Beruflich Dokumente

Kultur Dokumente

As D Calculators

Hochgeladen von

Patricio TamayoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

As D Calculators

Hochgeladen von

Patricio TamayoCopyright:

Verfügbare Formate

ASD ASD CALCULATORS CALCULATORS for for Fan Fan & & Pump Pump Applications Applications

Comparison of Inlet and Outlet Dampers

Page 2 of 14

Bonneville Power Administration

Revision No. 1

Comparison of Inlet and Outlet Dampers

Page 3 of 14

Bonneville Power Administration

Revision No. 1

Fan Drives Power Graphs

Eddy Current Drive Fan Flow Control

120.0

120.00

Adjustable Speed Drive Fan Flow Control

104.4

100.0

100.00

89.6

102.93

% of Design Input Power (kW)

80.0

75.7

% of Design Input Power (kW)

80.00

79.50

60.0

51.1

62.8

60.00

59.75

40.0

32.0 25.0

40.7

40.00 30.38 20.00 12.89 8.00 40 60 20.27

43.46

20.0

16.4

17.0

20.0

0.0 0 20 40

4.75

5.37 20

% of Design CFM

60

80

100

120

0.00 0

% of Design CFM or % of Full Speed RPM

80

100

120

The power curves above are used in the energy savings analysis. Curves developed from data obtained by measuring the operating characteristics of various fan systems and from information provided in "Flow Control", a Westinghouse publication, Bulletin B-851, F/86/Rev-CMS 8121. Curves are representative, not precise, final economic analysis should be based on actual power (kW) measurements of the fan system.

Page 4 of 14

Bonneville Power Administration

Revision No. 1

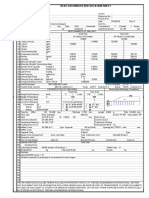

ADJUSTABLE SPEED DRIVE ENERGY SAVINGS CALCULATOR ~ Fan Applications ~

Fan Motor Information Enter Nameplate Horsepower: Enter Nameplate Efficiency: Enter Motor Load at Fan Design CFM: Power(kW) at Fan Design CFM: 100.00 94.56 78.56 61.98

hp % % KW

Facility Information Enter Hours per year fan operates: Enter Energy Charge: 8760 0.05

hrs/yr $/kwh

Existing Flow Control Method and Fan Type

Select Flow Control and Fan Type Below

Click to go to the Fan Types worksheet for more information

1 1 Inlet Guide Vane, FC Fans 2 Inlet Guide Vane, BI & Airfoil Fans 3 Inlet Damper Box Power Analysis

Existing System ASD System Percent of Design (kW) for ASD System

4 Outlet Damper, FC Fans 5 Outlet Damper, BI & Airfoil Fans 6 Eddy Current Drives

7 Selection 7 allows Measured

Power (kW) readings to be used in the analysis

Duty Cycle

Savings Analysis

Enter Enter Percent of Design Percent of Capacity (CFM) Time at this Existing System Percent of Capacity Design (KW)

Do Not Enter Data Below

Existing System Power (kW)

ASD System Power (kW)

Annual Energy Savings (Kwh/yr)

Annual Energy Cost Savings ($/yr)

0.0% 10.0% 20.0% 30.0% 40.0% 50.0% 60.0% 70.0% 80.0% 90.0% 100.0% Totals:

5.0% 5.0% 10.0% 10.0% 10.0% 10.0% 10.0% 10.0% 10.0% 10.0% 10.0% 100.0%

20.00 20.64 21.57 23.32 26.44 31.45 38.92 49.36 63.33 81.37 104.01

12.40 12.79 13.37 14.45 16.38 19.49 24.12 30.59 39.25 50.43 64.46 249,794.11 Kwh/yrexisting

5.90 4.75 5.37 8.00 12.89 20.27 30.38 43.46 59.75 79.50 102.93 199,722.78 Kwh/yrasd

3.66 2.94 3.33 4.96 7.99 12.56 18.83 26.93 37.03 49.27 63.80

3,827.60 4,314.46 8,794.78 8,315.66 7,354.41 6,073.93 4,637.09 3,206.77 1,945.83 1,017.16 583.64 50,071.33

$191.38 $215.72 $439.74 $415.78 $367.72 $303.70 $231.85 $160.34 $97.29 $50.86 $29.18 $2,503.57

Sample Duty Cycles (these can be used as a guide if the duty cycle is not known) Sample Duty Cycle - HIGH FAN LOADING Sample Duty Cycle - LOW FAN LOADING

70 Percent of Time at this Capacity 60 50 40 30 20 10 0 50 75 Percent of Design Capacity (cfm) 90

Summary Energy Savings: Cost Savings: Enter Materials Cost:

60

60

Percent of Time at this Capacity

55

50 40 30 20 10 0

30 50 70 Percent of Design Capacity (cfm) 15 5 90 25

20

20

50,071.33 KWH/yr $2,503.57 $-

Enter Labor Cost: Total Cost: Simple Payback:

$years

This calculator was developed by Chris Milan at the Bonneville Power Administration (BPA) and is intended to be used as an estimation of potential energy savings and simple payback for ASD installations. Final economic decisions should be based upon more extensive analysis tools than what is provided here.

If you have any questions or comments, please email Chris Milan at the following: More extensive analysis tools are available at the following DOE web site: You may download a copy of this calculator at the following BPA web site*: * This is an Excel 2000 file and is approximately 2.5 MB in size.

cbmilan@bpa.gov http://www.eere.energy.gov/industry http://www.bpa.gov/energy/N/projects/Industrial/

Page 5 of 14

Bonneville Power Administration

Revision No. 1

Common Fan Types

(FC) Forward-Curved Fans (BI) Backward-Inclined Fans Radial-Blade Fans Axial Fans

Descriptions and Fan Efficiencies

The fan blades curve in the direction of rotation. These fans are typically not as large as other fan types and structurally are not very rugged. Fan efficiencies are in the range of 55 to 65%.

