Beruflich Dokumente

Kultur Dokumente

View Content

Hochgeladen von

vinod_eicsCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

View Content

Hochgeladen von

vinod_eicsCopyright:

Verfügbare Formate

2003 ECI Conference on Advanced Materials for Construction of Bridges, Buildings, and Other Structures III

% FILE:

/main/production/doc/data/journals/services.bepress.com/advanced materials/assets/location.inc Switzerland% FILE: (cont)

/main/production/doc/data/journals/services.bepress.com/eci/assets/proceedings/pdftitlepage.te

Editors: % FILE: /main/production/doc/data/journals/services.bepress.com/advanced materials/assets/editors.incV Mistry, P.E., Oce of Bridge Technology, Federal Highway Administration, USA Dr. Atorod Azizinamini, Ph.D., P.E., Civil Engineering Department, University of Nebraska, USA John M. Hooks, P.E., Oce of Infrastructure Research & Development, Federal Highway Administration, USA % FILE: /main/production/doc/data/journals/services.bepress.com/eci/assets/proceedings/denes.tmpl (cont)

Year

Paper

Histar High Performance Hot-Rolled Beams

Lucien Weber

ARCELOR Long Commercial

Histar High Performance Hot-Rolled Beams

Abstract

The construction industry is continuously looking for superior building components. Innovative production processes are, in combination with tight quality control, the keys to structural steel grades with outstanding properties. Especially the thermomechanical treatment allows for combining material properties which were formerly thought to be incompatible: high yield strength for big material thicknesses, good toughness and excellent weldability. This paper presents the Quenching and Self-Tempering (QST) process which allows for the production of heavy hot-rolled H-beams in high strength structural steel grades with excellent weldability characteristics. The new steel grades fully comply and even exceed the requirements of the European and American structural steel standards. The good toughness and ductility of these grades also make them very suitable for applications in earthquake areas. Ten years of experience in producing and commercializing heavy beams in high strength grades world-wide also allow to present the economical use of these products in various structures, such as long span trusses, high-rise buildings, bridges and oshore applications.

http://services.bepress.com/eci/advanced materials/4 Copyright c 2005 by the author.

Weber: Histar High Performance Hot-Rolled Beams

HISTAR HIGH PERFORMANCE HOT-ROLLED BEAMS

Lucien WEBER ARCELOR Long Commercial 66, rue de Luxembourg, Esch-sur-Alzette, 4221, LUXEMBOURG T: +352 5313 3071, F: +352 5313 4279, lucien.weber@arcelor.com

ABSTRACT The construction industry is continuously looking for superior building components. Innovative production processes are, in combination with tight quality control, the keys to structural steel grades with outstanding properties. Especially the thermomechanical treatment allows for combining material properties which were formerly thought to be incompatible: high yield strength for big material thicknesses, good toughness and excellent weldability. This paper presents the Quenching and Self-Tempering (QST) process which allows for the production of heavy hot-rolled H-beams in high strength structural steel grades with excellent weldability characteristics. The new steel grades fully comply and even exceed the requirements of the European and American structural steel standards. The good toughness and ductility of these grades also make them very suitable for applications in earthquake areas. Ten years of experience in producing and commercializing heavy beams in high strength grades world-wide also allow to present the economical use of these products in various structures, such as long span trusses, high-rise buildings, bridges and offshore applications. INTRODUCTION Driven by strong competition, the H-beam market has developed over the last years towards sections with greater thicknesses and higher yield strength. High technology areas such as offshore structures and high-rise buildings require furthermore excellent toughness combined with improved fabrication properties. The conventional method for producing high-strength steels consists in adding alloying elements to the steel and rolling at controlled temperatures. This thermomechanical (TM) rolling technique is however limited by: the mechanical power of the rolling mills as this process asks for high deformation rates at relatively low temperatures, the impossibility of substantially reducing the carbon equivalent (CE) value of the steel and, as a consequence, of improving its weldability.

