

876A2138

875A2238

876A2238

875A2338

876A2338

877A2338

875A2438

876A2438

877A2438

875A2538

876A2538

877A2538

876A2638

877A2638

876A2738

877A2738

Overhung

Load

N

53723

41758

53704

41801

53684

41828

53665

41828

53681

41757

53651

87400

41686

53621

87381

41700

53592

87372

53497

87369

53454

87369

874A0146

873A0146

872A0146

874A0246

873A0246

872A0246

874A0346

873A0346

872A0346

874A0446

873A0446

875A0546

874A0546

873A0546

875A0646

874A0646

873A0646

875A0746

874A0746

873A0746

875A0846

874A0846

873A0846

875A0946

874A0946

873A0946

875A1046

874A1046

873A1046

875A1146

874A1146

873A1146

875A1246

874A1246

873A1246

875A1346

874A1346

876A1446

875A1446

874A1446

876A1546

875A1546

875A1646

875A1746

876A1846

875A1846

876A1946

875A1946

875A2046

877A2046

22778

11851

7440

24347

11801

7440

24965

11801

7440

25604

11721

34793

26865

11790

35596

27300

11651

36798

28147

11651

37796

28520

11651

38426

28622

11651

39040

28792

11600

40031

28526

11400

41000

29090

11500

41143

29090

53733

40150

28990

53716

41353

41866

41832

53682

41751

53653

41701

41760

87400

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

15

2089

2.25

14

2322

3.12

14

2311

2.10

14

2188

0.99

13

2551

3.39

13

2485

1.79

12

2733

2.92

12

2779

1.62

12

2368

1.17

10

3260

2.38

10

3200

1.65

10

2704

1.05

9

3732

2.13

9

3521

1.54

6.5

4974

1.68

6.5

4758

1.17

5.7

5324

1.59

5.7

5306

1.05

Unit

Selection

876A2046

877A2146

876A2146

875A2146

877A2246

876A2246

877A2346

876A2346

875A2246

877A2446

876A2446

875A2346

877A2546

876A2546

877A2646

876A2646

877A2746

876A2746

Overhung

Load

N

53624

87385

53594

41800

87400

53618

87400

53573

41800

87359

53528

41700

87338

53482

87332

53338

87332

53272

4.0KW MOTOR

173

173

173

130

130

130

116

116

116

100

100

90

90

90

80

80

80

70

70

70

65

65

65

58

58

58

50

50

50

45

45

45

40

40

40

35

35

33

33

33

29

29

26

22

20

20

18

18

16

15

193

197

192

267

275

265

301

308

291

329

344

369

370

346

431

428

435

483

485

491

519

509

480

574

570

534

636

626

597

765

734

772

819

810

746

913

915

1071

1040

1039

1189

1167

1247

1440

1655

1628

1827

1787

1951

2100

3.19

1.89

1.09

2.75

1.55

0.90

2.55

1.45

0.85

2.41

1.35

3.76

1.93

1.49

3.66

2.05

1.17

3.41

1.90

1.08

3.04

1.53

1.20

2.87

1.41

1.11

2.67

1.31

1.02

2.55

1.08

0.81

2.20

1.08

0.85

2.01

0.98

3.76

2.09

0.84

3.44

1.93

1.57

1.40

2.57

1.53

2.35

1.43

1.09

3.39

Drive Design & Maintenance Manual - 2006

179

(EURO MOUNT)

Unit

Selection

GEARED DRIVES

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

16

1082

0.95

16

1081

1.96

15

1211

1.78

14

1211

0.87

14

1229

1.09

14

1311

2.10

14

1280

3.79

13

1376

3.23

12

1421

0.94

12

1497

1.90

12

1539

2.92

10

1684

1.37

10

1772

2.98

9

1845

1.27

9

1950

2.78

7

2435

1.01

7

2635

2.12

6

2789

0.91

6

2939

1.90

4

3876

1.44

4

4064

2.17

Section

Fenner Series C Motorised Selection

Bold print denotes triple reduction gearbox. Higher ratios availableconsult your local Authorised Distributor