The fan blades tilt back, away from the direction of rotation. The main difference between fans in this category is the shape and construction of the blades. The Backward-Inclined Flat blades tend to be more rugged and allow some particulate to pass through but these blades are not very aerodynamic and therefore are the least efficient. The Backward-Inclined Curved blades are more efficient but their orientation with the air stream can allow moisture and particulate to collect on the blades which reduces fan performance and may cause excessive vibrations. The efficiency ranges from 75 to 85%. The Backward-Inclined Airfoil blade resembles the wing of an aircraft and is the most efficient fan type with efficiencies over 90%.

These fans are typically the most rugged of all types and can range from Paddle-Wheel design to Flat Blades with corrosion resistance coatings. These fans usually operate at lower volumes but higher pressures than other fan types. The wide openings between the blades allow larger material to pass through and also minimizes vibrations when operating during conditions when the flow and pressure drops. The construction of these fans allows them to be modified to meet specific applications and to be repaired at minimum costs. Typical ranges of fan efficiencies for Flat Blades is 55 to 65% and 60 to 75% for the Radial Tip.

This fan group includes Propeller, Tubeaxial, and Vaneaxial fans. The fan blades are installed perpendicular to the air stream. The majority of these fans can be operated in reverse which allow them to supply or exhaust the air. Propeller fans generate high airflows but minimum pressure and are the least expensive and least efficient. To increase the pressure and efficiency these fans are placed inside a hollow tube to form the Tubeaxial fan. To further increase the efficiency and develop a more unified air stream, outlet vanes are installed to form the Vaneaxial fan.

Performance Characteristics

The typical performance curve for a Forward Curved fan contains a dip in the static pressure curve to the left of the point of maximum static pressure. This region of the performance curve indicates that the characteristics of the air flow through the fan was not consistent. As the flow increases, the static pressure increases and decreases within this region. It is not recommended to operate the fan within this unstable region of the fan curve due to the unpredictable flow characteristics. This area is sometimes referred to as the "stall" region.

The fan performance curve for Backward Inclined fans is similar to the forward curve but typically has a smaller dip in the static pressure curve. The major difference of the backward inclined fans is the characteristics of the BHP curve. The horsepower curve does not increase to a maximum amount at maximum flow rate but instead will reach a peak and then drop off as the flow rate continues to increase to it's maximum amount. This characteristic allows the designer to select a motor size for the worst case(design) conditions and if any errors or changes occur that would increase the flow requirements, the fan will not be overloaded. This is typically referred to as a "non-overloading" power curve.

The performance curve for fans with Radial Blade wheels is typically a smooth curve showing the pressure steadily dropping from a maximum at zero flow to a minimum pressure at full flow. This characteristic allows stable operation of the fan throughout a wide range of flow(cfm) by adjusting the pressure. The corresponding BHP curve increases at a linear rate as the fan flow rate increases. The Radial Tip fan performance curve is a blend of the Backward- Inclined and Radial Blade curves. The BHP curve increases to a maximum amount at maximum flow. The Radial Tip is more efficient than the Radial Blade and therefore requires less horsepower to produce the same output.

The fan performance curve for this group of fans indicates that they are capable of providing high flow rates at lower pressures than other fan types. These fans will typically have a unique BHP curve that requires maximum power at zero flow rate. The horsepower and static pressure will increase and decrease as flow increases until finally reaching a minimum value at maximum flow rate. These variations in flow and pressure result in different flow rates at the same operating pressure, causing instability and control problems. Operating within this region should be avoided.

Due to the narrow openings between fan blades, these fans are not suited for airstreams containing particulate. These fans usually operate at low volumes and low speeds such as in residential HVAC units.

Applications

As stated above, these fans are typically "non-overloading" and this characteristic makes them a popular choice for applications were the system performance is uncertain at maximum flow rates. The inside of these blades are usually hollow to reduce their weight but the build up of moisture and particulate can lead to cavities which reduces their efficiency. The narrow openings can limit the size of particulate in the air stream they can tolerate. These fans are a good choice for installations on the clean side of the process air stream for material and dust handling systems and for forced-draft fans in boilers.

These fans are the fans of choice for moving material or air in harsh operating environments. They are used to convey everything from air filled with particulate to wood chips, rock or metal scrap

Propeller fans are common on cooling towers and inexpensive exhaust systems. Tubeaxial and Vaneaxial fans are used in HVAC exhaust applications were higher pressures and flow rates are required. All of these fans produce significant airflow noise when compared to other fans.

Reference: "Improving Fan System Performance" Industrial Technologies and Best Practices Web Site at: http://www.oit.doe.gov

Page 6 of 14

Bonneville Power Administration

Revision No. 1

Inlet Vane Graphs

120.0

Inlet Guide Vane Control, Forward Curve Fans

104.0

120.0

Inlet Guide Vane Control, BI & Airfoil Fans

power curve is over loading.go 105%

100.0

% of Design Input Power (kW)

100.0

84.6

99.8

80.0

63.3

81.4

% of Design Input Power (kW)

60.0

49.4

80.0

73.8 66.7 62.3

40.0

31.5 26.4 23.3

38.9

60.0

52.6 47.3

55.8

57.4

58.5

59.9

20.0

20.0

20.6

21.6

0.0 0 20 40

40.0

% of Design CFM

60

80

100

120

20.0

Inlet Damper Box, General Curve

120.0

0.0

106.7

20

40

100.0

91.9

60 % of Design CFM

80

100

120

% of Design Input Power (kW)

80.0

73.9

81.2 69.1

60.0

50.3

56.1

59.8

62.2

64.0

66.0

40.0 20.0 0.0

These power curves are used in the energy savings analysis. Curves developed from data obtained by measuring the operating characteristics of various fan systems and from information provided in "Flow Control", a Westinghouse publication, Bulletin B851, F/86/Rev-CMS 8121. Curves are representative, not precise. Final economic analysis should be based on actual power(kW) measurements of the fan system.