So, until recently, the heavy structural H-shapes were only available in the market with yield strengths up to 345 MPa (50 ksi) and the need for preheating during welding operations. Nowadays, the QST process allows, in combination with the classical TM rolling, to overcome these limitations and to combine high yield strength, good toughness and excellent weldability for the whole range of available heavy H-beams. The corresponding steels are known in the market as HISTAR

1

Produced by The Berkeley Electronic Press, 2011

Advanced Materials for Construction of Bridges, Buildings, and Other Structures III [2003], Vol. P05, Article 4

(High-Strength-ARBED) grades. They fulfil and even exceed the requirements for structural and offshore steels according to European standards (EN10025, EN10113, EN10225) as well as American standards (ASTM A913, A992). Test programs have confirmed the outstanding mechanical and technological properties of the HISTAR steels. MODERN PRODUCTION PROCESS FOR HIGH PERFORMANCE BEAMS The QST process uses water and the rolling heat as working substances. A prerequisite for a successful QST treatment of heavy beams is the homogeneous temperature profile of the whole cross-section before entering the cooling bank. This condition is fulfilled by applying a selective cooling during rolling to the hottest part of the beam, namely the flange-web intersection (Figure 1). Doing so, substantial temperature differences over the entire flange width can be eliminated. This process considerably improves the grain sizes and reduces the residual stresses in the core area.

Ar3

Rolling with selective cooling

Classical rolling

Temperature Figure 1. Selective cooling of heavy structural beams After the last rolling pass, an intense water-cooling is applied to the whole surface of the beam. Cooling is interrupted before the core is affected and the outer layers are tempered by the flow of heat from the core to the surface (Figure 2). At the exit of the finishing stand, directly at the entry of the cooling bank, the rolling temperature of the beam lies typically at 850C (1560F). After the quenching over the whole surface of the section, self-tempering is achieved at 600C (1110F). The parameters of this industrial process are controlled by computer. PROPERTIES OF HISTAR STEEL GRADES The QST process considerably increases the yield strength and the toughness of the steel. Due to much lower carbon equivalent values when compared with conventional structural steel grades, the weldability and the ductility of the steel grades are significantly improved.

2

http://services.bepress.com/eci/advanced_materials/4

Weber: Histar High Performance Hot-Rolled Beams

Quenching and Self Tempering

QST Bank

Recristallised austenite Te Nonmp recristallisederat austenite ure Ferrite + austenite Ferrite + pearlite

Deformation

Water cooling

Surface Core

Finishing stand QST Bank entry Quenching 850C Self Tempering 600C

Martensite

Time

Transformation TM-rolling QST- treatment

Figure 2. Schematic illustration of the QST-process Mechanical properties All HISTAR grades offer a constant guaranteed minimum value for yield strength over the whole range of product thicknesses. The main mechanical properties of these grades are given in Table 1 and Table 2. A comparison between the yield strength of HISTAR grades and conventional hot rolled fine grain grades in accordance with EN 10113-3:1993 is shown in Figure 3. Table 1. Mechanical properties of structural HISTAR grades

Tensile strength Rm [MPa] Yield strength ReH [MPa] tf 125 mm 355 420 460 Elongation A5 [%] Notch Impact test Tempera- Absorbed ture [C] Energy [J] -20 40 -50 27 -20 40 -50 27 -20 40 -50 27

HISTAR355 HISTAR355L HISTAR420 HISTAR420L HISTAR460 HISTAR460L

450 500 530

22 19 17

Table 2. Mechanical properties of HISTAR offshore grades

Tensile strength Rm [MPa] Yield strength ReH [MPa] tf HISTAR355 TZO HISTAR355 TZKO HISTAR420 TZO HISTAR420 TZKO HISTAR460 TZO HISTAR460 TZKO 460-620 500-690 530-720 125 mm 355 420 460 Through thickness tensile test Zz min (%) 25 35 25 35 25 35 Elongation (5,65 So) Amin (%) 22 19 17 Notch Impact test Longitudinal direction -20C ; 50J -40C ; 50J -20C ; 60J -40C ; 60J -20C ; 60J -40C ; 60J Transverse direction -20C ; 27J -40C ; 50J -20C ; 27J -40C ; 50J -20C ; 27J -40C ; 50J

3

Produced by The Berkeley Electronic Press, 2011

Advanced Materials for Construction of Bridges, Buildings, and Other Structures III [2003], Vol. P05, Article 4

500

min. yield strength (N/mm2)

460

HISTAR 460

440 430

450

420

S 460 M

HISTAR 420

400

400 390

S 420 M

355

HISTAR 355

345 335

350

S 355 M

300 0

16

25

50 75 40 Material thickness (mm)