GEARED DRIVES (EUROPEAN MOUNTING)

Fenner Series C Motorised Selection

Bold print denotes triple reduction gearbox. Higher ratios availableconsult your local Authorised Distributor

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

Unit

Selection

Overhung

Load

N

873A0154

874A0154

873A0254

874A0254

875A0254

875A0354

873A0354

874A0354

873A0454

874A0454

875A0454

873A0554

874A0554

875A0554

873A0654

874A0654

875A0654

874A0754

875A0754

873A0854

874A0854

875A0854

873A0954

874A0954

875A0954

874A1054

875A1054

875A1154

875A1254

875A1354

875A1454

876A1454

875A1554

876A1554

875A1654

875A1754

875A1854

876A1854

877A1854

875A1954

876A1954

877A1954

876A2054

877A2054

876A2154

877A2154

876A2254

877A2254

876A2354

877A2354

876A2454

877A2454

876A2554

877A2554

876A2654

877A2654

877A2754

11786

22426

11715

23887

31175

31897

11715

24437

11600

25025

32868

11700

26337

34371

11500

26550

35010

27269

36130

11500

27965

37210

11500

28141

37782

28452

38325

38975

40250

40512

39389

53698

41116

53673

41837

41775

41686

53622

85716

41615

53577

86407

53533

87400

53488

87374

53525

87400

53456

87400

53387

87325

53318

87287

53100

87275

87275

5.5KW MOTOR

175

175

130

130

130

119

110

110

100

100

100

90

90

90

77

77

77

72

72

65

65

65

58

58

58

54

54

46

41

37

33

33

29

29

27

23

21

21

21

19

19

19

16

16

14

14

13

13

12

12

10

10

9

9

6.5

6.5

6

180

270

265

377

366

371

413

422

412

472

452

457

474

507

506

596

587

591

665

662

658

698

711

732

781

787

858

871

1048

1122

1251

1425

1468

159

1629

1709

1973

2231

2268

2272

2448

2504

2606

2863

2878

3167

3182

3405

3496

3808

3745

4385

4467

4825

5114

6519

6816

7295

1.38

2.33

1.13

2.00

3.56

3.34

1.06

1.86

0.99

1.76

3.12

1.09

1.41

2.74

0.85

1.50

2.67

1.38

2.49

0.88

1.12

2.22

0.81

1.03

2.09

0.96

1.95

1.86

1.60

1.47

1.52

2.74

1.41

2.51

1.15

1.02

1.12

1.88

3.34

1.05

1.72

2.94

1.64

2.47

1.53

2.28

1.30

2.47

1.18

2.13

1.21

1.74

1.12

1.56

0.86

1.23

1.16

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

Unit

Selection

Overhung

Load

N

873A0156

874A0156

875A0156

873A0256

874A0256

875A0256

874A0356

875A0356

874A0456

875A0456

874A0556

875A0556

874A0656

875A0656

874A0756

875A0756

874A0856

875A0856

875A0956

875A1056

875A1156

875A1256

875A1356

875A1456

876A1456

877A1456

875A1556

876A1556

877A1556

875A1656

875A1856

876A1856

877A1856

876A1956

877A1956

876A2056

877A2056

876A2156

877A2156

876A2256

877A2256

876A2356

877A2356

876A2456

877A2456

876A2556

877A2556

877A2656

877A2756

11700

21957

28647

11600

23273

30675

23732

31350

24252

32243

25632

33809

25550

34229

26100

35239

27200

36429

36922

37370

37565

39250

39671