80 100 120

20

40

60

% of Design CFM

Page 7 of 14

Bonneville Power Administration

Revision No. 1

Outlet Damper Graphs

120.0

Outlet Damper Control, Forward Curve Fans

120.0 110.0

Outlet Damper Control, Radial Blade, Backward Inclined & Airfoil Fans

105.9

105.2

100.0

90.6

100.0

96.3

102.1

90.0

88.7 80.2 71.5 63.6

% of Design Input Power (kW)

80.0

% of Design Input Power (kW)

76.9

80.0 70.0 60.0 50.0 40.0 30.0 20.0 10.0

52.6 53.3

64.6

60.0

53.8 44.5

57.2

40.0

36.7 30.4 25.6 22.3

20.0

20.4

0.0 0 20 40

0.0

% of Design CFM

60

80

100

120

20

40

% of Design CFM

60

80

100

120

The power curves above are used in the energy savings analysis. Curves developed from data obtained by measuring the operating characteristics of various fan systems and from information provided in "Flow Control", a Westinghouse publication, Bulletin B-851, F/86/Rev-CMS 8121. Curves are representative, not precise, final economic analysis should be based on actual power(kW) measurements of the fan system.

Page 8 of 14

Bonneville Power Administration

Revision No. 1

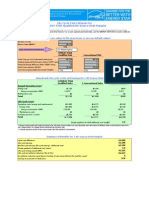

ADJUSTABLE SPEED DRIVE ENERGY SAVINGS CALCULATOR ~ Fan Applications ~

Motor Information Enter Nameplate Horsepower: Enter Nameplate Efficiency: Enter Motor Load at Fan Design CFM: Power(KW) at Fan Design CFM: 50.00 95.00 90.00 35.34

hp % % KW This Sample Input Sheet is for viewing This Sample Input Sheet is for viewingor purposes only. No values can be inputted purposesItonly. No values can be inputted or changed. is included here to give the user changed. It what is included here to give the an idea of types of values can beuser an idea of either what types of values can or be entered into the Fan Calculator entered into either the Fan Calculator or Pump Calculator worksheets. Facility Information Pump Calculator worksheets.

Enter Hours per year fan operates: Enter Energy Charge:

8760 0.05

hrs/yr $/kwh

Flow Control Method and Fan Type

Select Flow Control and Fan Type Below

Click to go to the Fan Types worksheet for more information

1 Inlet Guide Vane, FC Fans 2 Inlet Guide Vane, BI & Airfoil Fans 3 Inlet Damper, General Curve Power Analysis

Existing System ASD System Percent of Design (KW) for ASD System Annual Energy Savings (Kwh/Yr) ASD System Power (KW) Annual Energy Cost Savings ($/yr)

4 Outlet Damper, FC Fans 5 Outlet Damper, BI & Airfoil Fans 6 Eddy Current Drives

7 Measured kW Savings Analysis

Duty Cycle

Enter Percent of Design Capacity (CFM)

Enter Percent of Time at this Capacity

Existing System Percent of Design (KW)

25.0% 50.0% 70.0% 90.0%

15.0% 55.0% 25.0% 5.0%

54.90 71.53 88.71 102.08

Do Not Existing Enter Data System Power Below (KW) 19.40 25.28 31.35 36.07

6.42 20.27 43.46 79.50

2.27 7.16 15.36 28.09

22,511.26 87,270.91 35,022.55 3,494.89 0.00 0.00 0.00 0.00 0.00 0.00 0.00 148,299.60

$1,125.56 $4,363.55 $1,751.13 $174.74

Totals:

100.0%

231,719.64 Kwh/yrexisting

83,420.05 Kwh/yrasd

$7,414.98

Sample Duty Cycles (use these as a guide if the duty cycle is not known) Sample Duty Cycle - HIGH FAN LOADING Sample Duty Cycle - LOW FAN LOADING

70 60 50 40 30 20 10 0 50 75 Percent of Design Capacity (cfm) 90

Summary Energy Savings: (Note 1) Cost Savings: Enter Materials Cost: 148,299.60 KWH/yr $7,414.98 $950.00 20 20 60

60 50 40 30 20 10 0 30

55

Percent of Time at this Capacity

Percent of Time at this Capacity

25

15

70 Percent of50 Design Capacity (cfm)

90

Enter Labor Cost: Total Cost: Simple Payback:

$100,000.00 $100,950.00 13.61 years

This calculator was developed by Chris Milan at the Bonneville Power Administration (BPA) and is intended to be used as an indication of the potential energy savings and simple payback for ASD installations. If you have any questions or suggestions for improvements, please contact Chris Milan at cbmilan@bpa.gov. More extensive analysis tools are available at: http://www.eere.energy.gov/industry.

Page 9 of 14

Bonneville Power Administration

[Revision No. 1]

TYPES OF AIRFLOW CONTROL

Inlet Guide Vanes and Inlet Dampers

Inlet Guide Vanes are installed across the opening of the fan inlet. By opening and closing, they vary the amount of air entering the fan and change the profile of the entering airstream. As the air passes through the vanes it begins to swirl in the same rotation as the fan impeller, this pre-spinning of the air reduces the momentum that the fan blades can impact on the entering air and therefore reduces the velocity and pressure of the discharged air. As the vanes continue to close, this swirling action increases and continues to decrease the pressure and flow the fan delivers to the system. The fan horsepower is proportional to the flow and pressure, therefore the horsepower requirement also decreases. Because the inlet vane opening affects all three of these fan characteristics, a new fan performance curve is created whenever the vane position is changed. Inlet control does not affect the system curve, as vane positions change the fan performance curve rides up and down the system curve.