100

125

Figure 3. Min. yield strength ReH of HISTAR steels versus structural steel grades in accordance with EN 10113-3:1993 Weldability Figure 4 summarizes the relationship between chemical composition, product thickness and yield strength for the conventional rolling processes and the new QST process. In Europe, the grades HISTAR 355 to 460 have a maximum CE value of 0.39 %. In the range of normal heat inputs during welding (10-60 kJ/cm) and provided that low hydrogen filler metal and auxiliary products are used, a preheating is not necessary for temperatures of the structure over 0C (32F). In the USA, Grade 50 and Grade 65 in accordance with ASTM A913 (HISTAR 355 and 460) have been introduced in the AWS (American Welding Society) codes D1.1 in a category "weldable without preheating" if welded with low hydrogen electrodes (< 8 ml/100g). Toughness Nowadays, it is well established that a certain level of toughness of the steel is required in order to avoid the propagation of cracks associated with brittle fracture in the base material during welding or during seismic loading from earthquakes. Figure 5 displays the Charpy-V impact energy values measured after welding at various locations of the heat affected zone (HAZ) for different welding energy levels. Obviously excellent toughness values are guaranteed, mostly in excess of 100 J. In Europe, HISTAR 355 to HISTAR 460 are typically supplied with guaranteed toughness values of 47 J at 0 C. QST steels can also be supplied with better toughness at very low temperature. So, even a jumbo size HD 400x1086 kg/m (W14x730) in grade 460 MPa (gr 65) can be supplied with notch toughness values of 27J at 50C ! This explains why beams in HISTAR grades are extensively used for the construction of offshore platforms, for instance in North Sea projects.

4

http://services.bepress.com/eci/advanced_materials/4

Weber: Histar High Performance Hot-Rolled Beams

CE ( % )

0 ,8 0 ,7

T h i ck n e ss ( m m .)

125

80

0 ,6 0 ,5 0 ,4 0 ,3 0 ,2 0 ,1

235 290 345 4 2 0 4 5 05 0 0

Pr e h e a t i n g t e m p e r a t u r e C 130 100 70 50 20 0

40

Co n v e n t io n a l g ra d e s

10 125 80 40 10

H I STA R

M Pa Y i e l d St r e n g t h

CE (% ) = C ( % ) +

M n ( % ) + ( Cr + M o + V ) % + ( Cu + N i ) % 5 6 15

Figure 4. Weldability of HISTAR and conventional structural steel grades

MAG: 15 kJ/cm SAW: 30-80 kJ/cm [J] 1 200 4 100 0 Base material 15 30 1 2 3

no preheating

S460 M CEV: 0,38%

Charpy-V impact test -40 C

2 3 5

60 [

80 [kJ/cm] 1/4 t

t= 63 mm

Figure 5. Toughness measured in the weld material and the heat affected zone of an H-beam in steel grade HISTAR 460 (gr 65)

In the USA, after the Northridge earthquake in California, the task group revising the existing standards on earthquake design recommends for base metal minimum toughness requirements of 20J at 21C (70F) for enclosed structures and 20J at 4C (40F) for exposed structures. This is the reason why QST grade 65 /ASTM A913 (HISTAR 460) is the only steel with a yield higher than 345 MPa (50 ksi) that can be used in California for the columns of moment resisting frames. This steel is used in order to achieve the strong column weak beam concept, which is the most economical way to design framed structures in seismic zones.

5

Produced by The Berkeley Electronic Press, 2011

Advanced Materials for Construction of Bridges, Buildings, and Other Structures III [2003], Vol. P05, Article 4

Ductility Bend test on HISTAR samples typically show no cracks in the steel after bending at 180. This feature proves that QST steels have outstanding ductility which is a big advantage for seismic applications or any other applications requesting bending in the beams. Similar bend tests have also been performed after welding without preheating with different welding procedures and different heat inputs. In all cases, the conclusion is that welding does not affect the ductility of QST steels. ADVANTAGES AND SAVINGS FOR TYPICAL HISTAR APPLICATIONS When used as columns in buildings, for girders or as tension members in trusses, the new generation of HISTAR beams enables substantial savings in: structural weight, foundation costs, material costs, weld/fabrication costs, transportation and erection costs.