38375

53652

82939

40800

53616

83701

41800

41600

53541

84696

53476

85806

53412

87400

53347

87358

53400

87400

53300

87400

53200

87279

53100

87219

87200

87200

7.5KW MOTOR

180

180

180

130

130

130

118

118

107

107

92

92

82

82

72

72

66

66

59

53

46

41

37

33

33

33

29

29

29

26

21

21

21

19

19

16

16

14

14

13

13

12

12

10

10

9

9

6.5

6

Drive Design & Maintenance Manual - 2006

367

360

355

513

497

504

561

561

614

622

689

688

797

803

904

899

949

966

1070

1184

1424

1525

1701

1937

1995

1975

2173

2214

2188

2322

3032

3082

3087

3412

3541

3891

3911

4304

4324

4628

4751

5174

5089

5959

6070

6557

6949

9263

9913

1.01

1.71

3.20

0.83

1.47

2.62

1.37

2.46

1.30

2.30

1.04

2.02

1.10

1.97

1.02

1.83

0.82

1.63

1.54

1.44

1.37

1.18

1.08

1.12

2.02

3.61

1.04

1.85

3.32

0.84

0.82

1.38

2.46

1.26

2.17

1.21

1.82

1.10

1.67

0.96

1.82

0.87

1.57

0.89

1.28

0.83

1.15

0.90

0.85

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

Unit

Selection

Overhung

Load

N

874A0166

875A0166

876A0166

874A0266

875A0266

876A0266

874A0366

875A0366

876A0366

874A0466

875A0466

876A0466

875A0566

876A0566

875A0666

876A0666

875A0766

876A0766

875A0866

876A0866

877A0866

875A0966

876A0966

877A0966

875A1066

876A1066

877A1066

875A1166

876A1166

877A1166

875A1266

876A1266

877A1266

876A1366

877A1366

876A1466

877A1466

876A1566

877A1566

876A1666

877A1666

876A1766

877A1766

876A1866

877A1866

876A1966

877A1966

876A2066

877A2066

877A2166

877A2266

877A2366

877A2466

21137

28018

44500

22200

29800

47600

22500

30393

48700

22900

31150

50100

32825

53100

32862

53300

33681

53800

35062

53800

73000

35418

53800

74000

35700

53800

75400

35100

53800

75100

37500

53800

79400

53700

81000

53572

80522

53515

81258

53600

87400

53500

87400

53400

82911

53300

84754

53200

87400

87331

87400

87400

87200

11.0KW MOTOR

180

180

180

132

132

132

118

118

118

107

107

107

94

94

83

83

74

74

66

66

66

59

59

59

53

53

53

46

46

46

40

40

40

35

35

33

33

29

29

25

25

22

22

21

21

19

19

16

16

14

13

12

10

526

520

539

727

737

741

820

820

831

898

909

928

1005

1075

1174

1194

1315

1326

1413

1473

1520

1564

1652

1651

1731

1841

1869

2082

2078

2126

2229

2355

2424

2634

2601

2916

2887

3236

3198

3601

3753

4091

4231

4505

4512

4973

5176

5687

5716

6320

6945

7438

8873

1.17

2.19

3.93

1.01

1.79

3.26

0.94

1.68

3.05

0.89

1.57

2.85

1.38

2.40

1.35

2.45

1.25

2.29

1.12

1.98

3.55

1.05

1.85

3.35

0.98

1.73

3.05

0.94

1.73

3.01

0.81

1.48

2.50

1.38

2.36

1.38

2.47

1.26

2.27

1.13

1.76

1.04

1.60

0.95

1.68

0.86

1.48

0.83

1.25

1.15

1.25

1.07

0.87

GEARED DRIVES (EUROPEAN MOUNTING)