Outlet Dampers

Outlet dampers do not change the characteristics of the entering airstream. Outlet dampers control flowrate by restricting the amount of air being discharged. This restriction allows the air flow rate to be varied the same way a discharge throttle valve adjusts the volume of flow out of a pump. The resistance of flow through the system increases as the flow(cfm) of air increases. This relationship is shown graphically by plotting the flow and corresponding resistance(pressure) to generate the system resistance curve. When the system curve and fan performance curve are shown on the same graph, the intersection of these two curves defines a unique point of operation. When the fan is installed in this particular system and operates at this flow rate, it will produce this pressure. The fan can only operate as shown by it's performance curve, for a given pressure it will provide a unique flow or vice versa.

Adjustable Speed-Drives

Adjustable Speed Drives(ASDs) control the flowrate by electronically adjusting the speed of the motor driving the fan or pump. Similar to Inlet Guide Vanes, as the speed is reduced, the flowrate, pressure and horsepower requirement is reduced which results in a new performance curve for each speed setting. With ASDs, as speed is reduced the horsepower requirement is decreased according to the affinity laws within a squared to cubic relationship depending upon the amount of static pressure and how the system responds to changes in flow and pressure. A system containing static head and in which small increases in flow result in large pressure drops will have a system curve that rises steeply. By plotting this system curve and a system curve that does not rise steeply onto the same fan or pump performance curves at various speeds, one can see the following relationship. That for the same reduction in flow rate, the system curve that rises steeply will require more speed reductions to obtain this reduced flow and therefore the greater the opportunity for energy savings.

Operating Characteristics

Inlet dampers can be oriented to provide the same affect as inlet guide vanes but usually are not as effective at inducing the appropriate swirl. The blades typically operate in parallel with each other. If the inlet dampers are installed too far from the fan inlet or are not oriented properly, they only serve to restrict the entering airflow.

With outlet damper control, any new operating point is achieved by adjusting the characteristics of the system curve, not the fan performance curve. For example, in order to reduce the fan flow rate, as the outlet dampers begin to close, the system's resistance(pressure) increases and shifts the system curve upward until it intersects the fan performance curve to define a new operating point of increased pressure and reduced flow.

In determining the appropriate application of an ASD, the entire system should be evaluated. For example, if the fan or pump and electric motor is oversized, further reductions in operating speed could result in significant reductions in motor efficiency as well as the efficiencies of the fan, pump. In some cases the motor can be resheaved to confirm energy savings and system response to reduced speeds prior to purchasing the drive.

Advantages/ Disadvantages

Inlet Dampers are usually a better choice of flow control than Outlet Dampers because when properly installed, they allow the fan horsepower to be reduced as the flow is reduced. Inlet Guide Vanes usually provide more accurate control of fan performance than Inlet Dampers. Inlet Guide Vanes are an efficient method for controlling flow rates down to approximately 70% of capacity. This would correspond to a vane position of approximately 50% closed. If the desired fan flow rate requires that the vanes be closed more than 50%, adjustable speed drives usually provide more efficient controllability by reducing the fan speed rather than continuing to restrict the fan inlet with the guide vanes.

Dampers are an efficient method of fully open/closed flow control such as exhaust air or outside air intakes. Outlet dampers are the least efficient method of variable flow control. In order for the fan to compensate for this increase in system pressure when the dampers begin to close, it has to move to the left up along the performance curve to the higher operating pressure. For the majority of fans, as you continue to restrict flow and increase pressure, the fan operates in the least efficient and unstable region of the fan performance curve. Operating at higher system pressures than necessary to reduce the flow rate not only wastes energy but increases the air leakage throughout the system. Depending upon the variation in flow rates required by the system, inlet guide vanes or adjustable speed drives may provide more energy efficient flow control.

ASDs are an excellent choice of flow control if the system allows the fan or pump to operate at reduced flow rates and loads for a significant portion of the operating time. The ASDs provide quick and accurate adjustments to flow rate and pressure as required to maintain set point. Another advantage of ASD control is their soft starting capabilities which reduces the high in-rush currents at start-up. Operating at reduced speeds can increase the equipment life, reduce vibrations and noise. For fan applications were the flow rate does not vary significantly, inlet guide vanes may be a better choice of control. ASDs are not 100% efficient, therefore operating the motor at full speed with the ASD will increase the input power due to the inefficiency of the drive. ASDs typically require that they be placed in a clean, conditioned environment which could result in high installation costs.

Reference: "Improving Fan System Performance" Industrial Technologies and Best Practices Web Site at: http://www.oit.doe.gov

Page 10 of 14

Bonneville Power Administration

Revision No. 1

Pump Drives Power Graphs

Eddy Current Drive Pump Flow Control ASD Pump Flow Control

120.00 % of Design Input Power (kW) % of Design Input Power (kW) 100.00

89.64 104.45

120.00 100.00 80.00 60.00 40.00

30.37 43.19 59.53 79.40 102.79

80.00 60.00

51.06 62.77

75.69

40.00

32.01

40.75 25.03 16.40 17.04 19.98

20.00 0.00 0

20.00 0.00

21.07 14.32 13.05 15.30

20

40

60

80

100

120

10

20

30

40

50

60

70

80

90

100

110

% of Design Flow (gpm) Mechanical Speed Pump Flow Control 120 % of Design Input Power (kW) 100

86.46 104.88 96.29

% of Design Flow (gpm) or % of Full Speed(rpm)

80 60

53.72 64.76

75.81

40

33.38

43.12

These power curves are used in the energy savings analysis. Curves developed from data obtained by measuring the operating characteristics of various pumps and from information provided in "Flow Control", a Westinghouse publication, Bulletin B-851, F/86/Rev-CMS 8121. Curves are representative, not precise, final economic analysis should be based on actual power(kW) measurements of the pumping system.