Typically, the extra cost for HISTAR 460 compared to grade S355 steel is only about 5%. In case full advantage can be taken from the higher yield strength, a HISTAR 460 beam is ~25% lighter than a comparable section in S355 so that the economical advantage on the material side alone is about 20%. The savings are even higher in case HISTAR 460 can be used instead of S235. HISTAR steels should be used instead of conventional structural steels every time that the welding procedure requires preheating. For the same material cost, the steel fabricator can save the time and propane needed for the preheating of normal steels. HISTAR application in high-rise buildings When the design is not governed by drift or vibration problems, the use of high strength steel in gravity columns with normal buckling lengths (typically less than 5m or 16ft) allows the engineer to reduce the weight and the cost of the steel structure. Indeed, the use of HISTAR 460 results in weight reduction of the columns in average of 15-25 % when compared to S355 and of more than 45 % when compared to S235 steel columns. Because of the small extra of HISTAR 460, the steel fabricator can achieve substantial savings. Typically, the gravity columns of buildings featuring a concrete core which takes all the lateral loads can easily be designed with HISTAR 460 (Figure 6). HISTAR application in long span trusses For trusses, the use of HISTAR 460 is ideal in tension members such as the bottom chords and in compression members with short buckling length such as the top chords. The use of HISTAR 460 generally allows a weight reduction exceeding 15 % when compared to a solution using S355 grade (Figure 7). This reduction in weight

6

http://services.bepress.com/eci/advanced_materials/4

Weber: Histar High Performance Hot-Rolled Beams

is a function of the truss span and the importance of the dead loads. As an example, the weight savings for the 108m (355 ft) long span truss of the Boeing hangar in Seattle were about 35% when compared to a grade S355 solution. Besides, the use of HISTAR steels allows the fabricator to weld with low hydrogen electrodes without preheating.

M A PFRE TO W ER

Colum n design

42

Top floor

Buckling length: 3,3 m

Total column weight S 355 : 25,3 t S 460 : 19,3 t

35 30

200

400

24% weight reduction thanks to the use of HISTAR 460 steel

Column load (t)

S S 46 0 35

25 20

Number of floors

600

800

15

10

1000

1200

1400

Ground floor

0 100 200 300

400

Unit column weight (kg/m)

Figure 6. Weight savings in gravity columns through the use of HISTAR 460 steel grade

Weight Costs Weld volume

142 % 133 % 119 %

100 %

87 % 77 % 59 %

S 235 HD 400 x 1086

S 355 x 900

HISTAR 460 x 677

Figure 7. Cost savings in trusses through the use of HISTAR 460 steel grade

7

Produced by The Berkeley Electronic Press, 2011

Advanced Materials for Construction of Bridges, Buildings, and Other Structures III [2003], Vol. P05, Article 4

HISTAR application in bridge construction Typically bridge structures carry heavy, dynamic and cyclic loads over long spans and during a long life. Safety and durability criteria result in stringent requirements for material quality. Therefore the achievements in material properties enabled by the QST process generates substantial benefits for bridge construction. As a result of designing structural elements in high strength steel, the size of the cross section and especially the material thickness are reduced. Figure 8 shows the steel girder specification of comparative design in different steel grades for a typical small span composite bridge. In this case, the weight reduction from the use of S460 instead of S355 is as high as 25% and the material cost saving is 21%. Beyond material cost advantage, the weight reduction eases transport and erection. Also, lower permanent loads need lower foundation bearing capacity. This fact is essential in the case of reconstruction of bridge decks on existing piers and abutments. Dead weight of movable bridges governs design of mechanical parts and high strength steel allows cost saving which exceed by far the material cost advantage. Reduced material thickness is a great advantage in case of welded splices. Especially for highly stressed parts, weld volume reduction of butt splices is spectacular: 40% to 60% (V and double V full penetration).

Steel grade Section Construction depth (m) Steel weight Material cost (beams)

S235 HE 1000 M 1,38 +16% +7%

S355 HE 700 M 1,09 reference reference

S460 HE 800 A 1,17 -25% -21%

S460 HE 700 B 1,08 -20% -17%

Figure 8.