Overhung

Load

N

874A0168

875A0168

876A0168

875A0268

876A0268

875A0368

876A0368

877A0368

875A0468

876A0468

877A0468

875A0568

876A0568

877A0568

875A0668

876A0668

877A0668

875A0768

876A0768

877A0768

875A0868

876A0868

877A0868

876A0968

877A0968

876A1068

877A1068

876A1168

877A1168

876A1268

877A1268

876A1368

877A1368

876A1468

877A1468

876A1568

877A1568

876A1668

877A1668

877A1768

877A1866

877A1968

877A2068

877A2168

20200

27300

43852

28800

46717

29300

47715

60823

29900

49007

62817

31700

52131

66523

31300

51889

67047

31900

52636

68664

33500

53727

71917

53727

72823

53727

74061

53586

73069

53640

77673

53540

79147

53480

77759

53400

78467

53400

85327

85945

80870

83552

87400

87300

716

707

733

1001

1007

1115

1130

1116

1235

1261

1265

1366

1460

1482

1595

1622

1640

1787

1803

1766

1920

2002

2065

2245

2244

2501

2540

2824

2890

3200

3294

3579

3535

3963

3923

4398

4347

4894

5100

5750

6132

7034

7768

8589

0.86

1.61

2.89

1.32

2.40

1.24

2.25

3.99

1.16

2.10

3.70

1.02

1.77

3.19

0.99

1.80

3.16

0.92

1.69

3.02

0.82

1.46

2.61

1.36

2.47

1.27

2.25

1.27

2.21

1.09

1.84

1.02

1.74

1.02

1.82

0.93

1.67

0.83

1.30

1.18

1.24

1.09

0.92

0.84

Unit

Selection

Overhung

Load

N

876A0176

876A0276

877A0276

876A0376

877A0376

876A0476

877A0476

876A0576

877A0576

876A0676

877A0676

876A0776

877A0776

876A0876

877A0876

876A0976

877A0976

876A1076

877A1076

876A1176

877A1176

876A1276

877A1276

877A1376

876A1376

876A1476

877A1476

877A1576

877A1676

877A1776

877A1876

877A1976

43286

45945

59054

46853

60144

48051

62045

51284

65844

50655

66038

51618

67583

53663

70970

53663

71794

53663

72890

53400

71292

53500

76163

77526

53400

53400

75342

76025

83513

84672

79085

82500

876A0178

877A0178

876A0278

877A0278

876A0378

877A0378

876A0478

877A0478

876A0578

877A0578

876A0678

877A0678

876A0778

877A0778

876A0878

877A0878

876A0978

877A0978

876A1078

877A1078

877A1178

877A1278

877A1378

877A1478

877A1578

877A1678

877A1778

877A1878

42720

54676

45173

58426

45992

59464

47096

61273

50436

65164

49421

65029

50600

66502

53600

70023

53600

70764

53600

71719

69515

74652

75905

72925

73582

81700

83400

77300

18.5KW MOTOR

15.0KW MOTOR

183

183

183

132

132

118

118

118

106

106

106

91

91

91

82

82

82

75

75

75

66

66

66

57

57

51

51

46

46

39

39

35

35

33

33

30

30

25

25

22

21

18

16

14

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

183

133

133

120

120

106

106

88

88

82

82

74

74

64

64

57

57

51

51

46

46

39

39

35

35

33

33

30

25

22

21

18

895

1230

1251

1379

1362

1540

1544

1783

1809

1980

2002

2201

2156

2444

2522

2741

2739

3054

3101

3447

3528

3907

4021

4316

4369

4838

4790

5306

6226

7019

7486

8586

2.37

1.97

3.44

1.84

3.27

1.72

3.03

1.45

2.61

1.47

2.59

1.38

2.47

1.19

2.14

1.11

2.02

1.04

1.84

1.04

1.81

0.89

1.51

1.42

0.83

0.83

1.49

1.37

1.06

0.96

1.10

0.89

22.0KKW MOTOR

184

184

133

133

119

119

106

106

88

88

82

82

74

74

64

64

58

58

51

51

46

39

36

34

30

25

22

21

1064