20

13.51

24.92 18.16

0 0 20 40 60 % of Design Flow (gpm) 80 100 120

Values used in spreadsheet

Page 11 of 14

Bonneville Power Administration

Revision No. 1

ADJUSTABLE SPEED DRIVE ENERGY SAVINGS CALCULATOR

~ Pump Applications ~

Pump Motor Information Enter Nameplate Horsepower: Enter Nameplate Efficiency: Enter Motor Load at Pump Design GPM: Enter Power(KW) at Pump Design GPM: 100.00 95.00 80.00 62.82 hp % % KW Facility Information Enter Hours per year pump operates: Enter Energy Charge: 4000 0.05 hrs/yr $/kwh Existing Pump Flow Control Method Select Flow Control Method Below 1

Click to go to Pump Power Graphs for additional information

1 Throttling Valve 2 Eddy Current Clutch 3 Mechanical (Torque Converter) Power Analysis Existing System ASD System Percent of Design (kW) for ASD System 27.45 19.12 14.32 13.05 15.30 21.07 30.37 43.19 59.53 79.40 102.79

existing

4 Bypass, Recirculation Valve 5 Selection 5 allows Measured Power (kW) readings to be used

Duty Cycle

Savings Analy

Enter Percent Enter of Design Percent of Capacity Time at this (GPM) Capacity 0.0% 10.0% 20.0% 30.0% 40.0% 50.0% 60.0% 70.0% 80.0% 90.0% 100.0% Totals: 5.0% 5.0% 10.0% 10.0% 10.0% 10.0% 10.0% 10.0% 10.0% 10.0% 10.0% 100.0%

Existing System Percent of Design (KW) 55.21 61.39 67.19 72.61 77.65 82.31 86.59 90.49 94.01 97.15 99.91

Do Not Enter Data Below

Existing System Power (kW) 34.69 38.57 42.21 45.62 48.78 51.71 54.40 56.85 59.06 61.03 62.77 207,619.56 Kwh/yr

ASD System Power (kW) 17.24 12.01 9.00 8.20 9.61 13.24 19.08 27.13 37.40 49.88 64.58 101,095.47 Kwh/yr

asd

Annual Energy Savings (Kwh/yr)

3,488.44 5,310.66 13,284.77 14,967.19 15,668.60 15,388.99 14,128.38 11,886.75 8,664.10 4,460.44 -724.23 106,524.09

Sample Duty Cycles (these can be used as a guide if the duty cycle is not known)

Sample Duty Cycle - HIGH PUMP LOADING Sample Duty Cycle - LOW PUMP LOADING

70 60 Percent of Time at this Capacity 50 40 30 20 10 0

50 75 Percent of Design Capacity (gpm) 90

60

55

60 Percent of Time at this Capacity 50

40

30

25

20

20

20

15

10

0

30

Percent 50 of Design Capacity (gpm) 70

Summary Energy Savings: Cost Savings: Materials Cost: 106,524.09 KWH/yr $5,326.20 $Labor Cost: Total Cost: Simple Payback: $$-

This calculator was developed by Chris Milan at the Bonneville Power Administration (BPA) and is intended to be used as an estimation of potential energy s simple payback for ASD installations. Final economic decisions should be based upon more extensive analysis tools than what is provided here.

If you have any questions or comments, please email Chris Milan at the following: More extnesive analysis tools are available at the following DOE web site: You may download a copy of this calculator at the following BPA web site*: * This is an Excel 2000 file and is approximately 2.5 MB in size.

cbmilan@bpa.gov http://www.eere.energy.gov/industry

http://www.bpa.gov/energy/N/projects/I

Page 12 of 14

Bonneville Power Administration

Revision No. 1

ADJUSTABLE SPEED DRIVE ENERGY SAVINGS CALCULATOR

~ Pump Applications ~

Motor Information

ity Information

p Flow Control Method

k to go to Pump Power Graphs for additional information

Selection 5 allows Measured Power (kW) readings to be used in the analysis

Savings Analysis

Annual Energy Cost Savings ($/yr)

174.42 265.53 664.24 748.36 783.43 769.45 706.42 594.34 433.21 223.02 -36.21 $5,326.20

used as a guide if the duty cycle is not known)

Sample Duty Cycle - LOW PUMP LOADING

60

55

Percent of Time at this Capacity

50

40

30

25

20

15

10

5

0

30

Percent 50 of Design Capacity (gpm) 70

90

Summary

years

tion (BPA) and is intended to be used as an estimation of potential energy savings and upon more extensive analysis tools than what is provided here.

cbmilan@bpa.gov http://www.eere.energy.gov/industry http://www.bpa.gov/energy/N/projects/Industrial/

Page 13 of 14

Bonneville Power Administration

Revision No. 1

Throttle Valve Power Graphs

105

Constant Recirculation, Bypass Control

125

Throttling Valve Flow Control

100

100

94 90 87 82

97

100

% of Design (kW)

% of Design (kW)

95

75

67

78 73

90

50

85

25

80

10

20

30

40

% of Design Flow (gpm)

50

60

70

80

90

100

110

10

20

30

40 50 60 70 % of Design Flow (gpm)

80

90

100

110

The power curves above are used in the energy savings analysis. Curves developed from data obtained by measuring the operating characteristics of various pumps and from information provided in "Flow Control", a Westinghouse publication, Bulliten B-851, F/86/RevCMS 8121. Curves are representative, not precise, final economic analysis should be based on actual power (kW) measurements of the pumping system.