Comparative design of a 17m-span road bridge

HISTAR application in seismic areas The use of HISTAR 460 and HISTAR 355 allows the engineer to design moment frame structures with the economical strong column weak beam concept which is commonly used on the West Coast of the United States. Only the use of this type of steel with yield higher than 355 MPa is allowed in the columns of moment frame structures located in a seismic zone. In addition, our companys development of the so-called dog bone or reduced beam section (RBS), which consists in cutting a portion of the top and bottom flange of the beam, achieves a fuse in the structure

8

http://services.bepress.com/eci/advanced_materials/4

Weber: Histar High Performance Hot-Rolled Beams

(Figure 9). During an earthquake, this special connection between the frame beams and columns absorbs substantial energy and provides major contributions to the displacement ductility demand with the creation of a simple plastic hinge. RBS moment frame connections are designed so that no plastification can occur in the column or in the connection. Many tests have been performed with good success and up till now, fabrication costs of this execution are considered the lowest when compared to other systems.

Figur e 9. Strong column-weak beam layout in combination with the reduced beam section for seismic design HISTAR application in offshore structures HISTAR Offshore steel grades have been especially developed for offshore applications. In addition to their potential for the design of light offshore structures, they offer improved deformation properties in through-thickness direction with respect to the resistance of lamelar tearing as well as notch impact properties in transverse direction (Table 2). CONCLUSIONS Structural steel is considered nowadays an economical building material. In addition, new high performance steels such as the quenched and self-tempered HISTAR grades have recently been made available in the market. These steels offer a combination of properties that was impossible to achieve a decade ago: high minimum yield point up to 460 MPa (65 ksi) for heavy hot-rolled sections with a flange thickness up to 125mm (5 in), outstanding toughness up to 50C (-58F) low carbon equivalent resulting in improved weldability without loss of ductility.

9

Produced by The Berkeley Electronic Press, 2011

10

Advanced Materials for Construction of Bridges, Buildings, and Other Structures III [2003], Vol. P05, Article 4

Cost savings, resulting from weight reduction as well as ease of fabrication and erection, made the HISTAR high strength steels an immediate success in typical applications such as heavily loaded columns, truss members or bridge structures. The use of these high strength steels within structural concepts such as the strong columnweak beam, and combined with the reduced beam section, offer additional reliable solutions for seismic design. The favorable combination of high strength, high toughness at low temperatures and easy weldability also make these new steel grades very suitable for offshore applications. REFERENCES [1] Bouchard S., Axmann G., The Steel of Choice, Structural Engineer, September 2000 [2] Hever M., Schrter F., Modern Steel High Performance Material for High Performance Bridges, 5th International Symposium on Steel Bridges, Barcelona, 2003. [3] Les Aciers Thermomcaniques Une nouvelle gnration daciers hautes performances, AFPC/OTUA, ISSN 0150-6900, 1997 [4] ASTM A913 00 Standard specification for High-Strength Low-Alloy Steel Shapes of Structural Quality. Produced by Quenching and Self-Tempering Process (QST) [5] ASTM A992 98 Standard specification for Steel for Structural Shapes For Use in Building Framing [6] EN 10025:1993 Hot rolled products of non-alloy structural steels Technical delivery conditions [7] EN 10 113-3:1993 Hot-rolled products in weldable fine grain structural steels Part 3. Delivery conditions for thermomechanical rolled steels [8] EN 10 164:1993 Steel products with improved deformation properties perpendicular to the surface of the product Technical delivery conditions [9] EN 10225:2002 Weldable structural steels for fixed offshore structures Technical delivery conditions

10

http://services.bepress.com/eci/advanced_materials/4

Das könnte Ihnen auch gefallen

- New Microsoft Office Word DocumentDokument2 SeitenNew Microsoft Office Word Documentvinod_eicsNoch keine Bewertungen

- New Microsoft Office Word DocumentDokument2 SeitenNew Microsoft Office Word Documentvinod_eicsNoch keine Bewertungen

- IRCTC LTD, Booked Ticket Printing PDFDokument2 SeitenIRCTC LTD, Booked Ticket Printing PDFvinod_eicsNoch keine Bewertungen

- AppreciationDokument4 SeitenAppreciationvinod_eicsNoch keine Bewertungen

- Gmail - Call For Interview PDFDokument2 SeitenGmail - Call For Interview PDFvinod_eicsNoch keine Bewertungen

- Cement ProjectsDokument5 SeitenCement Projectsvinod_eicsNoch keine Bewertungen

- Curriculum Vitae: (Manager Projects & Planner For EPC Projects)Dokument3 SeitenCurriculum Vitae: (Manager Projects & Planner For EPC Projects)vinod_eicsNoch keine Bewertungen