1066

1462

1488

1640

1620

1831

1836

2120

2151

2355

2381

2617

2564

2906

2999

3250

3258

3632

3687

4195

4782

5133

5696

6310

7405

8347

8903

1.99

3.50

1.65

2.89

1.55

2.75

1.45

2.55

1.22

2.20

1.24

2.18

1.16

2.08

1.00

1.80

0.94

1.70

0.88

1.55

1.53

1.27

1.20

1.25

1.15

0.89

0.81

0.85

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

Unit

Selection

Overhung

Load

N

876A0188

877A0188

876A0288

877A0288

876A0388

877A0388

876A0488

877A0488

876A0588

877A0588

876A0688

877A0688

877A0788

877A0888

877A0988

877A1088

877A1188

877A1288

877A1388

877A1488

877A1588

41426

53641

43408

56991

44023

57911

44911

59508

48500

63611

46600

62723

64032

67858

68411

69042

65453

71200

72200

67400

68000

876A0194

877A0194

876A0294

877A0294

876A0394

877A0394

876A0494

877A0494

877A0594

877A0694

877A0794

877A0894

877A0994

877A1094

877A1194

40294

52735

41864

55735

42300

56552

43000

57964

62252

60705

61870

65964

66352

66700

61900

876A0195

877A0195

876A0295

877A0295

877A0395

877A0495

877A0595

877A0695

877A0795

877A0895

877A0995

39000

51700

40100

54300

55000

56200

60700

58400

59400

63800

64000

30.0KW MOTOR

184

184

134

134

120

120

106

106

88

88

83

83

76

63

58

51

46

39

36

34

30

1452

1454

1994

2029

2237

2209

2497

2504

2891

2934

3212

3247

3497

4089

4442

5028

5721

6520

6999

7767

8605

1.46

2.56

1.21

2.12

1.14

2.01

1.06

1.87

0.89

1.61

0.91

1.60

1.52

1.32

1.25

1.14

1.12

0.93

0.88

0.92

0.84

37.0KW MOTOR

185

185

134

134

120

120

106

106

89

83

76

63

58

51

46

1784

1787

2451

2494

2749

2715

3069

3078

3606

3991

4298

5026

5460

6181

7032

1.19

2.09

0.99

1.72

0.92

1.64

0.86

1.52

1.31

1.30

1.24

1.07

1.01

0.92

0.91

45.0KW MOTOR

185

185

134

134

122

108

89

83

76

63

58

2170

2173

2982

3033

3302

3743

4386

4854

5228

6113

6641

0.98

1.72

0.81

1.42

1.35

1.25

1.08

1.07

1.02

0.88

0.83

Drive Design & Maintenance Manual - 2006

181

(EURO MOUNT)

Unit

Selection

GEARED DRIVES

Nom. Output Max

Output Torque Service

Rev/Min

Nm

Factor

Section

Fenner Series C Motorised Selection

Bold print denotes triple reduction gearbox. Higher ratios availableconsult your local Authorised Distributor

GEARED DRIVES (EUROPEAN MOUNTING)

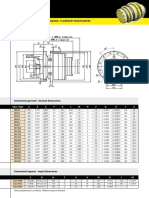

Fenner Series C Motorised Dimensions

4 x F

P1

P2

Protection

Cover

4 x F

W

M

V

B

L

Output Shaft Bore

D1

m1

m2

4 x F1

4 x F

Unit

Size

D1

H2

H1

On sizes 870873 feet are an

optional extra consult page 187

for product codes

* See motor dimensions on page 251

F1 H1

H2

H7

63

80

K DOUBLE REDUCTION

MOTOR FRAME SIZE

Triple

71

80

90 100/112 132

m1

m2

P1

P2

70

5.3 20 71

54 M8X15

35

28

45 197 201 214 224

213

56

40

40

124 104 70.5

57.0

63 22.9

871 100 15.0 30 86

64 M10X20 11

35

45

50 217 221 234 244

233

76

45

53

130 122 86.5 74.5 65.0

78 33.5

872 112 13.0 35 96

16

68 M10X18

11

45

55

55 236 240 253 263

252

95

77

65

140 127 96.5

84 38.5

10

90 M12X20 14

60

70

65 271 277 295 305

332

331

163

96

76

180 156 119.5 101

90.5 110 49.0

14

870

873 140 17.0 45 120 20

79

70.0