Page 14 of 14

Bonneville Power Administration

Revision No. 1

Das könnte Ihnen auch gefallen

- Centrifugal Curvebook 2020Dokument64 SeitenCentrifugal Curvebook 2020Ruwan Susantha PelawattaNoch keine Bewertungen

- Shell and Tube Heat Exchanger CalculationDokument9 SeitenShell and Tube Heat Exchanger CalculationKuldeep28883Noch keine Bewertungen

- Shell and Tube Heat Exchanger Design: Fig. 4 Fig. 2Dokument42 SeitenShell and Tube Heat Exchanger Design: Fig. 4 Fig. 2songjihyo16111994Noch keine Bewertungen

- Falling Film Evaporators For Water ChillersDokument42 SeitenFalling Film Evaporators For Water Chillerssandyengineer13Noch keine Bewertungen

- GEA PHE Evaporation enDokument16 SeitenGEA PHE Evaporation enGuerrero OmarNoch keine Bewertungen

- Sizing a Reciprocating Compressor for Natural Gas ServiceDokument6 SeitenSizing a Reciprocating Compressor for Natural Gas ServiceNikhil Ashok Badgu100% (1)

- NETZSCH General BrochureDokument19 SeitenNETZSCH General BrochureAnonymous T7zEN6iLHNoch keine Bewertungen

- Ventilation DesignDokument4 SeitenVentilation DesignPhyu Mar Thein KyawNoch keine Bewertungen

- Heat Exchanger RatingDokument10 SeitenHeat Exchanger RatingAnand BhiseNoch keine Bewertungen

- Flow CalculatorDokument45 SeitenFlow CalculatorIndrajit BorikarNoch keine Bewertungen

- Basics of Refrigeration - EvaporatorsDokument32 SeitenBasics of Refrigeration - Evaporatorsfarazgazanfar-1Noch keine Bewertungen

- Esp Calculation Exhaust Air-TaDokument4 SeitenEsp Calculation Exhaust Air-TaAshiq NishmaNoch keine Bewertungen

- Shell & Tube Condenser Design MethodDokument4 SeitenShell & Tube Condenser Design MethodwestewrNoch keine Bewertungen

- Mixing TankDokument3 SeitenMixing Tankleslie_adolfoNoch keine Bewertungen

- Pipe Roughness and C-Factors TableDokument48 SeitenPipe Roughness and C-Factors Tablesaroat moongwattanaNoch keine Bewertungen

- Refrigerant DistributionDokument4 SeitenRefrigerant DistributionjorgedvfNoch keine Bewertungen

- Roots blower data sheetDokument1 SeiteRoots blower data sheetPhượng NguyễnNoch keine Bewertungen

- CDA Data CollectionDokument2 SeitenCDA Data Collectiondford8583Noch keine Bewertungen

- SP SP VP V PR) : Velocity Pressure Method Calculation SheetDokument6 SeitenSP SP VP V PR) : Velocity Pressure Method Calculation SheetAnkit LonareNoch keine Bewertungen

- 00.02 Wear Calculations Chain ConveyorDokument1 Seite00.02 Wear Calculations Chain ConveyorSandy DumisaniNoch keine Bewertungen

- Pipe DimensionDokument7 SeitenPipe DimensionLily NurdianaNoch keine Bewertungen

- Steam HXDokument1 SeiteSteam HXrajachemNoch keine Bewertungen

- Yazd-System Description For Clean Drain System PDFDokument7 SeitenYazd-System Description For Clean Drain System PDFace-winnieNoch keine Bewertungen

- MODEL: PFTA 1500-4: Ratings & Performance DataDokument4 SeitenMODEL: PFTA 1500-4: Ratings & Performance DataAnonymous izGbhcNoch keine Bewertungen

- Dykewall CalculationDokument4 SeitenDykewall CalculationVipul GandhiNoch keine Bewertungen

- Duct velocity and inside velocity calculationsDokument4 SeitenDuct velocity and inside velocity calculationsAnonymous pVoSWn8yh0Noch keine Bewertungen

- Esp Pu-1Dokument1 SeiteEsp Pu-1Abdul Majeed KottaNoch keine Bewertungen

- Final HP Heater by Kerns MethodDokument5 SeitenFinal HP Heater by Kerns Methodbb84sharmaNoch keine Bewertungen

- Modified Vyas formula for S.D.P. treatment of organic and aqueous wasteDokument11 SeitenModified Vyas formula for S.D.P. treatment of organic and aqueous wasteNITIN P SHAHNoch keine Bewertungen

- Cyclone CalculatorDokument19 SeitenCyclone CalculatornarsingrameshNoch keine Bewertungen

- VSD Calculator for Fan Energy SavingsDokument10 SeitenVSD Calculator for Fan Energy SavingsCésar Christian JankoNoch keine Bewertungen

- Unit conversion program for engineering processesDokument9 SeitenUnit conversion program for engineering processesAnubhav KhandelwalNoch keine Bewertungen

- Preliminary Evaporator Design and Selection Rev2Dokument33 SeitenPreliminary Evaporator Design and Selection Rev2Steve WanNoch keine Bewertungen

- Perancangan CycloneDokument20 SeitenPerancangan CycloneDavid LambertNoch keine Bewertungen

- Product Heat Load CalculatorDokument7 SeitenProduct Heat Load CalculatorNafiz JaberNoch keine Bewertungen

- Test Cyclone ExcelDokument16 SeitenTest Cyclone Excelvivek mishraNoch keine Bewertungen

- Ashp Sav CalcDokument5 SeitenAshp Sav CalcsauroNoch keine Bewertungen

- Moist Air PropertiesDokument12 SeitenMoist Air PropertiesLily DianaNoch keine Bewertungen

- PV Elite 2020 Licensee: Tubesheet Check CalculationDokument8 SeitenPV Elite 2020 Licensee: Tubesheet Check CalculationAbhishek LadNoch keine Bewertungen

- Helical Coil - With AgitationDokument3 SeitenHelical Coil - With AgitationUmair FareedNoch keine Bewertungen

- Multiple Effect Evaporator Online CalculationsDokument1 SeiteMultiple Effect Evaporator Online CalculationsRajdeepsinhNoch keine Bewertungen

- STM Dosing and Feeding Systems For Air Pollution ControlDokument42 SeitenSTM Dosing and Feeding Systems For Air Pollution ControlJoseph RileyNoch keine Bewertungen

- MicrofilterDokument17 SeitenMicrofilterArrianne Jaye MataNoch keine Bewertungen

- Control Valve Sizing GuideDokument23 SeitenControl Valve Sizing GuideEnerprec SASNoch keine Bewertungen