- Vinod Kumar - K J S Cement PDFDokument4 SeitenVinod Kumar - K J S Cement PDFvinod_eicsNoch keine Bewertungen

- Sdgi VINODLATADokument1 SeiteSdgi VINODLATAvinod_eicsNoch keine Bewertungen

- UPSC - Candidate's Application Details (Registration-Id - 11311829489) PDFDokument1 SeiteUPSC - Candidate's Application Details (Registration-Id - 11311829489) PDFvinod_eicsNoch keine Bewertungen

- Design of My New Building PDFDokument1 SeiteDesign of My New Building PDFvinod_eicsNoch keine Bewertungen

- Reference For CoachDokument18 SeitenReference For Coachvinod_eicsNoch keine Bewertungen

- Design of My New Building4 PDFDokument1 SeiteDesign of My New Building4 PDFvinod_eicsNoch keine Bewertungen

- Work Schedule-Geic-001Dokument11 SeitenWork Schedule-Geic-001vinod_eicsNoch keine Bewertungen

- English Learning - P1Dokument7 SeitenEnglish Learning - P1vinod_eicsNoch keine Bewertungen

- Vinodkumar kjs-14.10.13 PDFDokument4 SeitenVinodkumar kjs-14.10.13 PDFvinod_eicsNoch keine Bewertungen

- KJS JL-28.08.13 PDFDokument2 SeitenKJS JL-28.08.13 PDFvinod_eicsNoch keine Bewertungen

- Additional Complex Number Problems PDFDokument2 SeitenAdditional Complex Number Problems PDFvinod_eicsNoch keine Bewertungen

- Machine or Component: This BOQ Applies To Order NO.: Machine: Stage 4-3 Riser Duct String 1Dokument2 SeitenMachine or Component: This BOQ Applies To Order NO.: Machine: Stage 4-3 Riser Duct String 1vinod_eicsNoch keine Bewertungen

- New Microsoft Office Word DocumentDokument2 SeitenNew Microsoft Office Word Documentvinod_eicsNoch keine Bewertungen

- AppreciationDokument4 SeitenAppreciationvinod_eicsNoch keine Bewertungen

- Basic Mathe-Unit Vi LaplacedDokument17 SeitenBasic Mathe-Unit Vi LaplacedVinod Kumar VermaNoch keine Bewertungen

- To Me, Timeoffice, Vinkumar - Hbti: 10:54 AM (22 Hours Ago)Dokument1 SeiteTo Me, Timeoffice, Vinkumar - Hbti: 10:54 AM (22 Hours Ago)vinod_eicsNoch keine Bewertungen

- Machine Calciner Section: This BOQ Applies To Order NO.: MachineDokument2 SeitenMachine Calciner Section: This BOQ Applies To Order NO.: Machinevinod_eicsNoch keine Bewertungen

- M/S. K J S Cement Limited: For-6000 TPD Cement PlantDokument3 SeitenM/S. K J S Cement Limited: For-6000 TPD Cement Plantvinod_eicsNoch keine Bewertungen

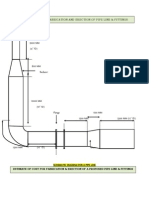

- Estimation of Cost For A Schematic Pipe Line Fabrication & ErectionDokument5 SeitenEstimation of Cost For A Schematic Pipe Line Fabrication & Erectionvinod_eicsNoch keine Bewertungen

- Agency:Vidhata Entreprises Bill No:Ra 04: Total 97747.70 97747.70Dokument5 SeitenAgency:Vidhata Entreprises Bill No:Ra 04: Total 97747.70 97747.70vinod_eicsNoch keine Bewertungen

- Material Handling (Ranjan Beg)Dokument3 SeitenMaterial Handling (Ranjan Beg)vinod_eicsNoch keine Bewertungen

- Report For Pipe Line-09.08.12Dokument4 SeitenReport For Pipe Line-09.08.12vinod_eicsNoch keine Bewertungen

- Cost Estimation For Fabrication and Erection of Pipe Line & FittingsDokument4 SeitenCost Estimation For Fabrication and Erection of Pipe Line & Fittingsvinod_eicsNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- JAMA The BeforeDokument1 SeiteJAMA The BeforeaznpianodreamNoch keine Bewertungen

- 9-Chinese Zodiac - MonkeyDokument5 Seiten9-Chinese Zodiac - MonkeyTere ChongNoch keine Bewertungen

- E36 Changing Handbrake LeverDokument6 SeitenE36 Changing Handbrake LeverDumitru Daniel AlexNoch keine Bewertungen

- Asia Review Domingo With Cover Page v2Dokument21 SeitenAsia Review Domingo With Cover Page v2Gintoki SakataNoch keine Bewertungen

- Binoria Menu 18-12-2022Dokument20 SeitenBinoria Menu 18-12-2022Asif MaqboolNoch keine Bewertungen

- Etl2 SampleDokument16 SeitenEtl2 Samplearturo201350% (2)

- Exercise On Topic 1Dokument3 SeitenExercise On Topic 1Nurhazwani Azureen AzizuddinNoch keine Bewertungen

- Catch Us If You CanDokument11 SeitenCatch Us If You Cano'Zill DZullNoch keine Bewertungen

- Lee Han-Byeol - Google SearchDokument1 SeiteLee Han-Byeol - Google Searchanastasia churaNoch keine Bewertungen

- Robert Graves - Poems 1938 To 1945Dokument80 SeitenRobert Graves - Poems 1938 To 1945tonyclassic2100% (4)

- Deutsche HospitalityDokument16 SeitenDeutsche Hospitalityd7oombautista1126Noch keine Bewertungen

- 111055.Bsc 01.Hw - Ardtel.waaz - Aa EnoDokument27 Seiten111055.Bsc 01.Hw - Ardtel.waaz - Aa EnoMikatechNoch keine Bewertungen

- Exam in PEDokument6 SeitenExam in PERam KuizonNoch keine Bewertungen

- Sno. Area Yamuna Sports Complex, Delhi Talkatora Stadium, Delhi InferencesDokument1 SeiteSno. Area Yamuna Sports Complex, Delhi Talkatora Stadium, Delhi InferencesSAKET TYAGINoch keine Bewertungen

- Valerie Thompson: Freelance PhotographerDokument1 SeiteValerie Thompson: Freelance PhotographerValerie Elise ThompsonNoch keine Bewertungen

- Week 2 Welcome To The Lord's TableDokument10 SeitenWeek 2 Welcome To The Lord's TableShower of RosesNoch keine Bewertungen

- Cpar ReviewerDokument7 SeitenCpar ReviewerAngela Marie CenaNoch keine Bewertungen

- Super ComputersDokument9 SeitenSuper Computers/ditya JadhavNoch keine Bewertungen

- The Lead Punch ArticleDokument11 SeitenThe Lead Punch ArticleSteven Resell100% (12)

- ArtemisDokument3 SeitenArtemisAxeliaNoch keine Bewertungen

- Overall TallyDokument10 SeitenOverall TallyMikaNoch keine Bewertungen

- 100 First Foods Checkoff Lists 1Dokument5 Seiten100 First Foods Checkoff Lists 1Ana-Maria AvramNoch keine Bewertungen

- Altec 436C PDFDokument6 SeitenAltec 436C PDFjoeeNoch keine Bewertungen

- Alchemy Gold Slot Demo RTP 96.78 Free PlayDokument1 SeiteAlchemy Gold Slot Demo RTP 96.78 Free Playbc287724Noch keine Bewertungen

- PageWide XL 5000Dokument4 SeitenPageWide XL 5000eric buzzNoch keine Bewertungen

- Winter Dubai Turki 2-11 Maret 2023Dokument4 SeitenWinter Dubai Turki 2-11 Maret 2023Hukma ShabiyyahNoch keine Bewertungen

- Susan Sontag - Sobre MurielDokument2 SeitenSusan Sontag - Sobre MurielAmanda Palma de AzevedoNoch keine Bewertungen

- ManasalamDokument2 SeitenManasalamRohan GhigeNoch keine Bewertungen

- Test and Monitoring Solutions For Fiber To The Home (FTTH)Dokument2 SeitenTest and Monitoring Solutions For Fiber To The Home (FTTH)Jesus LopezNoch keine Bewertungen

- English Formative Test 1Dokument2 SeitenEnglish Formative Test 1ima rohimaNoch keine Bewertungen