- Heat Exchanger (FT)Dokument9 SeitenHeat Exchanger (FT)Aron BalinesNoch keine Bewertungen

- Hydraulic calculation of boiler feedwater pump using Darcy methodDokument5 SeitenHydraulic calculation of boiler feedwater pump using Darcy methodLee JianNoch keine Bewertungen

- Burner specification document summaryDokument6 SeitenBurner specification document summaryHafiz Muhammad AbubakarNoch keine Bewertungen

- High Efficiency Packaged Boilers and Modular Boiler HousesDokument6 SeitenHigh Efficiency Packaged Boilers and Modular Boiler Housesdnageshm4n244Noch keine Bewertungen

- Calculation Sheet For Flares: User Supplied Inputs (Grey Cells)Dokument1 SeiteCalculation Sheet For Flares: User Supplied Inputs (Grey Cells)VishalNoch keine Bewertungen

- Tank Size CalculatorDokument3 SeitenTank Size CalculatorDinah Fe Tabaranza-OlitanNoch keine Bewertungen

- Cleaning Schedule DateDokument6 SeitenCleaning Schedule Datedanny mackNoch keine Bewertungen

- Fluid MixingDokument16 SeitenFluid MixingNajihah JaffarNoch keine Bewertungen

- Rotary LockDokument224 SeitenRotary LockTahirMutluNoch keine Bewertungen

- Double FdexchangerDokument8 SeitenDouble FdexchangerBoško IvanovićNoch keine Bewertungen

- VFD FP Calc2Dokument14 SeitenVFD FP Calc2danceNoch keine Bewertungen

- Fan Types: Technical Bulletin TBN007.0/1998Dokument7 SeitenFan Types: Technical Bulletin TBN007.0/1998hessam_seifiNoch keine Bewertungen

- Equations and Design Considerations for Axial Flow FansDokument9 SeitenEquations and Design Considerations for Axial Flow FansMohammad HaddadiNoch keine Bewertungen

- Fan 1Dokument5 SeitenFan 1HARSHANoch keine Bewertungen

- Ventilation FundamentalsDokument24 SeitenVentilation FundamentalsSomnath SenNoch keine Bewertungen

- Fan Fundamentals - Greenheck (May2005)Dokument24 SeitenFan Fundamentals - Greenheck (May2005)jagdishgharoteNoch keine Bewertungen

- Heat Exchanger VibrationDokument3 SeitenHeat Exchanger VibrationTim KuNoch keine Bewertungen

- Dust CollectionDokument6 SeitenDust Collectionkulov1592Noch keine Bewertungen

- Connections 1 FiguresDokument19 SeitenConnections 1 FiguresPatricio TamayoNoch keine Bewertungen

- Dust Control HandbookDokument314 SeitenDust Control HandbookJoseph RileyNoch keine Bewertungen

- Reologia de STEFFEDokument428 SeitenReologia de STEFFESarai SierraNoch keine Bewertungen

- Four Types of Industrial Dust CollectorsDokument43 SeitenFour Types of Industrial Dust Collectorskulov1592100% (1)

- Estimating Costs and Procedures for Dust Control SystemsDokument10 SeitenEstimating Costs and Procedures for Dust Control SystemsPatricio TamayoNoch keine Bewertungen

- Bill of Materials and Engineering DrawingsDokument1 SeiteBill of Materials and Engineering DrawingsFaull JackmanNoch keine Bewertungen

- CTHS430-02 IM S223.855.en-01Dokument80 SeitenCTHS430-02 IM S223.855.en-01Patricio Tamayo100% (2)

- HL 209Dokument22 SeitenHL 209Patricio TamayoNoch keine Bewertungen

- PROTECT STEEL WITH MOST USED PAINTSDokument12 SeitenPROTECT STEEL WITH MOST USED PAINTSsmartcharlinNoch keine Bewertungen

- CTHS430-02 OMM S223.857.en-01Dokument118 SeitenCTHS430-02 OMM S223.857.en-01Patricio Tamayo100% (5)

- Isometric Sketch SheetDokument1 SeiteIsometric Sketch SheetPatricio TamayoNoch keine Bewertungen

- Vessel Description: Pressure Vessel Engineering, LTDDokument40 SeitenVessel Description: Pressure Vessel Engineering, LTDSivateja NallamothuNoch keine Bewertungen

- Salt Storage Handbook 2013Dokument24 SeitenSalt Storage Handbook 2013Patricio TamayoNoch keine Bewertungen

- Untertrum 980 82 BedAnl EDokument31 SeitenUntertrum 980 82 BedAnl EPatricio TamayoNoch keine Bewertungen

- CTHS430-02 SPC R223.1394-01Dokument82 SeitenCTHS430-02 SPC R223.1394-01Patricio Tamayo100% (1)

- CTHS430 02 IMA S223.856-01.enDokument37 SeitenCTHS430 02 IMA S223.856-01.enPatricio Tamayo50% (2)

- Inbetr-Wartung Förderbänder (GB)Dokument5 SeitenInbetr-Wartung Förderbänder (GB)Patricio TamayoNoch keine Bewertungen

- CH430-02 WPC R223.1403-01Dokument22 SeitenCH430-02 WPC R223.1403-01Patricio Tamayo100% (3)

- CH430 01 02 - IMA - S223.651.en 02Dokument33 SeitenCH430 01 02 - IMA - S223.651.en 02Patricio Tamayo67% (3)

- Technische Daten MRS 001 (GB)Dokument2 SeitenTechnische Daten MRS 001 (GB)Patricio TamayoNoch keine Bewertungen

- Seilzugschalter Kiepe PRS GBDokument30 SeitenSeilzugschalter Kiepe PRS GBPatricio TamayoNoch keine Bewertungen

- 0 CH430-02 Declaration of Conformity S058.203.en-01Dokument1 Seite0 CH430-02 Declaration of Conformity S058.203.en-01Patricio TamayoNoch keine Bewertungen

- Technische Daten PRS (GB)Dokument4 SeitenTechnische Daten PRS (GB)Patricio TamayoNoch keine Bewertungen

- Technische Daten MRS 001 (GB)Dokument2 SeitenTechnische Daten MRS 001 (GB)Patricio TamayoNoch keine Bewertungen

- Schieflaufschalter-Kiepe MRS001 - GBDokument16 SeitenSchieflaufschalter-Kiepe MRS001 - GBPatricio TamayoNoch keine Bewertungen

- Seilzugschalter Kiepe PRS GBDokument30 SeitenSeilzugschalter Kiepe PRS GBPatricio TamayoNoch keine Bewertungen

- Technische Daten PRS (GB)Dokument4 SeitenTechnische Daten PRS (GB)Patricio TamayoNoch keine Bewertungen

- Schieflaufschalter-Kiepe MRS001 - GBDokument16 SeitenSchieflaufschalter-Kiepe MRS001 - GBPatricio TamayoNoch keine Bewertungen

- Spectacle Prop Shaft SupportsDokument2 SeitenSpectacle Prop Shaft Supportsshafwan1980Noch keine Bewertungen

- Control SystemsDokument8 SeitenControl Systemstriaulia100% (1)

- Appendix5 Syllabus Amsa Oral Exam Cert Competency EngineerDokument4 SeitenAppendix5 Syllabus Amsa Oral Exam Cert Competency EngineerCF LeeNoch keine Bewertungen

- Ts Pec HamiltonDokument72 SeitenTs Pec HamiltonederlucianoribeiroNoch keine Bewertungen

- Design of An Unmanned Hovercraft: International Journal of Computer Engineering in Research TrendsDokument5 SeitenDesign of An Unmanned Hovercraft: International Journal of Computer Engineering in Research TrendsH JNoch keine Bewertungen

- Energy For Sustainable Development: Martin Anyi, Brian KirkeDokument8 SeitenEnergy For Sustainable Development: Martin Anyi, Brian KirkeLuiz Angelo VillegasNoch keine Bewertungen

- Developed Blade Area Drawings For Raked PDFDokument7 SeitenDeveloped Blade Area Drawings For Raked PDFldigasNoch keine Bewertungen

- Internal Cutters: Manual E535Dokument23 SeitenInternal Cutters: Manual E535Wagner AmaralNoch keine Bewertungen

- Prediction and Measurement of Propeller Singing: C e C Ec e EeDokument1 SeitePrediction and Measurement of Propeller Singing: C e C Ec e EeArun SNoch keine Bewertungen

- Book Marine Propellers and Propulsion (CARLTON)Dokument18 SeitenBook Marine Propellers and Propulsion (CARLTON)Jhason ChristNoch keine Bewertungen

- Wärtsilä Enviroguard Pse DatasheetDokument4 SeitenWärtsilä Enviroguard Pse DatasheetWilfredo Salas MarcosNoch keine Bewertungen

- Bridge Control NotesDokument3 SeitenBridge Control NotesAmit PandeyNoch keine Bewertungen

- Wartsila O E W X62Dokument2 SeitenWartsila O E W X62Prasad PatilNoch keine Bewertungen

- Ekg March 2016Dokument74 SeitenEkg March 2016Thomas JoseNoch keine Bewertungen

- Heavy Duty Side Entry Mixers Technical ManualDokument26 SeitenHeavy Duty Side Entry Mixers Technical ManualMarina Fernández MirandaNoch keine Bewertungen

- Viktor Schauberger - InventosDokument11 SeitenViktor Schauberger - Inventoscleto1111100% (8)

- 706 - Performance Evaluation and General Operation - 007 PDFDokument72 Seiten706 - Performance Evaluation and General Operation - 007 PDFVignesh SivaNoch keine Bewertungen

- F4MHH F4amh'09Dokument33 SeitenF4MHH F4amh'09GermanDarioRussoNoch keine Bewertungen

- AE 412 - 01. Preliminary PeriodDokument46 SeitenAE 412 - 01. Preliminary PeriodjohnclientebooklibraryNoch keine Bewertungen

- Understanding Cavitation Details Crucial for Erosion PredictionDokument10 SeitenUnderstanding Cavitation Details Crucial for Erosion PredictionKriz Hor Jiunn ShyangNoch keine Bewertungen

- Practical Design of Ships and Other Floating Structures Vol 2Dokument646 SeitenPractical Design of Ships and Other Floating Structures Vol 2VOKRAMNoch keine Bewertungen

- Refitting Conical Orbital ScrewsDokument4 SeitenRefitting Conical Orbital ScrewsRelining MineralsNoch keine Bewertungen

- Transition Flight Modeling of A Fixed-Wing VTOL UAVDokument23 SeitenTransition Flight Modeling of A Fixed-Wing VTOL UAVkhoamaiNoch keine Bewertungen

- Om 02-02-4 6 Easa VersionDokument149 SeitenOm 02-02-4 6 Easa VersionCarlos TorresNoch keine Bewertungen

- Bow Thruster UnitDokument111 SeitenBow Thruster UnitFederico BabichNoch keine Bewertungen

- 20245F - Fu63 - LTC1550 InstrDokument148 Seiten20245F - Fu63 - LTC1550 InstrAleX JuniorNoch keine Bewertungen

- Agreement for Two WorkboatsDokument7 SeitenAgreement for Two WorkboatsAamir SirohiNoch keine Bewertungen

- Report PDFDokument54 SeitenReport PDFLusthya Resita ZNoch keine Bewertungen

- 706 - Performance Evaluation and General Operation - 007Dokument72 Seiten706 - Performance Evaluation and General Operation - 007Vignesh SivaNoch keine Bewertungen

- Woytowich R.calculation of Prope - dec.1979.JSRDokument7 SeitenWoytowich R.calculation of Prope - dec.1979.JSRJohn KokarakisNoch keine Bewertungen